Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Quick bagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

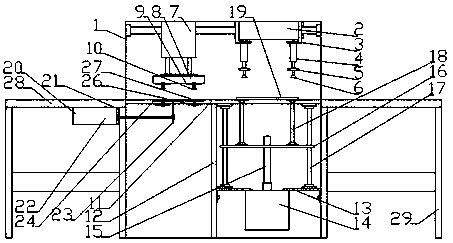

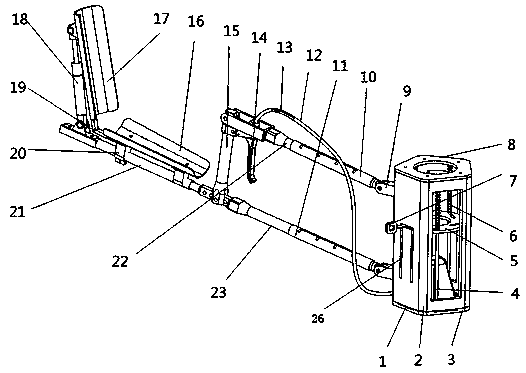

Device for fruit bagging

InactiveCN101167432AOutstanding FeaturesHighlight significant progressPlant protective coveringsEngineeringGas chamber

The invention discloses a fruit bagging device, which comprises a main body operating part and a gas compression storage part, which is characterized in that the gas storage chamber (5) of the gas compression storage part inflates the fruit bag through an air outlet hose (6), and the main body operates In part, the pulling of the right trigger (38) and the left trigger (39) drives the outer transmission member (28) and the inner transmission member (29) to move forward, so that the bag feeder (32), the front action arm (9), the inflation port (20), the front action arm transmission rod (21), the mouth stopper (13), the inflation switch (40), and the staple pressing sheet (18) act to complete the bagging process. The device is light, Durable, fast and reliable, it adopts the characteristics of three-point support, inflatable bag support and binding and sealing in the bagging process. The whole bagging process is smooth, standard, fast, easy and efficient, and the bags produced are standard, beautiful and Strong, resistant to weather and pests.

Owner:孙康云

Rapid automatic bagging machine

The invention discloses a rapid automatic bagging machine which is rapid, saves labor and is accurate in measurement. According to the technical scheme, the rapid automatic bagging machine is characterized in that a horizontal cylindrical rotary disc is installed in a storage hopper; a plurality of frame cavities are arranged on the outer edge peripheral line of the rotary disc; the outer edges of the left and right sides of the rotary disc are close to the inner side of the storage hopper; a loading bag is installed on a movable frame below a lower discharging port of the storage hopper; a transmission shaft in the center of the rotating disc is provided with a transmission wheel or a manual rotary disc and a tooth-missing gear; blanks as many as the frame cavities on the outer edge peripheral line of the rotary disc are reserved on the outer edge of the gear, and teeth on the tooth-missing gear are engaged with teeth on a rack on the movable frame below the tooth-missing gear. According to the acting principle, during rotation of the rotary disc, the frame cavities are loaded with materials when moving upwards and unloads the materials into the loading bag when moving downwards, at that time, the blanks on the tooth-missing gear are opposite to the rack, and the movable frame stops. Afterwards, engagement of the gear and the rack is carried out movably and alternately.

Owner:HEZE ZHONGHEJIANYUAN BIOLOGY TECH CO LTD

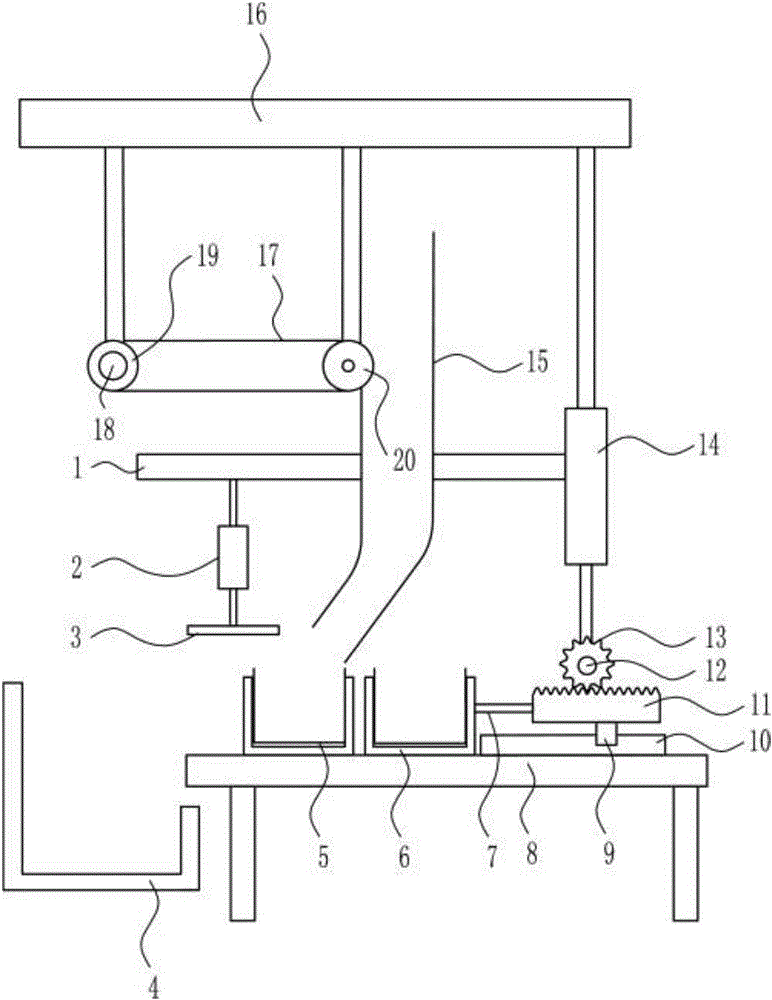

Bread rapid bagging device

ActiveCN106184880AConvenient bagging operationQuick baggingWrapper twisting/gatheringIndividual articlesFixed frameEngineering

The invention relates to a bread bagging device, in particular to a bread rapid bagging device. The technical problem to be solved is to provide a bread rapid bagging device which is easy to bag, convenient to operate and high in bagging speed. In order to solve the technical problem, the bread rapid bagging device is provided. The bread rapid bagging device comprises a supporting rod, an air cylinder I, a sealing device, a pushing rod, a collecting frame, a clamping sleeve, a placing frame, a sliding block, a sliding rail, a rack, a gear motor II, a gear, a fixed frame and the like. The collecting frame is arranged on the left side of the bottom of the placing frame. The clamping sleeve and the sliding rail are sequentially arranged at the top of the placing frame from left to right. The sliding block is slidably connected to the front side of the sliding rail. The rack is connected to the top of the sliding block. The pushing rod is arranged on the left side of the rack. The left end of the pushing rod makes contact with the clamping sleeve. A top plate is arranged above the placing frame. The bread rapid bagging device achieves the effects of being easy to bag, convenient to operate and high in bagging speed. By means of the bread rapid bagging device, bread can be rapidly bagged.

Owner:中山市仟亿健莱食品有限公司

Navel orange bagging auxiliary device for fruit deep processing

InactiveCN108839836AAvoid damageAchieve installationIndividual articlesPackaging fruits/vegetablesNavel orangeNavel

The invention relates to an auxiliary bagging device, in particular to a navel orange bagging auxiliary device for fruit deep processing. The invention aims to solve the technical problem so as to provide the navel orange bagging auxiliary device for fruit deep processing which is capable of quickly bagging navel oranges and not easy to damage the navel oranges. The invention has the technical scheme that the navel orange bagging auxiliary device for fruit deep processing comprises an N-shaped frame and the like, wherein a feeding hopper is arranged in the middle of the top part of the N-shaped frame; a treatment pipe communicating with the feeding hopper is arranged on the inner top part of the N-shaped frame; a pushing mechanism is arranged on the right side of the treatment pipe; a discharging pipe is connected to the left side of the bottom part of the treatment pipe; and a fixing mechanism is arranged on the bottom part of the discharging pipe. According to the navel orange bagging auxiliary device for fruit deep processing provided by the invention, through the interaction of the pushing mechanism and the fixing mechanism, the navel oranges can be quickly bagged; and meanwhile, the optimization of a rotating mechanism and a pulling mechanism is utilized, so that the navel orange bagging efficiency is high, and the effects of simple and reliable operation, capability of quickly bagging the navel oranges, and difficulty in damaging the navel oranges are achieved.

Owner:李泽朋

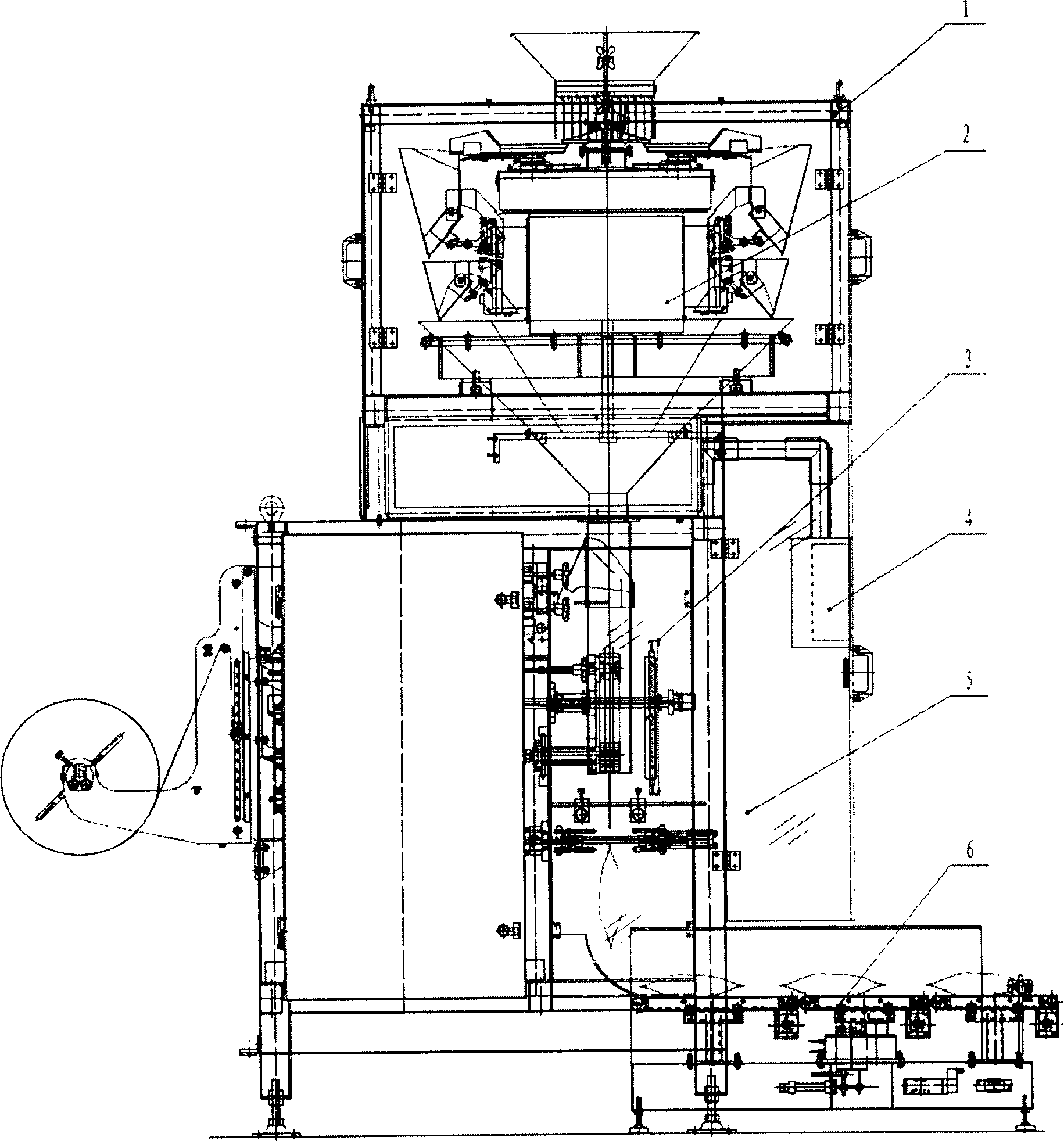

Full-automatic vertical quantitative package machine

InactiveCN1827478AReduce the overall heightSmall form factorWrappingPackaging automatic controlControl systemElectric machinery

The invention relates to a full-automatic upright quantitative packing device, which can apply the weighting, packing, transmitting and detecting on particle, sheet and abnormal materials. The invention combines the weighting device, the packing device and the weight detecting device; the feeding hopper of weighting device and the weighting hopper only have one motor for switching the material gate; the whole system uses PLC and computer as controller with one apparatus control system; the weight detecting device, according to preset weight value, detects the real packed weight and feeds back the result to said weighting device for dynamic adjustment, to make packed weight reach preset weight value; the weight detecting device first automatically adjusts itself after starting the system, then online adjusts each weighting hopper of weighting device to improve the weighting accuracy, to complete the automatic weighting, packing, weight detection and adjustment. The invention has tight structure, small size, less occupied area, easy operation, lower cost and wider application.

Owner:SAIMO ELECTRIC

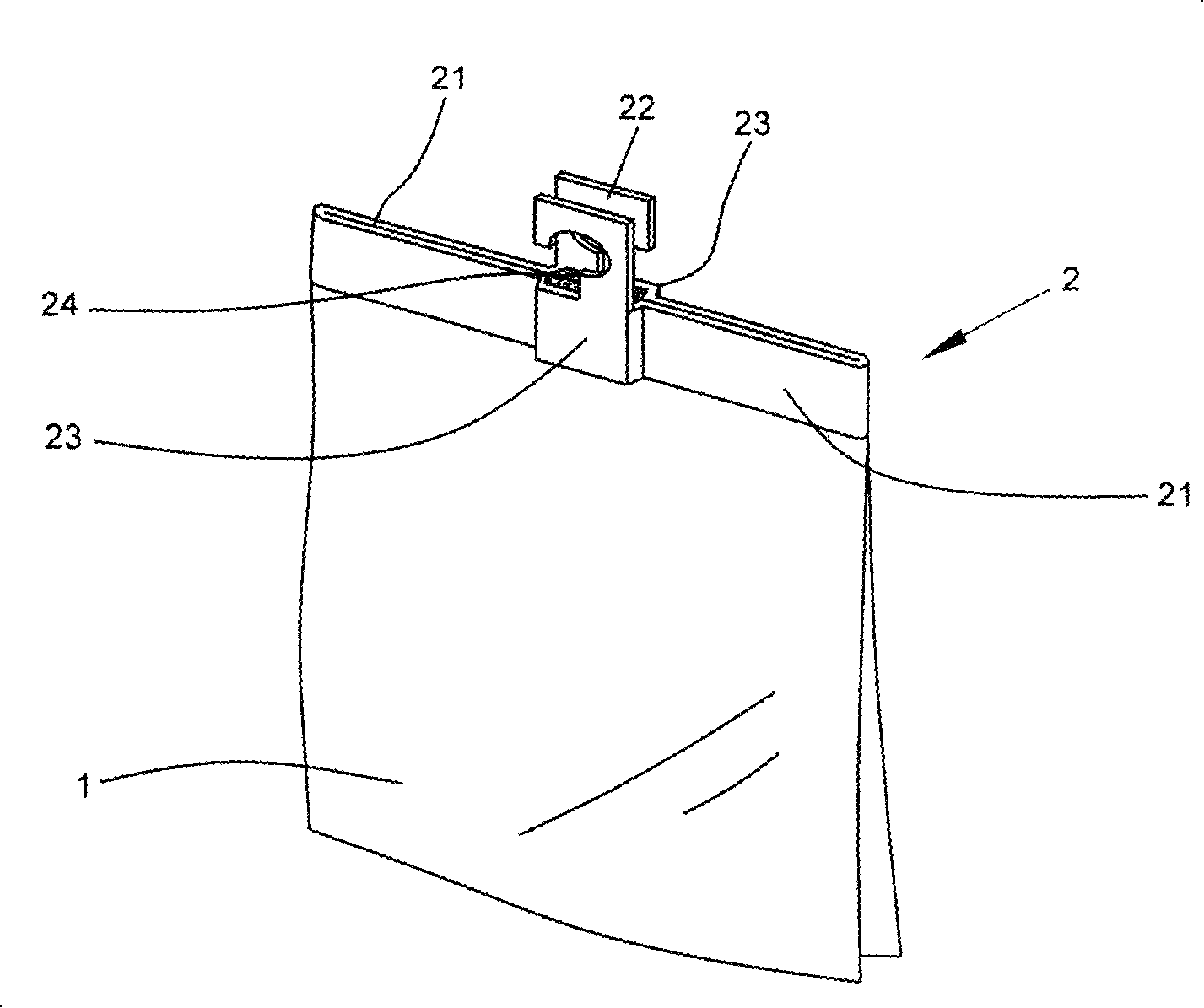

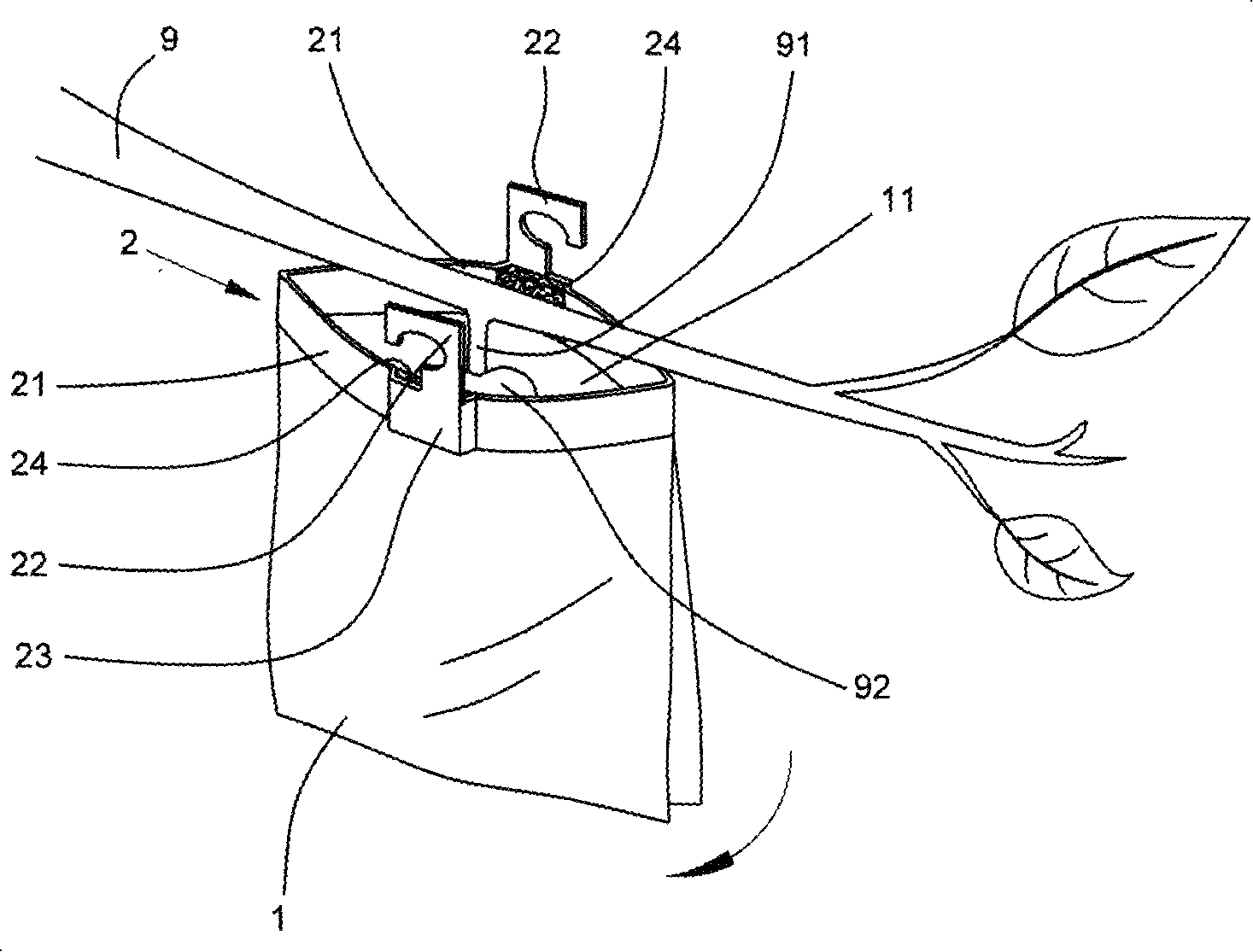

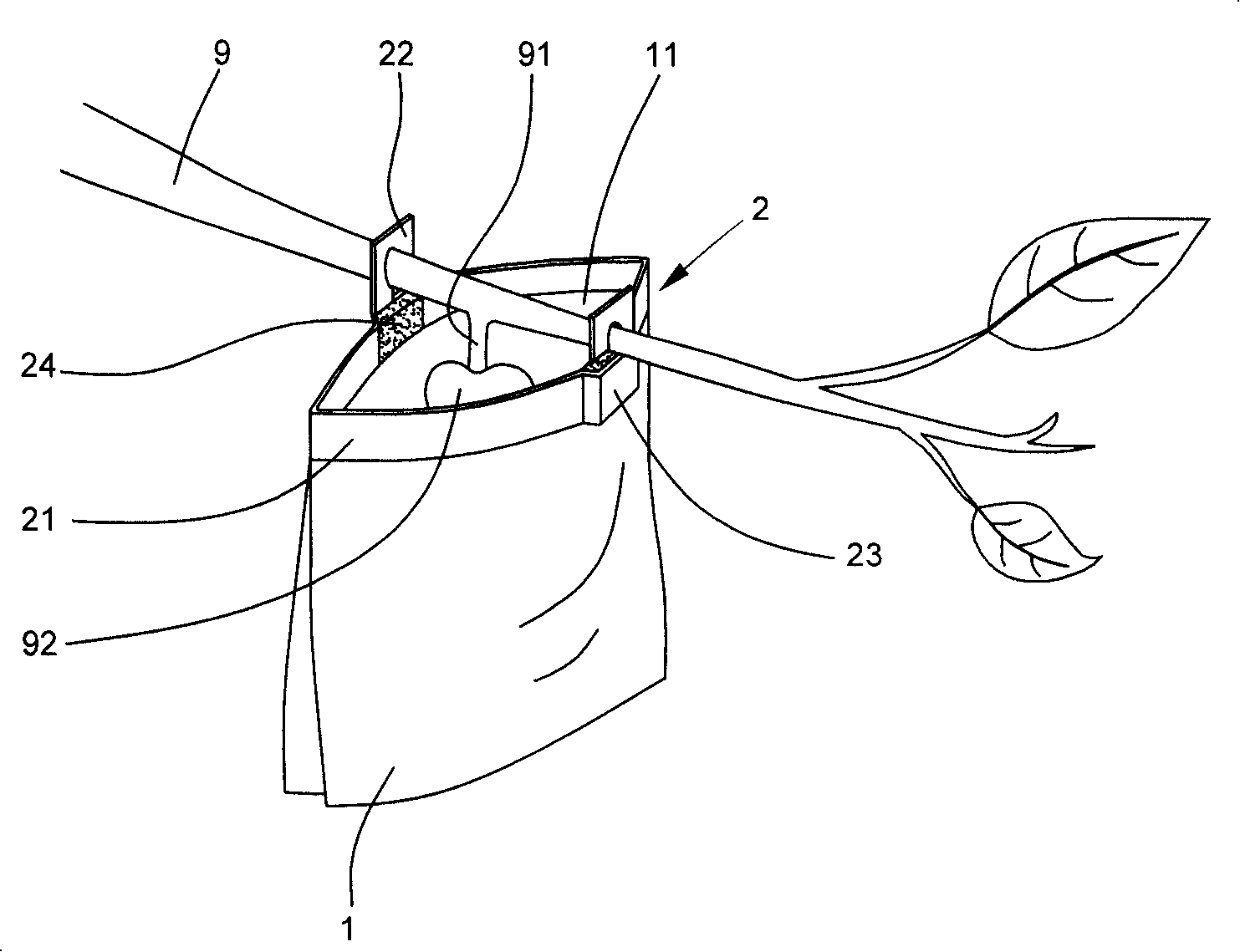

Fast bagging for crop

The invention discloses a quick bag for agronomic crops, which comprises a hollow bag, either side of the bag can be the open end, a closing clip which has the function of opening and closing is arranged at the open end, which is helpful for rapidly covering the bag to agronomic crops such as fruits. Besides, the closing clip can be extendingly provided with a hanging unit according to needs, and thereby the bag can be conveniently hung to a branch, or the closing clip can be extendingly provided with a cutting unit, and thereby the base of a fruit can be conveniently cut off in picking time, and the closing clip can also be provided with a combined hanging and cutting body. The single device can satisfy agronomic requirements such as covering bags, protecting fruits and picking fruits from the growing stage to the picking time of fruits. The invention not only is convenient to use but also substantially saves workhour and manpower to further reduce costs and increase benefits.

