Roller wheel mark rubbing device for mark sticking machine

A labeling machine and roller technology, applied in labeling machines, labels, packaging, etc., can solve problems such as difficulty in completion, impact, and poor labeling effect, and achieve simple structure, high labeling quality, and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

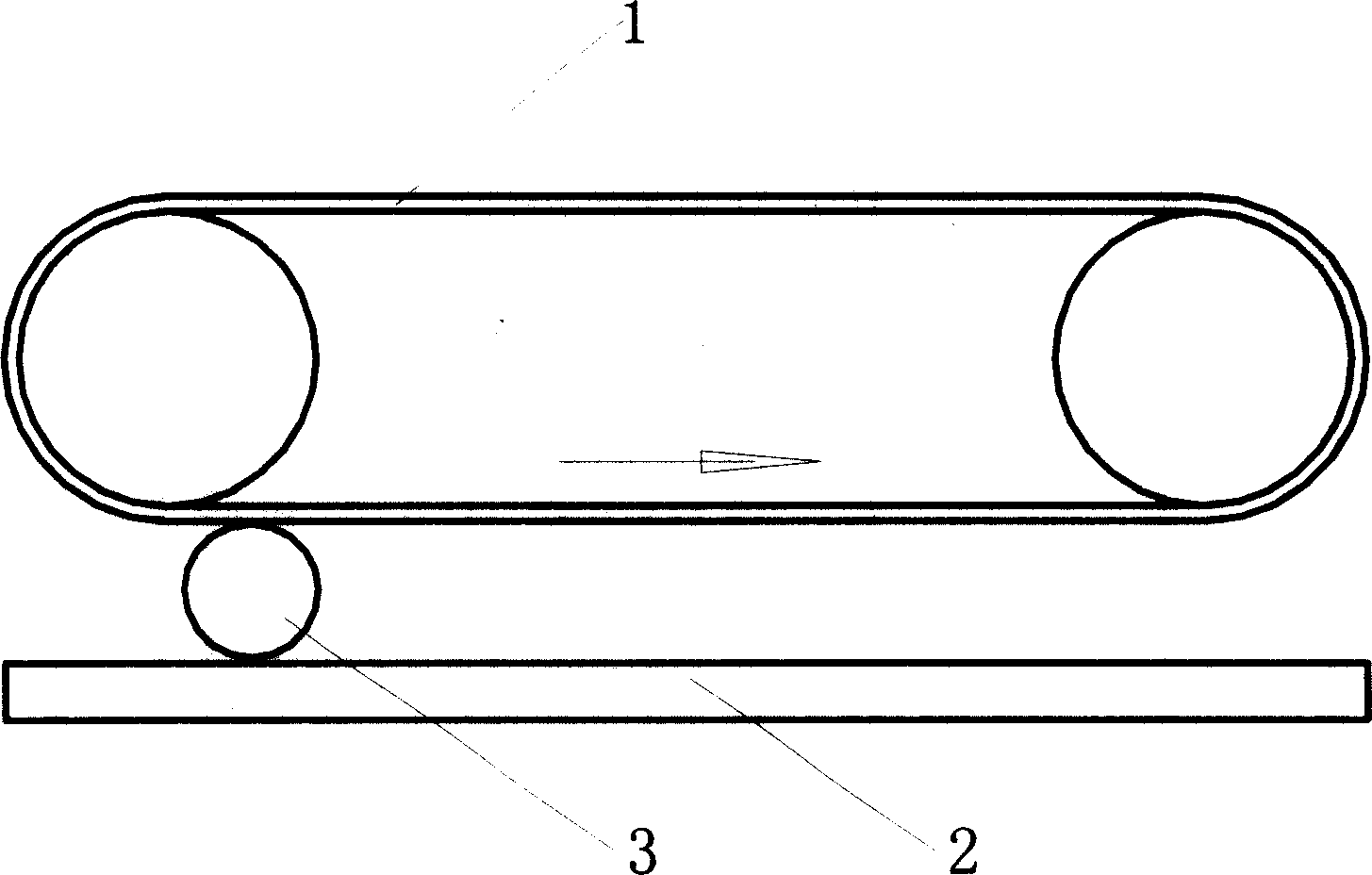

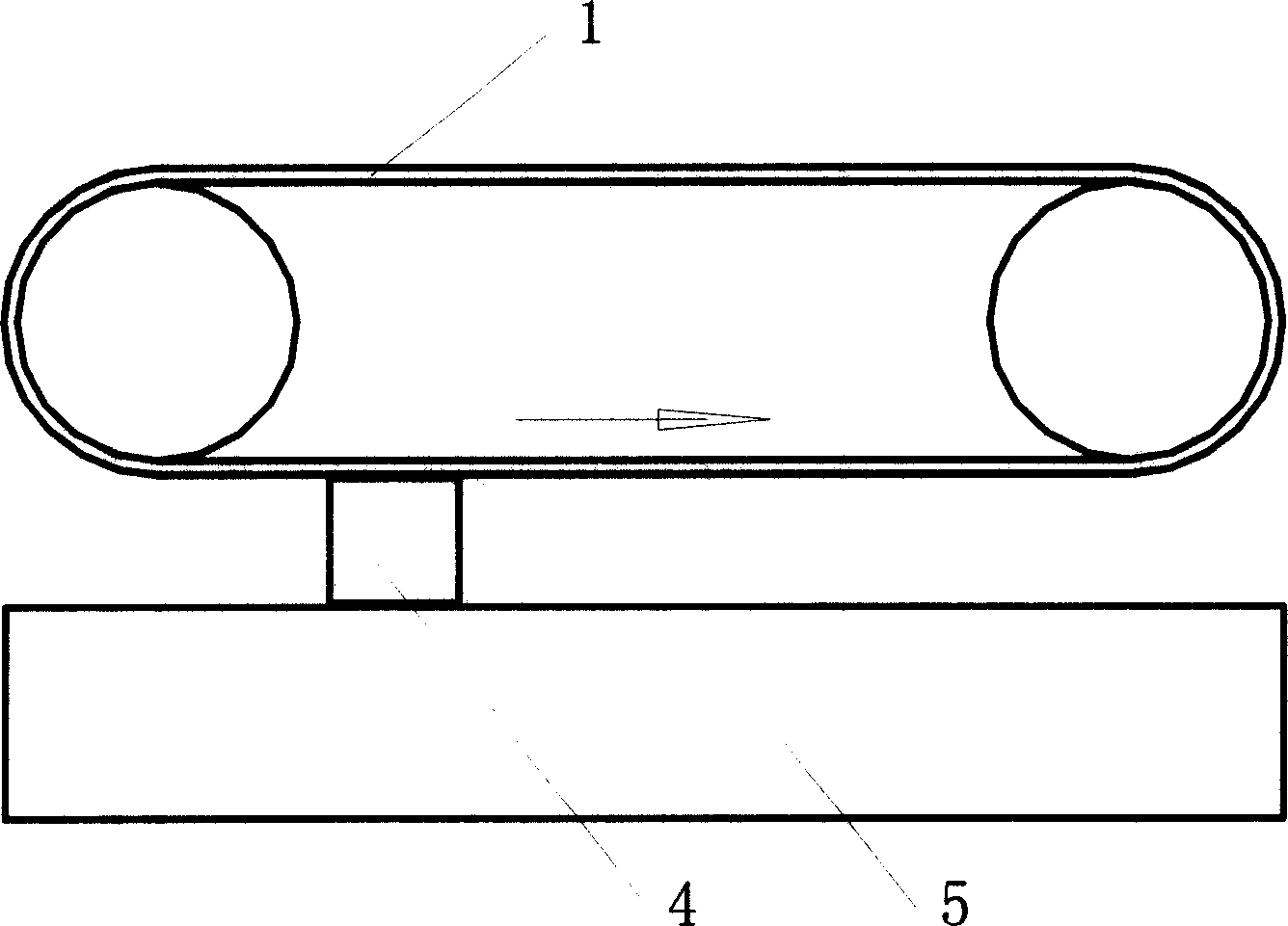

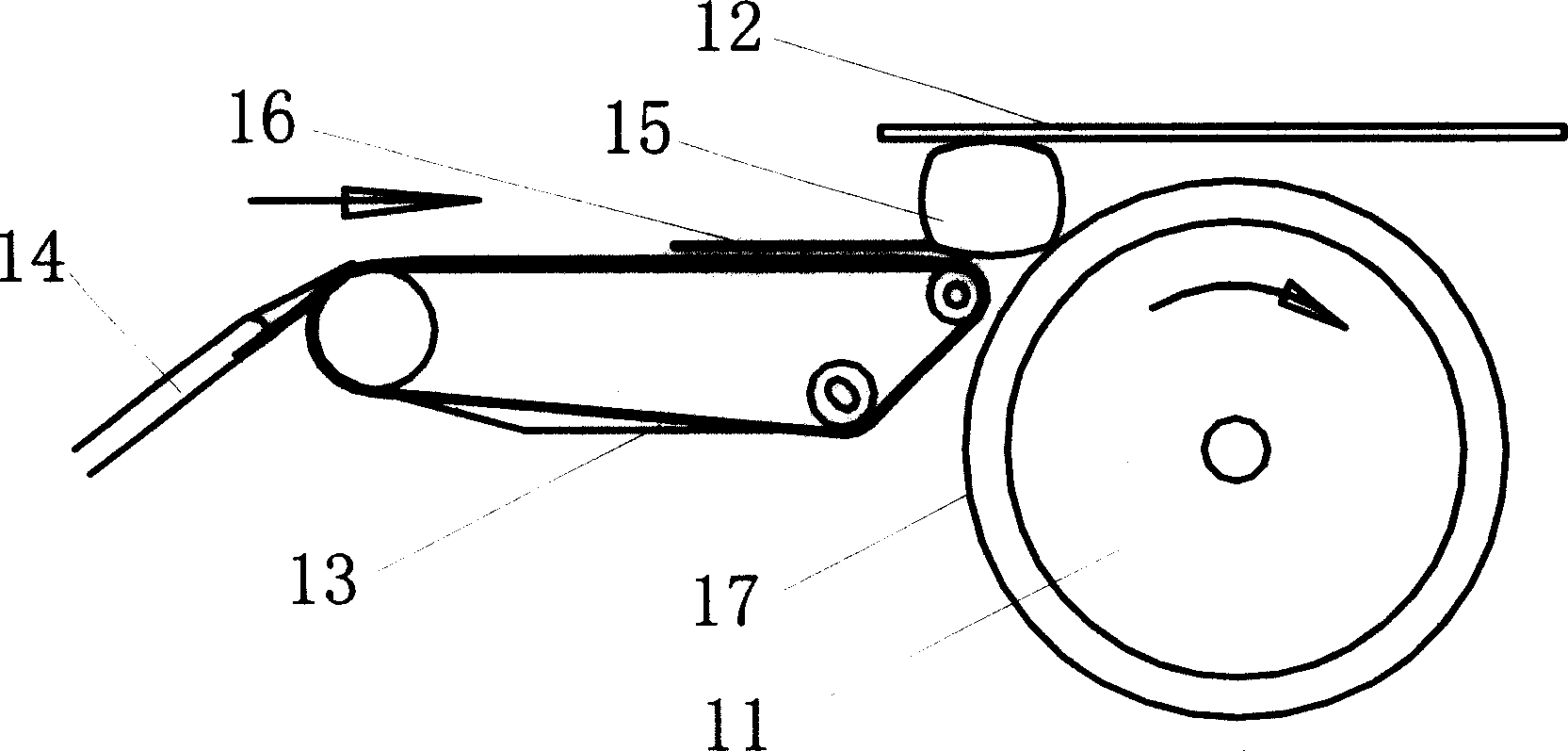

[0017] refer to image 3 , Figure 4 , the roller rubbing device of labeling machine, comprises a larger roller 11 and push plate 12, and push plate 12 is positioned at the working opposite of roller 11, and the outer surface of roller 11 is flexible material layer 17, and flexible material layer 17 is the rubber material that has been vulcanized in advance and has been finely ground. The circular runout error is not more than 0.02mm, and the end face runout error is not more than 0.03mm. The roller 11 is installed on the labeling machine through two precision bearings (omitted in the figure). The device only rotates around a fixed axis, and has undergone strict dynamic balance calibration, and runs smoothly. In addition, the roller 11 is a whole, and there is no phenomenon of deviation. The outer diameter of the larger roller 11 is between φ200mm-φ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com