Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88 results about "Atomic composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition of the Atom. The atom consists of a tiny nucleus surrounded by moving electrons. The nucleus contains protons, which have a positive charge equal in magnitude to the electron's negative charge. The nucleus may also contain neutrons, which have virtually the same mass but no charge.

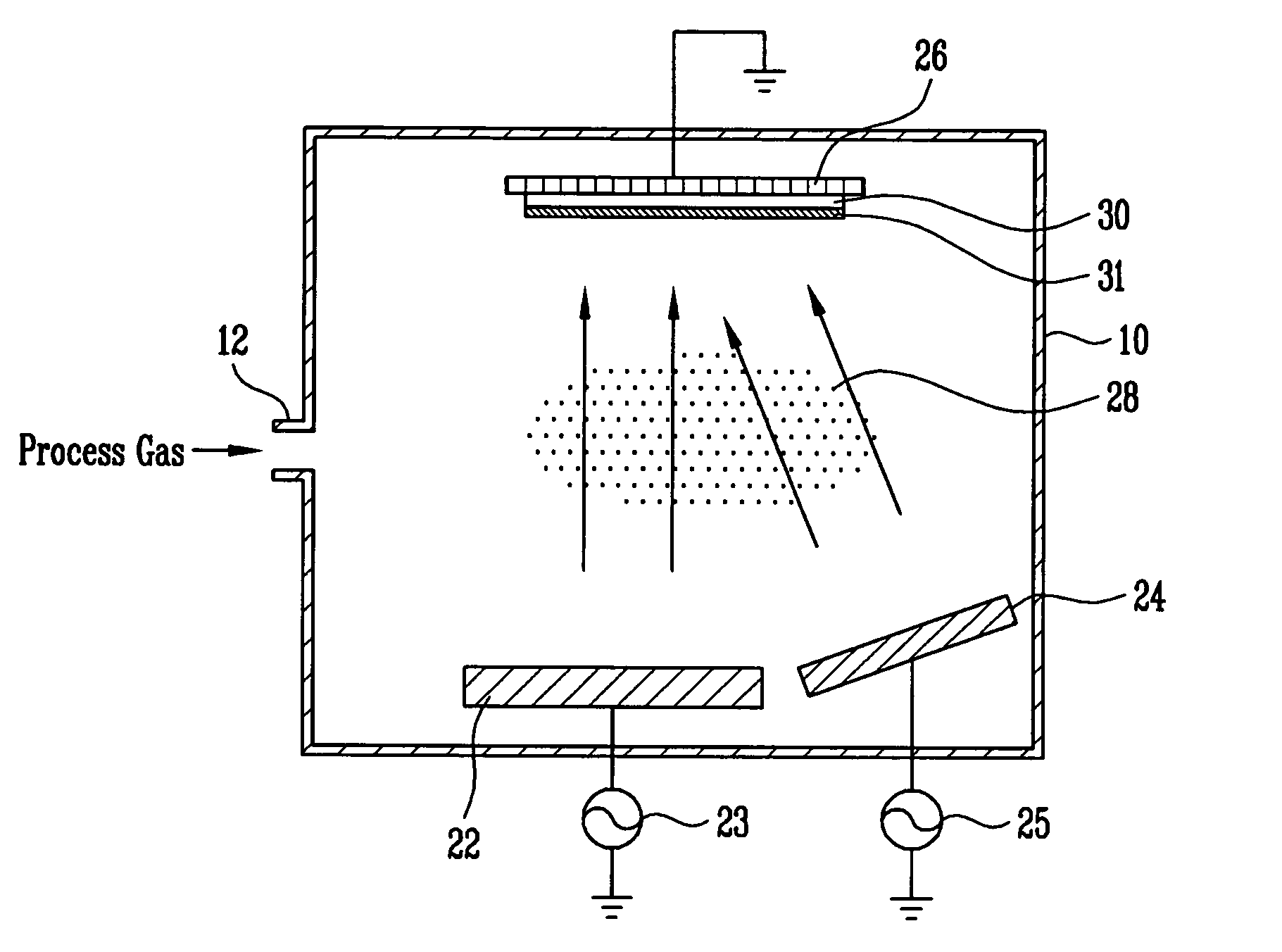

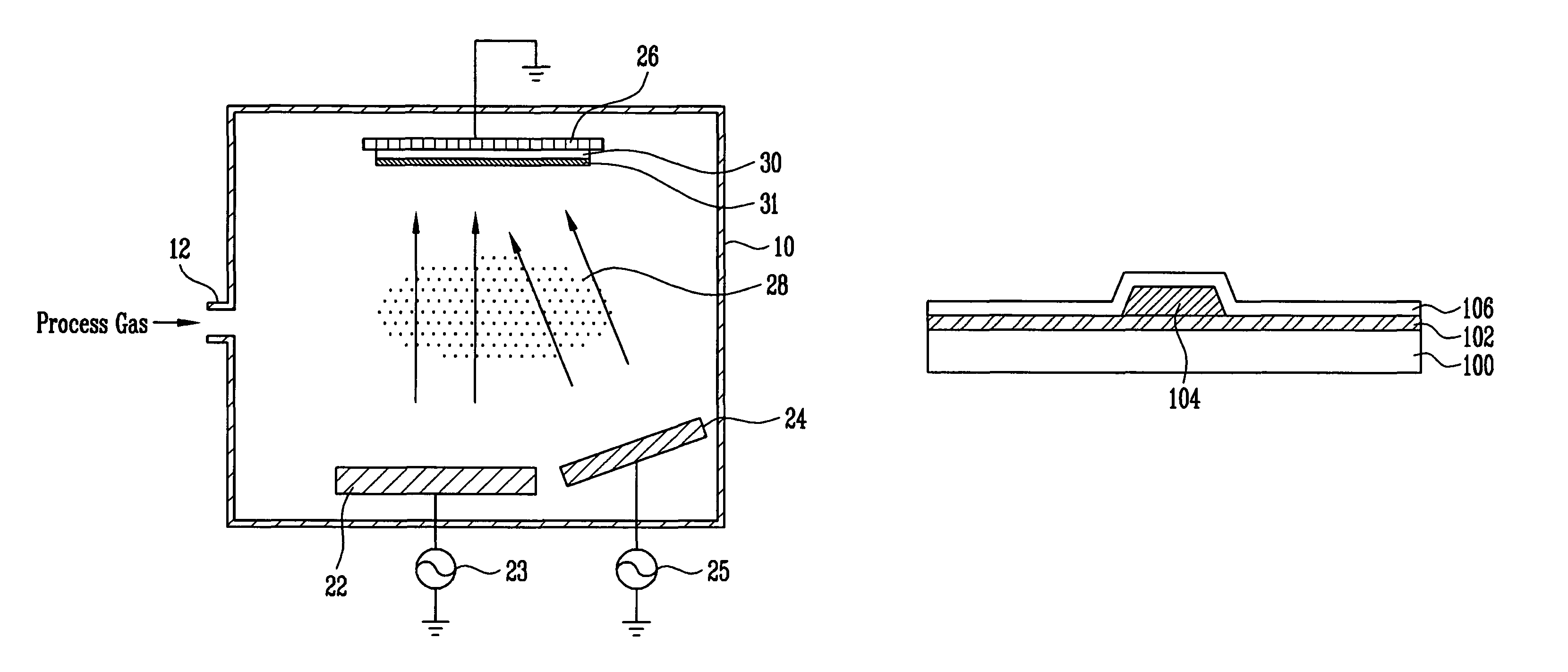

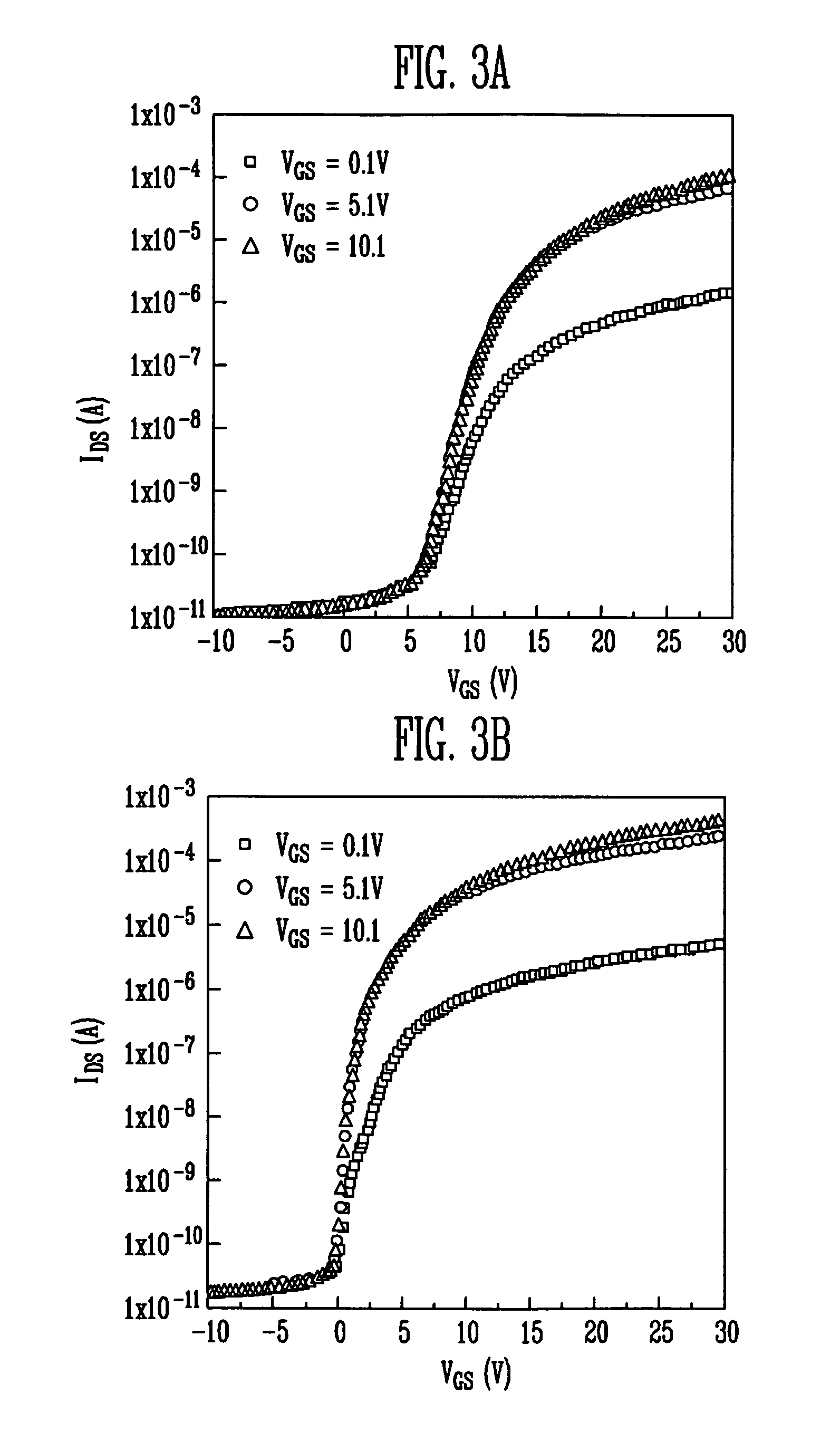

Oxynitride semiconductor

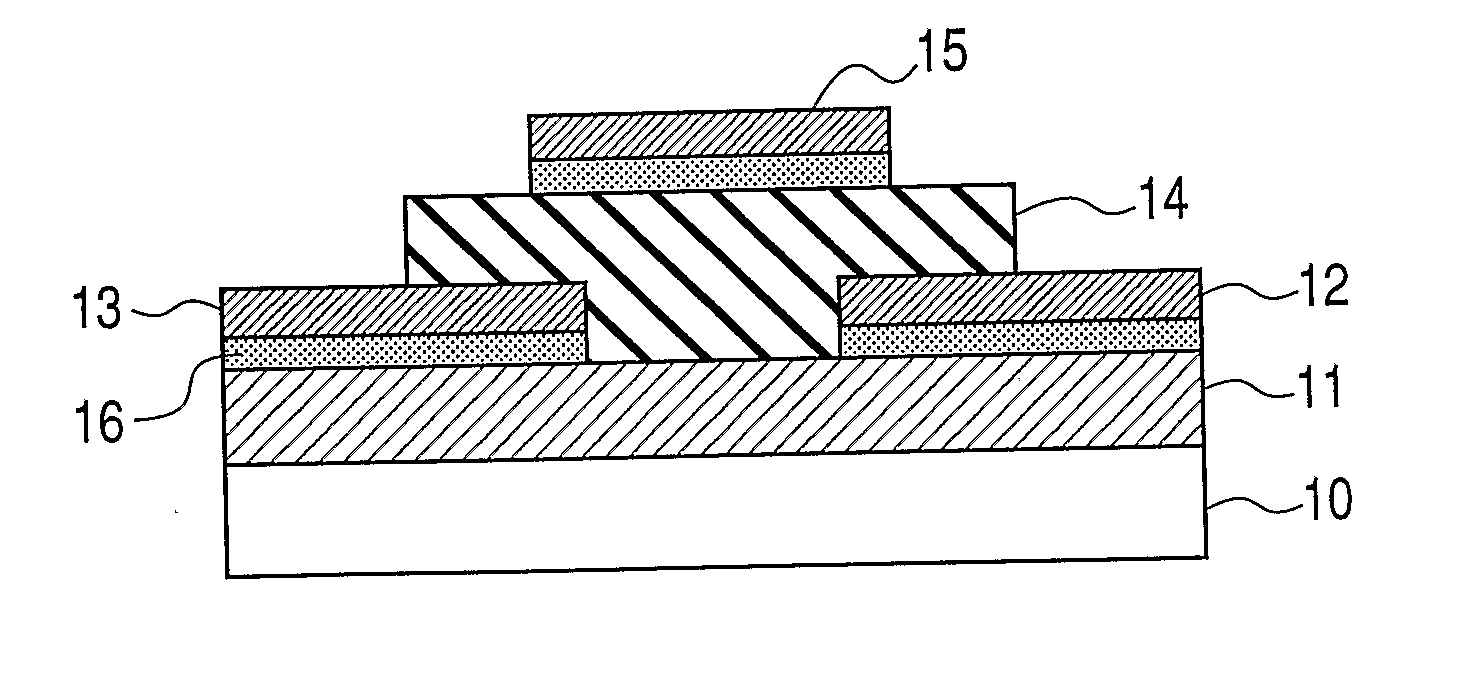

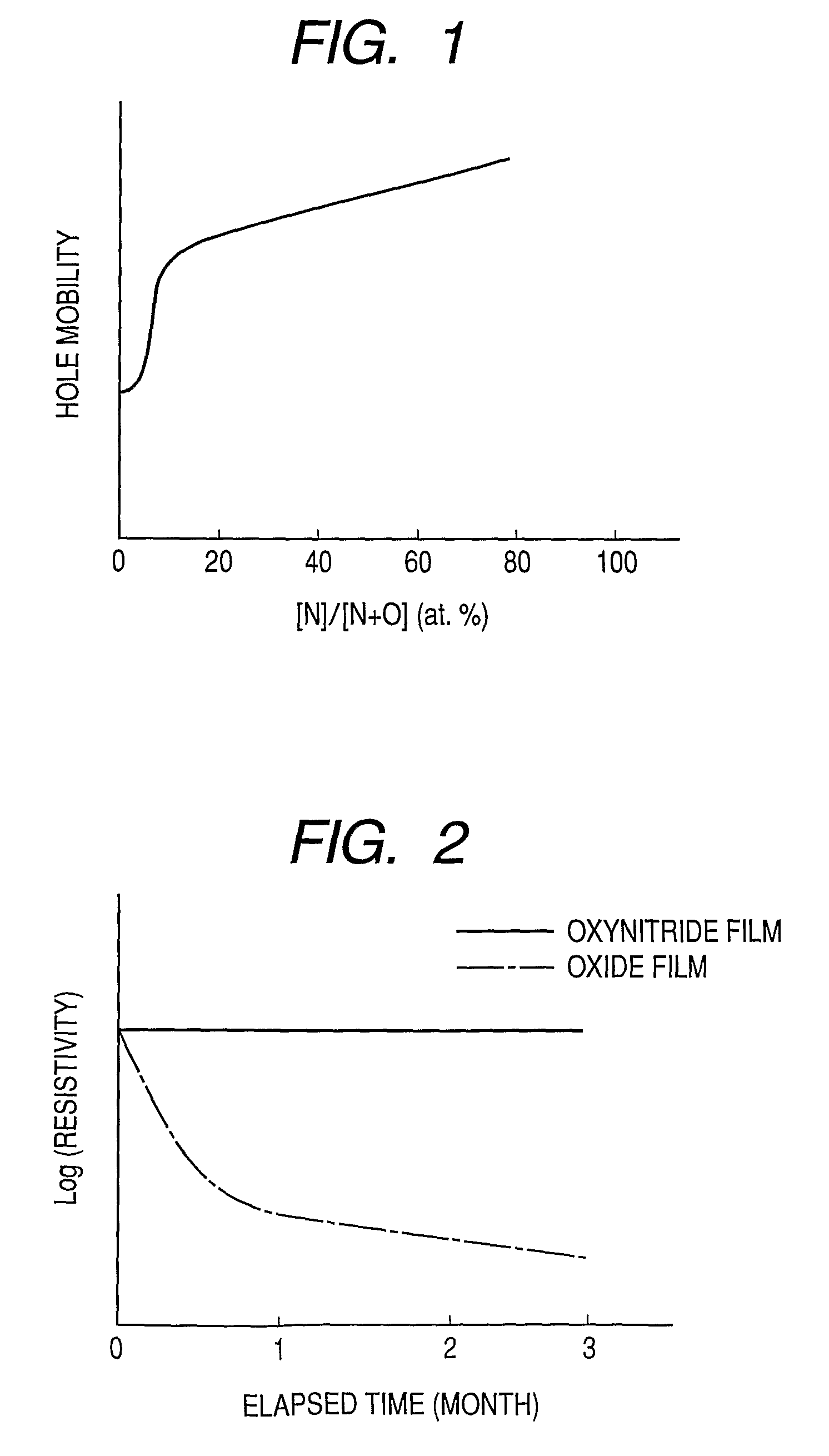

ActiveUS20100109002A1High mobility and environmental stabilityImprove mobilitySemiconductor devicesNitrogen oxideOxygen

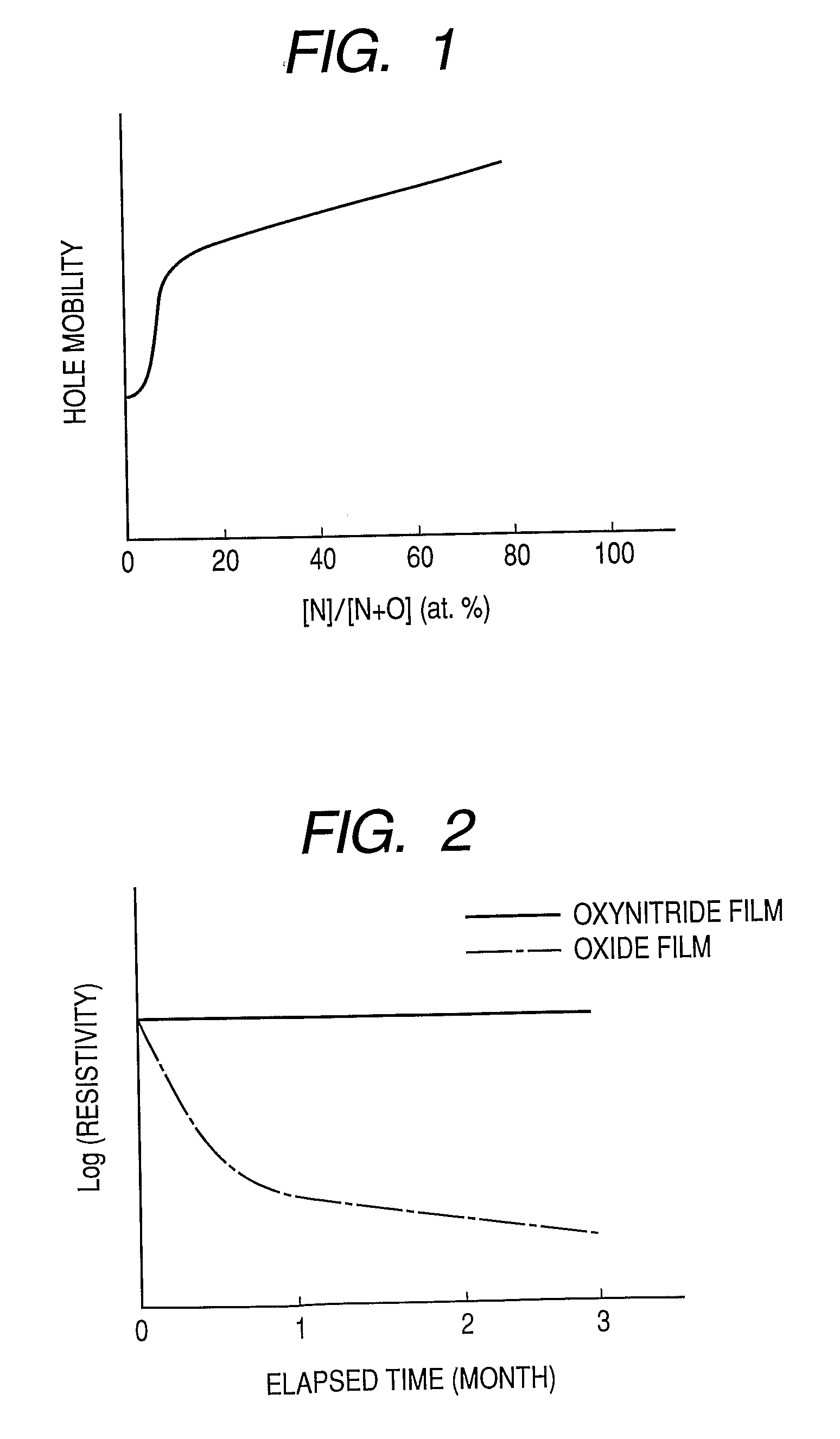

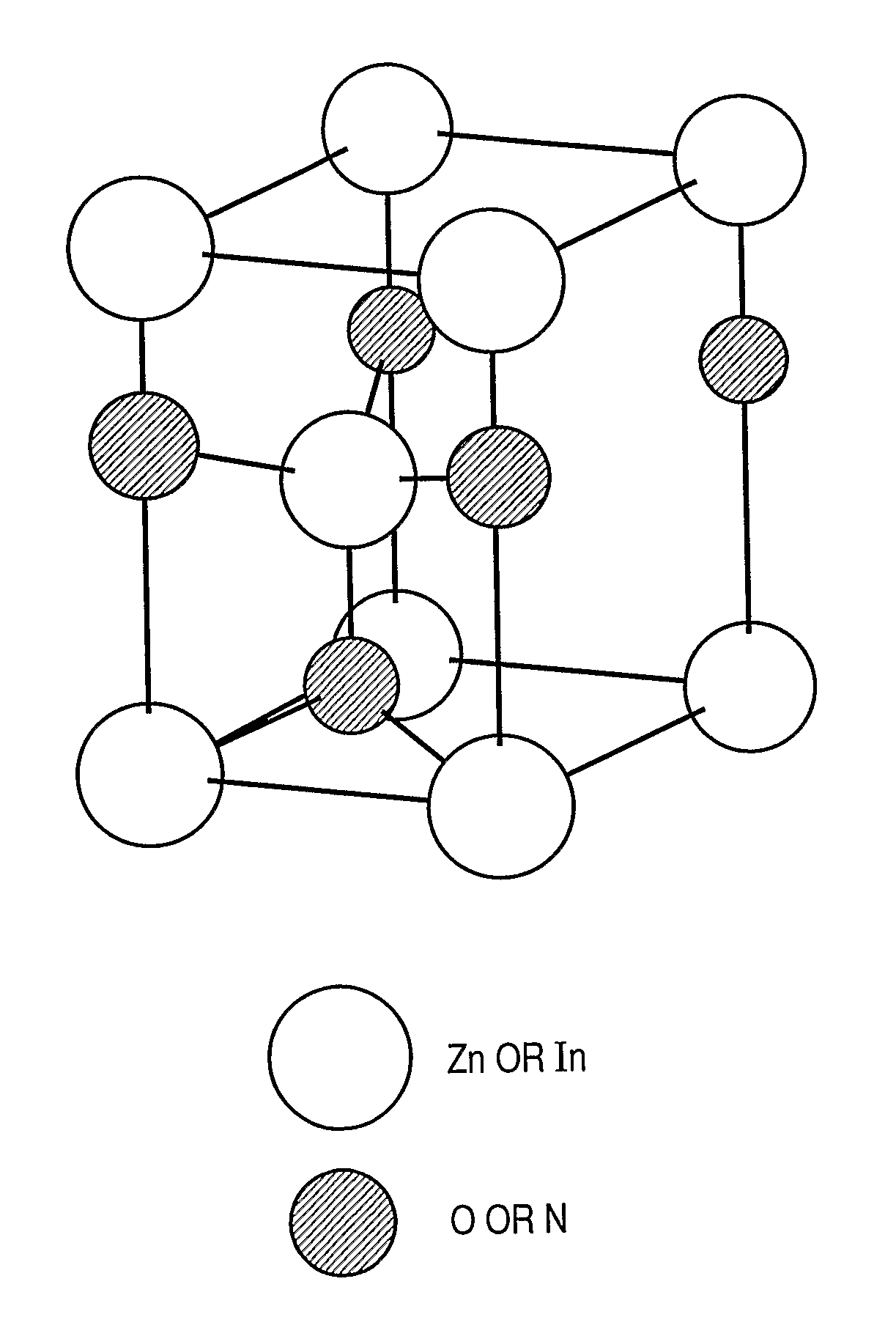

Provided is an oxynitride semiconductor comprising a metal oxynitride. The metal oxynitride contains Zn and at least one element selected from the group consisting of In, Ga, Sn, Mg, Si, Ge, Y, Ti, Mo, W, and Al. The metal oxynitride has an atomic composition ratio of N, N / (N+O), of 7 atomic percent or more to 80 atomic percent or less.

Owner:CANON KK

Metal oxynitride semiconductor containing zinc

ActiveUS8274078B2High mobility and environmental stabilityImprove mobilityPhotovoltaic energy generationSemiconductor devicesNitrogen oxideOxygen

Provided is an oxynitride semiconductor comprising a metal oxynitride. The metal oxynitride contains Zn and In and at least one element selected from the group consisting of Ga, Sn, Mg, Si, Ge, Y, Ti, Mo, W, and Al. The metal oxynitride has an atomic composition ratio of N, N / (N+O), of 7 atomic percent or more to 80 atomic percent or less.

