Genetic engineering strain, construction method and application in xylitol production

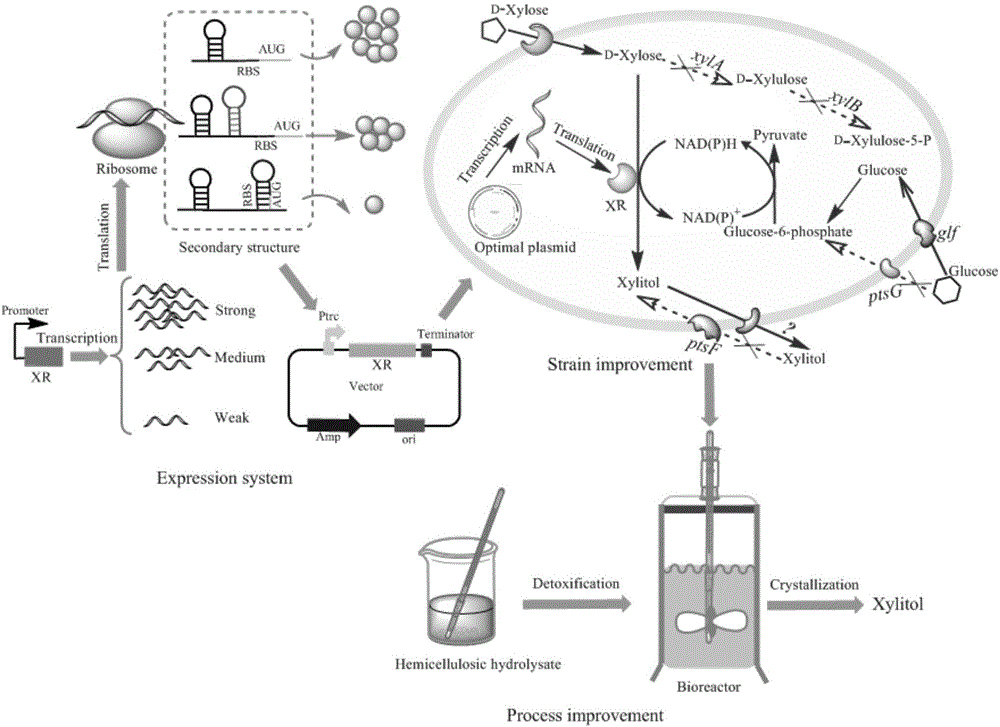

A genetically engineered bacteria and genetic technology, applied in the field of genetic engineering and biology, can solve the problems of xylose reductase catalytic efficiency, cell growth rate reduction, etc., to achieve the effects of increased production rate, recovery of growth defects, and reduced utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0185] Embodiment 2 utilizes the example of engineering bacterium HK402 to produce xylitol

[0186] 1. Engineering bacteria use corncob hemicellulose hydrolyzate to produce xylitol

[0187] In order to verify whether the constructed engineering bacteria can utilize hemicellulose hydrolysis to produce xylitol, the engineering bacteria HK402 was used to carry out shake flask fermentation (250ml, liquid volume is 50ml).

[0188] (1) Inoculate the overnight seed medium with engineering bacteria HK402 at 2%, and cultivate it at 30°C for 8 hours to obtain the seed solution;

[0189] The formula of seed medium and fermentation medium is: 1L of medium contains 4-6g Na 2 HPO 4 ,2~5g KH 2 PO 4 ,1~2g NH 4 Cl, 1~5g NaCl, 1~5mM MgSO 4 ,1~5mM CaCl 2 , 2-10g / L yeast extract.

[0190] (2) Concentrate the hemicellulose hydrolyzate with a rotary evaporator until the xylose content is 20%-50%, sterilize the concentrated hemicellulose hydrolyzate and add it to the sterilized fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com