Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

596results about How to "Increase production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

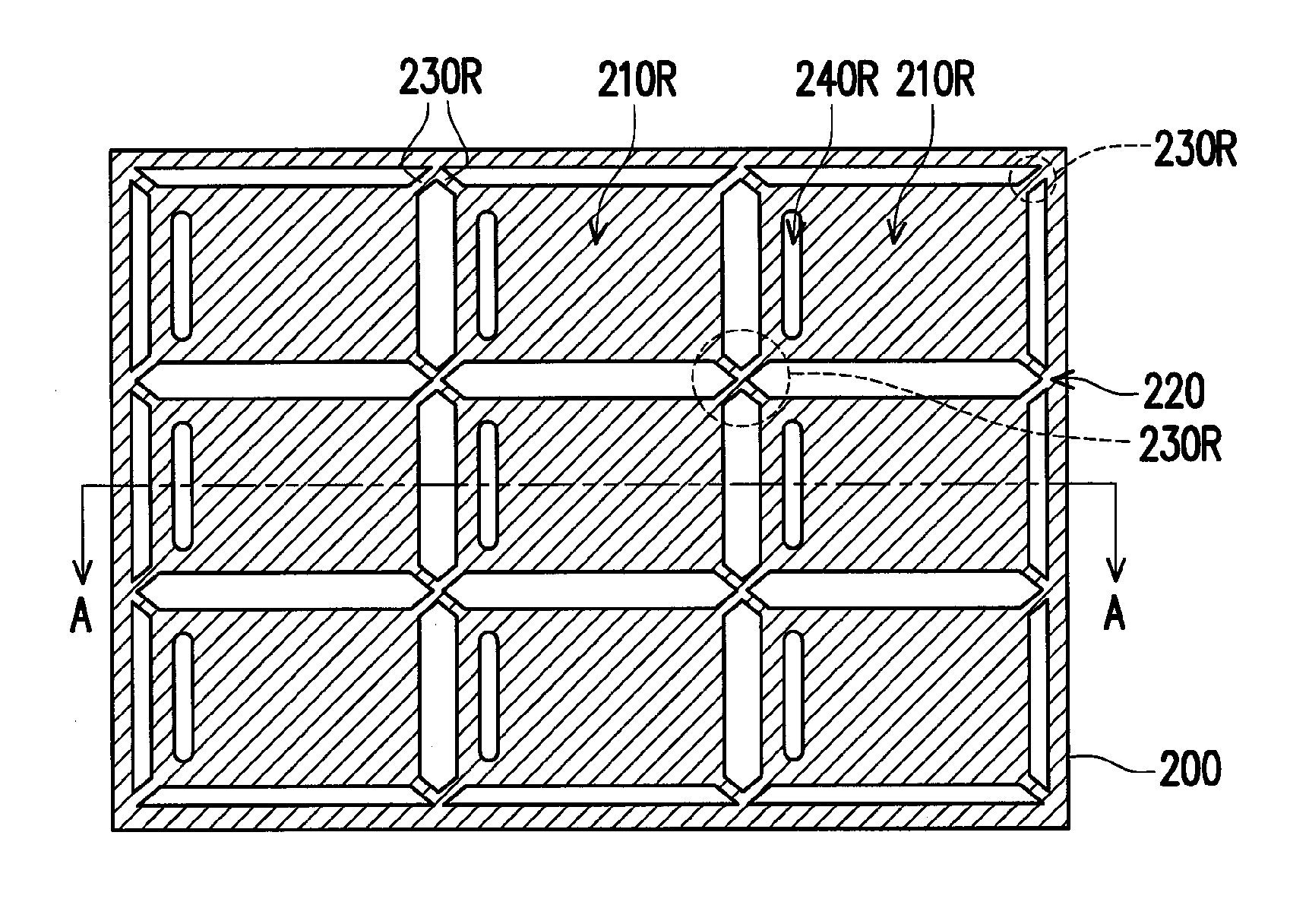

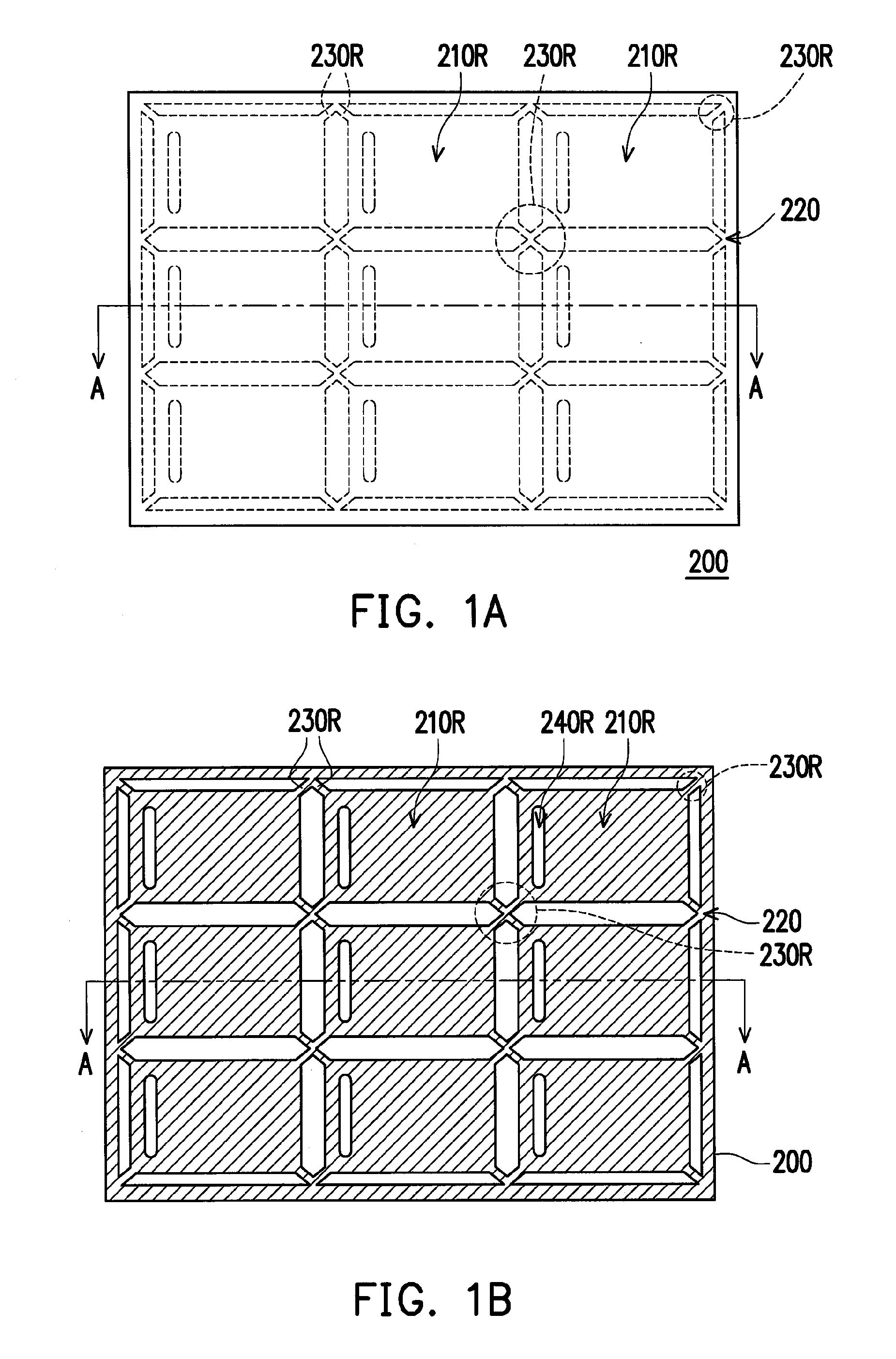

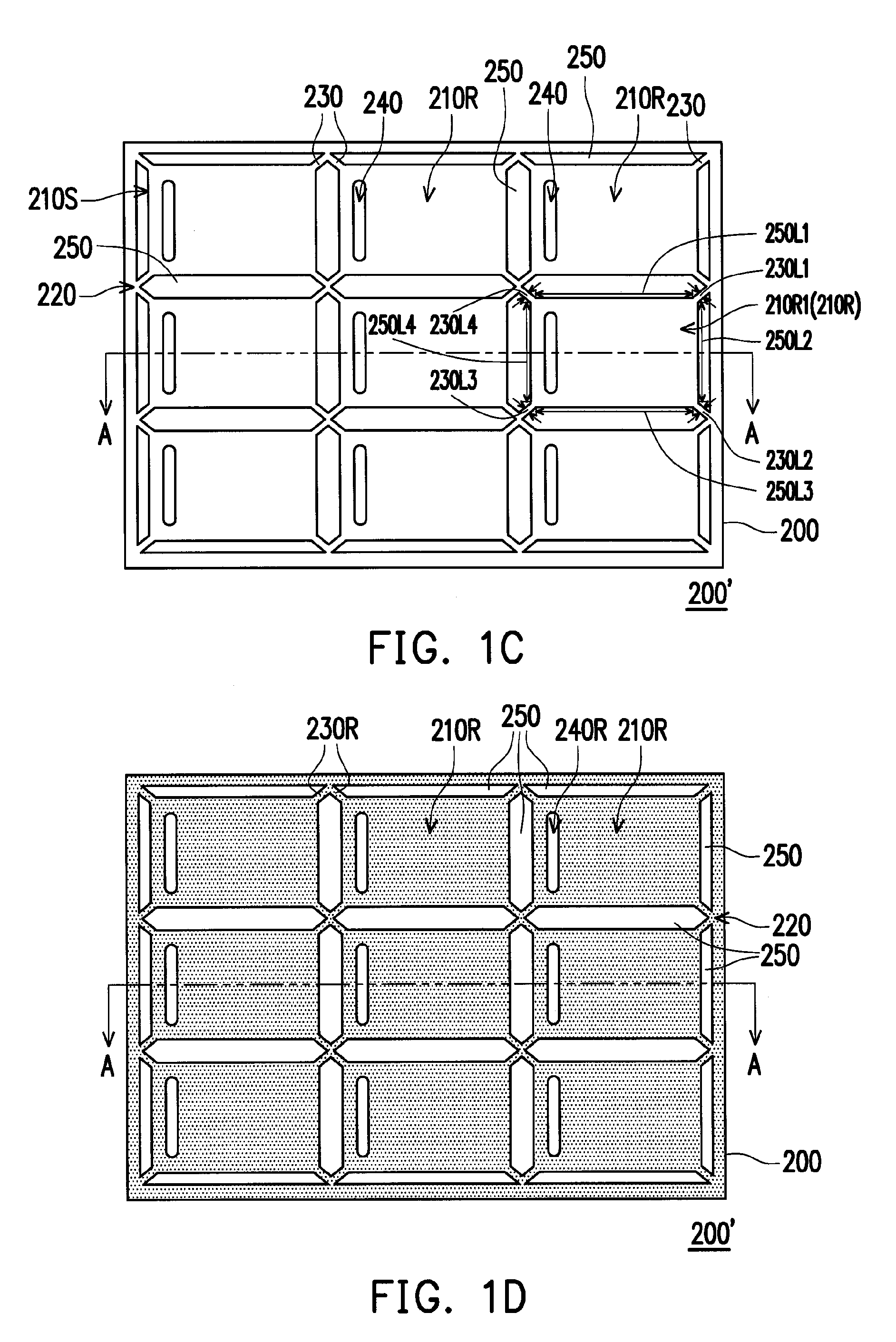

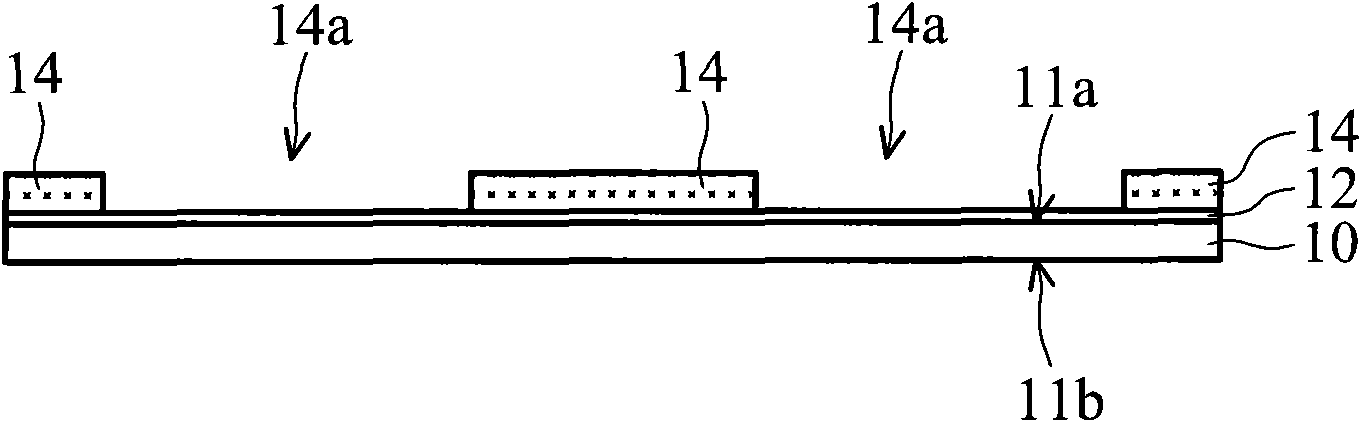

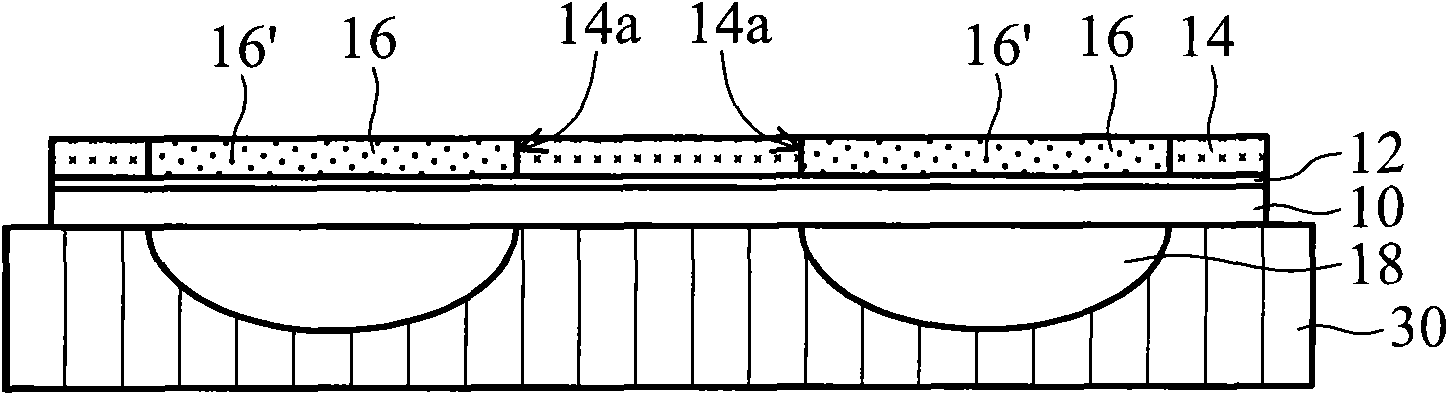

Reinforced glass cell and method for fabricating the same and cover glass having the reinforced glass cell

InactiveUS20130037308A1Increase production rateImprove yield ratePrinted circuit detailsCellulosic plastic layered productsEngineeringCover glass

A method of fabricating a reinforced glass cell including the following steps is provided. First, a mother glass having a plurality of glass cell predetermined regions is provided. A portion of the mother glass disposed on the outer edge of each glass cell predetermined region is removed, so as to form at least one through trench and at least one linking bridge. Herein, the through trench exposes the periphery section of each glass cell predetermined region, and the glass cell predetermined regions are formed as an entire patterned mother glass by the linking bridges. A reinforcing process is performed to the entire patterned mother glass, so that the exposed periphery sections of the glass cell predetermined regions are formed into reinforced sections. The linking bridges are removed so as to separate the glass cell predetermined regions having the reinforced sections to form a plurality of reinforced glass cells.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

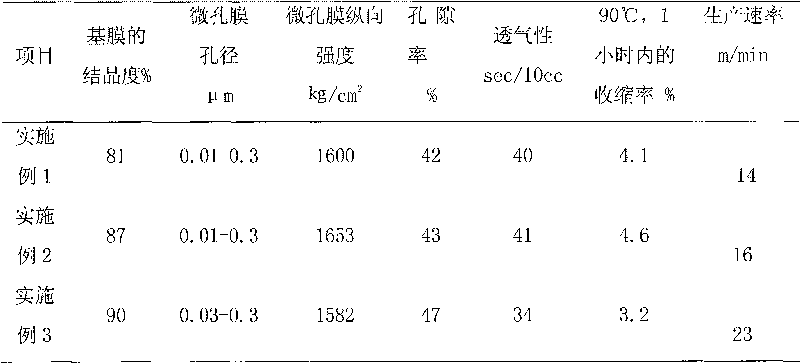

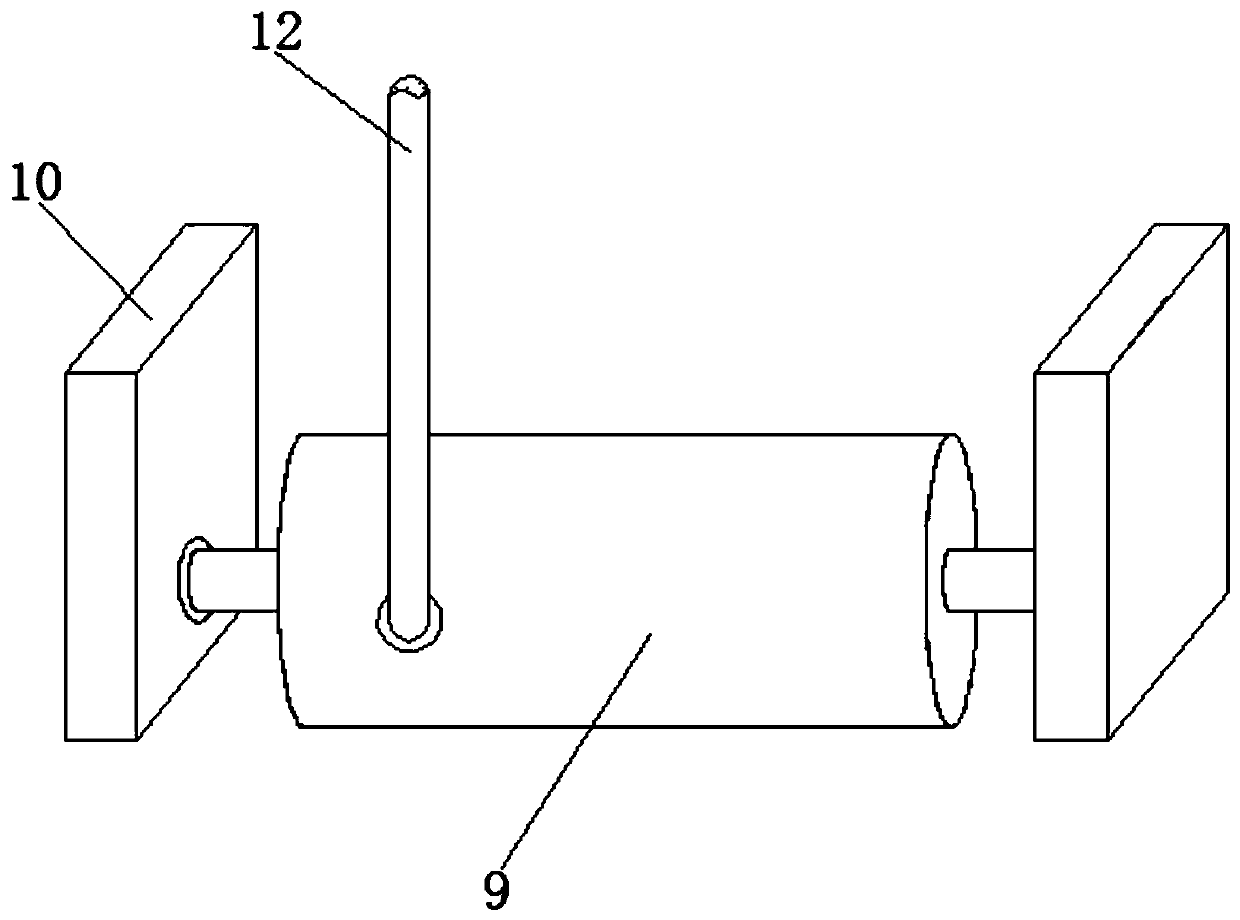

Preparation method of polyolefin microporous film

The invention relates to a preparation method of a polyolefin microporous film, aiming to solve the problems that the traditional preparation method of the polyolefin microporous film has complicated process, low production speed and poorer uniformity of microporous space. A polyolefin microporous film product is prepared by the following steps: a. base film preparation by casting; b. multi-stage annealing processing; c. hole forming by multipoint stretching; and d. heat setting processing. The method does not need solvent, has no pollution to the environment, low equipment investment, high production speed and uniform microporous space, and is suitable for preparing various polyolefin microporous films used for poromeric materials, ultra filtration, film filtration, super capacitors, battery diaphragm materials and the like.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

