Automatic bagging machine

A bagging machine and automatic technology, applied in the field of mechanical equipment, can solve problems such as poor production speed, difficulty in controlling weight, and slow material bagging speed, so as to avoid the trouble of bagging, improve bagging speed and product production rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

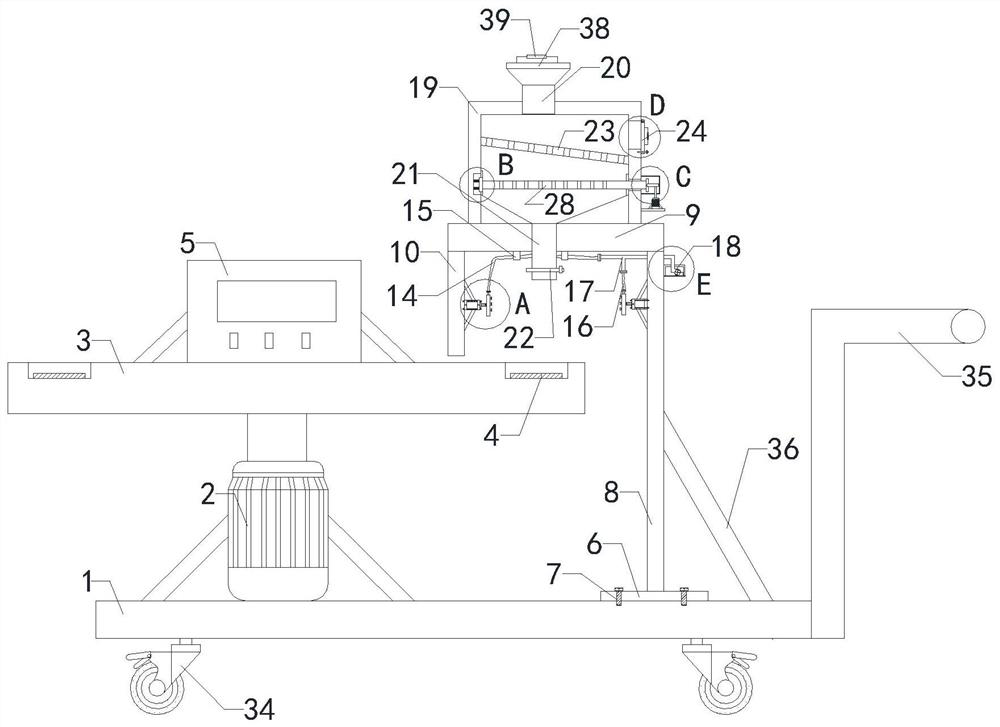

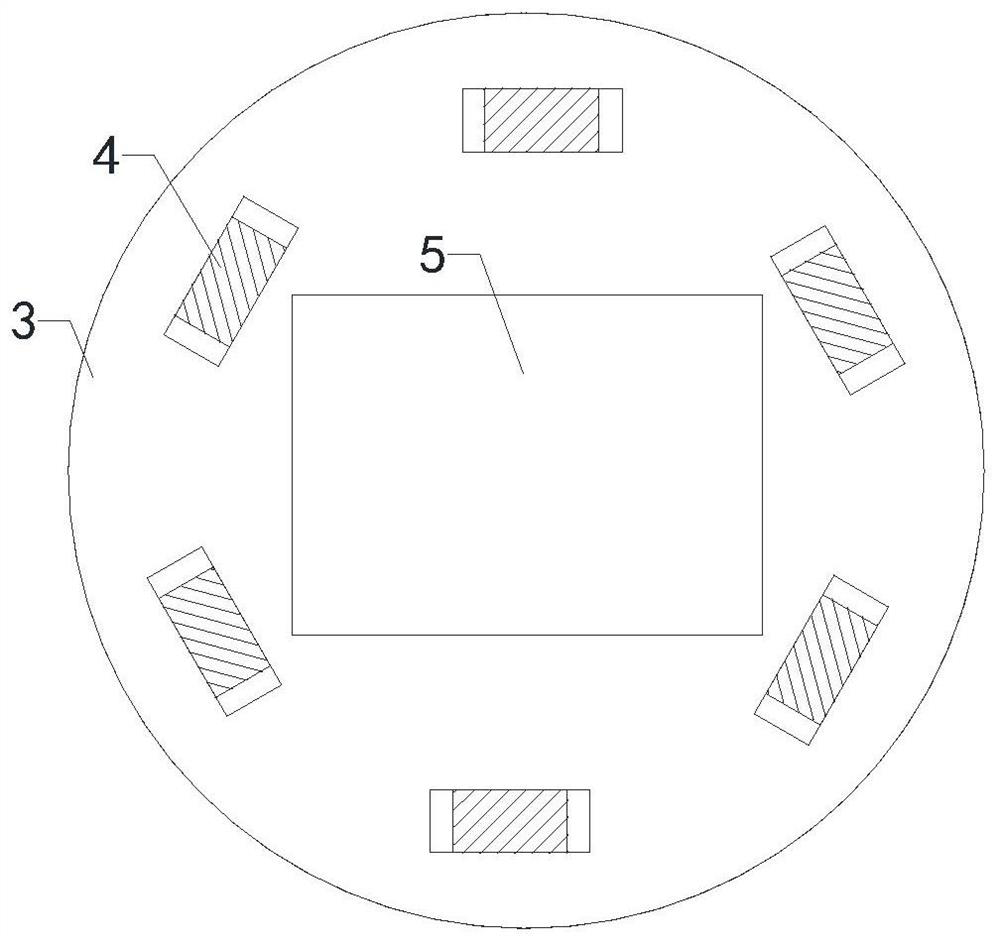

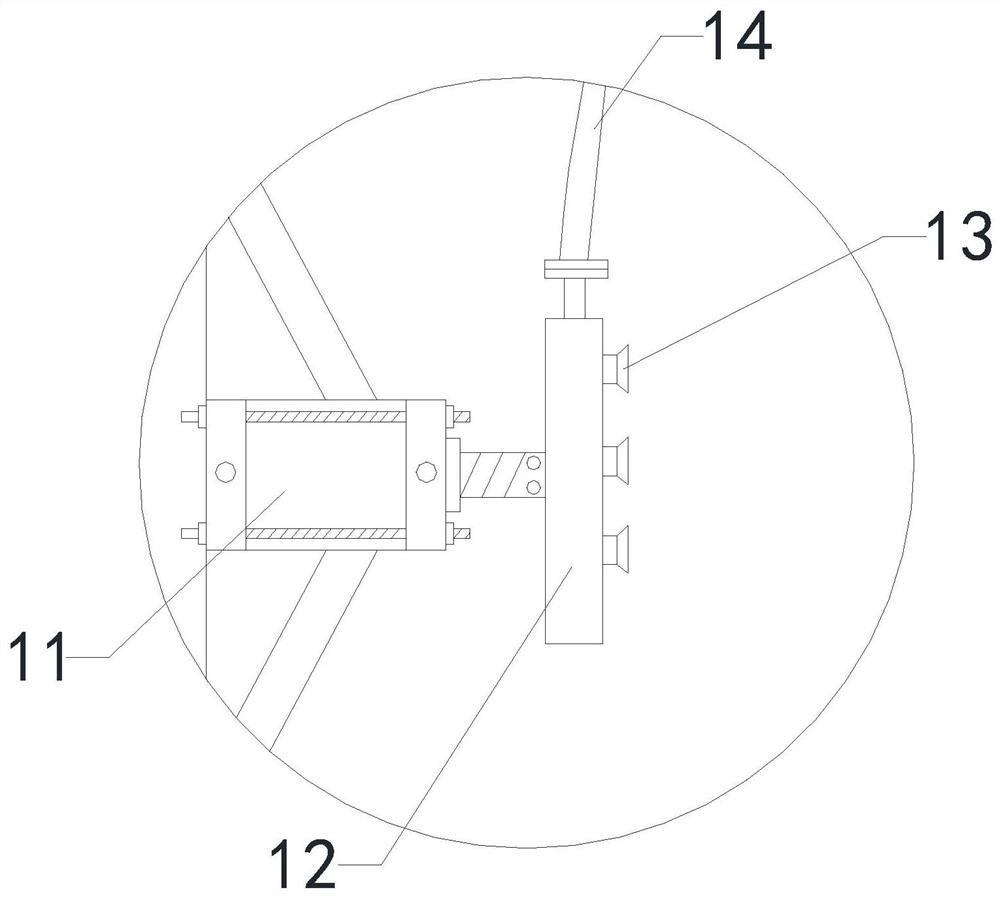

[0022] Such as Figure 1 to Figure 7 As shown, an automatic bagging machine of the present invention includes a base 1, a servo motor 2, a rotating disk 3, multiple sets of electronic scales 4, a PLC control device 5, a fixing plate 6, multiple sets of first fastening bolts 7, the first A support plate 8, an upper top plate 9, a second support plate 10, two sets of electric push rods 11, two sets of suction cups 12, multiple sets of suction nozzles 13, a first hose 14, two sets of fixing blocks 15, and a second hose 16 , three-way pipe 17, aspirator 18, material storage box 19, feed funnel 20, discharge pipe 21 and magnetic control valve 22, servo motor 2 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com