Owner:CANON KK

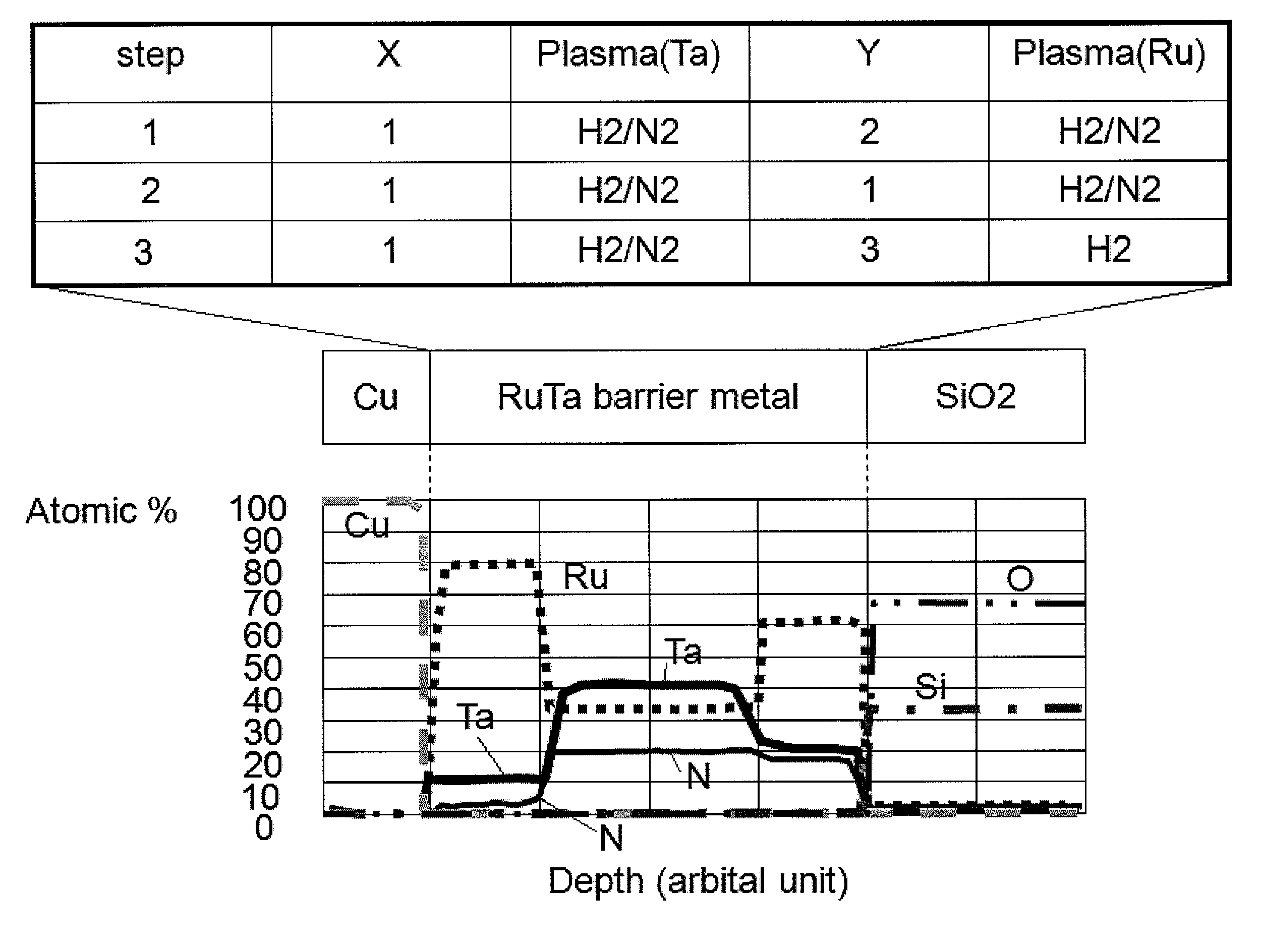

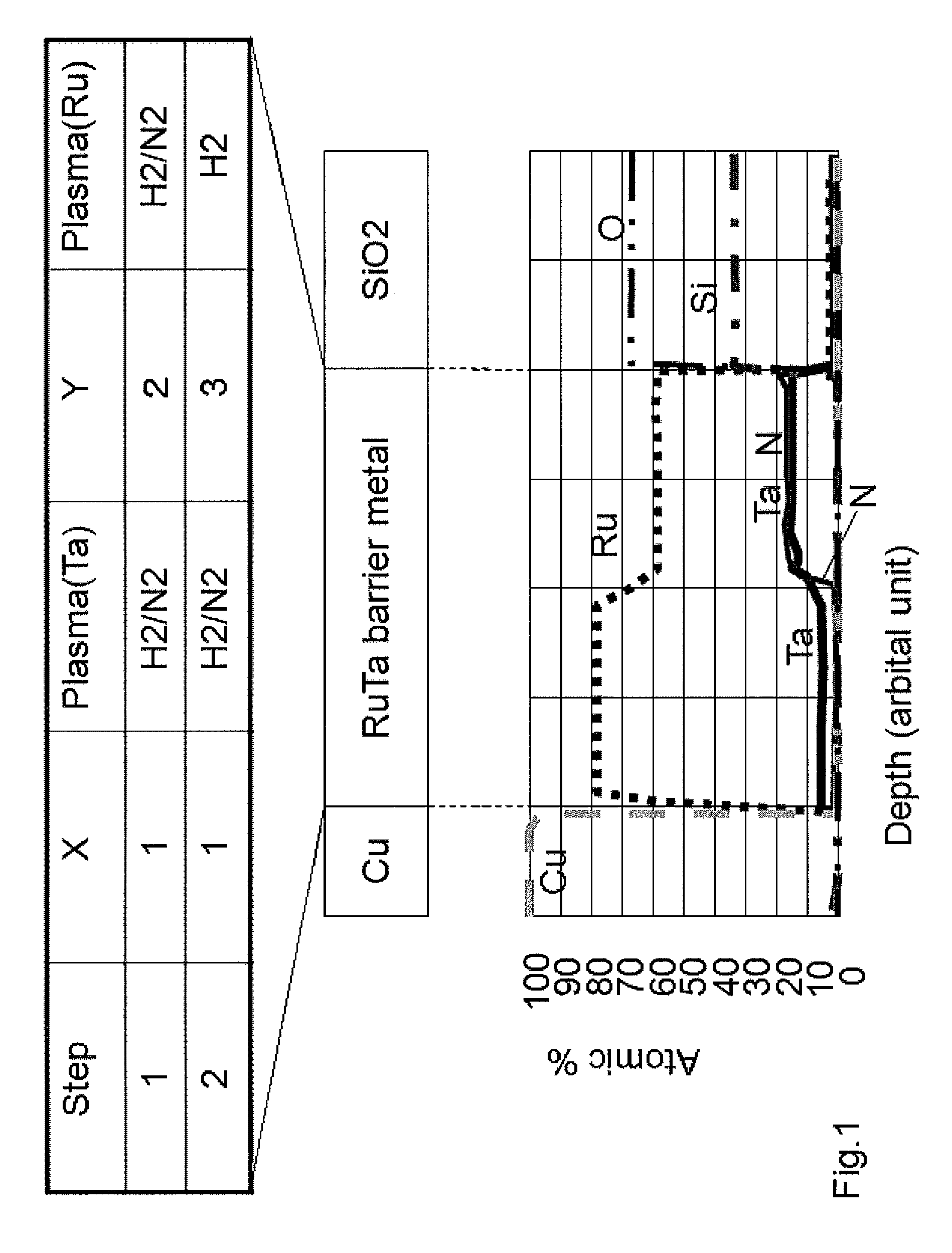

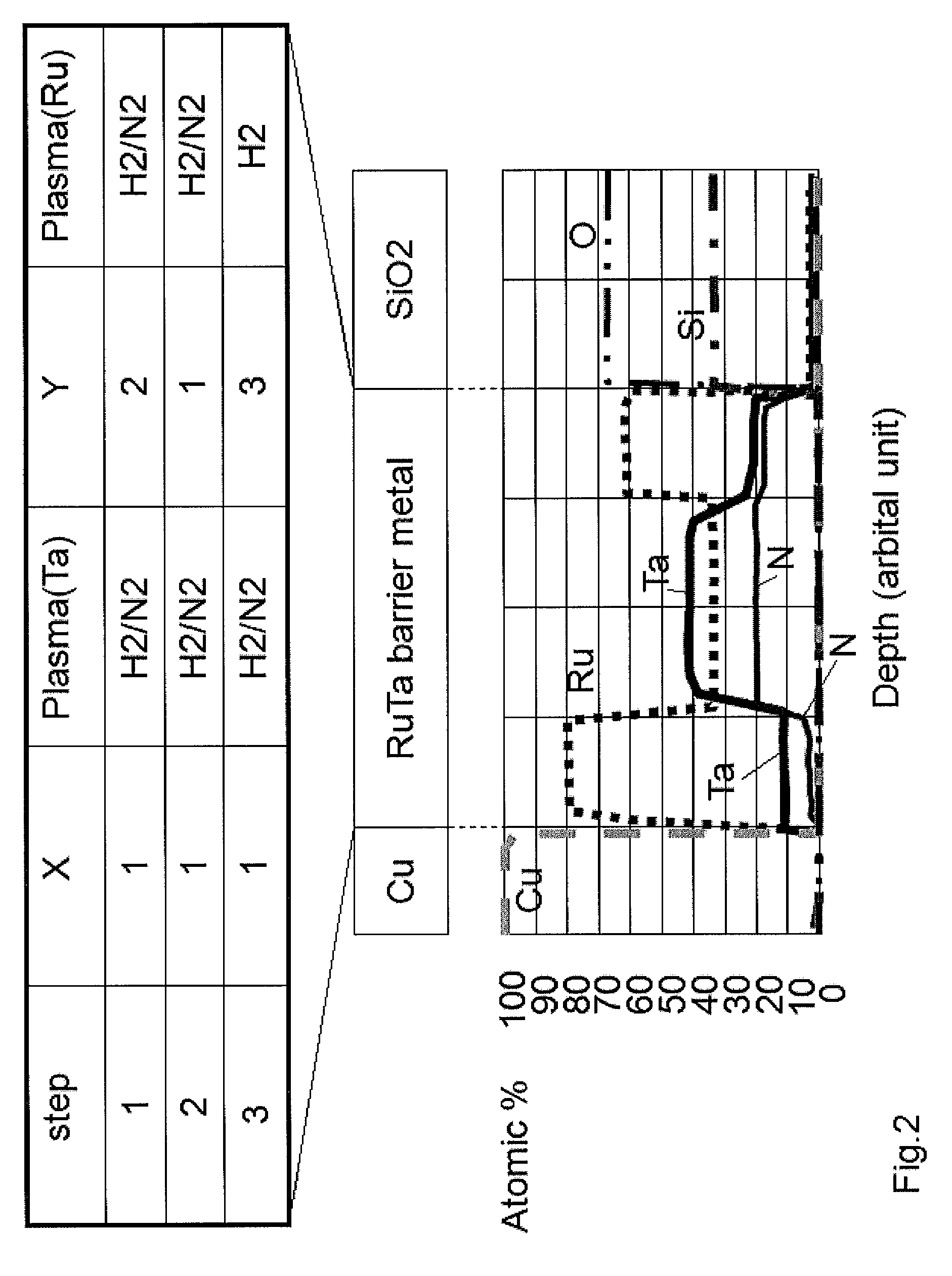

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

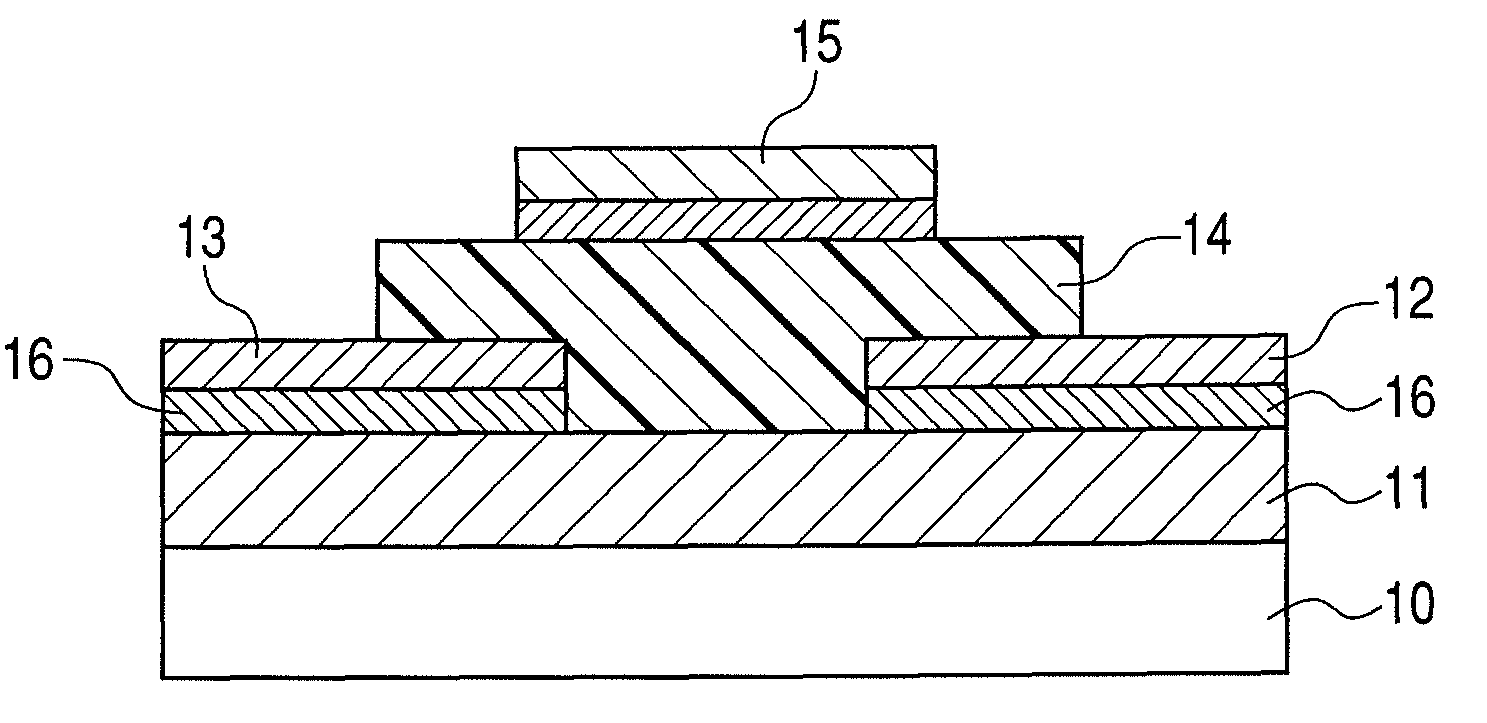

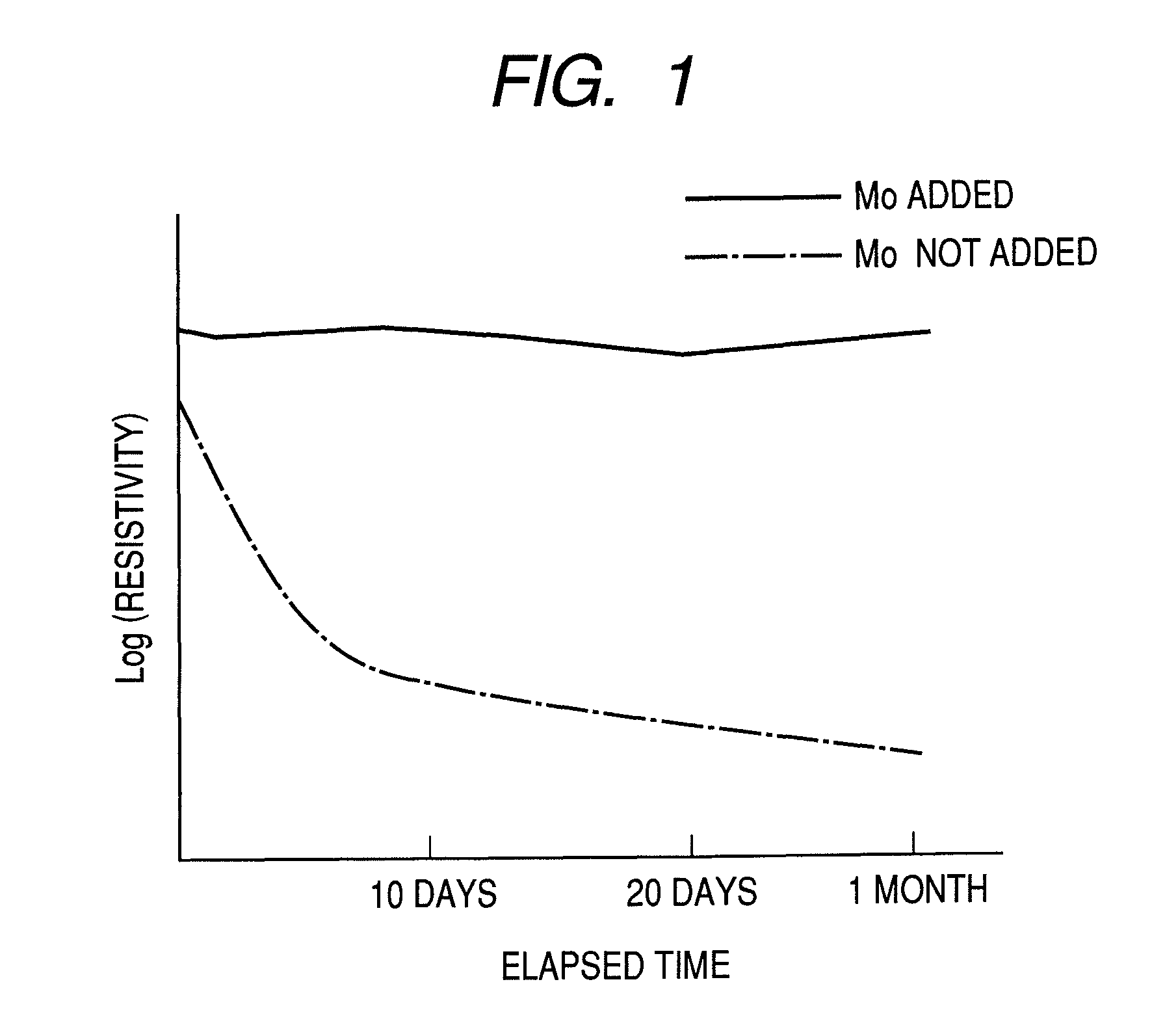

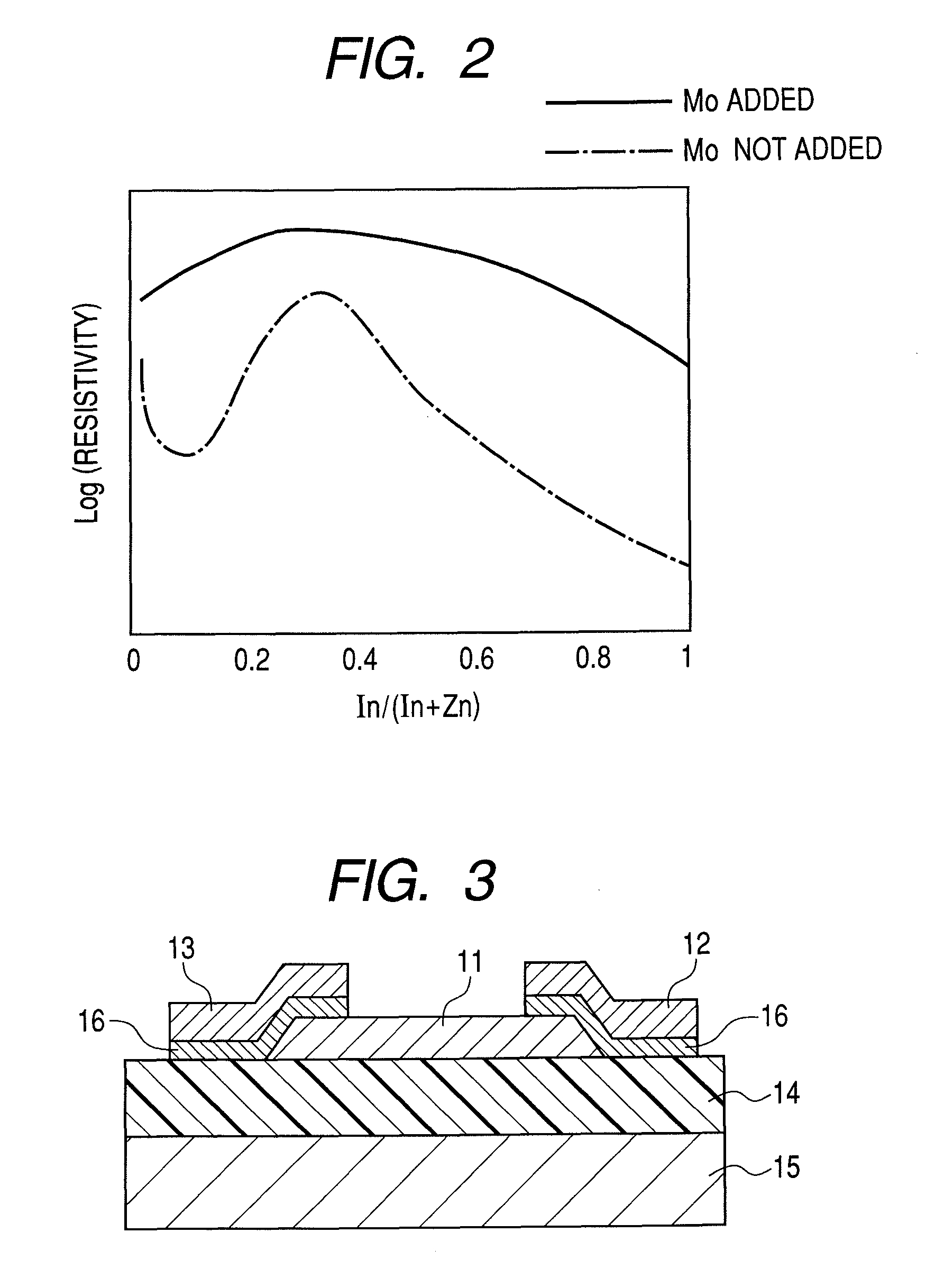

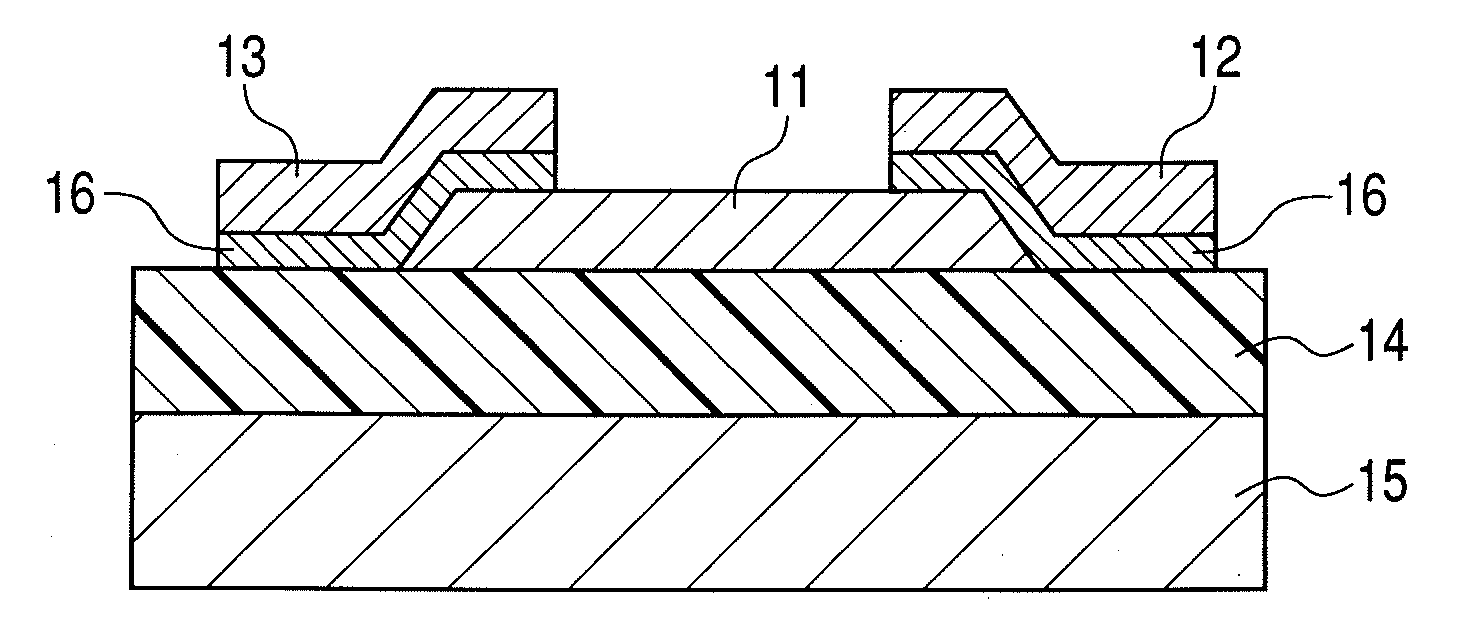

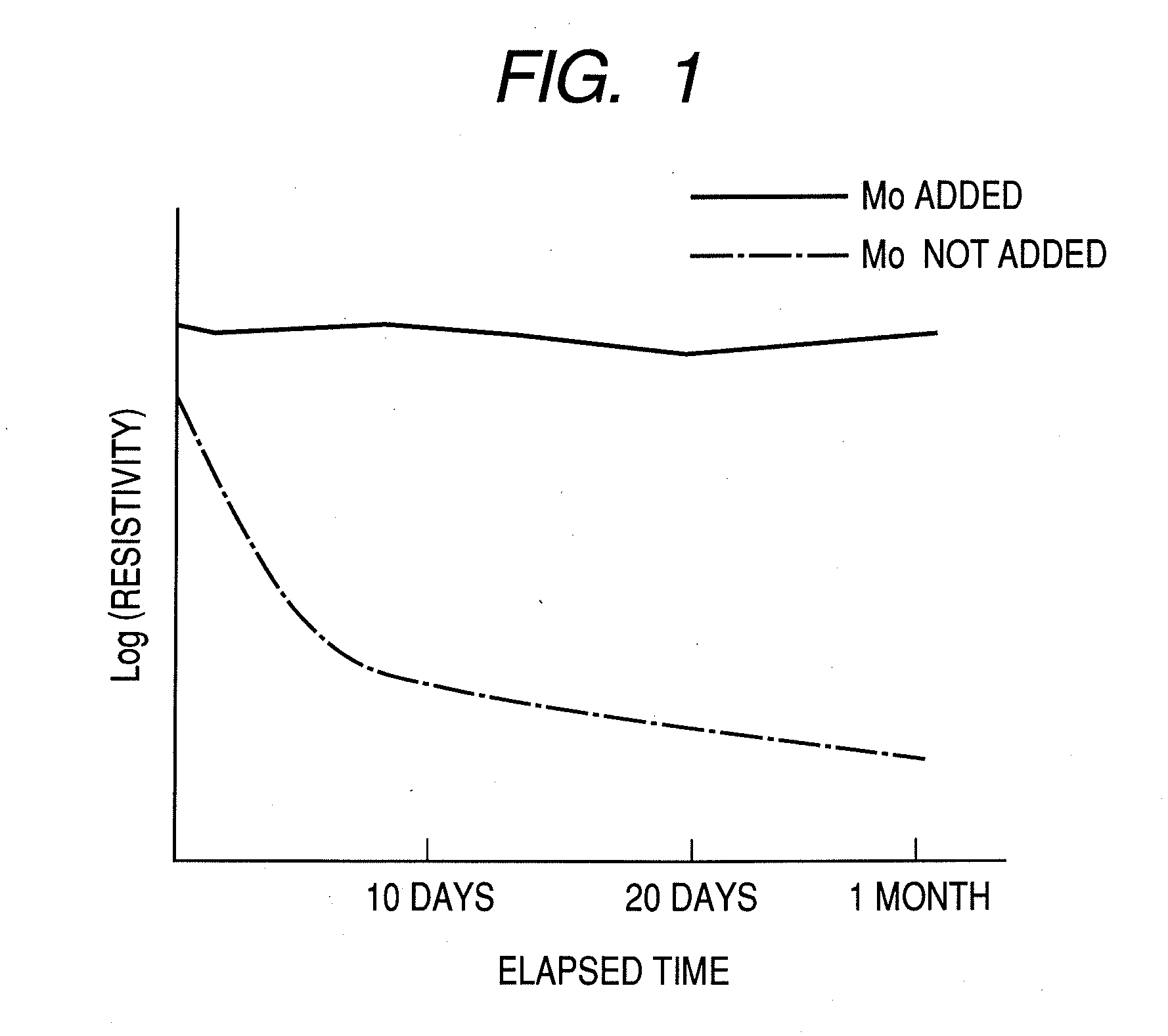

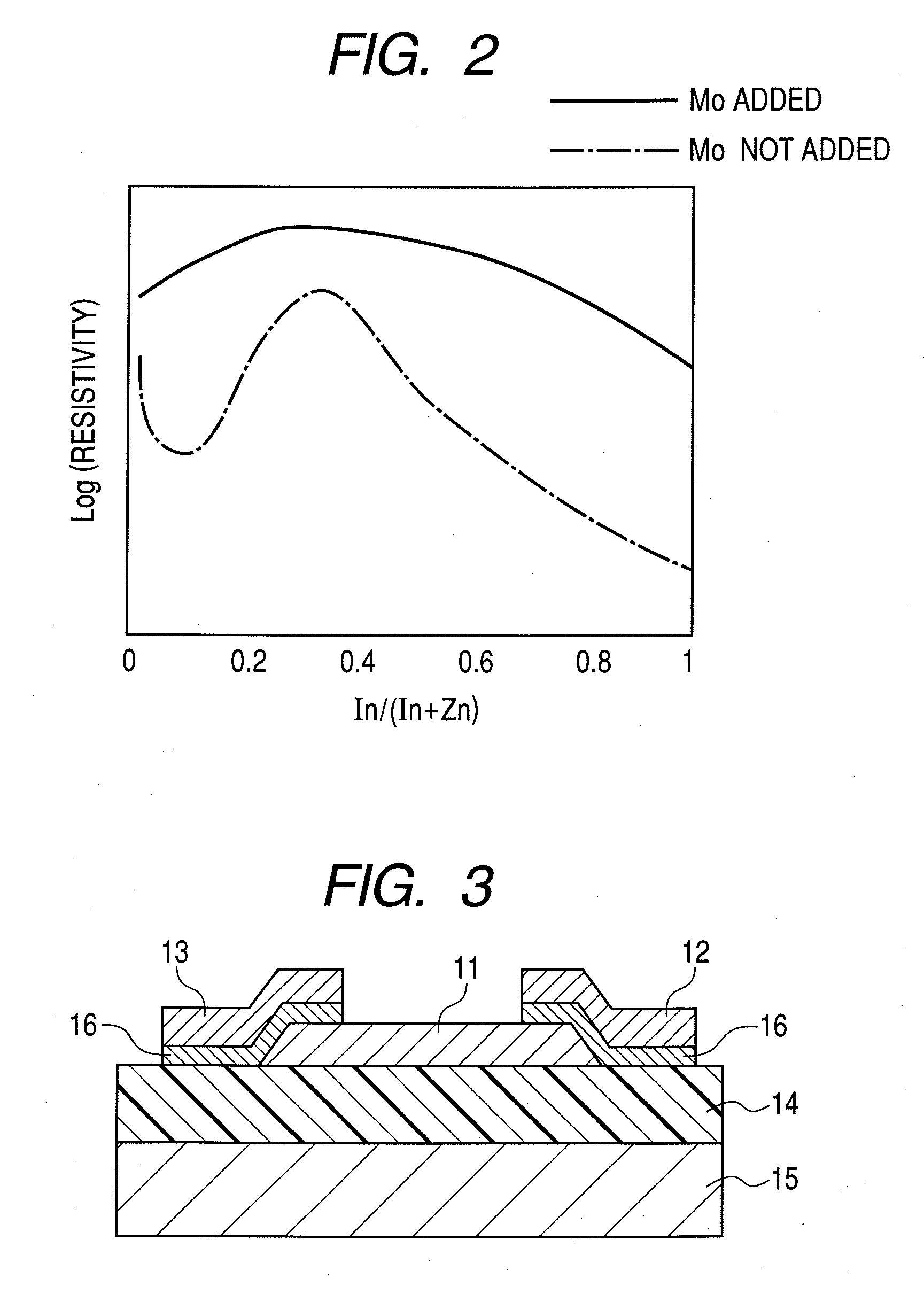

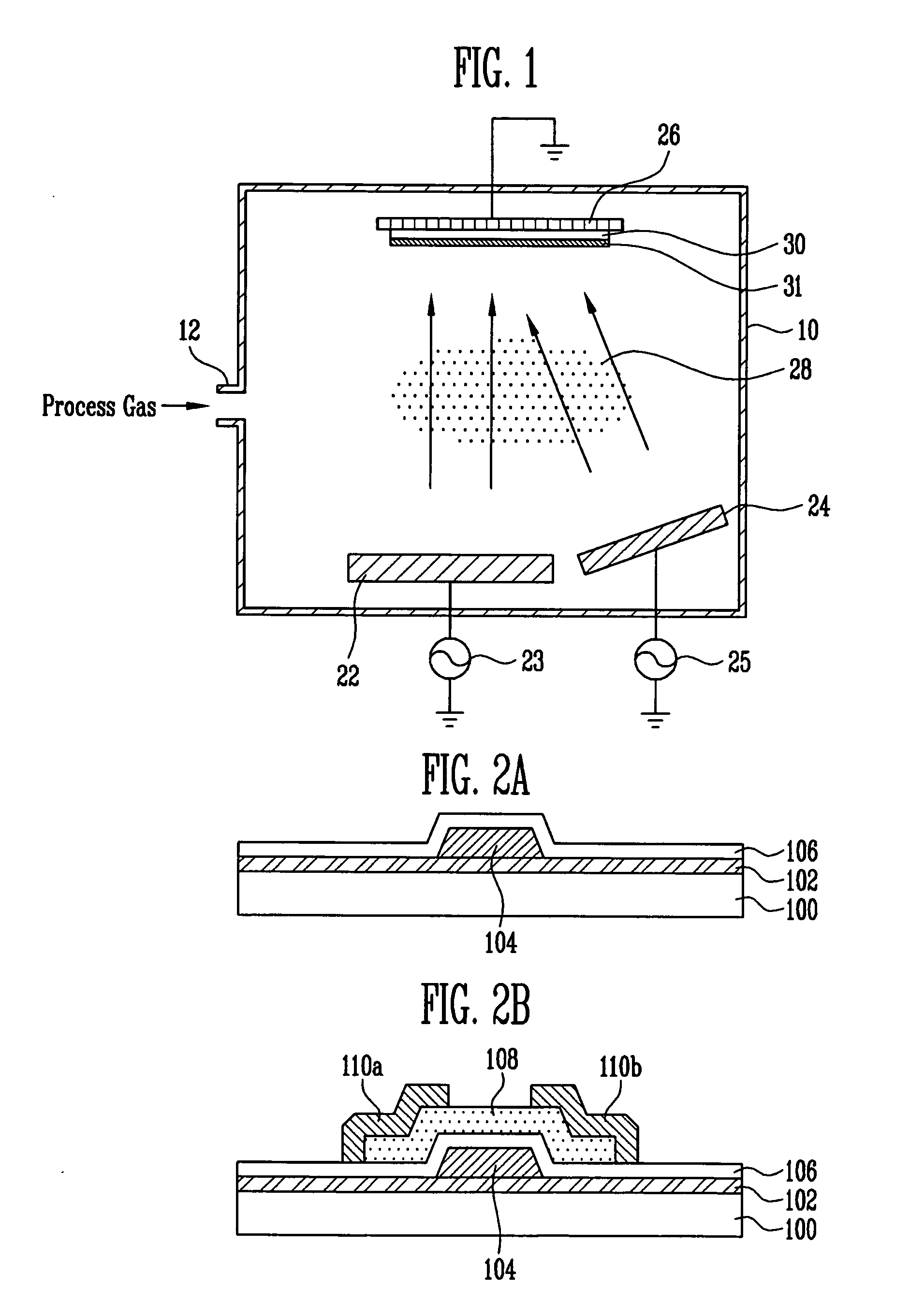

