Method of manufacturing color metal zipper and apparatus therefor

A technology of colored metal and metal, applied in the field of forming of colored metal zippers and its devices, can solve problems such as cracks, lack of rigidity, uneven color treatment, etc., and achieve the effect of high color prominence and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

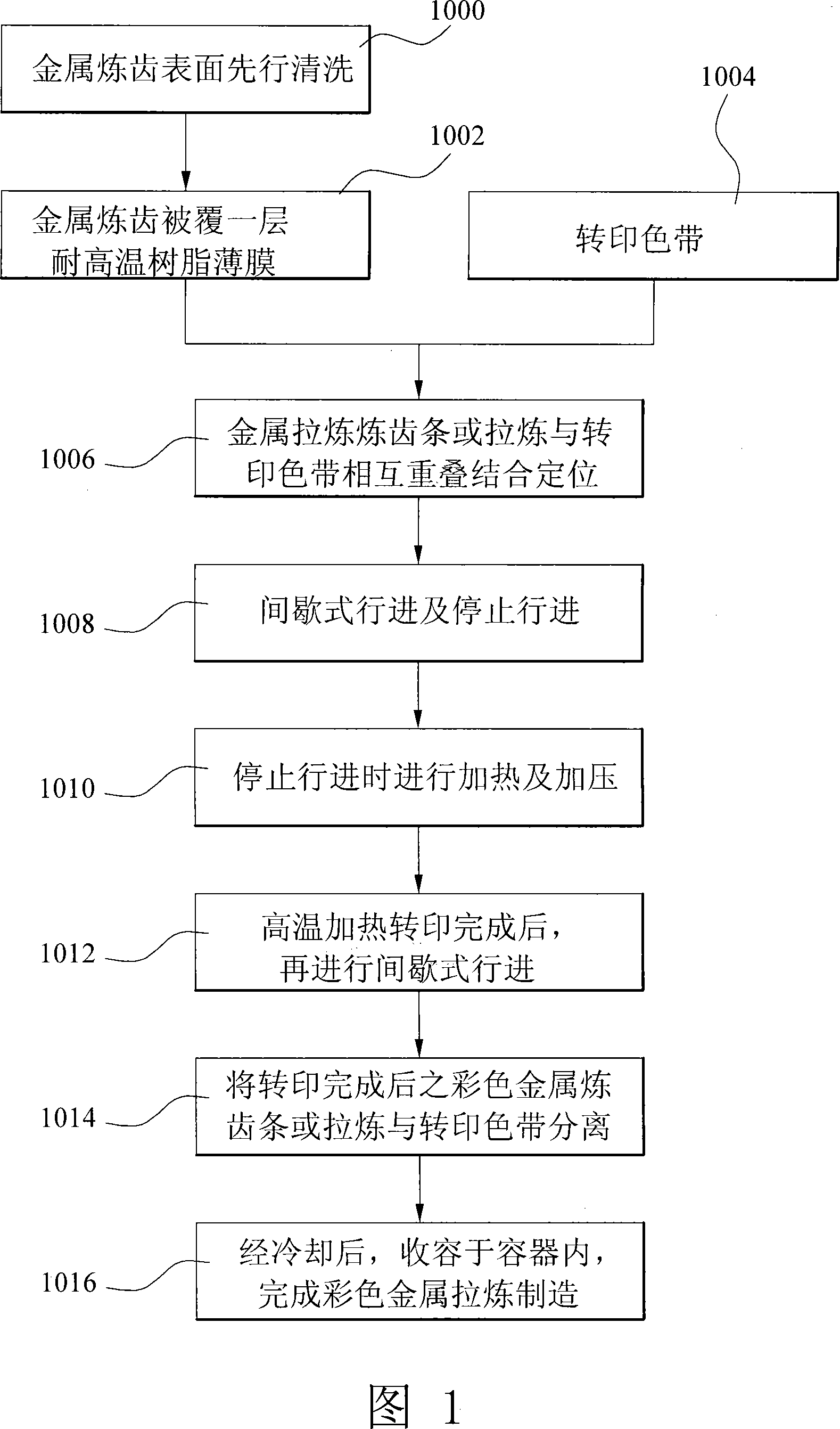

[0083] Please refer to FIG. 1 , which is a production flow chart of the method for forming colored zippers and teeth of the present invention. As shown in the figure: the forming method of the color zipper of the present invention and refining teeth, its steps comprise:

[0084] In a lamination step:

[0085] Provide a metal smelting rack or squeegee, preferably a continuous metal smelting rack or squeegee. First, the surface of the metal smelting gear is cleaned with a cleaning process and cleaning material, as in step 1000; then, in step 1002. Coat the surface of the above-mentioned cleaned metal tines with a high-temperature-resistant surface film, preferably a surface film that can withstand above 180°C, such as a group of resin-based materials. Any one of the best resin materials such as epoxy resin or similar;

[0086] In a material combination step:

[0087] Provide a transfer ink ribbon, as in step 1004, the above-mentioned transfer ink ribbon is a continuous belt-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com