Owner:冯 金星

Full-automatic mask production line

PendingCN108100737AQuick cropQuick baggingWrapping material feeding apparatusArticle deliveryProduction lineEngineering

The invention belongs to the technical field of mask production, and particularly relates to a full-automatic mask production line. Materials of a mask unwinding device and a mask film-covering unwinding device are superimposed through a deviation rectifying device and then enter a first roller die-cutting machine so as to form mask structures on a first belt conveying line; a mask packaging bag unwinding device is connected with a second roller die-cutting machine so as to form mask packaging bags on a second belt conveying line; the mask structures are left-right folded through a mask left-right folding seat and then form folded mask structures; and the mask packaging bags are opened after entering a bag opening device, and an air cylinder telescopic arm is arranged on the first belt conveying line, so that the folded mask structures fall into the mask packaging bags after being stamped and folded through the air cylinder telescopic arm, and meanwhile, the mask packaging bags on thesecond belt conveying line are continuously opened through the bag opening device. The functions of quick cutting, quick folding and quick bagging of masks are realized accordingly, and meanwhile, thefull-automatic mask production line realizes uninterrupted feeding by arranging an AGV trolley and an automatic splicing device.

Owner:上海德辉供应链有限公司

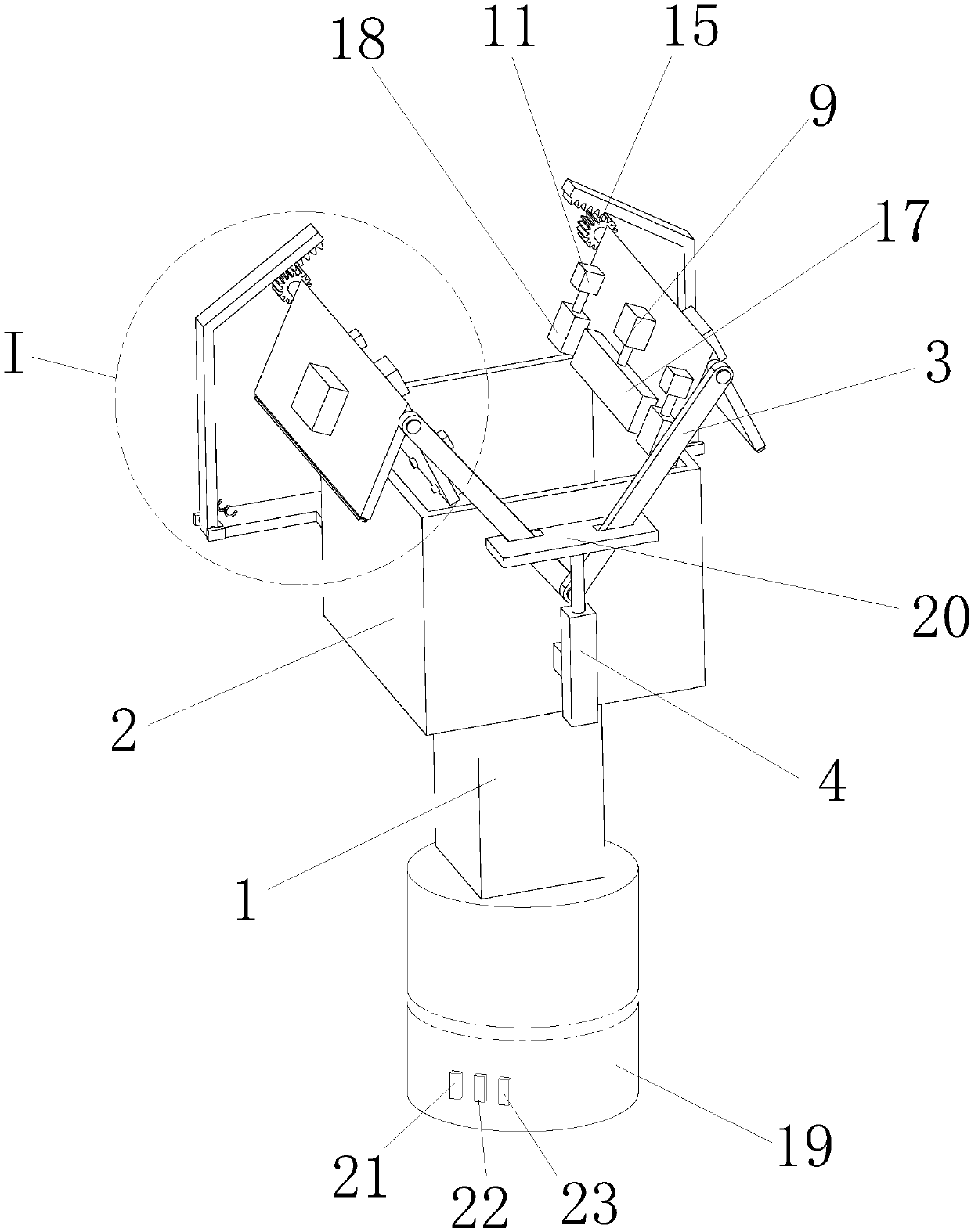

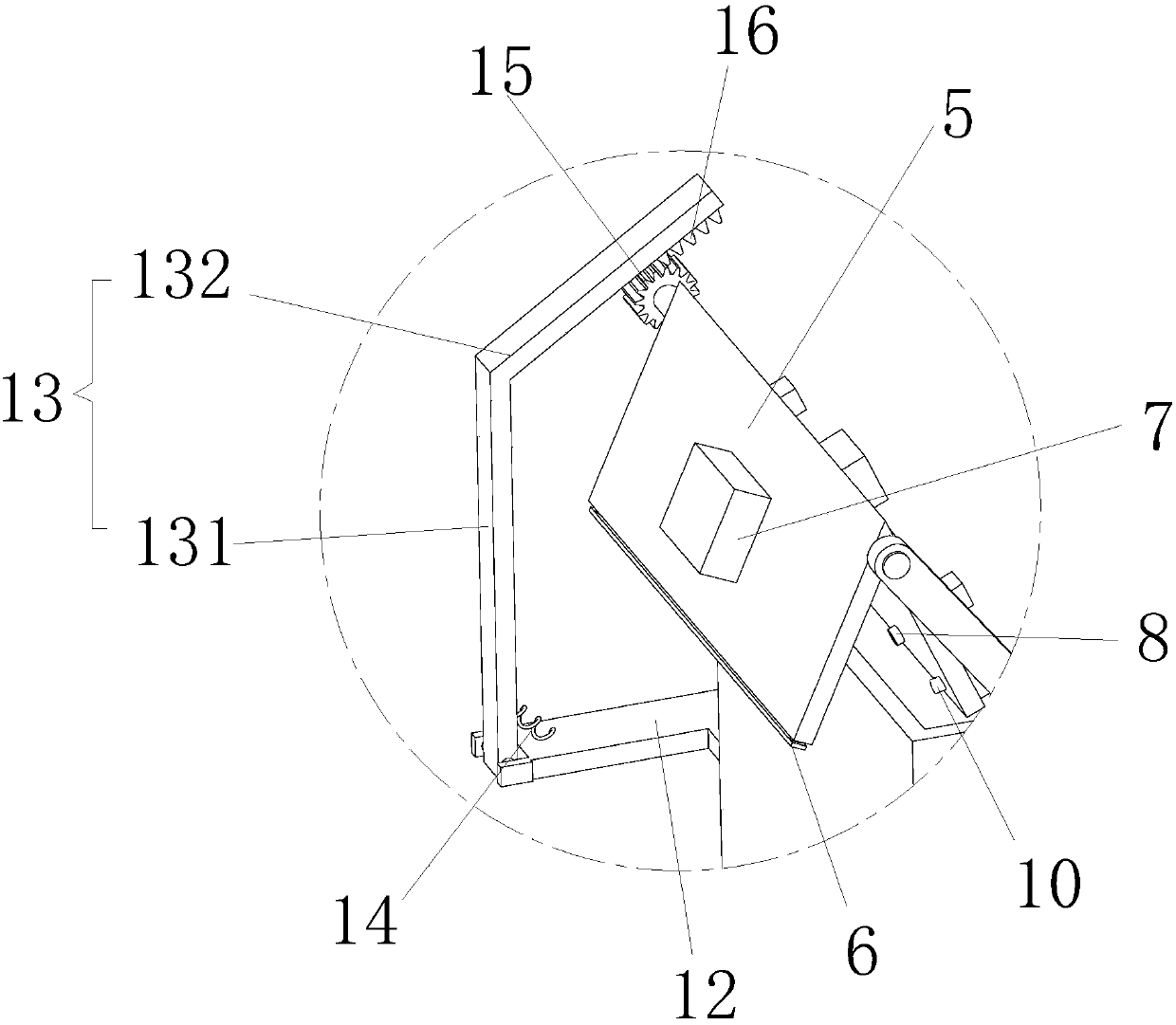

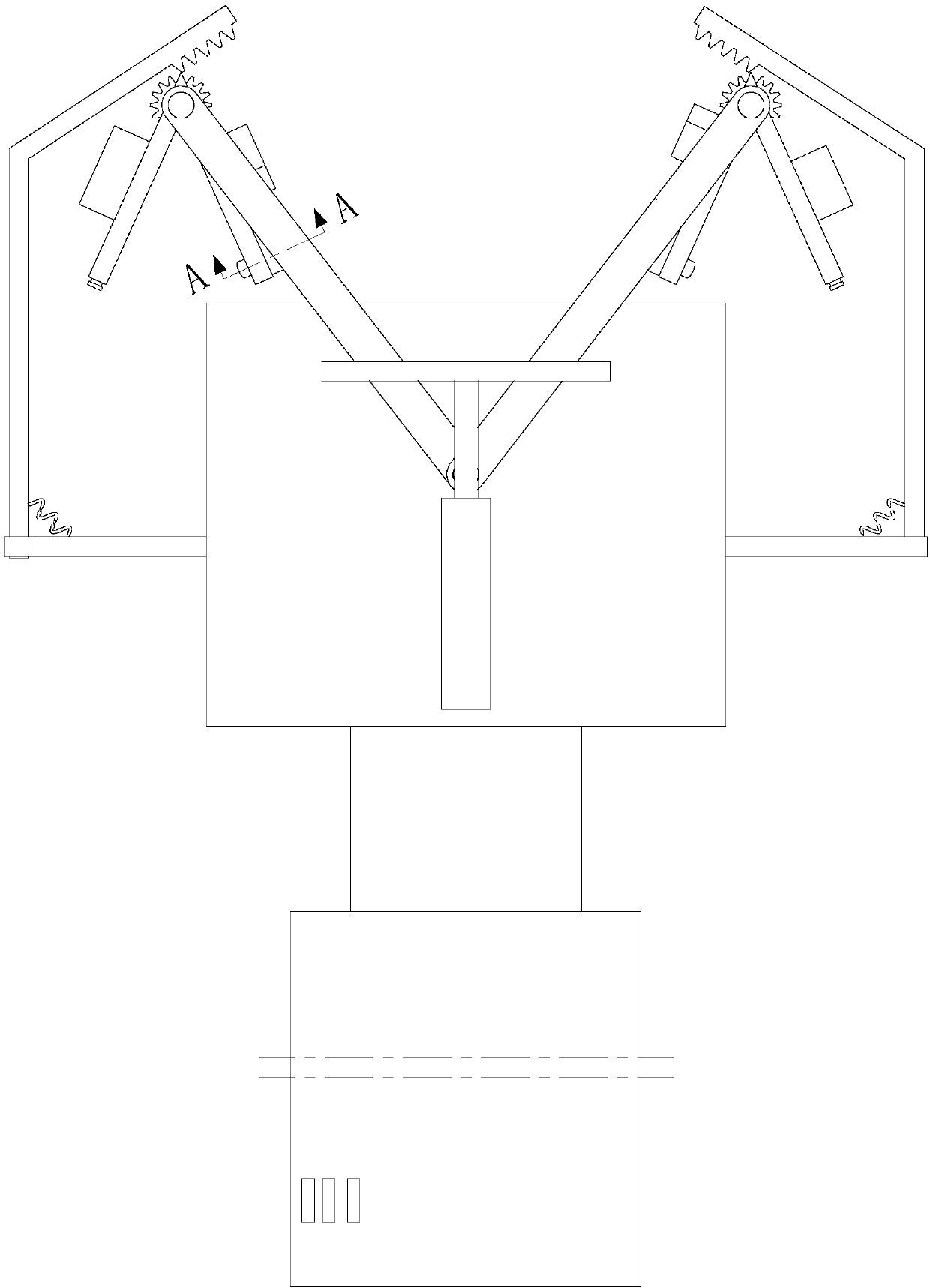

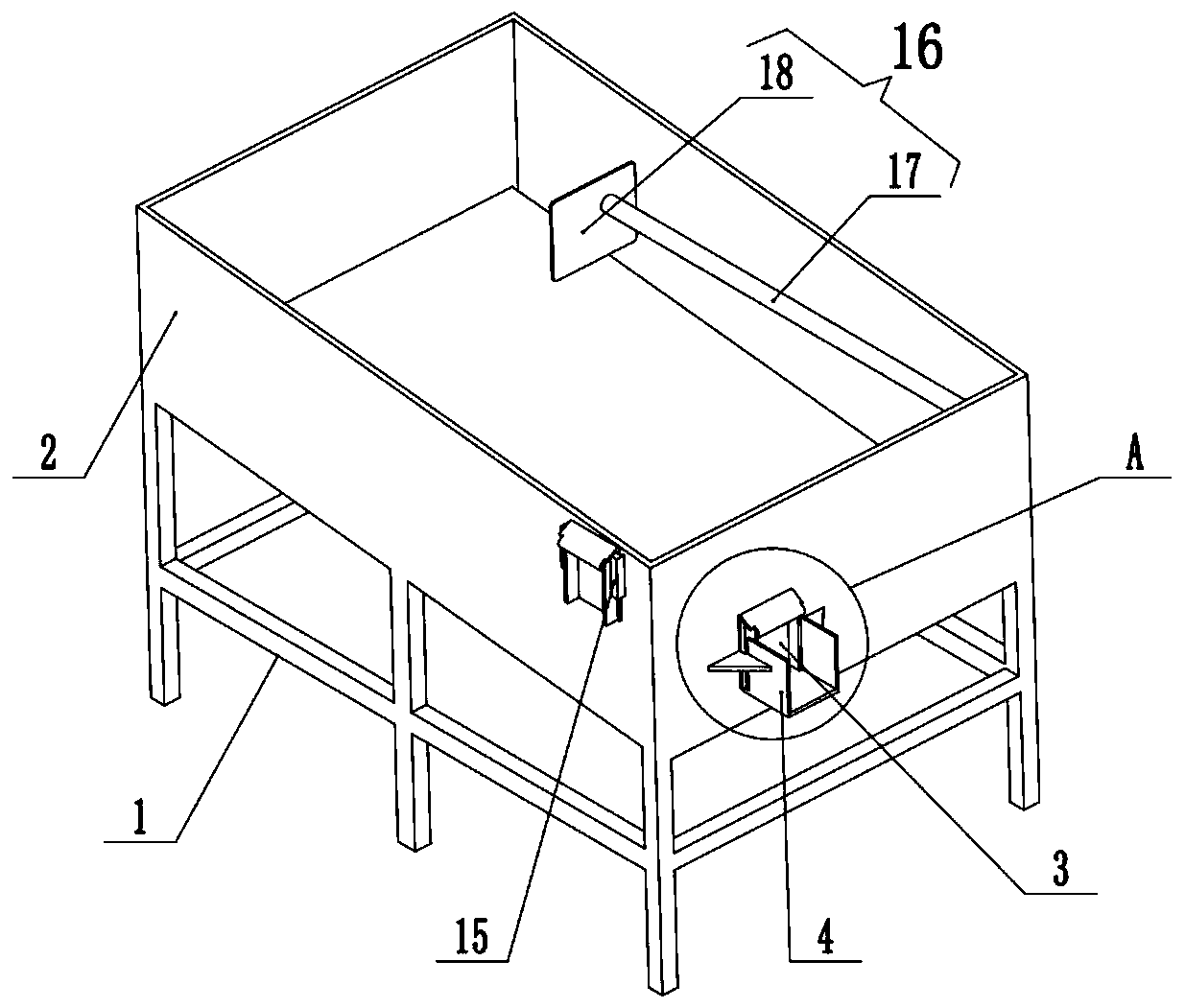

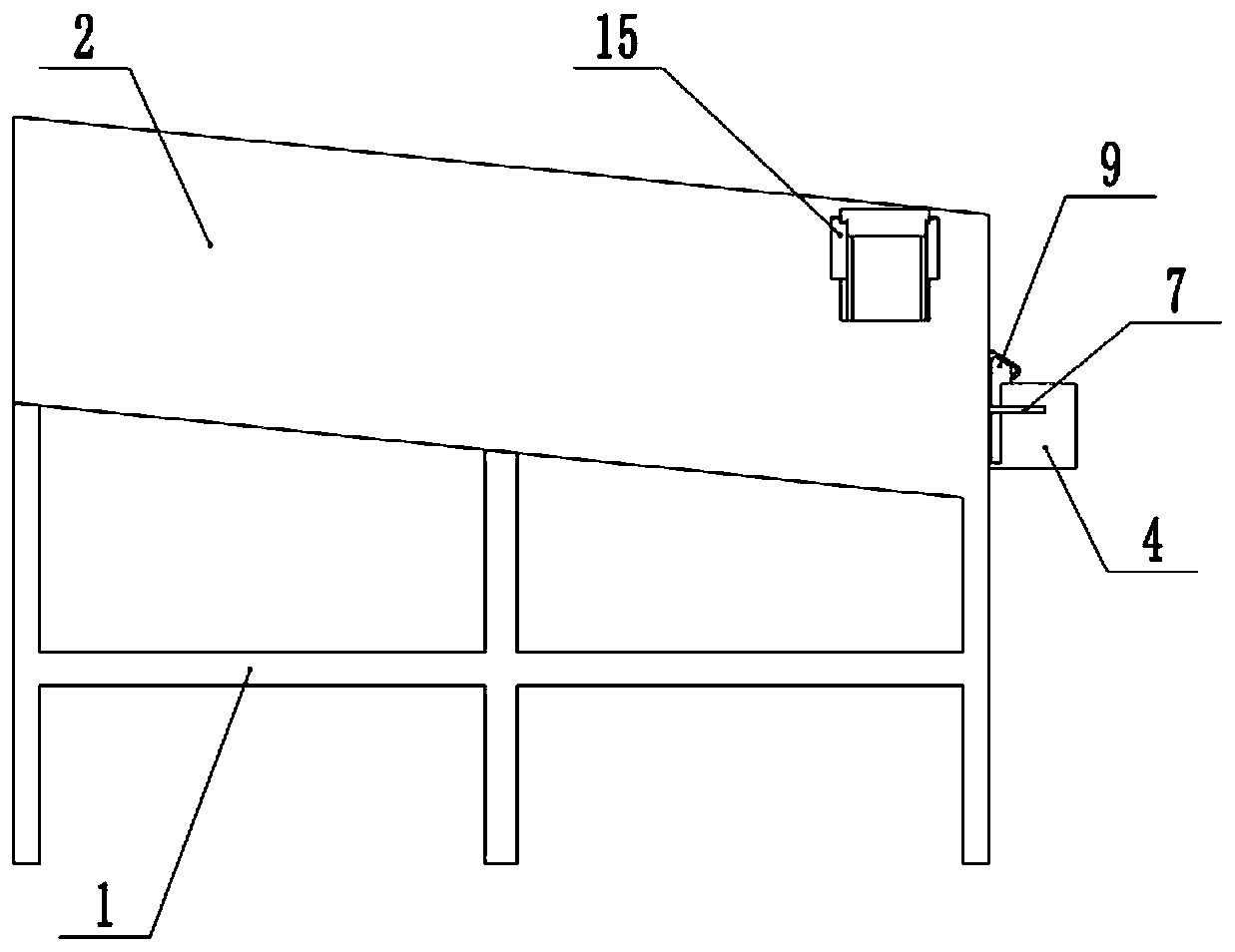

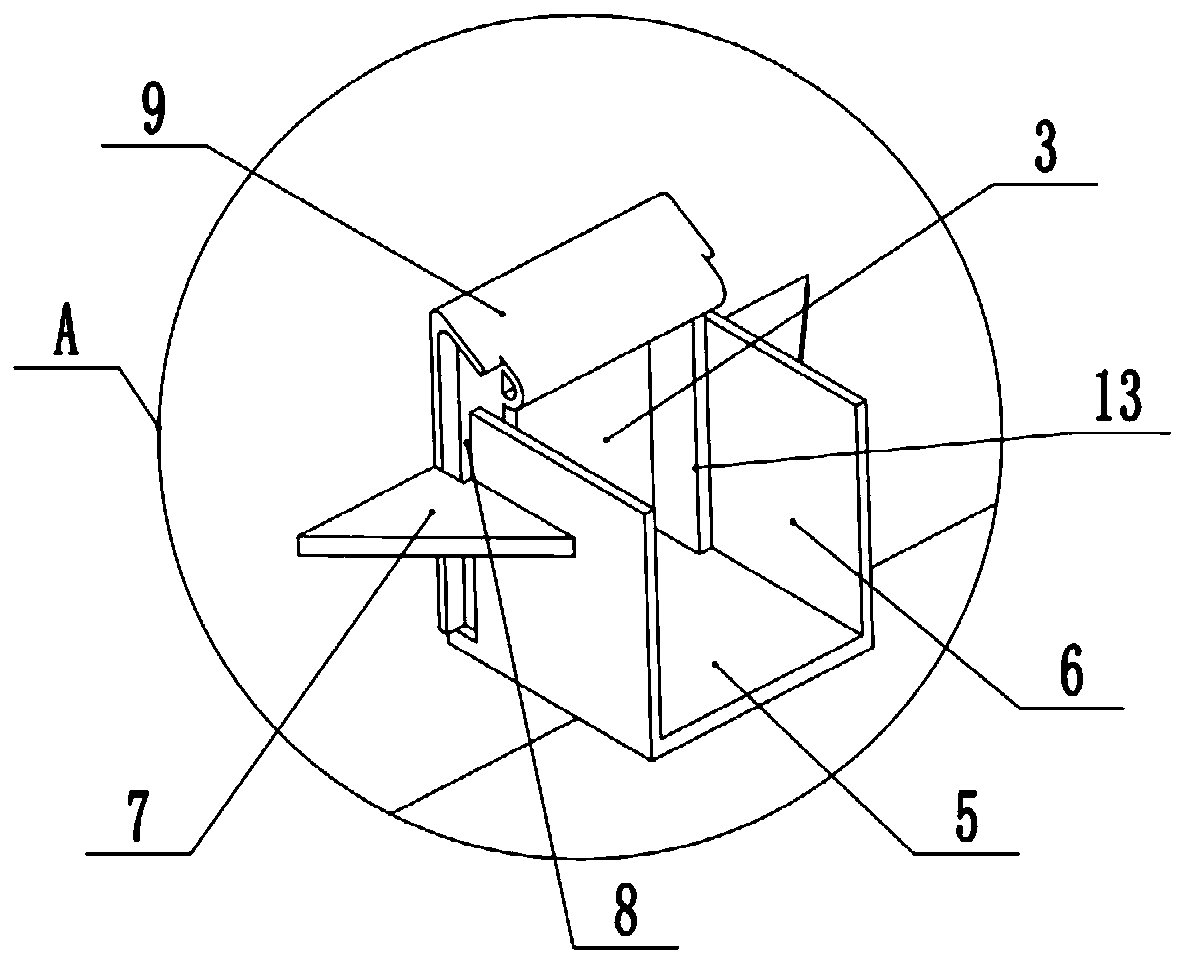

Automatic bagging device for winter peaches

InactiveCN107757995AQuick baggingEasy plantingWrapper twisting/gatheringIndividual articlesHydraulic cylinderSemi automatic

The invention relates to an automatic bagging device for winter peaches. The automatic bagging device comprises a main rod and a box body; two connecting rods which are hinged and distributed in the V-shape are connected on the front end surface of the box body; a hydraulic cylinder is fixed on the box body ad s connected with a push plate glidingly mounted on the connecting rods; symmetrically-distributed packaging mechanisms are connected on the two connecting rods; guide mechanisms for driving the packaging mechanisms to rotate are fixed on the box body; each packaging mechanism comprises aV-shaped plate, a heating plate, a power supply, No.1 air pipes, a miniature air suction fan, No.2 air pipes and miniature air blowers; and each guide mechanism comprises a supporting plate, a bent plate, a spring, a pinion and a rack which is connected at the upper end of the bent plate and meshes with the pinion during swinging of the corresponding V-shaped plate. According to the automatic bagging device, the traditional method of bag tying by the aid of iron wires is replaced with heating fusion welding, the winter peaches can be bagged quickly, the bagging effect is good, the multiple winter peaches can be bagged continuously through one-time operation, the working efficiency is improved, large-scale semi-automatic operation is favorably realized, and planting of the winter peaches is greatly facilitated.

