Full-automatic vertical quantitative package machine

A quantitative packaging and fully automatic technology, applied in packaging, conveying and weighing, weighing of flake and irregular block materials, and granular fields, can solve the complex structure of the combined scale, large footprint, inconvenient operation, etc. Problems, to achieve a wide range of practicability, small footprint, improve the effect of weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

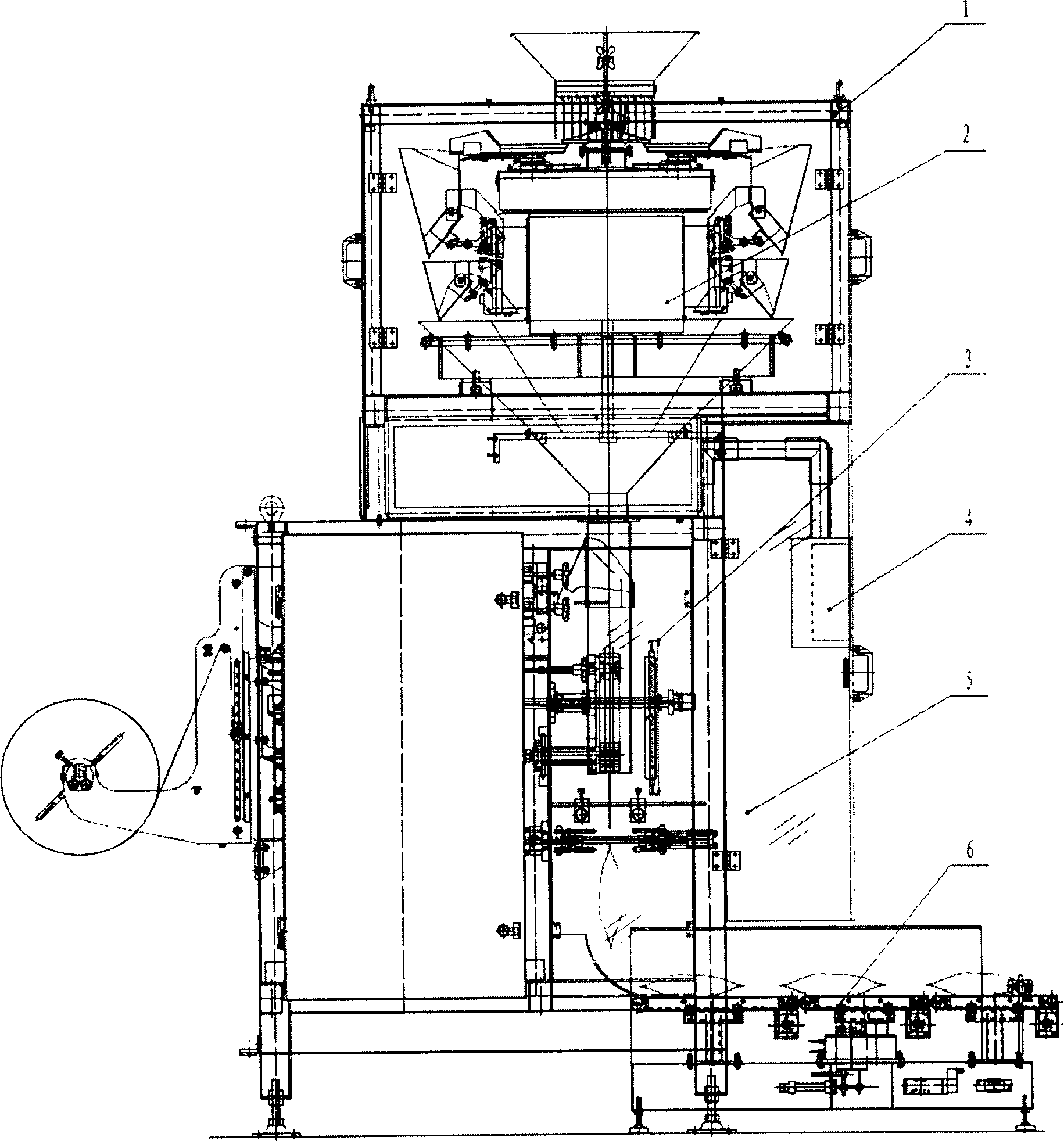

