Automatic fruit bag sheathing device

A bagging device and fruit bag technology, applied in the direction of plant protection cover, etc., can solve the problems of reducing fruit quality, slow manual bagging operation, low qualification rate, etc., and achieve the advantages of improving bagging speed, simple structure and labor saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

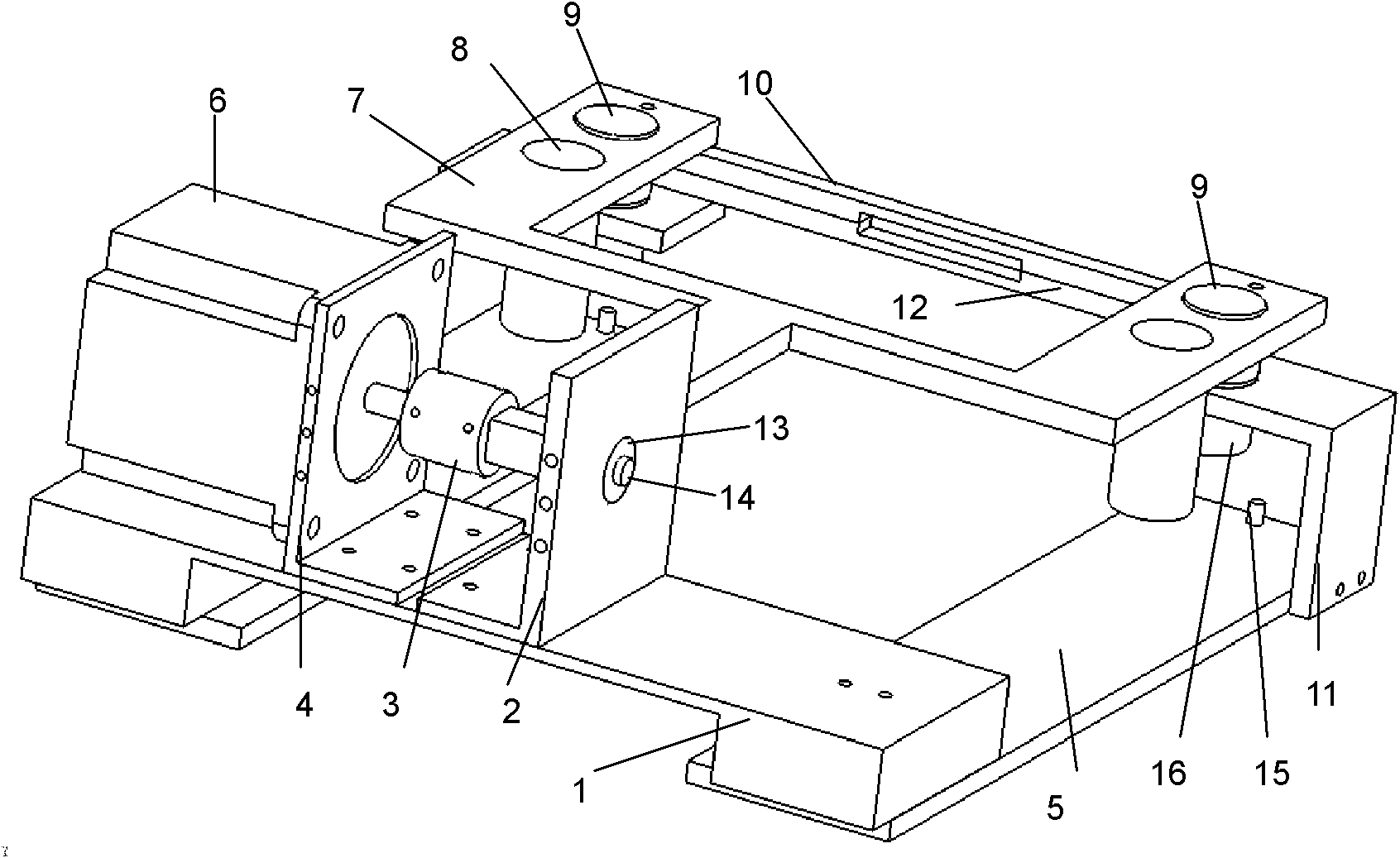

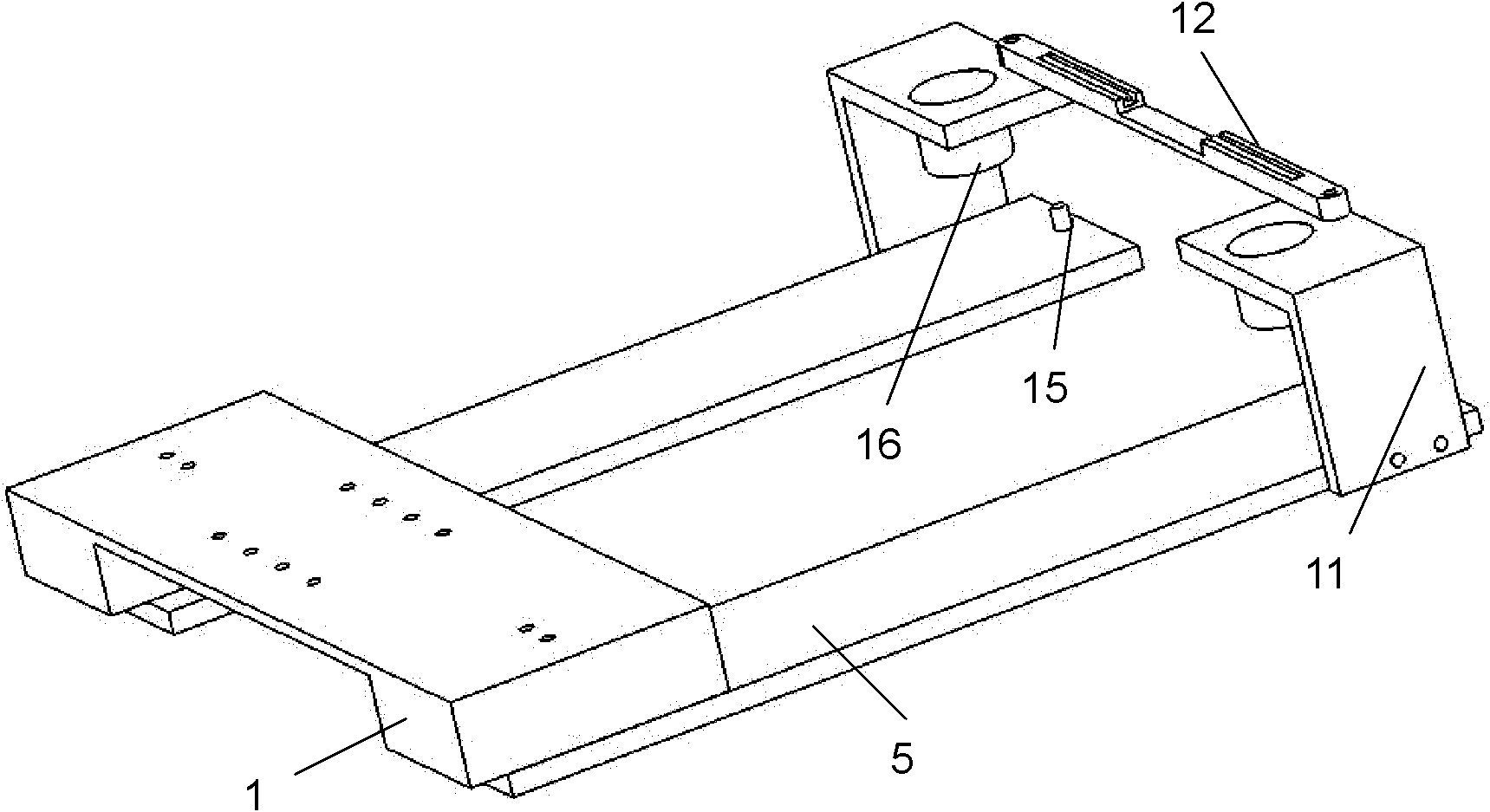

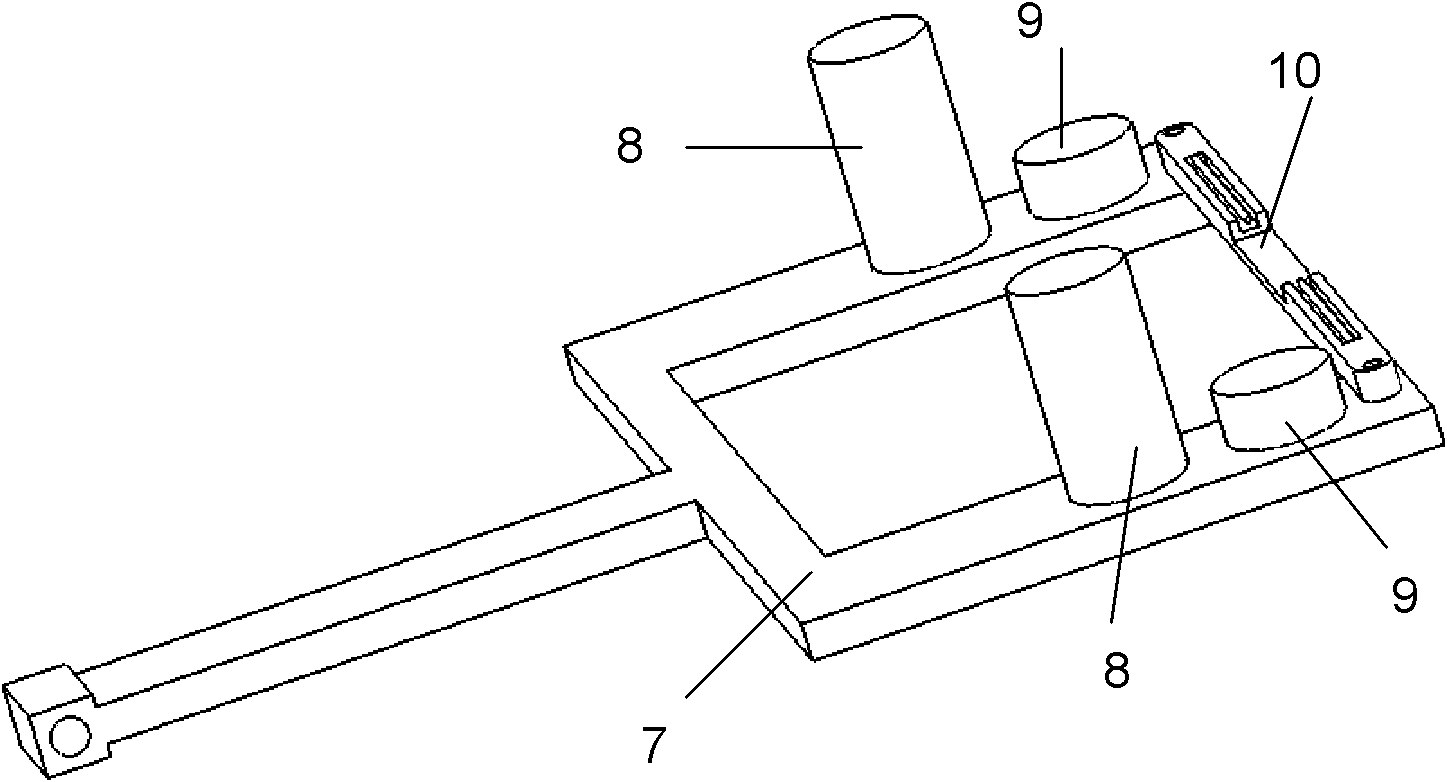

[0016] Example: such as Figure 1-3 As shown, the present invention comprises motor 6, support seat 1, rocker mechanism 7, fruit bag support plate 5, fruit bag fixing bolt 15 and chuck 11, and described rocker mechanism 7 comprises the compression cylinder 9 that symmetrically arranges, the long The glue stick 8 and the sealing jaw 10, the motor 6 is fixed on the support seat 1 through the motor seat 4, the output shaft of the motor 6 is connected with the rocker shaft 14 through the coupling 3, and the relative position of the rocker shaft 14 and the rocker 7 is fixed, Fruit bag support plates 5 are installed symmetrically on both sides of the support seat 1, fruit bag fixing bolts 15 and chucks 11 are symmetrically arranged on the two fruit bag support plates 5, and short glue sticks corresponding to the position of the compression cylinder 9 are symmetrically installed on the two chucks 11 16. The sealing jaw 12 spans between the two chucks 11.

[0017] Such as Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com