Owner:无为县雲桃家庭农场

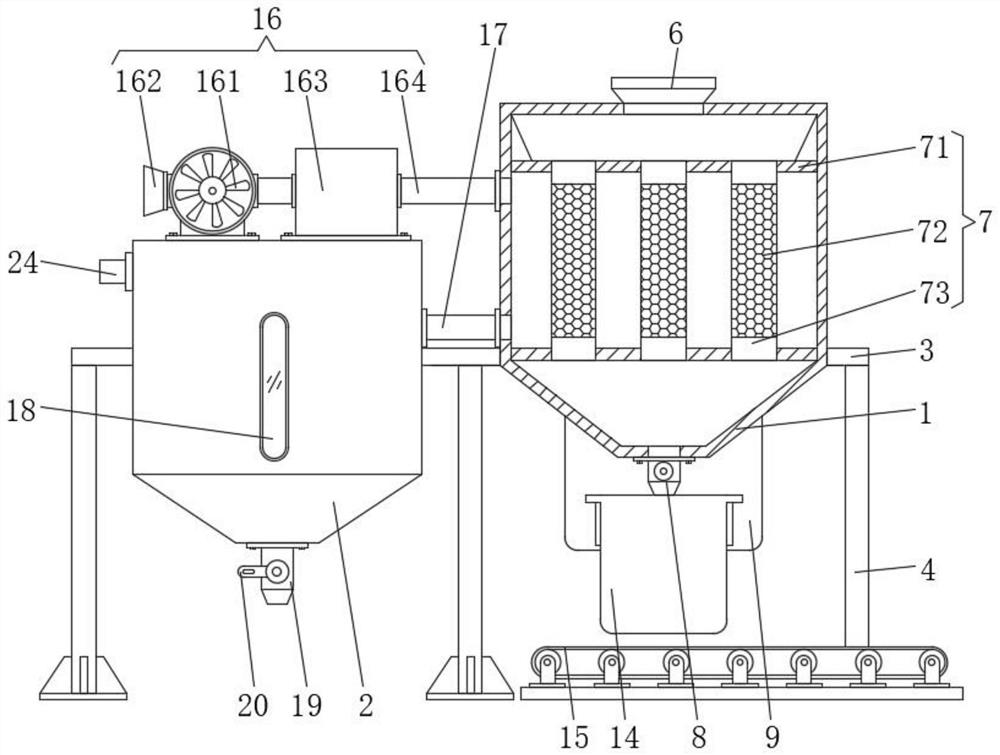

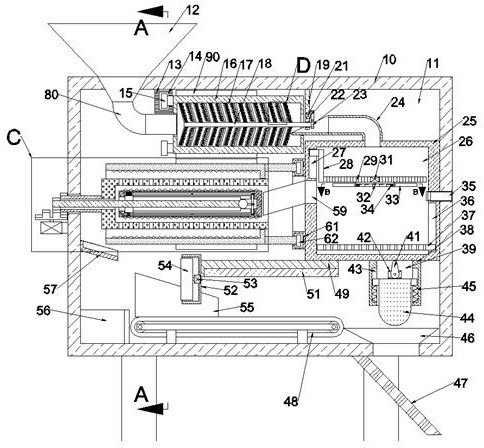

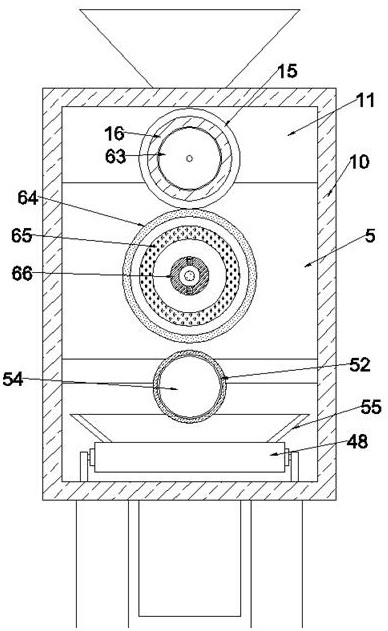

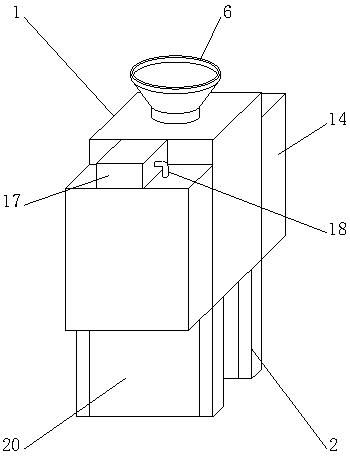

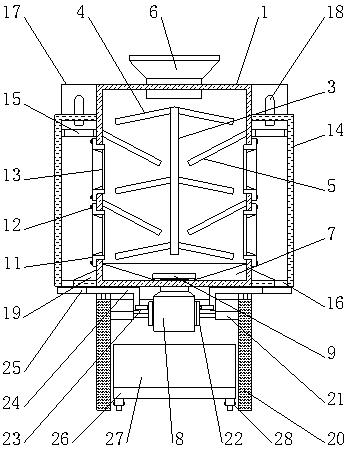

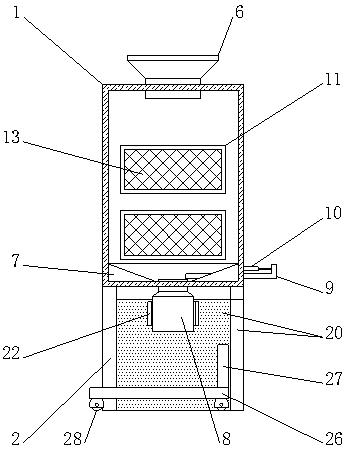

Multifunctional machine for tea stalk removal, weighing and packaging

ActiveCN110641746AQuick baggingImprove qualityGas current separationPackaging by pressurising/gasifyingElectric machineryEngineering

The invention discloses a multifunctional machine for tea stalk removal, weighing and packaging. The multifunctional machine comprises a machine body. A feeding opening is arranged in the machine body. A communicating primary election cavity is arranged on the lower side of the feeding opening. A large wind cavity is arranged on the right side of the primary election cavity. A re-election cavity is arranged on the lower side of the primary election cavity in a communicating manner. A stirring cavity is arranged on the upper side of the re-election cavity in a communicating manner. A main motoris started, a motor shaft is driven to rotate, a first main wheel, a second main wheel and a third main wheel are driven to rotate, a large sector wheel is driven by a first belt to rotate, and a large fan rotates to generate wind power; a second auxiliary wheel is driven by a second belt to rotate, and a linkage wheel rotates; and a small sector wheel is driven by a conveying belt to rotate, anda small fan rotates to generate small wind power. By means of the machine, tea stalks and other impurities in tea can be automatically removed, on the premise of guaranteeing quantification, automatic vacuum packaging is carried out, the quality of produced tea is improved, the labor intensity of workers is reduced, and the tea production efficiency is improved.

Owner:安徽省万佛山农业综合开发有限公司

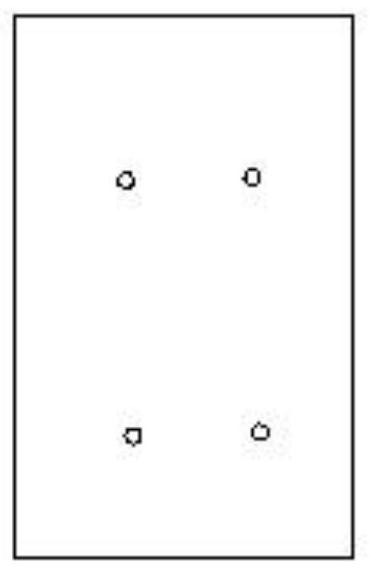

High-speed bagging machine for organic fertilizer production

InactiveCN109319219AImprove bagging efficiencyRealize one-way intermittent rotationPackagingAgricultural engineeringOrganic fertilizer

The invention discloses a high-speed bagging machine for organic fertilizer production. For the problem of the low bagging efficiency in the existing fertilizer production process, the following scheme is provided, the high-speed bagging machine comprises a base, and a motor is fixedly arranged on the top wall of the base; an output shaft of the motor is connected with a groove wheel mechanism; arotating shaft is rotationally arranged in the center of the base; a supporting plate is fixedly arranged at the other end of the rotating shaft; the groove wheel mechanism is fixedly connected to theouter wall of the rotating shaft; four bagging mechanisms are fixedly arranged on the top wall of the supporting plate and are distributed in an annular array manner; each bagging mechanism comprisesangle iron, a supporting rod and hooks; the angle iron is fixedly mounted on the supporting plate; the supporting rods are welded to the angle iron; the hooks are arranged at the tops of the supporting rods; and a discharging opening is arranged over one bagging mechanism. By means of the high-speed bagging machine, the bagging efficiency is greatly improved, manpower is reduced, and the work efficiency is improved.

Owner:郑州启汇果品有限公司

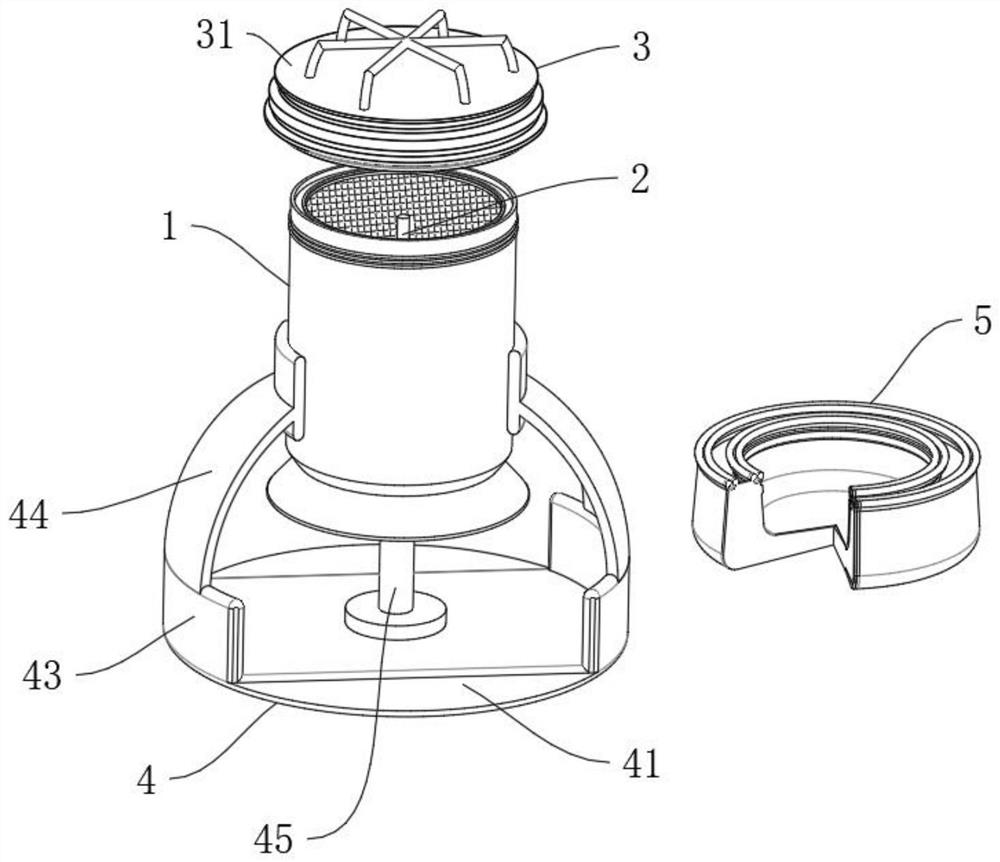

Crushing device used for traditional Chinese medicinal material preparation

ActiveCN111686881AAchieve the crushing effectImprove the uniformity of powder thicknessSievingScreeningStructural engineeringProcess engineering

The invention discloses a crushing device used for traditional Chinese medicinal material preparation, and specifically relates to the field of traditional Chinese medicinal material preparation. Thecrushing device used for traditional Chinese medicinal material preparation comprises a treatment box mechanism, wherein a crushing mechanism is fixedly installed in an inner cavity of the treatment box mechanism, a cover body mechanism is connected to the top of the treatment box mechanism through a thread, a support mechanism is fixedly installed at the bottom of the treatment box mechanism through a bolt, and a disposable bagging mechanism is connected between the treatment box mechanism and the support mechanism in an insertion manner; and the treatment box mechanism comprises an externaltreatment bucket body, an annular insertion-connection frame is fixedly installed at the top and the bottom of the external treatment bucket body through a bolt separately, and an annular filter meshpad is connected to an inner cavity of the external treatment bucket body in an insertion manner and through the corresponding annular insertion-connection frame. According to the crushing device usedfor traditional Chinese medicinal material preparation, through the arrangement for the treatment box mechanism, preliminarily-crushed traditional Chinese medicinal materials are impacted onto the inner walls of the annular filter mesh pads, and the traditional Chinese medicinal materials fall into an inner cavity of a first hollow movable groove while reaching a corresponding number, so that thecrushing thicknesses uniformity of the traditional Chinese medicinal materials is relatively increased.

Owner:QINGDAO MUNICIPAL HOSPITAL

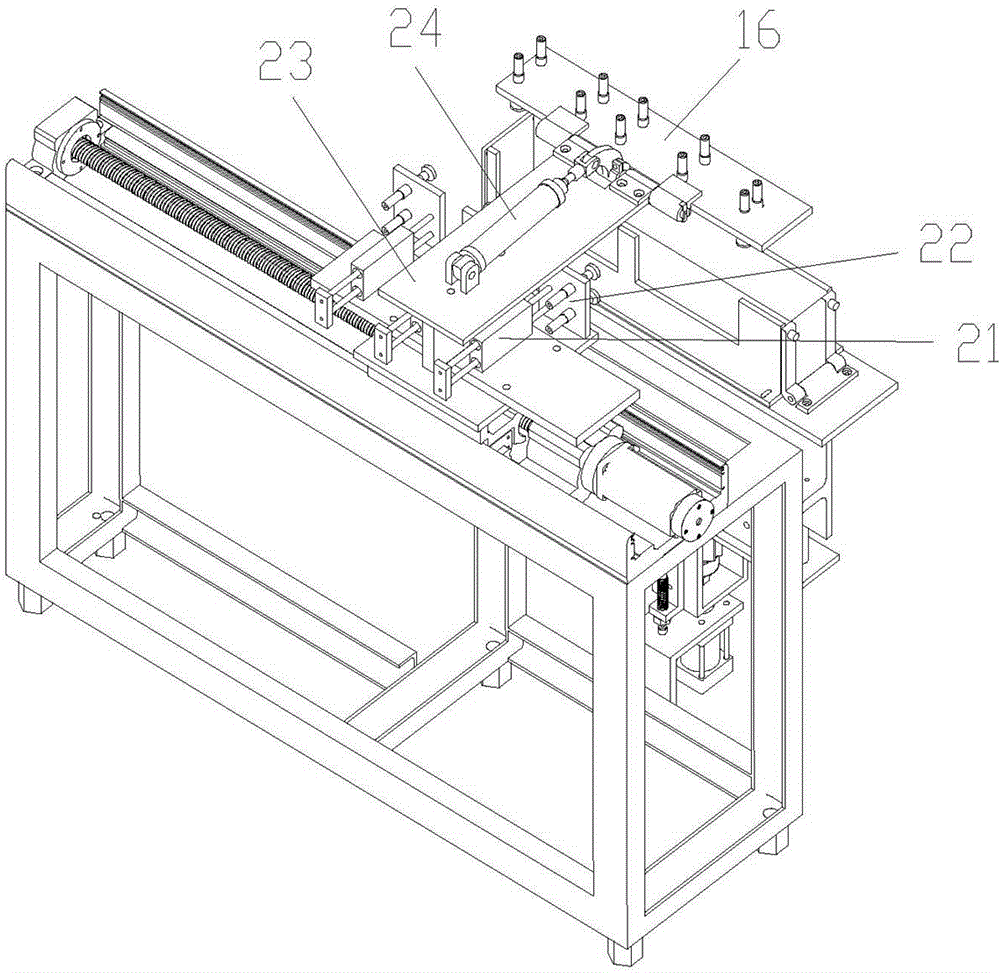

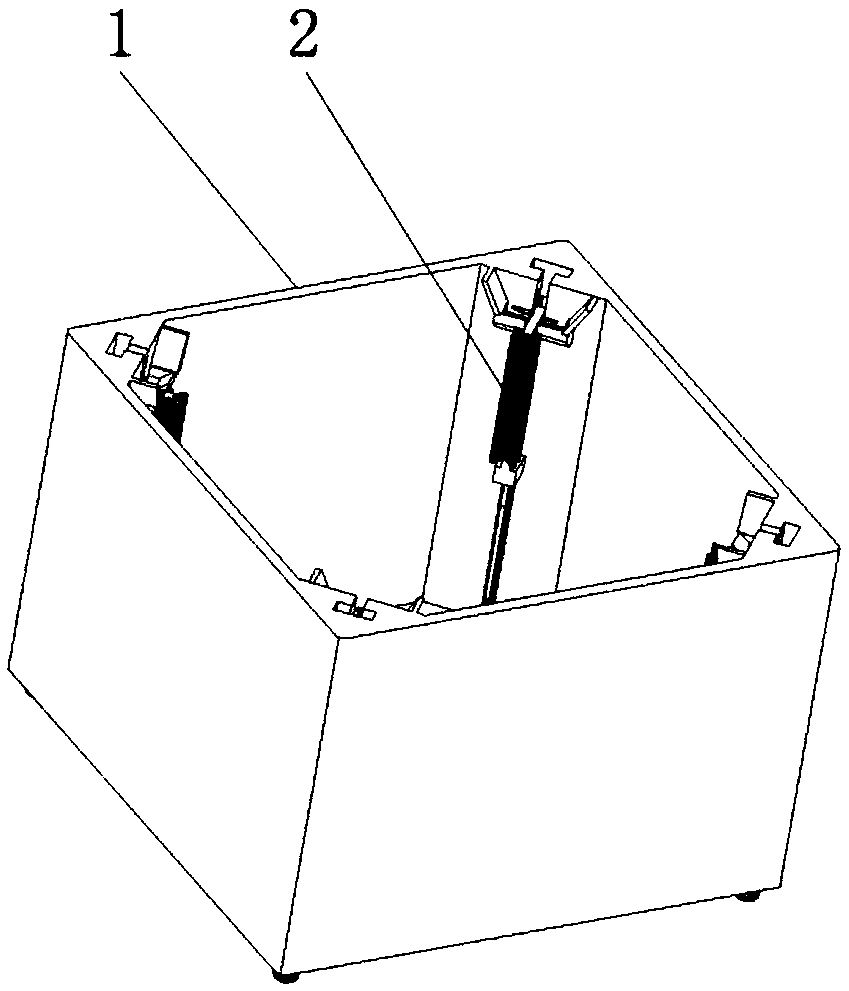

Automatic bagging assembling device for fishing net and fishing line

InactiveCN108583956ACompact structureInnovative design ideasIndividual articlesEngineeringCylinder block

The invention discloses an automatic bagging assembling device for a fishing net and a fishing line. The automatic bagging assembly device comprises a rack, wherein two ends of the support rod of an air cylinder are symmetrically and transversely connected with the front and rear sides of the top of the rack; L-shaped support plates are symmetrically connected with the two ends of the cylinder block of the air cylinder; small air cylinders are connected with the lower planes of the support plates; the telescopic stretching rod ends of the small air cylinders are connected with end plates in the longitudinal direction; a plurality of sucking discs are mounted on the lower planes of the end plates; a middle air cylinder is mounted at the upper part of the upper left side of the rack; the telescopic rod end of the middle air cylinder is fixedly connected with a bottom plate; two upper sucking discs are connected with the lower plane of the bottom plate in bilateral symmetry; and a layer board is arranged in the middle of the rack. The automatic bagging assembling device is compact in structure and novel and unique in design thought, after conveyor feeding, a conveyor conveys fishing net and fishing line bags onto the layer board, the air cylinders drive the sucking discs to strut the bag openings for bagging operation, and at the same time, during the conveying process of the fishing net and fishing line bags, a bracing plate is adopted to support a group of overlapped fishing net and fishing line bags for automatic feeding, so that the automatic bagging assembling device is high in working efficiency and fast in bagging, greatly lowers the labor cost and saves the labor time.

