Method for forming isotropic neodymium-iron-boron magnet

An isotropic, NdFeB technology, applied in the field of forming isotropic NdFeB magnets, can solve problems such as oxidation, high organic content, and imperfect binder system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

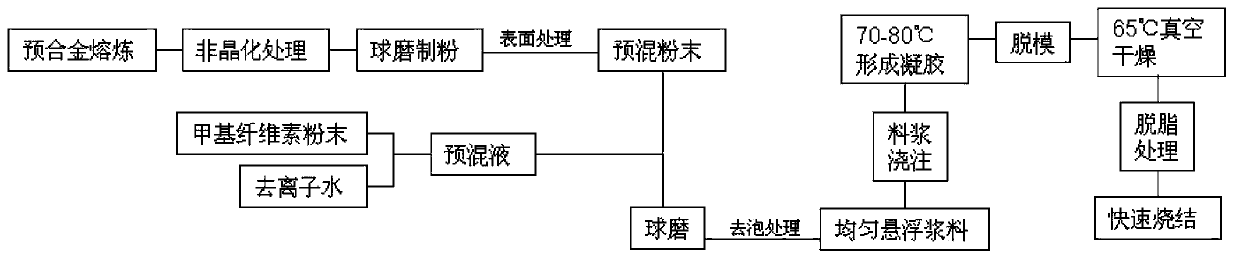

Method used

Image

Examples

Embodiment

[0031] A specific embodiment of the present invention will be described in more detail below by means of an example.

