Automatic weighing, code scanning and labeling equipment

An automatic weighing and labeling technology, applied to the detailed information of weighing equipment, weighing auxiliary equipment, labels, etc., can solve the problems that the efficiency cannot meet the production needs, the labeling accuracy and quality requirements cannot be guaranteed, and the labeling can be achieved. The effect of good quality, high work efficiency and accurate weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

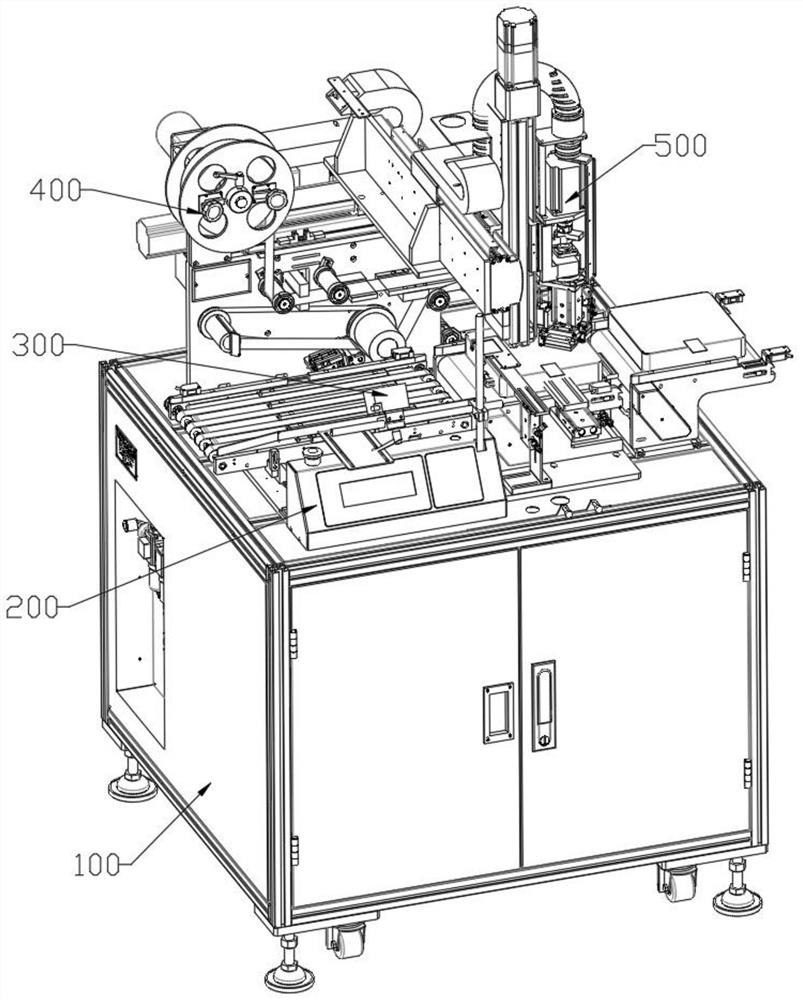

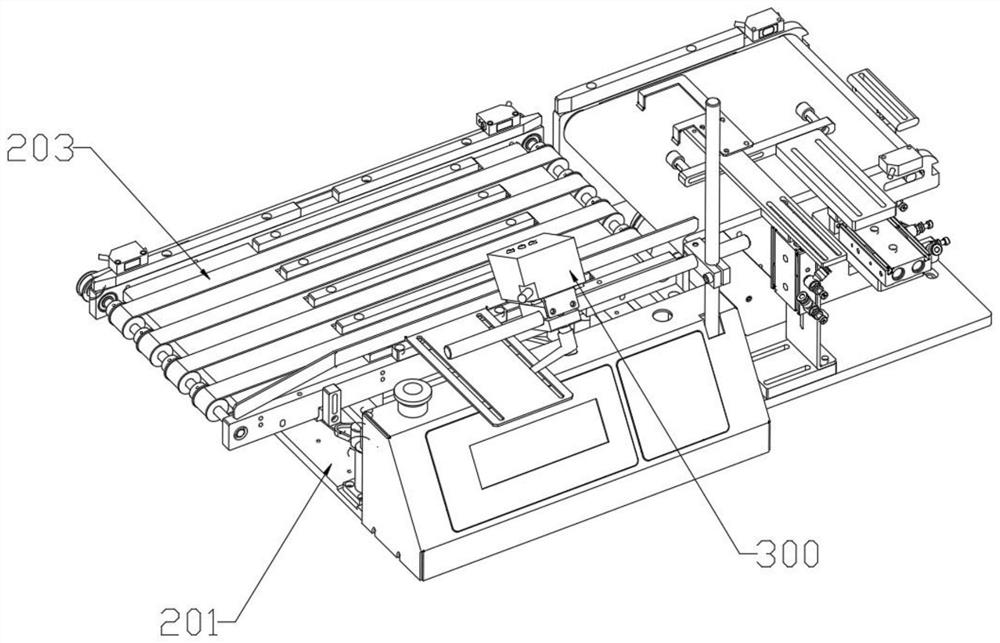