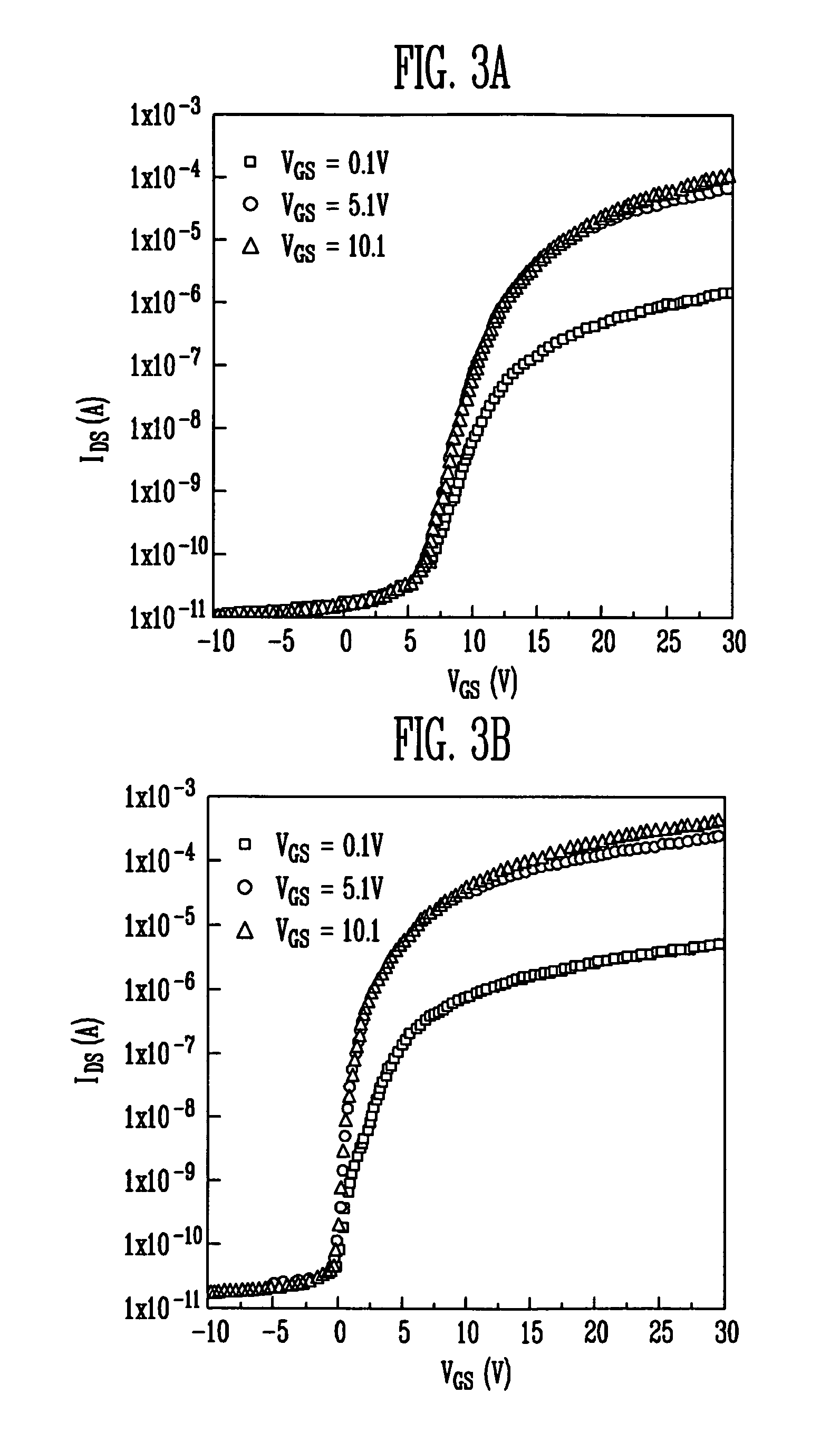

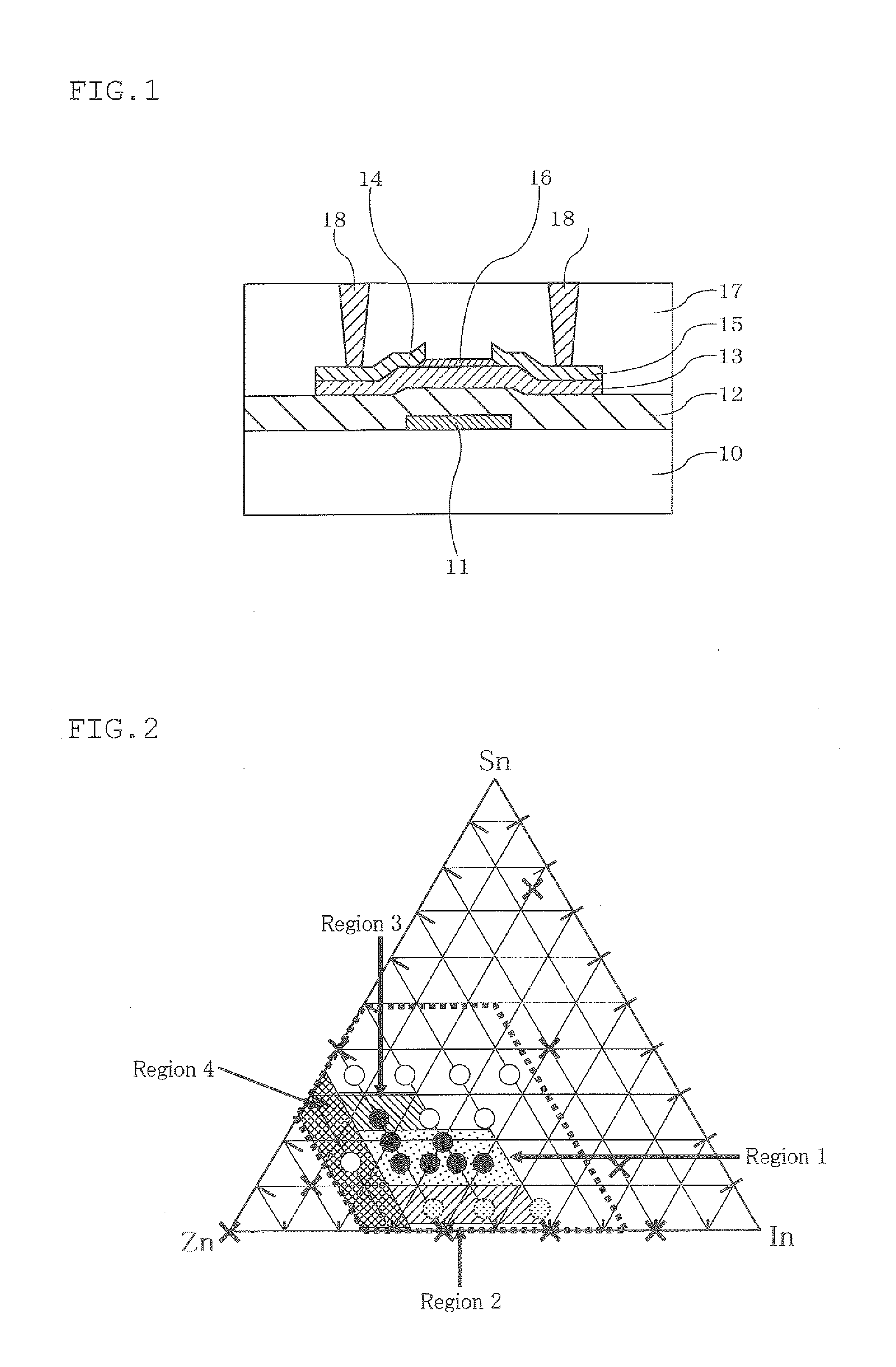

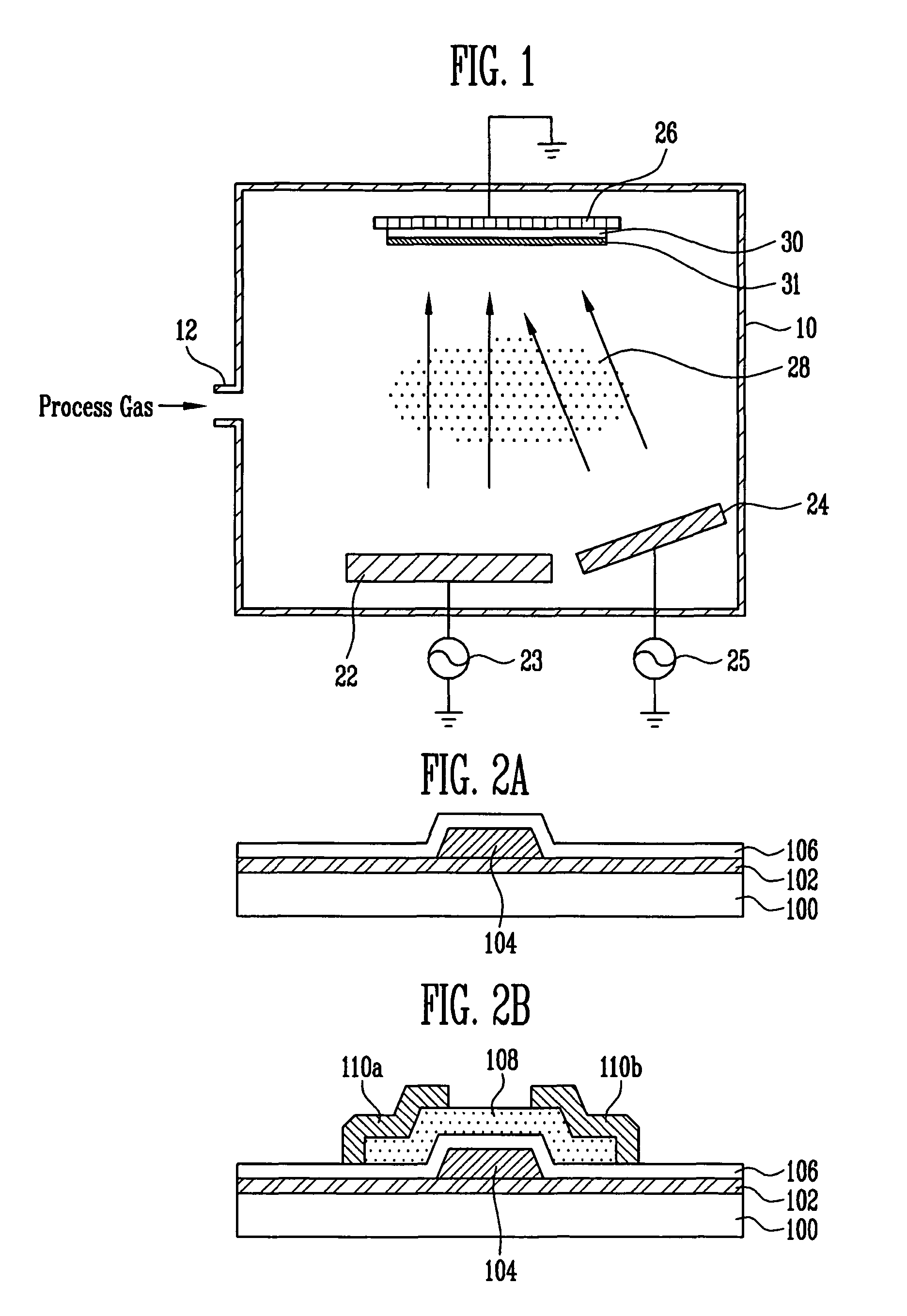

Amorphous oxide and field effect transistor

ActiveUS8212248B2Improve featuresIncrease profitSemiconductor devicesField-effect transistorAtomic composition

An amorphous oxide at least includes: at least one element selected from the group consisting of In, Zn, and Sn; and Mo. An atomic composition ratio of Mo to a number of all metallic atoms in the amorphous oxide is 0.1 atom % or higher and 5 atom % or lower.

Owner:CANON KK

Amorphous oxide and field effect transistor

ActiveUS20100276685A1Improve featuresIncrease profitSemiconductor devicesField-effect transistorAtomic composition

An amorphous oxide at least includes: at least one element selected from the group consisting of In, Zn, and Sn; and Mo. An atomic composition ratio of Mo to a number of all metallic atoms in the amorphous oxide is 0.1 atom % or higher and 5 atom % or lower.

