Method and device for labelling containers with stretch sleeves

A label sleeve and labeling technology, which is applied in the direction of labeling and labeling short rigid containers, labels, etc., can solve the problems that the compressed air output cannot be coordinated accurately enough, and the container cannot be grasped and lifted correctly, so as to improve the reliability Reproducibility, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

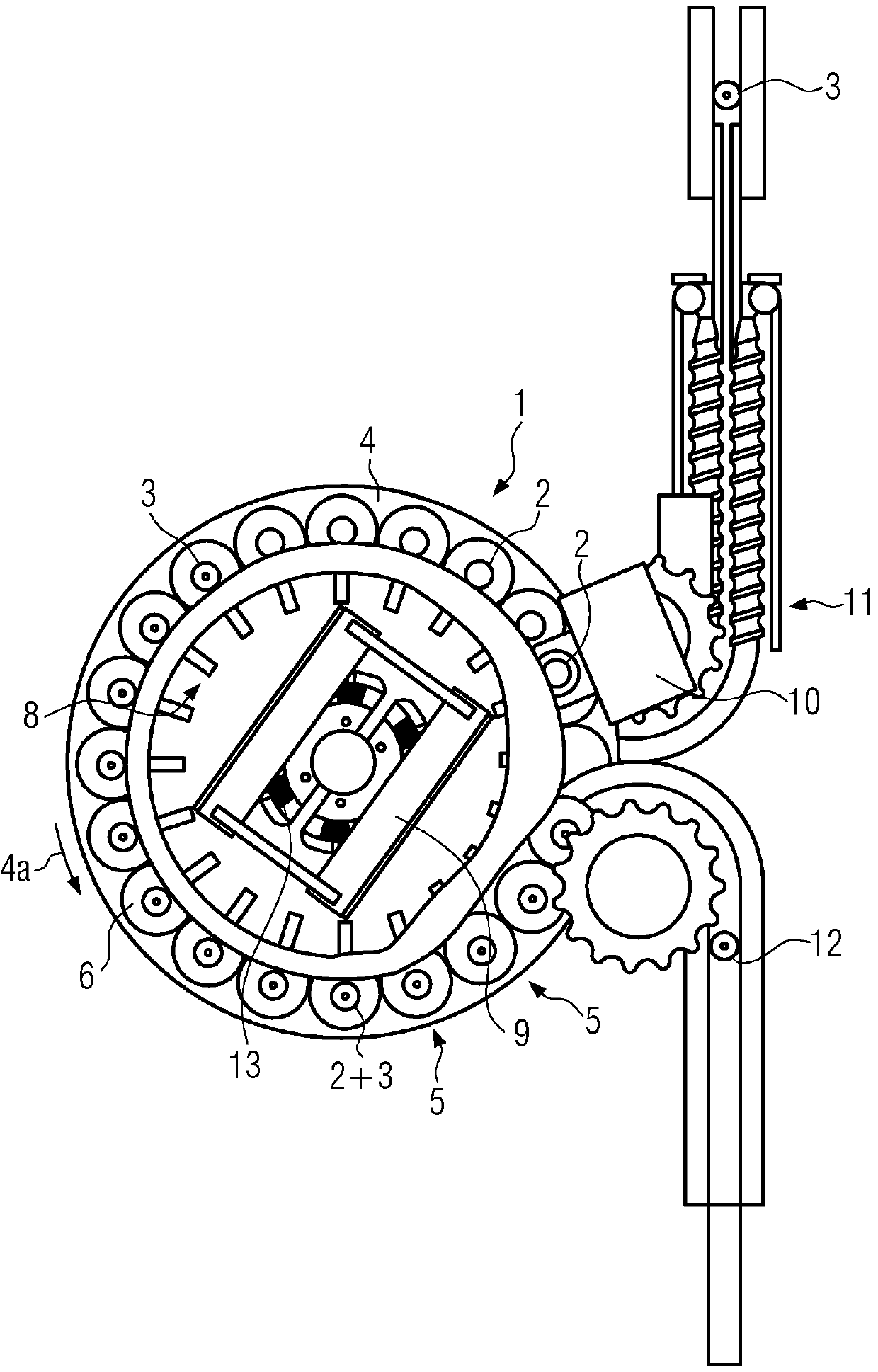

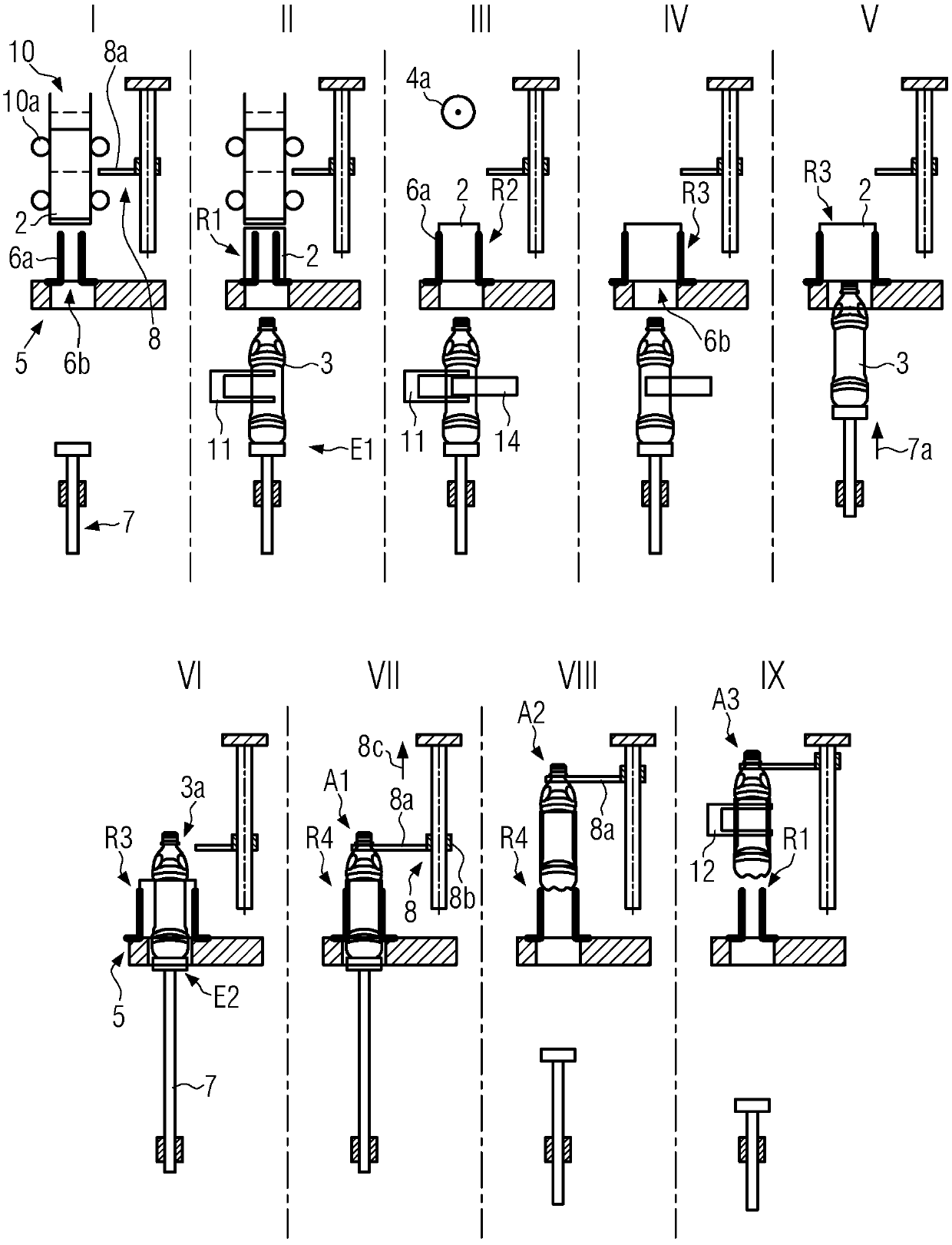

