Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Fast bagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Planting method of ecological pear

InactiveCN104303939AImprove temperature conditionsAvoid influenceRenewable energy machinesCultivating equipmentsPesticide residuePear tree

The invention discloses a planting method of an ecological pear. The ecological pear without pesticide residue is planted by adopting a grass culturing and intercropping mode, adopting an organic fertilizer as a main fertilizer, and using physical and trapping ways to kill insects. According to the planting method, the problems that an existing pear tree planting method is low in the land use rate, high in pesticide residue and low in fruit quality can be overcome; furthermore, the planting method is free from pesticide residue and high in fruit quality, and the land can be effectively used.

Owner:GUIZHOU SHANLIHONG FRUIT & VEGETABLE DEV

Feed bagging device

Owner:常熟泉兴营养添加剂有限公司

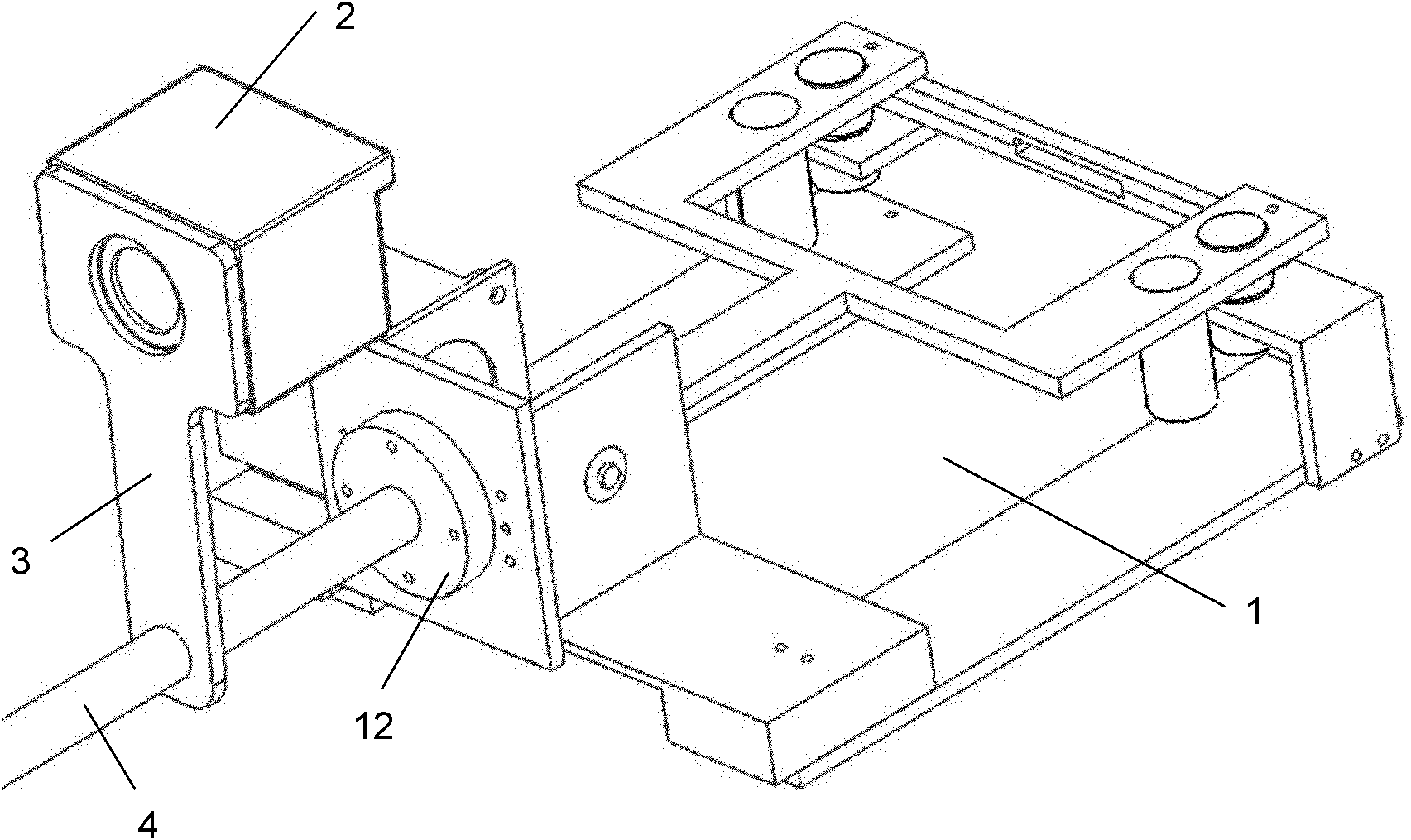

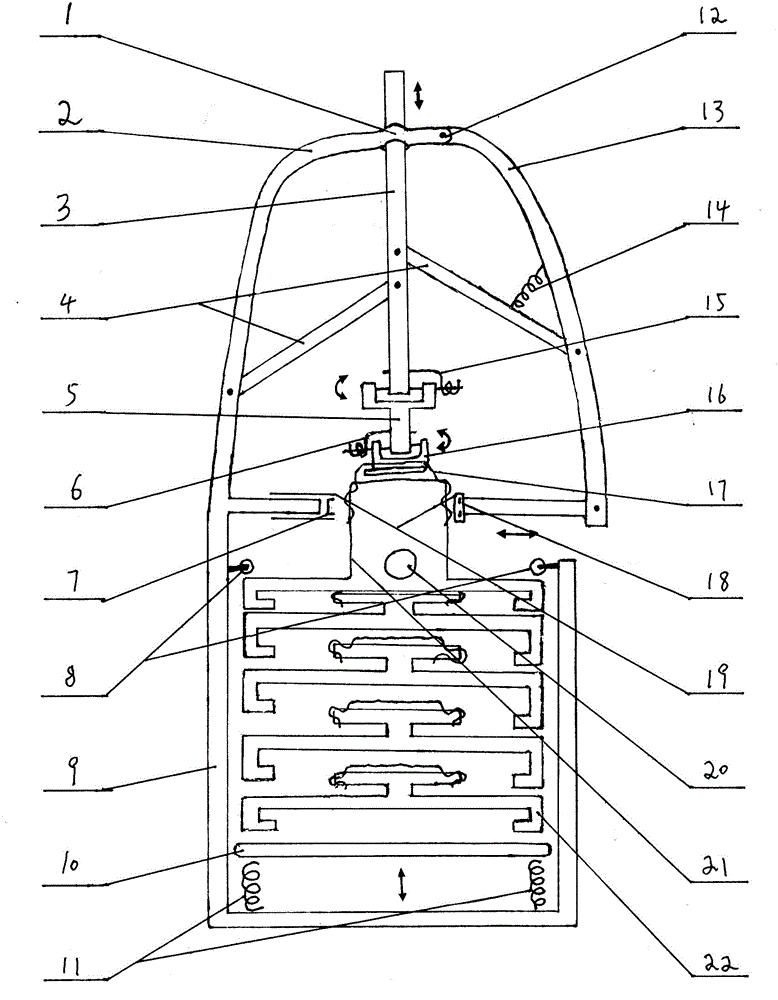

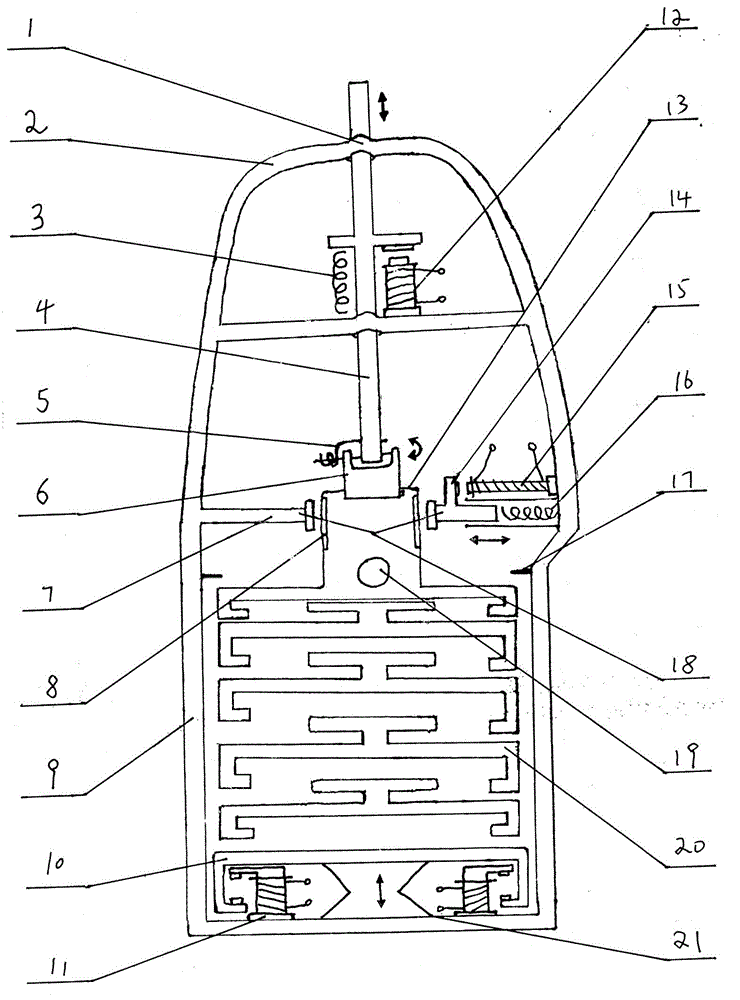

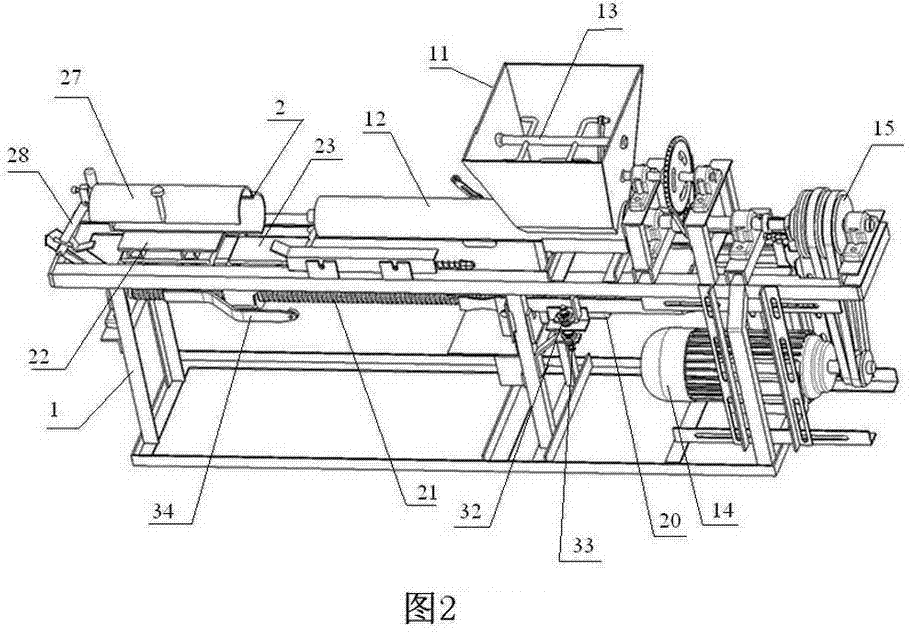

Fruit paper bag bagging device

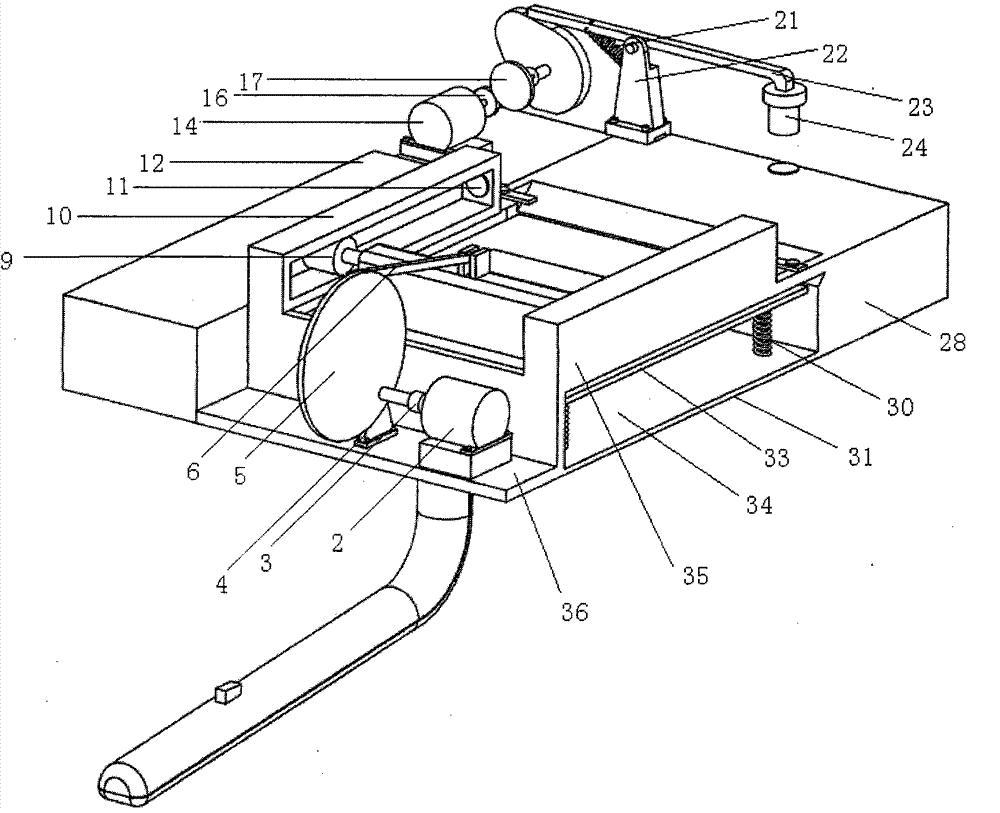

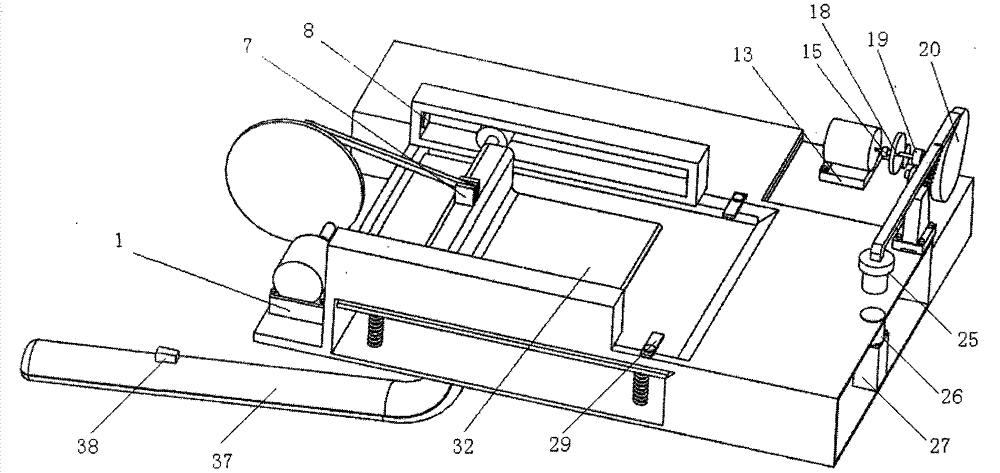

InactiveCN103828663AEasy to operateFast baggingPlant protective coveringsPulp and paper industryEngineering

The invention discloses a fruit paper bag bagging device. The bagging device comprises a bag placing device, a bag delivering device, a bag opening and sealing device, special paper bags and a fruit paper bag bagging control device. The special paper bags are delivered into a bag opening and sealing base through an eccentric wheel mechanism, and then bag opening and sealing operation is achieved through a cam mechanism and direct-current sucker type electromagnets. Semi-automation of fruit bagging is achieved, efficiency of fruit bagging is improved, besides, fruit stems can be prevented from being damaged in the process of fruit bagging, and the fruit paper bag bagging device has very good practical value and broad market prospects.

Owner:NORTHWEST A & F UNIV

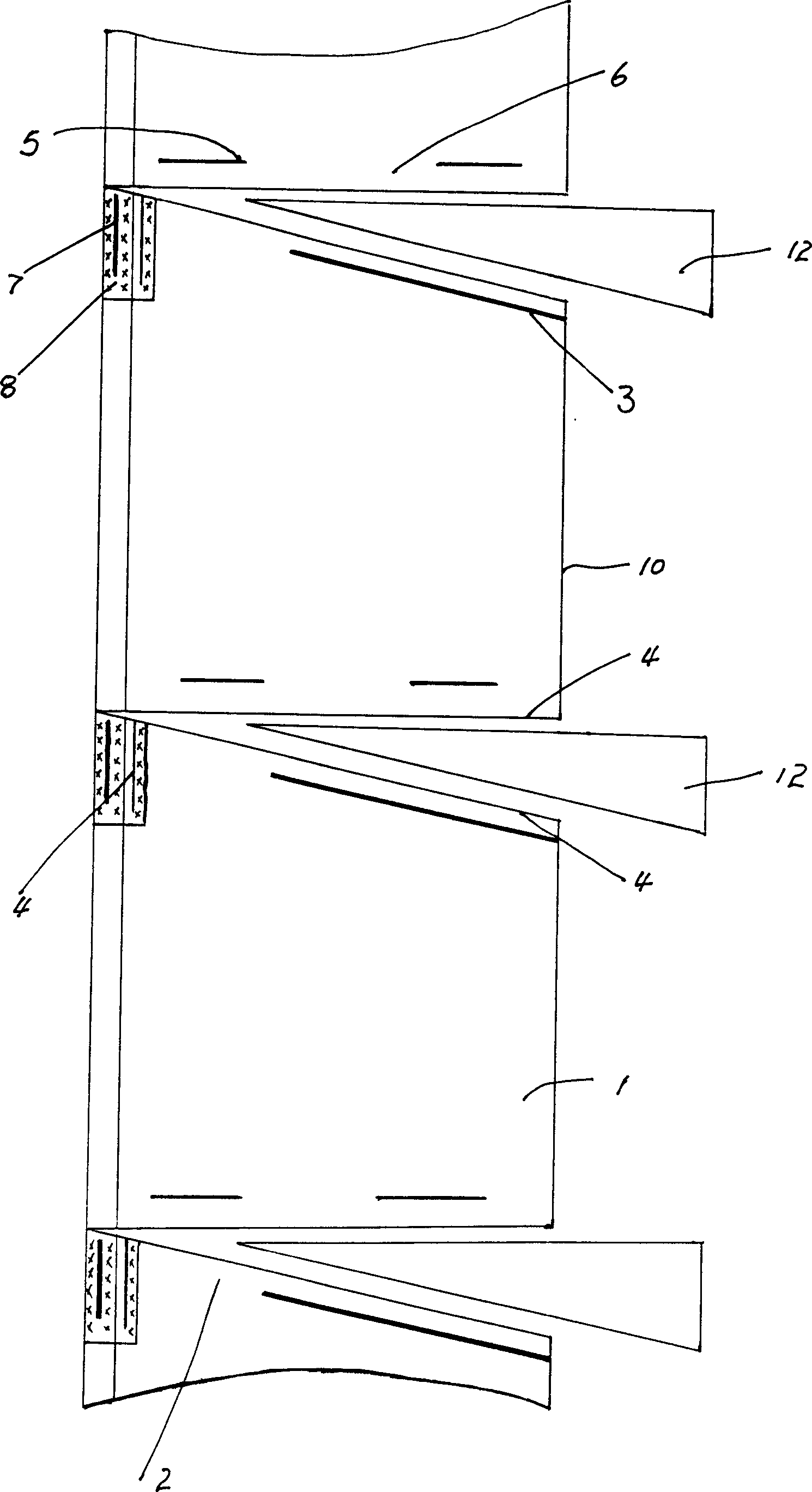

Apple bag with two jointed hemispherical surfaces

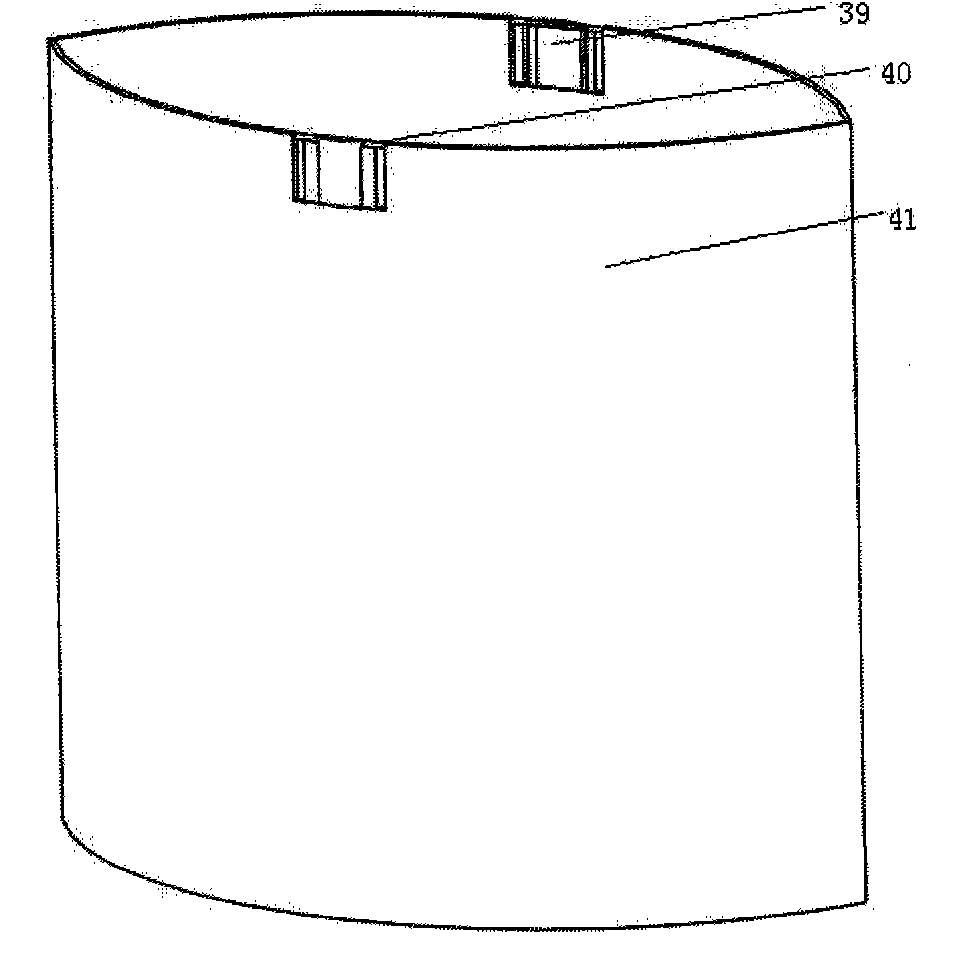

InactiveCN102668937AImprove labor productivityFast baggingPlant protective coveringsEngineeringNatural hazard

The invention relates to an apple bag with two jointed hemispherical surfaces, characterized in that an air vent and an apple steam clamping hole are arranged on each hemispherical plastic body. The two hemispherical plastic bodies are jointed into a whole via a hemispherical plastic body jointing line. Magnetic rubber surfaces on the hemispherical plastic bodies are mutually closely attracted together under the magnetic action. the material of the apple bag with two jointed hemispherical surfaces must be very light hard composite plastic; once made, the apple bag can be used for many years, generally four to five years, and can be recovered and repeatedly produced after being outworn. The apple bag with two jointed hemispherical surfaces made of the hard composite plastic can effectively prevent hail from damaging apples, and reduce the damage degree of natural hazard. Bagging speed is greatly increased, thus increasing production efficiency; and through calculation, the bagging speed of common apple bags is 12 seconds per apple, and the bagging speed of the apple bags disclosed by the invention is 1 second per apple, so the labour production efficiency is increased by 12 folds.