Process for preparing coal-based agglomerated activated carbon

The invention discloses a process for preparing coal-based agglomerated activated carbon. The process has the following beneficial effects: the non-caking coal produced in the wide ditches is taken as a main raw material; the special caking coal type, namely gas-fat coal, is blended in the coal blending procedure; furthermore, the oxidation procedure is added in the process; the process parameters such as pulverized coal particle distribution, forming pressure, coal activation temperature and time and the like in the general production process are adjusted; at the same time, the slow carbonization technology is used instead of the traditional rapid carbonization procedure; and oxygen-enriched air is fed into activation equipment. The coal-based activated carbon prepared by the process can ensure the product strength and bulk density on the basis of satisfying the iodine adsorption of the activated carbon and is better in industrial application value.

Owner:SHENHUA XINJIANG ENERGY

Process of preparing propionic acid and coproducing vitamin B12 with Propionibacterium freudenreichii NX-4

InactiveCN101045910AEasy to operateExtensive culture conditionsBacteriaFermentationInorganic saltsPropanoic acid

The present invention discloses one kind of Propionibacterium freudenreichii NX-4 and the production process of propionic acid and vitamin B12 therewith. Propionibacterium freudenreichii NX-4 is preserved in the preservation number of CCTCC No. M 207015. Through inoculating Propionibacterium freudenreichii into culture medium containing carbon source, nitrogen source, inorganic salt and water, and static culturing, propionic acid or coproduced propionic acid and vitamin B12 may be prepared. The strain can utilize several kinds of carbon source and nitrogen source, and has extensive culture condition, simple operation, high propionic acid yield and low production cost.

Owner:NANJING UNIV OF TECH

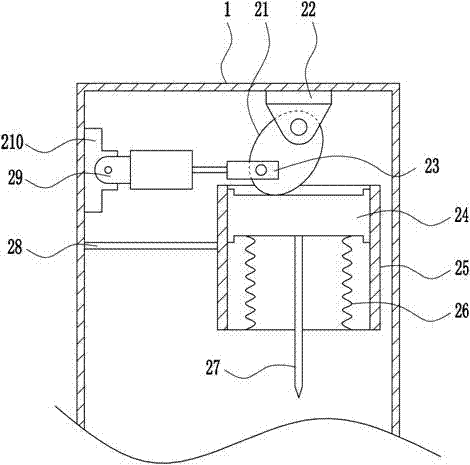

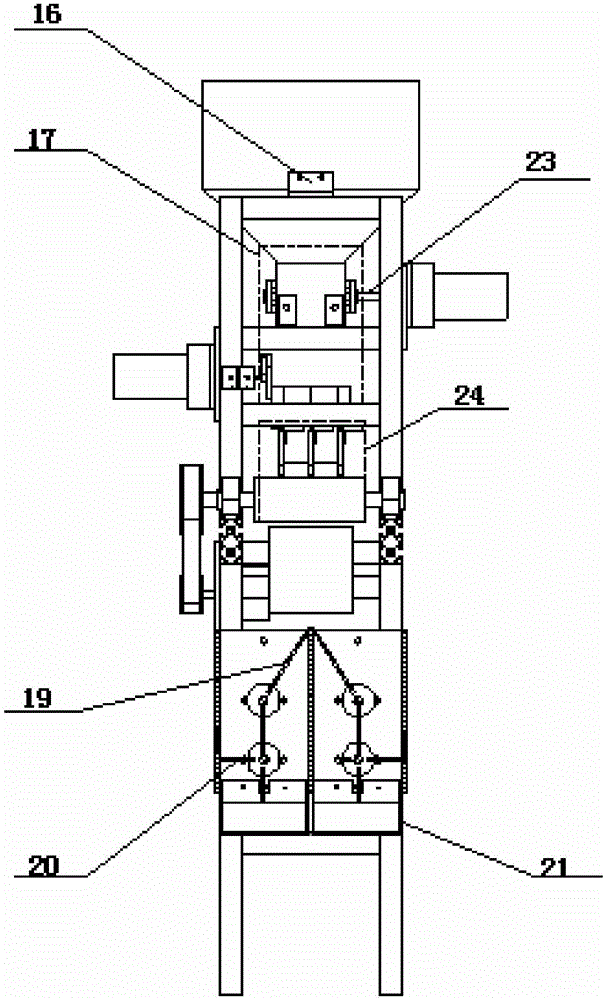

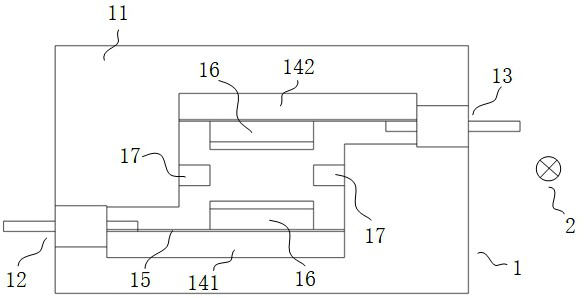

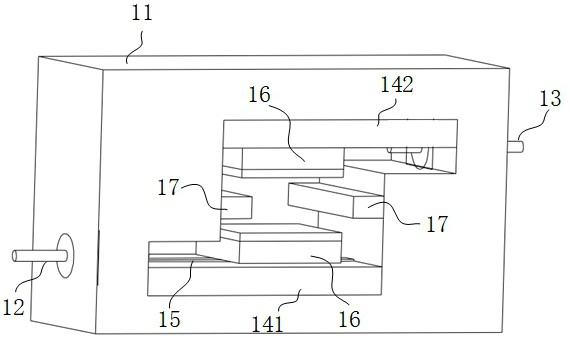

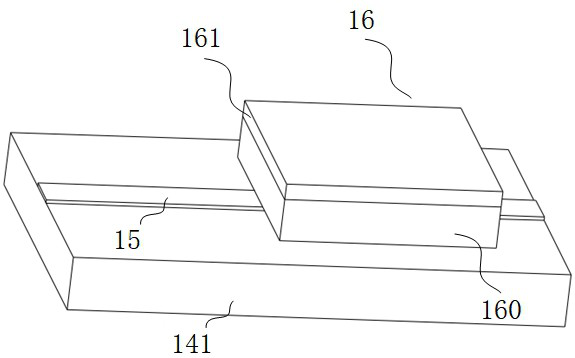

Medicinal material cutting and breaking device for pharmaceutical factory

InactiveCN106985175AEasy to collectReduce workloadGrain treatmentsMetal working apparatusProduction rateEngineering

The invention relates to a cutting and breaking device, in particular to a medicinal material cutting and breaking device for the pharmaceutical factory and aims at achieving the technical purpose of providing the medicinal material cutting and breaking device for the pharmaceutical factory, wherein the medicinal material cutting and breaking device for the pharmaceutical factory is high in cutting strength, high in breaking efficiency and capable of increasing the production rate. To achieve the above technical purpose, the medicinal material cutting and breaking device for the pharmaceutical factory is provided and comprises a first box, a cutting mechanism, a pushing mechanism, a first support column, a falling mechanism and the like. The first support column is arranged on the left side of the bottom of the first box, a second support column is arranged at the lower portion of the right side of the first box, the cutting mechanism is arranged on the top in the first box, the pushing mechanism is arranged at the bottom of the left wall in the first box, and the falling mechanism is arranged at the bottom of the first box. The medicinal material cutting and breaking device achieves the effects that the cutting strength is high, the breaking efficiency is high, and the production rate can be increased.

Owner:嘉兴嘉湖骨科医院管理有限公司

Mesenchymal stem cell serum-free medium and culture method

ActiveCN108251359AFast growthNormal growthCulture processCell culture supports/coatingSerum free mediaOsteoblast

The invention discloses a mesenchymal stem cell serum-free medium and a culture method, the serum-free medium comprises a basal medium and an additive component, the additive component comprises hypoxia-inducible factor-1 and a force growth factor, the concentration of the hypoxia-inducing factor -1 is 10-20 ng / ml; and the concentration of the force growth factor is 20-50 ng / ml. The serum-free medium is used for culturing mesenchymal stem cells under 5% hypoxic culture conditions. The serum-free medium is determined in component and controllable in quality, can be used for tissue adherent separation of the mesenchymal stem cells, can make growth of the mesenchymal stem cells normal; the serum-free medium is combined with the hypoxic culture conditions to play a synergistic effect on the growth of the mesenchymal stem cells, and the growth of the mesenchymal stem cells is greatly improved. At the same time, the '' stemness'' of the mesenchymal stem cells and differentiation capability of the mesenchymal stem cells into osteoblast, chondrocyte, adipocyte and other cells are remained after several passages.

Owner:SHANGHAI HUAXIN HIGH BIOTECH

Gluing device for conductive aluminum foil tape processing

InactiveCN110586410AAffecting workAffect the coating effectPretreated surfacesCleaning using toolsEngineeringAluminum foil

The invention discloses a gluing device for conductive aluminum foil tape processing. The device comprises a box body. A supporting plate is arranged on the outer wall of one side of the box body. A winding roller is arranged on the outer wall of the top of the supporting plate. An aluminum foil tape body is wound around the outer wall of the winding roller. A storage box is arranged on the outerwall of the top of the box body. A corrugated pipe is inserted into the outer wall of one side of the storage box. A second electric push rod is arranged on the inner wall of the top of the box body.A second mounting plate is arranged on the outer wall of one end of the second electric push rod. A second fixing plate is arranged on the outer wall of the bottom of the second mounting plate. A gluing roller is arranged on the outer wall of one side of the second fixing plate. According to the gluing device for conductive aluminum foil tape processing, glue in the storage box is sprayed out froma spray head and flows out from a glue outlet hole, meanwhile, the second electric push rod is started, the second electric push rod drives the gluing roller to tightly press the aluminum foil tape body for gluing, and the gluing effect of the device on the aluminum foil tape is improved.