Owner:CANON KK

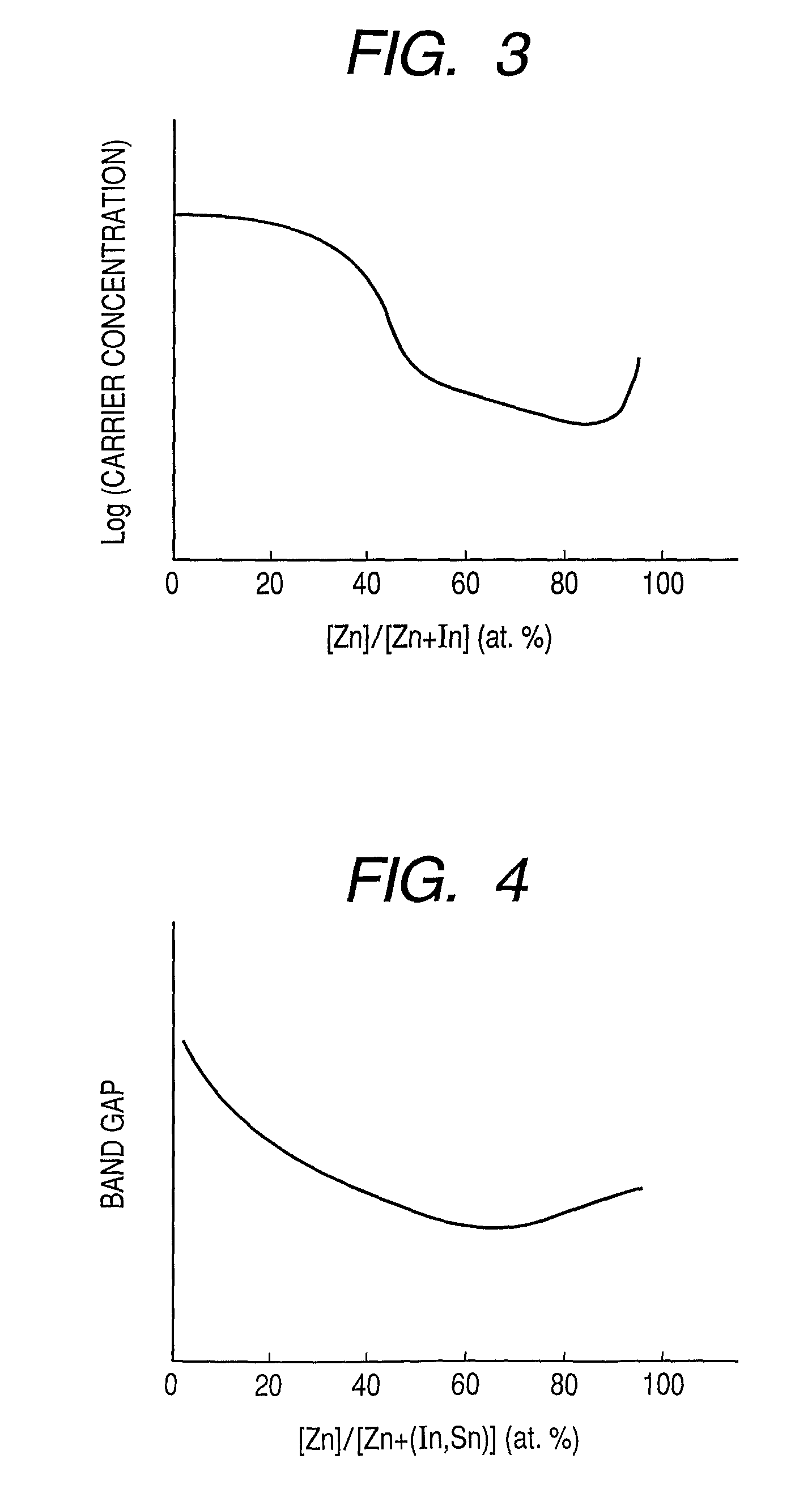

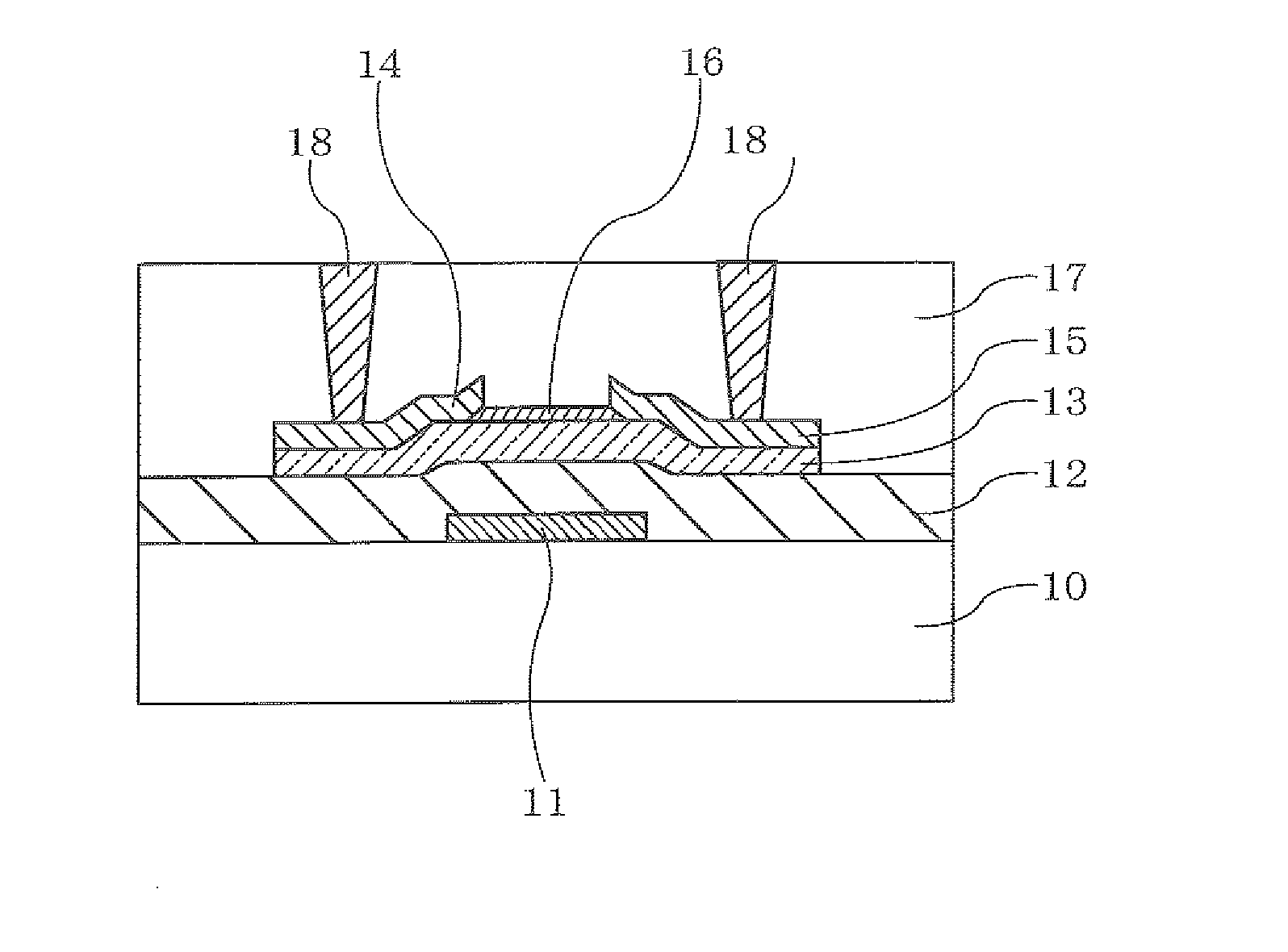

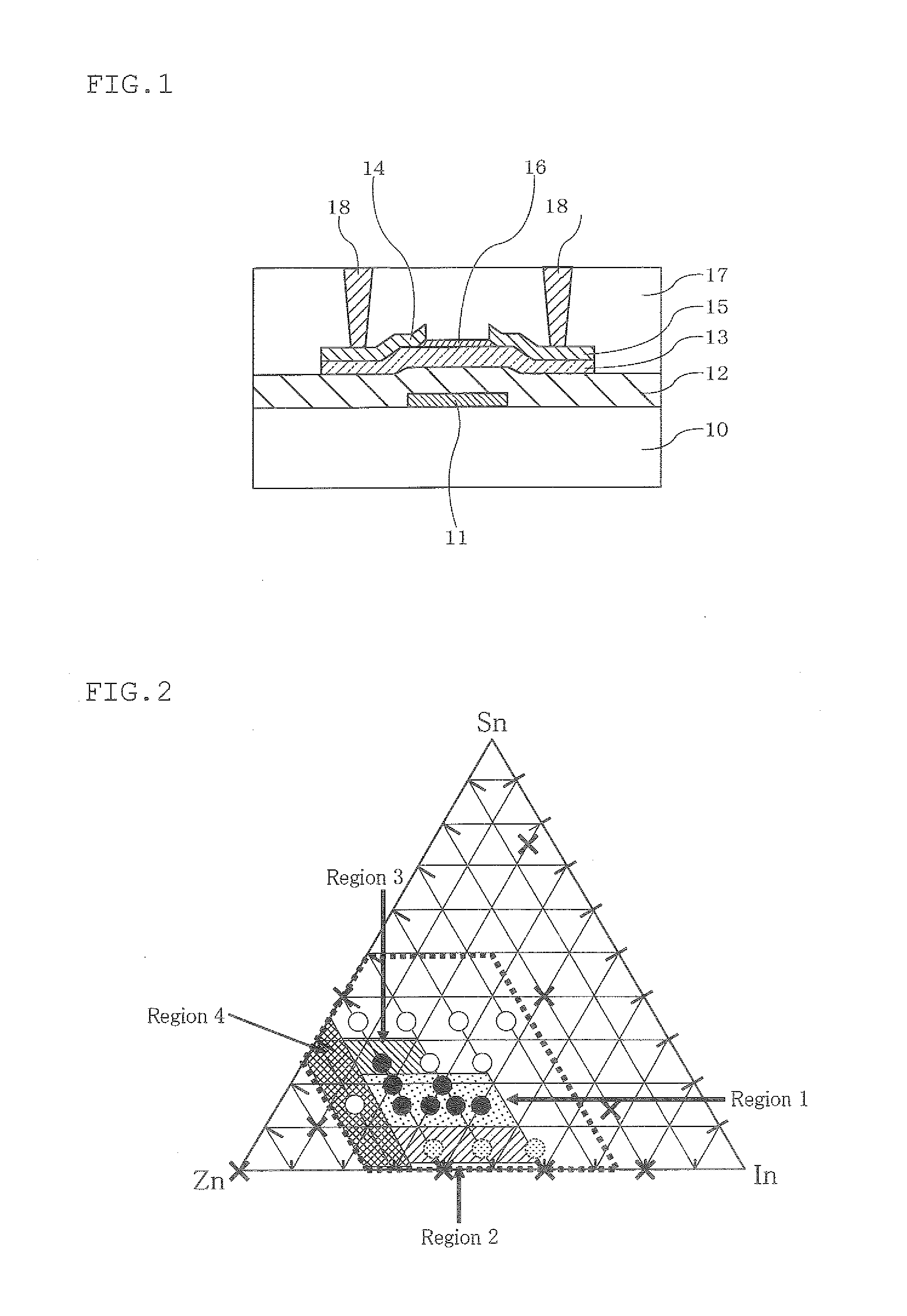

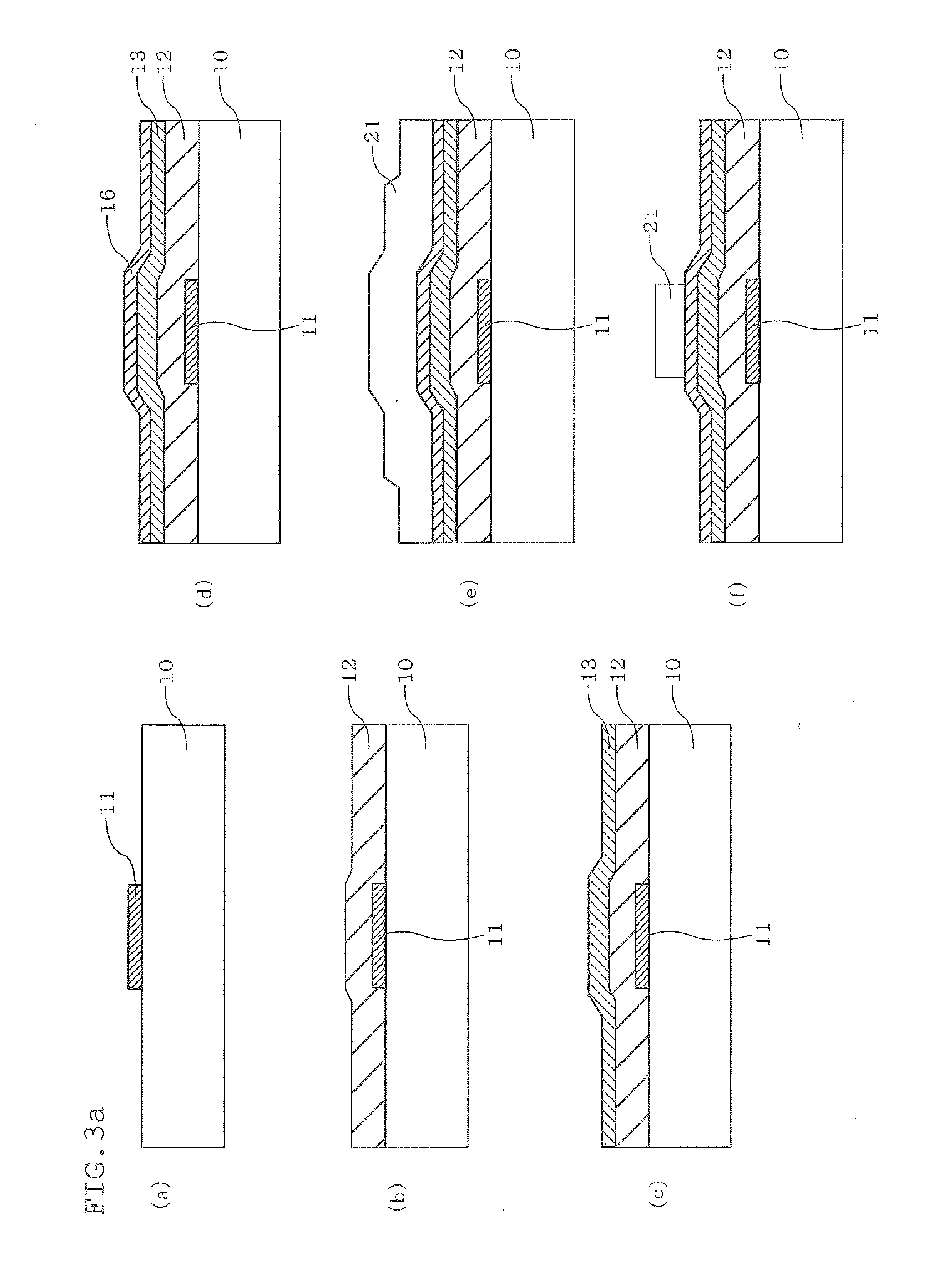

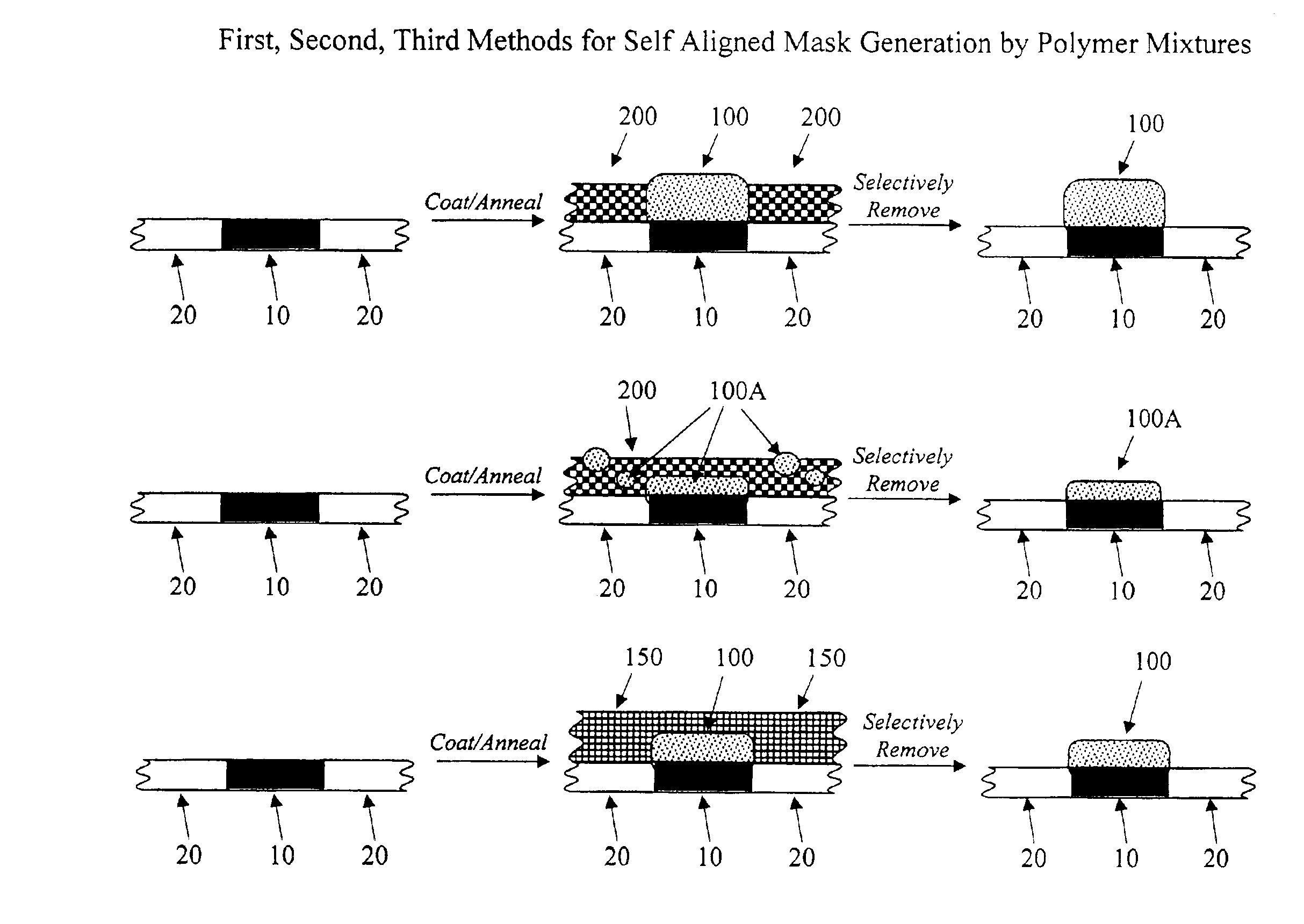

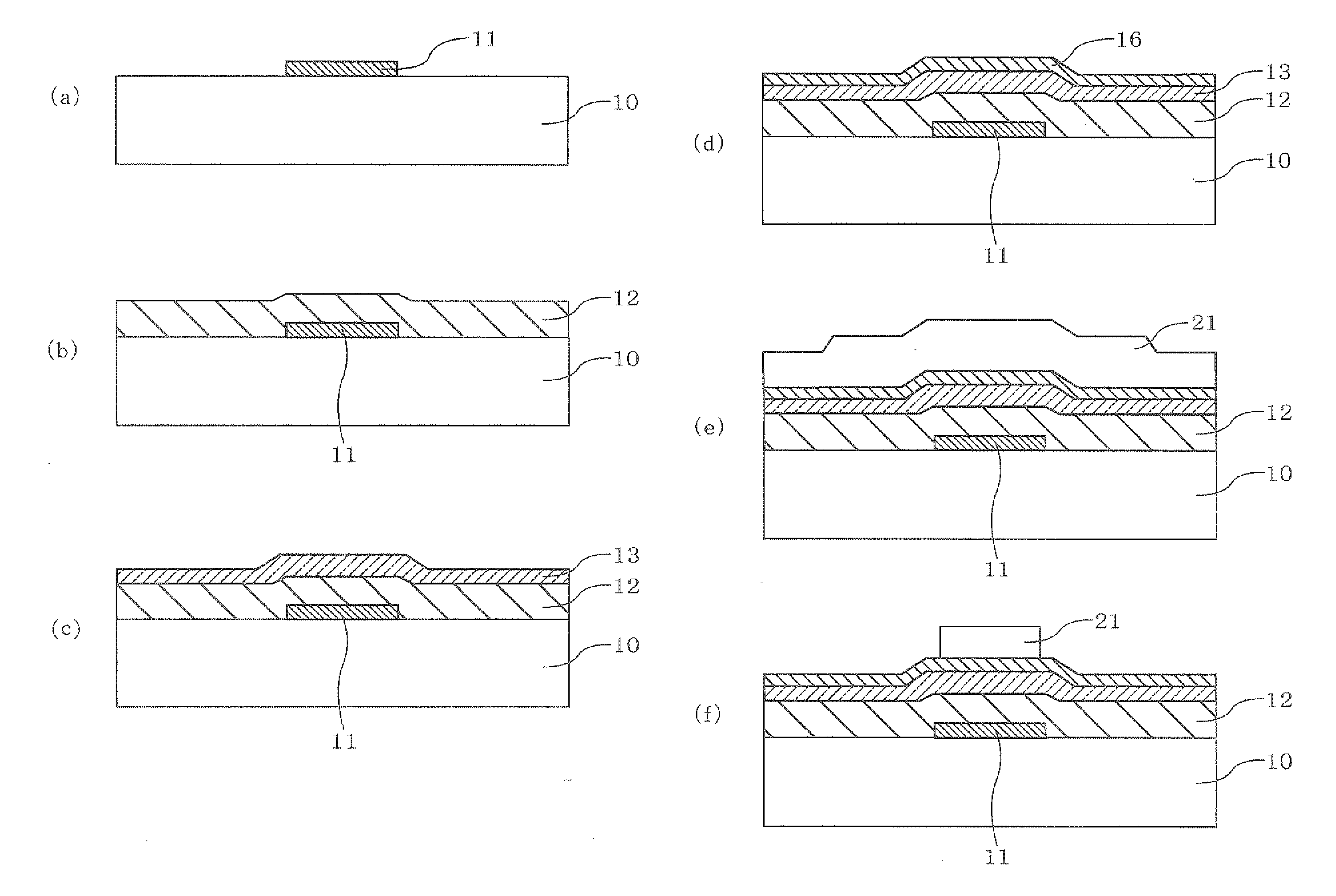

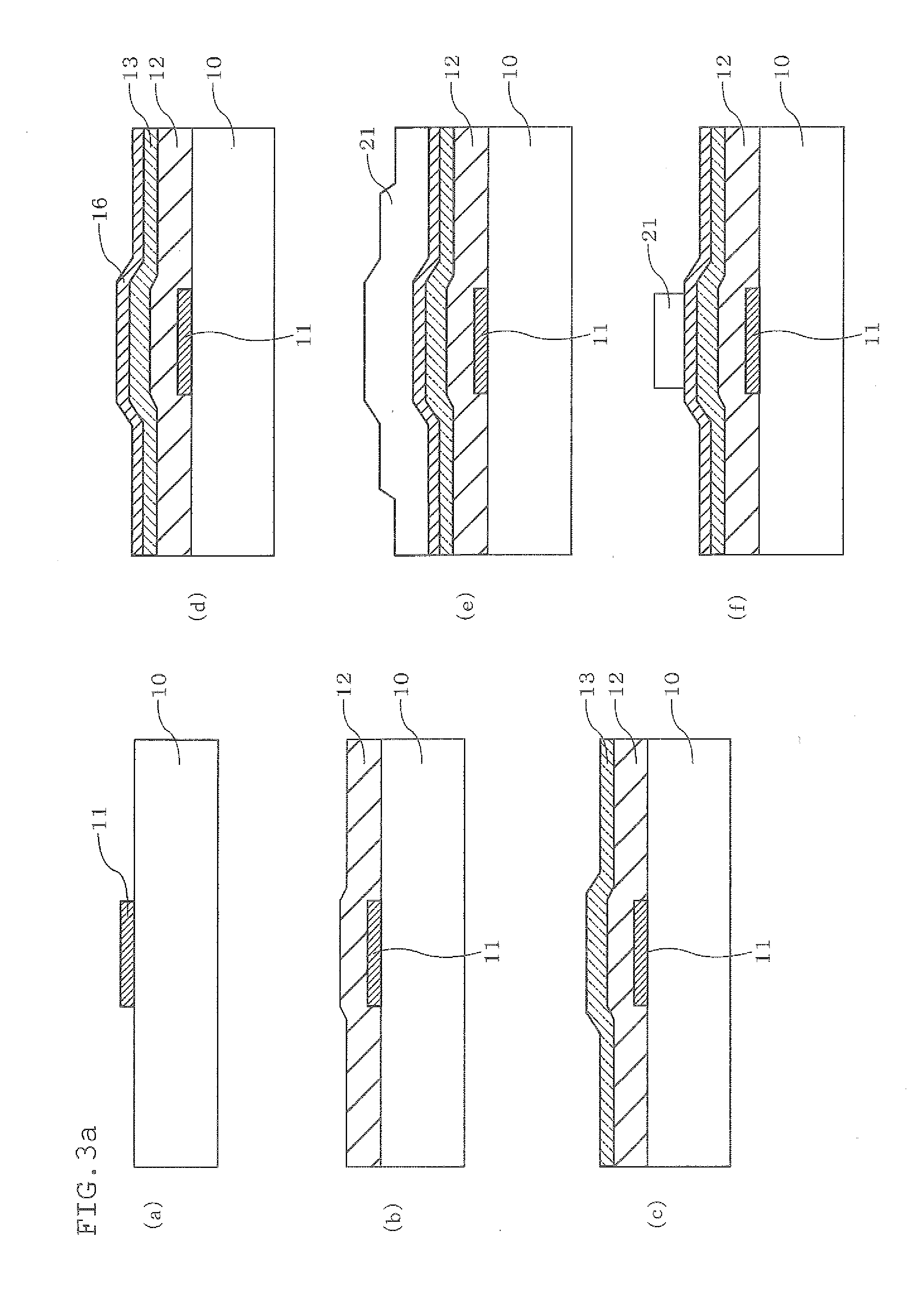

Field effect transistor, method for manufacturing the same, and sputtering target

ActiveUS20110240988A1Easy to produceEliminate the effects ofTransistorCellsField-effect transistorAtomic composition

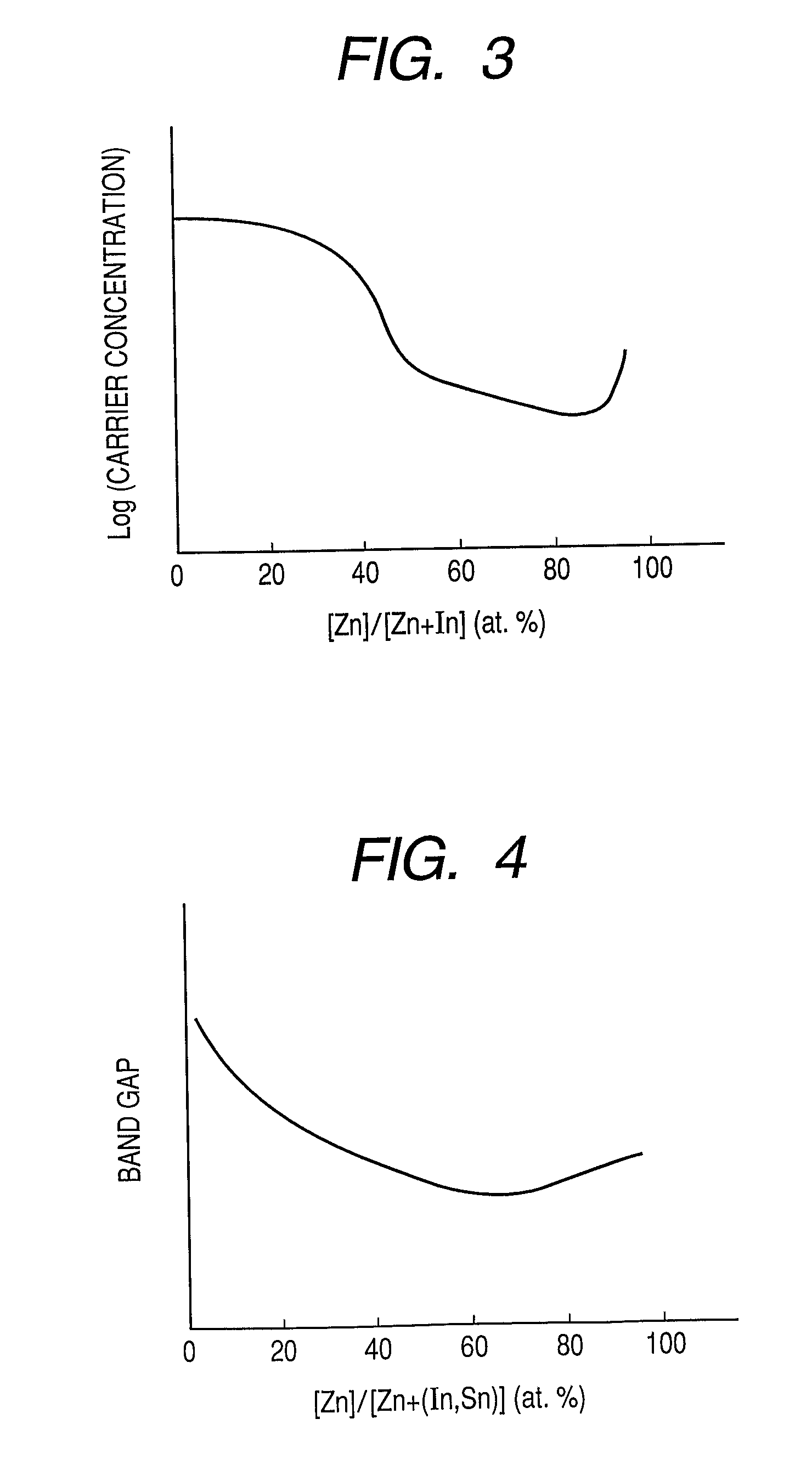

A field effect transistor including: a substrate, and at least gate electrode, a gate insulating film, a semiconductor layer, a protective layer for the semiconductor layer, a source electrode and a drain electrode provided on the substrate, wherein the source electrode and the drain electrode are connected with the semiconductor layer therebetween, the gate insulating film is between the gate electrode and the semiconductor layer, the protective layer is on at least one surface of the semiconductor layer, the semiconductor layer includes an oxide containing In atoms, Sn atoms and Zn atoms, the atomic composition ratio of Zn / (In+Sn+Zn) is 25 atom % or more and 75 atom % or less, and the atomic composition ratio of Sn / (In+Sn+Zn) is less than 50 atom %.