Owner:CHAOHU XIANGYU FISHING GEAR

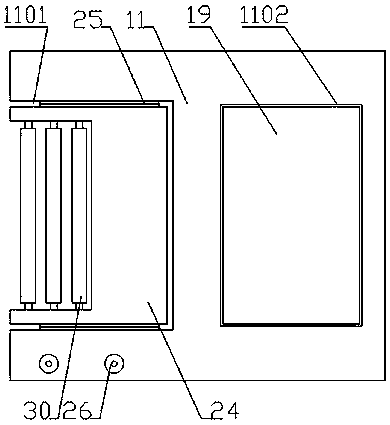

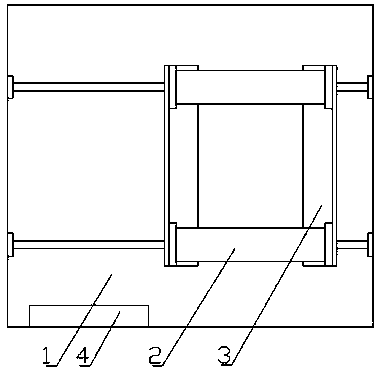

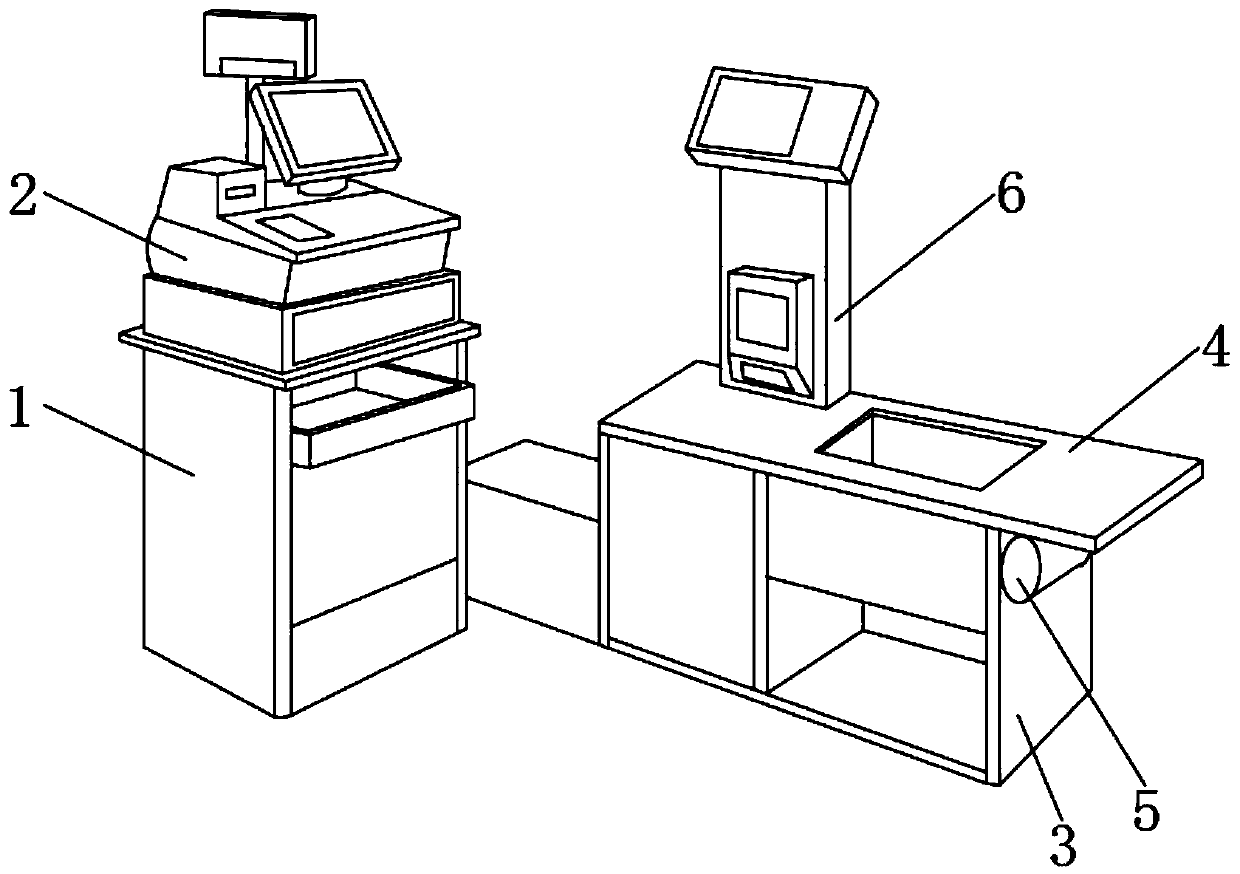

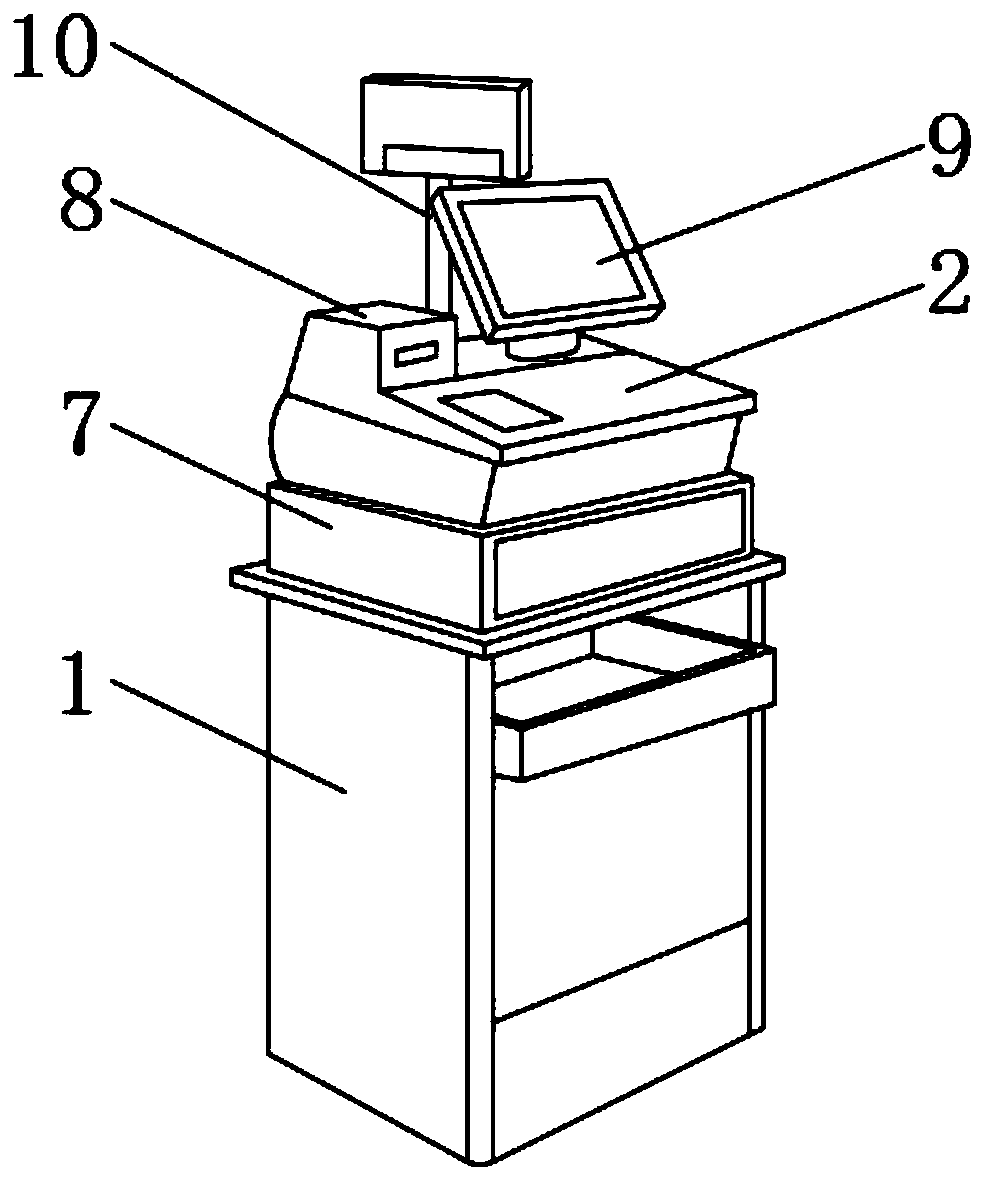

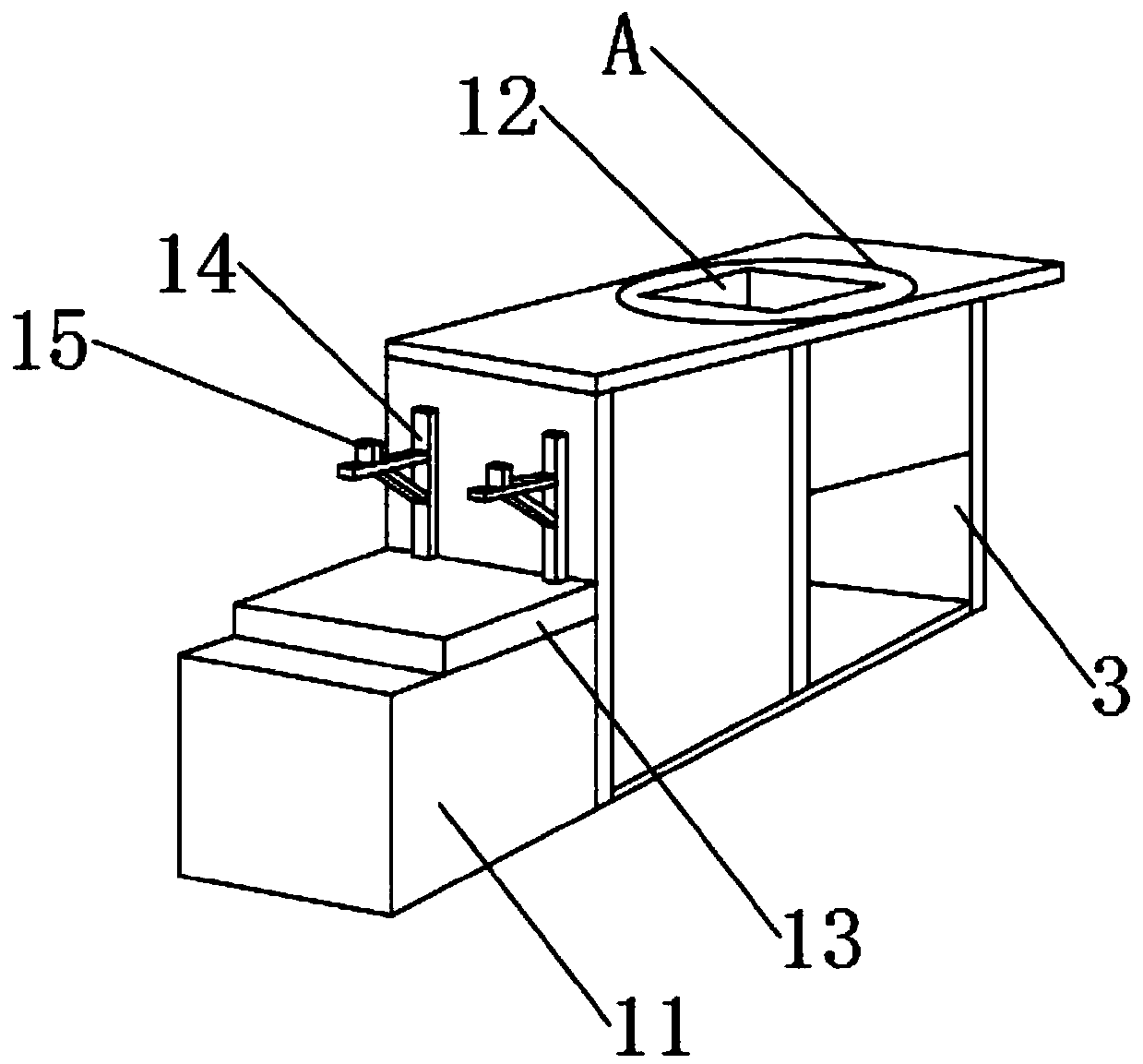

Supermarket cashier device

The invention discloses a supermarket cashier device comprising a cashier base, a cashier computer, a table base and a table top, wherein the cashier computer is located at the upper end of the cashier base. According to the supermarket cashier device, a containing frame is provided, so that the shopping basket can be placed. the problem of inconvenient goods picking up and scanning caused by theshopping basket being placed too high for cashier can be avoided, rapid goods scanning by a cashier can be facilitated; a No.2 code scanner is provided, so that the goods with different marking positions can be scanned, the small item may be scanned by the No.2 code scanner and the large item may be scanned by a No.1 scanner and the scanner is convenient for cashiers to use rapidly; a buffer pad is provided, so that goods can be quickly bagged by a provided bag supporting frame, the buffer pad arranged at the bottom of the frame can play a buffer protection effect on the items and rapid checkout is achieved while the items is protected from damage, certain practicability is achieved and a better use prospect is brought.

Owner:安徽霸嘟科技有限公司

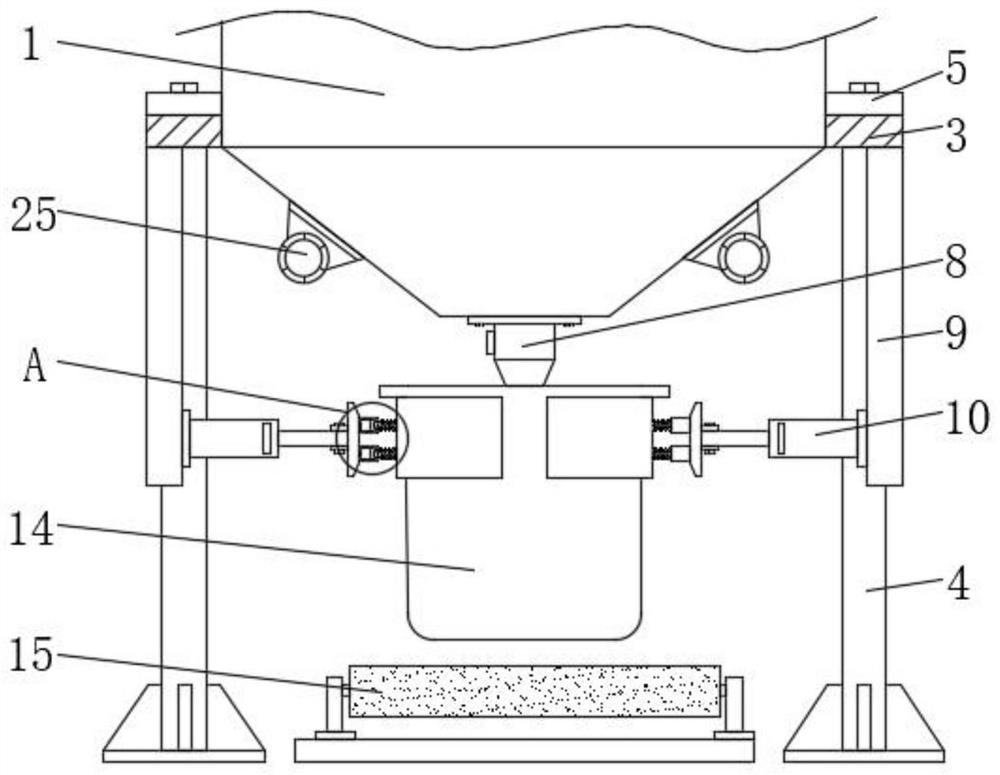

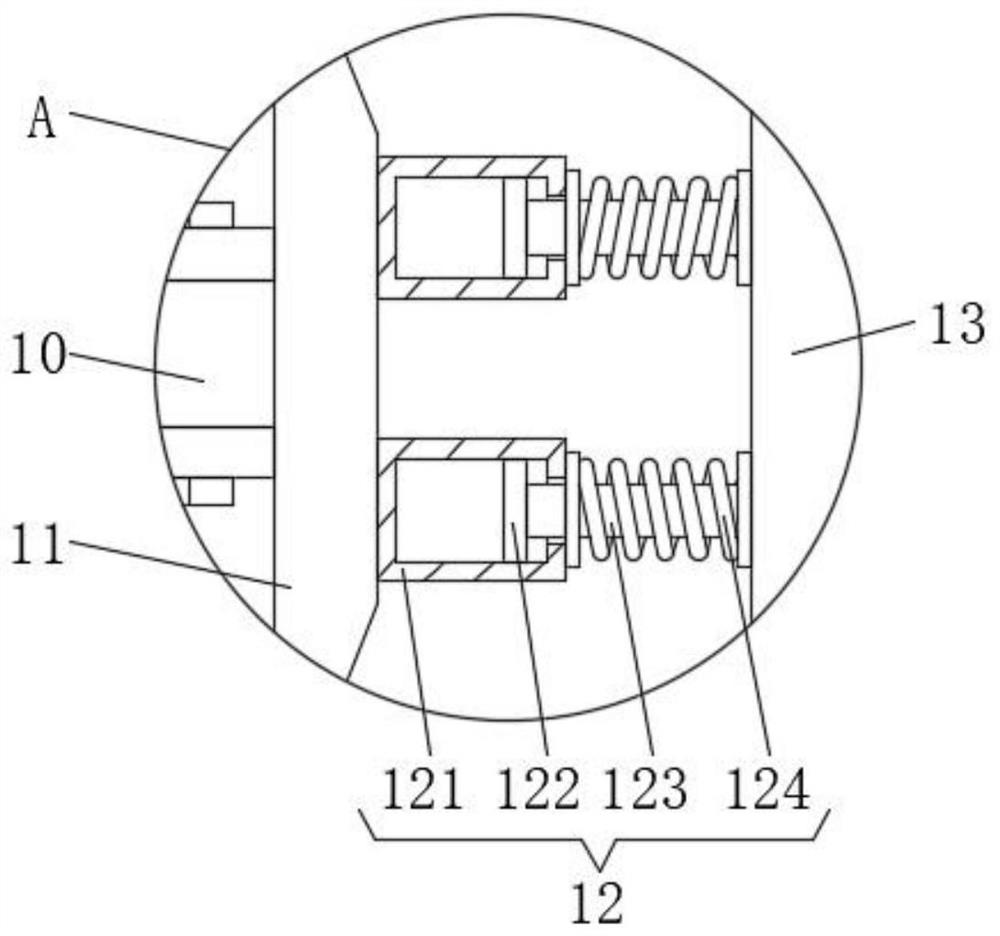

Multi-specification bagging auxiliary device for chemical fertilizer

ActiveCN111924148AAchieve suctionQuick baggingSolid materialControl engineeringAgricultural engineering

The invention provides a multi-specification bagging auxiliary device for chemical fertilizer. The multi-specification bagging auxiliary device for the chemical fertilizer comprises a bracket, an adjusting mechanism and a clamping mechanism, wherein the adjusting mechanism is connected to one side of the bracket and used for adjusting packaging bags with different sizes. The multi-specification bagging auxiliary device for the chemical fertilizer has a function of rapidly bagging chemical fertilizer granules and can clean dust residues in the produced chemical fertilizer granules, a motor is started to drive bevel gears to rotate through a power shaft, fan blades are driven to rotate through bevel gear transmission, and therefore, the dust in the chemical fertilizer granules can be absorbed; and the device can realize clamp bagging of the packaging bags with multiple specifications and sizes, by means of pushing a pull handle, a telescopic circular ring fixedly mounted with a rack I and a rack II is driven to be subjected to telescopic adjusting, and thus, the size adjustment of the packaging bags with multiple specifications can be realized.

Owner:湖北省八峰生物科技股份有限公司

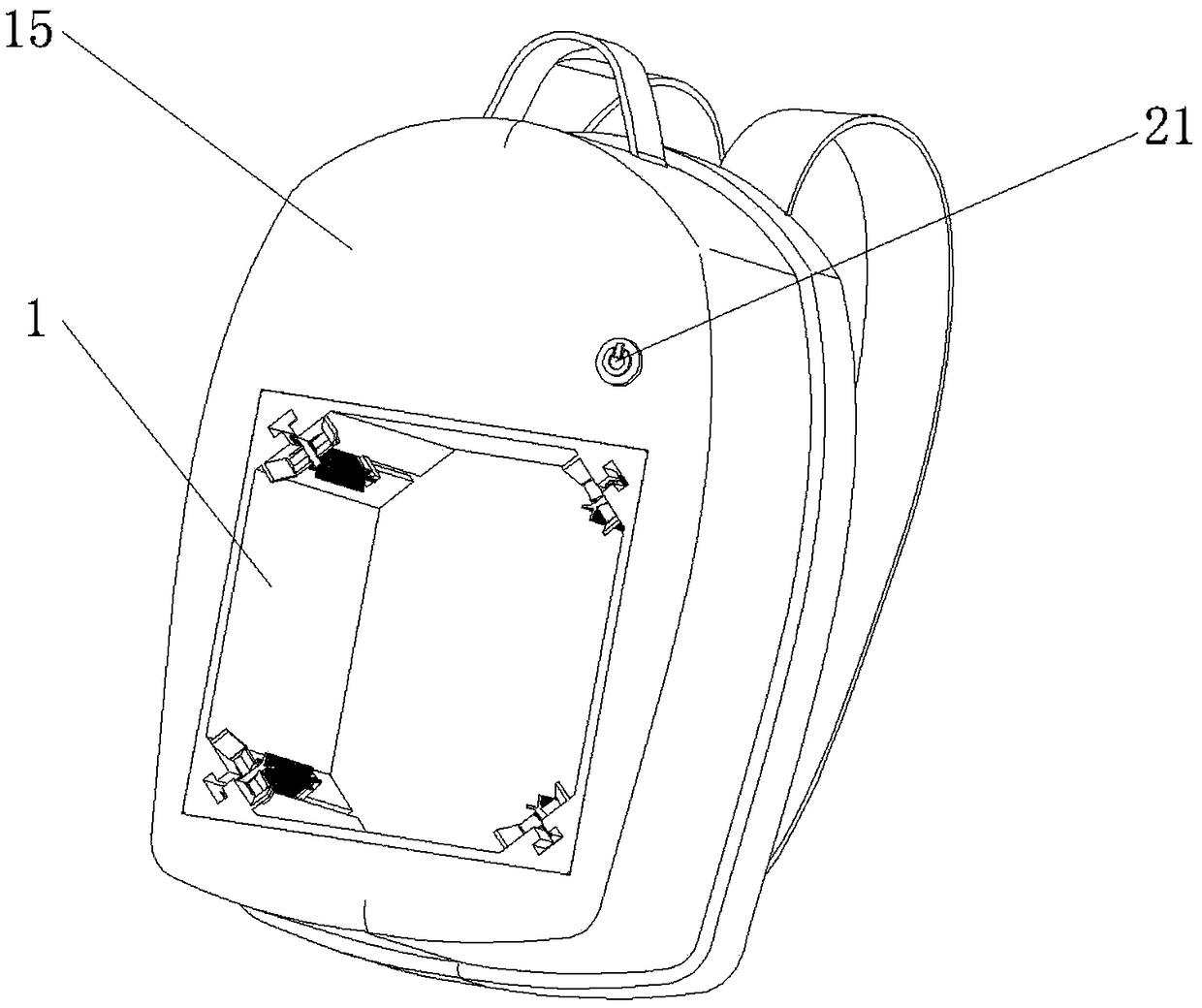

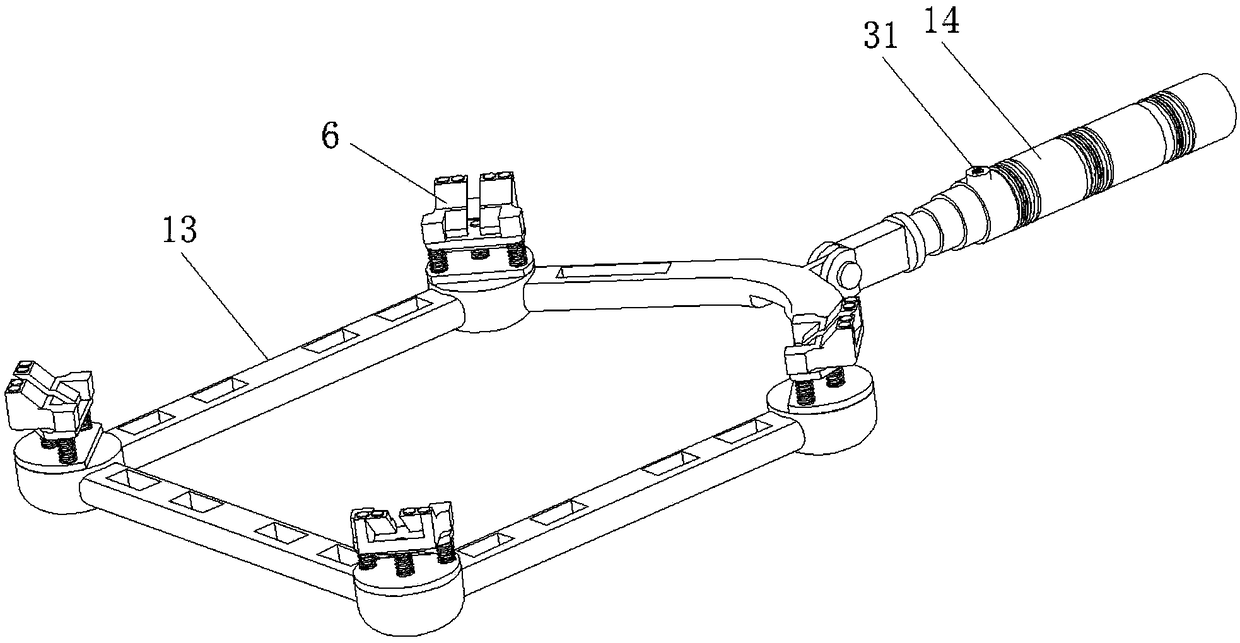

Portable pineapple bagging assistance device

ActiveCN109197282AAchieve movementRealize resetPlant protective coveringsEngineeringUltimate tensile strength

Owner:WENZHOU UNIVERSITY

Automatic bagging equipment for fruits and vegetables

PendingCN112298649AIngenious structural designReduce manufacturing costPackaging fruits/vegetablesHorticultureElectric machinery

The invention relates to automatic bagging equipment for fruits and vegetables, and belongs to the technical field of automatic bagging equipment structures for fruits and vegetables. The automatic bagging equipment comprises a fixed mounting plate, wherein a bag opening driving motor is mounted in the center of the fixed mounting plate; an output shaft of the bag opening driving motor is connected with a lead screw which vertically extends downwards through a coupling; a nut is mounted on the lead screw; a connecting plate is mounted below the nut; a fruit and vegetable net cover taking device used for pulling a fruit and vegetable net cover upwards is mounted on the connecting plate; and a fruit and vegetable bag opening grabbing device used for opening the fruit and vegetable net coverand grabbing the fruits and vegetables is mounted outside the fruit and vegetable net cover taking device. The automatic bagging equipment is simple in structure, can quickly lift the fruit and vegetable net cover upwards, and meanwhile has the effects of bag opening, bagging and grabbing; the working efficiency is improved; and the production cost is reduced.