Owner:湖北富和冠电子材料有限公司

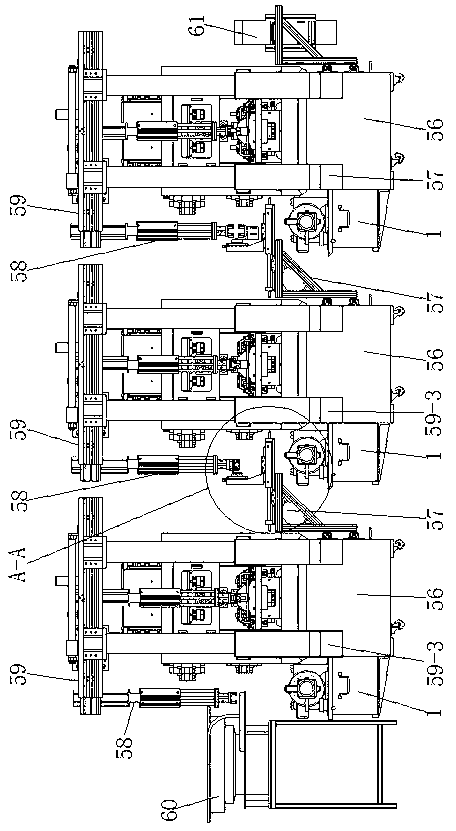

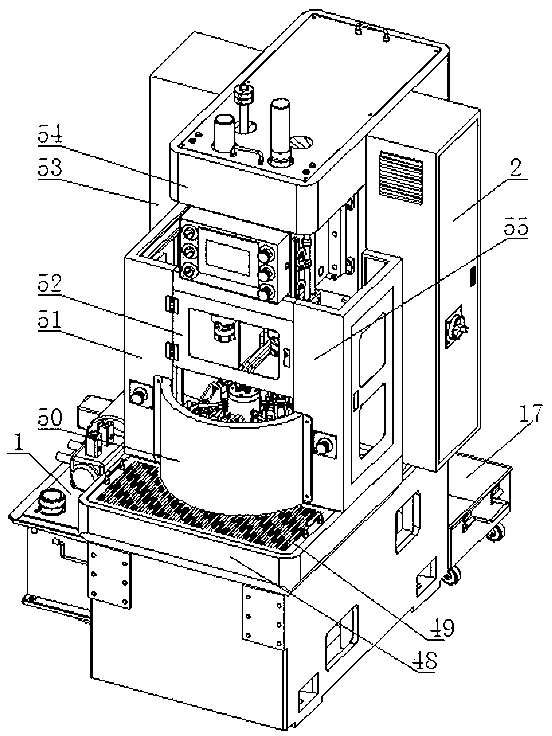

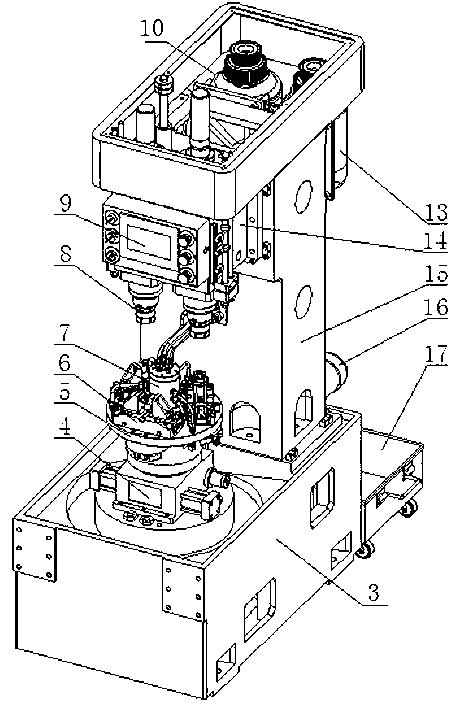

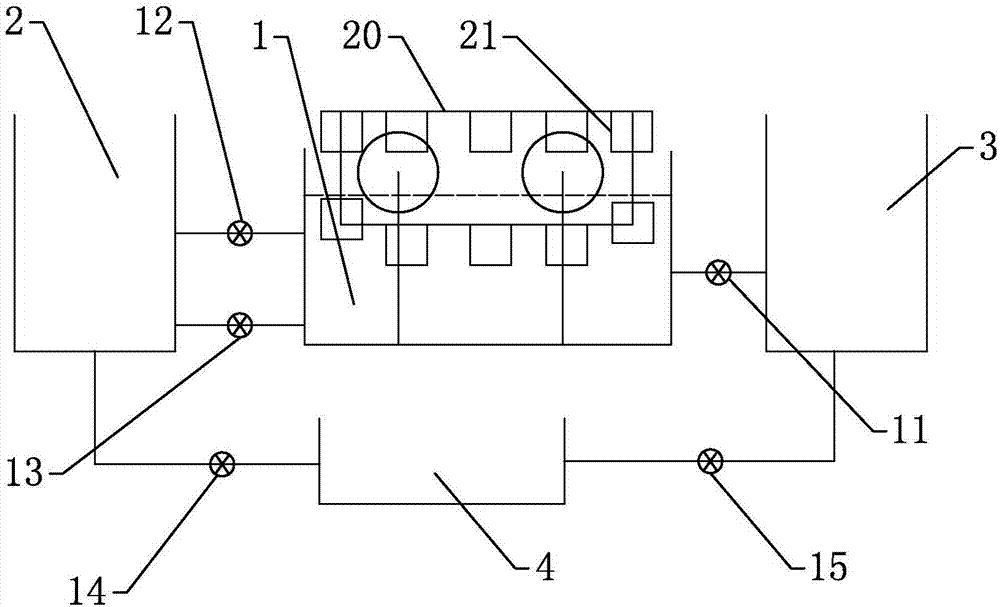

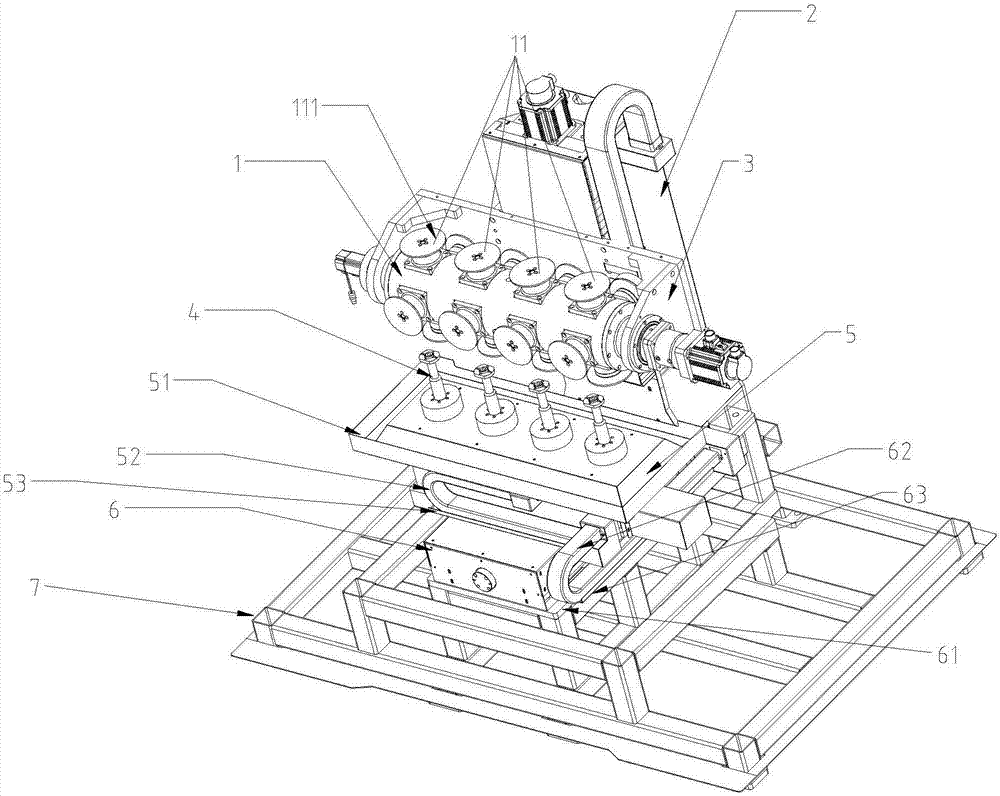

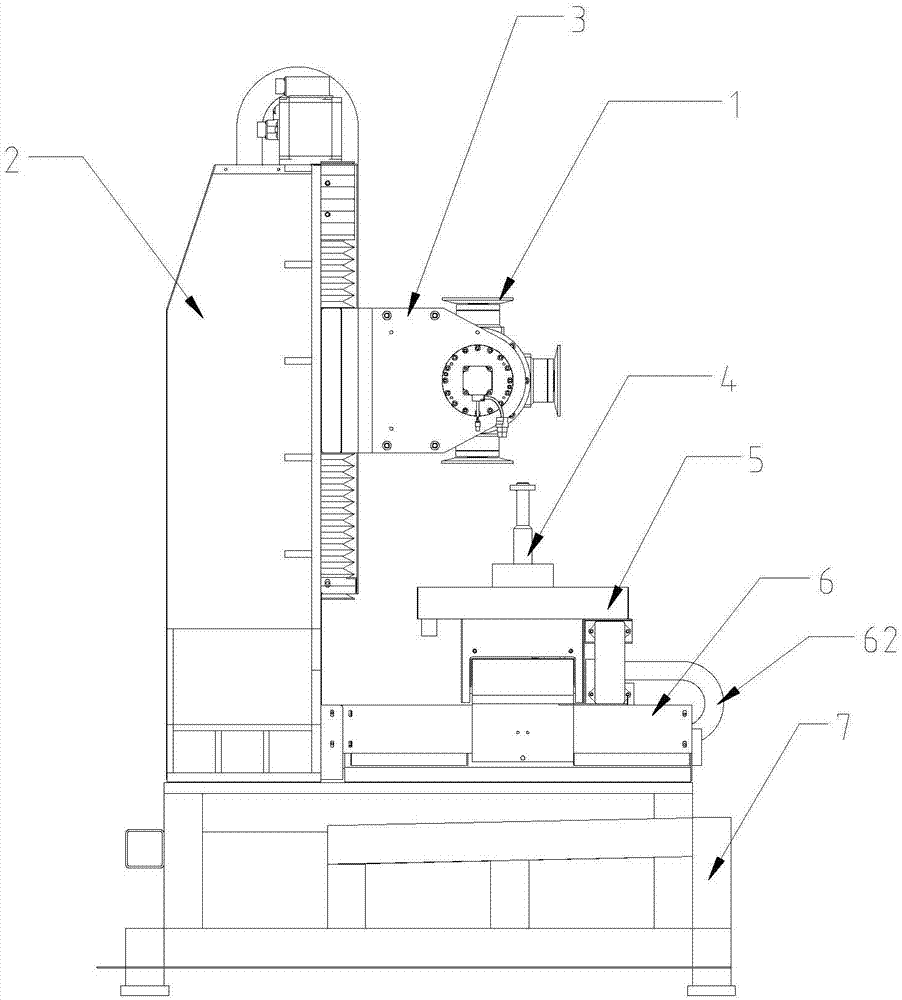

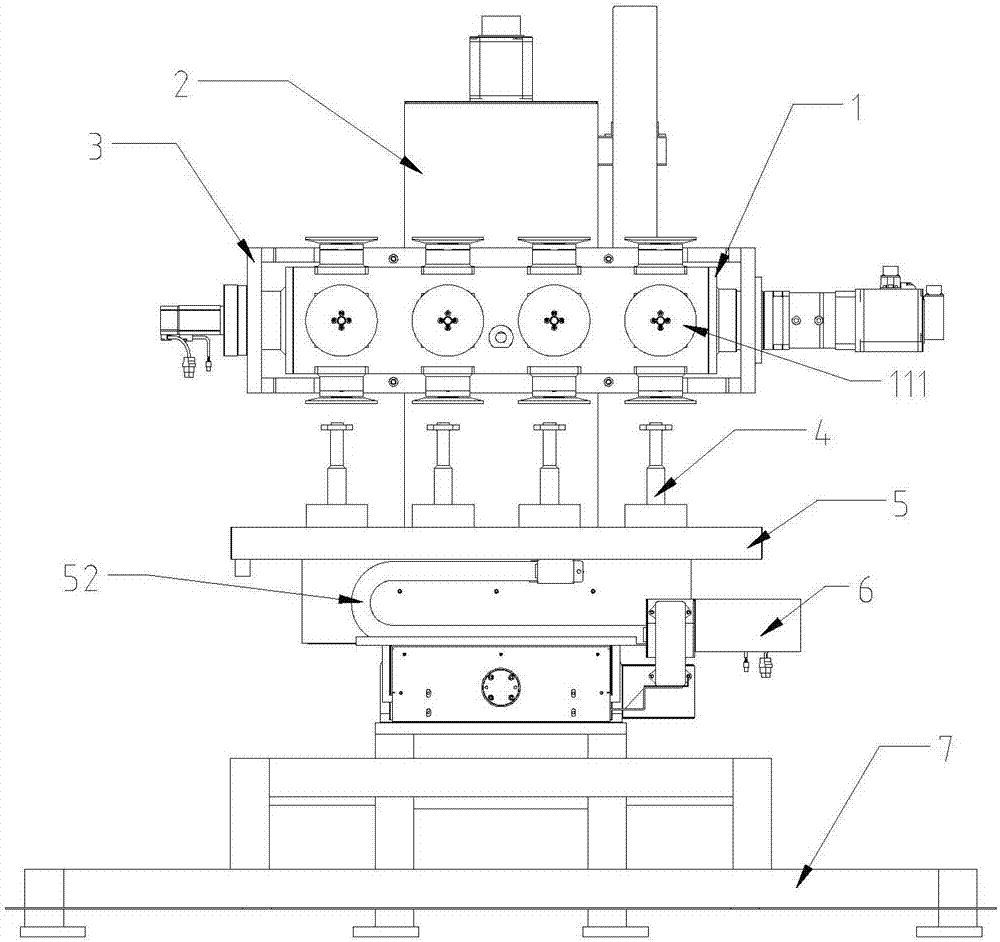

Automatic combination processing production line of double-shaft drilling machines

InactiveCN103341761AReduce allocationReduce labor costsOther manufacturing equipments/toolsLarge fixed membersProduction lineRobotic arm

The invention discloses an automatic combination processing production line of double-shaft drilling machines. The automatic combination processing production line of the double-shaft drilling machines comprises a plurality of double-shaft drilling machines, every two double-shaft drilling machines are connected through a transferring mechanism and a mechanical arm mechanism, a transverse feed mechanism is arranged on each double-shaft drilling machine, the mechanical arm mechanisms are connected with the transverse feed mechanisms, a vibrating type feed plate assembly is arranged on one side of the first double-shaft drilling machine, and a blanking mechanism is arranged on one side of the last double-shaft drilling machine. The production line is formed by conveying automatic feeding and blanking to the double-shaft drilling machines through a transferring mechanisms to carry out processing and combination in three different directions, multiple devices can be controlled by one person, and the automatic combination processing production line of the double-shaft drilling machines has the advantages of being high in producing rate, high in product quality, low in composite cost and the like, and is suitable for processing parts of multiple types on a large scale.

Owner:南安市瑜鼎投资管理有限公司

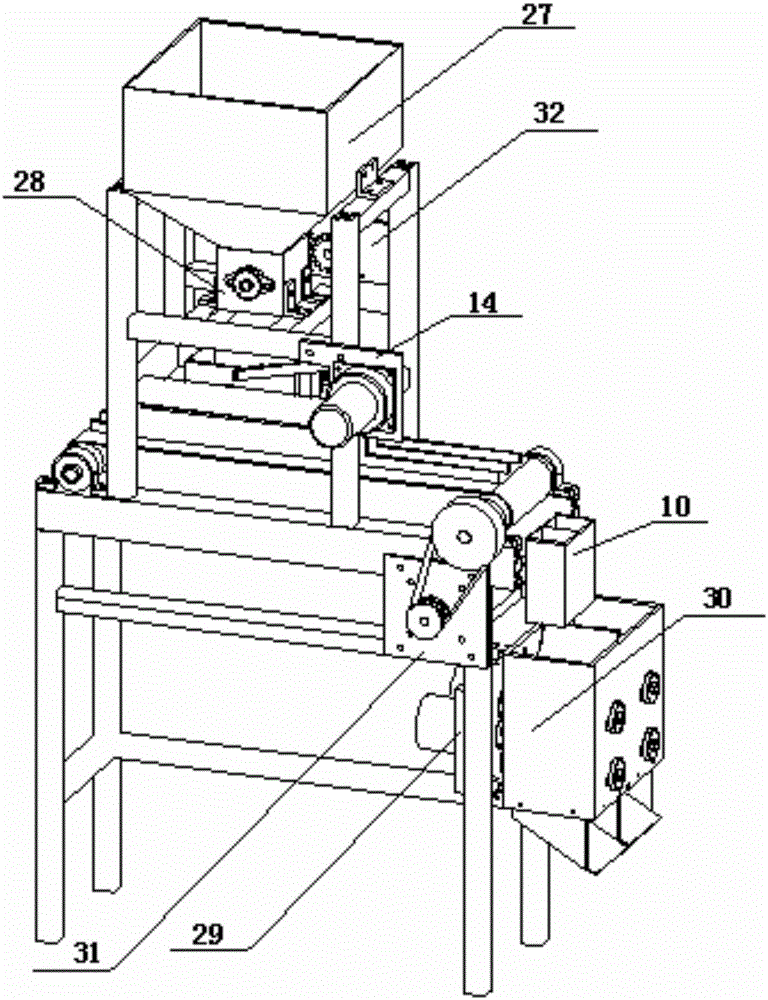

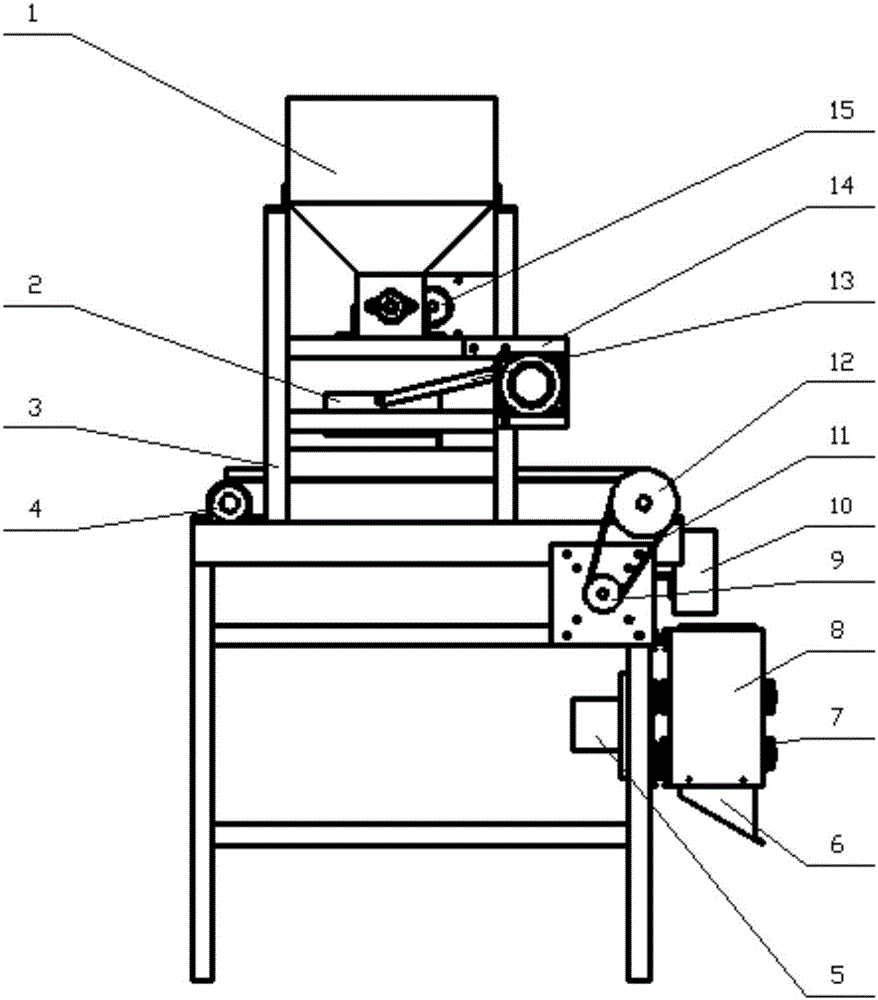

Hair ring split charging machine

InactiveCN106218962ARealize accurate counting and dispensingFill the gap in packingConveyorsPackaging automatic controlEngineeringMechanical engineering

The invention discloses a hair ring split charging machine. At present, ring packaging is manually operated, and the packaging efficiency is low. The hair ring split charging machine comprises a feeding hopper, a rotation mechanism, a transverse moving screening mechanism, a material dividing device, counters and a discharging device; the rotation mechanism is arranged at the bottom of a discharging hopper, the transverse moving screening mechanism is arranged below the rotation mechanism, and raw materials are evenly discharged; three split strips are arranged between a conveying belt mechanism of the material dividing device and a screen of the transverse moving screening mechanism, the position, between every two adjacent split strips, of the output end of the conveying belt mechanism is provided with one counter, and the discharging device is arranged below the counters and comprises a discharging barrel, first rotating shafts, second rotating shafts and a flow combining part; and the discharging barrel is divided into two discharging chambers, first discharging clamping rings are fixed to the first rotating shafts in the discharging chambers, clamping grooves in the tops of the first discharging clamping rings are fixed to first baffles, second discharging clamping rings are fixed to the second rotating shafts, and two second baffles are fixed in two clamping grooves in the bottoms of the second discharging clamping rings. A gap of flexible material split charging in industrial production is filled up by means of the hair ring split charging machinej.

Owner:HANGZHOU DIANZI UNIV

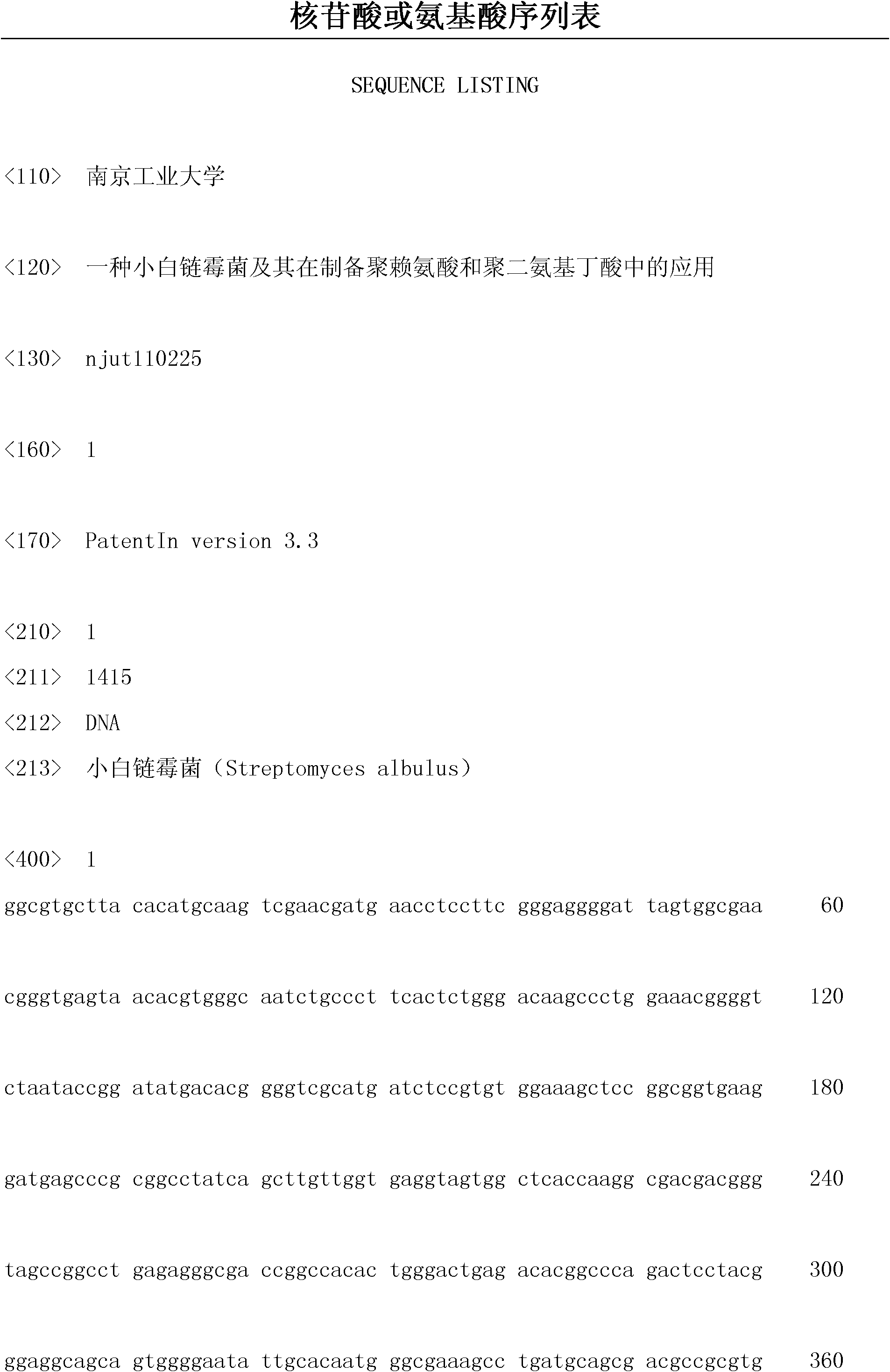

Streptomyces albulus and application thereof in preparing polylysine and poly-diamino-butyric acid

ActiveCN102174448AEasy to operateExtensive culture conditionsBacteriaMicroorganism based processesStreptomyces albulusMicrobiology

The invention discloses streptomyces albulus. The streptomyces albulus has a classification name of streptomyces albulus PD-1 and is preserved in China Center for Type Culture Collection with a registered number of CCTCC NO: M2011043 and a preservation date of 21st, February, 2011. The invention also discloses an application of the streptomyces albulus in preparing polylysine and poly-diamino-butyric acid. In the invention, the strain of the streptomyces albulus serves as the fermentation strain; primary and secondary seed amplification culture and fermentation production are carried out; and after extraction, the output of the polylysine can reach more than 30g / L, and the output of the poly-diamino-butyric acid can reach more than 12g / L. The strain features applications of carbon sources and hydrogen sources, extensive culture conditions, convenience and simpleness in operation, high output of polylysine and poly-diamino-butyric acid and low production cost.

