Automatic tag removing and labeling machine

An automatic and labeling technology, applied in labeling machines, labels, packaging, etc., can solve the problems of small application range, low labeling efficiency, and large space occupation, and achieve wide application range, good labeling quality, and The effect of high standard efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

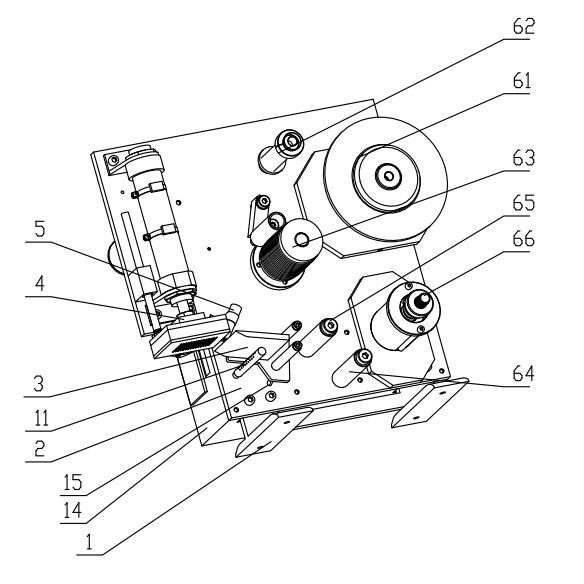

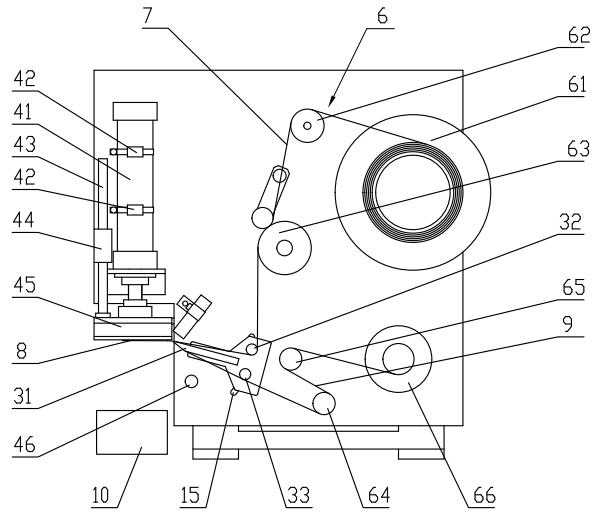

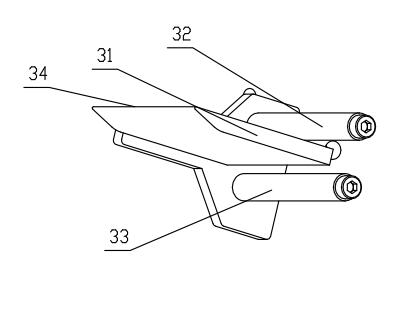

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, the present invention includes a label peeling device 3 , a labeling device 4 and a label tape feeding device 6 , which are installed on the mounting panel 2 on the support base 1 . The labeling cylinder 41 of the labeling device 4 is vertically installed on one side of the installation panel 2, the cylinder body of the labeling cylinder 41 is provided with a magnetic switch 42 up and down, and the labeling head 45 is fixedly connected to the piston of the labeling cylinder 41. On the rod, the bottom surface of the labeling head 45 is provided with an adsorption plate with a small hole that communicates with the vacuum pipeline; the positioning rod 43 is parallel to the labeling cylinder 41, and the root is fixed on the upper surface of the labeling head 45, and the rod is connected to the mounting panel. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com