Owner:烟台拓伟智能科技股份有限公司

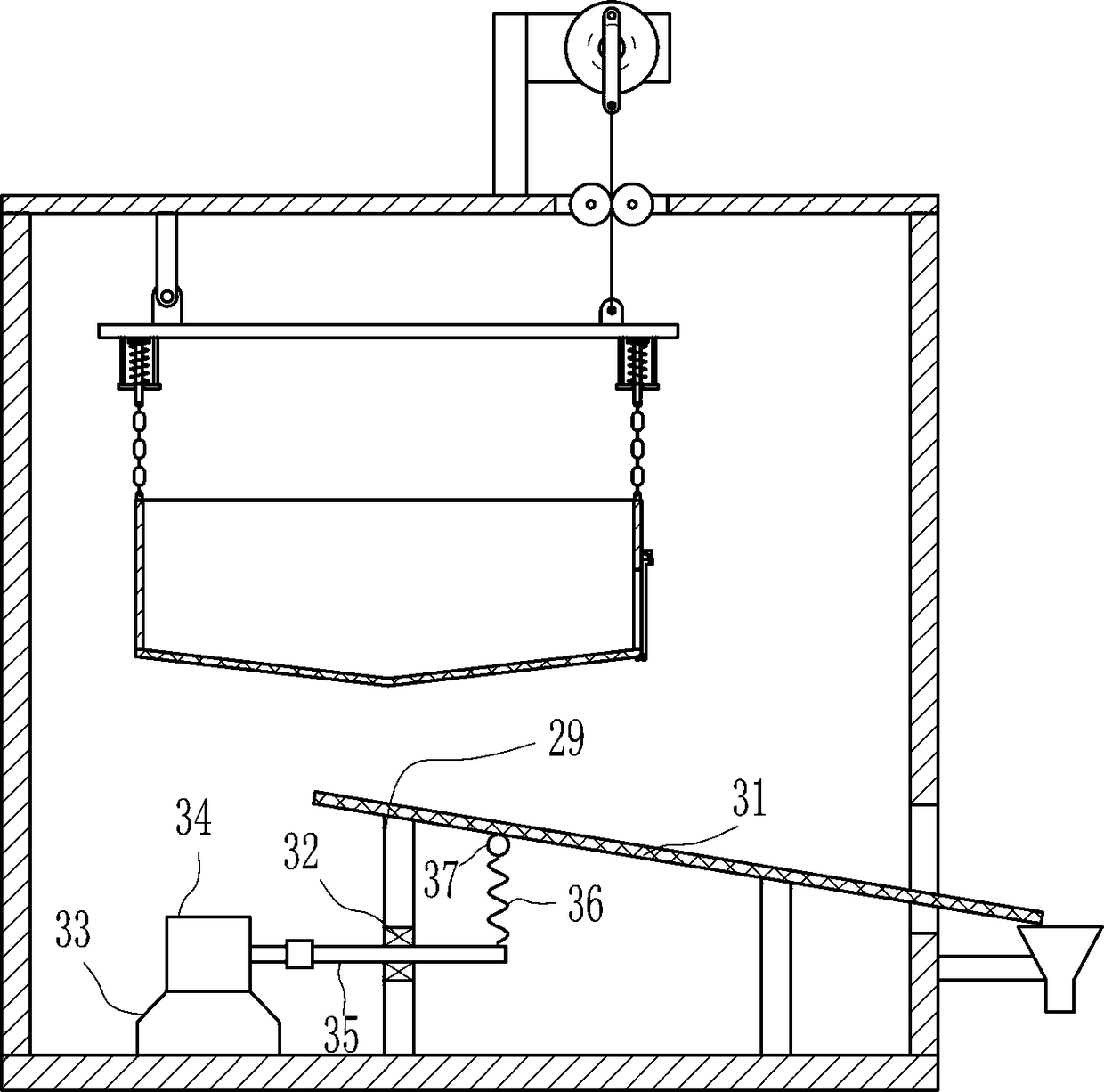

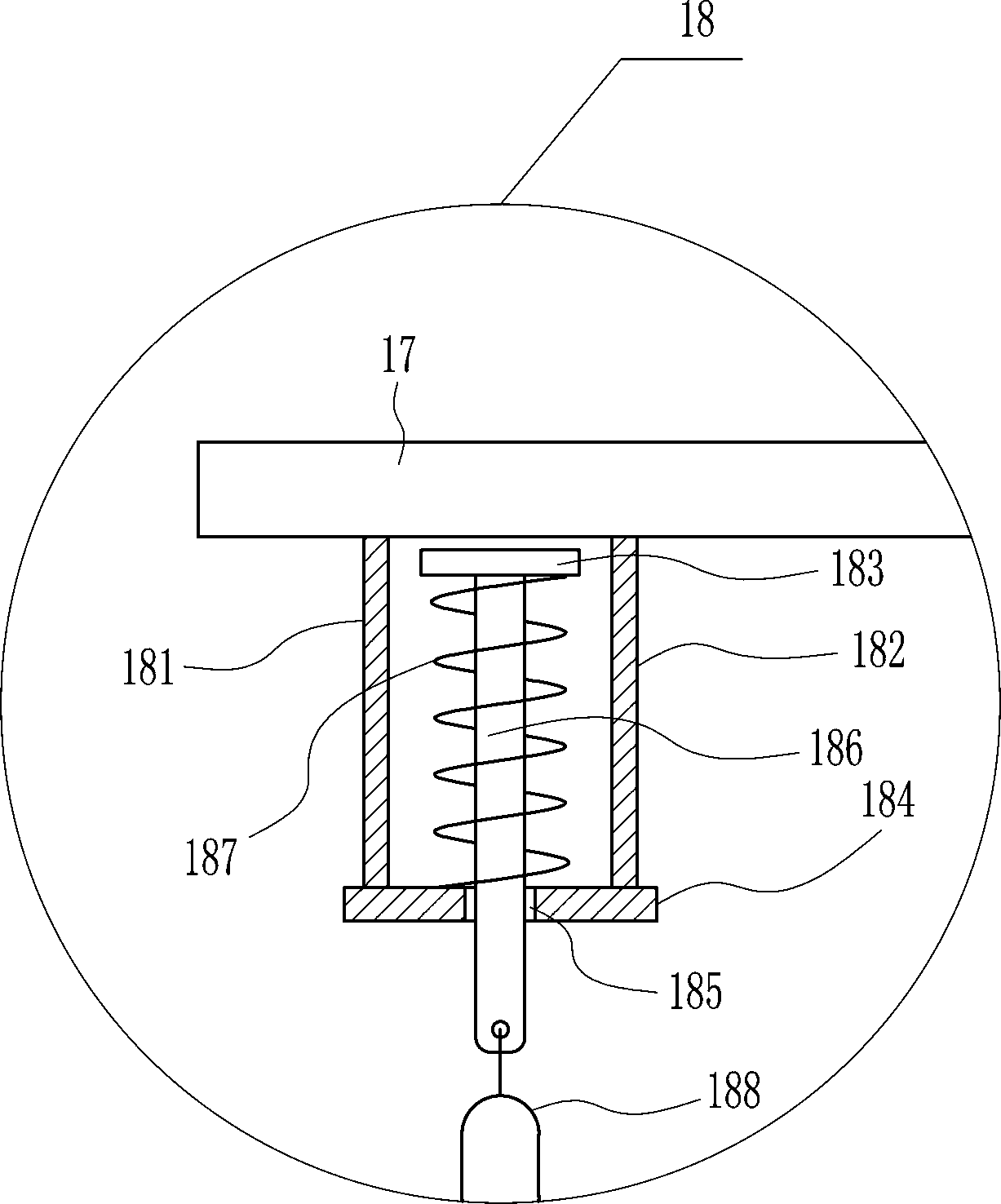

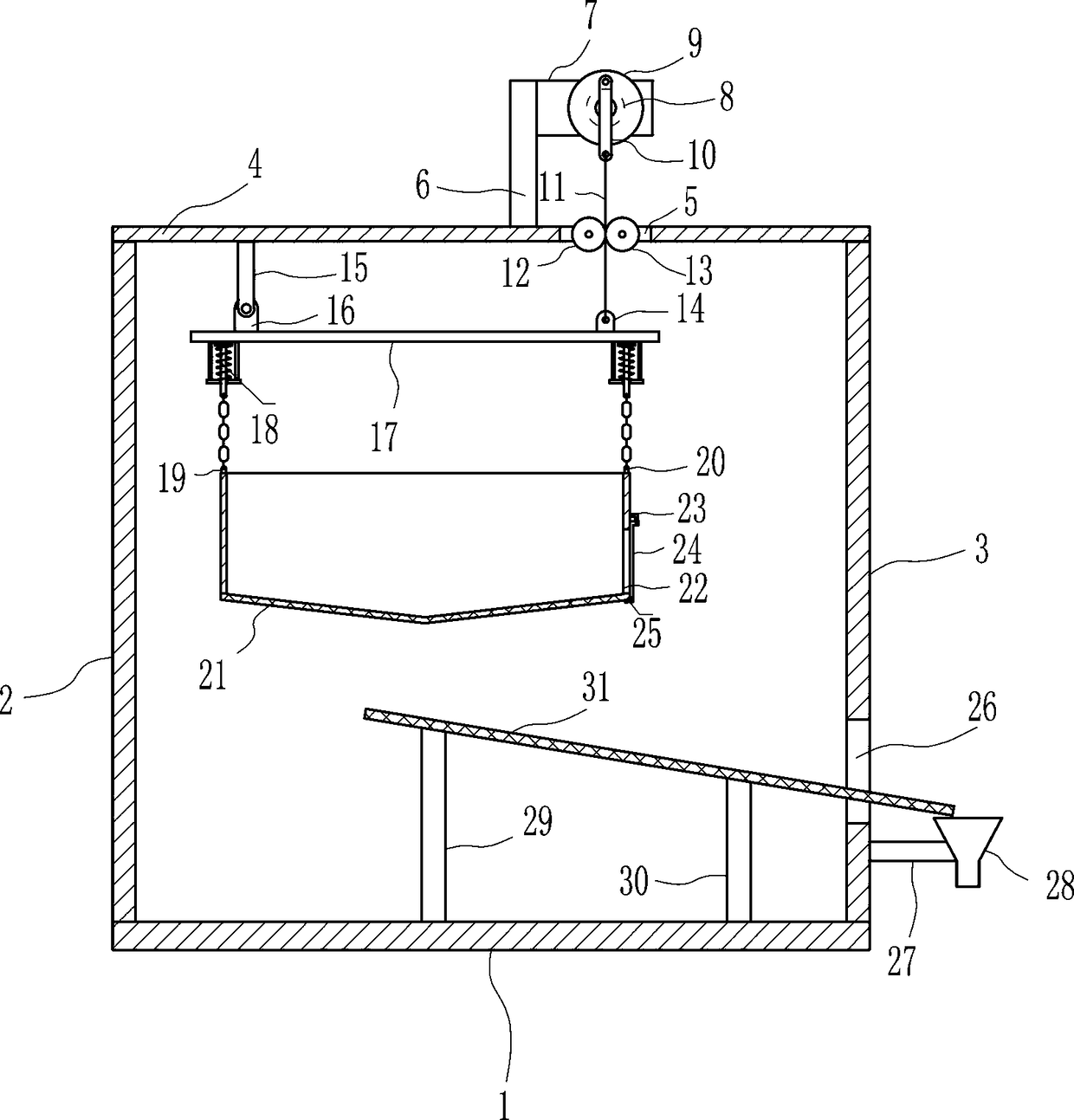

Sun-dried walnut sieving and bagging equipment

The invention relates to bagging equipment, in particular to sun-dried walnut sieving and bagging equipment. The technical effects that the provided sun-dried walnut sieving and bagging equipment is rapid in bagging, easy to operate and clean in bagging are achieved. In order to achieve the technical effects, the provided sun-dried walnut sieving and bagging equipment comprises a base, a first support, a second support, a third support, a first fixing plate, a second fixing plate, a first motor, a rotary plate, a connecting rod, a steel wire rope, a first guiding wheel, a second guiding wheel,a first swing base, a second swing base, a third swing base, a fourth support, a damping device, a fourth swing base, a fifth swing base, a sieve frame, a supporting rod, a baffle, a switch device, athird fixing plate, a bag hanging funnel, a fourth fixing plate, a fifth fixing plate and a discharging plate. The bagging function of sun-dried walnuts is achieved, the walnuts are swung and cleaned, in addition, damping is conducted, the walnuts are rapidly bagged, and the sun-dried walnut sieving and bagging equipment has the characteristics of being easy to operate, clean in bagging, rapid inbagging and the like.

Owner:金寨县富东生态农业开发有限公司

A bagging device for rice production and processing

ActiveCN112373860BEfficient removalKeep dry and cleanPackaging protectionPackaging machinesAgricultural engineeringDust control

The invention relates to the technical field of rice production equipment, in particular to a bagging device for rice production and processing. A support column is bolted on the bottom, a fixing block is bolted on the surface of the storage box, the fixing block and the fixing plate are bolted, and a feeding hopper is bolted on the top of the storage box; The setting of material box, dust box, screening mechanism, air cylinder, clamping mechanism, conveyor belt and ventilation mechanism can effectively remove dust and moisture in the rice, ensure that the rice is dry and clean, and can quickly bag and convey the rice. , which can improve the quality of rice production and the advantages of bagging efficiency, solve the problem that the bagging device currently used in rice production has a single function, cannot effectively fix the rice bag, and the rice bag is easy to fall, causing rice waste, and can not deal with the dust in the rice in time. question.

Owner:HUNAN DONGTINGCHUN RICE IND

Corn Mahua and preparation method thereof

InactiveCN108651578AGreat tasteFull of nutritionDough treatmentModified nutritive productsYeastBiotechnology

The invention relates to corn Mahua. The corn Mahua comprises corn flour, millet flour, flour, fruits, fungus and algae foods, Chinese chestnuts, honey, brown sugar, yeast, corn oil and the balance ofwater. The corn Mahua is prepared by the following method: crushing the fungus and algae foods, adding the corn flour, the millet flour and the flour, conducting uniform mixing, adding the water andthe honey, adding the yeast, conducting stirring to obtain dough, then carrying out curing, flattening the cured dough, segmenting the dough into sections, painting the section surfaces with the cornoil and fruit juice obtained by squeezing fruits, then spreading a Chinese chestnut sauce made of the Chinese chestnuts and the brown sugar on the section-shaped dough, rolling and twisting the doughinto strips which look like Mahua in shape, putting the strips into an oil pan, frying the strips until golden, and conducting rapid cooling, sterilization and bagging. The corn Mahua is not only softand delicious in taste, but also rich and balanced in nutrients, and has good health-care effects.

Owner:马鞍山中粮生物化学有限公司

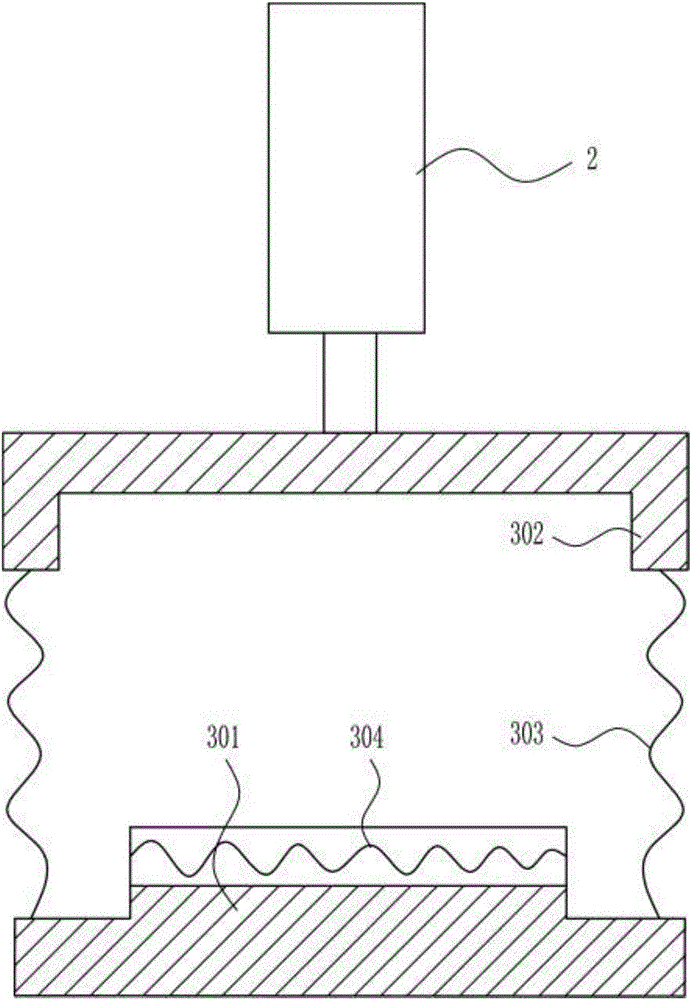

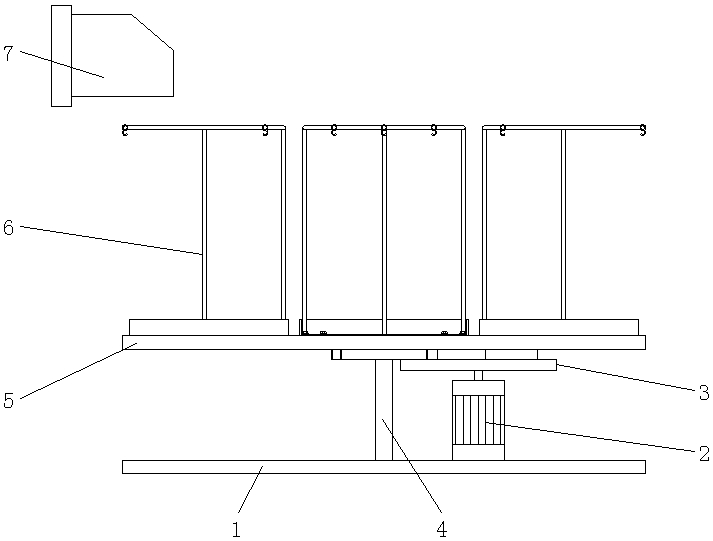

Rolled tissue rowed bagging equipment

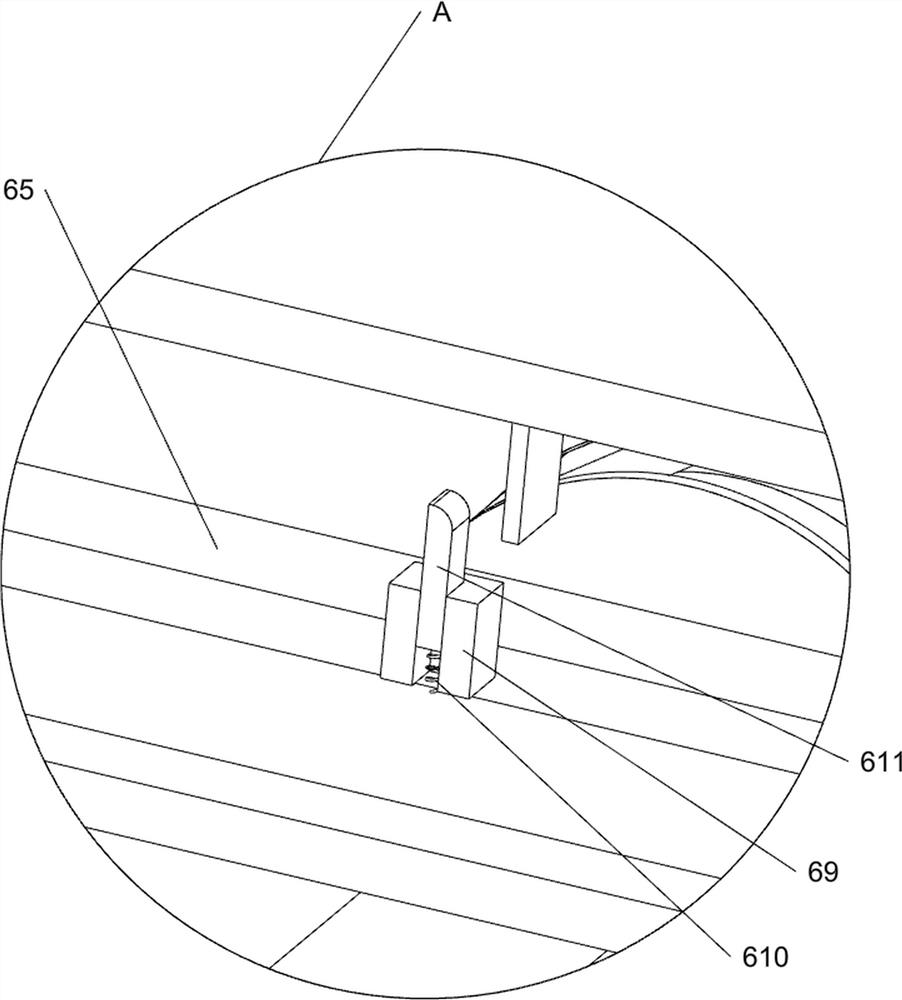

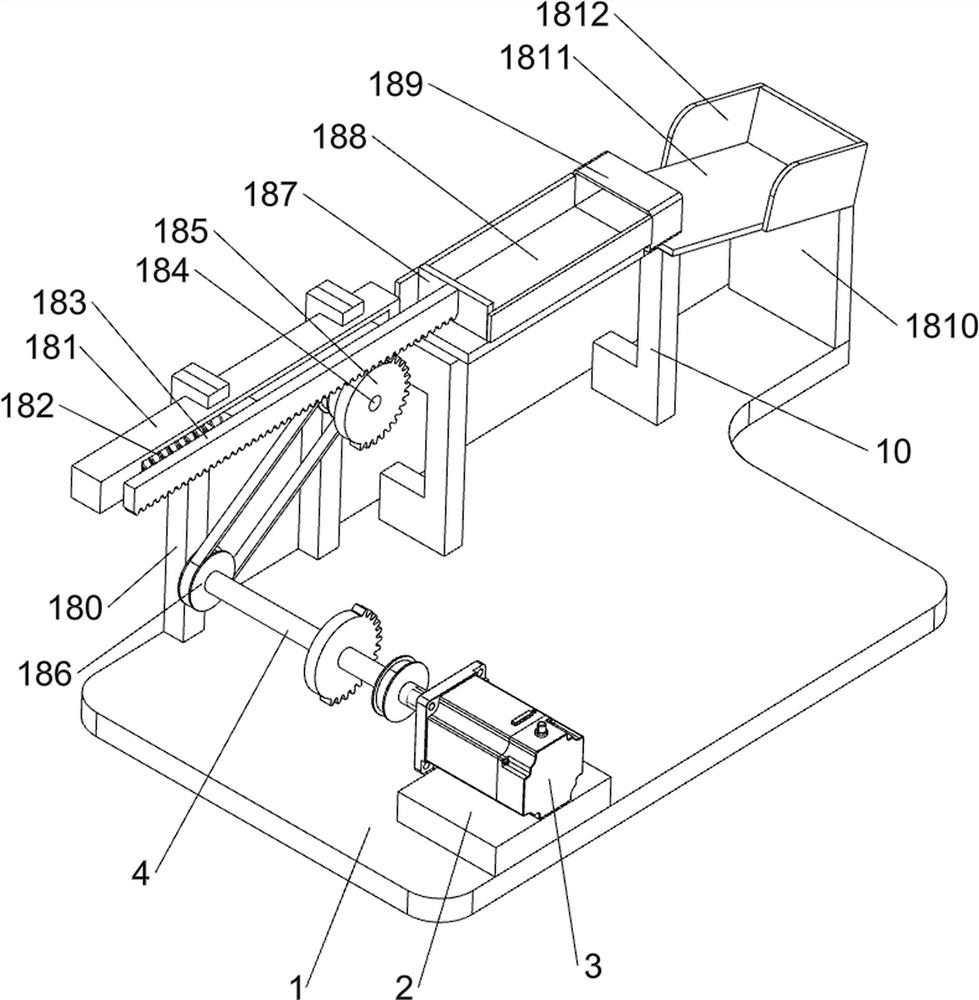

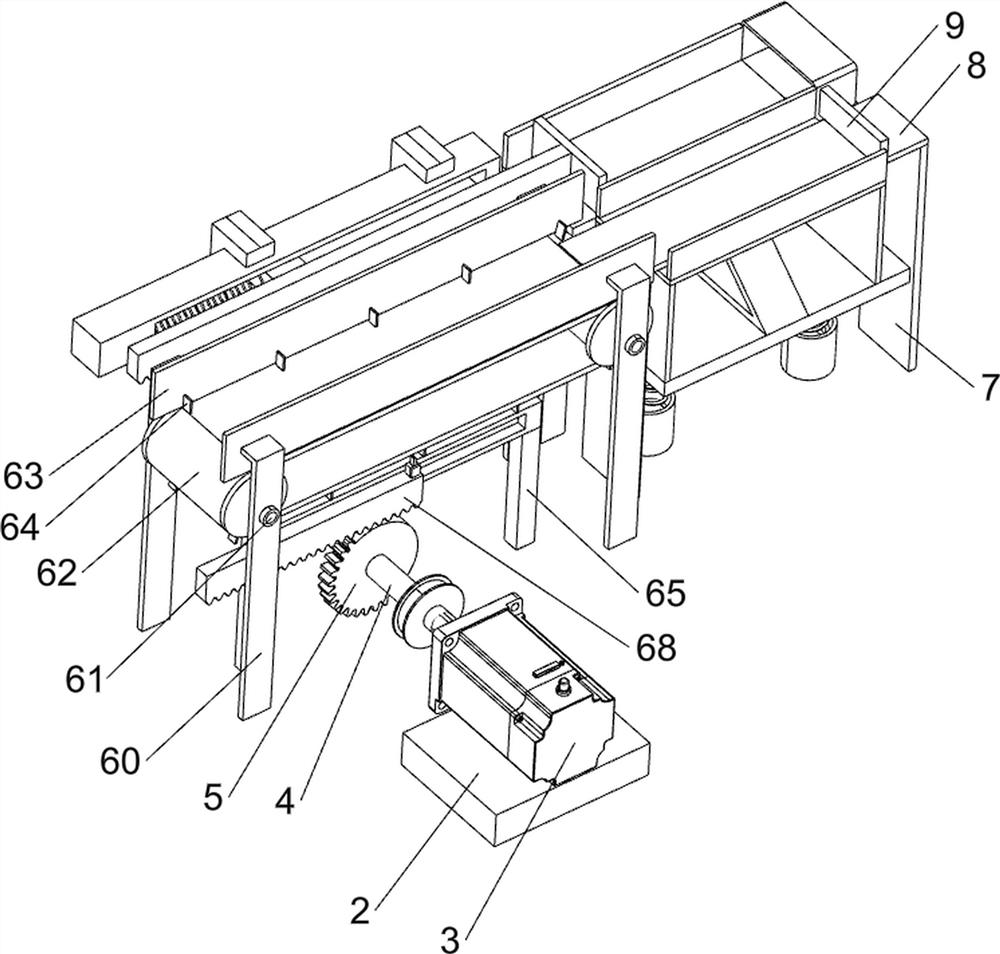

InactiveCN111891459AQuick baggingRealize the effect of continuous baggingIndividual articlesGear wheelControl engineering

The invention relates to bagging equipment, in particular to rolled tissue rowed bagging equipment. The invention provides the rolled tissue rowed bagging equipment which comprises a bottom plate, a base, a servo motor, a first rotating shaft and a first incomplete gear. The bottom plate is used for mounting the whole equipment; the base is arranged on one side of the upper part of the bottom plate; the servo motor is arranged on the upper part of the base; the first rotating shaft is arranged on an output shaft of the servo motor; and the first incomplete gear is arranged on the first rotating shaft. The equipment achieves an effect of bagging rolled tissue quickly. By placing the paper needed to be bagged on a conveyor belt, the conveyor belt moves to a first connecting plate, and as a push plate moves front and back to push the rolled tissue to a fourth supporting plate continuously, so that a continuous bagging effect is achieved.

