Plastic particle charging bin

A technology for plastic granules and hoppers, which is applied in packaging, solid materials, transportation and packaging, etc. It can solve the problems of manual fatigue and low efficiency of manual bagging, reduce labor intensity, improve bagging efficiency, and be easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

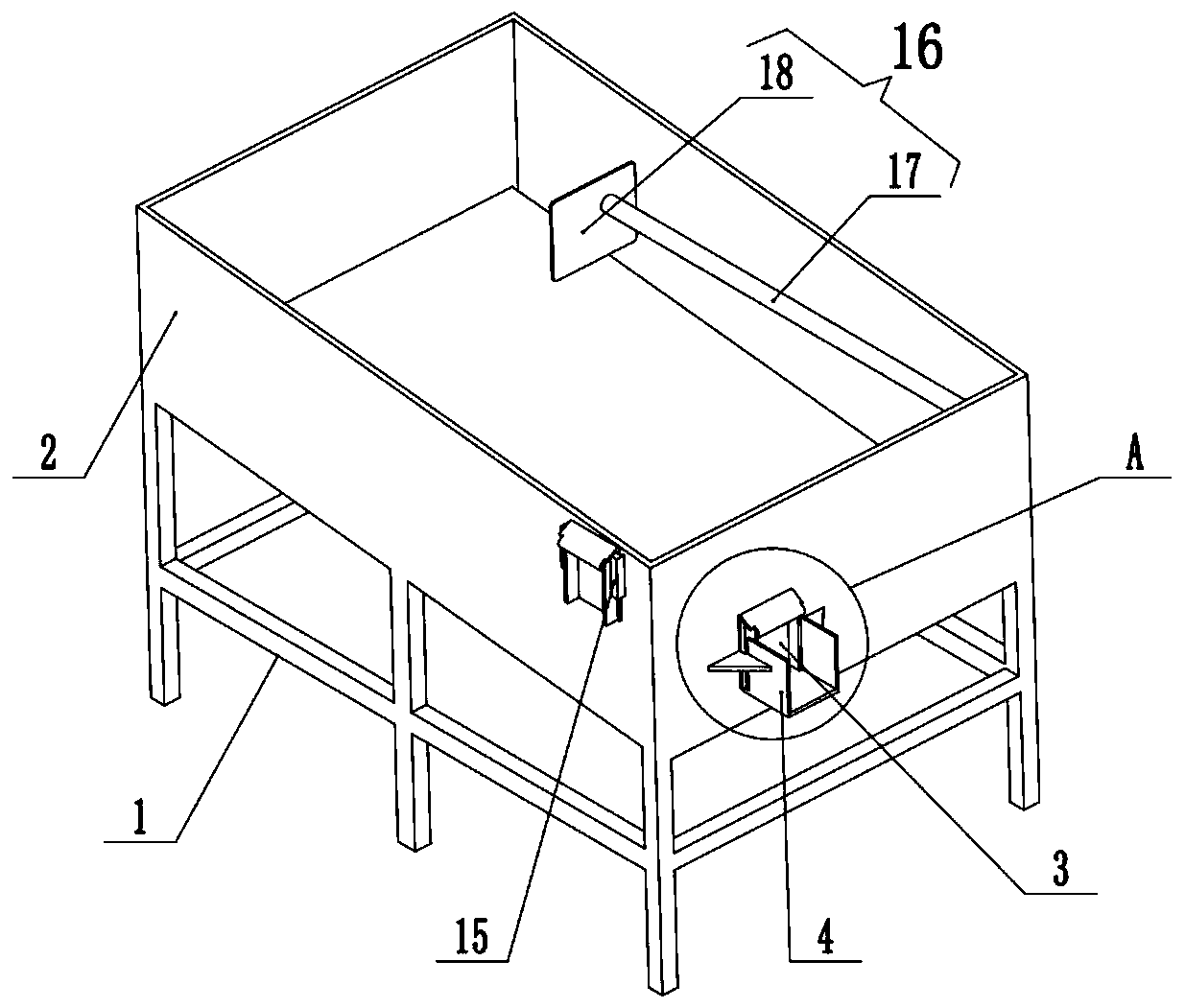

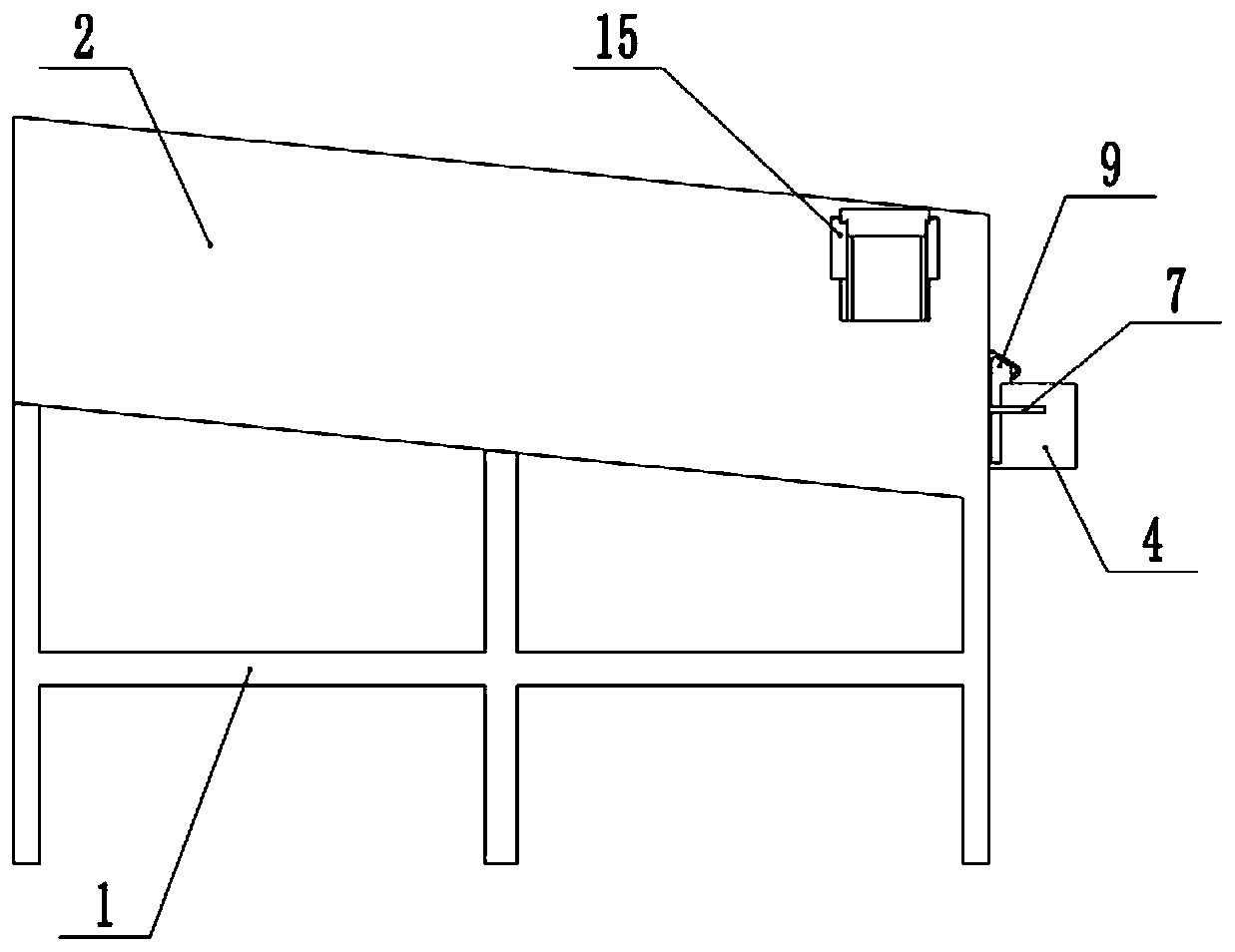

[0037] Embodiment one is basically as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a plastic granule loading bin includes a support frame 1 on which a storage bin 2 with an open upper end is welded.

[0038] combine figure 1 and figure 2 , the bottom plate of the storage bin 2 is set in an inclined state with the left side high and the right side low. There is a discharge port 3 on the right side wall of the storage bin 2, and the bottom end of the discharge port 3 is flush with the upper surface of the right end of the bottom plate of the storage bin 2. When the plastic particles are poured into the storage bin 2 from the top of the storage bin 2, the plastic particles slide to the right under the action of their own gravity, so as to gather at the discharge port 3.