Owner:NANJING TECH UNIV

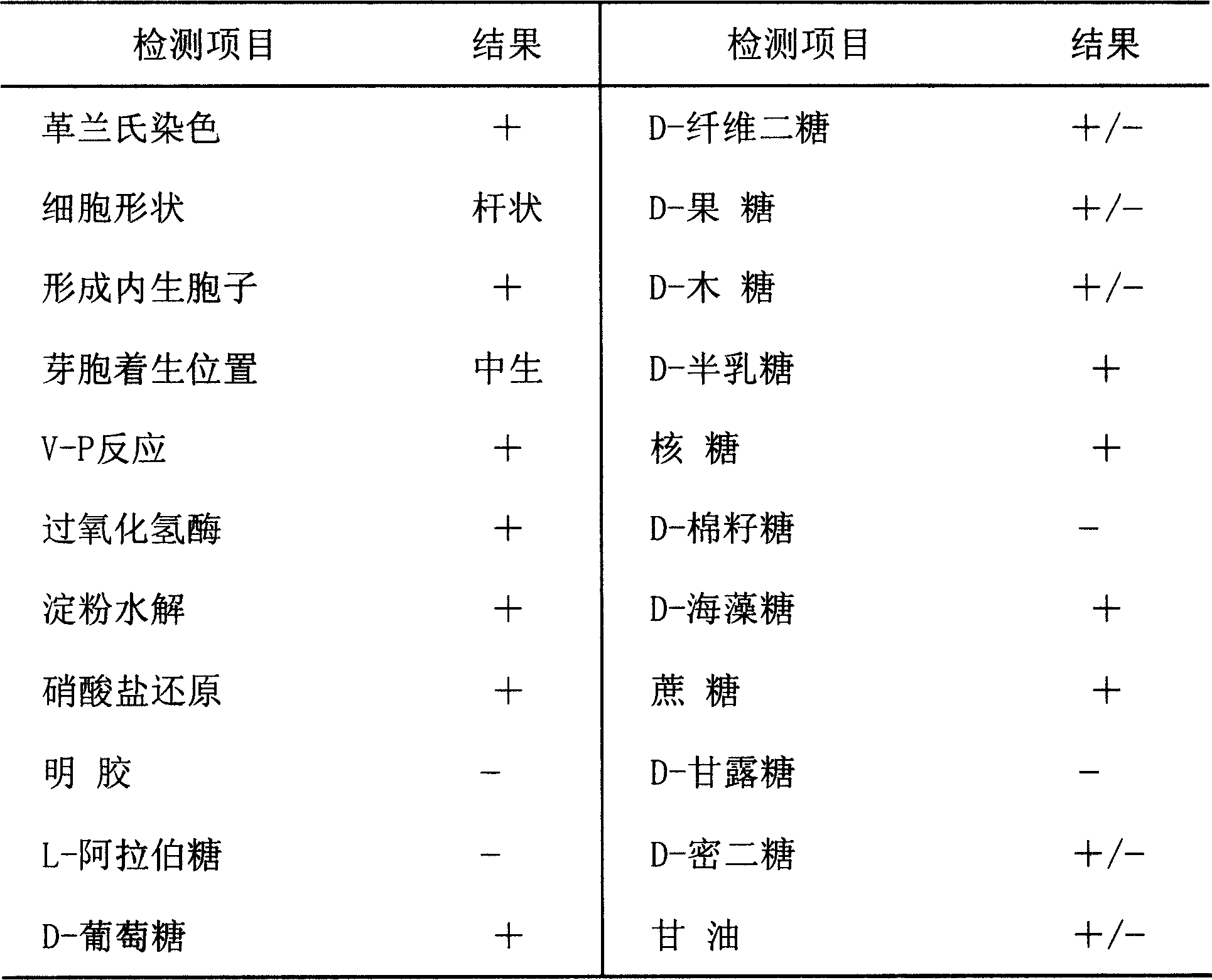

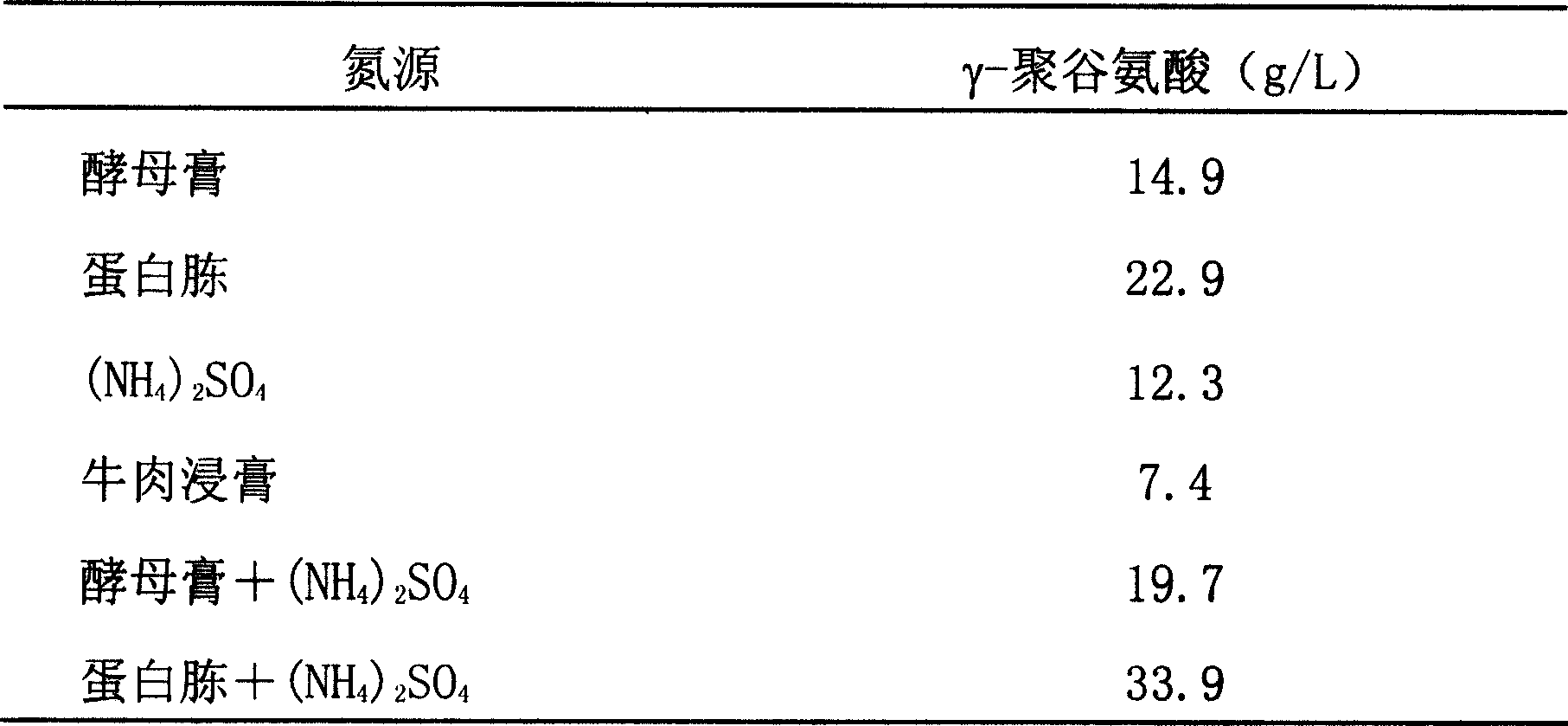

Bacillus subtilis and method for preparing gamma-polyglutamic acid by using the same

InactiveCN101486977AIncrease productionIncrease production rateBacteriaMicroorganism based processesBacillus subtilisCulture mediums

The invention discloses a bacillus subtilis and a Gamma-polyglutamic acid preparation method that uses the bacillus subtilis strain. The strain is bacillus subtilis XN01 and is preserved in China Center for Type Culture Collection (CCTCC) on March 18th, 2008 with CCTCC NO. of M 208044; the Gamma-polyglutamic acid can be prepared with the strain through the steps of strain cultivation and preservation, seed fluid preparation, shaking fluid fermentation and Gamma-polyglutamic acid extraction. The Gamma-polyglutamic acid preparation method can achieve high synthesis efficiency of Gamma-polyglutamic acid in a low-cost fluid culture medium, is simple and has strong operability.

Owner:NORTHWEST A & F UNIV

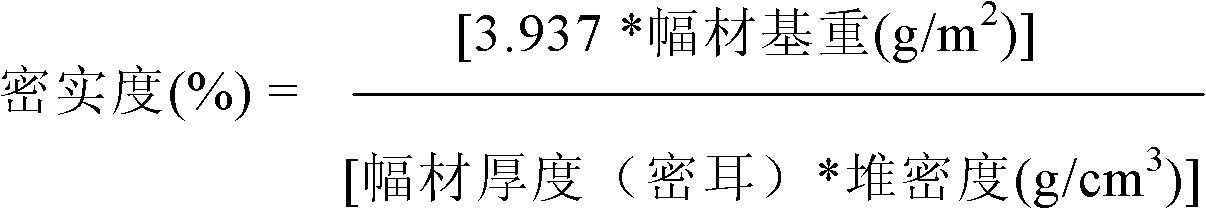

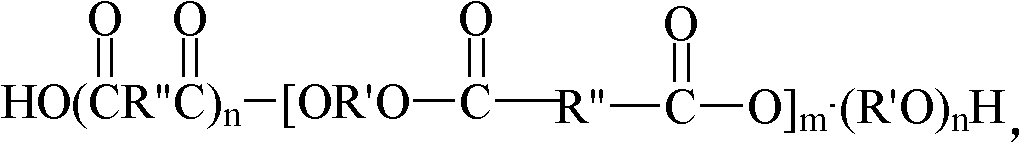

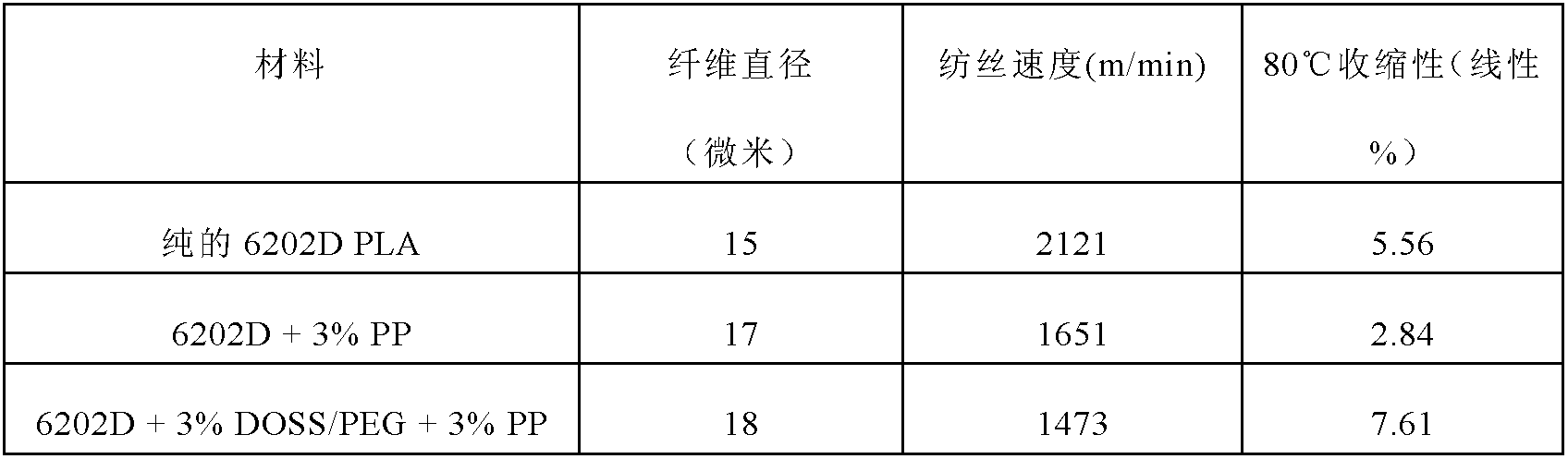

Dimensionally stable nonwoven fibrous webs and methods of making and using the same

InactiveCN102439210AGood absorption propertiesHigh tensile strengthAbsorbent padsNon-woven fabricsPolyesterFiber

Dimensionally stable nonwoven fibrous webs include a multiplicity of continuous fibers formed from one or more thermoplastic polyesters and polypropylene in an amount greater than 0% and no more than 10% by weight of the web. The webs have at least one dimension which decreases by no greater than 10% in the plane of the web when heated to a temperature above a glass transition temperature of the fibers. When the thermoplastic polyester is selected to include aliphatic and aromatic polyesters, a spunbond process may be used to produce substantially continuous fibers that exhibit molecular orientation. When the thermoplastic polyester is selected from aliphatic polyesters, a meltblown process may be used to produce discontinuous fibers that do not exhibit molecular orientation.; The webs may be used as articles for filtration, sound absorption, thermal insulation, surface cleaning, cellular growth support, drug delivery, personal hygiene, medical apparel, or wound dressing.

