Kitchen waste and sludge hydrogen-producing acidification pretreatment method capable of increasing methane production rate

A technology for kitchen waste and pretreatment, which is applied in biological sludge treatment, microorganism-based methods, biochemical equipment and methods, etc. The effect of increasing the production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

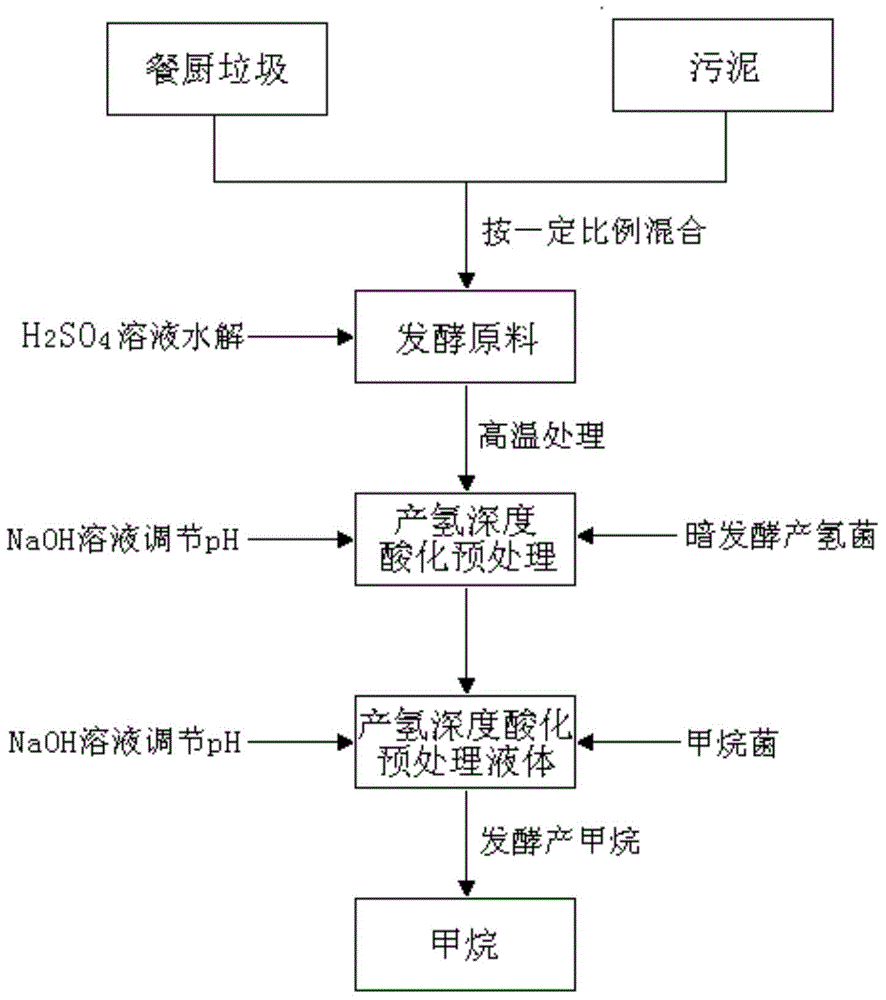

Image

Examples

Embodiment 1

[0027] After the food waste and sludge are pulverized and pretreated, they are mixed according to a mass ratio of 1:1 to obtain pretreated raw materials. Then with 1% H 2 SO 4 The solution is prepared into a mixed solution with a pretreatment raw material concentration of 20g / L, and the mixed solution is hydrolyzed at a high temperature of 135°C for 15 minutes to obtain a fermented raw material; 200ml of fermented raw material is added to a fermentation bottle with a volume of 600ml. NaOH adjusted the pH of the mixture to 6.4. Add 0.2g of yeast powder, inoculate 20ml of dark fermentation hydrogen-producing bacteria, pass high-purity nitrogen gas for 20 minutes to create an anaerobic fermentation environment, and then carry out deep acidification pretreatment of dark fermentation hydrogen production at a constant temperature of 37°C; dark fermentation hydrogen production bacteria are collected from anaerobic digestion The sludge is separated, and the sludge is heated to kill ...

Embodiment 2

[0030] After the food waste and sludge are pulverized and pretreated, they are mixed according to a mass ratio of 1:1 to obtain pretreated raw materials. Then with 1% H 2 SO 4The solution is prepared into a mixed solution with a pretreatment raw material concentration of 25g / L, and the mixed solution is hydrolyzed at a high temperature of 135°C for 15 minutes to obtain a fermentation raw material; 300ml of the high-temperature-treated mixed solution is added into a 600ml fermentation bottle, and the mass concentration is The pH of the mixed solution was adjusted to 6.5 by 6mol / L NaOH. Add 0.3g of yeast powder, inoculate 30ml of dark fermentation hydrogen-producing bacteria, pass high-purity nitrogen gas for 20 minutes to create an anaerobic fermentation environment, and then carry out deep acidification pretreatment of dark fermentation hydrogen production at a constant temperature of 37°C; dark fermentation hydrogen production bacteria are collected from anaerobic digestion ...

Embodiment 3

[0033] After the food waste and sludge are pulverized and pretreated, they are mixed according to a mass ratio of 1:1 to obtain pretreated raw materials. Then with 1% H 2 SO 4 The solution is prepared into a mixed solution with a pretreatment raw material concentration of 30g / L, and the mixed solution is hydrolyzed at a high temperature of 135°C for 15 minutes to obtain a fermentation raw material; 500ml of the high-temperature-treated mixed solution is added to a fermentation bottle with a volume of 600ml, and the mass concentration is The pH of the mixed solution was adjusted to 6.6 by 6mol / L NaOH. Add 0.5g of yeast powder, inoculate 50ml of dark fermentation hydrogen-producing bacteria, pass high-purity nitrogen gas for 20 minutes to create an anaerobic fermentation environment, and then carry out deep acidification pretreatment of dark fermentation hydrogen production at a constant temperature of 37°C; dark fermentation hydrogen production bacteria are collected from anae...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com