Owner:苟小平

Bread rapid bagging device

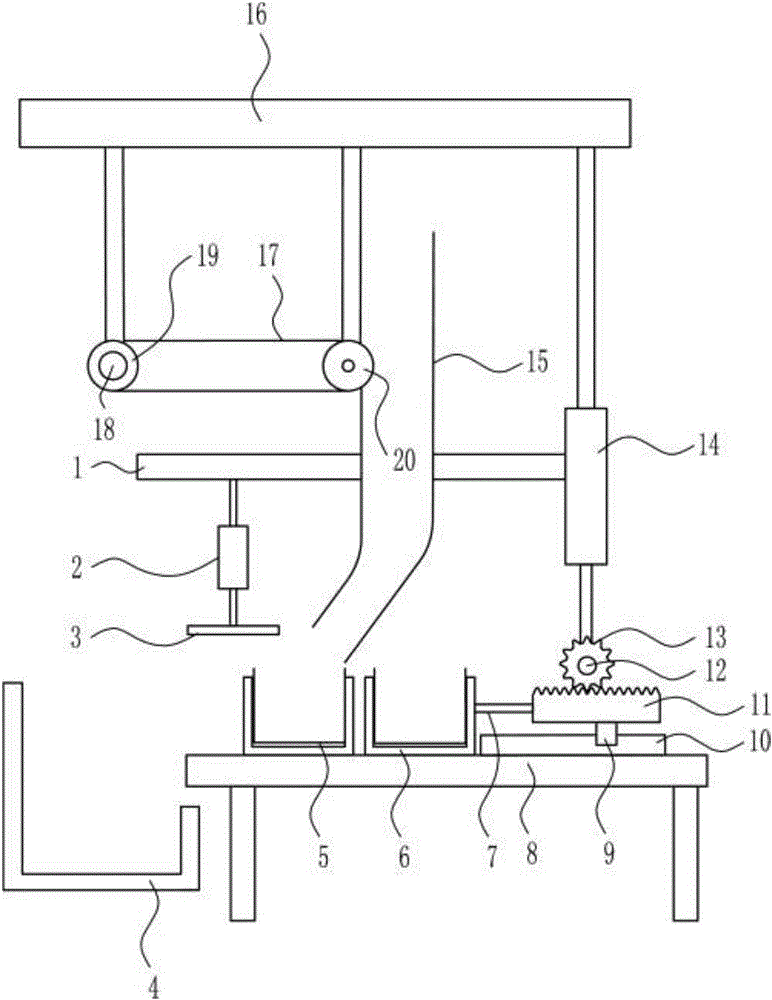

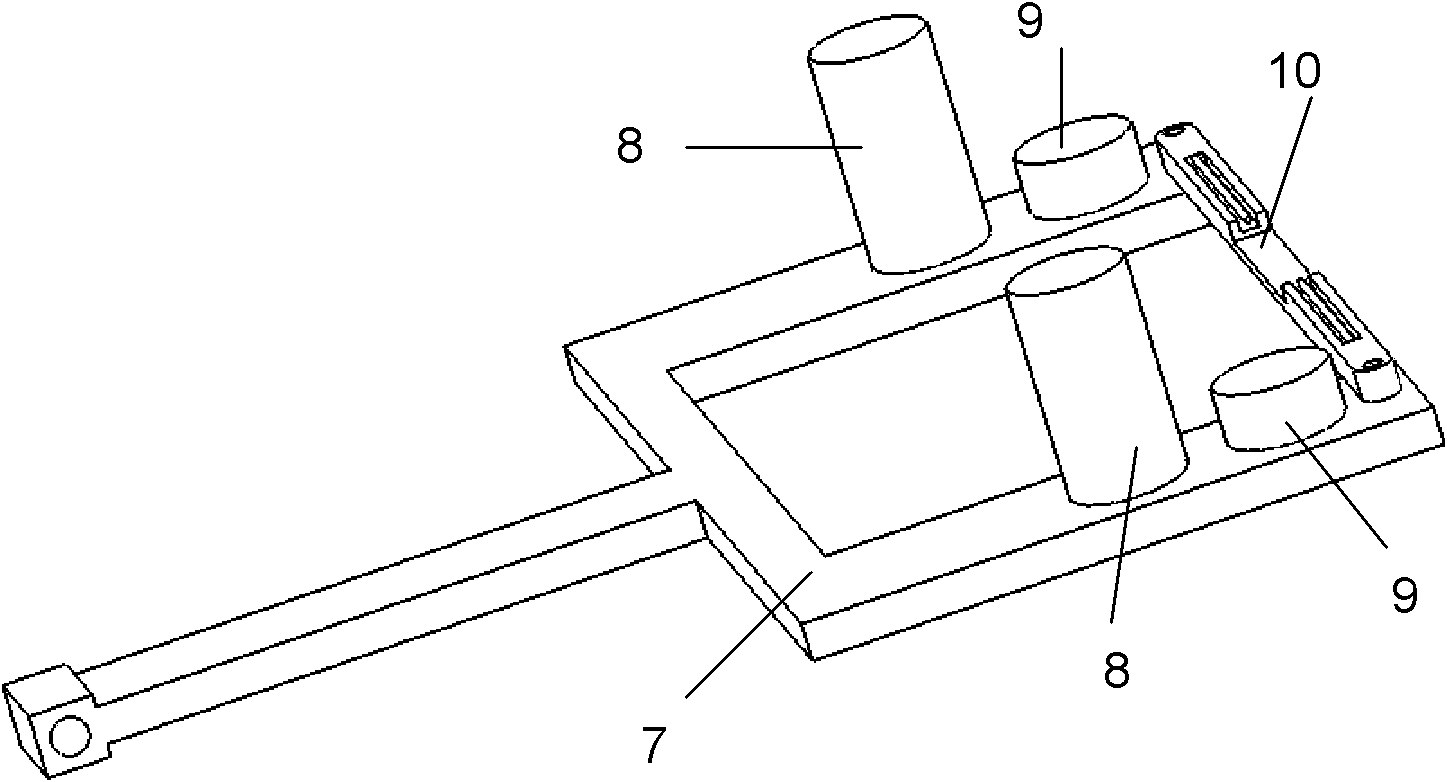

ActiveCN106184880AConvenient bagging operationQuick baggingWrapper twisting/gatheringIndividual articlesFixed frameEngineering

The invention relates to a bread bagging device, in particular to a bread rapid bagging device. The technical problem to be solved is to provide a bread rapid bagging device which is easy to bag, convenient to operate and high in bagging speed. In order to solve the technical problem, the bread rapid bagging device is provided. The bread rapid bagging device comprises a supporting rod, an air cylinder I, a sealing device, a pushing rod, a collecting frame, a clamping sleeve, a placing frame, a sliding block, a sliding rail, a rack, a gear motor II, a gear, a fixed frame and the like. The collecting frame is arranged on the left side of the bottom of the placing frame. The clamping sleeve and the sliding rail are sequentially arranged at the top of the placing frame from left to right. The sliding block is slidably connected to the front side of the sliding rail. The rack is connected to the top of the sliding block. The pushing rod is arranged on the left side of the rack. The left end of the pushing rod makes contact with the clamping sleeve. A top plate is arranged above the placing frame. The bread rapid bagging device achieves the effects of being easy to bag, convenient to operate and high in bagging speed. By means of the bread rapid bagging device, bread can be rapidly bagged.

Owner:中山市仟亿健莱食品有限公司

Plastic bag bagging device

InactiveCN101416599AEasy to operateSimple structurePlant protective coveringsElastic componentHand held

A plastic film bag bagging device for improving bagging work of fruit growers is characterized by comprising a bagging arm, a sealing arm, a double-hook type bagging fixing component, a bagging groove, an end enclosure, a glue box, a metal wafer switch, a power supply, an elastic component and a screw. The bagging arm and sealing arm are connected with a resetting elastic component arranged therebetween; the double-hook type bagging fixing component and bagging groove are arranged on the bagging arm; the end enclosure is arranged on the sealing arm with the glue box arranged at the middle thereof; and the metal wafer switch is arranged at the hand-hold part of the sealing arm for connecting and disconnecting the power supply. The invention has the advantages of convenient operation, miniature size, simple structure, fast bagging, good sealing effect and availability by one hand.

Owner:郭亚州

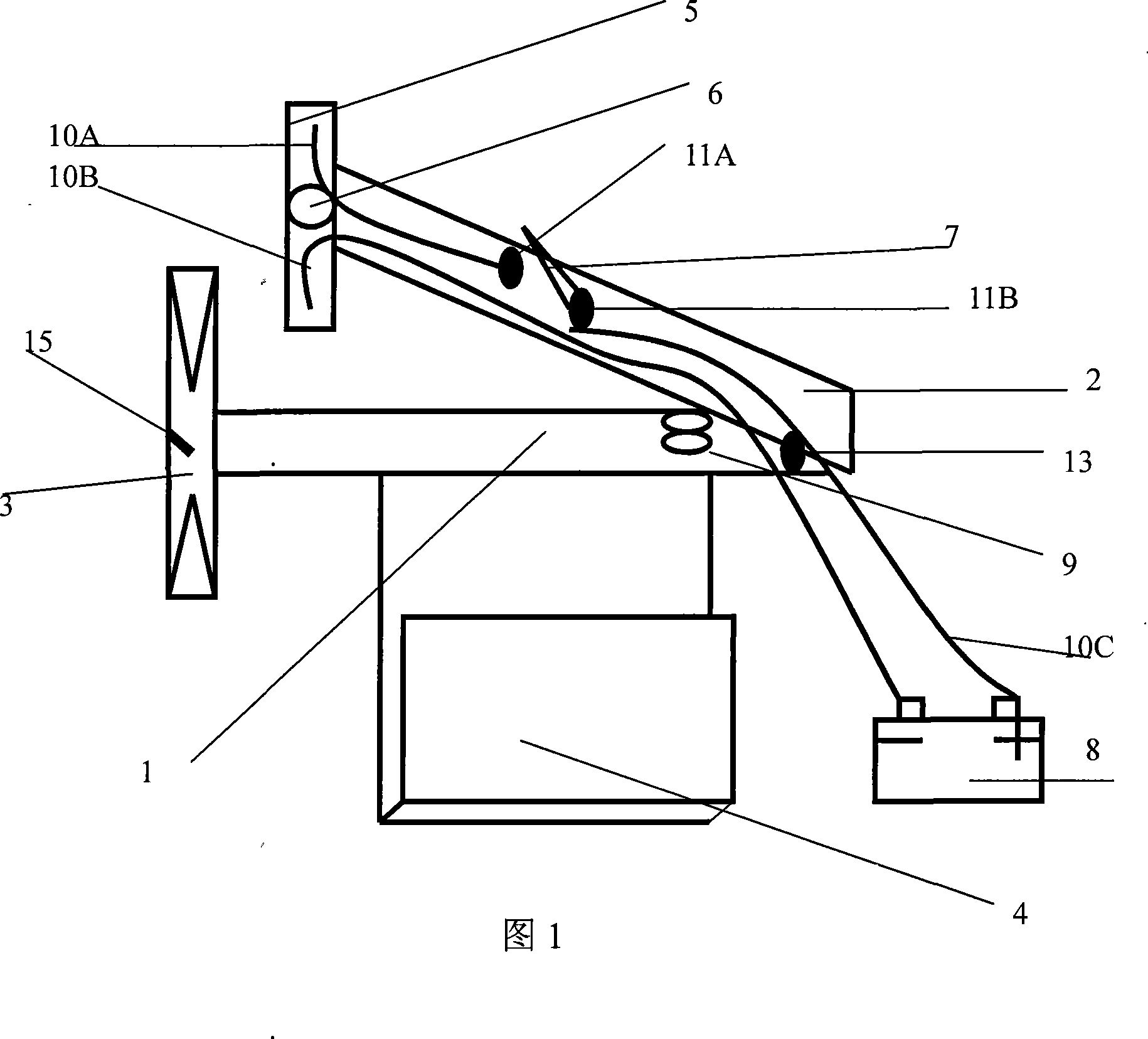

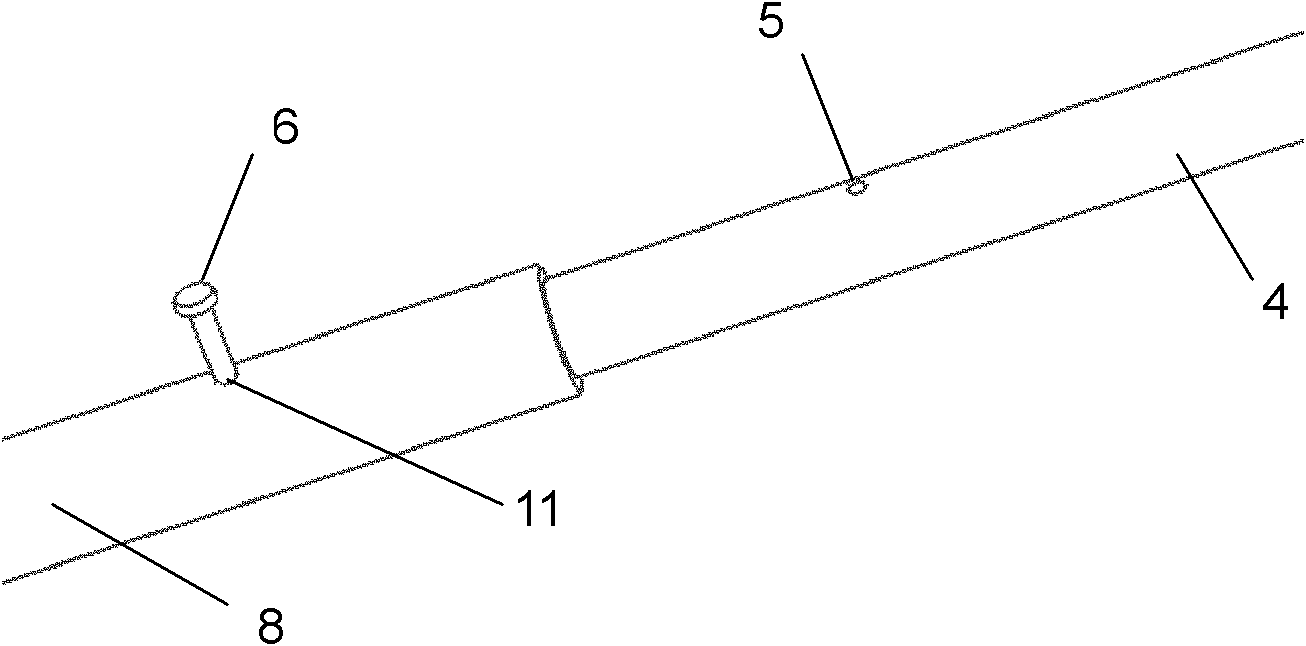

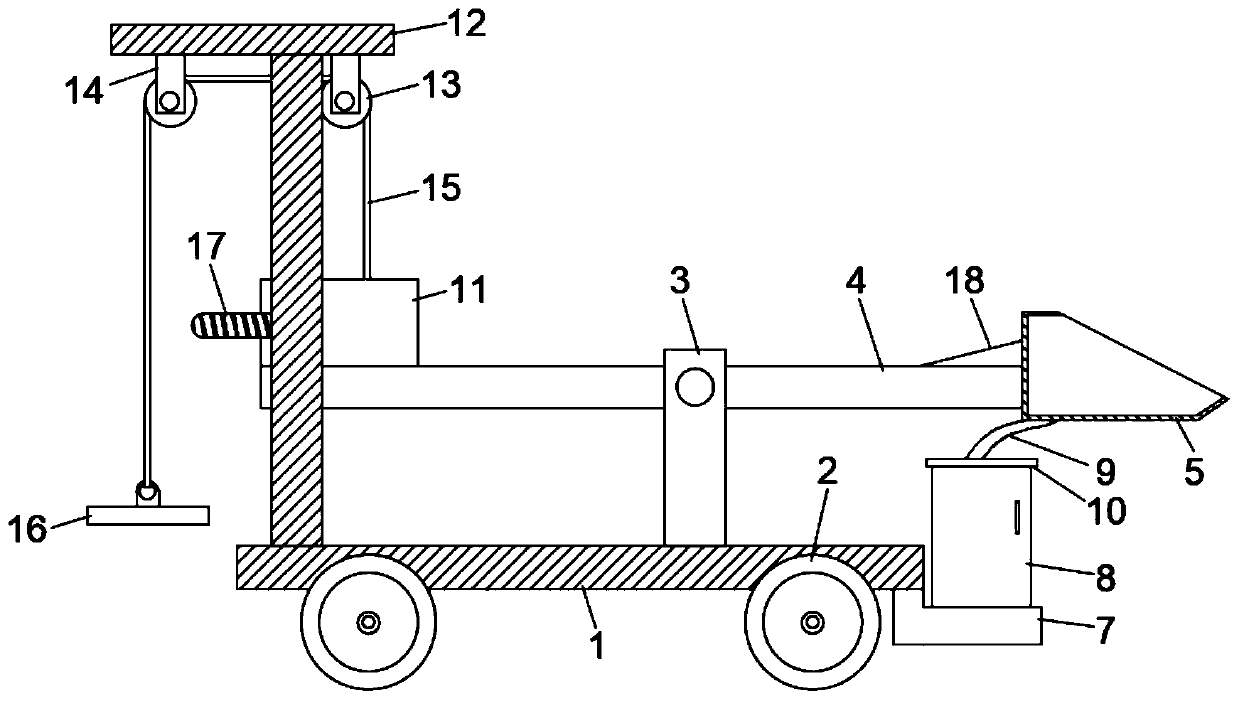

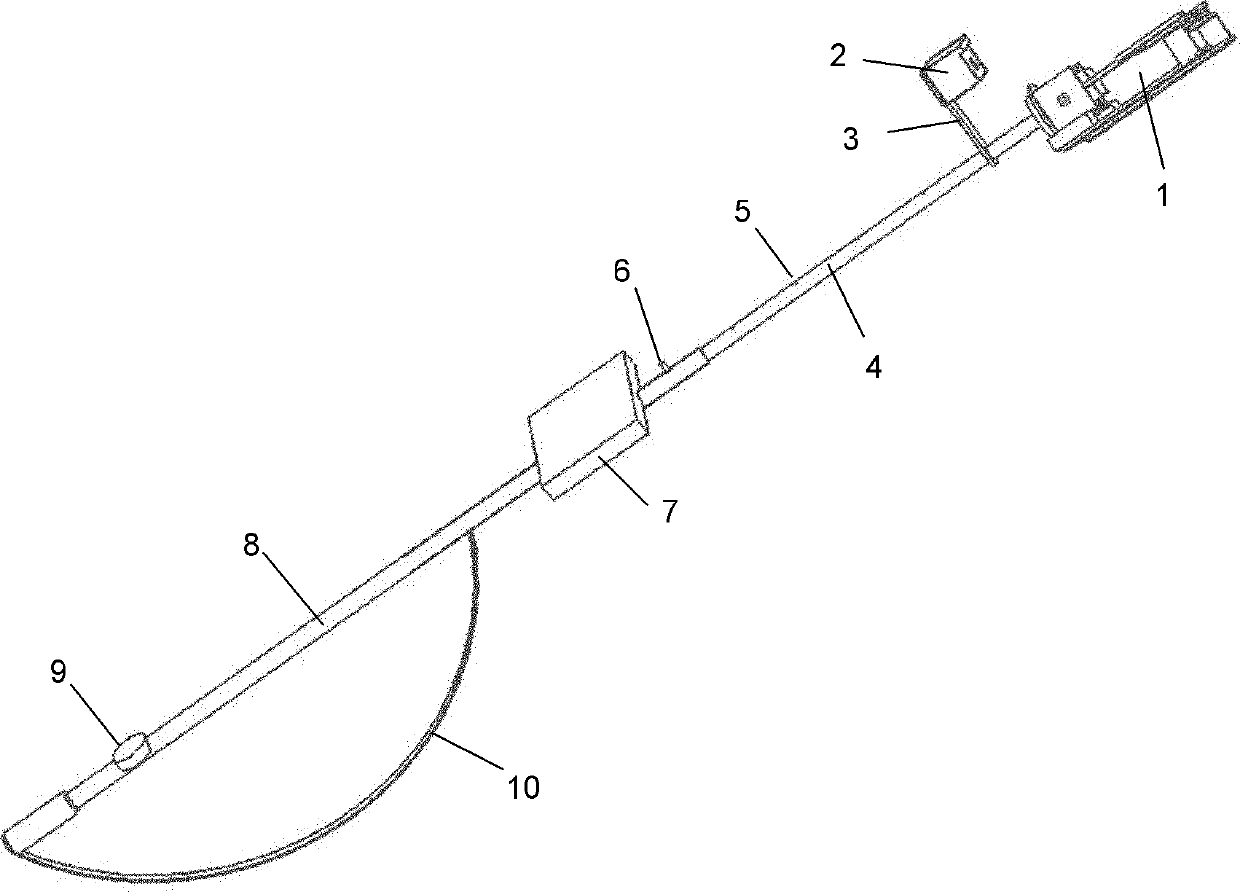

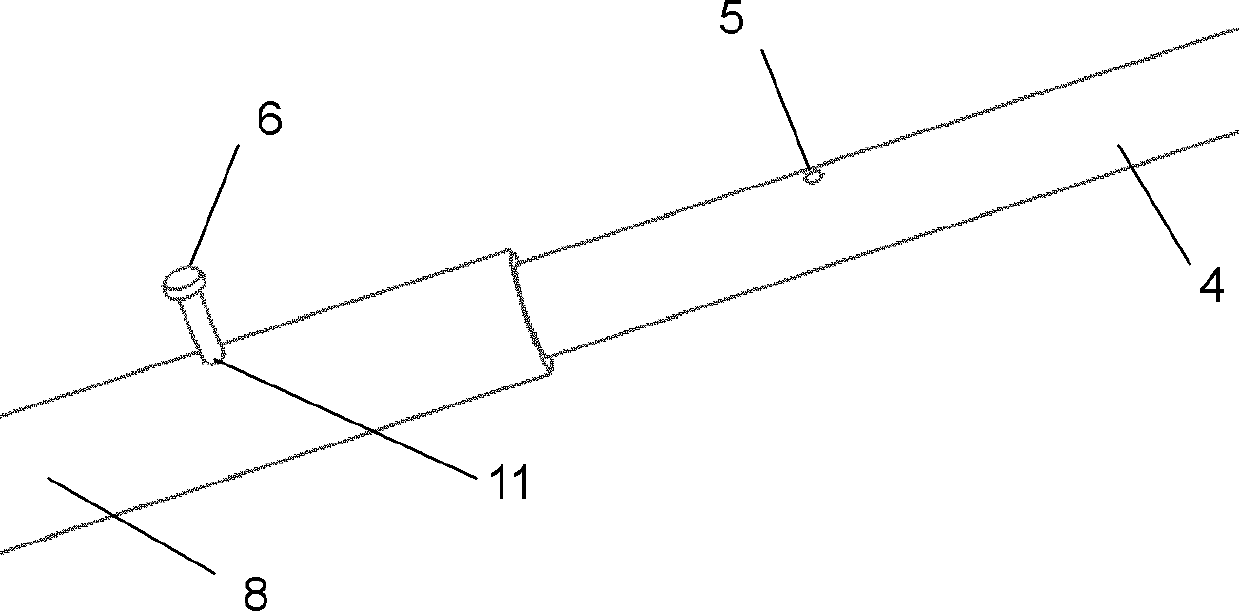

Fruit bag sheathing operation tool

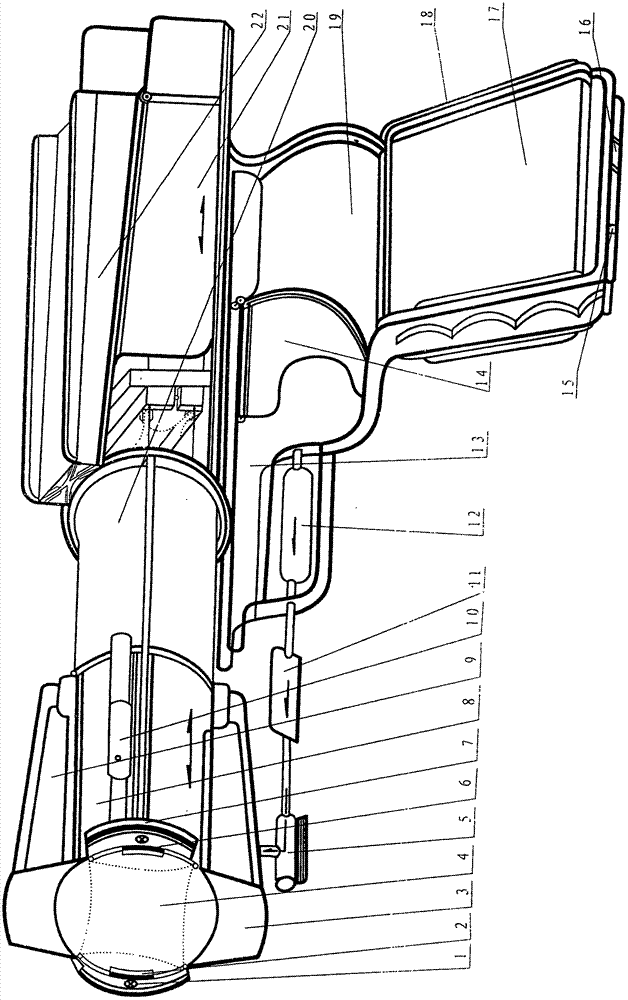

InactiveCN102484975AExpand the scope of workOperation Process VisualizationPlant protective coveringsFruit treeHand held

