Gluing device for conductive aluminum foil tape processing

A technology of aluminum foil tape and gluing device, which is applied in the direction of surface coating liquid device, coating, cleaning method and utensils, etc., which can solve the problems that the aluminum foil tape cannot be coated evenly, does not have drying work, and the production efficiency is reduced. problems, to achieve the effect of improving the glue coating effect, increasing the production rate, and speeding up the drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

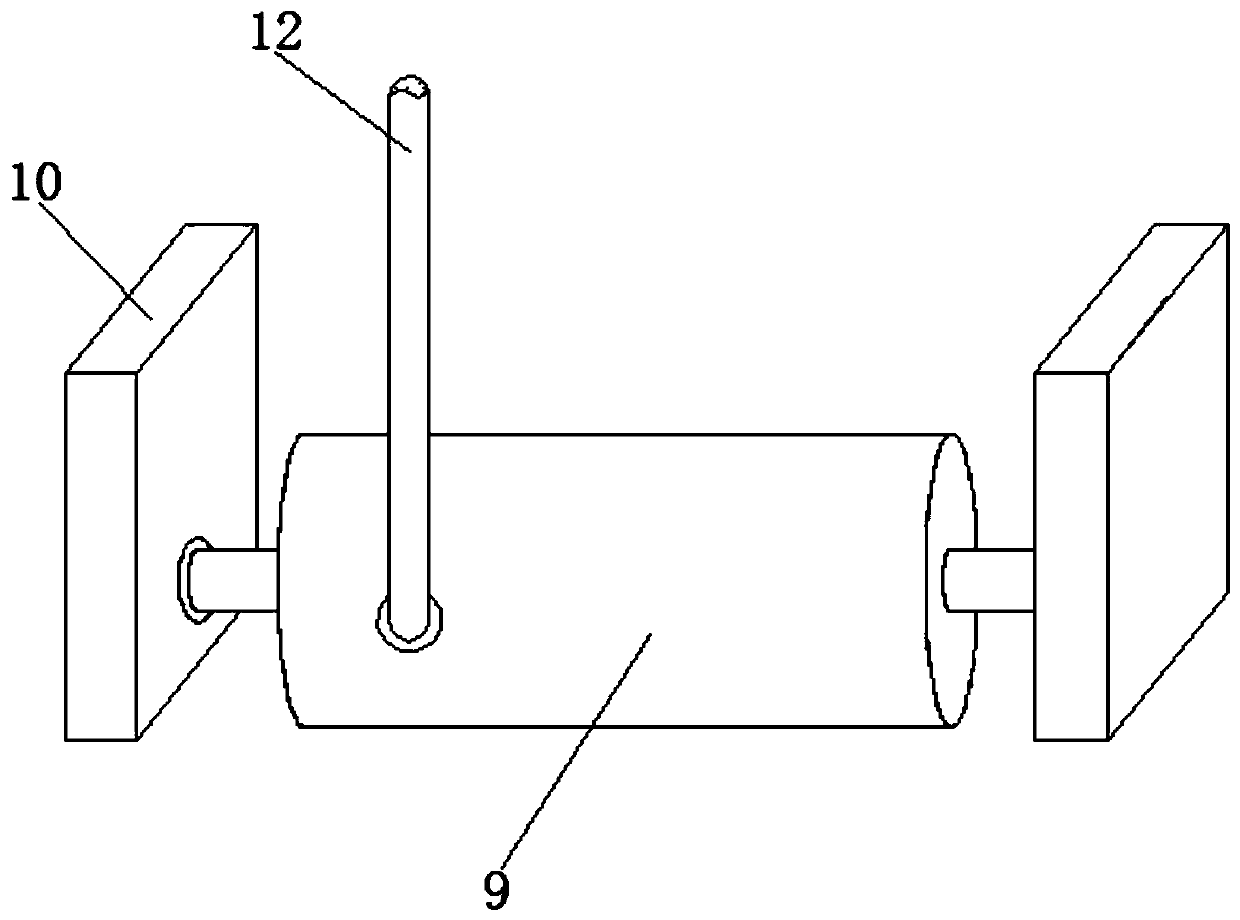

[0026] refer to Figure 1-3 , a kind of gluing device for conductive aluminum foil tape processing, comprising a box body 1, one side outer wall of the box body 1 is connected with a support plate by bolts, and the top outer wall of the support plate is provided with a winding roller 7, and the outer wall of the winding roller 7 The aluminum foil tape body 6 is wound, the top outer wall of the box body 1 is connected with a storage box 13 by bolts, and a bellows 12 is plugged into one side of the outer wall of the storage box 13, and the top inner wall of the box body 1 is connected by a second bolt. Electric push rod 11, and the outer wall of one end of the second electric push rod 11 is welded with a second mounting plate, the bottom outer wall of the second mounting plate is connected with the second fixing plate 10 by bolts, and one side of the outer wall of the second fixing plate 10 passes through Glue roller 9 is connected with the bolt, and the bottom outer wall of glu...

Embodiment 2

[0030] refer to Figure 4 , a gluing device for conductive aluminum foil tape processing. Compared with Embodiment 1, the outer wall of one side of the box body 1 is connected with a blower 18 by bolts, and the outer wall of one side of the blower 18 is plugged with an air outlet pipe. The outer wall of one end of the air outlet pipe is plugged with a heating box 20, and the inside of the heating box 20 is provided with a resistance wire. An air outlet bucket 19 is threadedly connected to the inner wall of one end of the air guide pipe 21 .

[0031] Working principle: when in use, pass the aluminum foil tape body 6 through the rectangular slot 8, and before the device applies glue to the aluminum foil tape body 6, the brush plate 4 can be used to remove dust from the aluminum foil tape body 6 to avoid the aluminum foil tape There is a lot of dust on the surface of the main body 6, which affects its gluing work and gluing effect, and then the first electric push rod 14 is star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com