Owner:3M INNOVATIVE PROPERTIES CO

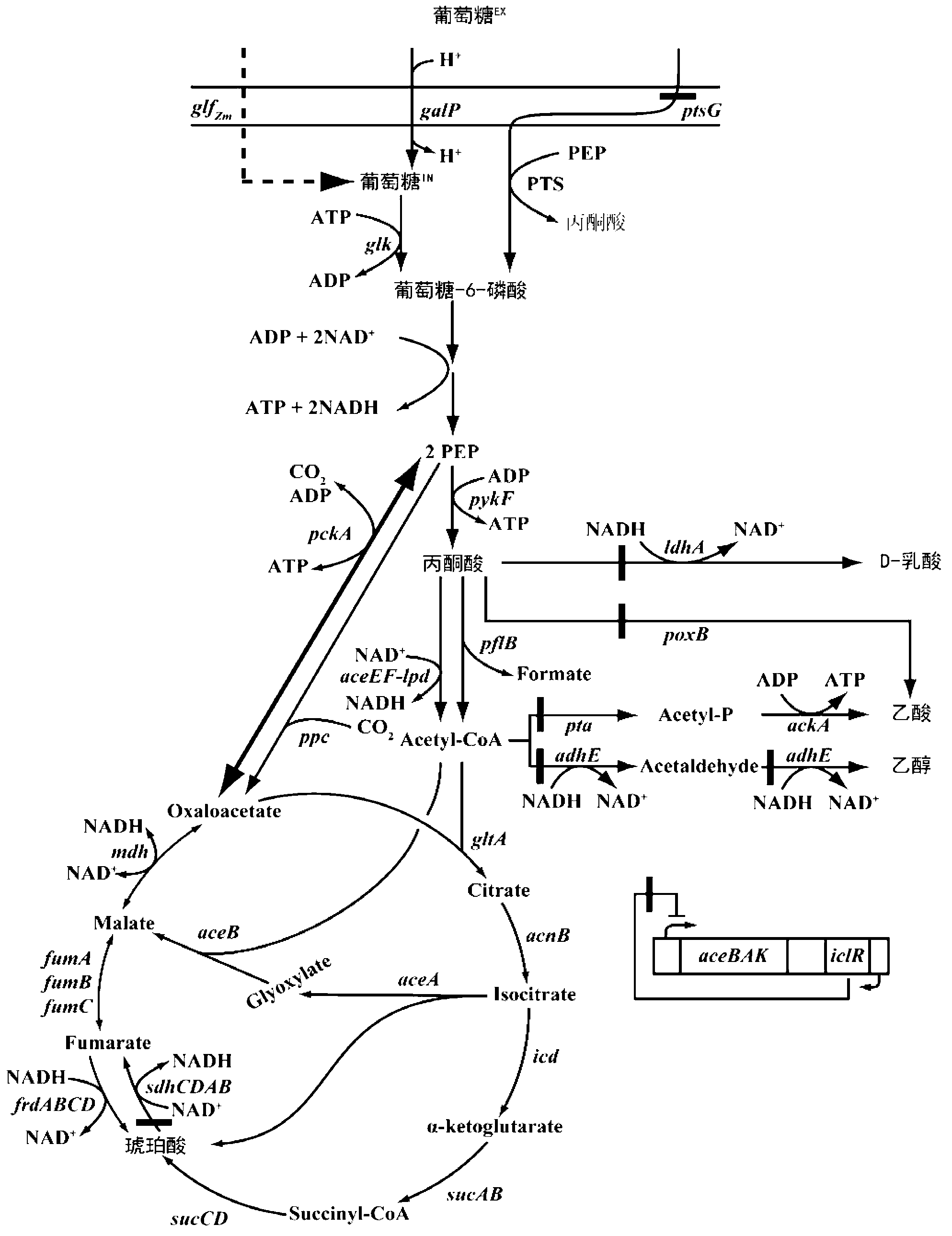

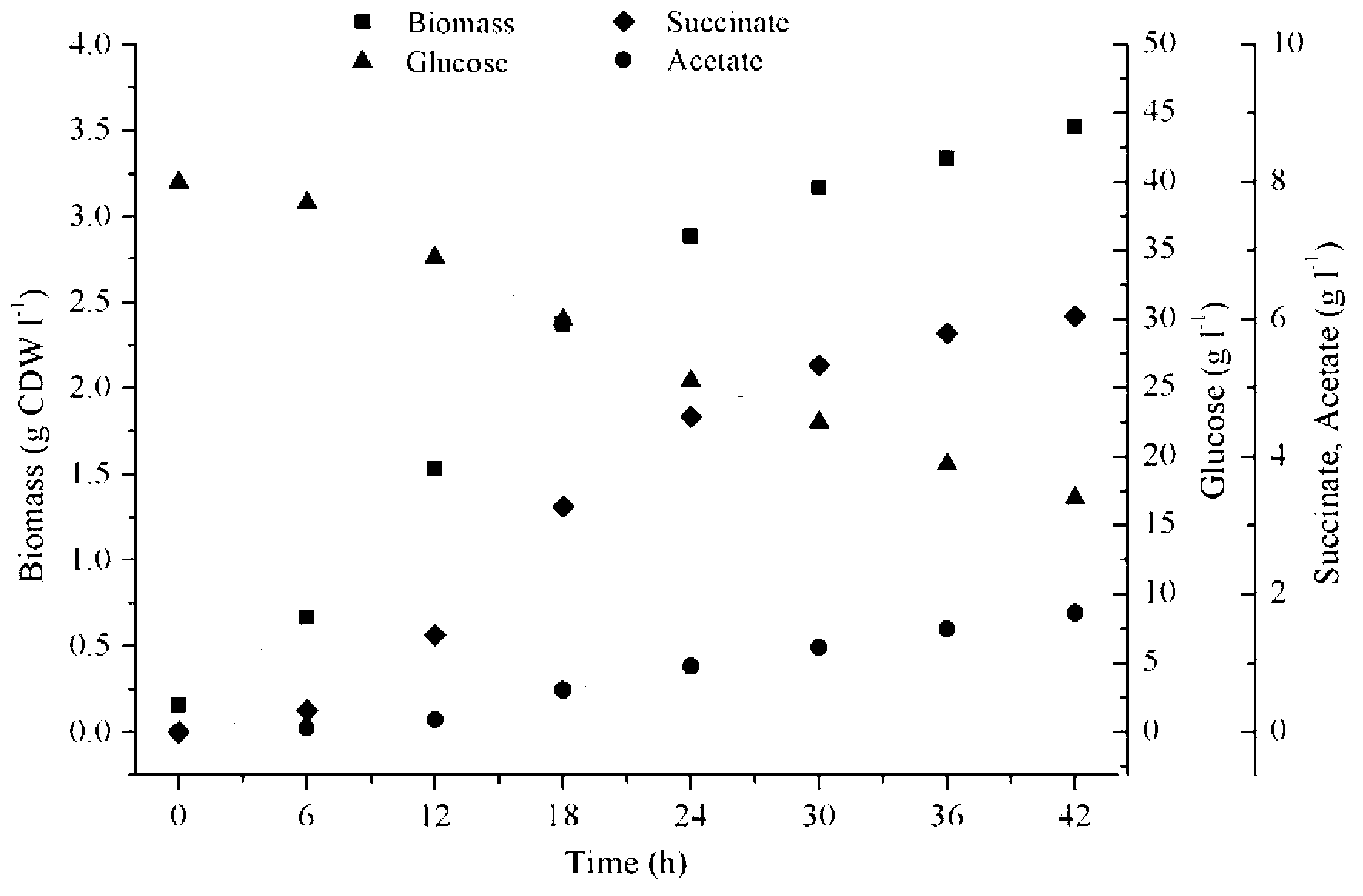

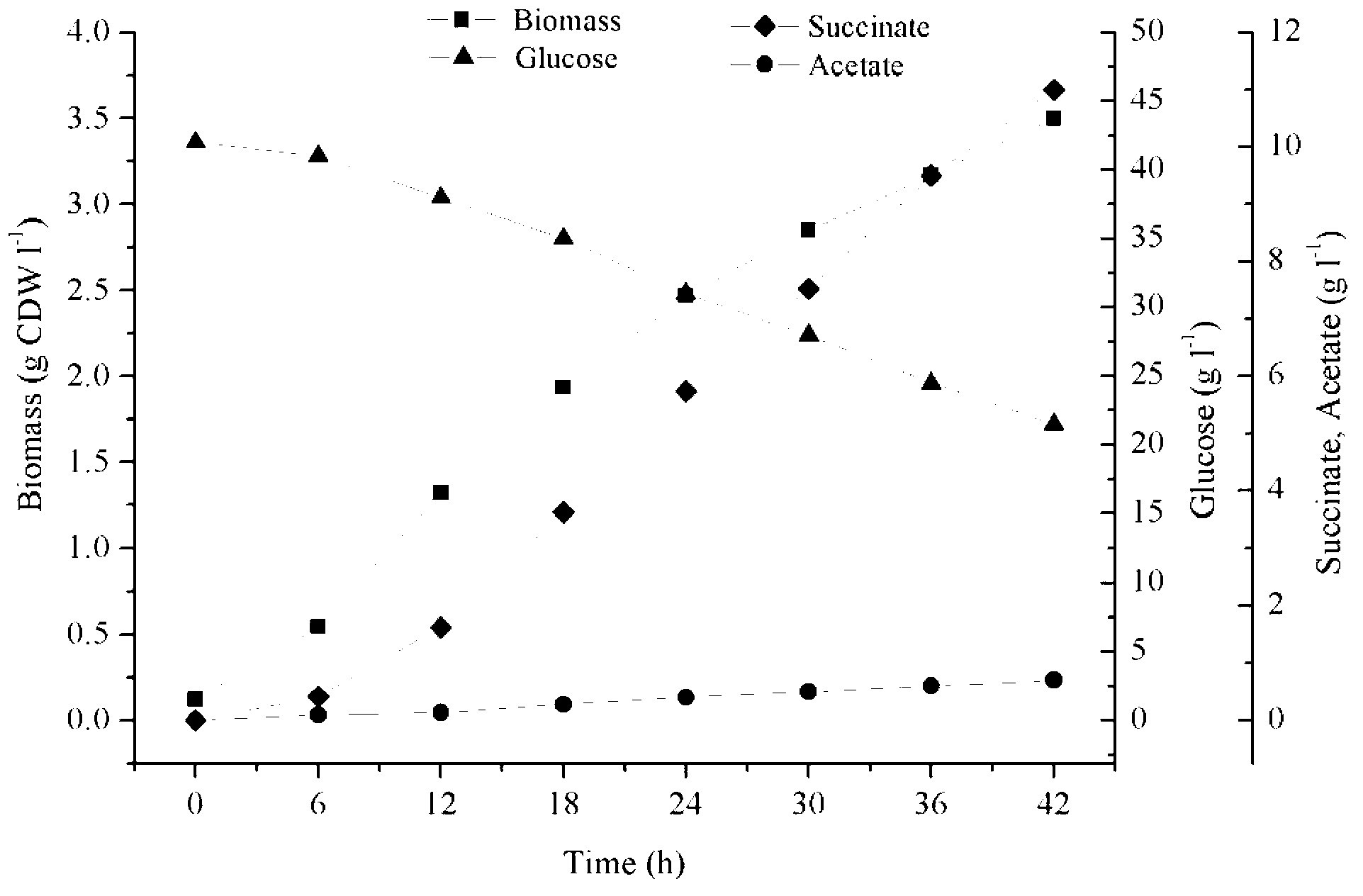

Escherichia coli engineered strain and application in succinic acid production through aerobic-microaerobic-anaerobic full-stage fermentation of Escherichia coli engineered strain

InactiveCN103243064AIncrease productionAccelerate transmembrane transportBacteriaMicroorganism based processesEscherichia coliPhacus

The invention discloses an Escherichia coli engineered strain and application in succinic acid production through the aerobic-microaerobic-anaerobic full-stage fermentation of the Escherichia coli engineered strain. The name of the engineered strain is Escherichia coli YL106. The genotype of the strain is a formula shown in a drawing. The strain is collected by China Center for Type Culture Collection (CCTCC) on April 17th, 2013 and has the collection number of CCTCC NO: M2013149. According to the engineered strain disclosed by the invention, succinic acid is produced under the condition of aerobic-microaerobic-anaerobic full-stage fermentation, a large amount of succinic acid can be accumulated efficiently, and the total productivity (2.13 g / (L.h)) of the engineered strain is the highest among literature reports related to the succinic acid production using Escherichia coli currently, so that the engineered strain disclosed by the invention and an aerobic-microaerobic-anaerobic full-stage succinic acid fermentation process have considerable industrial application values and prospects.

Owner:SHANDONG UNIV

Silky fine matt ceramic tile and production method thereof

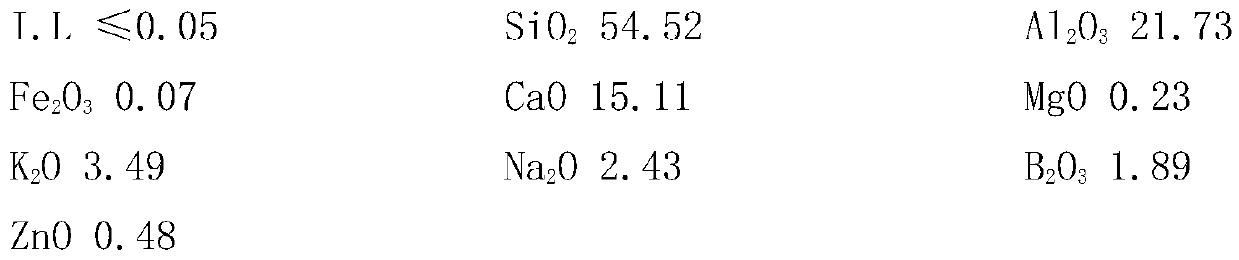

ActiveCN110204306AReduce consumptionSimplify product processCeramic shaping apparatusCeramic materials productionCeramic tilesPotassium

The invention relates to a silky fine matt ceramic tile and a production method thereof. The blank material of the ceramic brick comprises 10-15% of nepheline powder, 5-10% of high-carbon mud, 20-25%of low-carbon mud, 10-15% of medium-and-high-carbon mud, 5-10% of recovered waste blanks, 5-10% of potassium and sodium stone powder, 20-25% of paving albite powder, 5-10% of waste porcelain powder, 0-7% of desulfurization waste residues, 20-30% of edging and polishing waste residues, 0.3-1.0% of a liquid dispergator and 0.2-0.8% of a liquid reinforcing agent. The production method comprises the following processes: proportioning and ball milling of blank raw materials, spray drying, aging, blank compression molding, drying, blank polishing, water spraying, glazing, pattern decoration and firing.

Owner:JIANGXI HEMEI CERAMICS +4

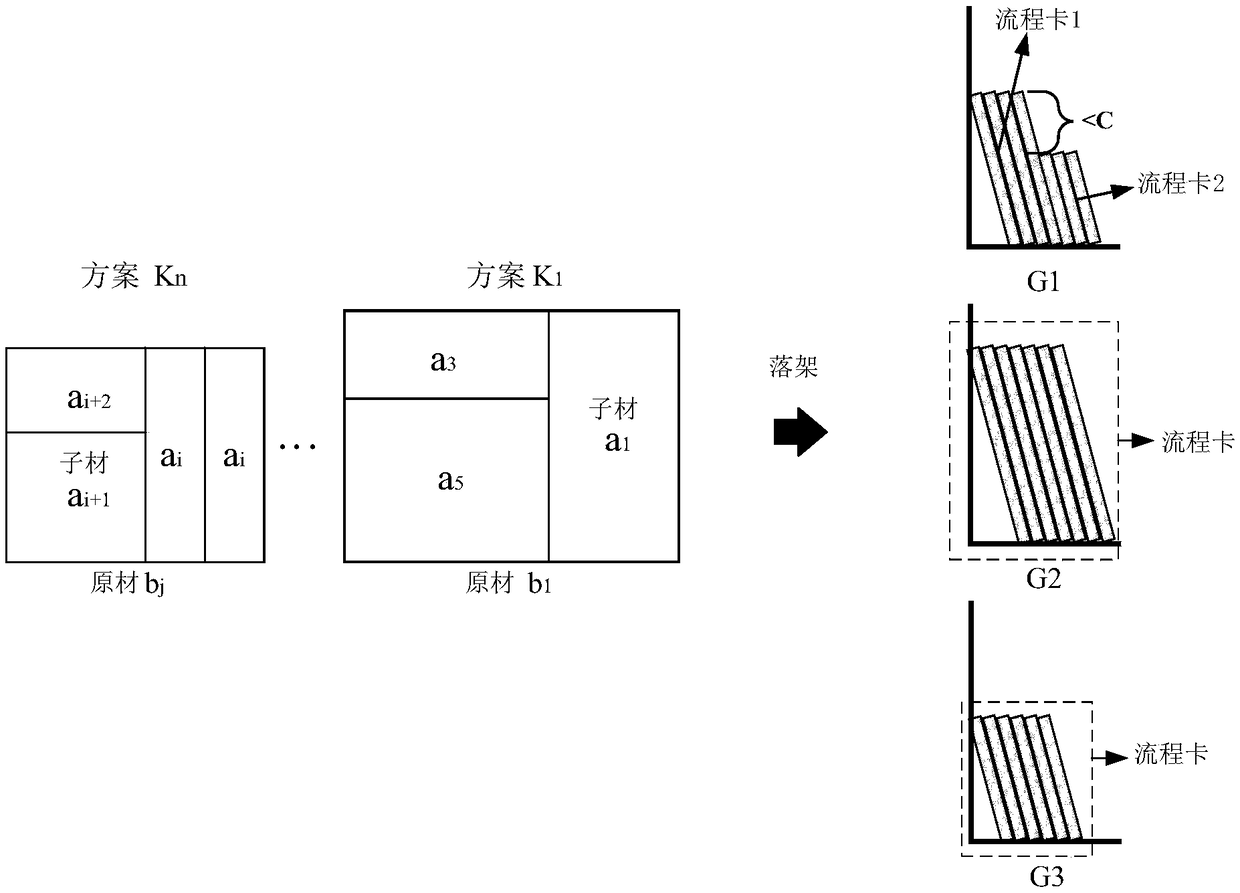

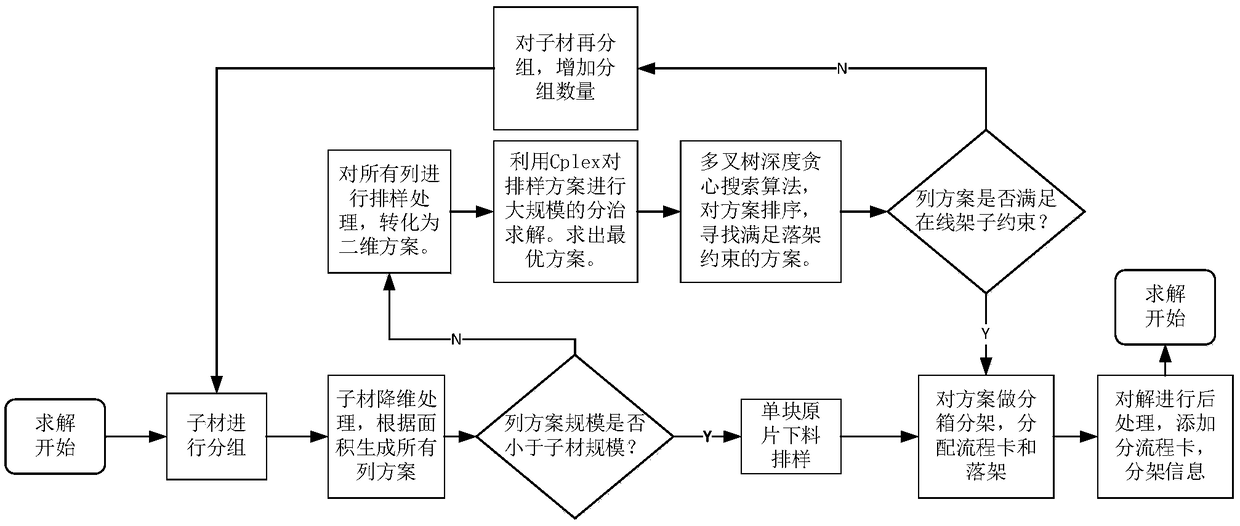

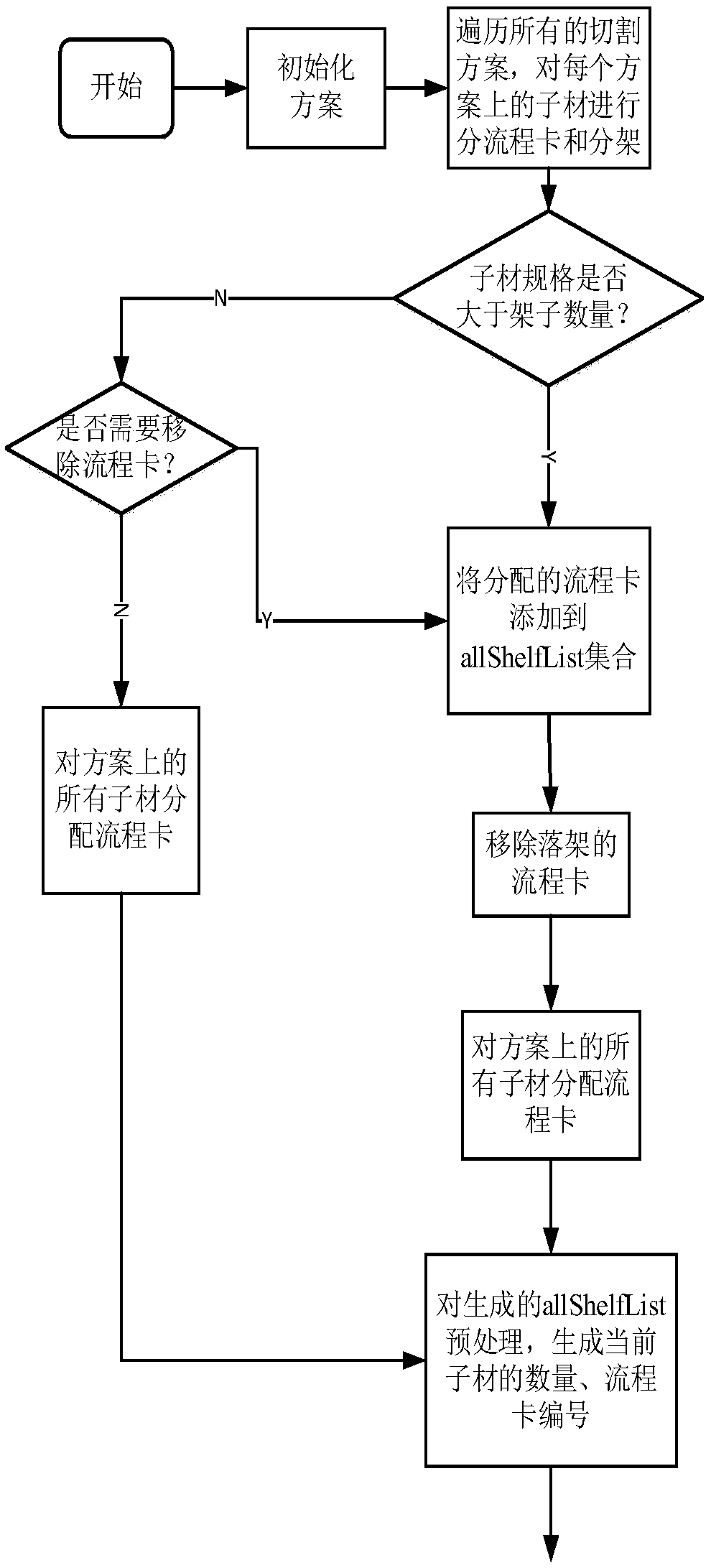

Method for integrating and optimizing plate type product cut and blanking, box dividing and rack dividing

ActiveCN109118002AIncrease profitIncrease the level of automationForecastingManufacturing computing systemsProduction rateProduction line

A method for integrating and optimizing plate-type product cut, blanking, dividing into boxes and rack includes such steps as A, grouping sub-materials, generating layout column scheme according to sub-material area, and returning that column scheme to two-dimensional layout scheme by using grouping strategy when the generated column scheme is larger than sub-material scale, otherwise, the blanking and nesting of a single block of raw material being directly carried out by using the histochemical strategy; B, dividing and conquering the two-dimensional layout scheme of the step A by an integrated Cplex engine to obtain a plurality of approximate optimal layout schemes; C, searching for a layout scheme that satisfies the falling frame constraint; when the closest optimal layout scheme doesnot satisfy the drop-off constraint, returning to step A, dismantling the molecular material again, increasing the number of sub-material grouping, and generating a new layout scheme; D: carrying outcase division and shelving. The integrated optimization method not only improves the utilization rate of raw materials, but also improves the automation level of the production line, speeds up the production rate of the products and improves the operation efficiency of the production line.