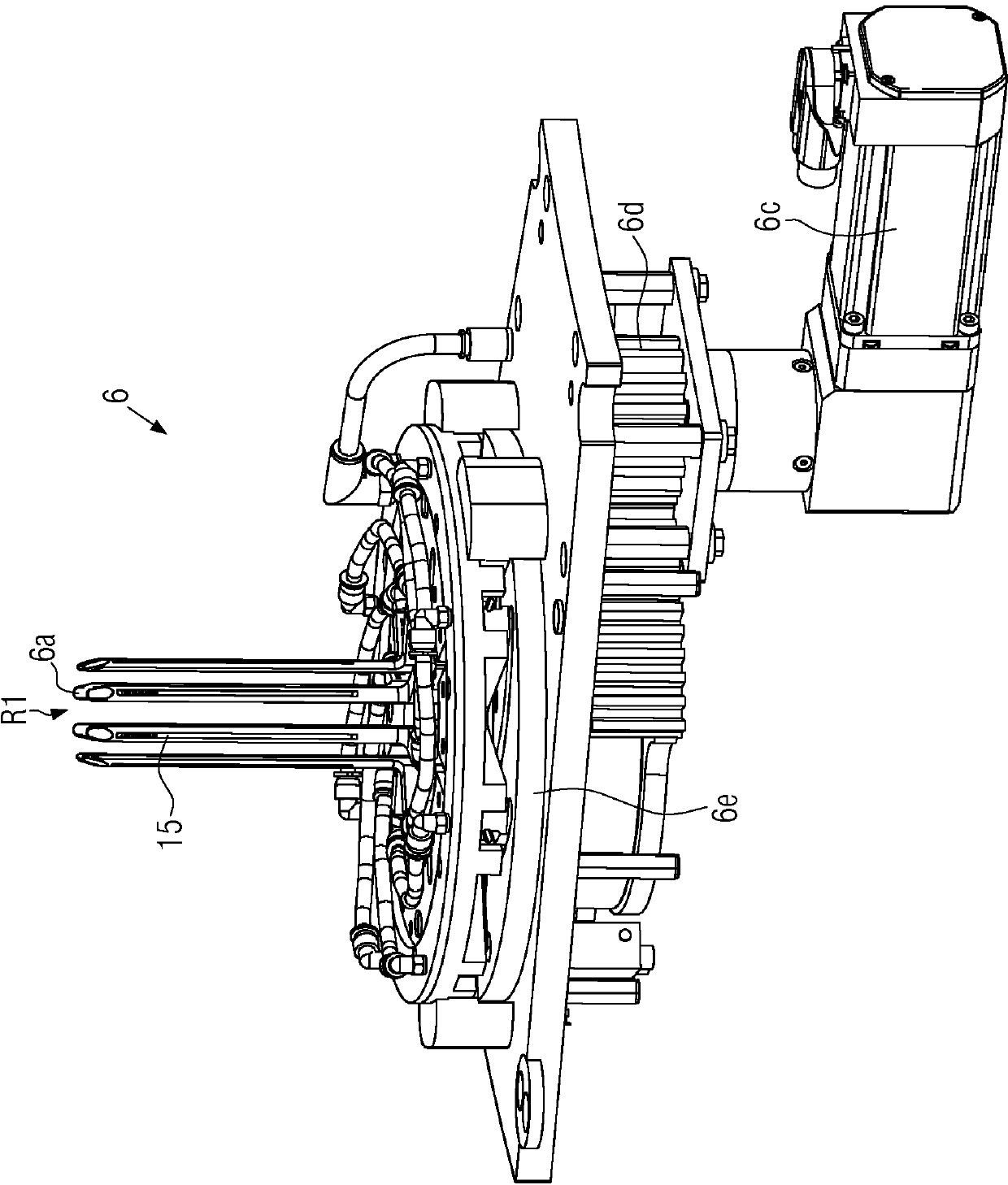

[0032] Depend on figure 1 and figure 2 It can be seen that a preferred embodiment of the labeling device 1 according to the invention for applying elastic label sleeves 2 to containers 3, such as plastic bottles, comprises a labeling wheel 4 on which labeling wheels are arranged uniformly distributed along the circumference. Station 5. These labeling stations each comprise a spreading unit 6 for receiving and spreading the label sleeve 2, a positioning unit 7 for receiving and lifting the container 3 to be labeled into the spreading unit 6, and an open side for gripping the container 3 Section 3 a and extraction unit 8 for pulling container 3 out of expansion unit 6 .

[0033] figure 1 Also shown in the figure are the handling unit 9, the label dispenser 10, the inlet starwheel 11 for inputting the containers 3 to be labeled, the outlet starwheel 12 for outputting the labeled containers 3 and the Open unit 6 to supply valve group 13 for vacuum or compressed air. exist f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com