[0038] like Figure 1 to Figure 11 As shown, an automatic weighing code scanning and labeling equipment includes a frame 100, and also includes a weighing mechanism 200, a code scanning mechanism 300, a label stripping mechanism 400, and a labeling mechanism 500 all arranged on the frame 100. And the runner mechanism 600;

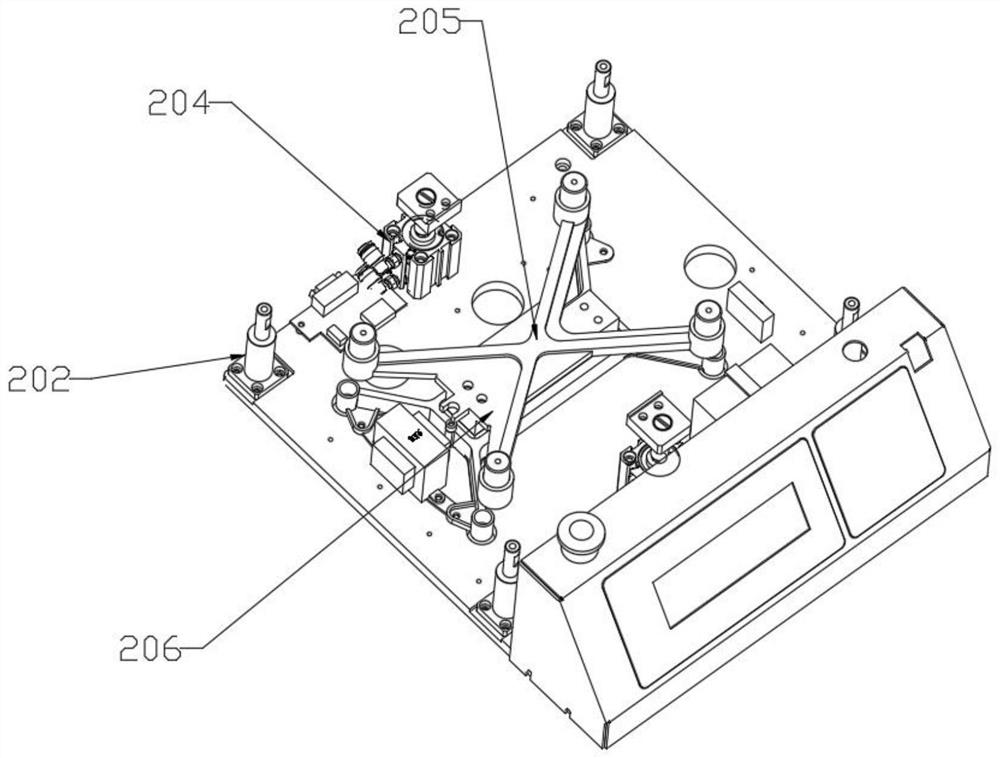

[0039]The weighing mechanism 200 includes a weighing device 201, a linear bearing 202, a weighing conveyor belt 203, a lifting drive device 204, and a weighing support block 205, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com