Owner:邹麟相

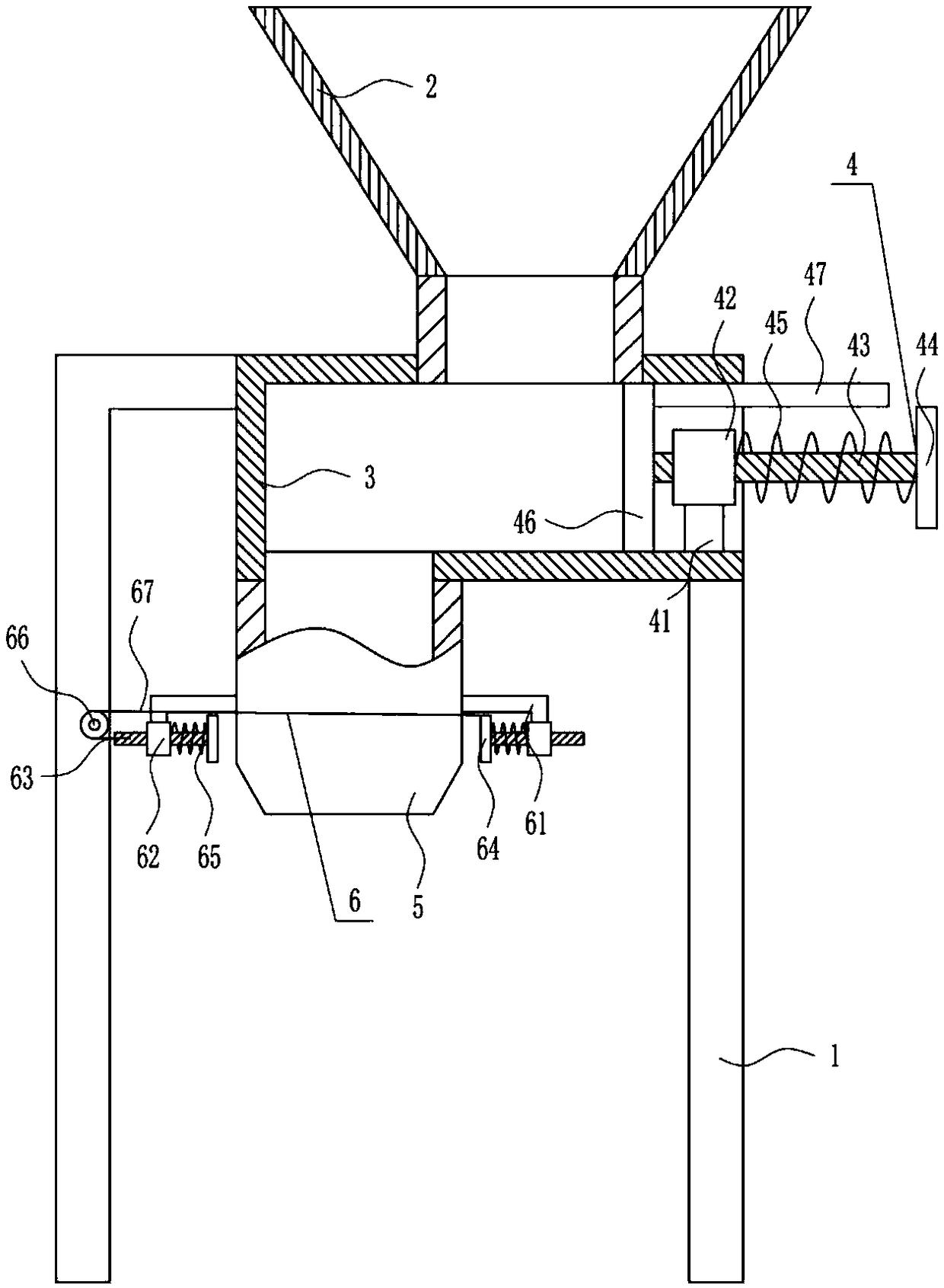

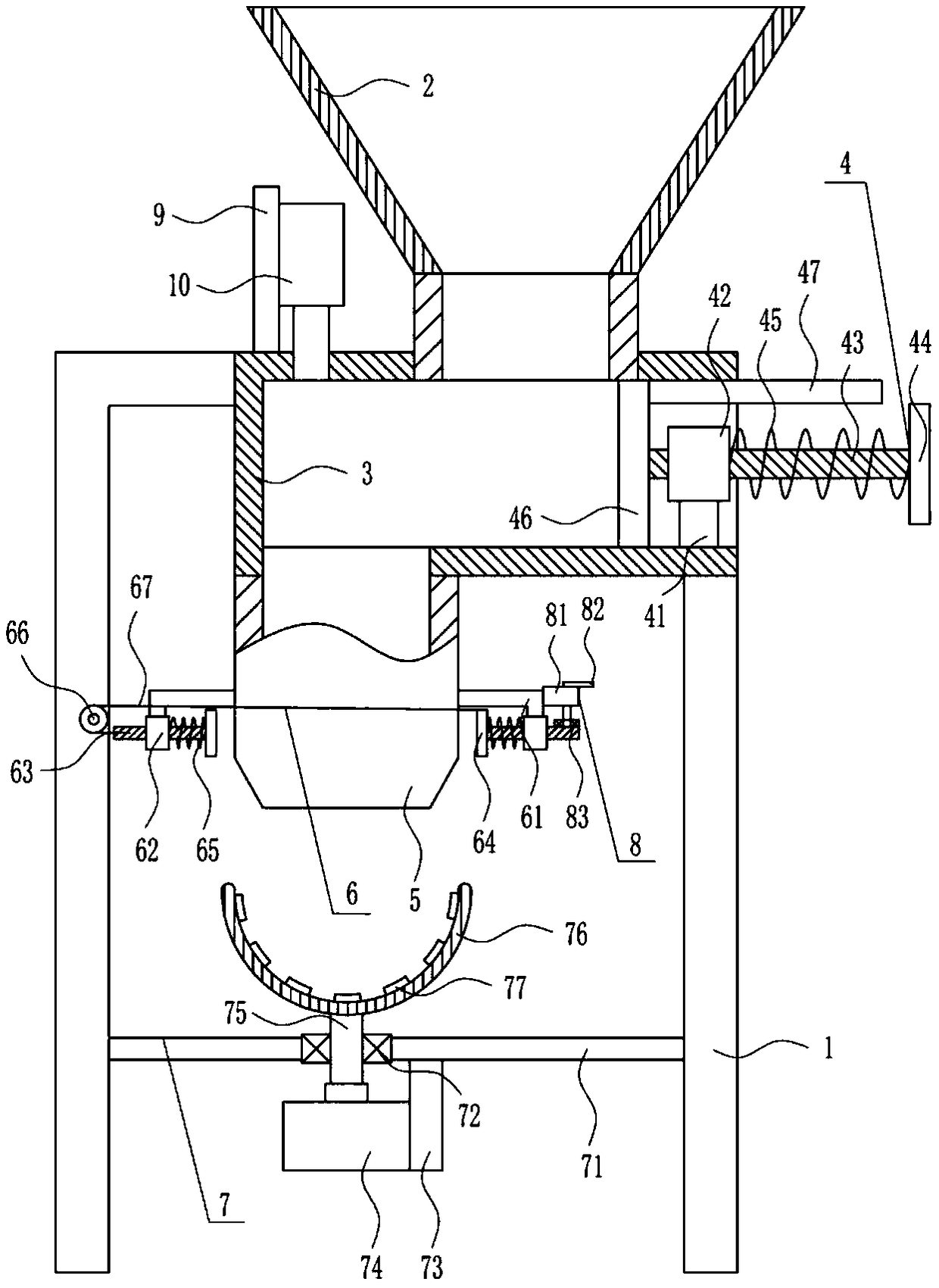

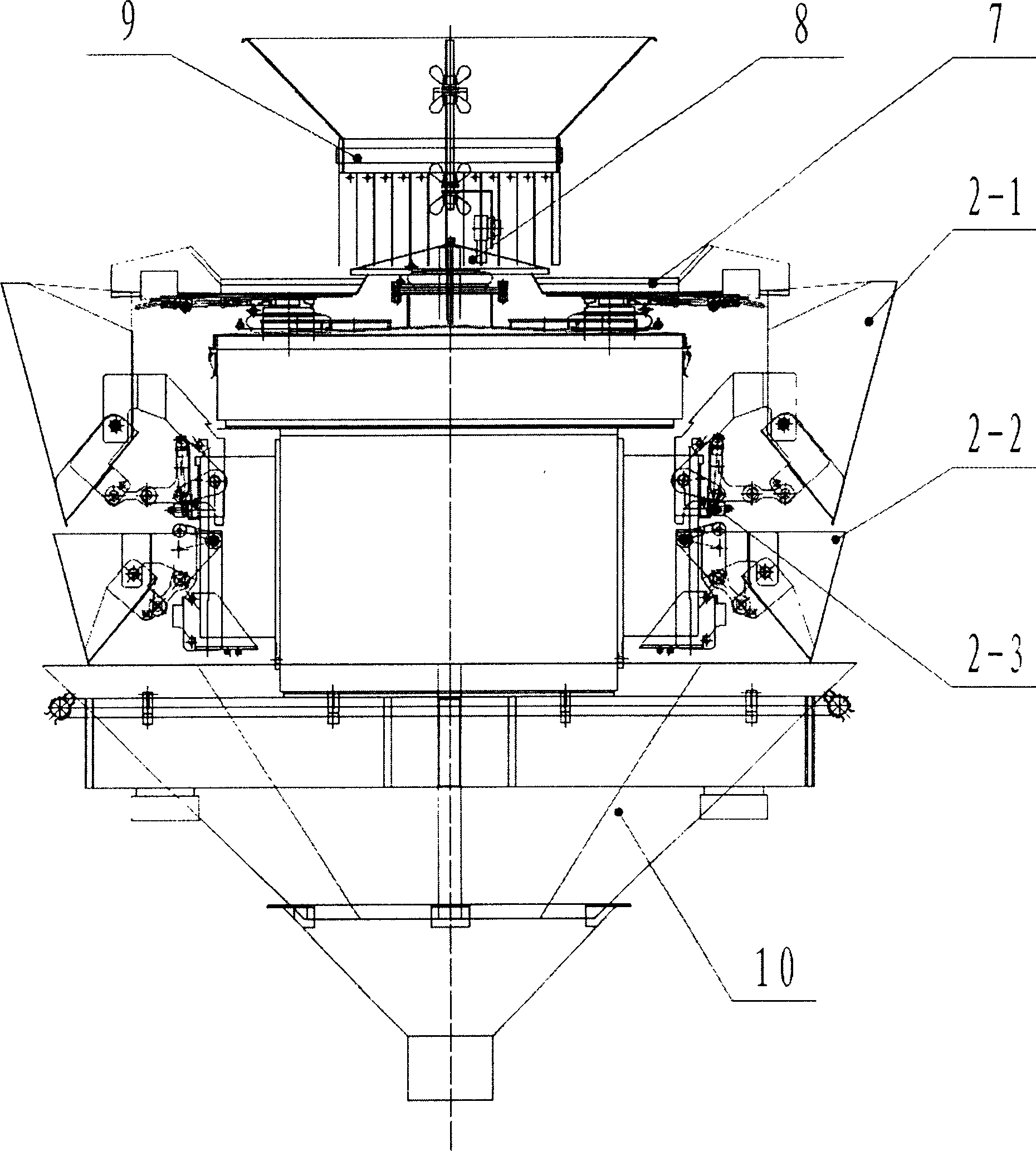

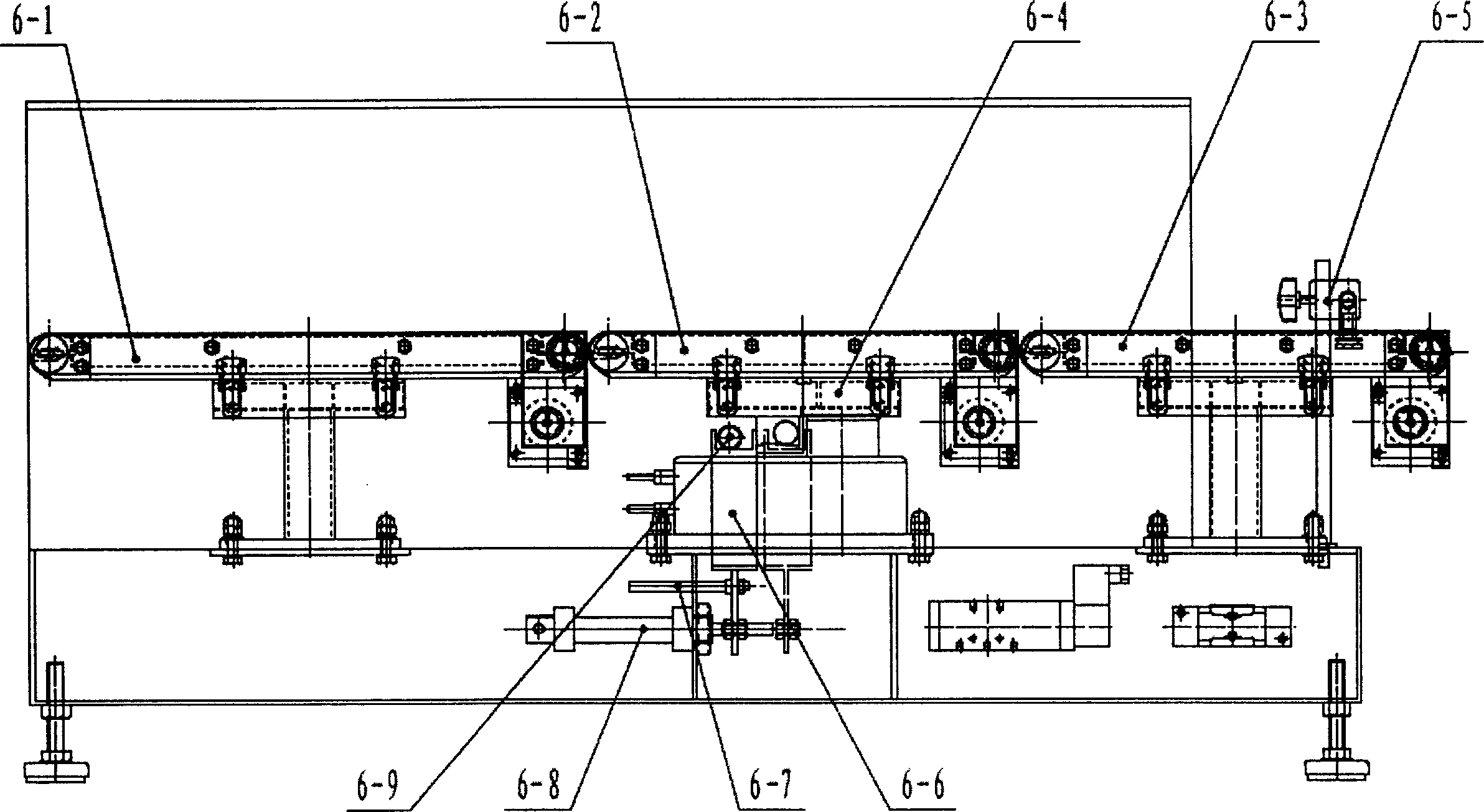

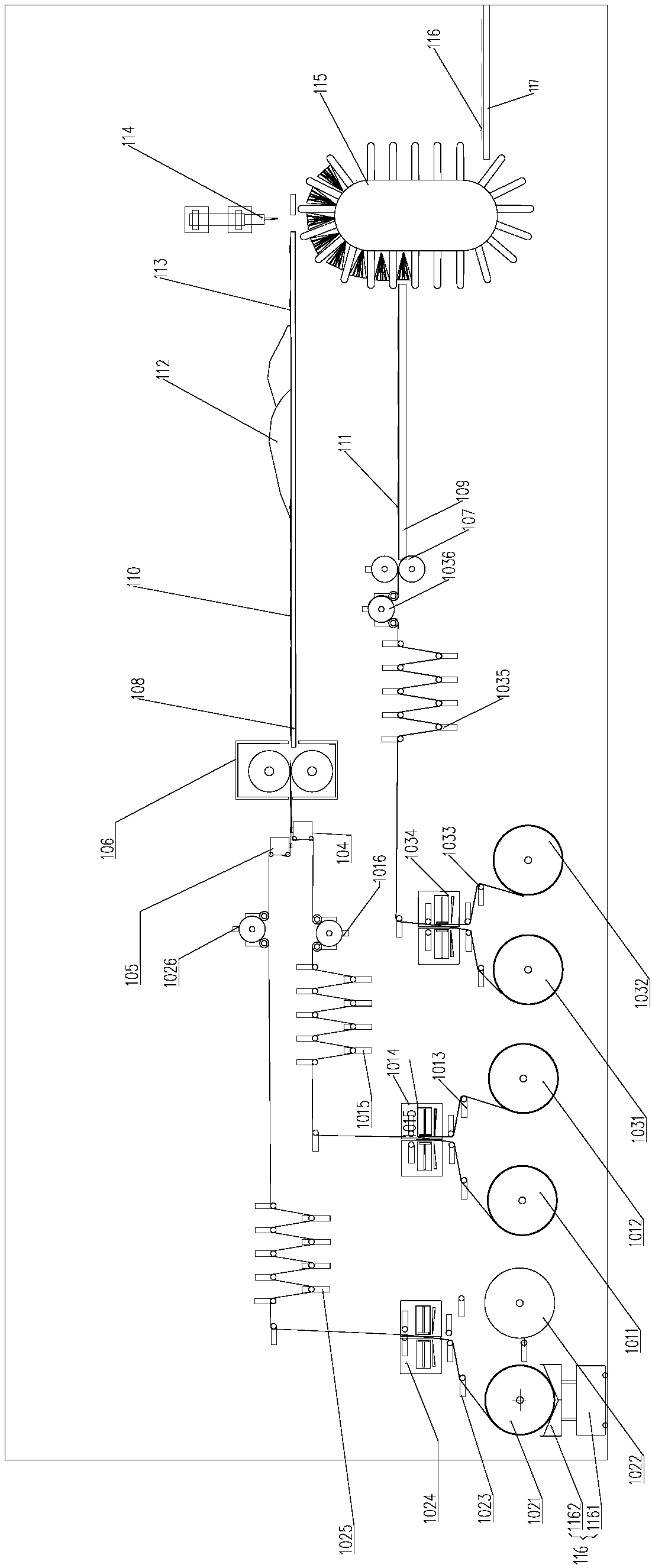

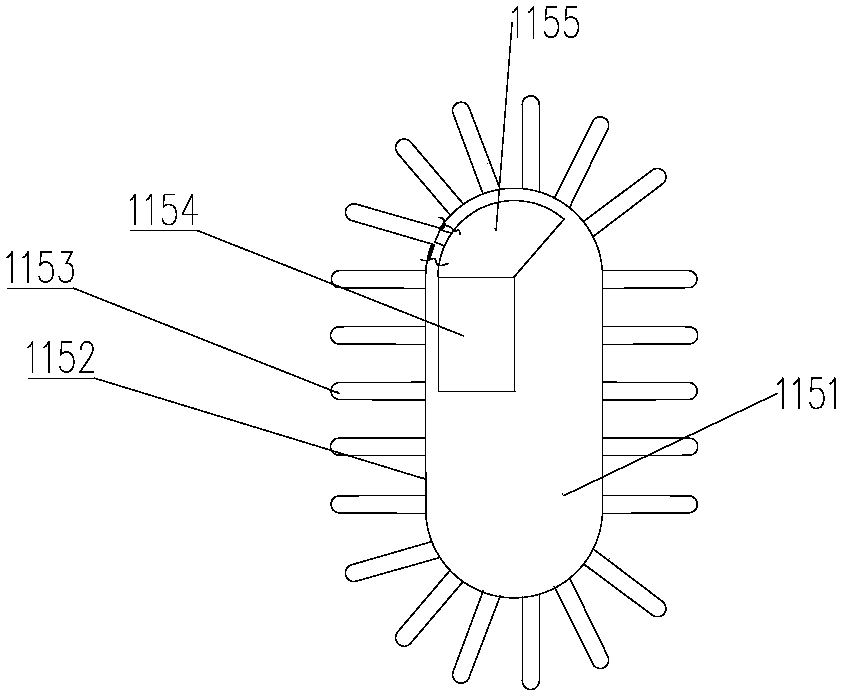

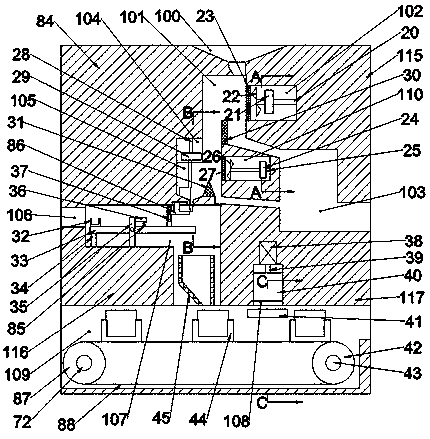

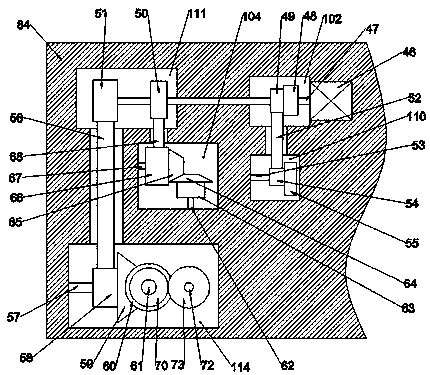

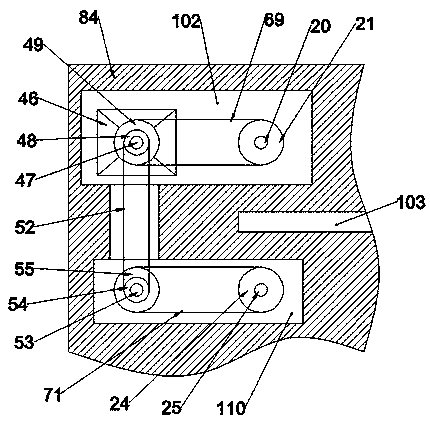

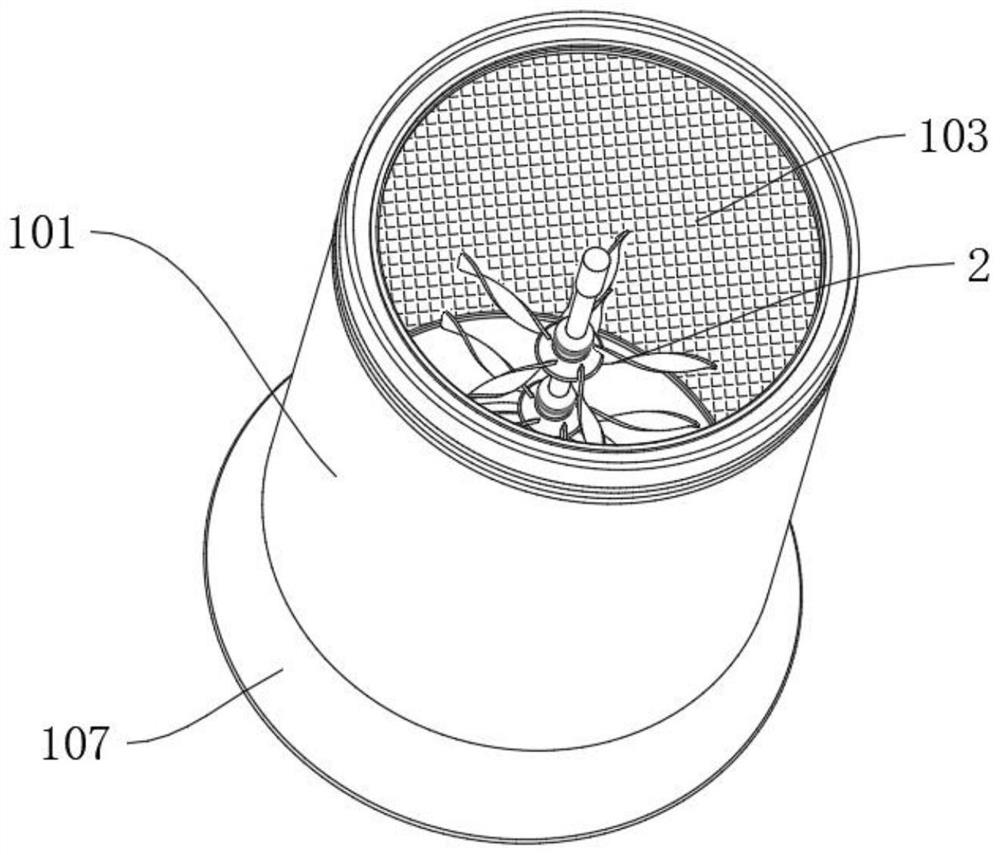

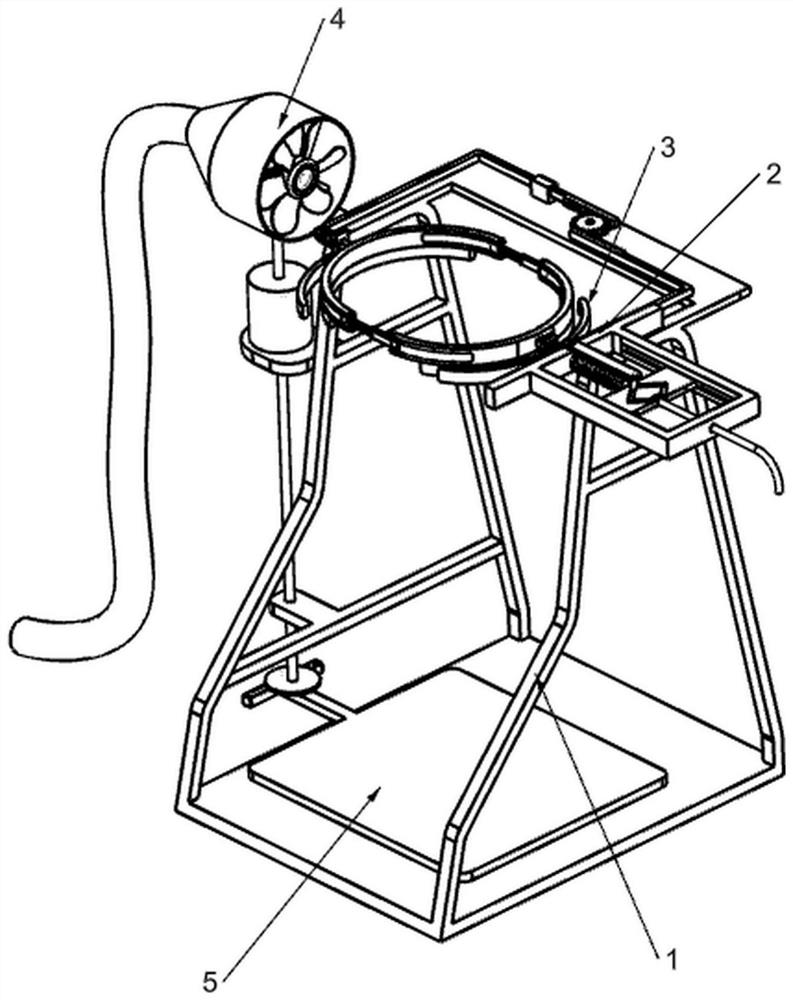

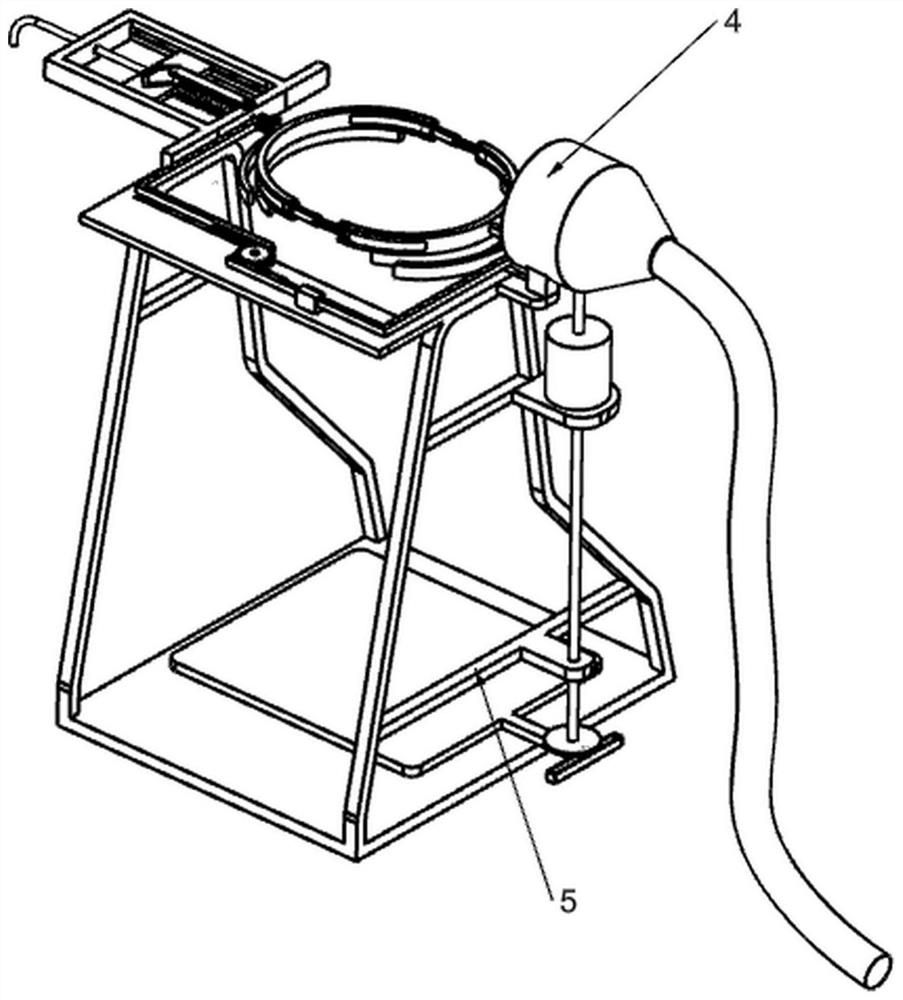

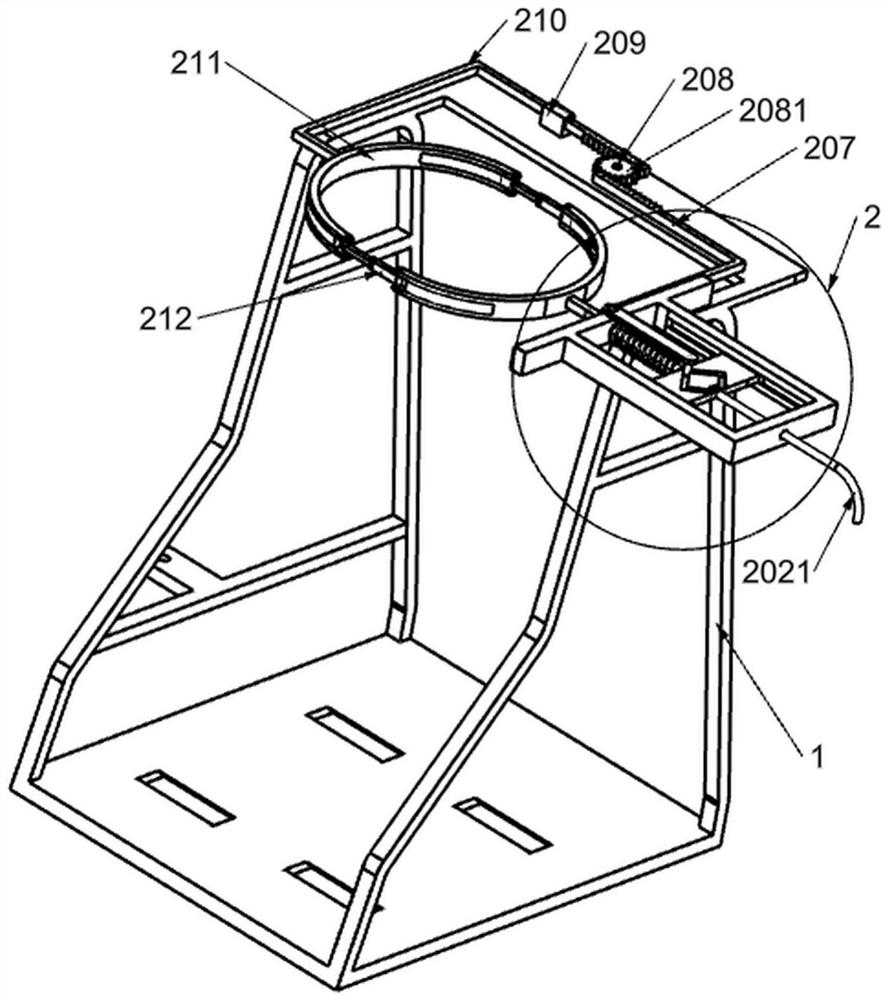

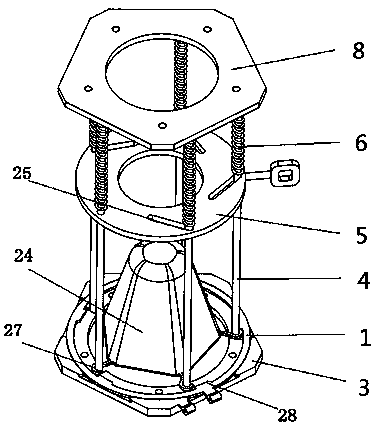

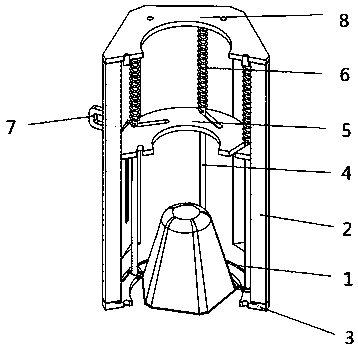

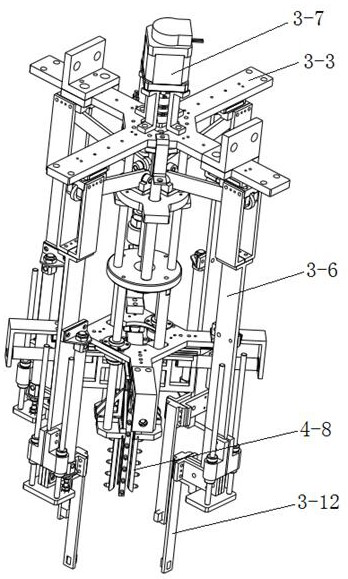

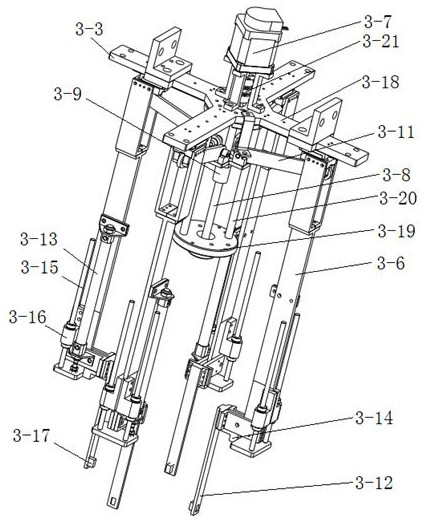

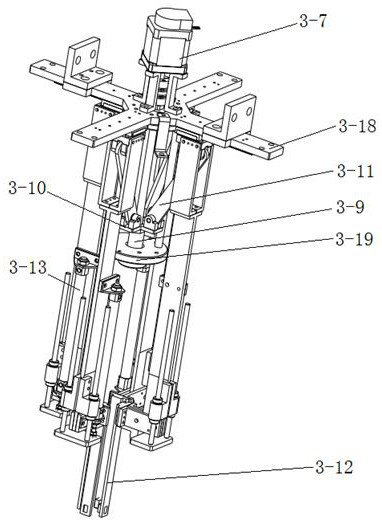

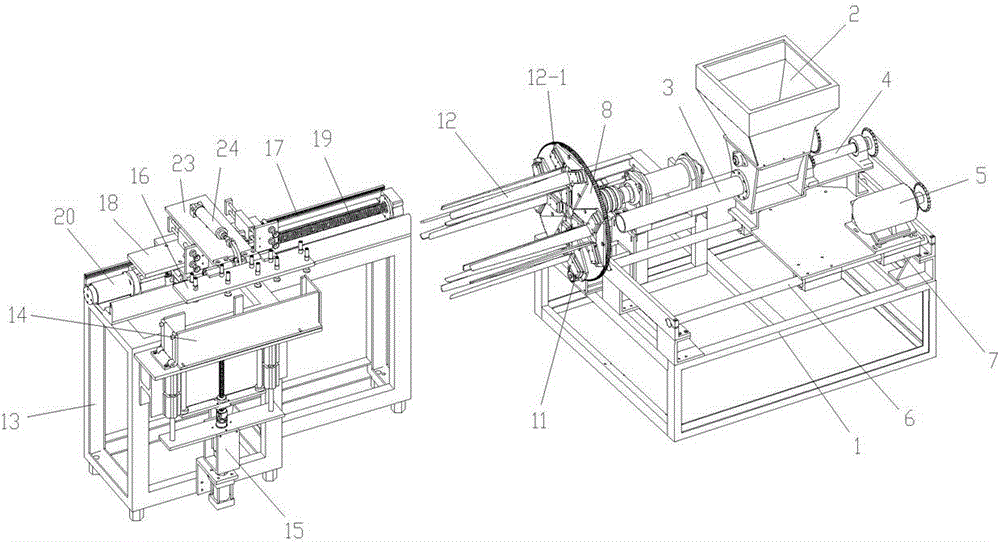

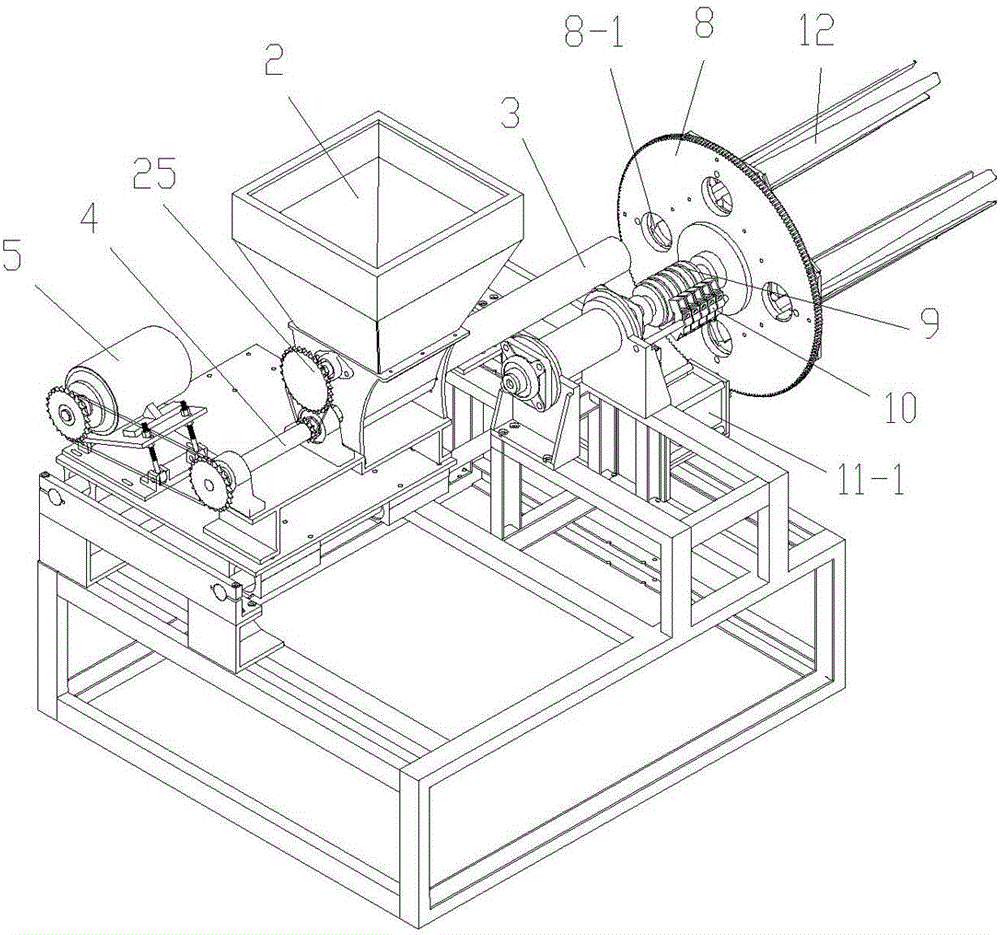

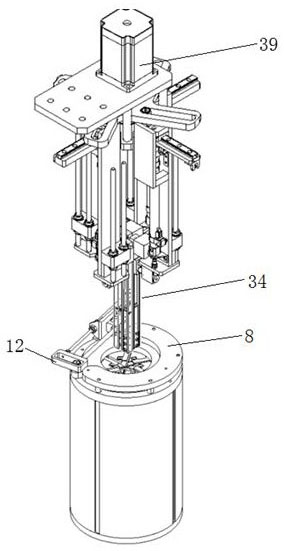

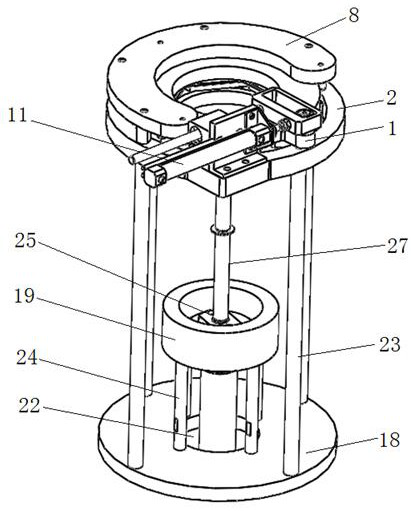

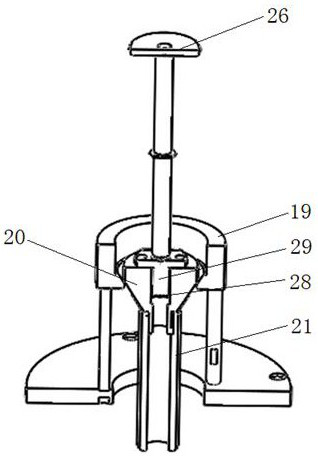

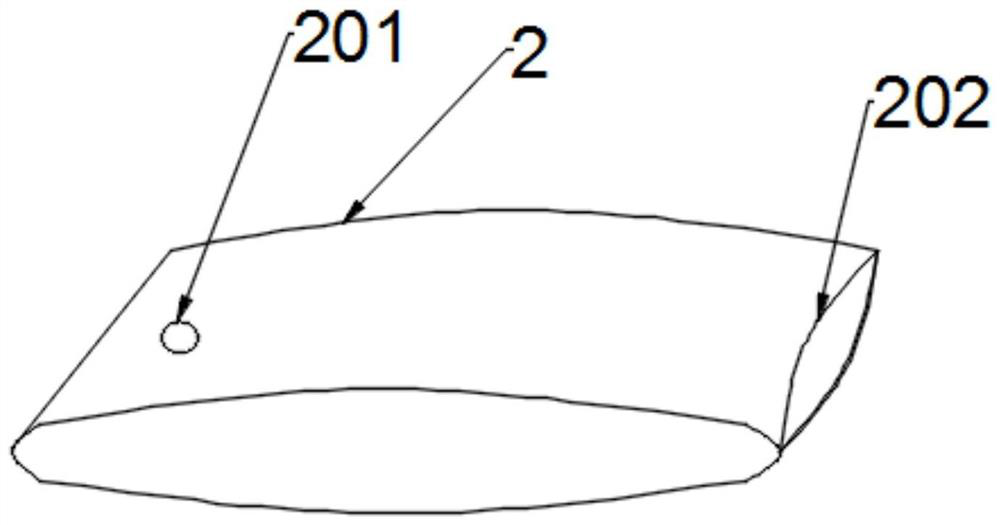

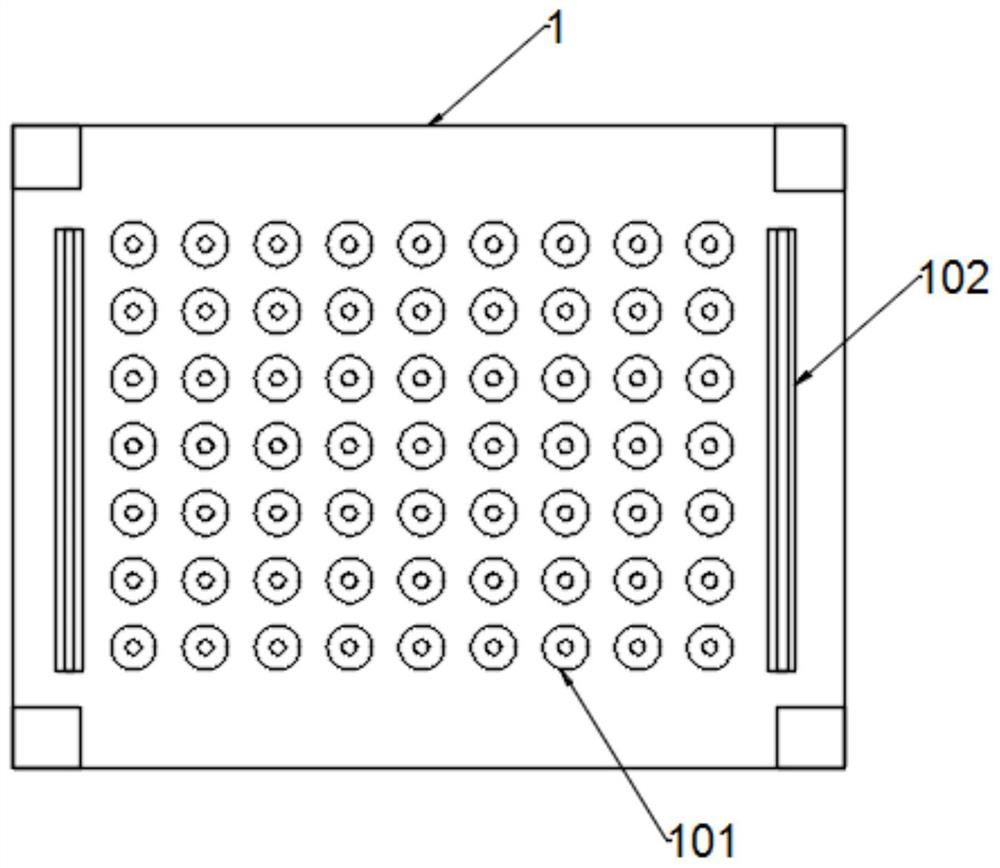

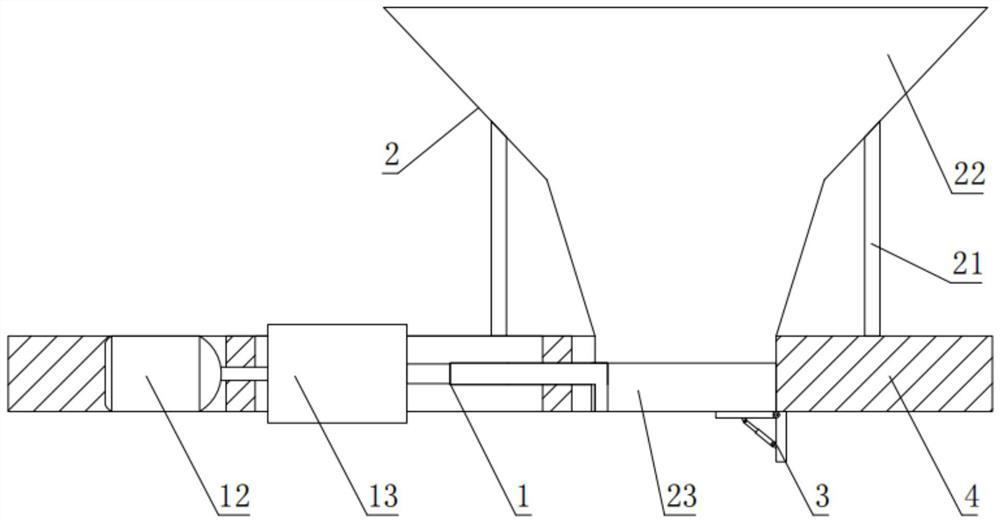

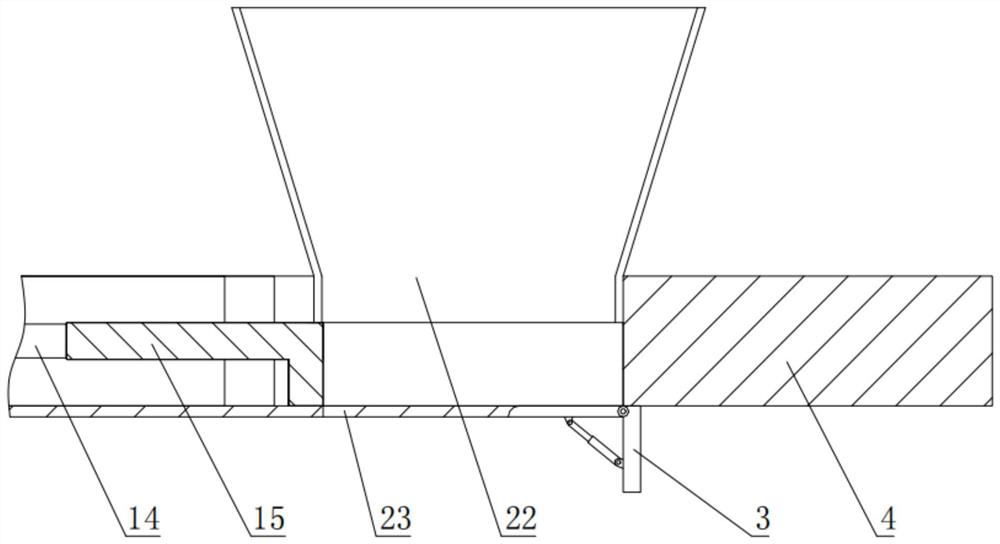

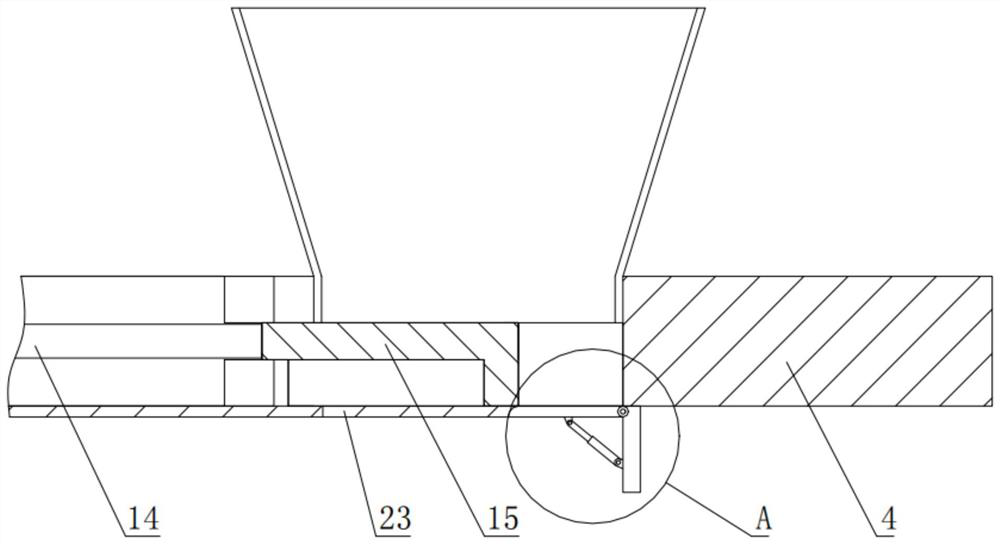

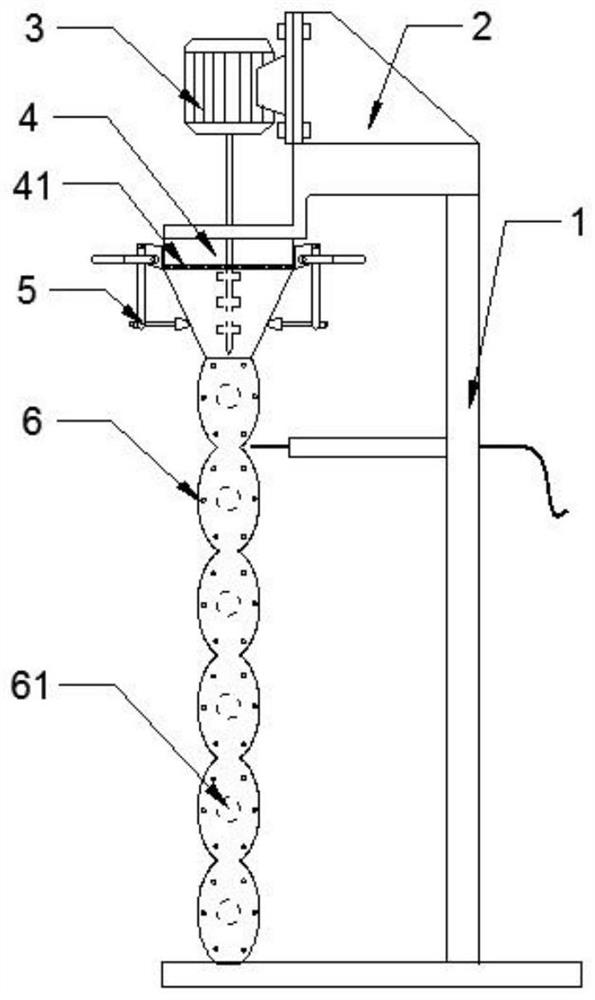

Automatic edible mushroom stick bagging bagging machine

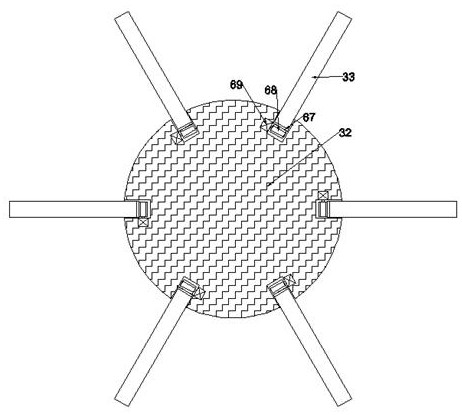

ActiveCN103858671BOvercoming Difficult-to-Automate BaggingQuick baggingHorticultureGear wheelPush pull

The invention relates to a fully-automatic edible-fungus-stick bagging machine, which comprises a machine frame, wherein a hopper is arranged on the machine frame, a discharging pipe which is horizontally and transversely arranged is arranged at the lower end of the hopper, a conveying rod is arranged in the discharging pipe, the conveying rod is connected with a driving motor, the hopper is installed on a transverse sliding rail, the transverse sliding rail is fixedly arranged on the machine frame, and a push-pull cylinder which is used for enabling the hopper to slide is installed on the machine frame; a rotary disk is arranged at the right end of the machine frame, a group of through holes which are used for being penetrated by the discharging pipe are arranged at intervals in the rotary disk, the rotary disk is installed on the machine frame through a rotating shaft, an angle positioning controller is installed on the rotating shaft, a gear slot is arranged in the periphery of the rotary disk, a gear which is engaged with the gear slot is arranged on the machine frame, and the gear is installed on a rotating motor; a group of expanding rods which are arranged at intervals are arranged at the outer side of each through hole, the expanding rods are installed on the outer lateral surface of the rotary disk and surround the periphery of each through hole, and the expanding rods and the rotary disk are in internal and external sliding fit through a sliding seat and a cylinder; a bagging device is arranged on the right of the rotary disk.

Owner:庆元县菇星节能机械有限公司

A rice processing equipment that removes fascia by secondary rice rolling

ActiveCN112387329BUniform removalQuick baggingGrain huskingGrain polishingAgricultural engineeringElectrical and Electronics engineering

Owner:佛山市南海区丽强米业有限公司

Slag removal device for feed production

The invention discloses a slag removal device for feed production. The slag removal device comprises supporting legs mounted at the bottom of a box body, a flow guide mechanism, a filtering mechanismand a packaging mechanism, wherein the flow guide mechanism comprises a partition plate, flow distribution plates and flow guide plates; the filtering mechanism comprises shells, frames, particle filtering nets, dust filtering nets and fans; and the packaging mechanism comprises surrounding plates, second electric push rods, rotating rods and baffles. By arranging the flow distribution plates andthe flow guide plates in the box body, generated disintegrating slag can be removed, the production quality of feeds is guaranteed, and the disintegrating slag can be collected and treated in a centralized mode. By arranging the shells, storage of the disintegrating slag can be achieved, dust can be removed through air circulation, the disintegrating slag can be cleared while feed bagging is performed, and it is guaranteed that the disintegrating slag can be treated in time after each time of production. By arranging pressing plates, tight attachment of packaging bags can be achieved, baggingtreatment of the feeds is facilitated, and fractional treatment of the feeds can be achieved in cooperation with movement of a cover plate.

Owner:SHEYANG COUNTY SHEYANG GANGHONG TAIYANG FEED FACTORY

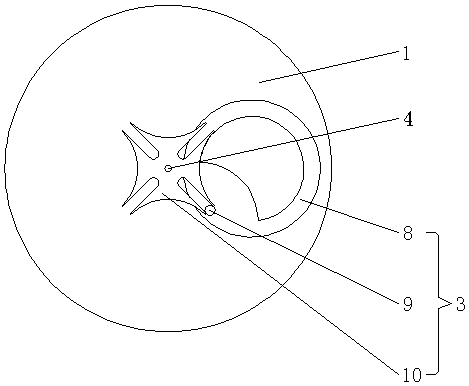

Fruit and vegetable net sleeve cutting and bagging device

PendingCN113273418ASimple structureSimple structural designPlant protective coveringsAgricultural engineeringEngineering