Owner:GUANGDONG UNIV OF TECH

Adjustable band-pass filter

ActiveCN113540717AImprove assembly efficiencySimple preparation processWaveguide type devicesResonant cavitySoftware engineering

The invention provides an adjustable band-pass filter, which includes a filter main body located in an external magnetic field, wherein the filter main body comprises a resonant cavity, an upper substrate and a lower substrate arranged in the resonant cavity, a radio frequency input end arranged at one end of the resonant cavity and a radio frequency output end arranged at the other end of the resonant cavity, the upper substrate and the lower substrate are vertically opposite and arranged at an interval, the opposite surfaces are provided with microstrip lines, the radio frequency input end is connected with the microstrip line of the lower substrate, the radio frequency output end is connected with the microstrip line of the upper substrate, the upper substrate and the lower substrate are respectively provided with a YIG substrate, the YIG substrates are connected with the microstrip lines, each YIG substrate comprises a GGG substrate connected with the microstrip line and a YIG film arranged on the top surface of the GGG substrate, and a preset distance is formed between the surfaces of the YIG film of the upper YIG substrate and the lower YIG substrate. Through the structural design of the resonant cavity and the YIG substrate formed by the YIG film and the GGG substrate, the center frequency in a certain frequency band range is adjustable while the resonant cavity has the advantages of being simple in structure and easy to assemble.

Owner:成都威频科技有限公司

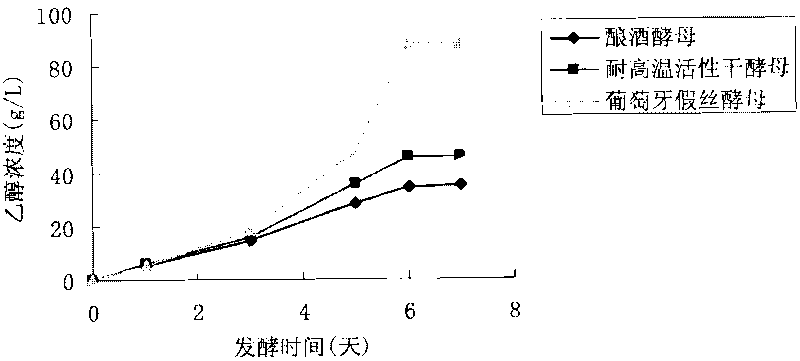

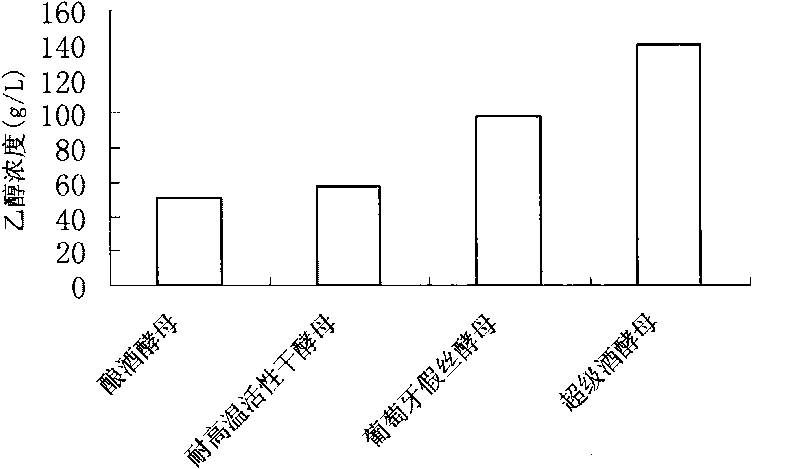

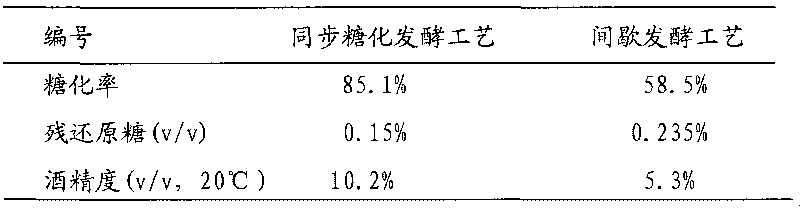

Production method of cellulose ethanol

The invention discloses a production method of cellulose ethanol, which comprises the following steps of: (1) adding a culture medium containing the raw materials of cellulose and / or hemicellulose into a fermentation reaction kettle; (2) adding cellulase into the fermentation reaction kettle and inoculating Candidalusitaniae; and (3) carrying out synchronous diastatic fermentation under the combined action of the cellulase and the Candidalusitaniae and separating to obtain the cellulose ethanol. The Candidalusitaniae used for the synchronous diastatic fermentation in the invention has higher ethanol tolerance and higher ethanol throughput rate and can prepare the cellulose ethanol by the synchronous diastatic fermentation with high efficiency through taking the cellulose and the hemicellulose as the raw materials under the combined action of the cellulase.

Owner:ANGELYEAST CO LTD

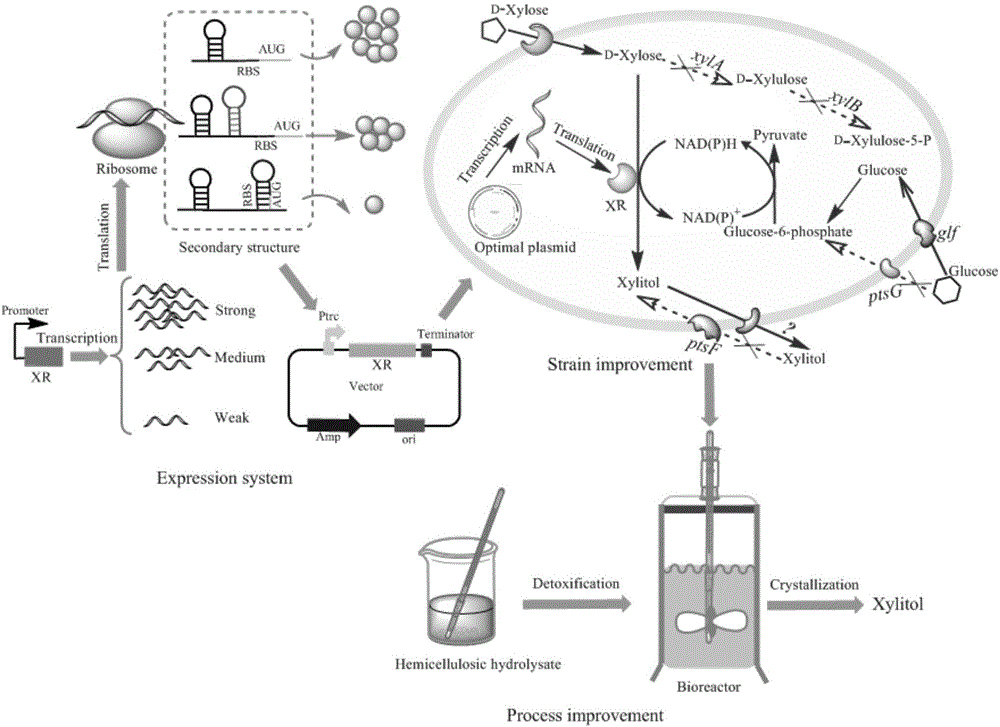

Genetic engineering strain, construction method and application in xylitol production

ActiveCN104593308AEfficient expressionUtilization rate reductionBacteriaMicroorganism based processesEscherichia coliInclusion bodies

The invention discloses a genetic engineering strain, a construction method and application thereof in xylitol production. The genetic engineering strain includes Escherichia coli and an expression vector transferred into the Escherichia coli. An XR gene is inserted to the downstream of the expression vector's promoter, the base sequence of the XR gene is shown as SEQ ID No.4, the promoter is Trc promoter, the 5' end of the XR gene has RBS from pET30a, and at least one of ptsG, xylA, xylB and ptsF genes in the Escherichia coli is inhibited or knocked out. Through translation initiation rate screening on xylose reductase gene and selection of appropriate RBS and promoter, the XR gene in the genetic engineering strain can obtain high efficiency expression at 30DEG C, and no inclusion body is generated. By knockout of the ptsG gene, the glucose effect is eliminated, and through knockout of the xylA, xylB and ptsF genes, xylose metabolism and xylitol phosphorylation are blocked.

Owner:ZHEJIANG UNIV

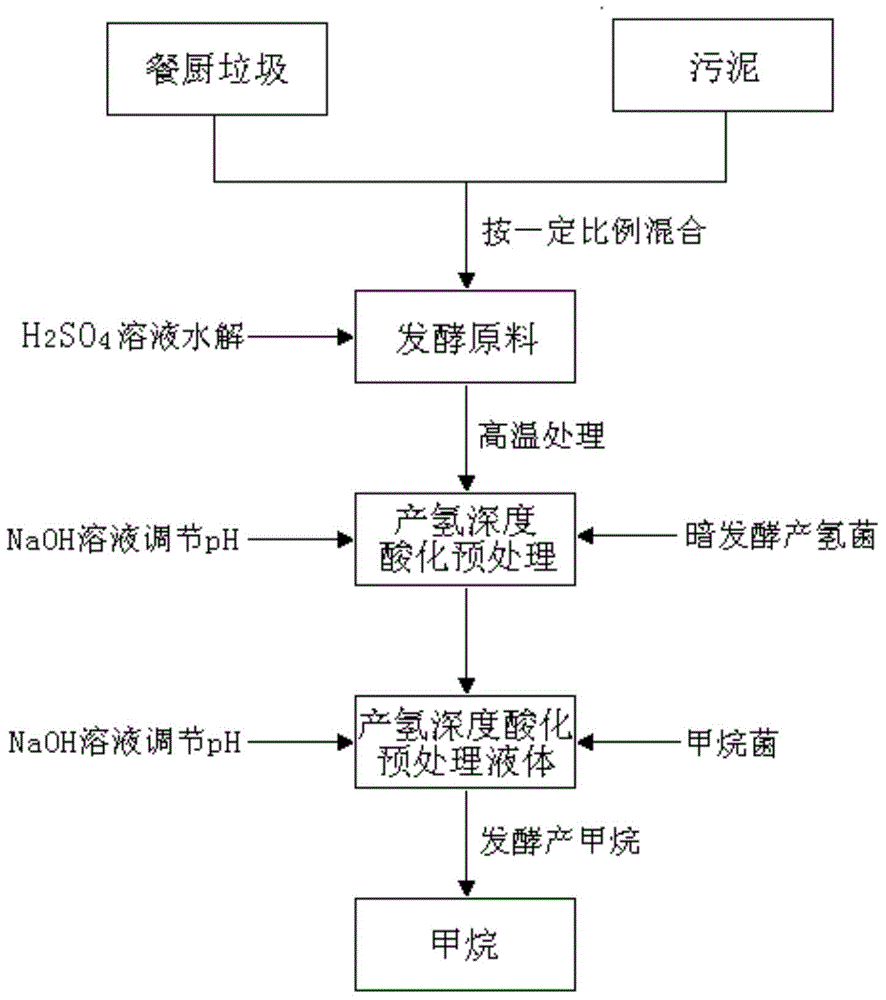

Kitchen waste and sludge hydrogen-producing acidification pretreatment method capable of increasing methane production rate

ActiveCN104561222AIncrease production rateIncrease throughputMicroorganism based processesWaste based fuelPretreatment methodSludge

The invention relates to the technology of biomass energy utilization, and aims to provide a kitchen waste and sludge hydrogen-producing acidification pretreatment method capable of increasing the methane production rate. The method comprises the following steps: mixing the kitchen waste and the sludge after crushing pretreatment, using the mixture and a sulfuric acid solution to prepare a mixed liquid, performing hydrolysis on the mixed liquid at 135 DEG C to obtain a starting crude; adding yeast powder into the starting crude, inoculating dark-fermentation hydrogenogens, feeding high-purity nitrogen to build an anaerobic fermentation environment, then performing dark-fermentation hydrogen-producing deep acidification pretreatment at the constant temperature of 37 DEG C, and obtaining a hydrogen-producing deep acidification pretreatment liquid; adding methanogens into the liquid, keeping the anaerobic environment at 37 DEG C, and performing methane fermentation and coproduction. According to the method disclosed by the invention, the hydrogen-producing deep acidification pretreatment is utilized to obviously increase the methane production rate; the rate peak time of the produced methane is reduced by about 50%; the waste treatment and degradation time of the fermentation tank with a unit volume is reduced by about 50%; the waste treatment capacity of the single equipment in unit time is improved by about one time.

Owner:ZHEJIANG UNIV

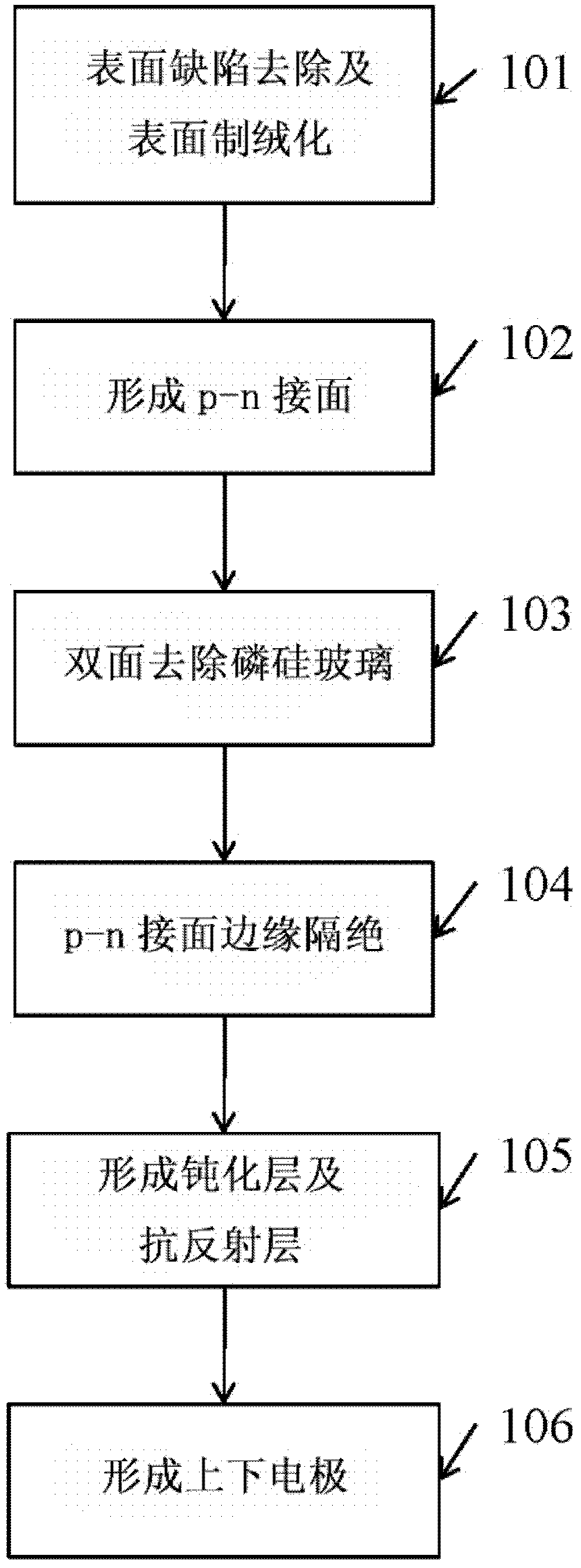

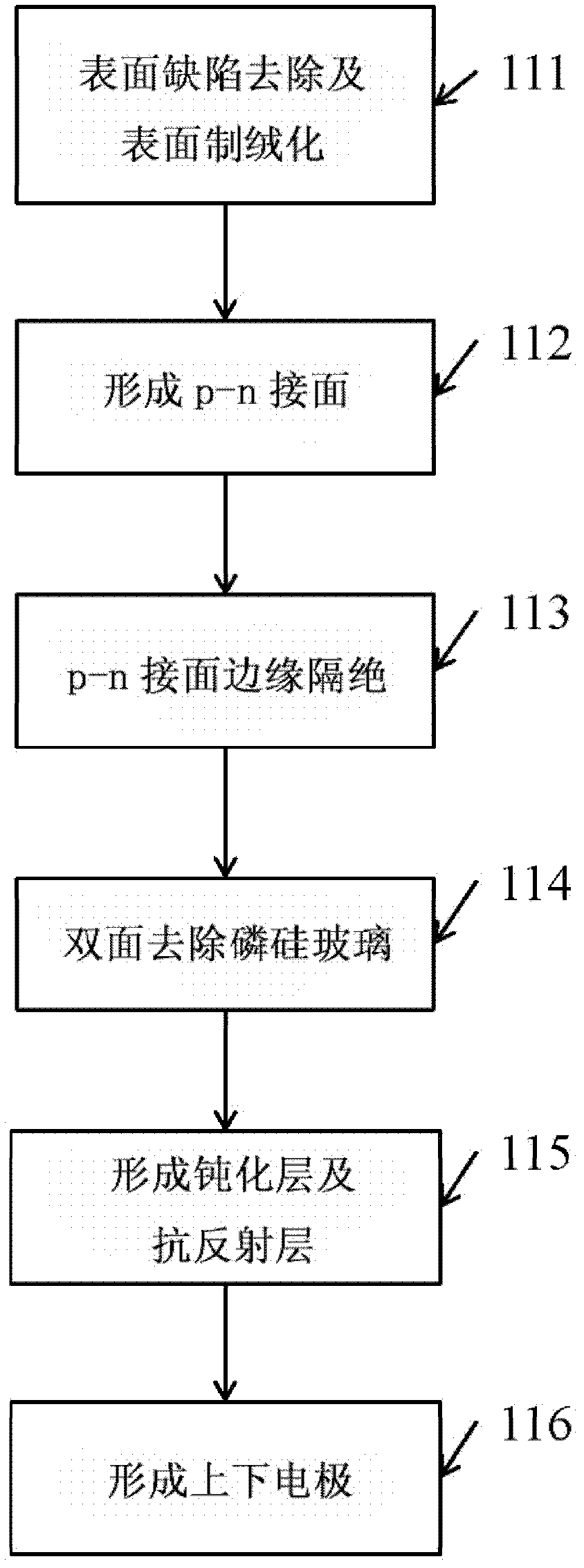

Method for fabricating silicon wafer solar cell

InactiveCN102456771AImprove photoelectric conversion efficiencyIncrease production rateFinal product manufacturePhotovoltaic energy generationCompound (substance)Solar cell

The invention provides a method for fabricating a silicon wafer solar cell, comprising the following steps: texturing a silicon wafer, forming a p-n junction, performing a wet chemical surface treatment, performing a passivation layer formation process, and performing electrodes formation process, wherein the wet chemical surface treatment comprises the following specific process flow: performing a backside phosphosilicate glass (PSG) removal process, performing an edge isolation and backside polish process, performing a double-side phosphosilicate glass and oxide removal process, and performing a front-side shallow junction formation process.