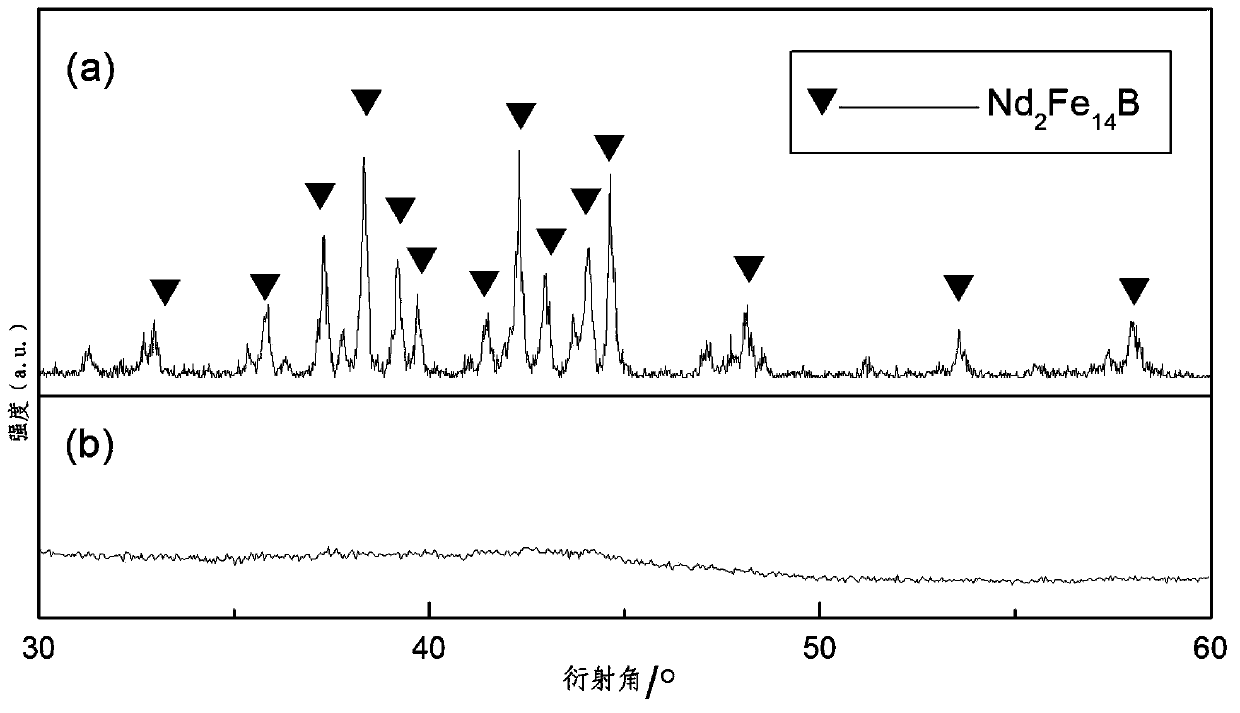

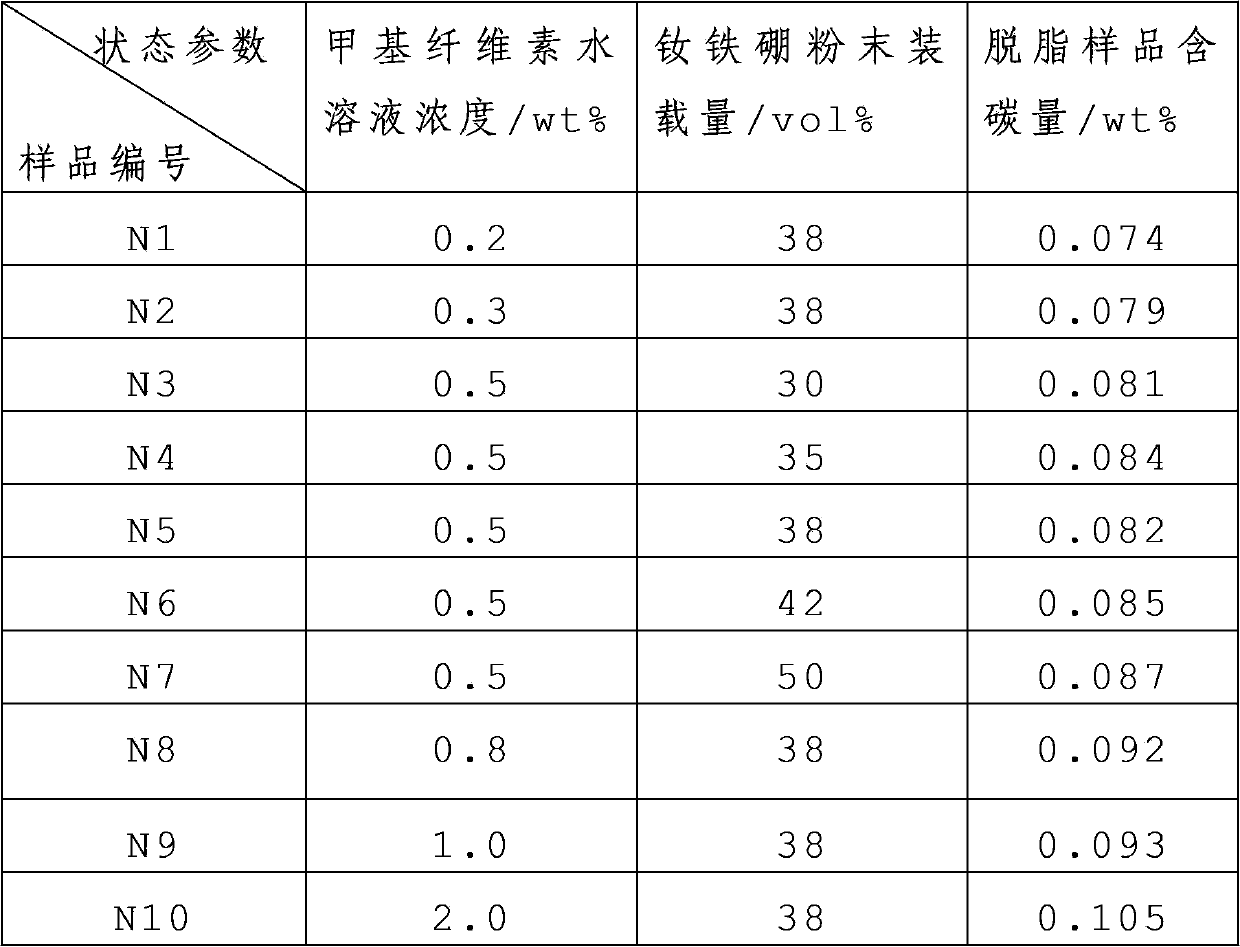

[0032] The pre-alloyed ingot was prepared by arc vacuum melting process, and the melting formula was: industrial grade pure iron, niobium, and neodymium were 62g, 2.8g, and 32g respectively, and the boron content was 4.9g of ferroboron with a boron content of 20.21wt%, and the atomic composition was Nd. 14 Fe 78 Nb 2 B 6 pre-alloyed ingots. The pre-alloyed ingot was subjected to vacuum remelting and quick quenching treatment to obtain quick quenching strip fragments. The selected equipment was a single copper roller rapid condensation furnace, and the surface speed of the copper roller was 37m / s. Mix the obtained quick-quenching belt fragments with an appropriate amount of alcohol, put them into an ordinary ball mill for ball milling for 4 hours, the speed of the ball mill is 65r / min, and the weight ratio of grinding steel balls to quick-quenching belt frag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com