Portable plant tip-control bagging machine

A portable, plant-based technology, applied in the field of agricultural machinery, can solve the problems of restricting the development of crop production, many man-hours and labor input, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

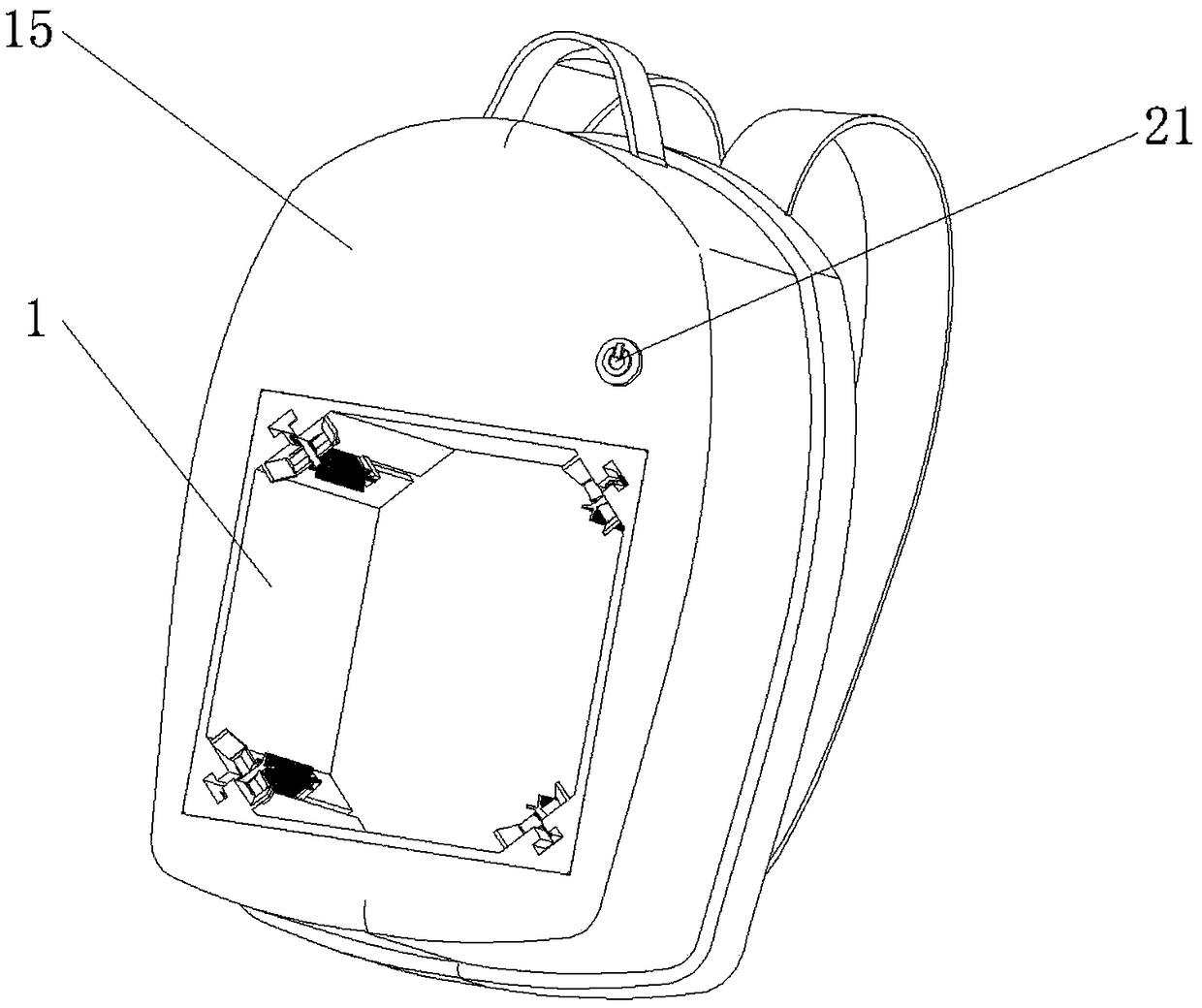

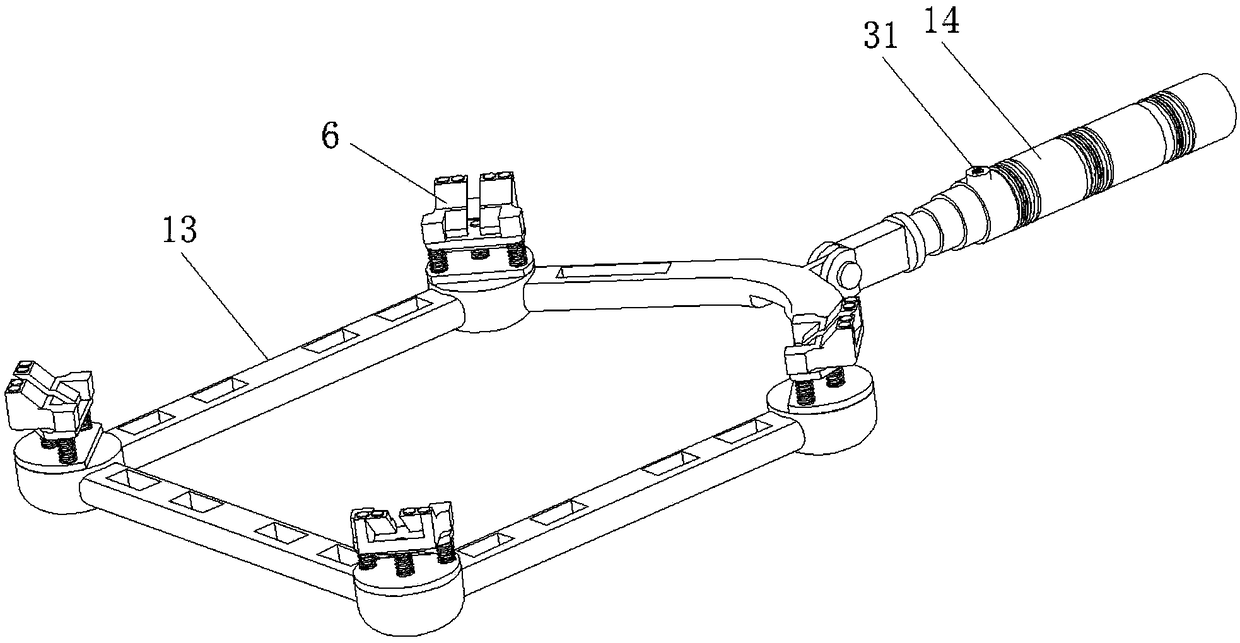

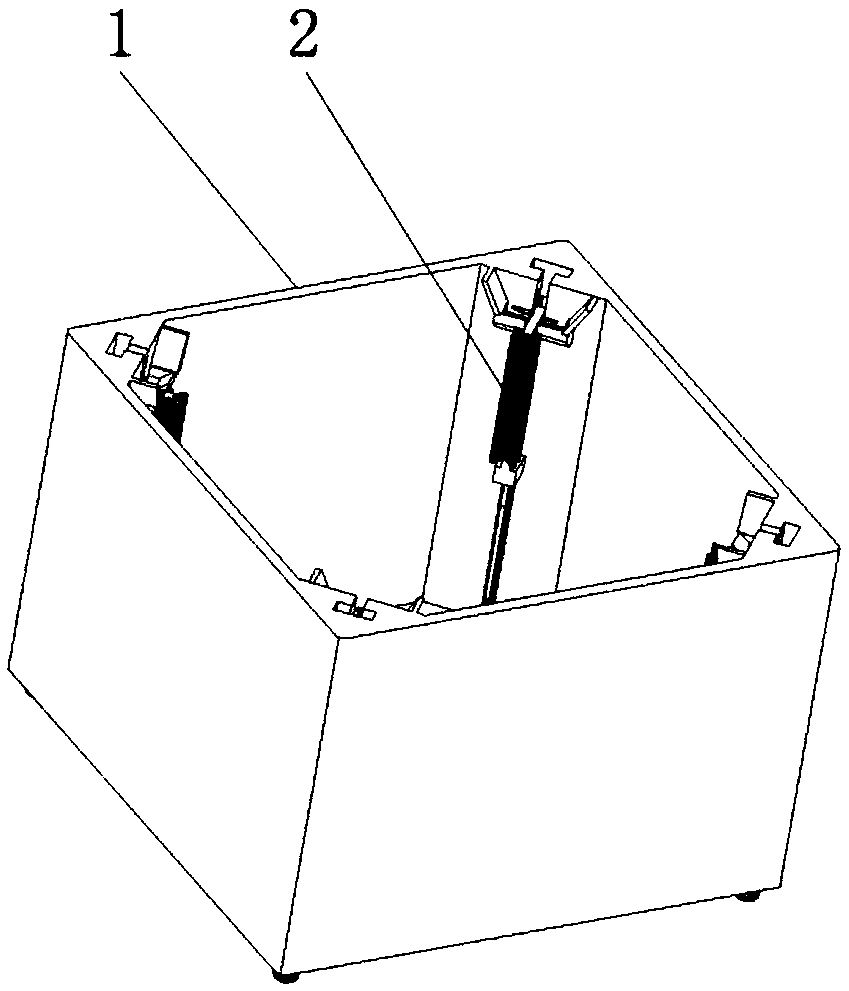

[0039] figure 1 It is a structural schematic diagram of the storage bag assembly of the present invention; figure 2 It is a schematic diagram of the structure of the hand-held actuator; image 3 It is a schematic diagram of the structure of the storage bag body; Figure 4 It is a schematic diagram of the connection structure between the bag body and the T-shaped sheet; Figure 5 It is a schematic diagram of the T-shaped slot structure; Figure 6 Schematic diagram of the assembly structure for the spring column; Figure 7 It is a schematic diagram of the normal gear position structure of the R-shaped block; Figure 8 Schematic diagram of the release gear structure for the R-shaped block; Figure 9 It is a schematic diagram of the assembly structure of the extraction mechanism and the release mechanism (the T-shaped sheet has just entered the receiving groove); Figure 10 It is a schematic diagram of the assembly structure of the extraction mechanism and the release mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com