Owner:WAKOM SEMICON CORP

Method for preparing beta-alanine by coupled enzymatic reaction

InactiveCN103320480ALow costReduce equipment investmentFermentationEnzyme catalysisIon-exchange resin

The invention belongs to the biotechnical field, and in particular relates to a method for preparing beta-alanine by a coupled enzymatic reaction. The method comprises the following steps: by using ammonium fumarate as a raw material, mixing bacterial cells respectively comprising aspartase and aspartic acid-alpah-decarboxylase or a crude enzyme liquor of the two enzymes with an ammonium fumarate aqueous liquor, wherein pH of the ammonium fumarate aqueous liquor is 7.0-7.5; performing enzymatic reaction at 25-55 DEG C; obtaining high purity beta-alanine by separating converted products by isoelectric point crystallization or a method combining isoelectric point crystallization or ion exchange resin. The beta-alanine is prepared by coupled enzymatic reaction, and the method has the advantages of wide source of raw materials, low cost, simplicity and convenience in operation, short enzymatic conversion time, low production cost and the like.

Owner:NANJING UNIV

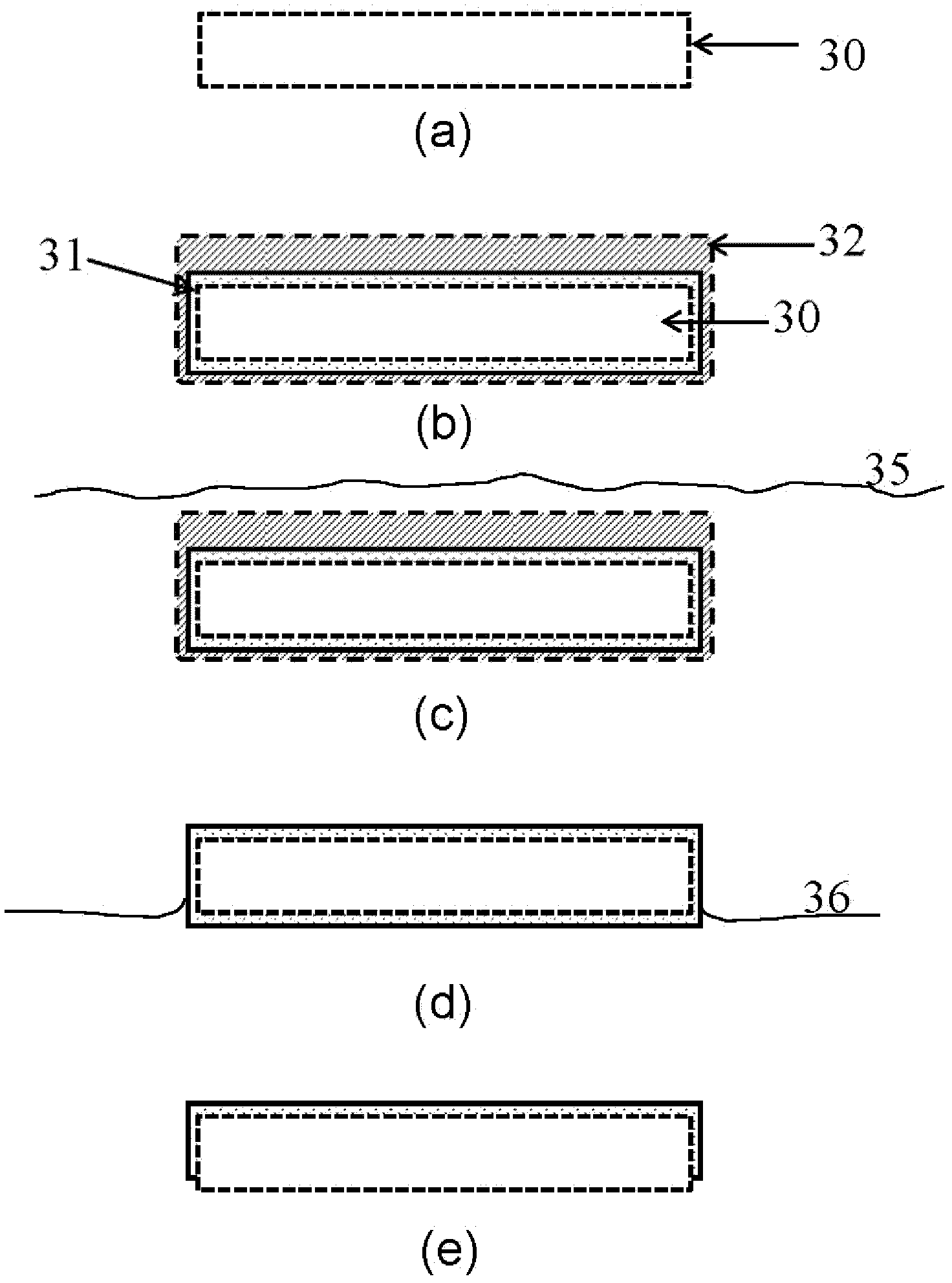

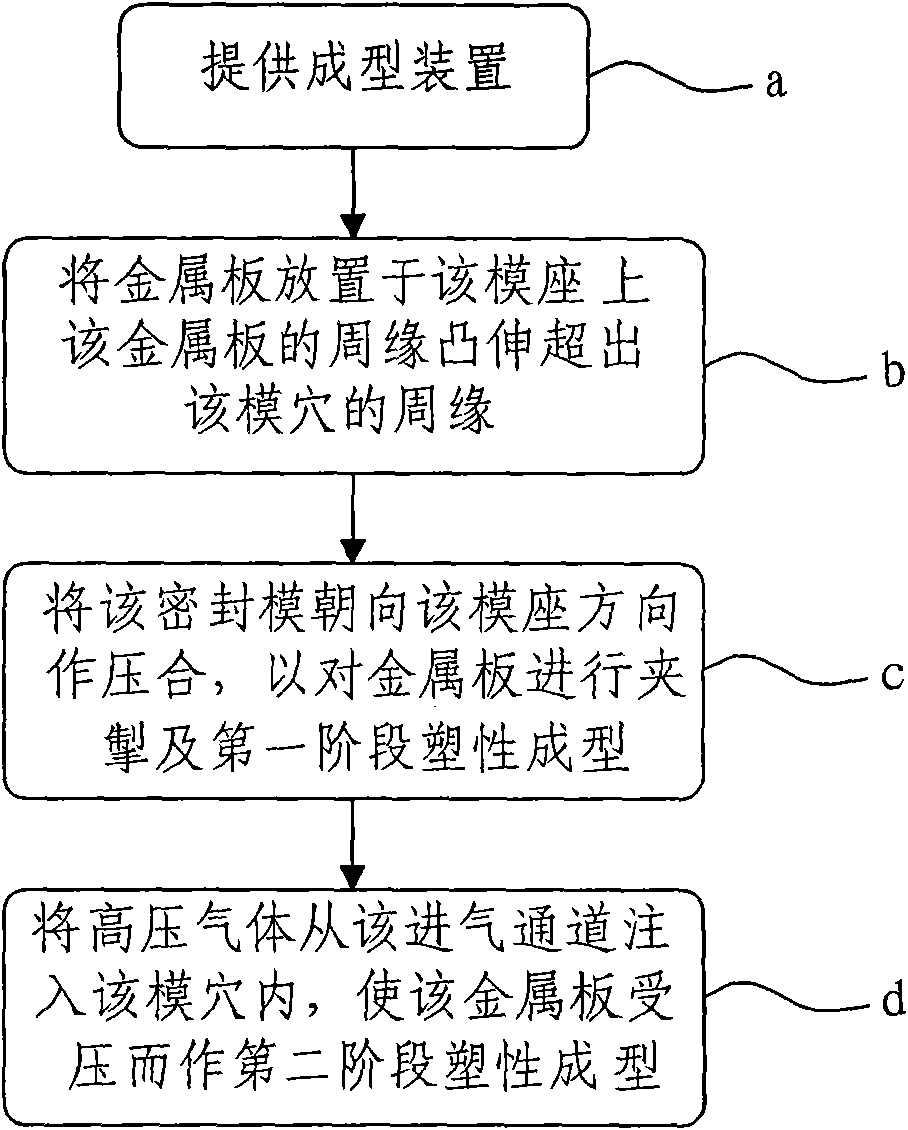

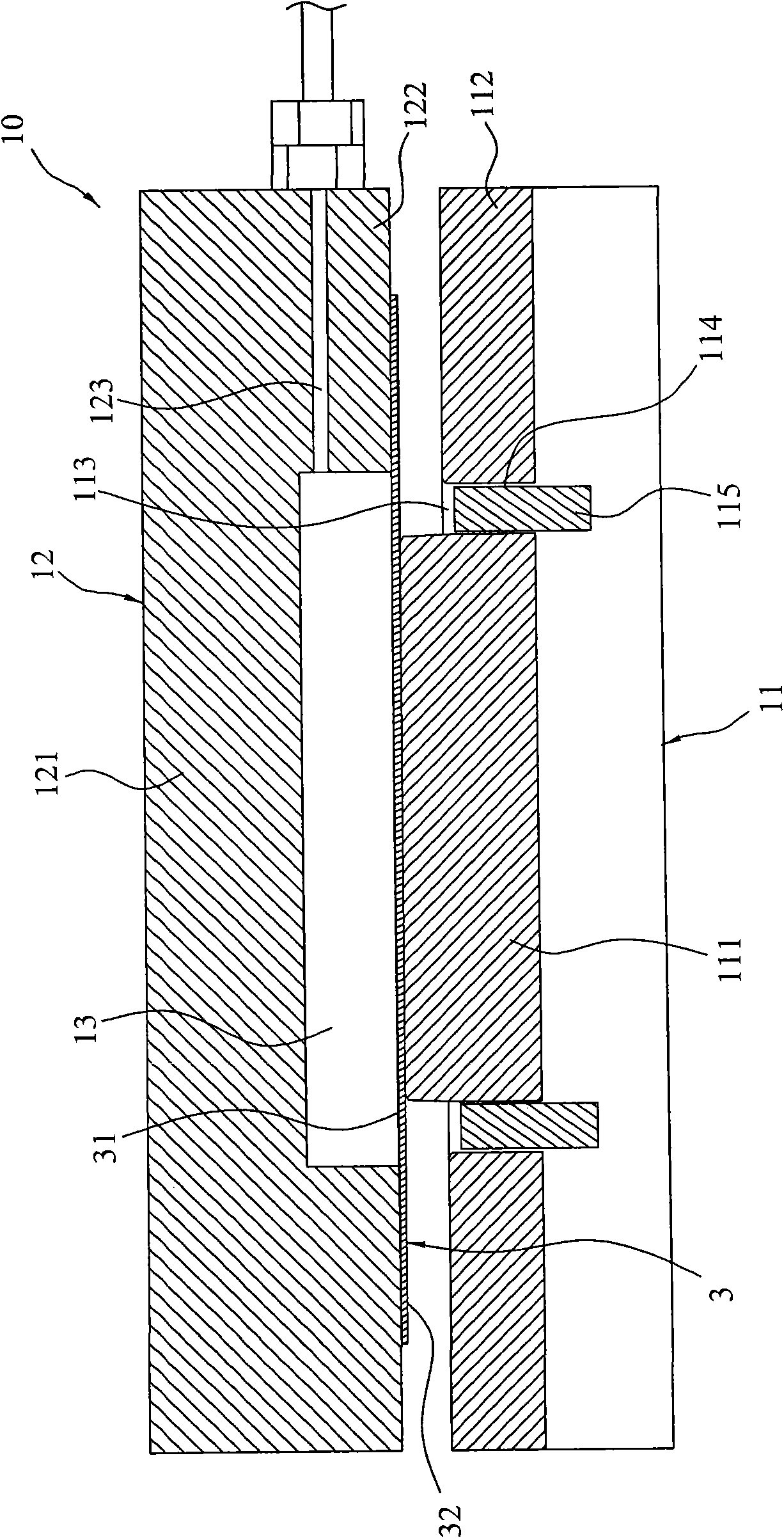

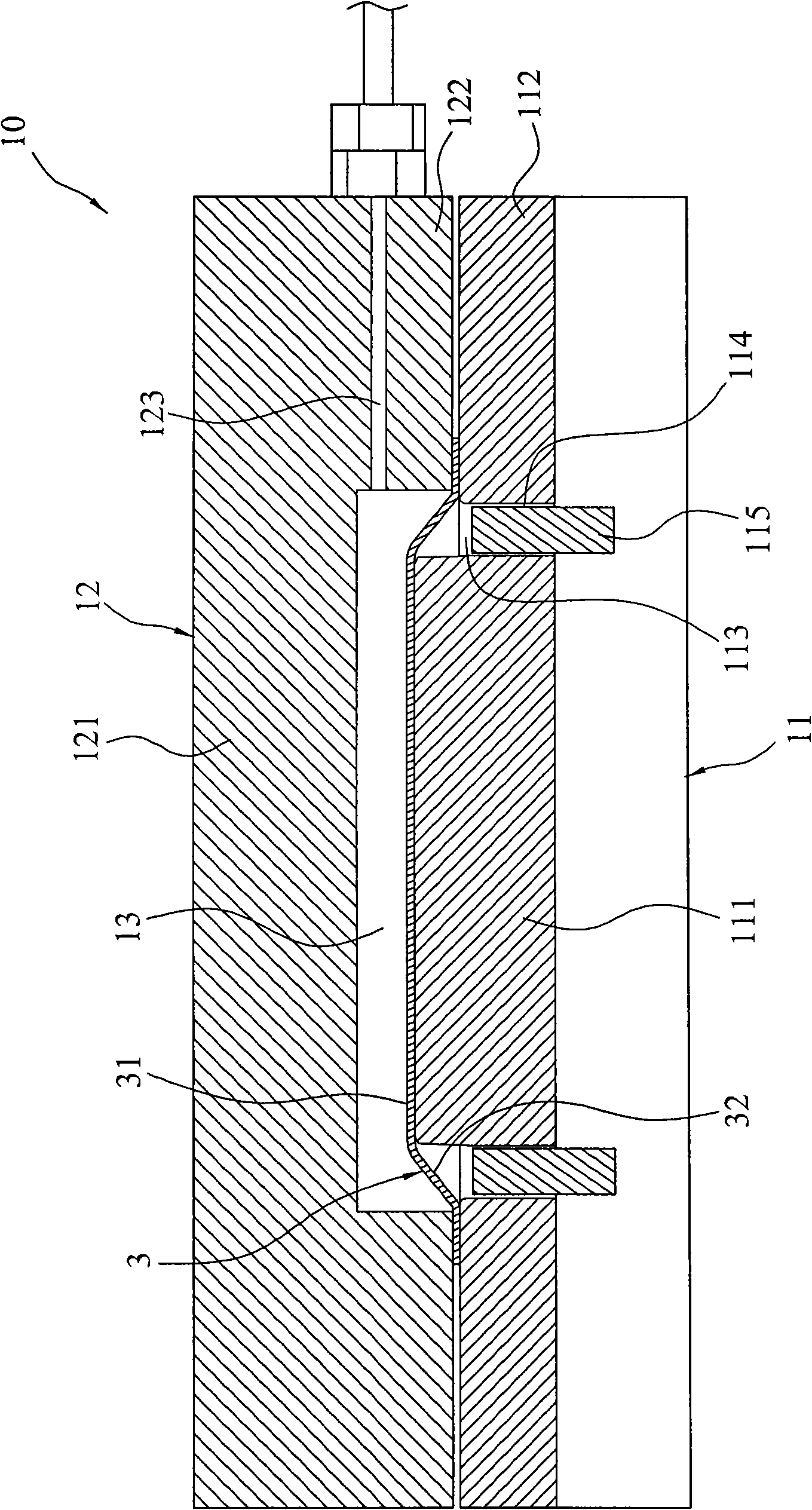

Two-section type molding method of metal plate

The invention relates to a two-section type molding method of a metal plate. The method comprise the following steps: providing a molding device comprising a die holder and a sealing die, wherein the sealing die is covered on the die holder to form a die cavity, and the sealing die is provided with a gas inlet channel communicated with the die cavity; placing the metal plate on the die holder to ensure that the circumference edge of the metal plate extends exceeding the circumference edge of the die cavity; pressing the sealing die towards the direction of the die holder and carrying out griping and a first stage of plastic molding on the metal plate; and injecting gas to the die cavity from the gas inlet channel, and pressing the metal plate for a second stage of plastic molding. . The two-section type molding method of the metal plate not only can enhance the production rate and the efficiency, but also can reduce the elastic recovery and residual stress of the metal plate.

Owner:ICHIA TECH

Forging process for forge piece

ActiveCN107282839AShort heating timeIncrease production rateHandling devicesSurface finishSurface cleaning

The invention discloses a forging process for a forge piece and aims to provide a forging process for a forge piece with high structural strength and surface smoothness. According to the technical scheme of the forging process, the forging process for the forge piece is characterized by comprising the following steps of (1) charging, (2) heating, (3) dummying, (4) die forging forming, (5) trimming , (6) heat treatment, (7) surface cleaning, (8) flaw detection and (9) inspection. The forging process is suitable for a forging machining process.

Owner:TAIZHOU YUPENG MACHINE FORGING

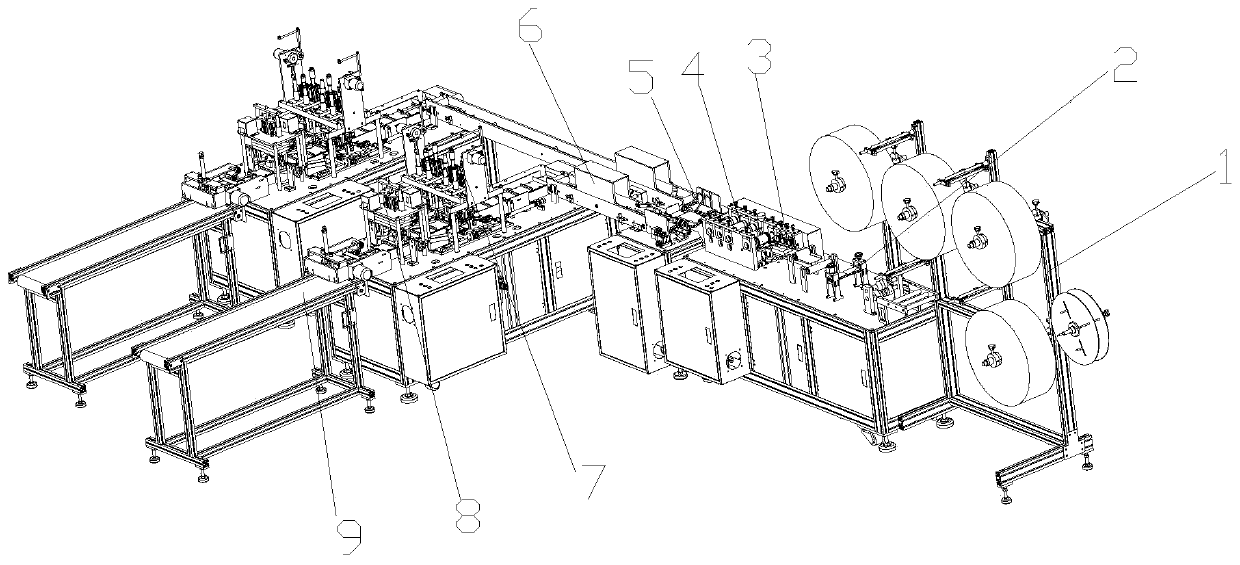

Mask production line

PendingCN111493433AReduce waiting timeIncrease production rateProtective garmentClothes making applicancesNasal bridgeUltrasonic welding

The invention discloses a mask production line, which comprises a rack, wherein the rack is sequentially provided with a placing frame, a shaping mechanism, a cutting and flanging mechanism, an ultrasonic welding and cutting-off mechanism, an edge separating mechanism, a first overturning mechanism, a second overturning mechanism, an ear belt line welding mechanism, an ear belt folding mechanism and a discharging mechanism, wherein the placing rack for placing mask cloth and a nose bridge line; the shaping mechanism is used for shaping the mask cloth; the cutting and flanging mechanism is usedfor cutting off a nose bridge strip and flanging the mask cloth; the ultrasonic welding and cutting-off mechanism is used for welding the nose bridge strip in the mask cloth and cutting off the maskcloth; the edge separating mechanism is used for separating edges of the mask; the first overturning mechanism and the second overturning mechanism are connected with the edge separating mechanism andused for overturning the mask; the ear belt line welding mechanism is connected with the first overturning mechanism and the second overturning mechanism and used for welding ear belt lines to the mask; the ear belt folding mechanism is used for hot-pressing and shaping the ear belt lines; and the discharging mechanism is used for discharging the mask. According to the mechanism, the ear belt line welding is designed into two stations, so that the reasonable distribution of the working time of each station is realized, the station waiting time during mask production is reduced, and the production rate during mask production is increased.

