Dimensionally stable nonwoven fibrous webs and methods of making and using the same

A web and fiber technology, applied in the field of non-woven fiber webs, can solve the problems that non-woven webs cannot be made into the same fiber diameter, high melt viscosity, limited applications, etc., and achieve superior tensile strength and low production Effects of cost, high production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

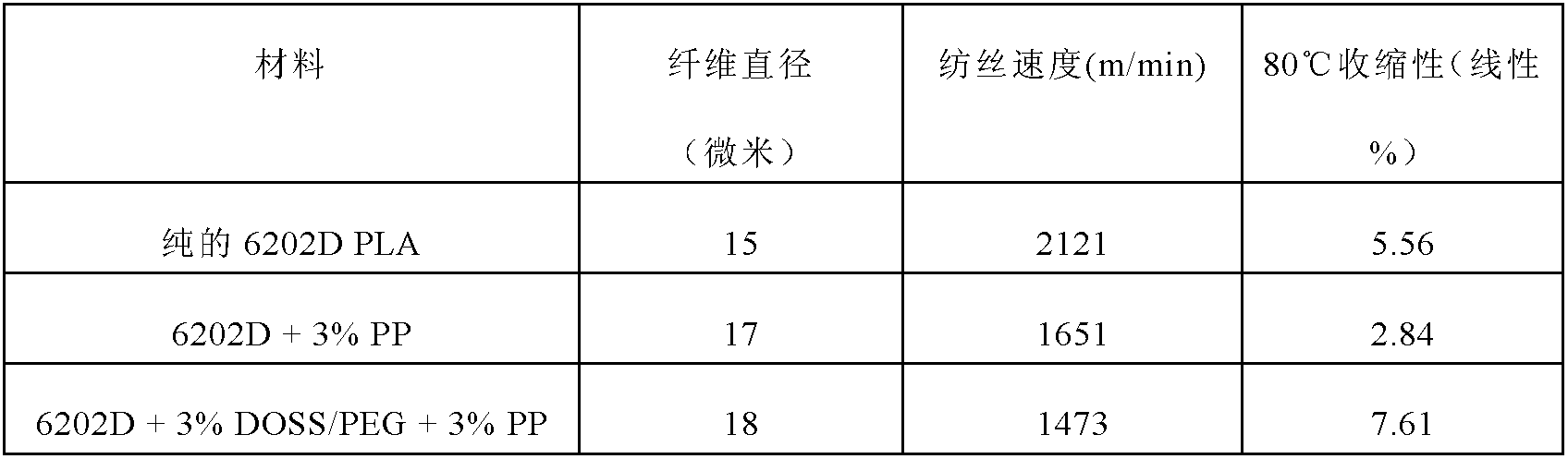

[0239] Example 1: Spunbond PLA using polypropylene .

[0240] Nonwoven webs were produced from pure polylactic acid (PLA) and blends of PLA and polypropylene (PP) using a spunbond process. The PLA used was grade 6202D from Natureworks, LLC (Minnetonka, MN). The PP used was grade 3860X from Total Petrochemicals (Houston, TX). One sample also contained a 50 / 50 mixture of dioctyl sulfosuccinate sodium salt (DOSS) and polyethylene glycol (PEG) as plasticizer, diluent and hydrophilic surfactant. The DOSS / PEG blend was compounded with 6202D PLA and added to the spunbond process as a masterbatch.

[0241] The spunbond equipment used was that described in US Patent No. 6,196,752 (Berrigan et al.). The extruder used was a 2 inch single screw extruder from Davis-Standard (Pawcatuck, CT). The die used had an effective width of 7.875 inches and was fed polymer melt from a metering pump at a rate of 42 pounds per hour. The die had 648 holes, each hole was 0.040 inches in diameter, w...

example 2

[0246] Example 2: Meltblown PLA using polypropylene

[0247] Nonwoven webs were made from polylactic acid (PLA) and polypropylene (PP) using a melt blowing process. The PLA used was grade 625 ID from Natureworks, LLC (Minnetonka, MN). The PP used was grade 3960 from Total Petrochemicals (Houston, TX).

[0248] The melt-blown device consists of a twin-screw extruder, a metering pump, and a melt-blown die. The extruder used was a 31 mm conical twin-screw extruder (C.W. Brabender Instruments (South Hackensack, NJ)). After the extruder, a positive displacement gear pump is used to meter and pressurize the polymer melt. The metered melt is sent to the drilled orifice melt blown die. Drilled orifice meltblowing dies are described in US Patent No. 3,825,380. The die used was 10 inches wide with 20 polymer orifices per inch of width, each orifice 0.015 inches in diameter. The die was run at a temperature of 225°C. Different mixtures of polymer pellets were fed into the proces...

example 3

[0252] Example 3: Meltblown PLA Utilizing Viscosity Adjusting Salt

[0253] Nonwoven webs are manufactured using the meltblown process using PLA and various salts that cause the apparent viscosity of the melt to drop significantly during processing. The fiber diameter of the finished nonwoven web was also smaller when salt was added. Polypropylene was also added to some mixtures to reduce shrinkage of the nonwoven web. The resulting web has properties of reduced fiber diameter and reduced shrinkage. The polypropylene used was grade 3960 from Total Petrochemicals (Houston, TX). The PLA used was grade 625 ID from Natureworks, LLC (Minnetonka, MN). Additives tested included:

[0254] Calcium stearoyl lactylate (CSL) (trade name: Patationic CSL from RITA Corp. (Crystal Lake, IL));

[0255] Sodium stearoyl lactylate (SSL) (trade name: Patationic SSL from RITA Corp. (Crystal Lake, IL));

[0256] Calcium stearate (Ca-S) from Aldrich (St. Louis, MO);

[0257] Sodium behenyl l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com