The invention relates to a fruit bag sheathing operation tool, which comprises a fruit bag sheathing device, a hand holding arm, a telescopic arm, regulation screw bolts, a camera, a display screen and a control box, wherein one end of the telescopic arm is connected with the fruit bag sheathing device, the other end of the telescopic arm is inserted into the hand holding arm and is fixed throughthe regulation screw bolts, the camera is fixedly arranged at the end of the telescopic arm near the fruit bag sheathing device through a camera support frame, the display screen and the control box are arranged on the hand holding arm, and the control box is connected with a driving motor of the fruit bag sheathing device. Regulation holes matched with the regulation screw bolts are arranged on the telescopic arm at intervals and are used for regulating the total length of the hand holding arm and the telescopic arm. The fruit bag sheathing operation tool has the advantages that the structure is simple, the length of the telescopic arm is adjustable, the bag sheathing process is visible, the operation is simple and fast, the bag sheathing efficiency is effectively improved, the manual work intensity and the danger are reduced, and the fruit bag sheathing operation tool can be widely applied to the fruit tree and fruit bag sheathing field operation production.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

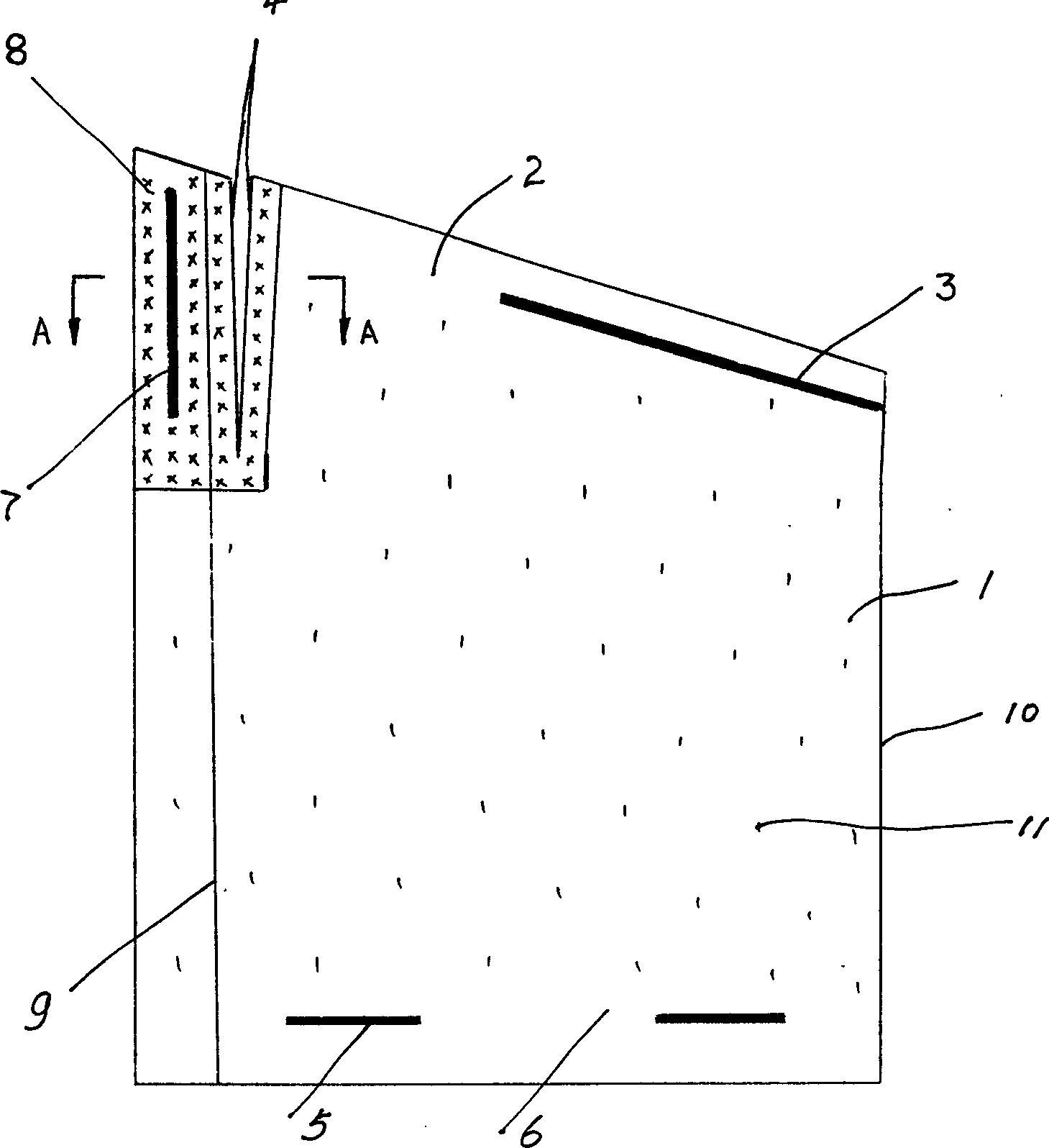

Air permeable bagging with iron wire available for seizing fruitage

InactiveCN1759662AReduce dosageAvoid enteringHorticulture methodsPlant protective coveringsEngineeringPlastic film

An air-permeable sleeve bag for protecting the fruit on the tree is a plastic film bag which has higher left and lower right. It has an upper thermosealing line for sealing part of top edge to leave a fruit entrance, a lower thermosealing line for sealing part of bottom edge to leave an air and water permeable opening and an iron wire for banding the bag.

Owner:徐世慧

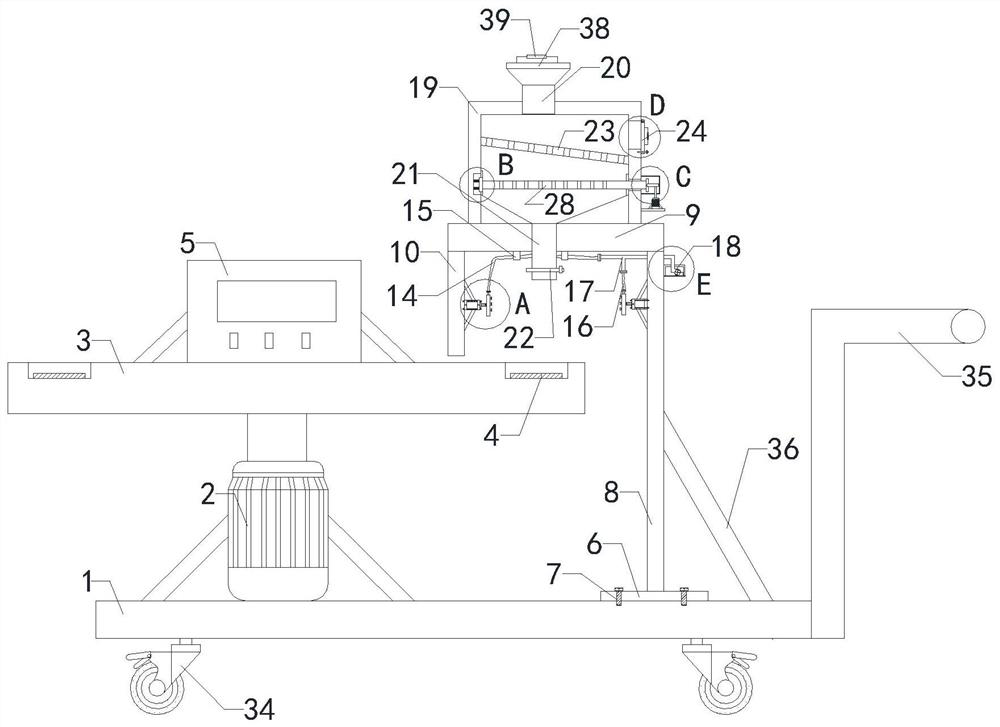

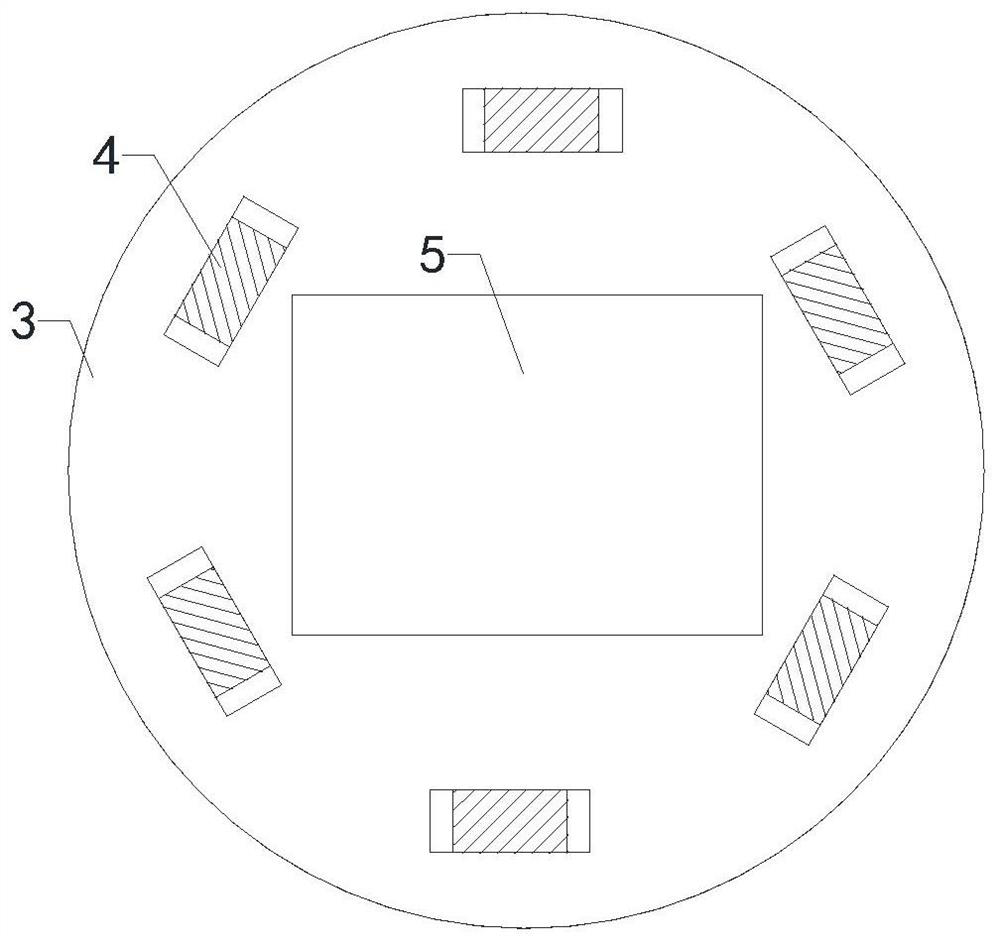

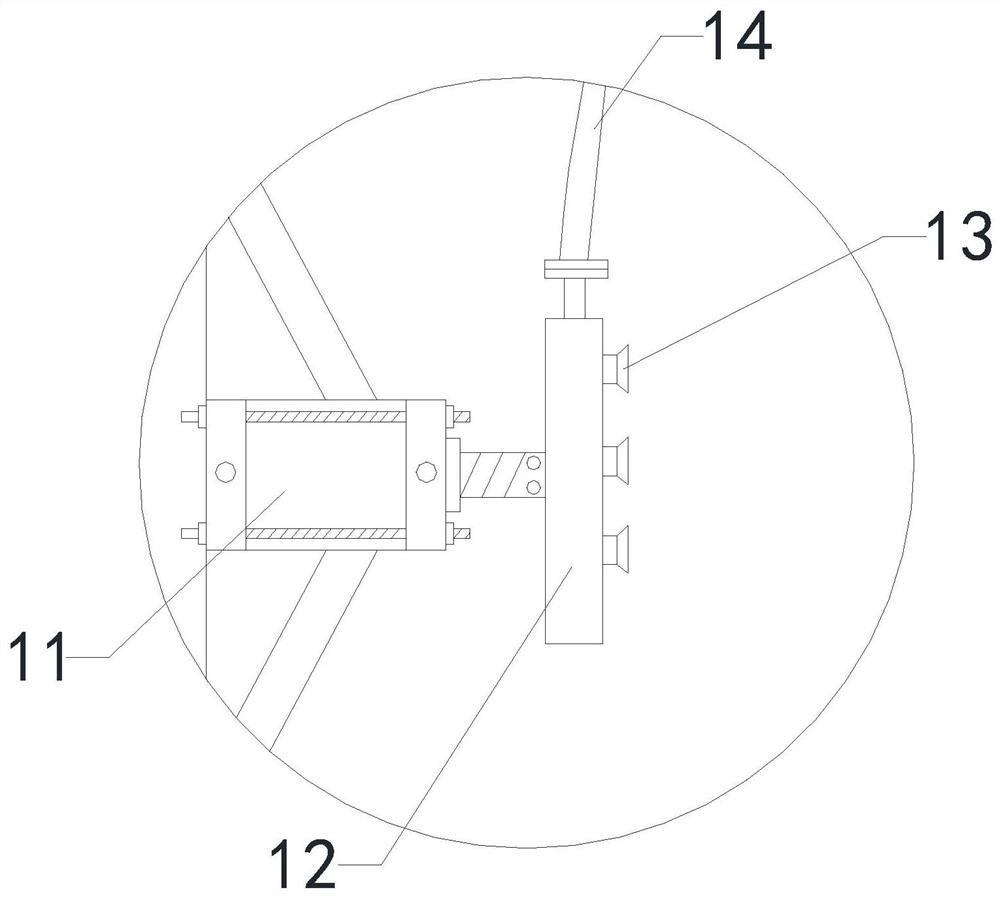

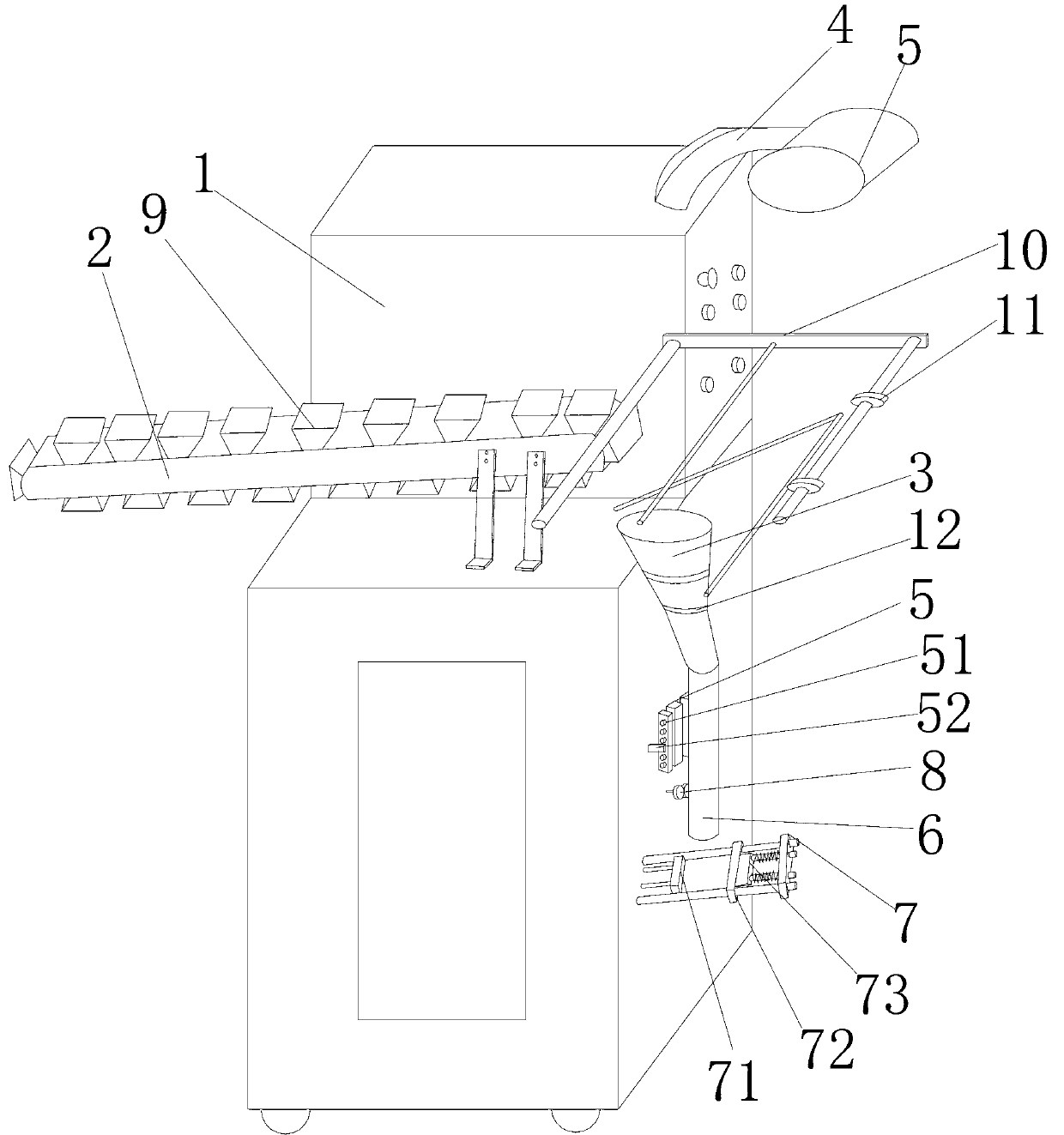

Automatic bagging machine

InactiveCN112046857AAvoid the hassle of manual baggingFast baggingSievingScreeningProcess engineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to an automatic bagging machine which completes automatic rapid bagging, avoids the trouble of manual bagging and improves the bagging speed and the production rate of products. The automatic bagging machine comprises a base, a servo motor, a rotating disc, multiple sets of electronic scales, a PLC, a fixing plate,multiple sets of first fastening bolts, a first supporting plate, an upper top plate, a second supporting plate, two sets of electric push rods, two sets of suction cups, multiple sets of suction nozzles, a first hose, two sets of fixing blocks, a second hose, a three-way pipe, an air suction machine, a storage box, a feed hopper, a discharge pipe and a magnet control valve, wherein the servo motor is fixed to the left side of the top end of the base, an output end of the servo motor is connected with the rotating disc, multiple sets of containing grooves are formed in the bottom end of the rotating disc, the multiple sets of electronic scales are sequentially and correspondingly fixed into the containing grooves, and the PLC is fixed to the center of the rotating disc.

Owner:YANCHENG INST OF TECH

Eye mask packaging machine

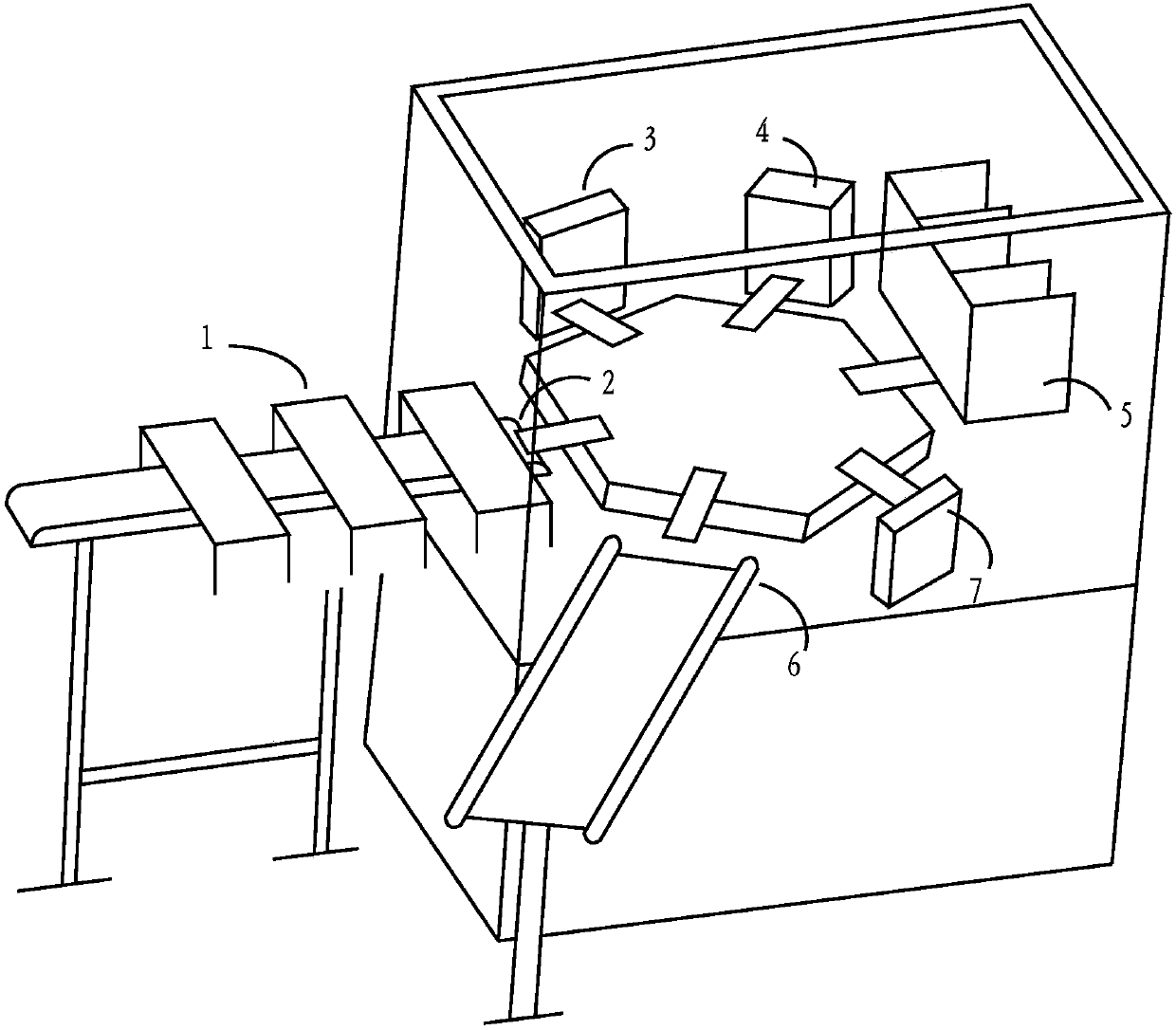

PendingCN107776955ASmall footprintIncrease productivityPaper article packagingPackaging automatic controlOpticsPackaging machine

The invention provides an eye mask packaging machine which comprises a rotatable worktable. At least one pickup component is fixedly arranged at the edge of the worktable and can rotate along with theworktable, an eye mask input system, an eye mask bagging system and an eye mask output system are arranged on the periphery of the worktable, the worktable drives the pickup component to rotate, eyemasks are clamped from the eye mask input system and placed into packaging bags at the eye mask bagging system, and the packaging bags with the eye masks are outputted from the eye mask output system.The eye mask packaging machine is small in occupied space, high in production efficiency, high in eye mask bagging speed and stable in running and has the function of detecting the number of the eyemasks to be packaged, so that the number of the bagged eye masks is accurate.