Owner:苏州德尔富自动化科技有限公司

Method for making artificial leather release paper in radiation curing manner

The invention discloses a method for making artificial leather release paper in a radiation curing manner. A device for making artificial leather release paper in a radiation curing manner is adopted in the method, and is sequentially provided with a first coating device, a first radiation curing device, a second curing device, a patterned roll and a second radiation curing device from an unreeling device and a reeling device, wherein the second radiation curing device covers on the patterned roll. The method comprises the following steps: (1) performing first-time coating on base paper by adopting a coating solution, and then performing first-time radiation curing to obtain the base paper on which a first coating is coated; and (2) performing second-time coating on the base paper on which the first coating is coated by adopting the coating solution, and then embossing by virtue of the patterned roll and performing second-time radiation curing to obtain the artificial leather release paper. The method disclosed by the invention comprises two procedures, and the coating solution is divided into two parts which are singly and respectively subjected to radiation curing, so that the curing rate can be improved, the travel speed is increased, and the production efficiency is improved.

Owner:浙江池河科技有限公司

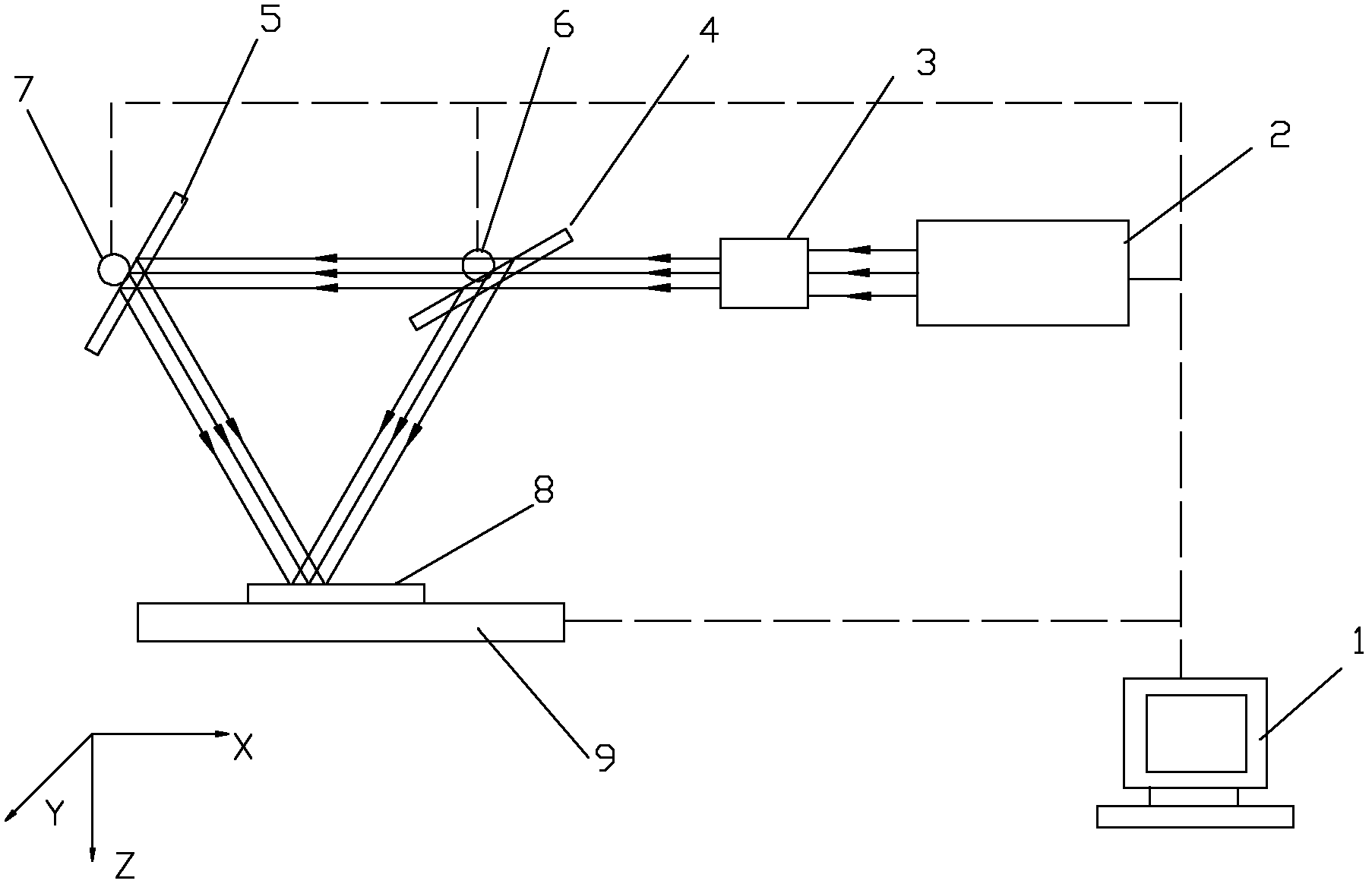

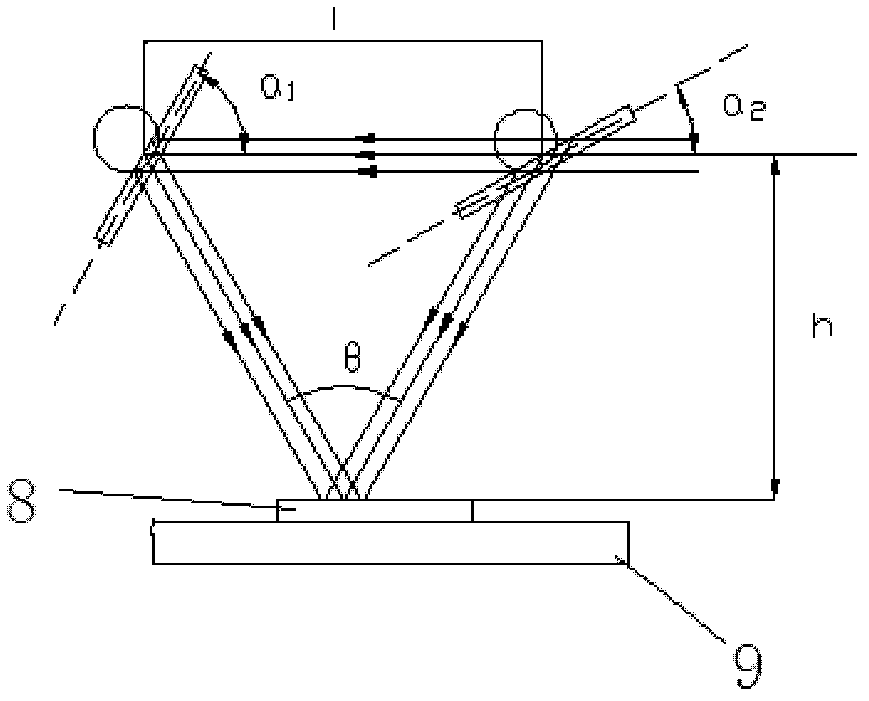

Surface microstructure-forming system based on coherent laser

InactiveCN102319959AReduce consumptionIncrease production rateLaser beam welding apparatusServomotorChemical process

The invention discloses a surface microstructure-forming system based on coherent laser. The surface microstructure-forming system based on coherent laser comprises a laser generator, a beam-shaping module, a first semireflector and a second total reflector which are sequentially connected along a light path, an electrically controlled movable operating platform is arranged under the first semireflector and the second total reflector, a matrix is placed on the electrically controlled movable operating platform, the first semireflector and the second total reflector are provided with servomotors, and the electrically controlled movable operating platform, the servomotors and the laser generator are connected with a computer. The surface microstructure-forming system based on coherent laser can ensure that melting, convection, vaporization or other physical and chemical processes can take place on the material of the specified part of the surface of the matrix, so that the surface shape of the material can be changed, and thereby a needed periodic surface can be formed; and the technical means disclosed by the invention is simple and feasible, has a positive significance, and is convenient to popularize and apply.

Owner:SOUTH CHINA UNIV OF TECH

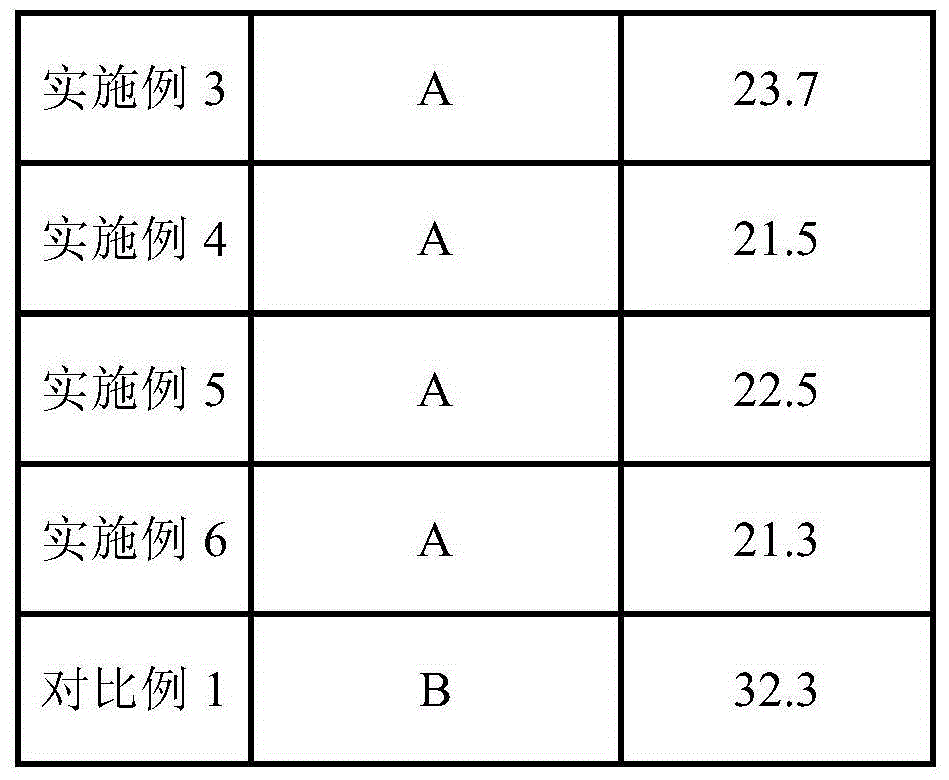

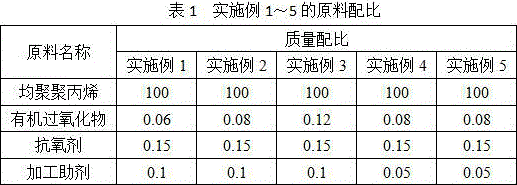

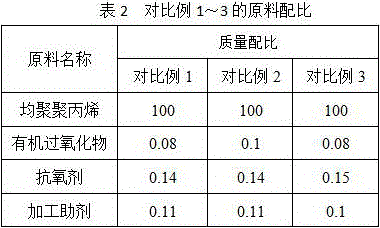

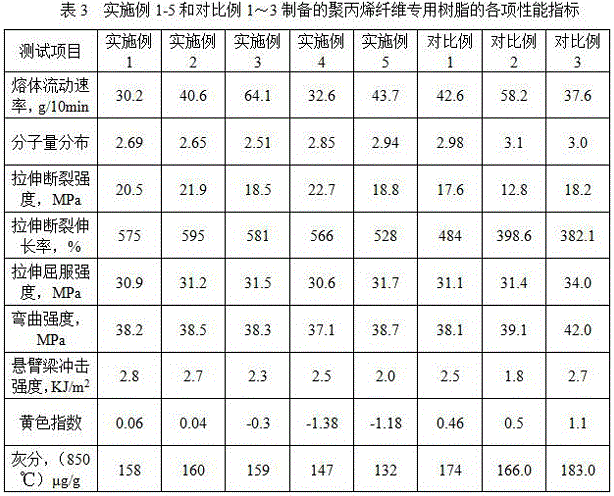

Special high-flowability resin for polypropylene fibers and preparation method thereof

ActiveCN105733093AImprove liquidityNarrow molecular weight distributionMonocomponent polyolefin artificial filamentArtifical filament manufactureProcedure AgentsPolymer science

The invention discloses a special high-flowability resin for polypropylene fibers. The resin is mainly prepared from a homopolymer polypropylene resin, organic peroxides, an antioxidant and processing aids. On the basis of the mass of the homopolymer polypropylene resin, the mass ratio of the homopolymer polypropylene resin to the organic peroxides is 100:(0.04-0.12), the mass ratio of the homopolymer polypropylene resin to the antioxidant is 100:(0.10-0.25), and the mass ratio of the homopolymer polypropylene resin to the processing aids is 100:(0.05-0.15). The special high-flowability resin for polypropylene fibers has the advantages of high melt index, narrow molecular weight distribution, excellent mechanical properties, higher elongation at break, low ash content, favorable chroma and other favorable fiber forming properties.

Owner:CHINA PETROLEUM & CHEM CORP

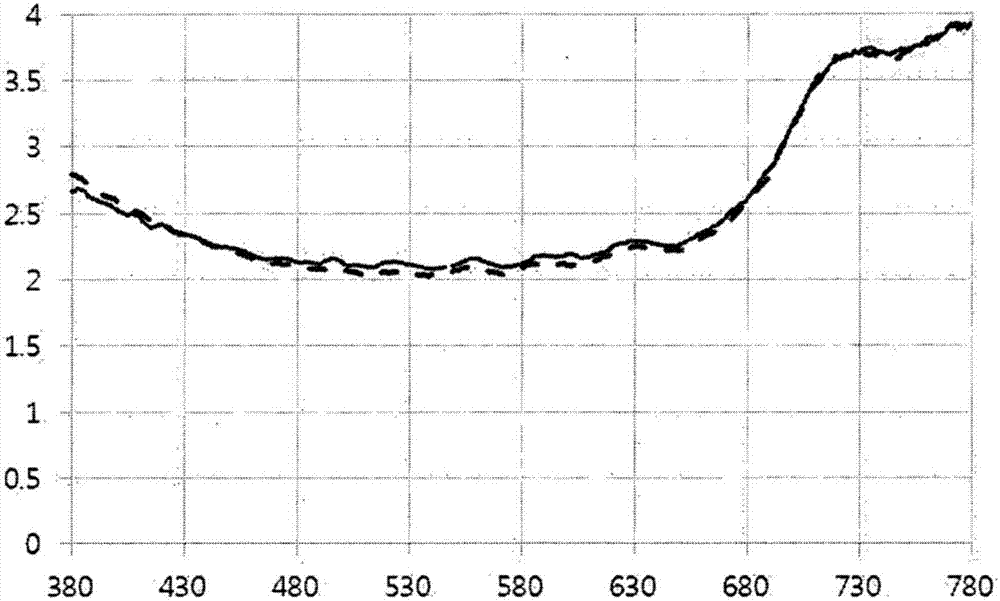

Low refractive layer and anti-reflection film comprising same

ActiveCN107110996AExcellent optical propertiesImprove reflectivityCoatingsOptical elementsProduction ratePolymer resin

The present invention relates to a low refractive layer and an anti-reflection film comprising same. The low refractive layer can exhibit both excellent optical properties, i.e. low reflectance and high light transmittance, and excellent mechanical properties, such as high abrasion resistance and scratch resistance, while having no adverse effect on the color of a polymer resin forming the low refractive layer. In particular, the low refractive layer can maintain said excellent physical properties, even after alkali treatment, due to excellent alkali resistance. Accordingly, in the case of being introduced to a display device, the low refractive layer can simplify the production process and is expected to significantly increase the production rate and output.

Owner:LG CHEM LTD

Semiconductor device and method for fabricating same

InactiveCN101661979AImprove thickness uniformityIncrease production rateSolid-state devicesSemiconductor devicesManufacturing cost reductionProduction rate

The invention discloses a semiconductor device and a method for fabricating the same. The semiconductor device comprises a semiconductor substrate, a light-emitting diode chip disposed in a cavity ofthe semiconductor substrate, at least two isolated outer wiring layers disposed on the bottom surface of the semiconductor substrate and electrically connected to the light-emitting diode chip, serving as input terminals and a lens module adhered to the top surface of the semiconductor substrate to cap the cavity, in which the lens module comprises a molded lens and a transparent conductive layercoated with a fluorescent material under the molded lens. The invention can improve the thickness uniformity of the fluorescent layer, moreover, since the fluorescent layers are formed by electrophoresis and the LED devices are packaged by a wafer level package, high production rate can be obtained and manufacturing costs can be reduced.

Owner:VISERA TECH CO LTD +1

All-directional automatic polishing machine and polishing method

PendingCN107097131AAchieve rotationRealize simultaneous processingGrinding carriagesGrinding drivesMechanical engineering

The invention discloses an all-directional automatic polishing machine and a polishing method. The polishing machine comprises a polishing frame, a lifting mechanism, a grinding disc power mechanism, a tool mechanism and a translation mechanism; the tool mechanism is arranged on the translation mechanism; the translation mechanism is arranged on the polishing frame; the bottom of the lifting mechanism is connected to the polishing frame; the translation mechanism comprises an X-axle slide table mechanism and a Y-axle slide table mechanism; the grinding disc power mechanism is connected to the side surface of the lifting mechanism through a support frame; the grinding disc power mechanism comprises a grinding disc group, a grinding disc fixing module and a transmission module; the grinding disc group is assembled on a grinding disc bearing base; the grinding disc group consists of multiple grinding disc sets; and the grinding disc sets consist of multiple unit grinding discs. Multiple grinding disc sets with different specifications are provided; rotating angles of grinding disc fixed pipes are adjusted; the grinding disc sets are used for polishing bent surfaces of workpieces; and the all-directional polishing of the surfaces of the workpieces by multiple grades of precision through the grinding disc sets with different specifications is achieved.

Owner:广东遂联智能装备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com