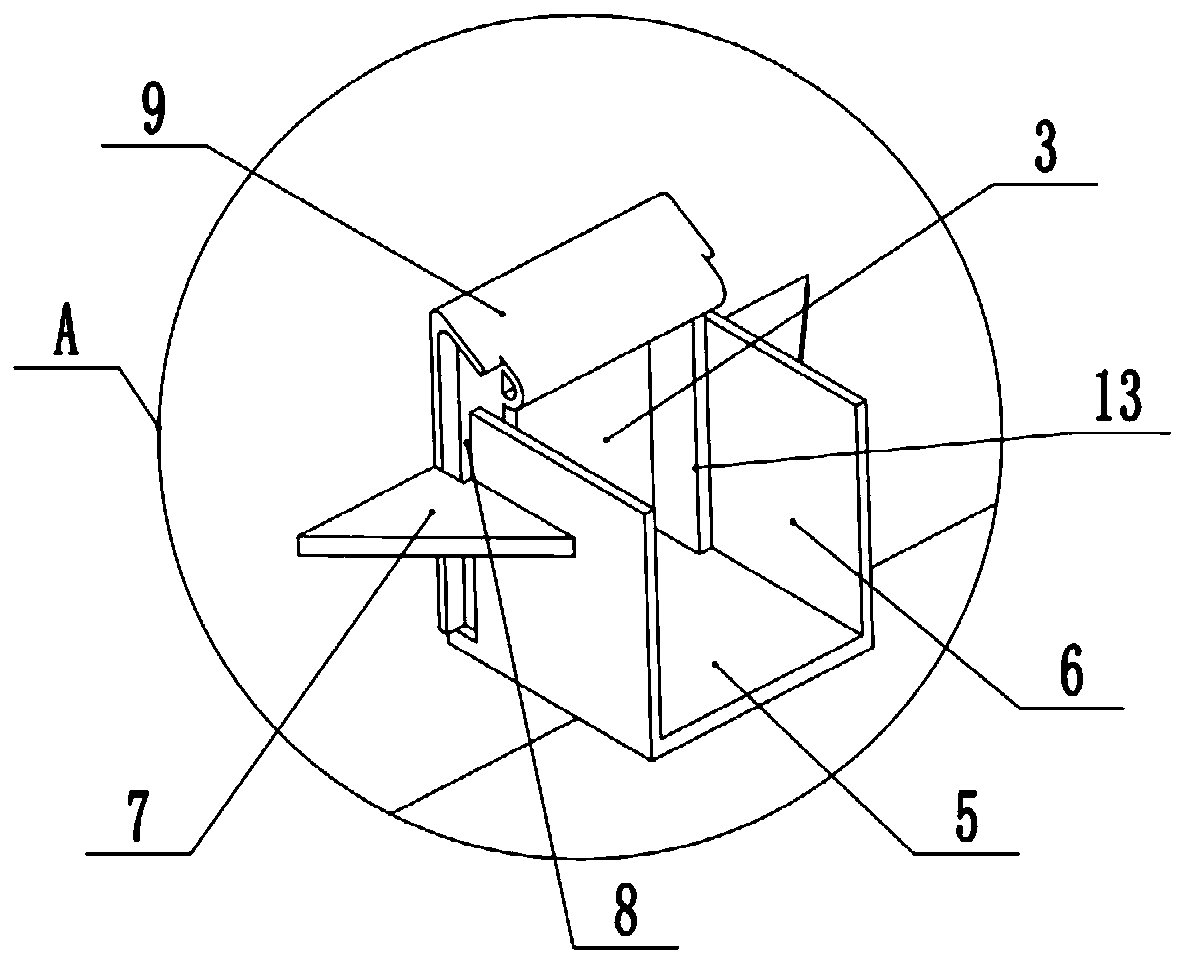

[0039] Such as figure 1As shown, the right side of the discharge port 3 is provided with a diversion groove 4, and the diversion groove 4 includes a transverse plate 5...

Embodiment 2

[0052] Such as Figure 7 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the number of outlets 3 is two, so that two people can perform bagging operations on the same storage bin 2 at the same time, improve bagging efficiency, and ensure bagging speed .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com