Owner:郑州市新视明科技工程有限公司

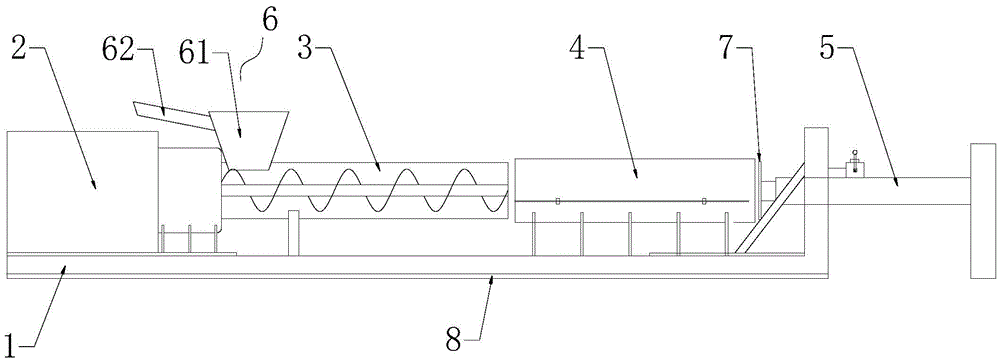

Bagging machine

InactiveCN105584648ASimple structureEasy to operateSolid materialPackaging automatic controlHydraulic cylinderEngineering

The invention id suitable for the technical field of automatic equipment, and provides a bagging machine. The bagging machine comprises a base as well as a drive device, a feeding device, a bag bin and a pressure measuring device which are sequentially arranged on the base, wherein the drive device drives the feeding device to rotate; a feeding bin is arranged on the feeding device; the discharge hole of the feeding device is provided with the barrel-shaped bag bin; the tail end of the bag bin is provided with the pressure measuring device; the pressure measuring device comprises a hydraulic cylinder; the end part of the piston rod of the hydraulic cylinder is provided with a platform; and the platform can enter the bag bin in a telescopic mode. The bagging machine is simple in structure, is easy to operate, and is low in manufacturing cost; automatic bagging is realized through a packing auger conveying device, and pressure in a bag is measured in real time by the pressure measuring time, so that automatic filling with constant pressure is realized, and therefore, the bagging speed is high, the labor power is saved, the problem that the degree of tightness of the bagging is uneven is effectively solved, and the pressure precision is high.

Owner:徐述山

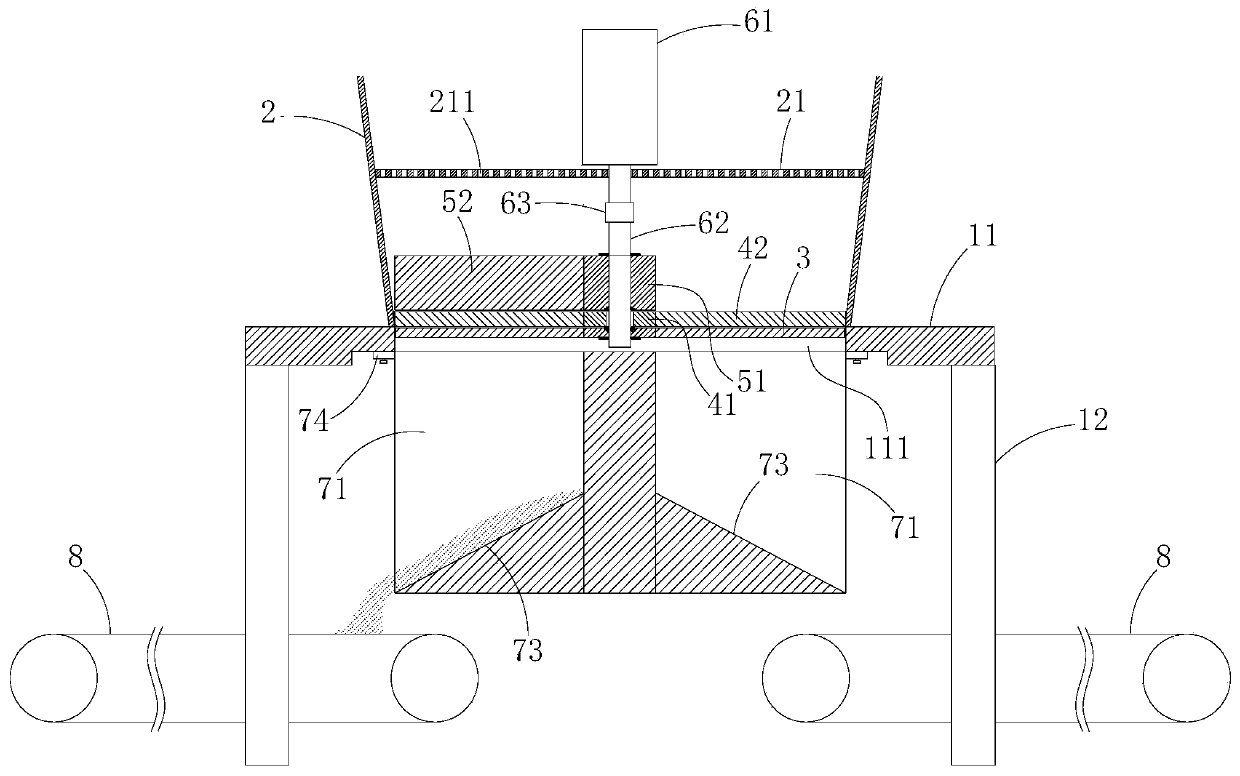

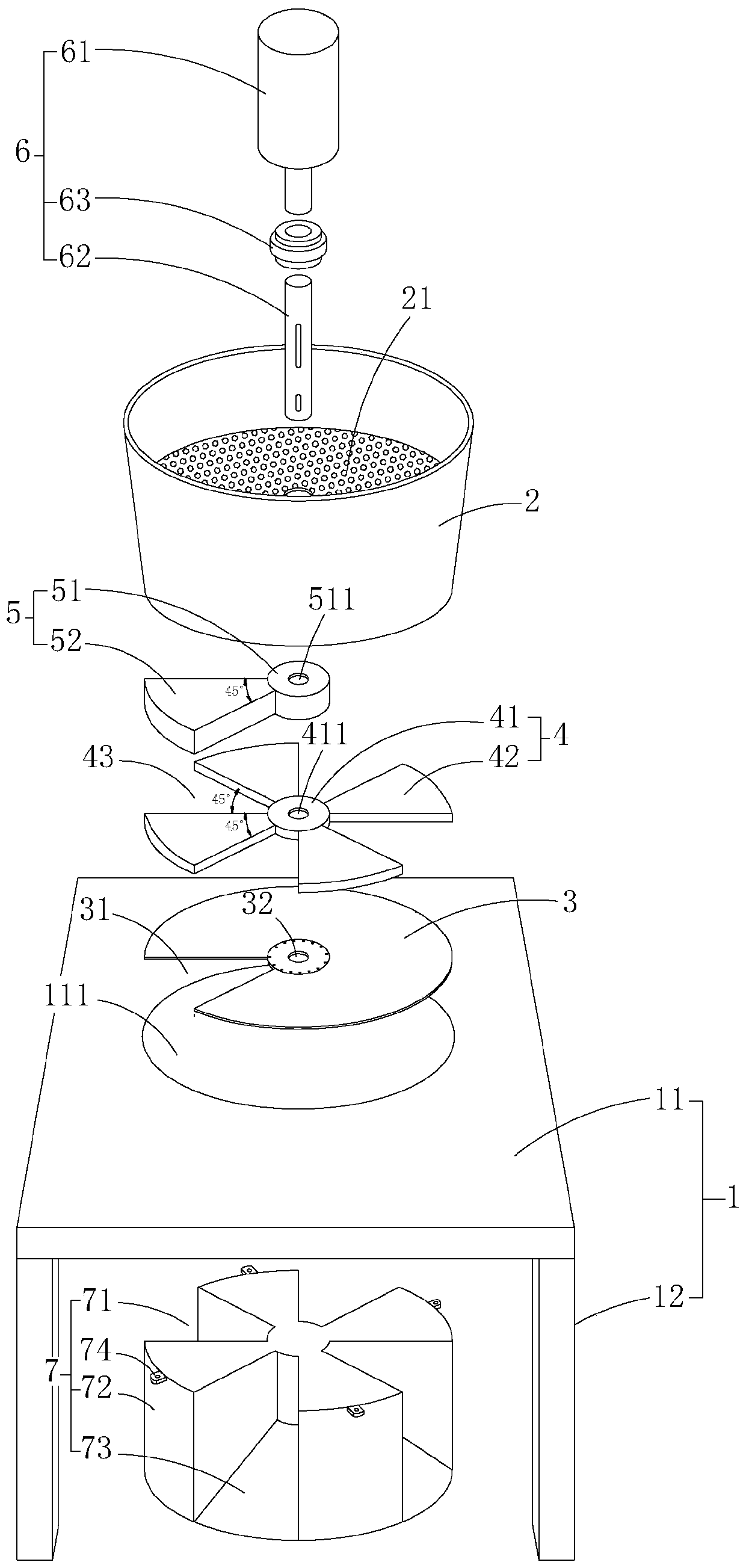

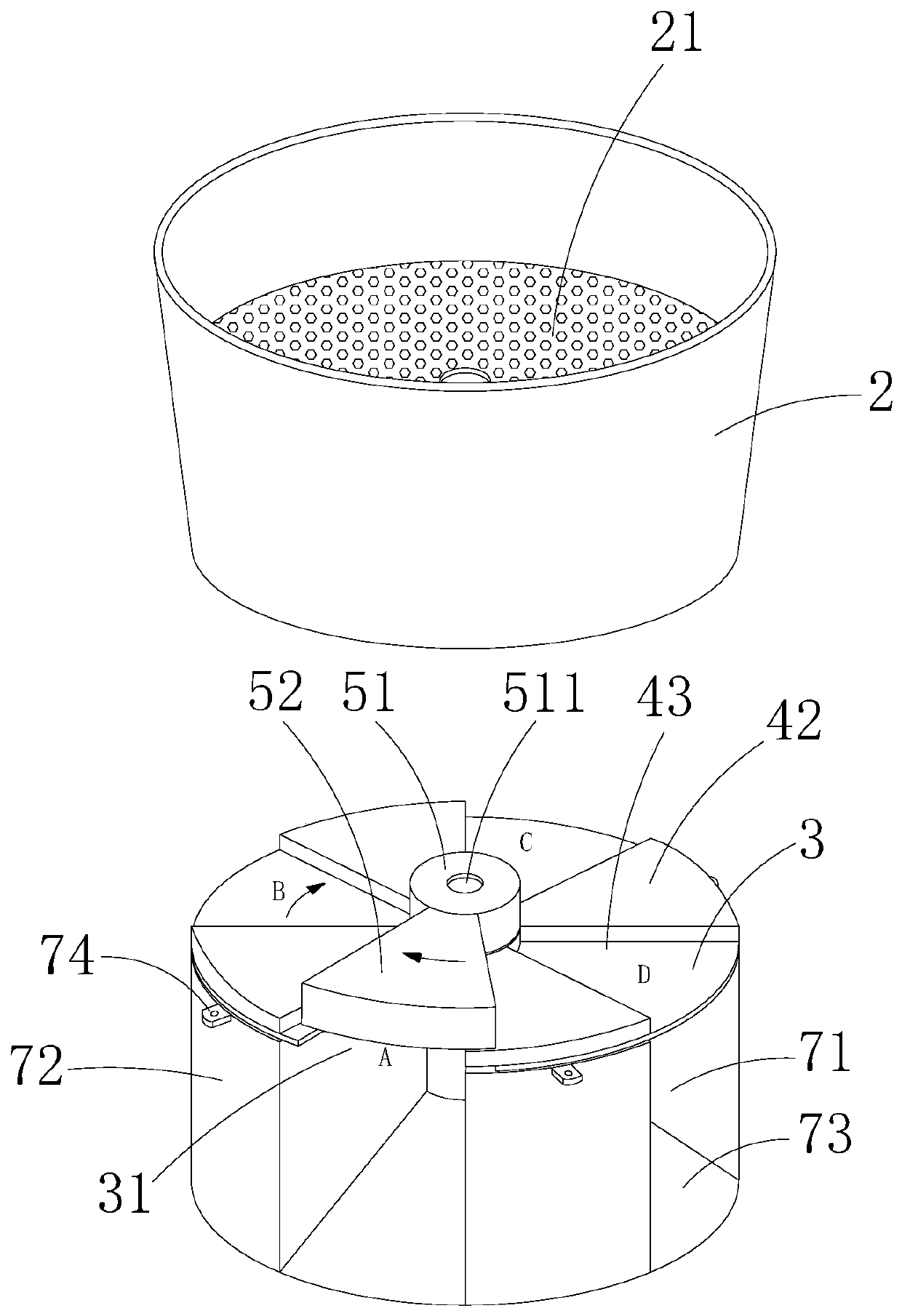

Material distributing device for medicine packaging

The invention discloses a material distributing device for medicine packaging. The material distributing device comprises a rack, a hopper, a material leaking disc, a material distributing disc, a material poking device and a material receiving device, wherein the rack comprises a workbench, and a circular opening is formed in the workbench; the hopper is positioned above the workbench, and the circular opening is enclosed therein; the material leaking disc is installed in the circular opening of the workbench and can freely rotate, and a material leaking port is formed in the material leakingdisc; the material distributing disc is installed above the material leaking disc and fixed to the hopper, the material distributing disc comprises four first fan blades distributed annularly and atintervals; the material poking device is mounted above the material distributing disc and can freely rotate, the material poking device comprises a second fan blade, the second fan blade can just cover the first fan blades, and the second fan blade is arranged corresponding to the material leaking port; the power assembly is used for driving the material leaking disc and the material poking deviceto rotate synchronously; and the material receiving device is installed below the material leaking disc and is provided with four material receiving grooves which are used for receiving the materialsleaking from the four first fan blades respectively. According to the material distributing device, the medicament powder poured into the hopper can be divided into small parts with same mass, so that when the medicament powder is bagged, the weighing step is omitted, and the working efficiency is improved.

Owner:刘越

Vertical anti-explosion bag filling machine

The invention discloses a vertical anti-explosion bag filling machine which consists of a machine frame, a feeding device, a bag filling cylinder and a lifting device, wherein the feeding device is arranged on the top plate of the machine frame. The feeding device consists of a hopper, a stirrer and a feeding pipe. The stirrer and a spiral feeder are driven by a motor. A feed port of the feeding pipe is provided with a material control valve. A pull rod is fixed at the rear of the material control valve. Another end of the pull rod is fixed on a lifting rod which penetrates through a sleeve which is communicated with the top plate of the machine frame. The lower end of the lifting rod is positioned on a horizontal plate of a beam of the lifting device. The lifting rod can lift along with the lifting of the lifting device. The lifting device consists of a sliding rod, a sliding sleeve and a beam. The bag filling cylinder is a circular cylinder which consists of a main board and two lateral plates. The two lateral plates are pivoted on both sides of the main board. The two lateral plates can be opened and closed along the pivoting position. The vertical anti-explosion bag filling machine has the advantages that: the machine saves labor and power and is economic, and thick thin or thick plastic bags with various specifications can be used.

Owner:闫文广

Fruit bagging device

Owner:张德胜

Quick bagging device for drying rice

The invention discloses a quick bagging device for drying rice. The quick bagging device comprises a mounting seat, wherein rolling wheels are arranged at the bottoms of the front end and the rear endof the mounting seat; two fixed seats are fixedly connected at the upper end of the mounting seat; a rotating column is rotatably connected between the two fixed seats; a bucket is welded at the right end of the rotating column; a notch matched with the rotating column and the bucket is also formed at the front end of the mounting seat; two brackets are symmetrically welded at the bottom of the front end of the mounting seat; a material receiving frame is fixedly connected to the two brackets; two discharging holes are formed in the inner bottom of the bucket; and a corrugated pipe is fixedlymounted in each discharging hole. According to the quick bagging device provided by the invention, rice can be shoveled up and automatically bagged without manually dragging a bag opening and manually shoveling the rice, so that the labor intensity is greatly reduced; moreover, the rice can be prevented from spilling in a bagging process, the bagging speed is faster, the manpower is saved, and the operation is convenient and quick.

Owner:惠安县南兴电子科技有限公司

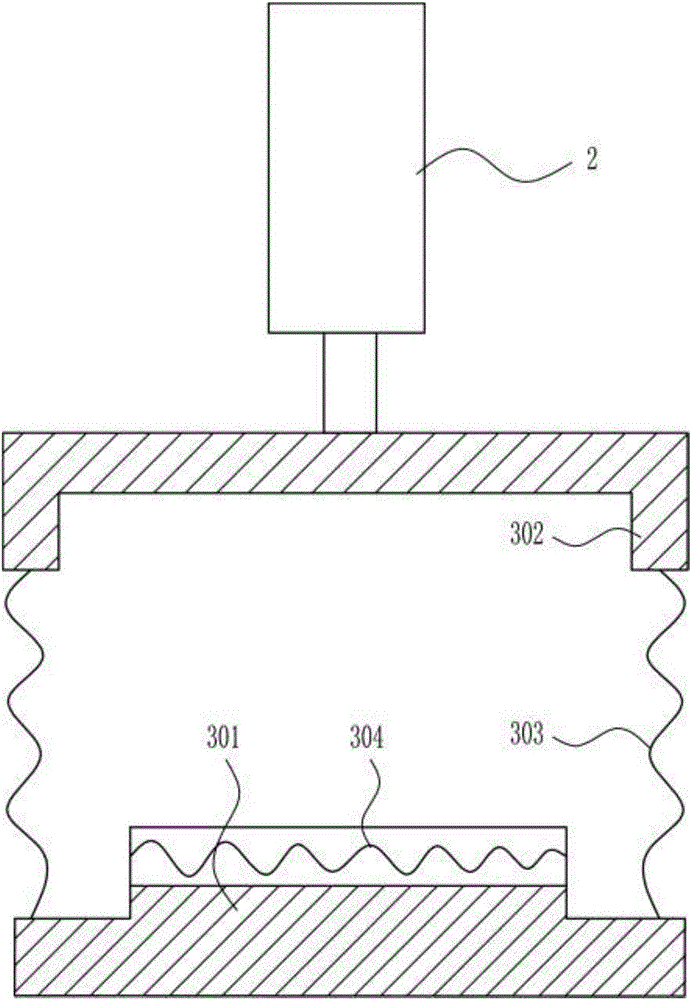

Glass fiber and phenolic composite core material vacuum heat insulation plate and preparing method thereof

InactiveCN100473886CLow costEasy to acceptThermal insulationPipe protection by thermal insulationPhenolVacuum chamber

The present invention relates to vacuum insulating plate (VIP), and is VIP with core of composite glass fiber and phenolic aldehyde material and its preparation process. The VIP is one three layer structure, including the upper glass fiber layer, the lower glass fiber layer and the middle foamed phenolic aldehyde layer. The preparation process includes the following steps: reacting water solution of phenol and formaldehyde and sodium hydroxide at 80 deg.C, cooling and adding formic acid to neutralize, and decompressing; foaming the dewatered resin with glycol, DC-193 silicone oil, pore creating agent and foaming agent in a mold, curing, slotting and setting getter; heating foamed phenolic resin and glass fiber in a furnace while vacuuming, cooling to below 80 deg.c; taking out the core material, packing into packing bag, opening the getter, vacuumizing, sealing the packing bag; and taking the VIP after filling air into the vacuum chamber.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

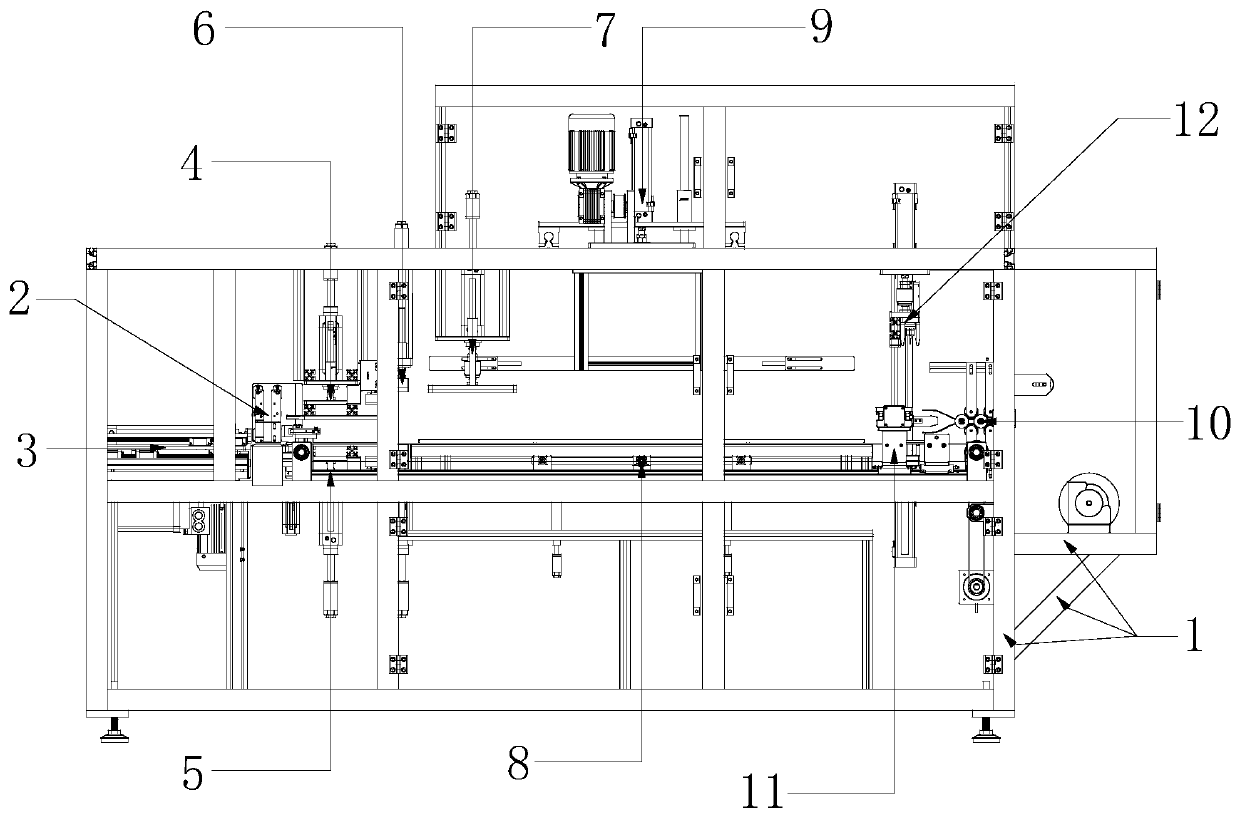

Full-automatic bagging machine

InactiveCN109969477AImprove work efficiencyHigh degree of automationWrapper twisting/gatheringPackaging bottlesEngineeringBottle

The invention discloses a full-automatic bagging machine. The full-automatic bagging machine comprises a rack, and a conveying mechanism, a bottle pushing mechanism, an upper bag opening mechanism, alower bag opening mechanism, a front bag sealing mechanism, a pre-pressing mechanism, a bottle guiding mechanism, a forming and pushing mechanism, bag supporting mechanisms, a bag pulling mechanism and a bag sealing and cutting mechanism, which are arranged on the rack, wherein the bottle pushing mechanism is arranged on the side of the conveying mechanism; the upper bag opening mechanism and thelower bag opening mechanism are arranged on the side of the conveying mechanism; the front bag sealing mechanism is arranged on the side of the lower bag opening mechanism; the pre-pressing mechanismis arranged on the side of the front bag sealing mechanism; the bottle guiding mechanism and the forming and pushing mechanism are arranged on the side of the pre-pressing mechanism; the bag sealing and cutting mechanism and the bag pulling mechanism are arranged on the side of the bottle guiding mechanism; the bag sealing and cutting mechanism and the bag pulling mechanism are dead against each other in an up-down manner; and the bag supporting mechanisms are arranged on the sides of the bag sealing and cutting mechanism and the bag pulling mechanism. The full-automatic bagging machine is high in automation degree and high in work efficiency.

Owner:东莞市鑫正机械有限公司

Packing machine capable of conveying multiple materials

A packing machine capable of conveying multiple materials comprises a workbench, a side plate and a guide rail assembly. The workbench is divided into a left workbench body and a right workbench body. The side plate is divided into a left side plate body and a right side plate body. The guide rail assembly comprises a guide rail A and a guide rail B. The guide rail A is composed of a left guide rail body and a right guide rail body, and the left guide rail body and the right guide rail body are installed on the left side plate body and the right side plate body respectively. The packing machine capable of conveying the multiple materials is characterized in that a pitch shifting fork is arranged between the left guide rail body and the right guide rail body, the pitch shifting fork is divided into a pitch shifting fork body A and a pitch shifting fork body B, the pitch shifting fork body A and the pitch shifting fork body B are kept on the same straight line in the longitudinal direction, the left workbench body and the right workbench body are symmetrically installed on the left guide rail body and the right guide rail body, a pulling tray is arranged below the workbench, the pulling tray is divided into a pulling tray body A and a pulling tray body B, and the pulling tray body A and the pulling tray body B are installed below the left workbench body and the right workbench body respectively. When the packing machine capable of conveying the multiple materials is used, the multiple regular articles can be automatically fed, the bagging speed is increased, manpower and material resources are saved, work efficiency is improved, the structure is simple, and the packing machine is suitable for being popularized.