The invention relates to a fruit and vegetable net sleeve cutting and bagging device, and belongs to the technical field of fruit and vegetable packaging equipment. The fruit and vegetable net sleeve cutting and bagging device comprises a net sleeve cutting mechanism and a bagging device, wherein the net sleeve cutting mechanism comprises a net sleeve cutting knife set, the net sleeve cutting knife set comprises a lower limiting support, a steering plate and an upper limiting support, six cutters are arranged between the lower limiting support and the steering plate, and a driving mechanism used for driving the six cutters to be opened or closed is installed on the lower limiting support; and the bagging device comprises a guide rail set composed of guide rails, a folding and unfolding driving mechanism is arranged above the guide rail set, a vertical installation plate is installed below each guide rail sliding block, a bag stripping air cylinder is installed in the length direction of the vertical installation plate, a finger frame is installed at the bottom of the vertical installation plate, a finger plate is hinged to the finger frame, a plurality of finger pins are arranged at the lower position of the finger plate, and the movable end of the bottom of the bag stripping air cylinder is connected with a finger plate driving mechanism used for rotating the finger plate. The fruit and vegetable net sleeve cutting and bagging device is simple in structure, capable of rapidly cutting and sleeving net sleeves and high in working efficiency.

Owner:烟台拓伟智能科技股份有限公司

Efficient sandbag machine for flood fighting and emergency rescues

InactiveCN112124647ASolve the inconvenience of carryingSolve the problem of time-consuming and laborious filling on siteBagsSacksEmergency rescueArchitectural engineering

The invention relates to an efficient sandbag machine for flood fighting and emergency rescues, and belongs to the technical field of flood prevention equipment. The machine comprises a storage box and a sandbag; a discharging opening is formed in the storage box; a one-way valve is arranged on the sandbag; the discharging opening communicates with the one-way valve; and a slidable switch is arranged at the discharging opening. According to the machine, the one-way valve on the sandbag communicates with the discharging opening of the storage box, objects in the storage box enter the empty sandbag through the discharging opening and the one-way valve, the discharging opening abuts against the one-way valve to complete rapid filling of the sandbag, and the sandbag is not required to be sealed, so that the problems that the sandbag is inconvenient to carry in the flood-fighting and emergency-rescuing process and the time and the labor are wasted during on-site filling can be effectively solved.

Owner:陈德强

Feed compressing and bagging device for feed production workshop and bagging method of feed compressing and bagging device

The invention discloses a feed compressing and bagging device for a feed production workshop and a bagging method of the feed compressing and bagging device. The feed compressing and bagging device comprises an extruding assembly, a feeding assembly, a bagging assembly and a working table, the extruding assembly is in contact connection with the output end of the feeding assembly, and the bottom end of the feeding assembly is in contact connection with the bagging assembly, wherein the extrusion assembly extrudes the loose feed in the feeding assembly and extrudes the loose feed into feed blocks, the pressed feed blocks are rapidly bagged under the synergistic effect of the bagging assembly, specifically, a driving motor drives a driving cylinder to rotate, the rotating driving cylinder forces an insertion frame and an extrusion folding plate to do reciprocating motion, the extrusion folding plate extrudes the loose feed in an inner cavity of a compression pipeline, the pressed feed blocks are rapidly bagged under the synergistic effect of the bagging assembly, so that the whole bagging method is simpler, and the feed packaging speed is greatly increased; meanwhile, the feed pressing process is small in leakage amount, good in sanitation and environmental protection performance and average in pressing quality every time.

Owner:ANHUI TECH BANK BIO TECH

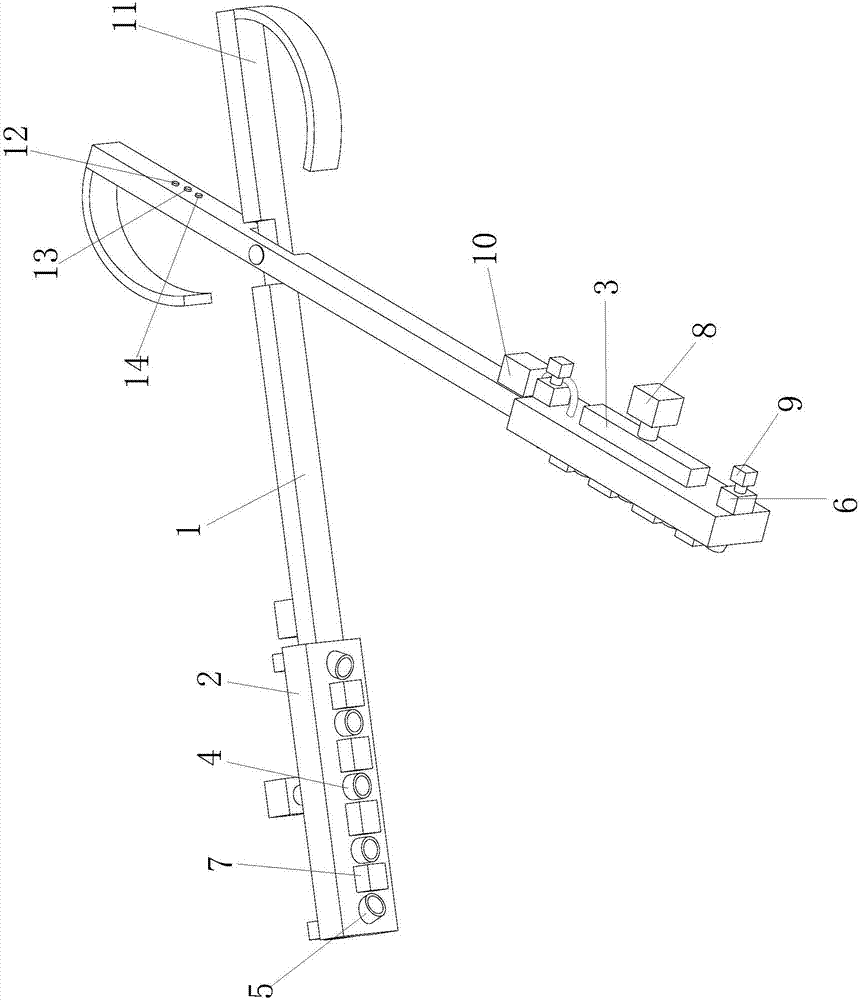

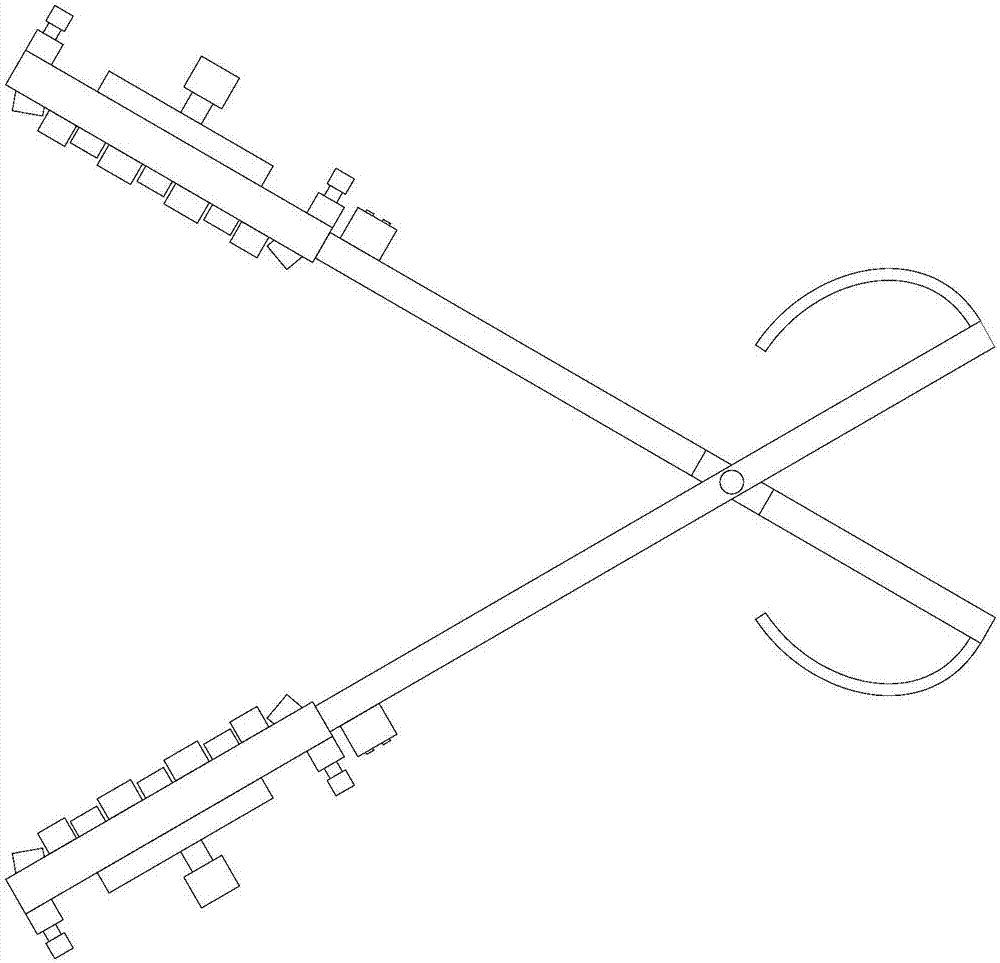

Manual winter peach bagging machine