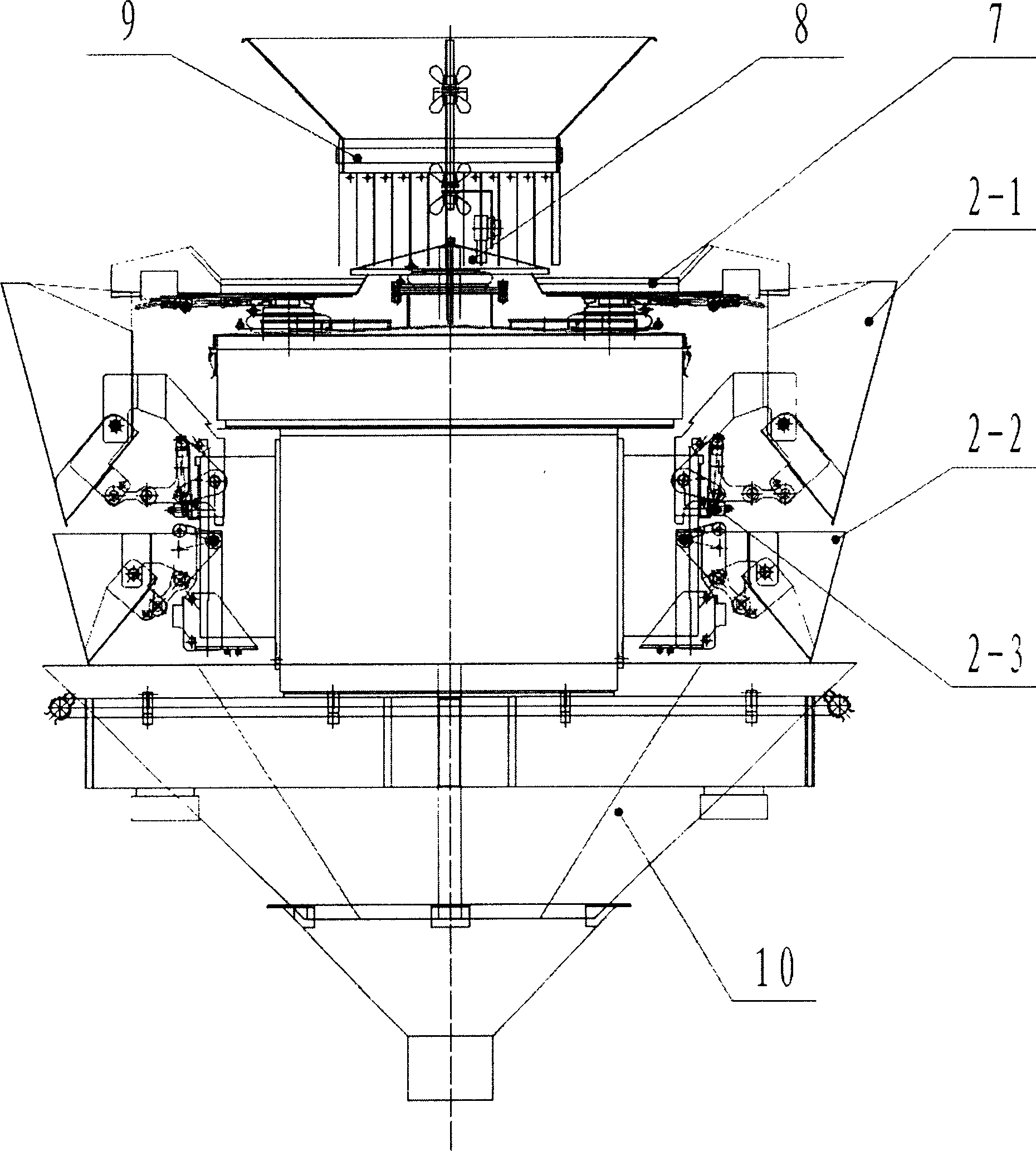

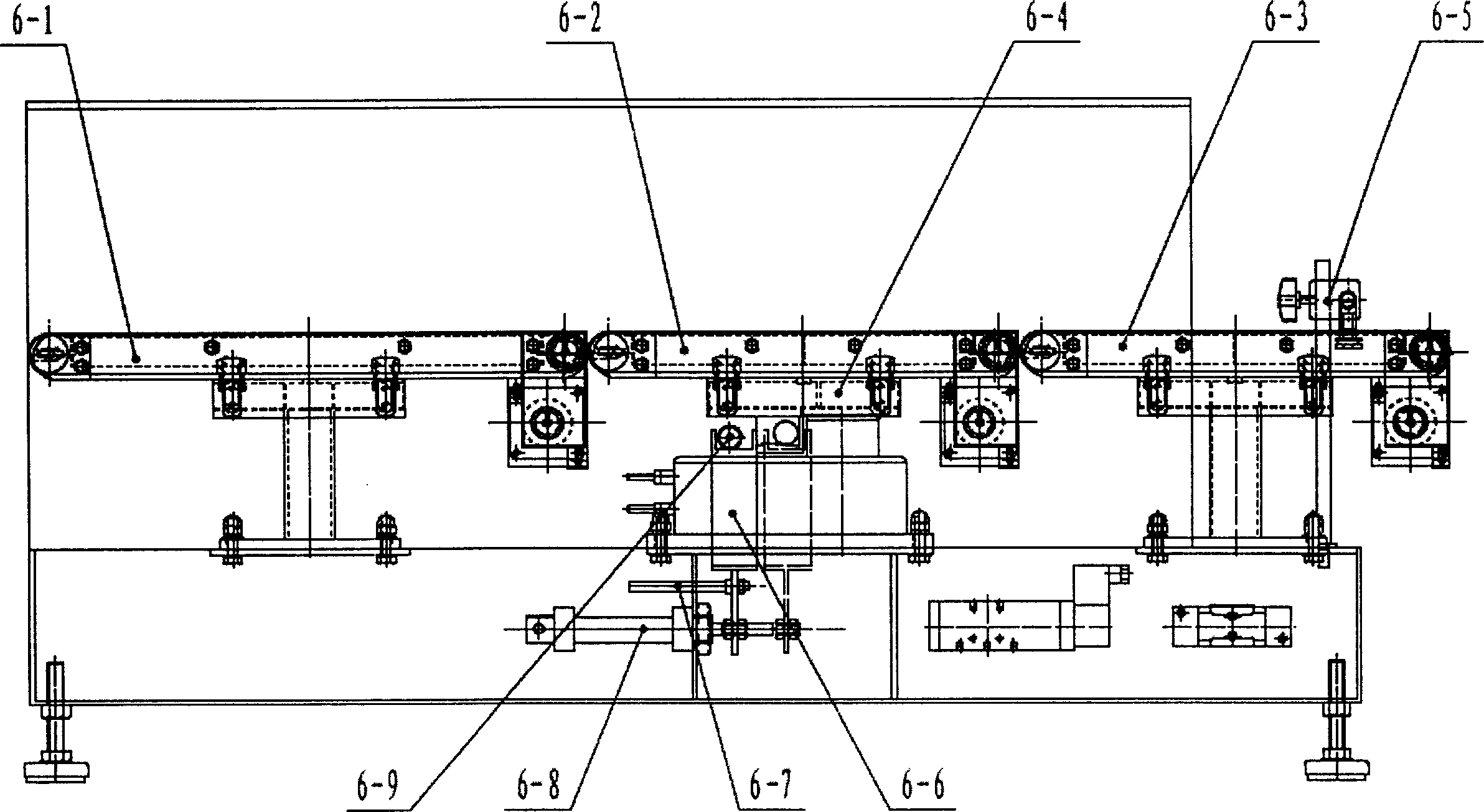

[0012] Fully automatic vertical quantitative packaging machine of the present invention, as figure 1 As shown, it is mainly composed of a frame 1, a weighing device 2, a packaging device 3, and a weight detection device 6. The outer side of the frame (1) is provided with a control cabinet for controlling the weighing device 2, packaging device 3 and weight detection device 6. 5 and display 4. The feeding hopper 2-1 of the weighing device 2 and the opening of the weighing hopper 2-2 are controlled by a common drive motor, and a weight detection device 6 is provided below the finished product outlet of the packaging device 3, and the weight detection device 6 is connected with the weighing device. Device 2, packaging device 3 are connected as a whole, and the outer surface of frame (1) is provided with a control cabinet 5 and display 4 that simultaneously co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com