Owner:QINGDAO HUADELI MACHINERY

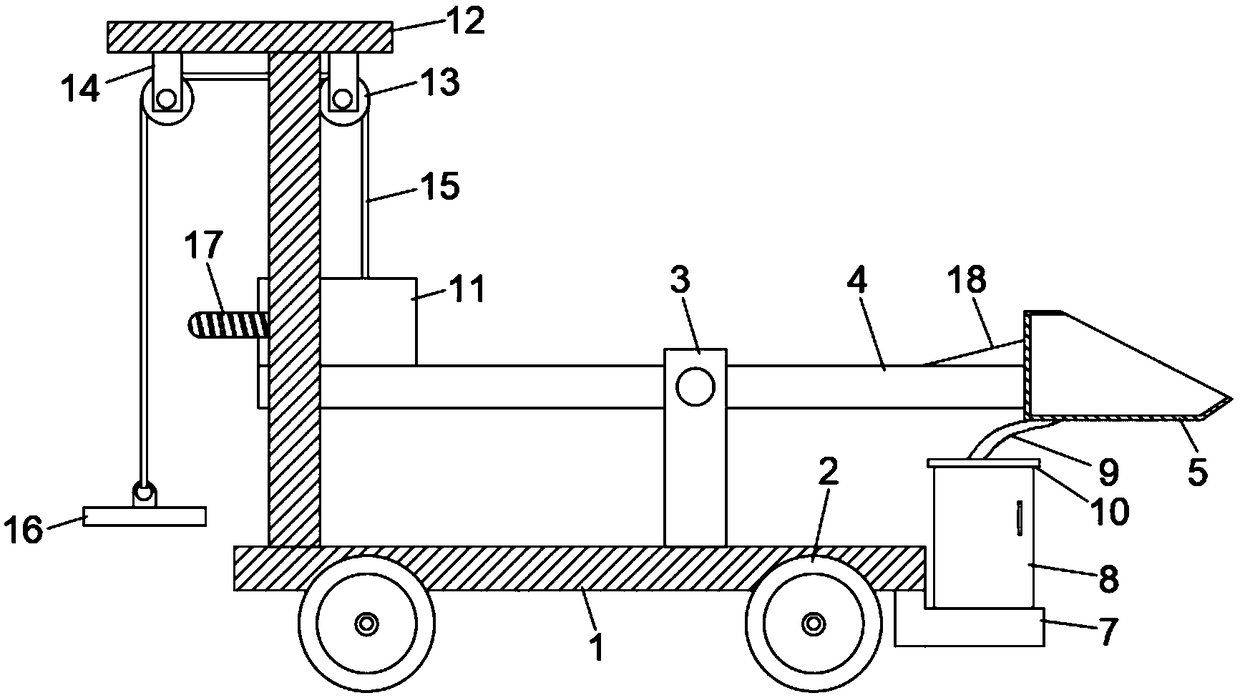

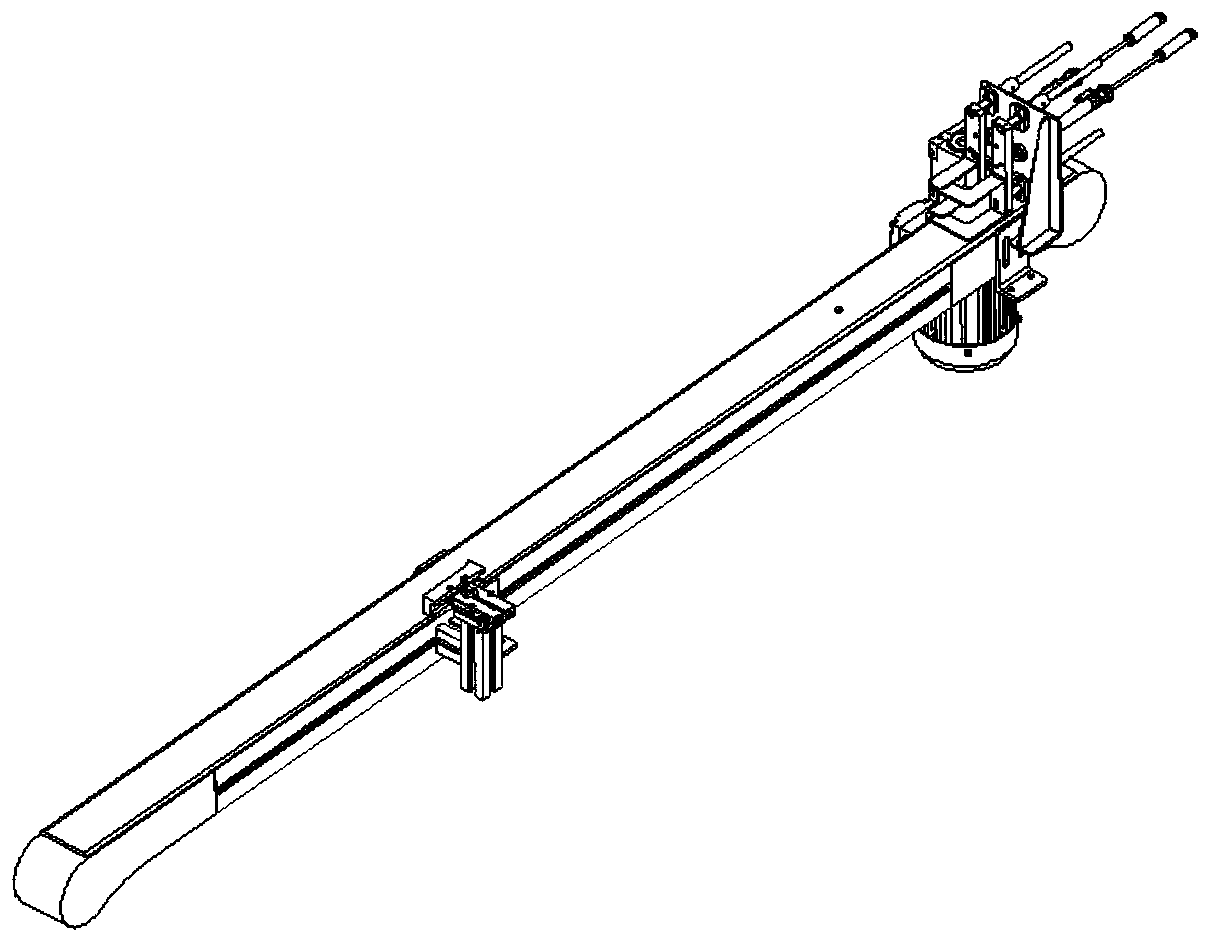

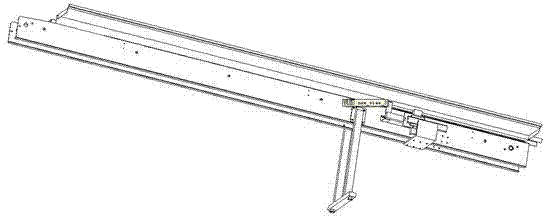

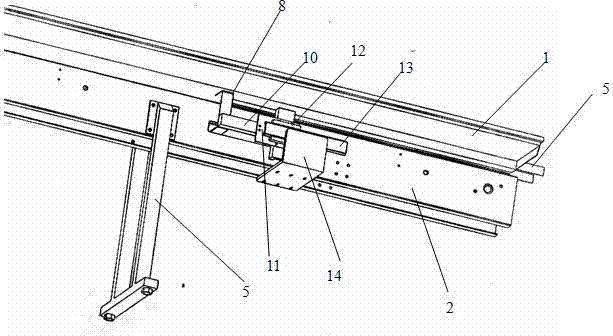

A fast bagging device for rice drying

ActiveCN109081127BReduce labor intensityFast baggingConveyorsSolid materialAgricultural engineeringStructural engineering

The invention discloses a quick bagging device for drying rice. The quick bagging device comprises a mounting seat, wherein rolling wheels are arranged at the bottoms of the front end and the rear endof the mounting seat; two fixed seats are fixedly connected at the upper end of the mounting seat; a rotating column is rotatably connected between the two fixed seats; a bucket is welded at the right end of the rotating column; a notch matched with the rotating column and the bucket is also formed at the front end of the mounting seat; two brackets are symmetrically welded at the bottom of the front end of the mounting seat; a material receiving frame is fixedly connected to the two brackets; two discharging holes are formed in the inner bottom of the bucket; and a corrugated pipe is fixedlymounted in each discharging hole. According to the quick bagging device provided by the invention, rice can be shoveled up and automatically bagged without manually dragging a bag opening and manually shoveling the rice, so that the labor intensity is greatly reduced; moreover, the rice can be prevented from spilling in a bagging process, the bagging speed is faster, the manpower is saved, and the operation is convenient and quick.

Owner:惠安县南兴电子科技有限公司

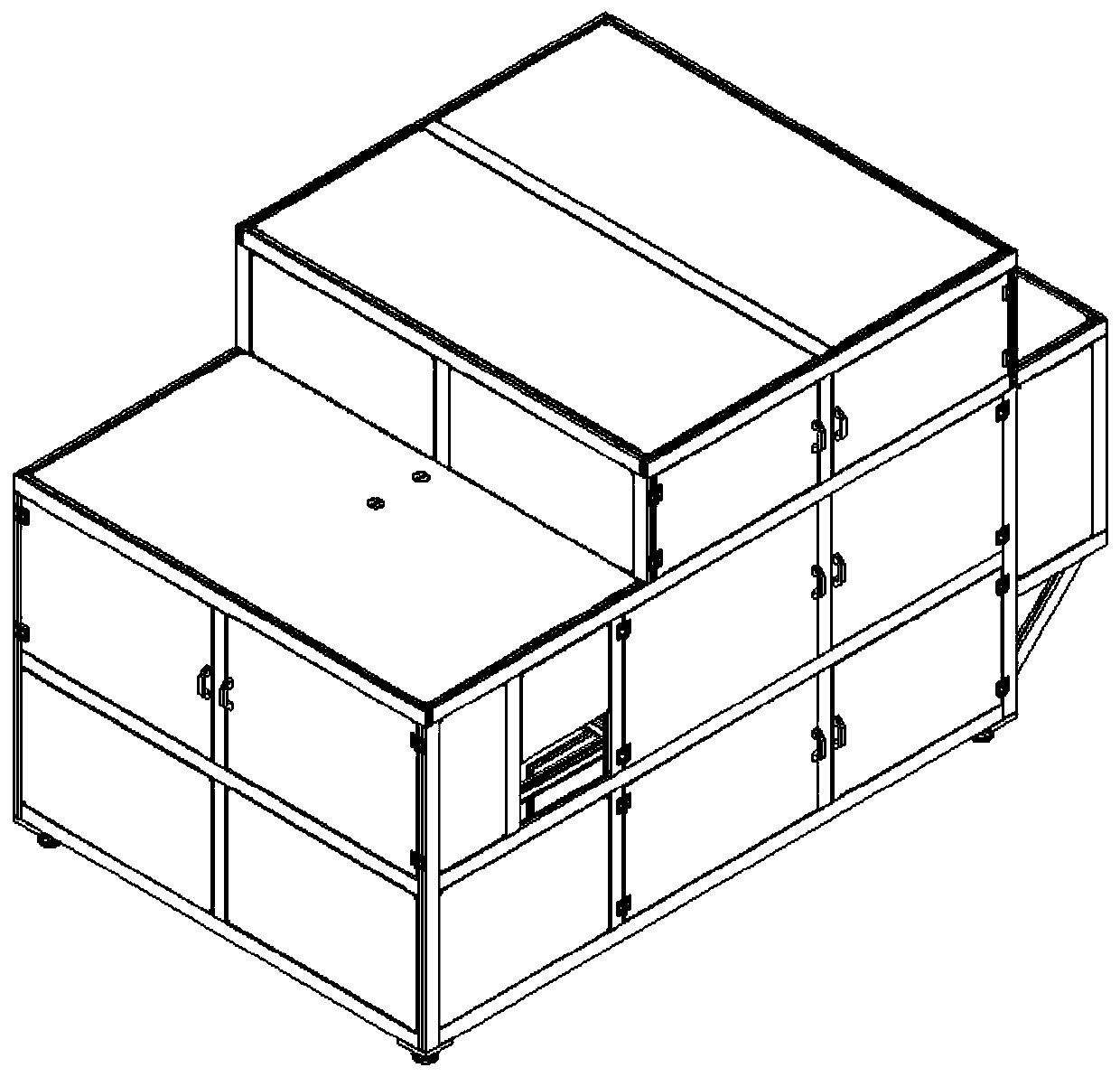

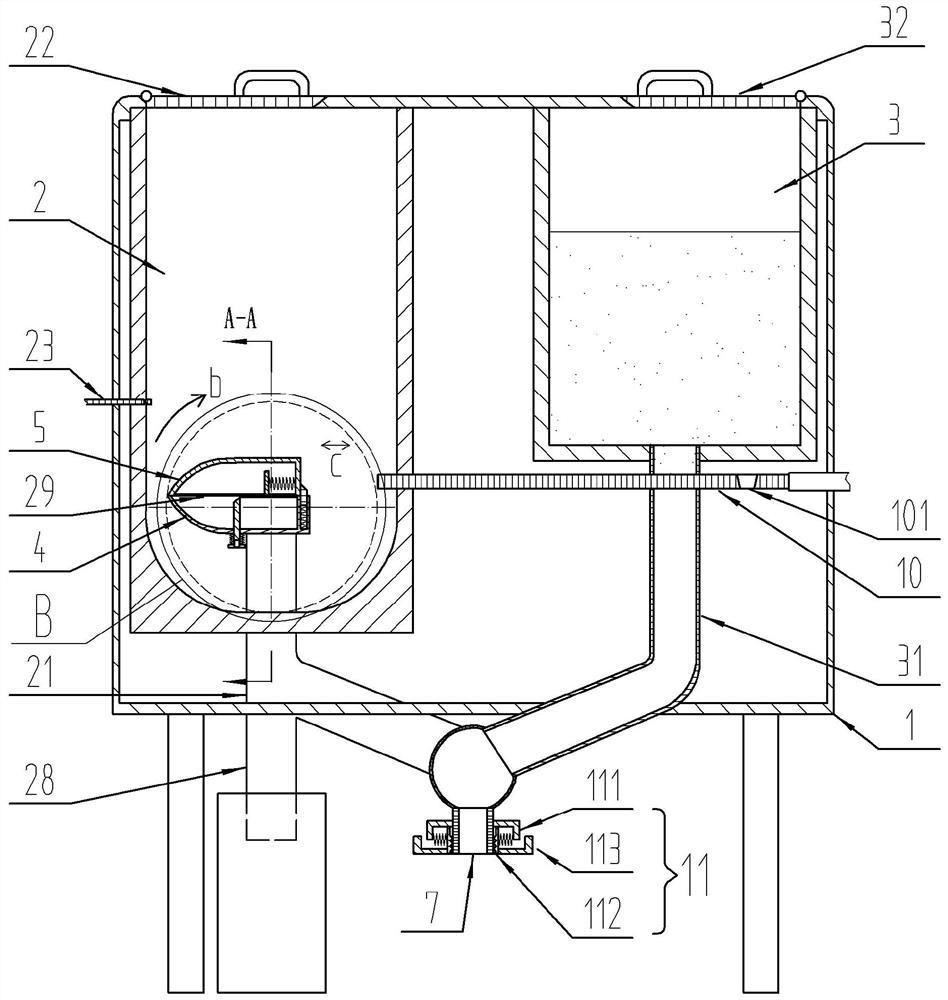

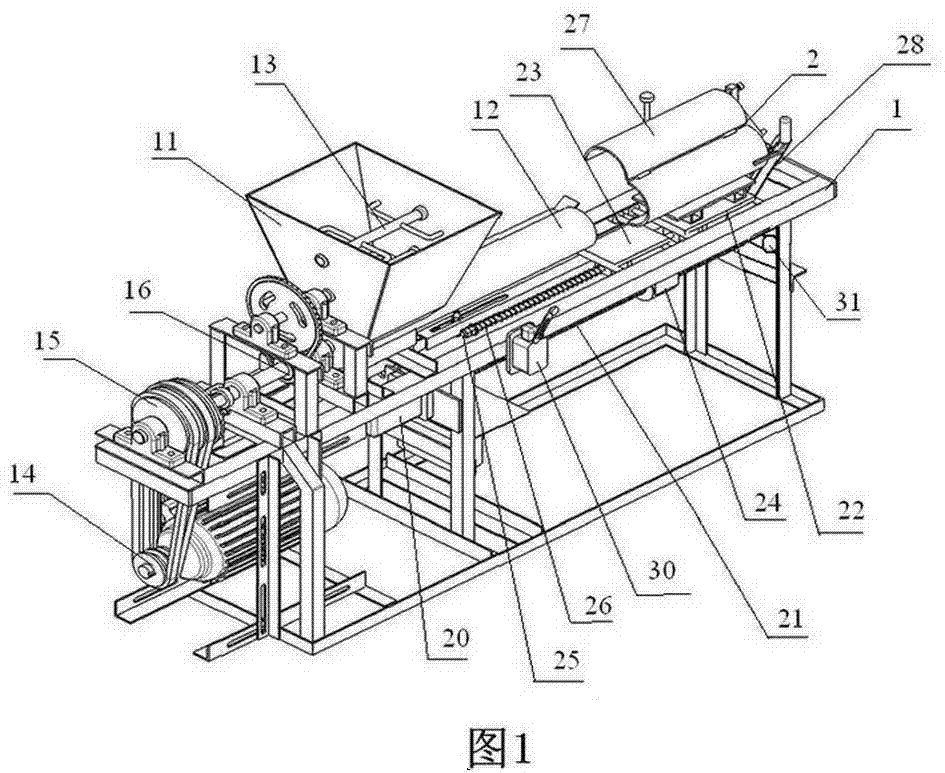

Pickled pepper food bagging machine

ActiveCN109353558BImprove liquidityNo damageWrapper twisting/gatheringLiquid materialChicken-clawsProcess engineering

The invention belongs to the technical field of food processing equipment, and particularly discloses a pickled pepper food bagging machine. The pickled pepper food bagging machine comprises a box body, a solid storage bin, a liquid storage bin, a discharging pipe, a solid conveying pipe and a liquid conveying pipe are arranged in the box body, a solid feeding hole is formed in the solid storage bin, a scooping piece and a sealing piece are arranged in the solid storage bin, a material inlet is formed in one side of the scooping piece, a communicating hole is formed in the bottom of the scooping piece, the communicating hole is connected with a partition plate in a sealed and sliding mode, the partition plate can divide the scooping piece into a containing cavity and a material leaking cavity, a water draining pipe further communicates with the solid conveying pipe, a liquid feeding hole is formed in the top of the liquid storage bin, the liquid storage bin communicates with the discharging pipe through the liquid conveying pipe, and the pickled pepper food bagging machine further comprises a power mechanism capable of driving the scooping piece to rotate horizontally. The bagged pepper food bagging machine has the advantages that the bagging speed is high, and chicken feet with pickled peppers, pigskin with the pickled peppers and other solid substances are hardly exposed in air.

Owner:HUNAN JUNJIE FOOD TECH CO LTD

Mechanical packaging equipment capable of conveying multiple materials

InactiveCN104494907ARealize automatic feedingFast baggingPackaging machinesPitch shiftMaterial resources

The invention discloses mechanical packaging equipment capable of conveying multiple materials. The mechanical packaging equipment comprises working tables, side plates and a guide track component, wherein the working table consists of a left working table and a right working table; the side plates consist of a left side plate and a right side plate; the guide track component comprises a guide track A and a guide track B; the guide track A consists of a left guide track and a right guide track; the left guide track and the right guide track are respectively mounted on the left side plate and the right side plate. The mechanical packaging equipment is characterized in that pitch shifting forks are arranged between the left guide track and the right guide track; the pitch shifting forks comprise a pitch shifting fork A and a pitch shifting fork B; the pitch shifting fork A and the pitch shifting fork B are longitudinally kepted on one same straight line; the left working table and the right working table are symmetrically mounted on the left guide track and the right guide track; pull plates are arranged below the working tables; the pull plates consist of a pull plate A and a pull plate B which are respectively mounted below the left working table and the right working table. The mechanical packaging equipment capable of conveying multiple materials has the advantages that the automatic feeding of multiple regular articles is implemented, the bagging speed is increased, the manpower and material resources are saved, the working efficiency is improved, and the structure is simple, thereby being suitable for popularization.

Owner:WUXI G&Z FLUID EQUIP

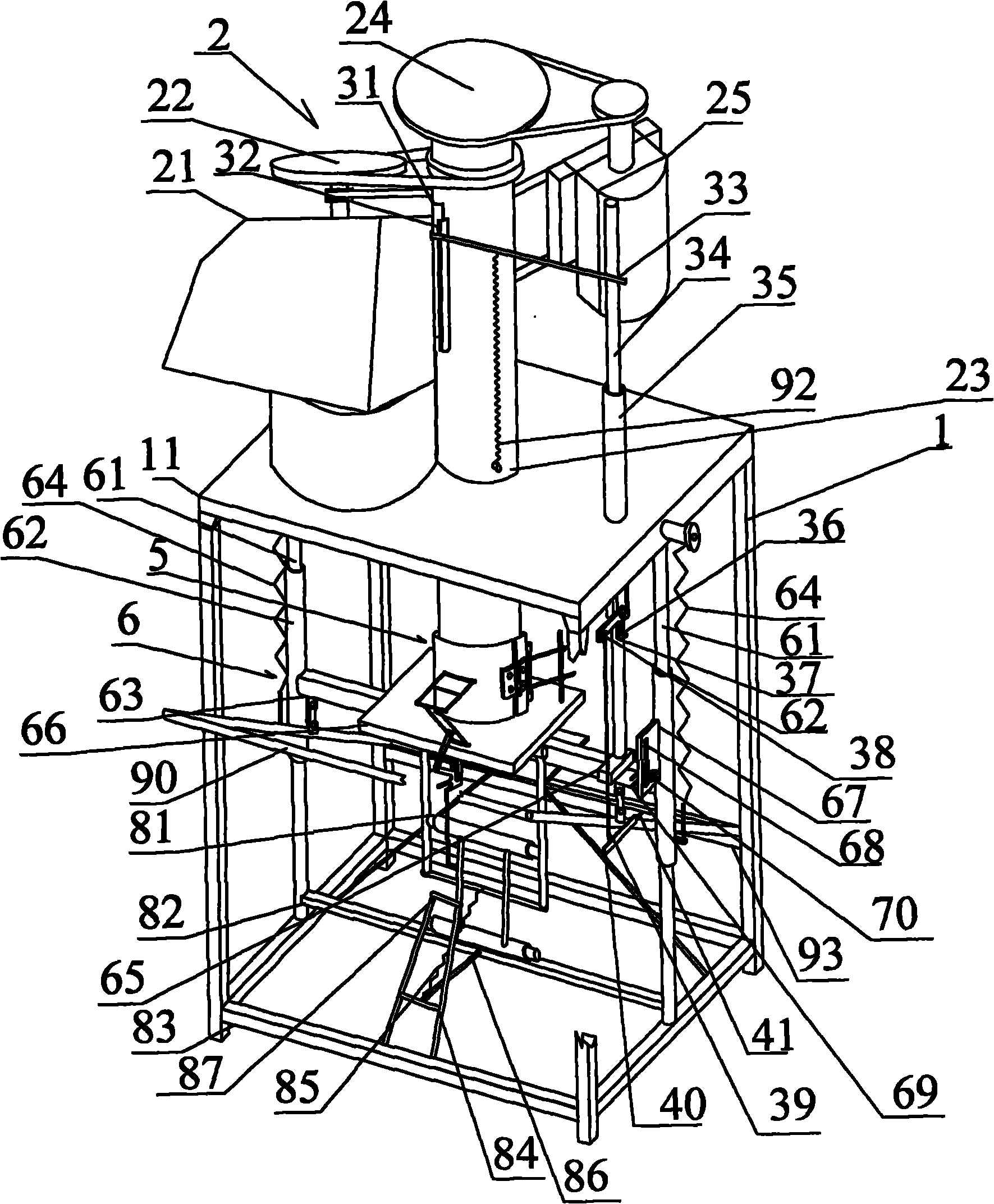

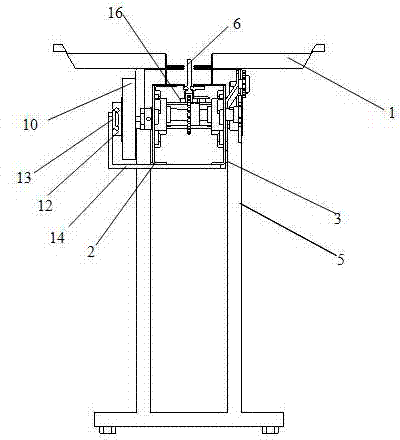

Horizontal automatic control bagging machine

InactiveCN103477874BIncrease productionGuaranteed supplyHorticultureAutomatic controlControl engineering

Owner:李明波

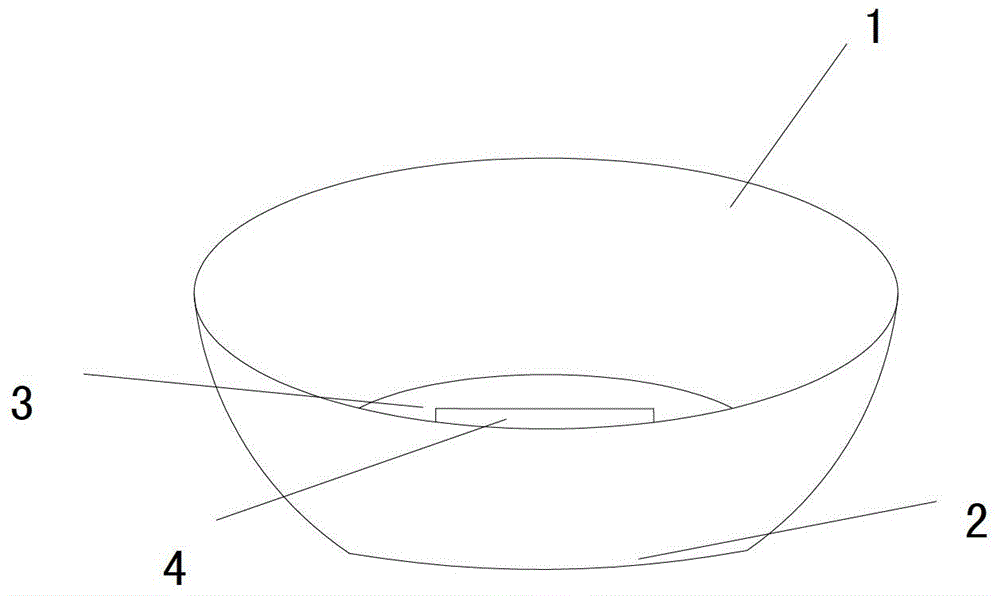

Rapidly-bagged fast food bowl

The invention discloses a rapidly-bagged fast food bowl which comprises a bowl bottom, a bowl opening and a bag rolling shaft, wherein the bowl bottom is provided with the bag rolling shaft; the bag rolling shaft is provided with a support plate; a food bag is rolled on the bag rolling shaft and sleeves the bowl opening; the bowl opening is provided with a bag staying buckle; rolled bags for take-away fast food of a noshery are rolled on the bowl bottom; when one rolled bag is drawn off, the next rolled bag can be draw out, and the two rolled bags are rapidly separated by virtue of a breakpoint line, so that the fast food bagging speed can be effectively quickened, the workload of a user can be alleviated, the waiting time of customers is reduced and the rapidly-bagged fast food bowl is quite practical.