The invention relates to a manual winter peach bagging machine. The manual winter peach bagging machine comprises two long plates which intersect in the middle and are hinged together, and packaging mechanisms are symmetrically connected to the two long plates; each packaging mechanism comprises a bearing plate, a suction chamber connected to the bearing plate, first air pipes which are arranged on the bearing plate and communicated with the suction chamber, second air pipes which are arranged on the bearing plate and distributed on the portion close to the center of the bearing plate in an inclined mode, an air blowing chamber which is fixed to the bearing plate and connected with the second air pipes and heating blocks which are installed on the bearing plate and located between the adjacent first air pipes; micro suction fans connected with the suction chambers through hoses and micro blowers connected with the air blowing chambers are fixed to the long plates, and power supplies connected with the heating blocks through wires are fixed to the long plates. Accordingly, rapid bagging on winter peaches can be achieved, a plastic bag is stuck in a hot melting mode, the bagging time is shortened, the work efficiency is improved, the labor intensity of fruit growers can be lowered, the optimal management time is guaranteed, and winter peach planting is facilitated.

Owner:无为县雲桃家庭农场

Plastic particle charging bin

InactiveCN110143301AReduce labor intensityImprove bagging efficiencySolid materialEngineeringFeeling tired

The invention relates to the technical field of plastic particle processing, in particular to a plastic particle charging bin. The plastic particle charging bin comprises a supporting frame. A storagebin is fixedly connected with the supporting frame. The upper end of the storage bin is open, and a base plate of the storage bin is arranged to be inclined. A discharging outlet is formed in the position, close to the lower end of the base plate, of the side wall of the storage bin. A transverse plate is fixedly connected with the outer side of the discharging outlet. Vertical plates are fixedlyconnected with the two sides of the transverse plate. A U-shaped flow guiding groove is formed by the transverse plate and the vertical plates. An interval exists between each vertical plate and theside wall of the storage bin, and a rabbet plate capable of blocking the discharging outlet is arranged in the intervals in a sliding connection manner. According to the plastic particle charging bin,because the base plate of the storage bin is arranged to be inclined, plastic particles slide towards the discharging outlet under the action of the gravity of the plastic particles; and because thedischarging quantity of the discharging outlet is controlled through the rabbet plate, manual bagging can be carried out more conveniently and quickly, and the problems in manual bagging that workersare prone to feeling tired, and the bagging efficiency is low are solved.

Owner:CHONGQING JINGBANG HIGH MOLECULAR MATERIAL CO LTD

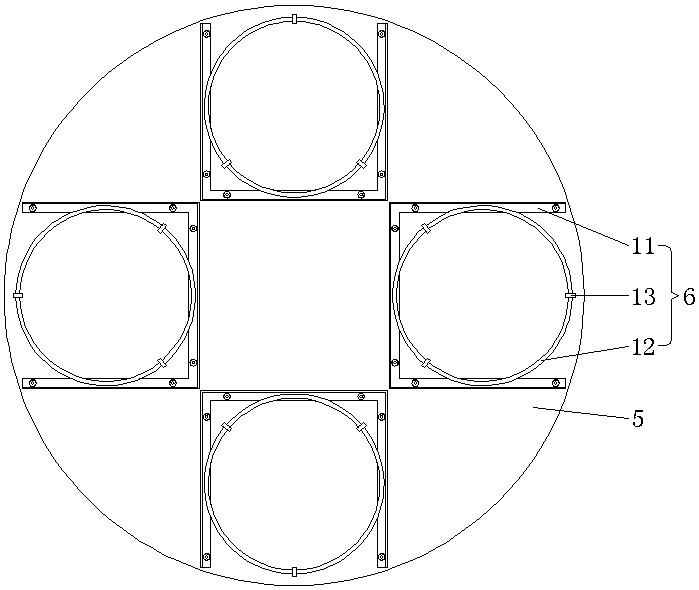

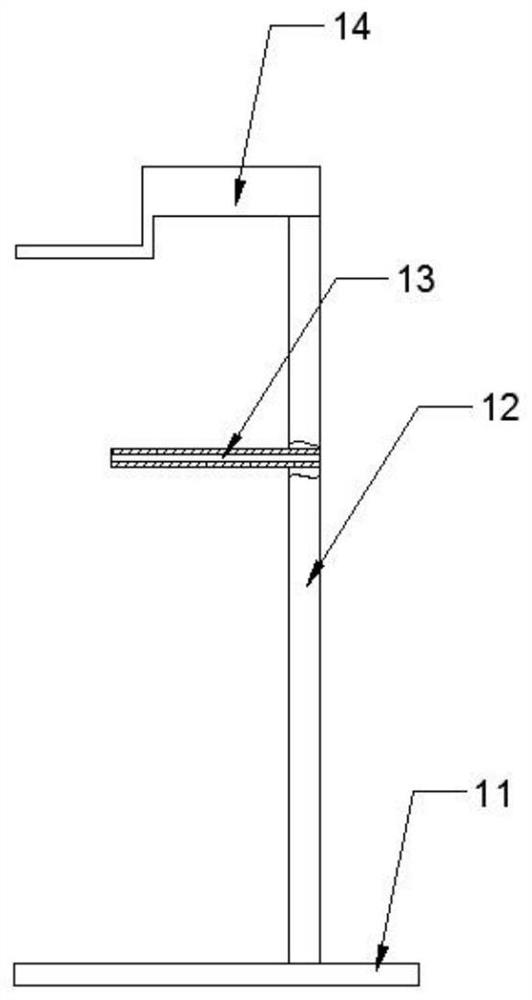

A kind of watermelon seedling planting bag and its bagging machine

ActiveCN110301268BMeet planting requirementsFast baggingCultivating equipmentsFlower-pot fillingElectric machineAgricultural engineering

The invention discloses a watermelon seedling planting bag and a bagging machine thereof. The planting bag is formed by connecting six oval bags, and the connection is in a connected state. One side of the six oval bags included in the planting bag is provided with Circular embossing, the embossing consists of spaced cracks, the six oval bags are also provided with ventilation holes, and one end of the six oval bags is connected with a trumpet-shaped bag mouth. The bagging machine includes a bracket, a motor seat, a micro motor, a hopper and a clamp, the motor seat is mounted on the top of the bracket, the micro motor is fixed on the motor seat, and the hopper is installed on the bracket corresponding to the micro motor, The output shaft of the micro motor is provided with a stirring rod, and the stirring rod extends into the inside of the hopper. The side of the hopper is provided with a quick clamp. The planting bag can not only meet the planting requirements of watermelon seedlings, but also can be quickly bagged when used with the bagging machine, which improves the bagging speed of the watermelon seedling planting bag.

Owner:NANNING UNIV

Portable plant tip-control bagging machine

The invention discloses a portable plant tip-control bagging machine, comprising a bag storage component for storing bags and a handheld actuating component separate from the bag storage component andused with the same for extracting the bags from the bag storage component and bagging plants with the bags before releasing. The portable plant tip-control bagging machine is compact in structure, small in size, light in weight and easy to carry; the handheld actuating component and the bag storage component are separate, so that it is convenient to hold the handheld actuating component for operation; bag extracting is simple; positioning is easy; bagging efficiency is high; the portable plant tip-control bagging machine is energy efficient and green.

Owner:CHONGQING UNIV OF ARTS & SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com