Owner:XIAN TENGJI BIO TECH

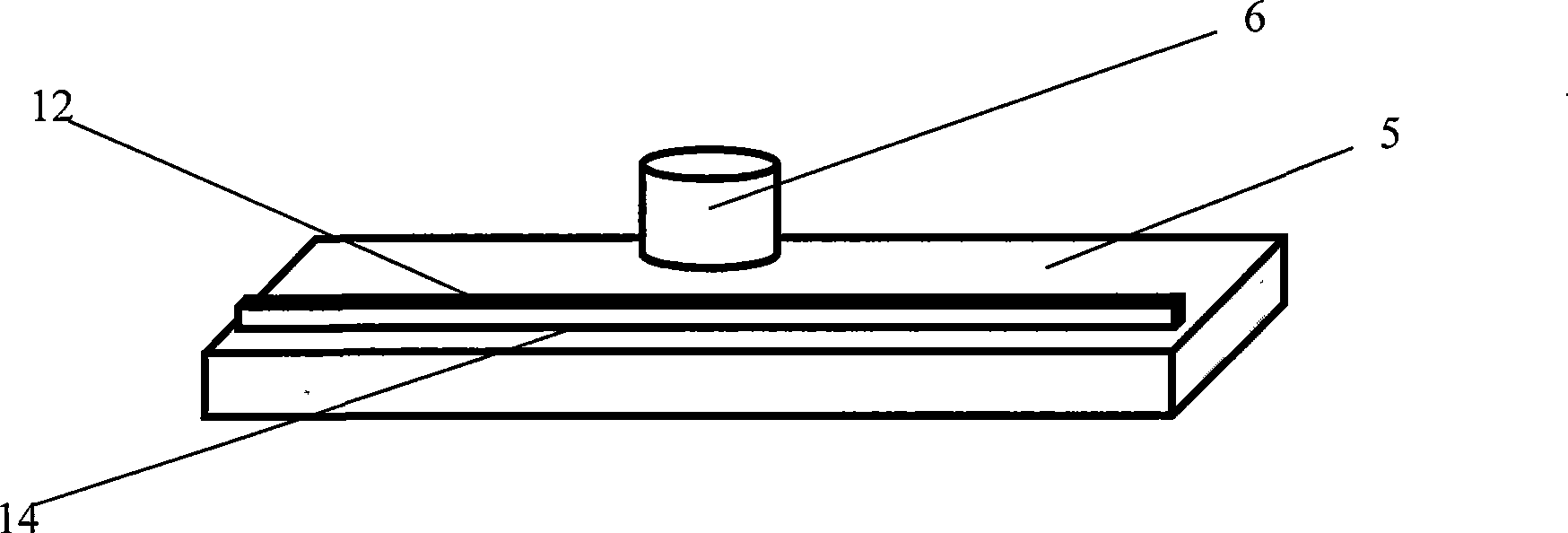

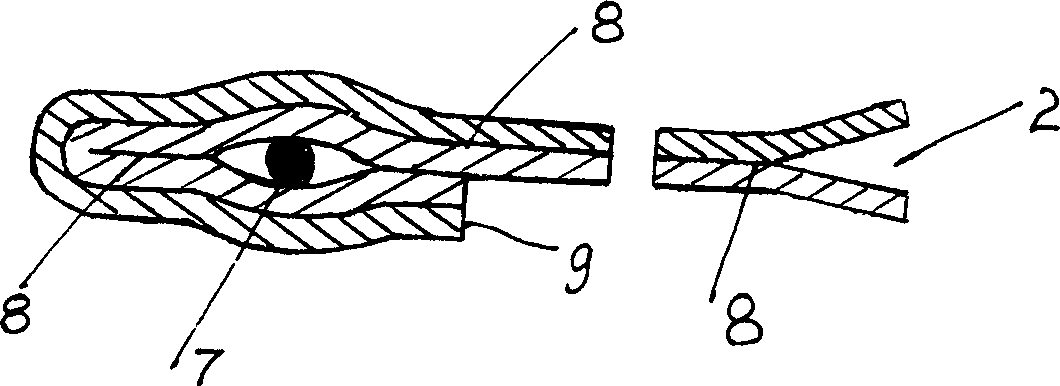

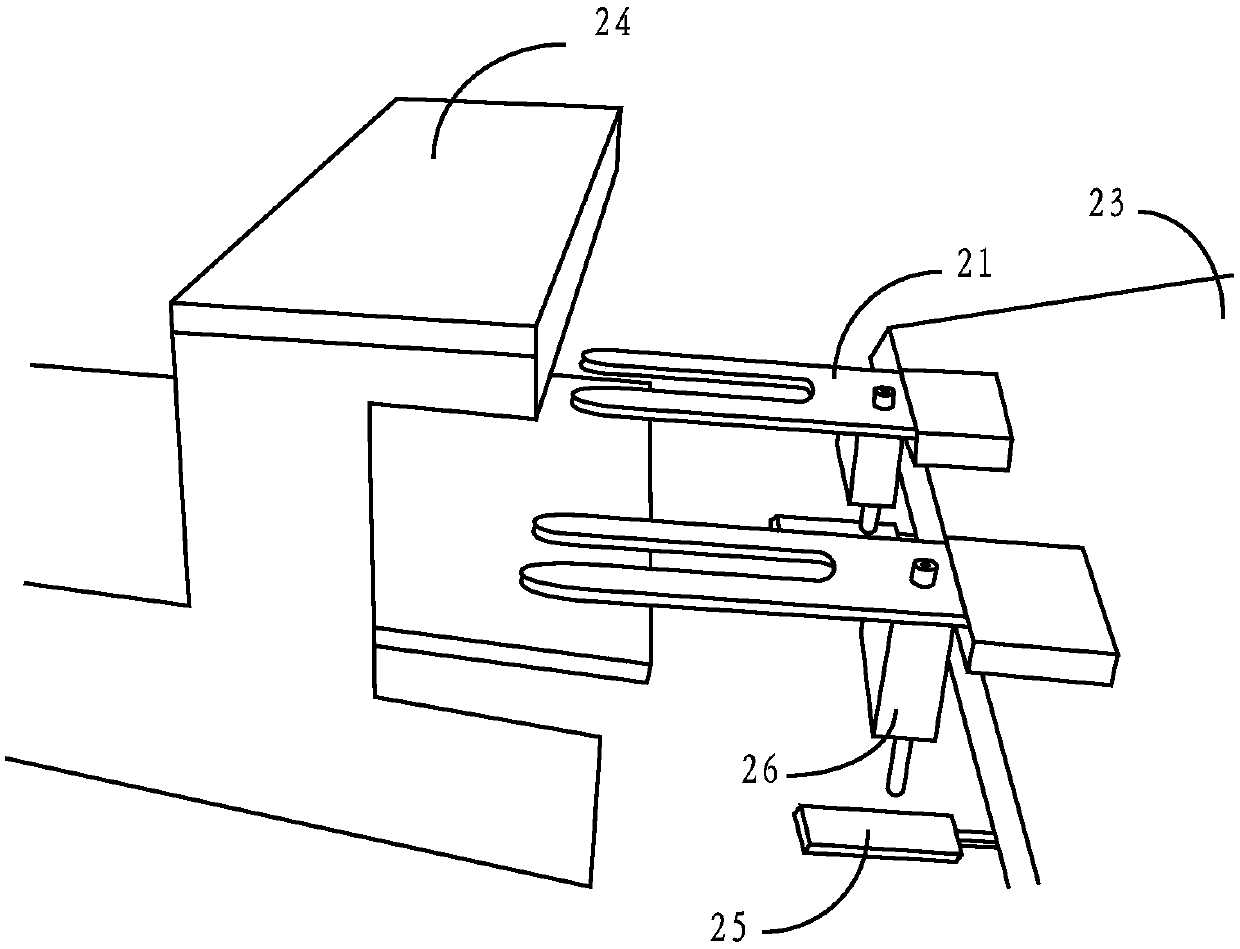

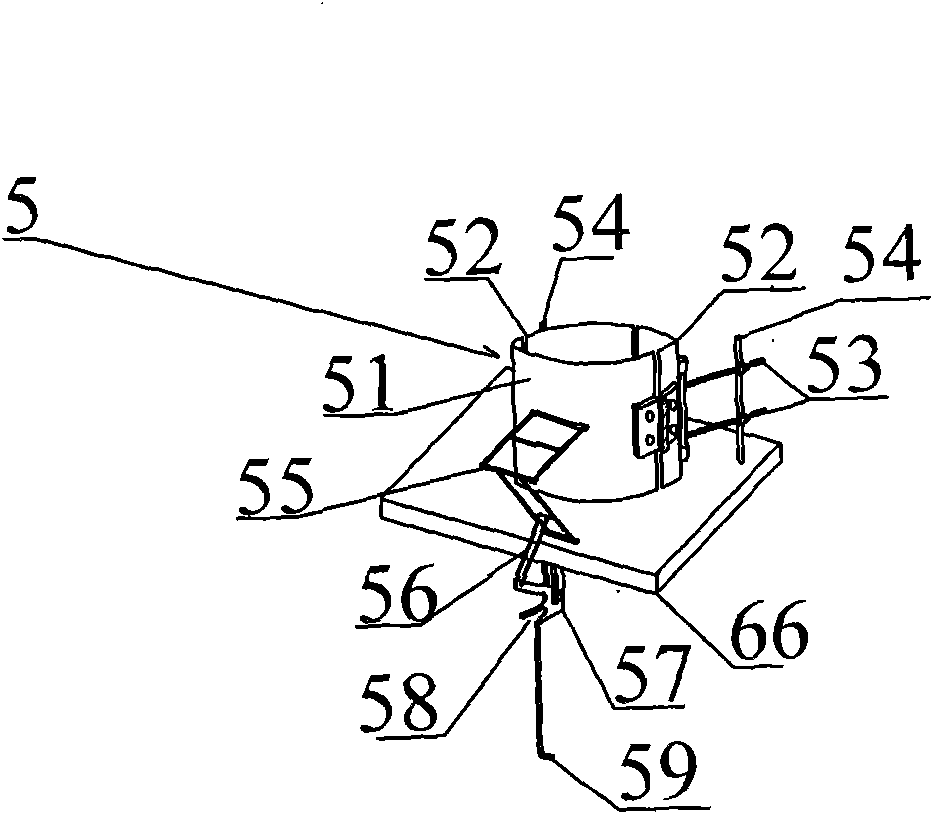

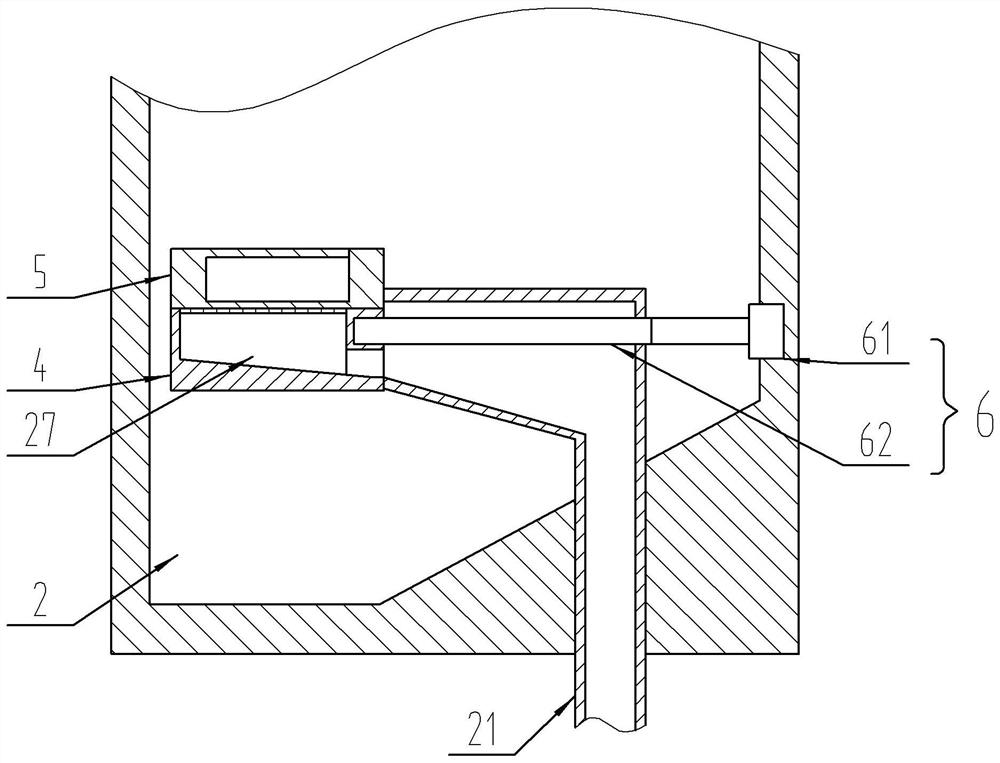

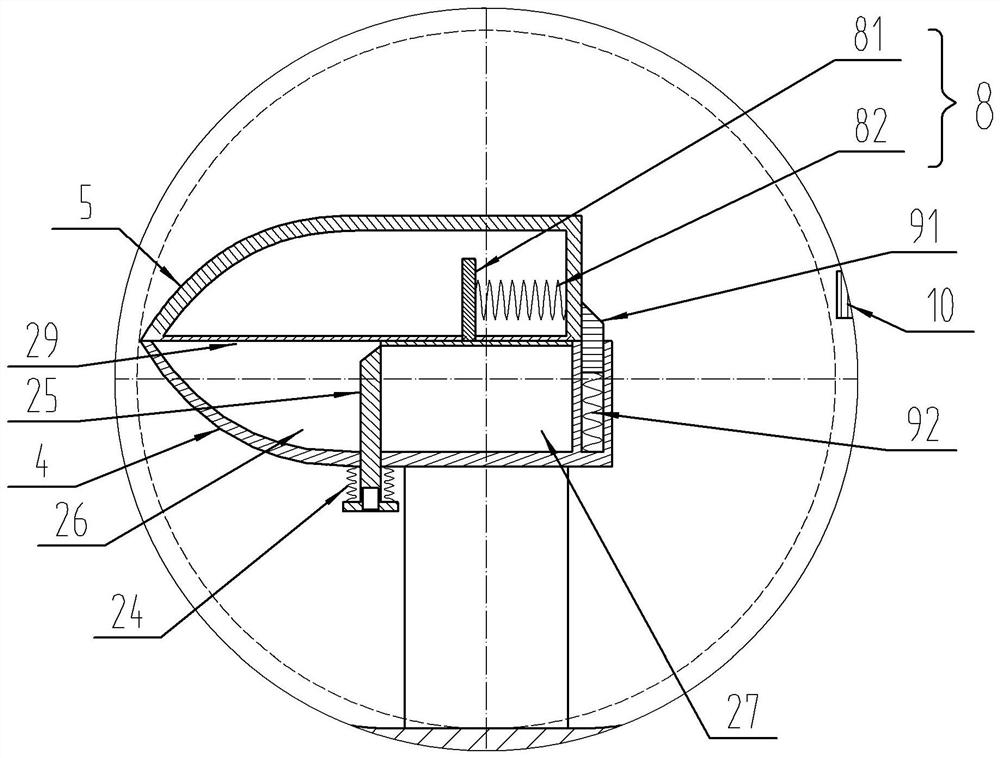

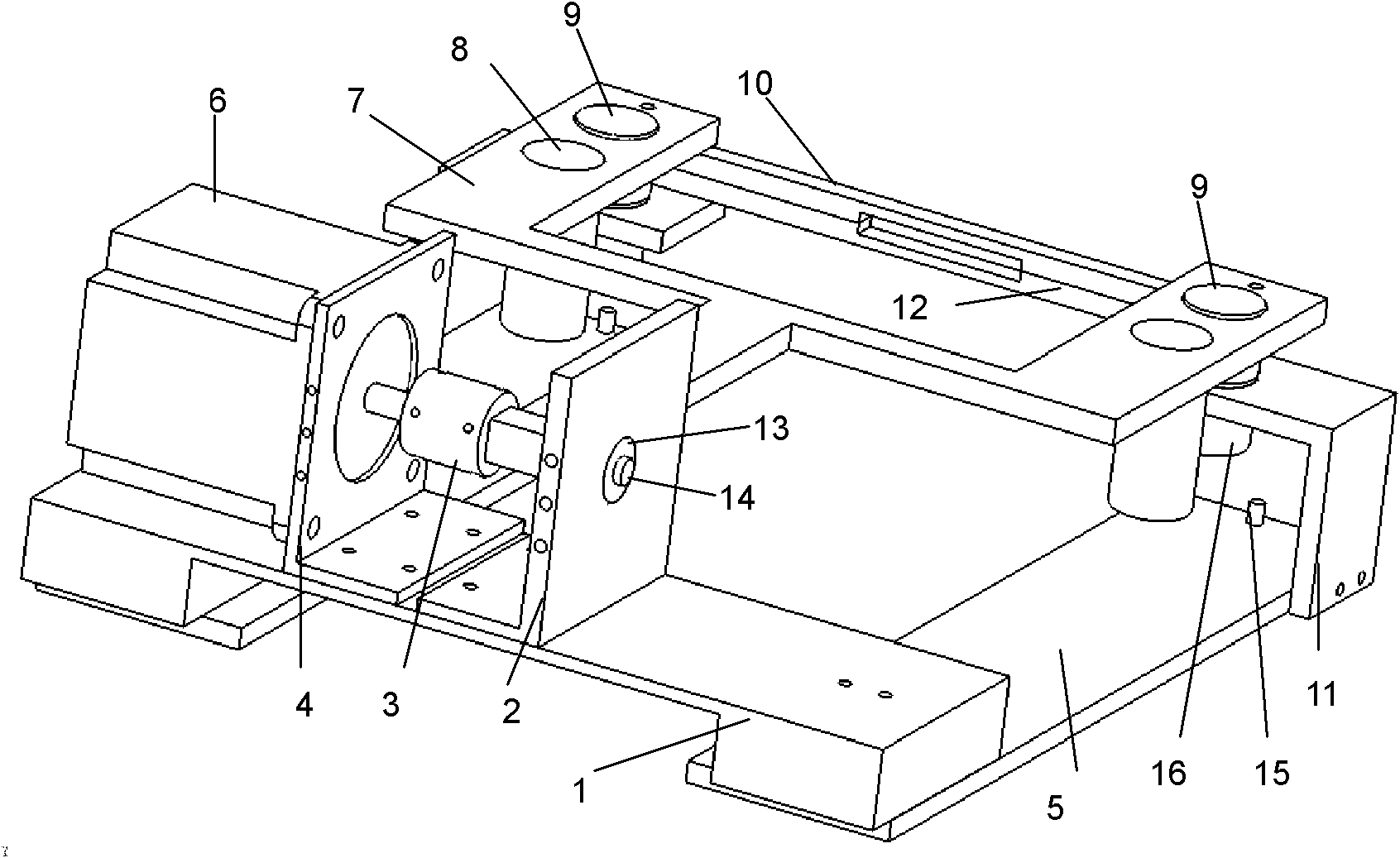

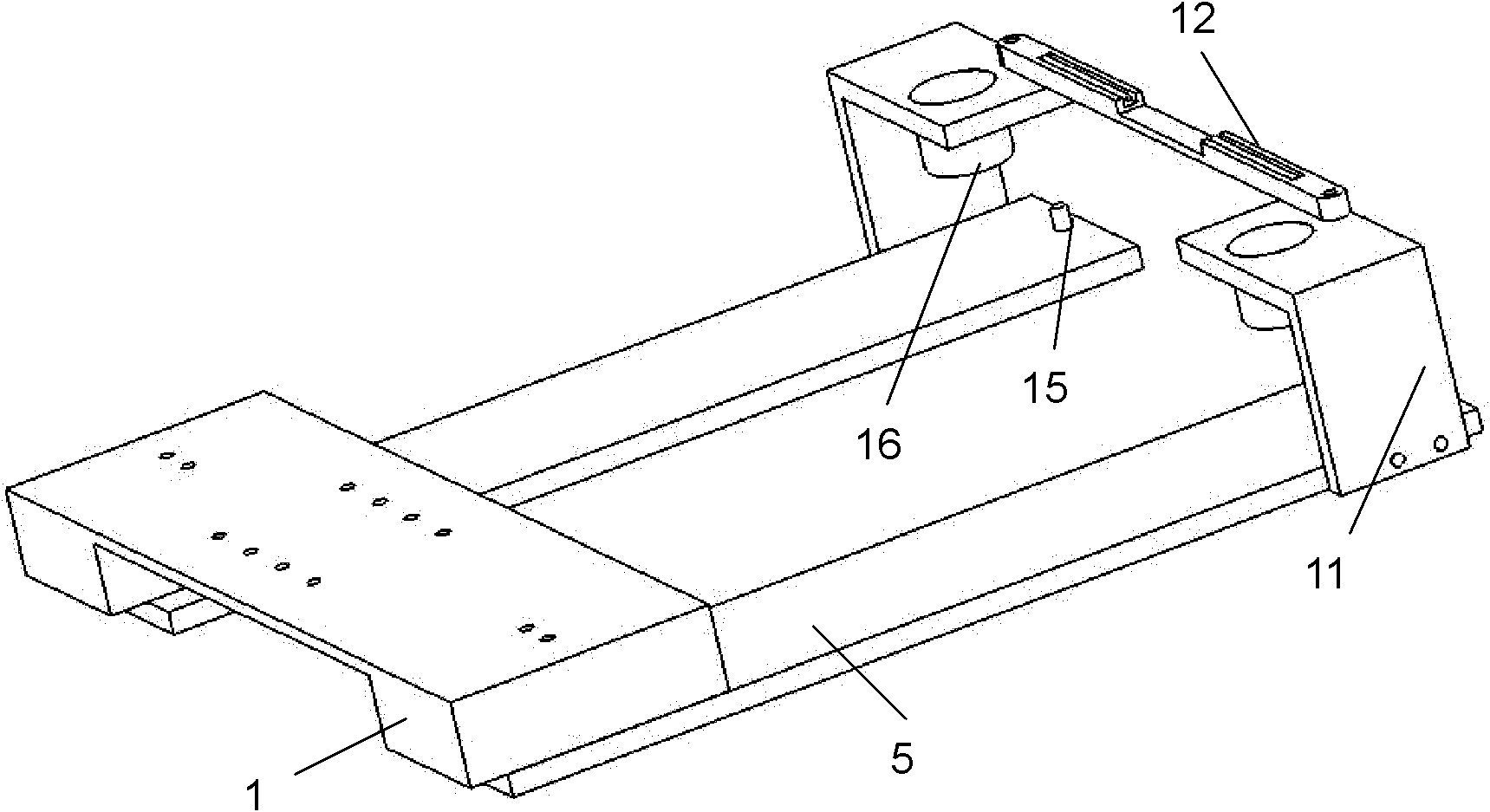

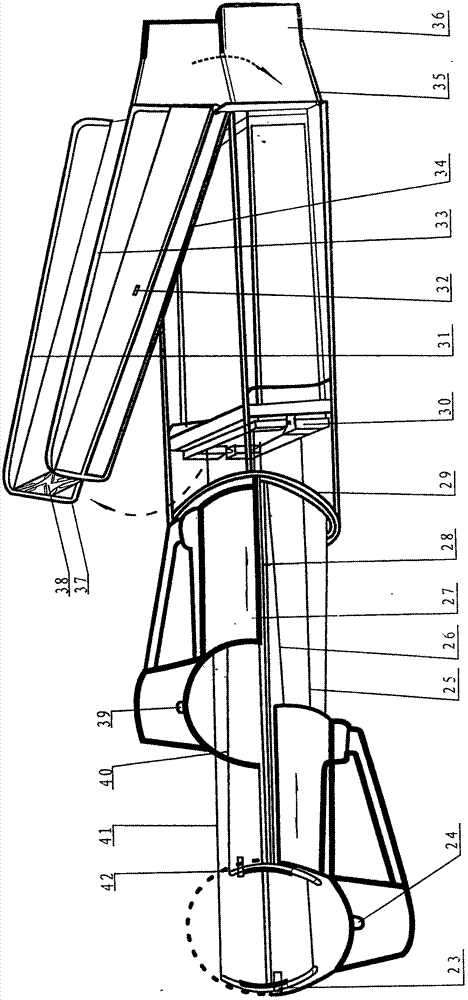

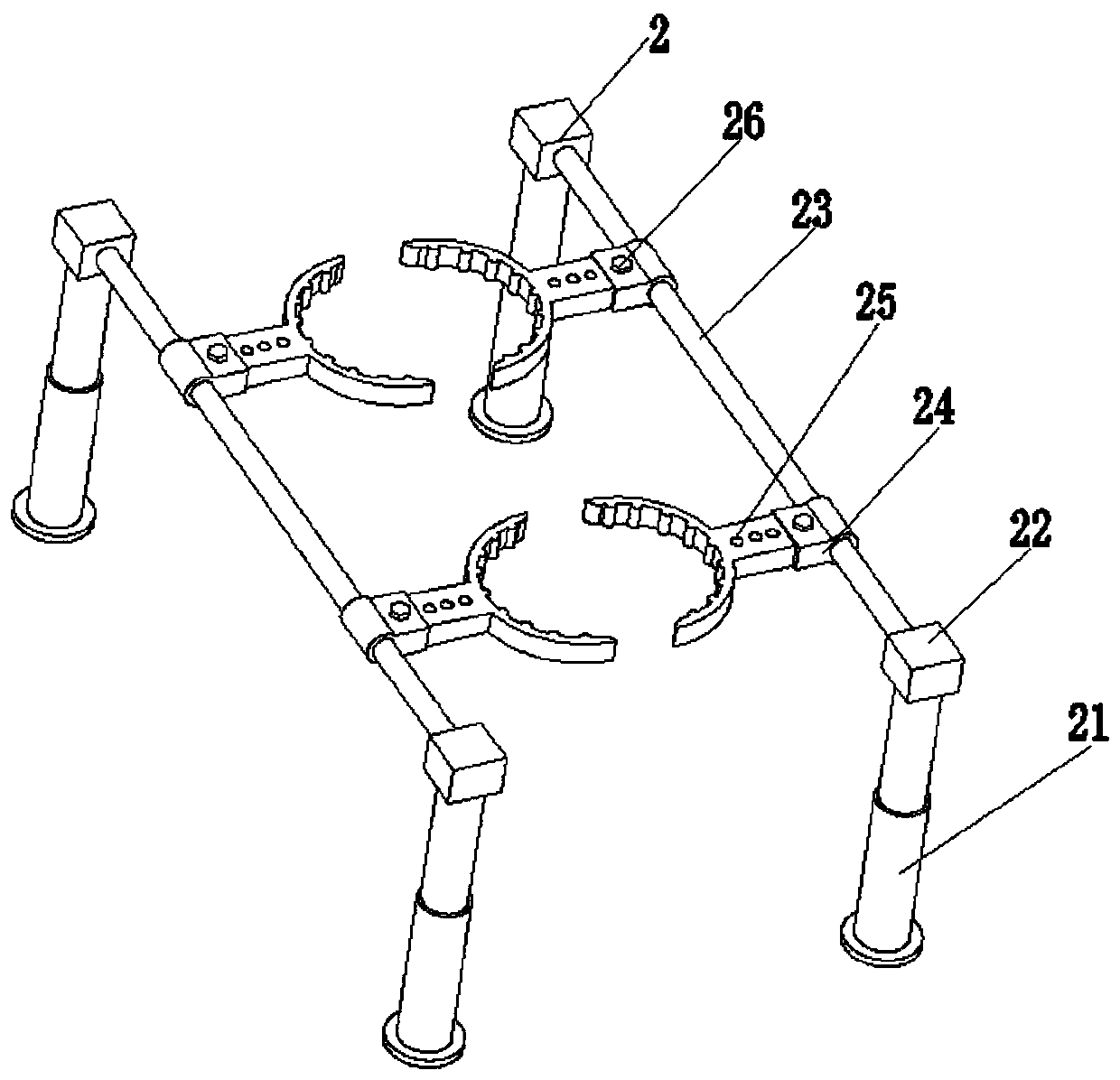

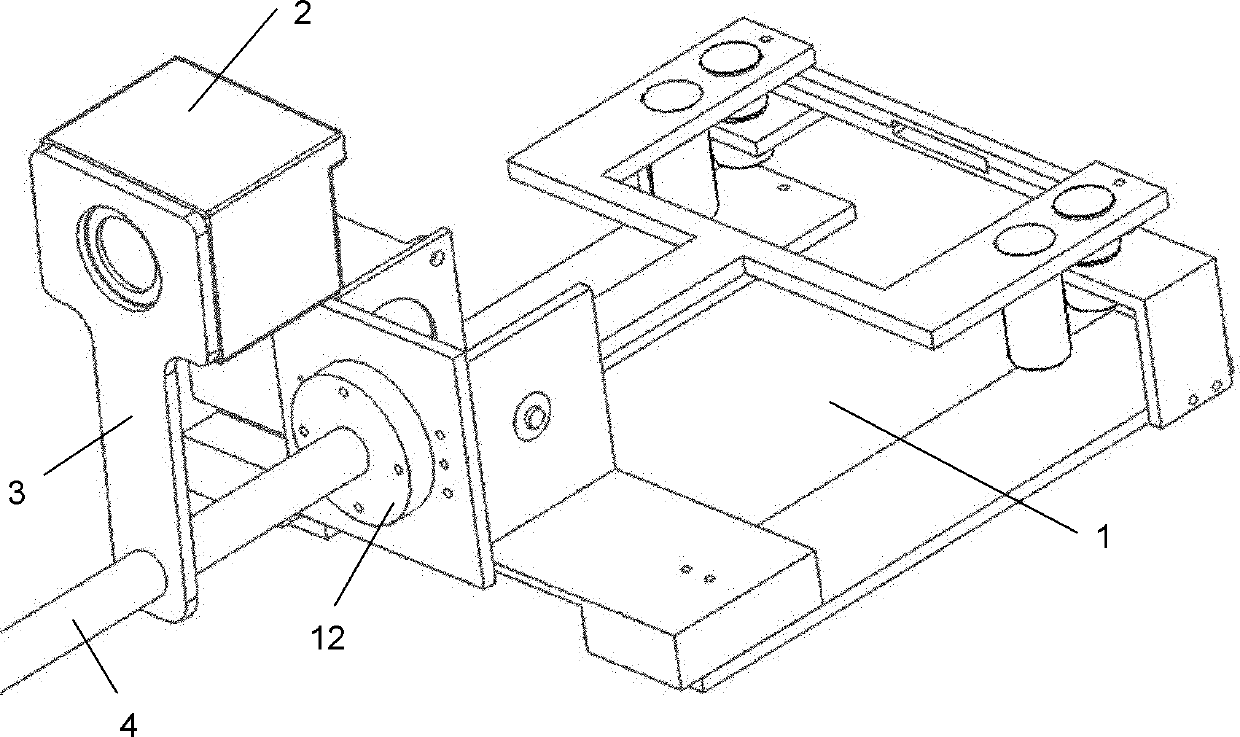

Automatic fruit bag sheathing device

InactiveCN102484976BEasy to operateFast baggingPlant protective coveringsComputer engineeringElectric heating

The invention relates to an automatic fruit bag sheathing device, which comprises a motor, a support seat, a rocking bar mechanism, fruit bag support plates, fruit bag fixing screw bolts and chucks, wherein the rocking bar mechanism comprises a compression round post, a long rubber rod and opening sealing jaws, the compression round post is in symmetrical arrangement, the motor is fixedly arranged on the support seat through a motor seat, an output shaft of the motor is connected with a rocking bar shaft through a shaft coupler, two sides of the support seat are symmetrically provided with the fruit bag support plates, the fruit bag fixing screw bolts and the chucks are symmetrically arranged on the two fruit bag support plates, short rubber bars corresponding to the compression round post are symmetrically arranged on the two chucks, the opening sealing lower jaw is transversely spanned between the two chucks, the opening sealing upper jaw and the opening sealing lower jaw are in symmetrical structure, notches are respectively arranged in the middle parts of the upper jaw and the lower jaw, two sides of the notches are respectively provided with grooves, and electric heating plates are arranged in the grooves. The automatic fruit bag sheathing device adopts the single motor for driving rocking bars to rotate, the bag taking, bag supporting and bag sealing operation of fruit bags can be automatically realized, the structure is simple, the speed is high, the reliability is realized, the operation of the whole bag sheathing process is easy, the speed and the efficiency are high, and the automatic fruit bag sheathing device can be widely applied to the fruit bag sheathing field operation production.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

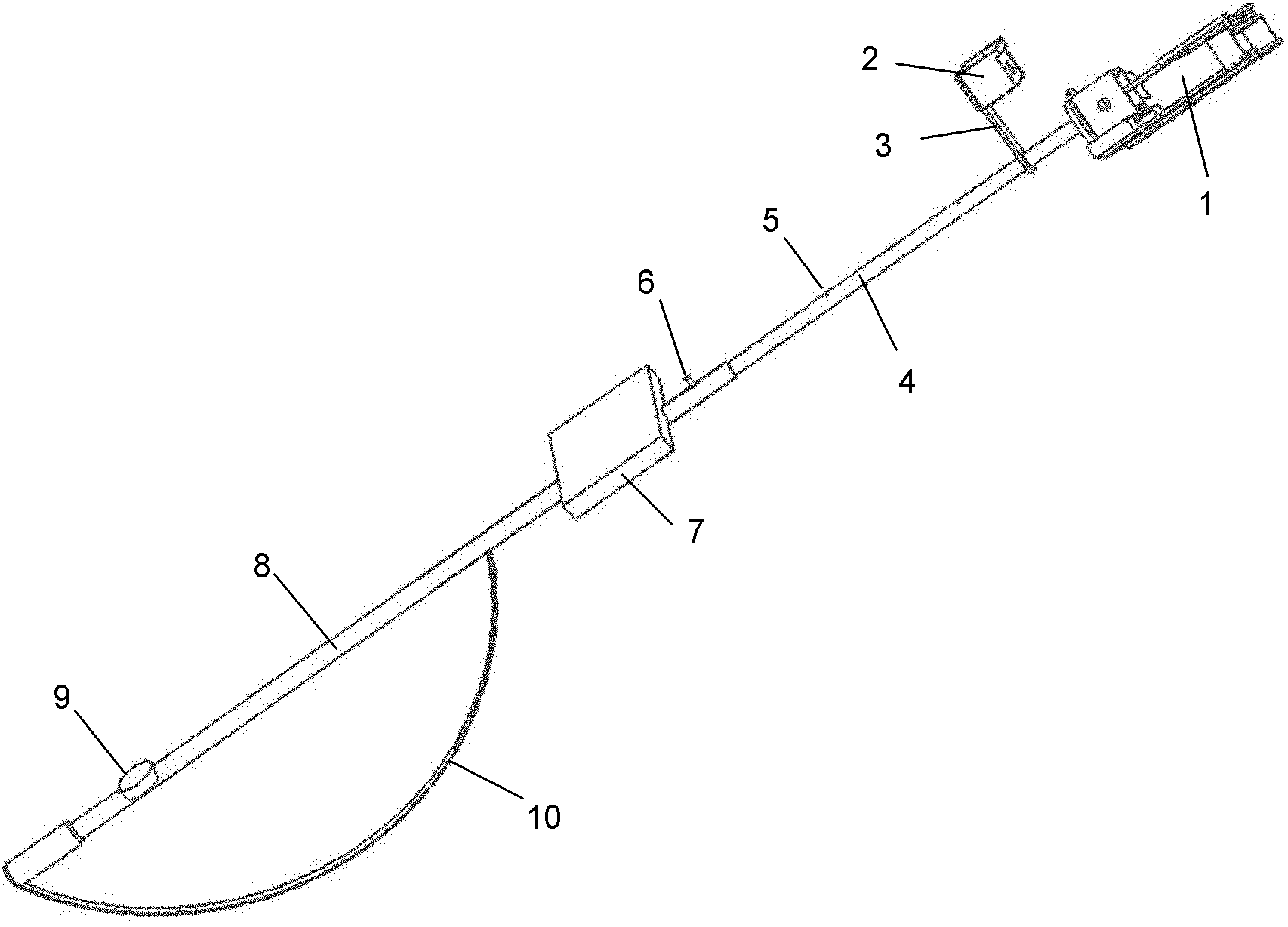

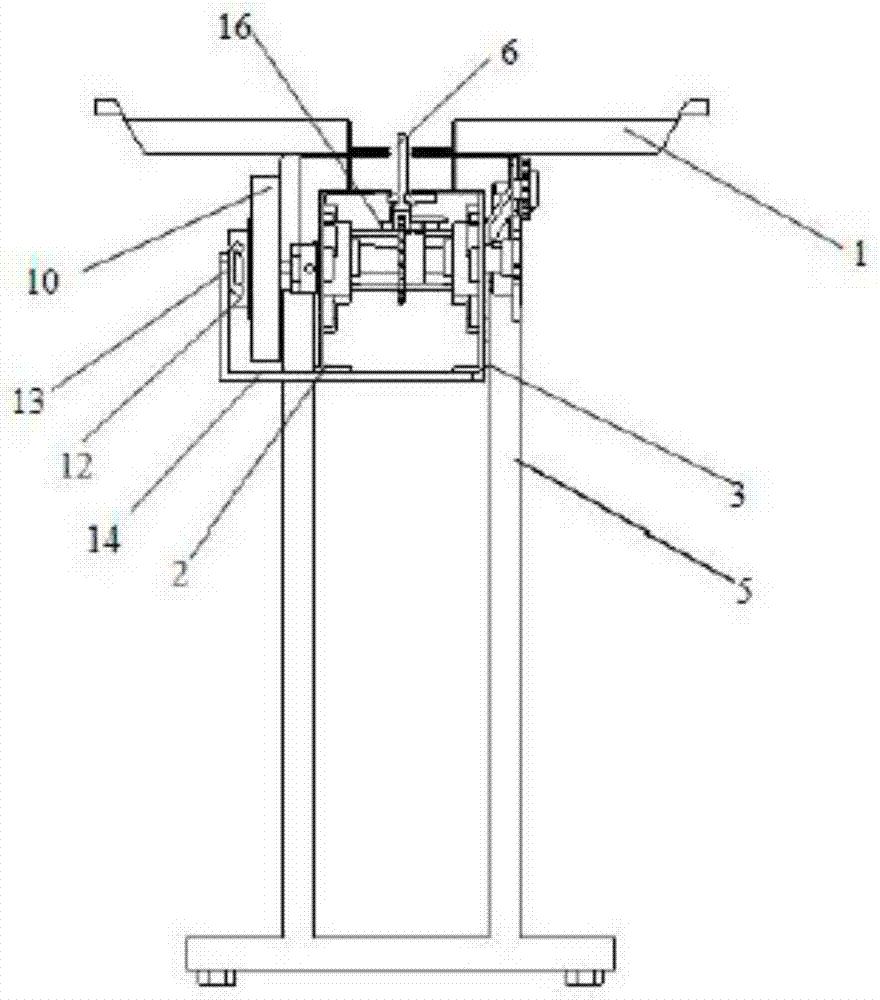

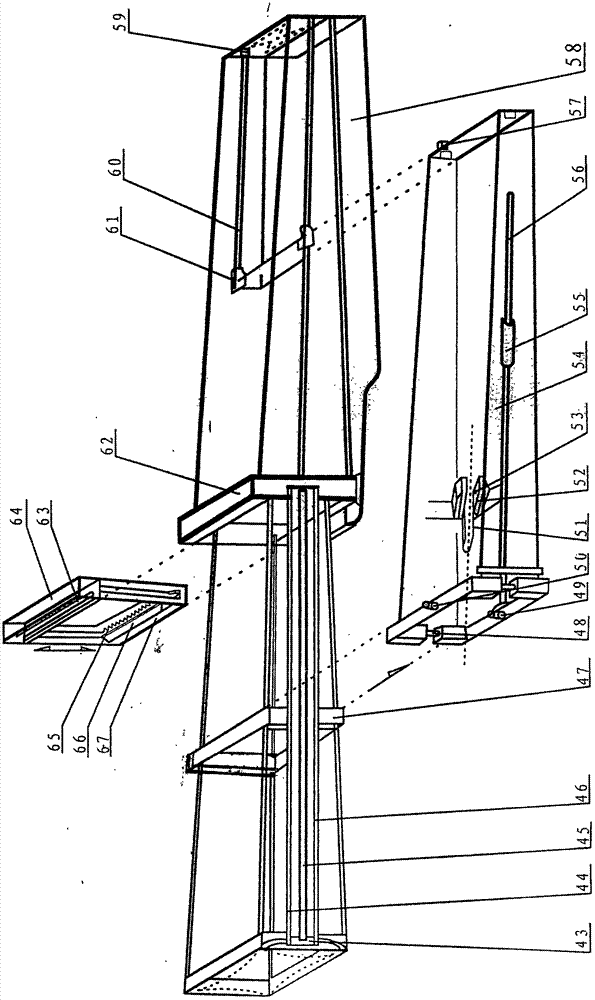

Quick-sterilization automatic fruit bagging device

PendingCN107439277AReduce volumeReduce weightPlant protective coveringsInsect catchers and killersMechanical engineeringIndustrial engineering

The invention belongs to the technical field of machine manufacturing and relates to a quick-sterilization automatic fruit bagging device. The quick-sterilization automatic fruit bagging device is mainly characterized in that a fruit bagging device and an agent mist spraying device are arranged on a handle; the fruit bagging device is characterized in that a bagging device and a spraying device are arranged at one end of a round fixed shell which is fixedly arranged on a support, a bag supply device and a bag inlet device are arranged at the other end of the round fixed shell which is formed by fastening of two semicircular shells namely an upper bagging chamber and a lower bagging chambers, the upper bagging chamber and the and lower bagging chamber are in slide connection with an upper groove rail and a lower groove rail passing through the round fixed shell, a bag closing and binding device is arranged at the end of an upper bagging chamber and lower bagging chamber combination through a rotating mechanism, and a fruit bag cutting device is arranged on the bagging device. The quick-sterilization automatic fruit bagging device has advantages of small size, light weight, one-time completion of agent spraying, bagging and binding, high automation degree, quickness in bagging and integration of agent mist spraying, sterilizing, bagging and binding, and accordingly manpower resources can be greatly saved.

Owner:陈上海

Automatic bagger

InactiveCN103129762ACompact structureEasy to operateWrapper twisting/gatheringSuccessive articlesCircular discEngineering

The invention provides an automatic bagger which comprises a body. A feeding rail for conveying parts is arranged on the body, a film support is arranged at the top of the body, a film disk is arranged on the film support, a film receiving hopper is arranged on the body and positioned at the tail end of the feeding rail, the periphery of the film receiving hopper is sleeved on the film disk, a film thermoplastic device is used for treating a film sleeved on the receiving hopper in a thermoplastic manner to form a packaging bag and is arranged on the body, the receiving hopper is provided with a feed opening, and the parts are placed into the packaging bag through the feed opening. The automatic bagger is compact and simple in structure, convenient to operate, fast in bagging, stable and reliable in work, low in labor intensity, fine in accuracy and high in work efficiency.

Owner:海盐福美瑞五金制造有限公司

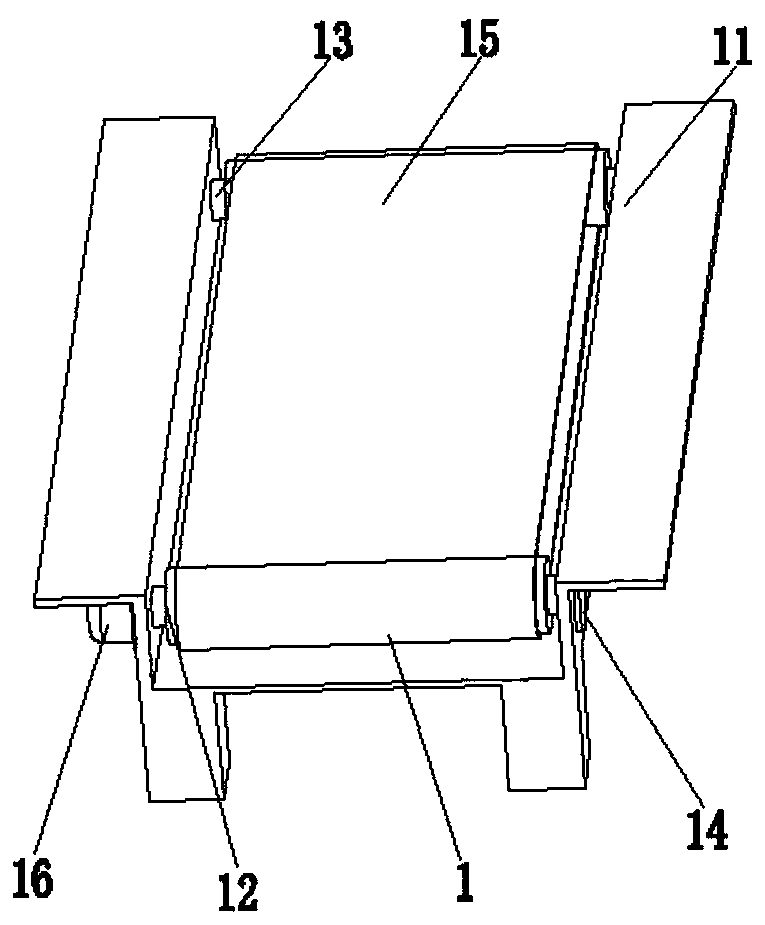

Improved wind power overturning rapid inner film sleeved method

InactiveCN109774246AImprove flatnessEasy to manufactureBag making operationsPaper-makingEngineeringWind power

The invention discloses an improved wind power overturning rapid inner film sleeved method. Equipment of the improved wind power overturning rapid inner film sleeved method comprises a rack, the rackis provided with an inner film platform and a woven bag platform correspondingly, the side, close to the inner film platform, of the woven bag platform is provided with a woven bag opening device, thejoint between the woven bag platform and the inner film platform is provided with an inner film clamping device, bagging blowing mouths are arranged above the inner film clamping device and directlyface the woven bag platform, the heights of the bagging blowing mouths are higher than the height of the woven bag platform, the inner film clamping device comprises a front clamping plate and a rearclamping plate, the front clamping plate is fixed to one side of the woven bag platform and is perpendicular to the woven bag platform, the rear clamping plate is parallel to the front clamping plateand is capable of moving front and back, the bagging blowing mouths comprise the upper bagging blowing mouth and the lower bagging blowing mouth, the upper bagging blowing mouth is arranged above theinner film platform, and the lower bagging blowing mouth is arranged below the inner film platform.

Owner:陈金选

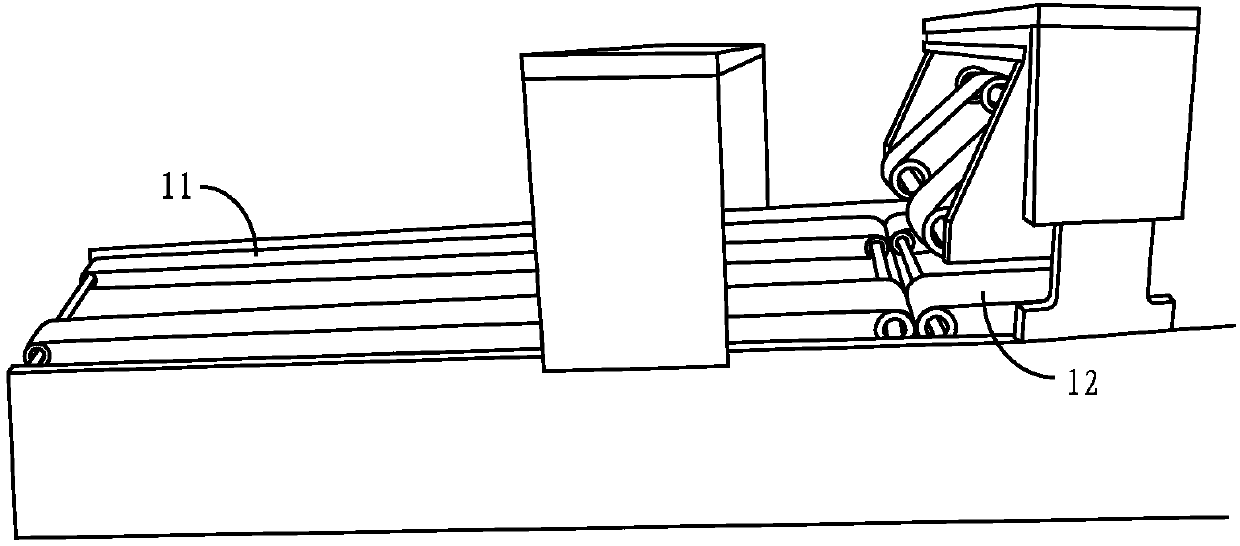

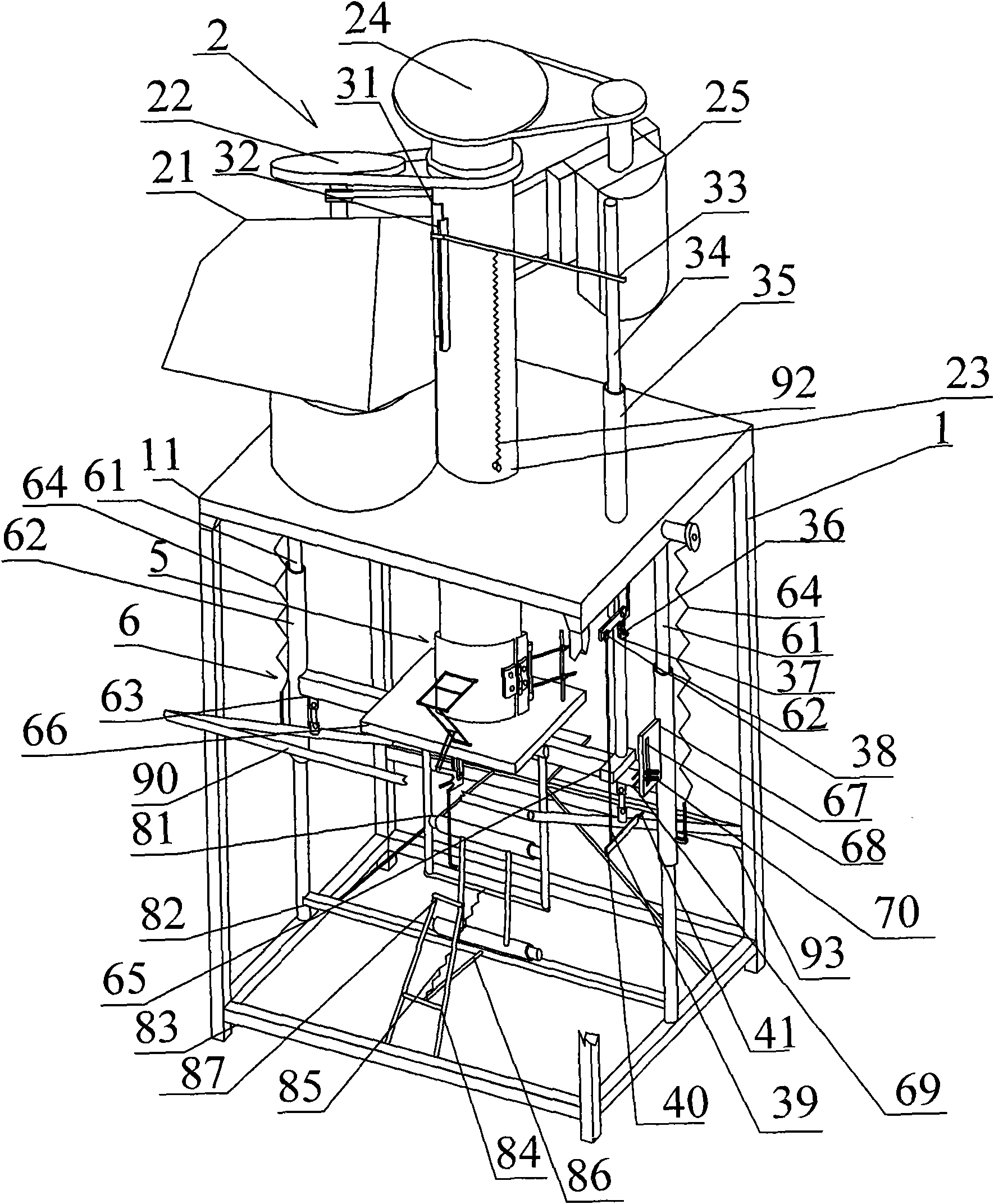

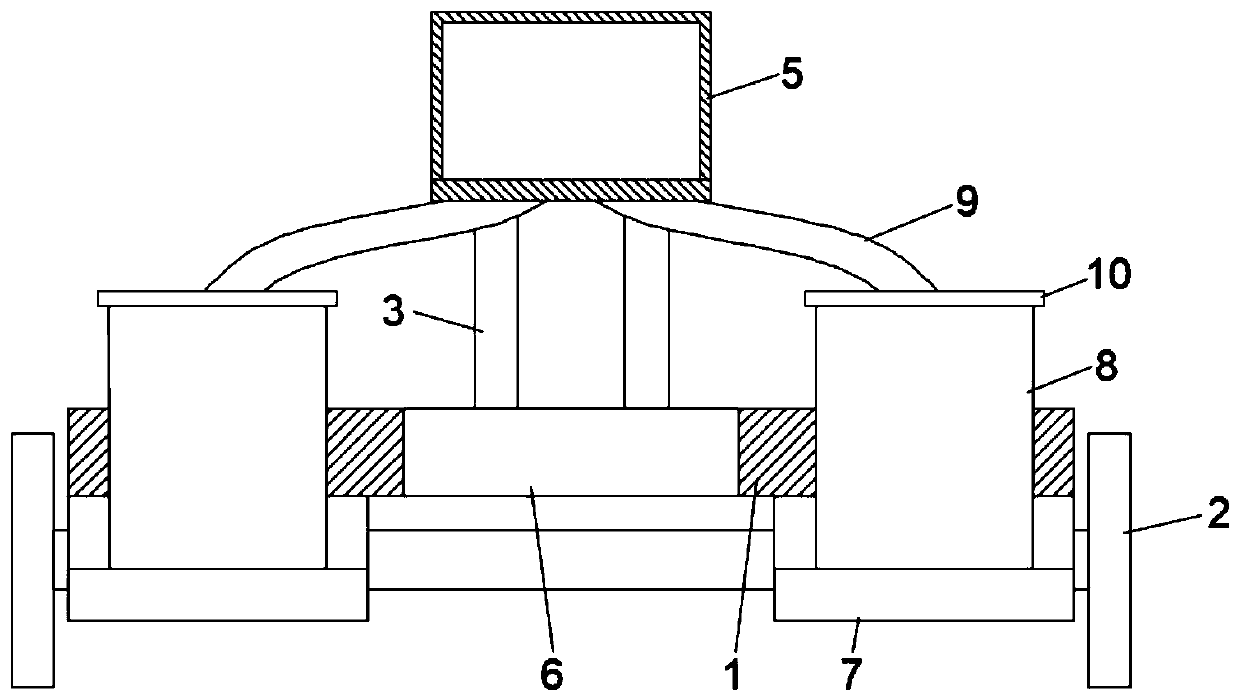

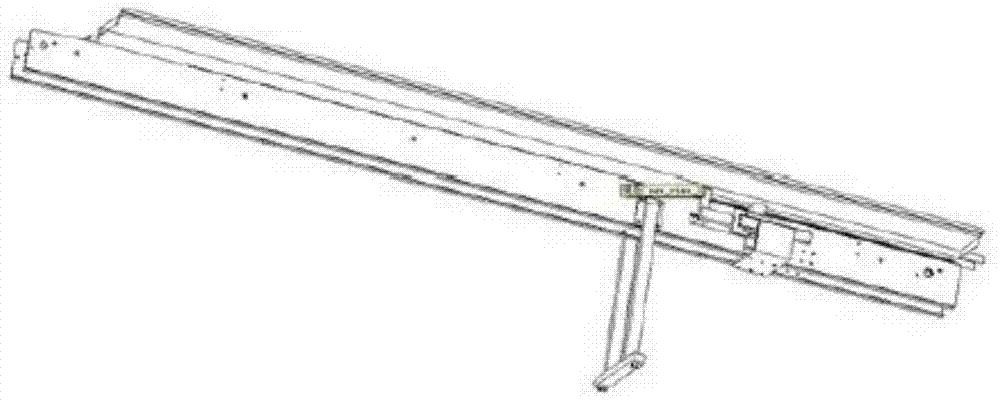

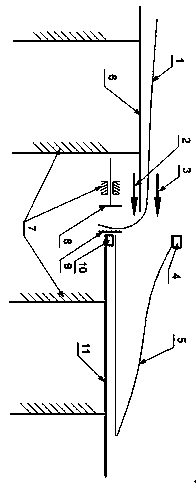

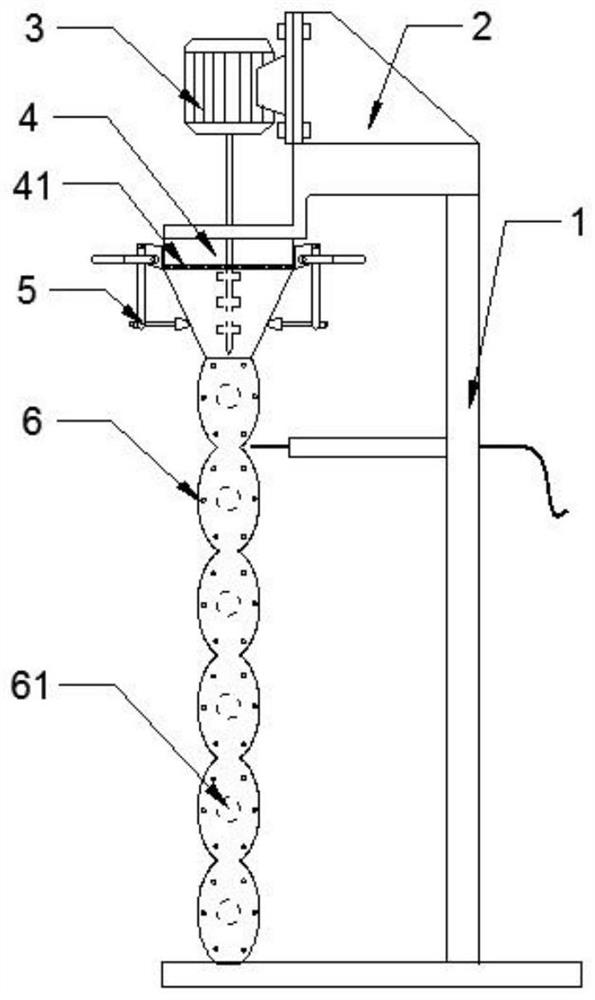

A kind of winter melon harvesting automatic bagging machine

ActiveCN106628324BHeight adjustablePrevent dumpingIndividual articlesPackaging fruits/vegetablesGourdBENINCASA HISPIDA FRUIT

The invention relates to an automatic bagging machine for white gourd harvesting. The automatic bagging machine for white gourd harvesting comprises a conveying device, a clamping device and a bagging device, wherein the clamping device is located over the conveying device and fixedly connected with the conveying device, and the bagging device is located right in front of the conveying device and tightly attached to the conveying device. The automatic bagging machine for white gourd harvesting can conduct conveying, clamping fastening and automatic bagging on white gourds, and avoid the problems that during white gourd harvesting, the speed of manual bagging is low, the efficiency is low, and white gourds are prone to prick the hand.

Owner:徐州鼎禾农业科技有限公司

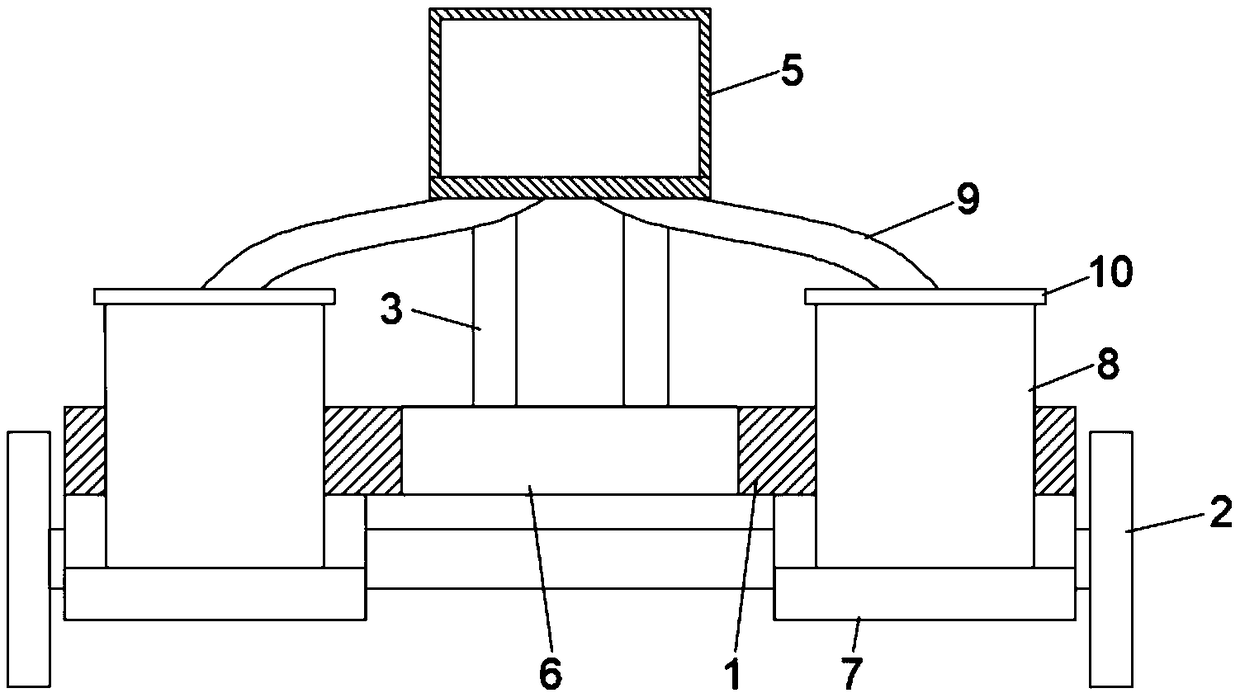

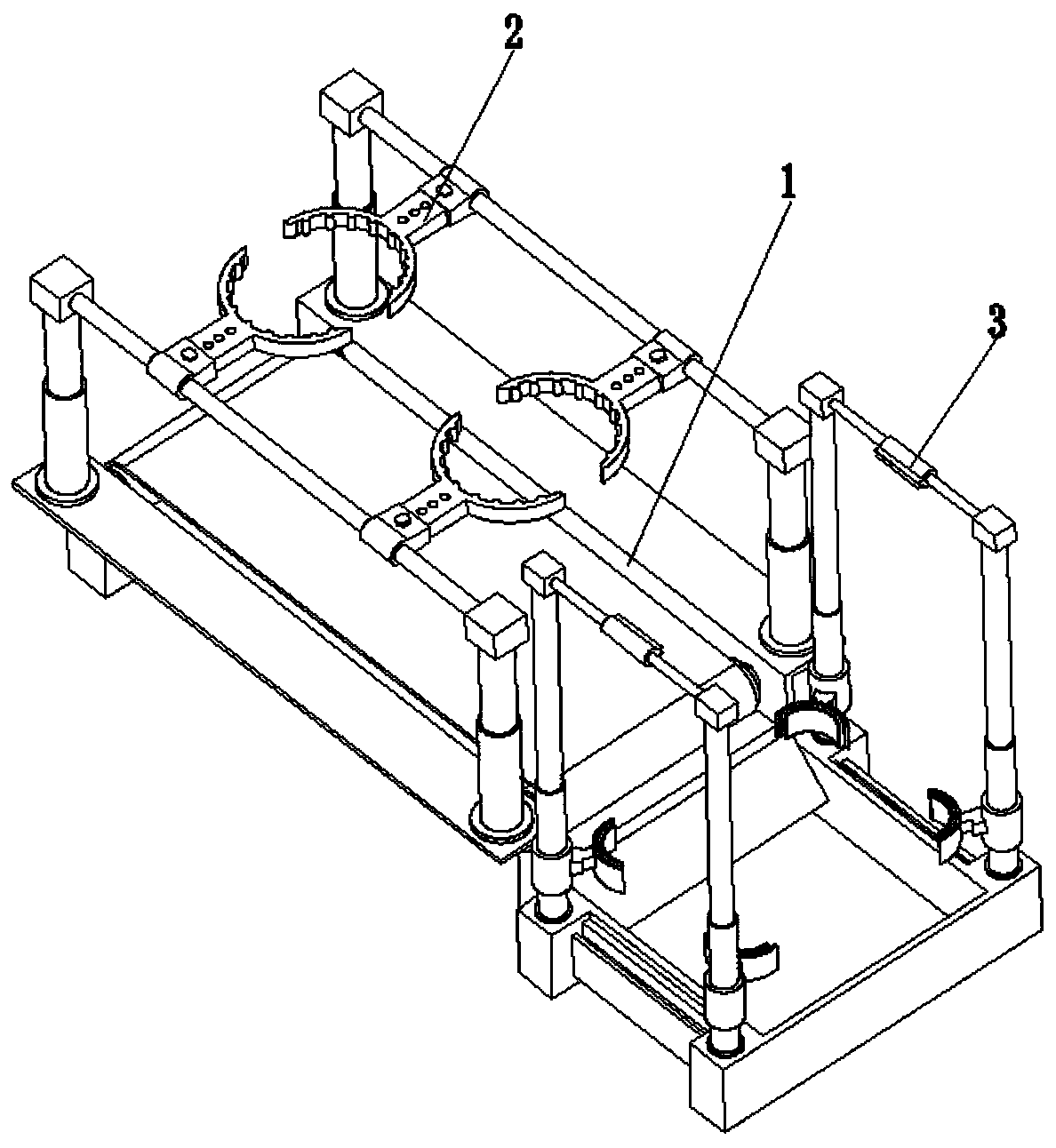

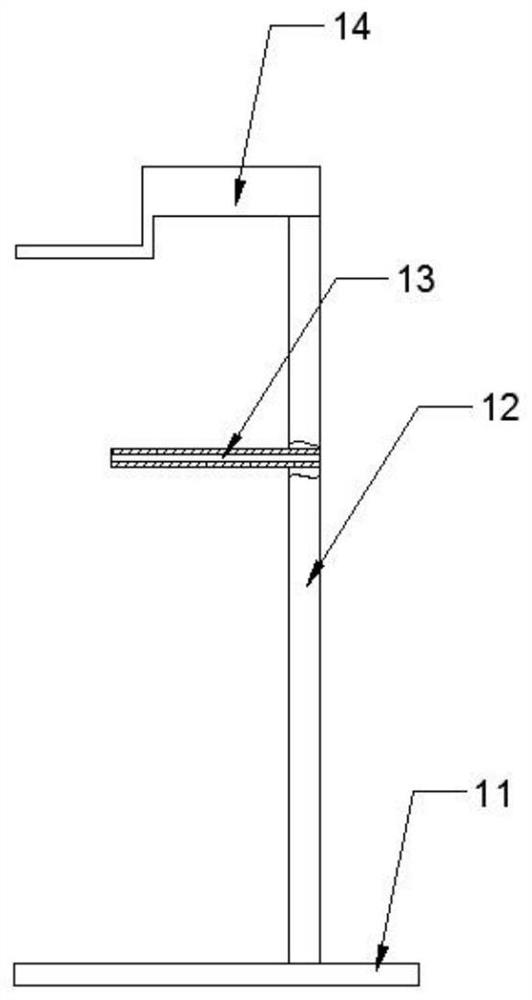

A kind of watermelon seedling planting bag and its bagging machine

ActiveCN110301268BMeet planting requirementsFast baggingCultivating equipmentsFlower-pot fillingElectric machineAgricultural engineering

The invention discloses a watermelon seedling planting bag and a bagging machine thereof. The planting bag is formed by connecting six oval bags, and the connection is in a connected state. One side of the six oval bags included in the planting bag is provided with Circular embossing, the embossing consists of spaced cracks, the six oval bags are also provided with ventilation holes, and one end of the six oval bags is connected with a trumpet-shaped bag mouth. The bagging machine includes a bracket, a motor seat, a micro motor, a hopper and a clamp, the motor seat is mounted on the top of the bracket, the micro motor is fixed on the motor seat, and the hopper is installed on the bracket corresponding to the micro motor, The output shaft of the micro motor is provided with a stirring rod, and the stirring rod extends into the inside of the hopper. The side of the hopper is provided with a quick clamp. The planting bag can not only meet the planting requirements of watermelon seedlings, but also can be quickly bagged when used with the bagging machine, which improves the bagging speed of the watermelon seedling planting bag.

Owner:NANNING UNIV

Fruit bag sheathing operation tool

InactiveCN102484975BExpand the scope of workOperation Process VisualizationPlant protective coveringsFruit treeHand held

The invention relates to a fruit bag sheathing operation tool, which comprises a fruit bag sheathing device, a hand holding arm, a telescopic arm, regulation screw bolts, a camera, a display screen and a control box, wherein one end of the telescopic arm is connected with the fruit bag sheathing device, the other end of the telescopic arm is inserted into the hand holding arm and is fixed throughthe regulation screw bolts, the camera is fixedly arranged at the end of the telescopic arm near the fruit bag sheathing device through a camera support frame, the display screen and the control box are arranged on the hand holding arm, and the control box is connected with a driving motor of the fruit bag sheathing device. Regulation holes matched with the regulation screw bolts are arranged on the telescopic arm at intervals and are used for regulating the total length of the hand holding arm and the telescopic arm. The fruit bag sheathing operation tool has the advantages that the structure is simple, the length of the telescopic arm is adjustable, the bag sheathing process is visible, the operation is simple and fast, the bag sheathing efficiency is effectively improved, the manual work intensity and the danger are reduced, and the fruit bag sheathing operation tool can be widely applied to the fruit tree and fruit bag sheathing field operation production.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com