Owner:IDEMITSU KOSAN CO LTD

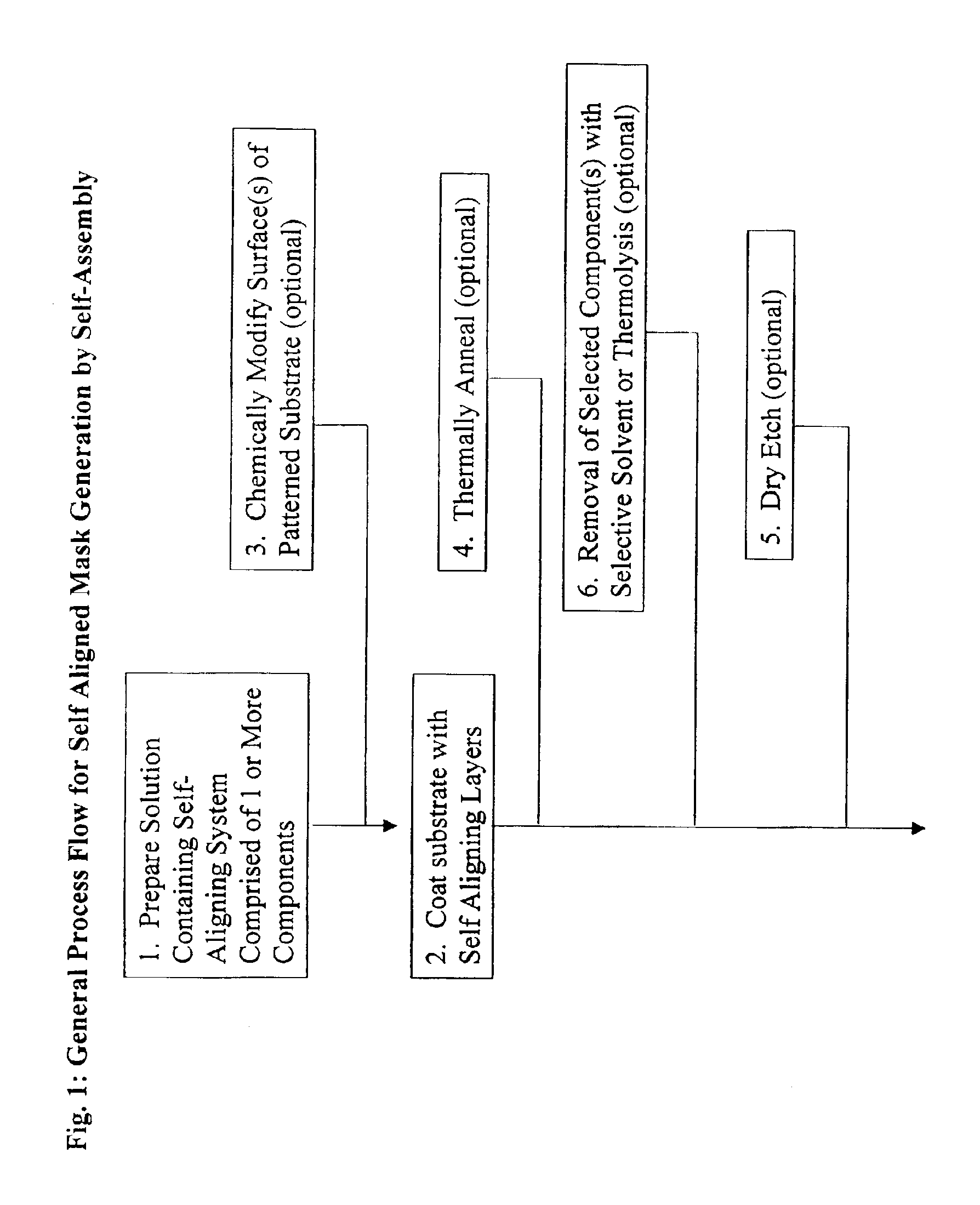

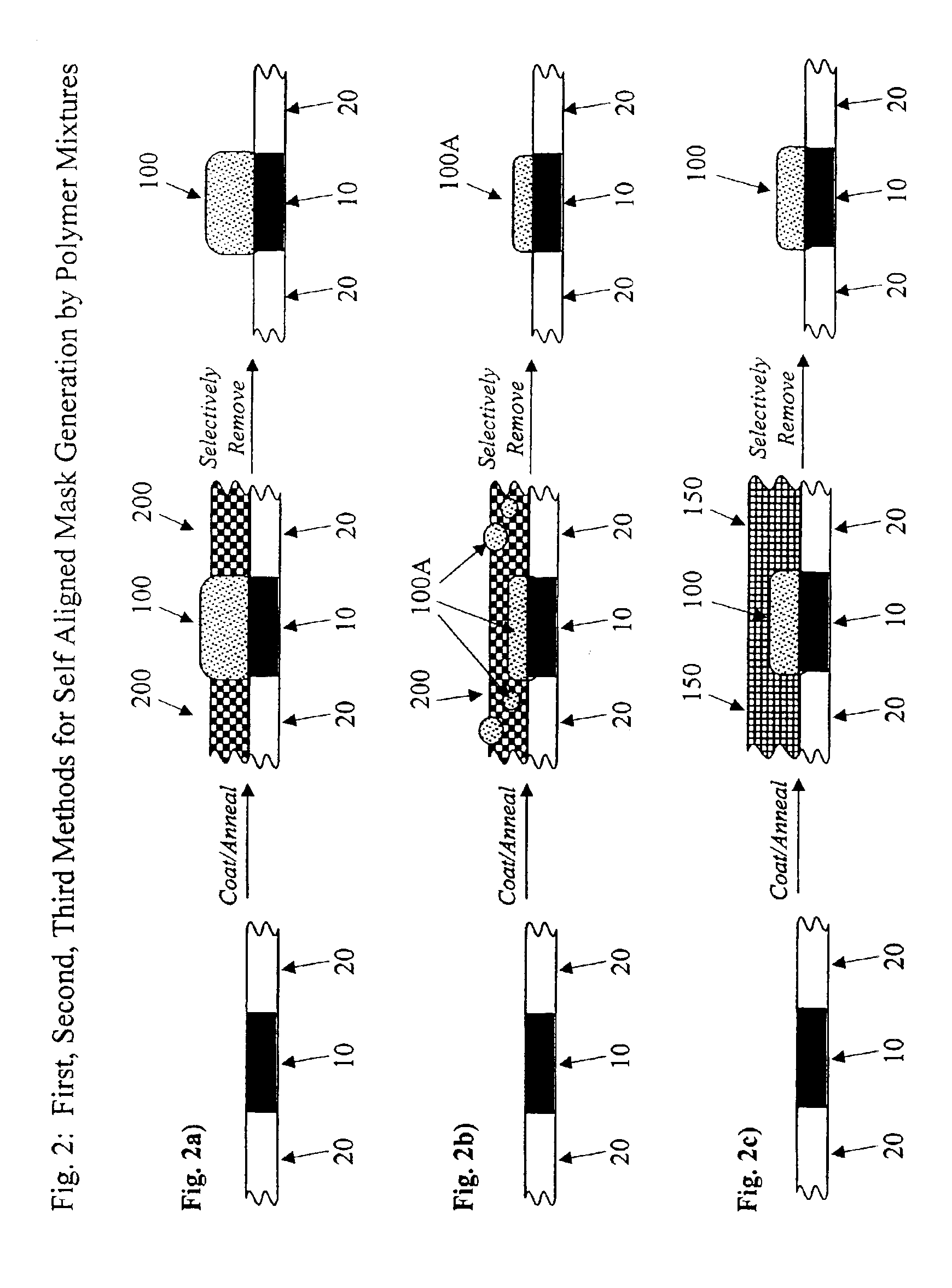

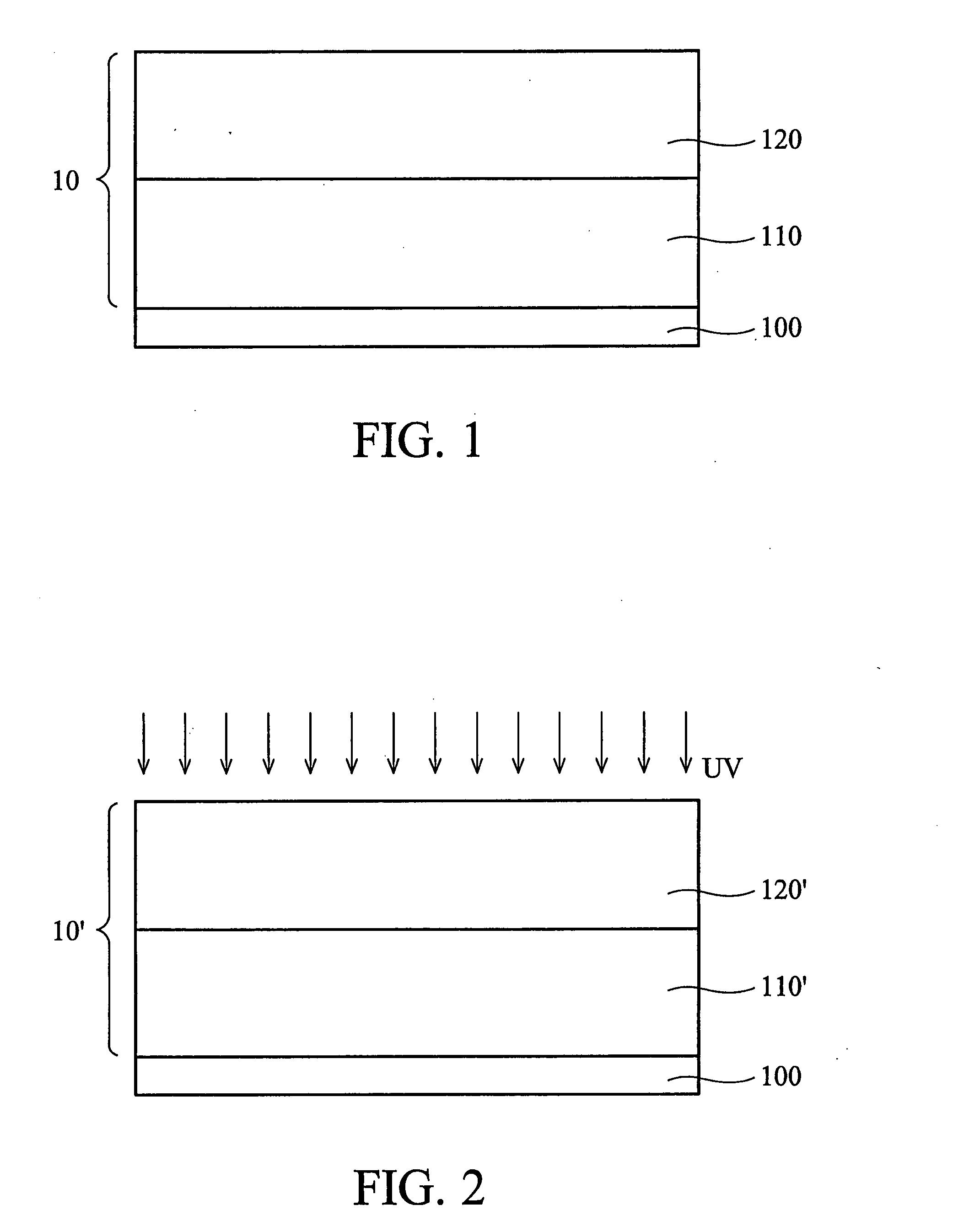

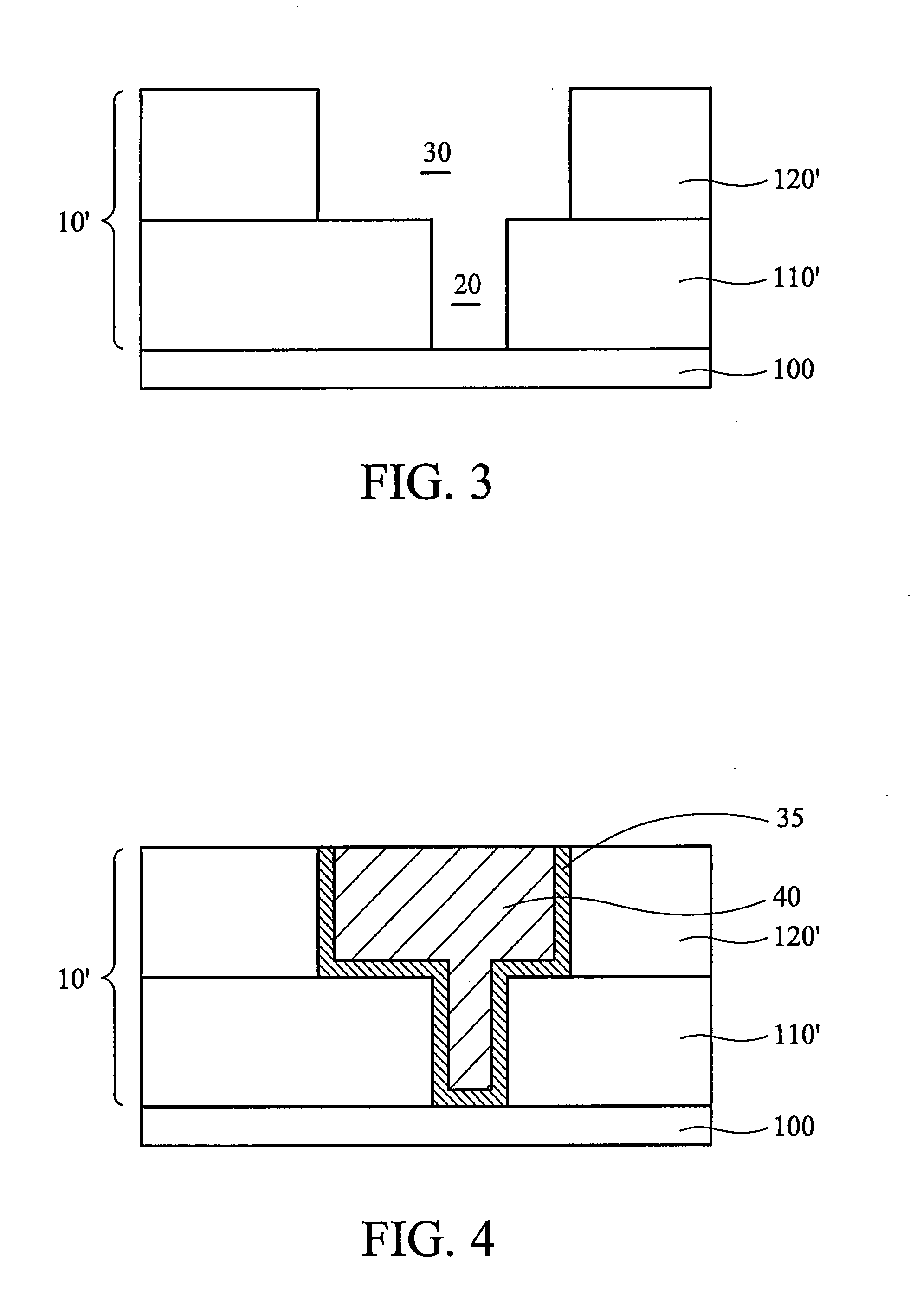

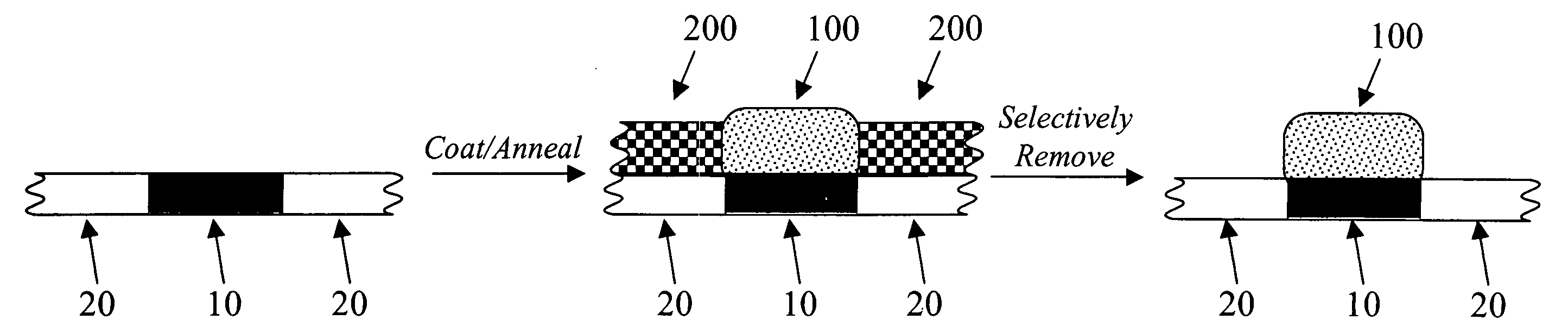

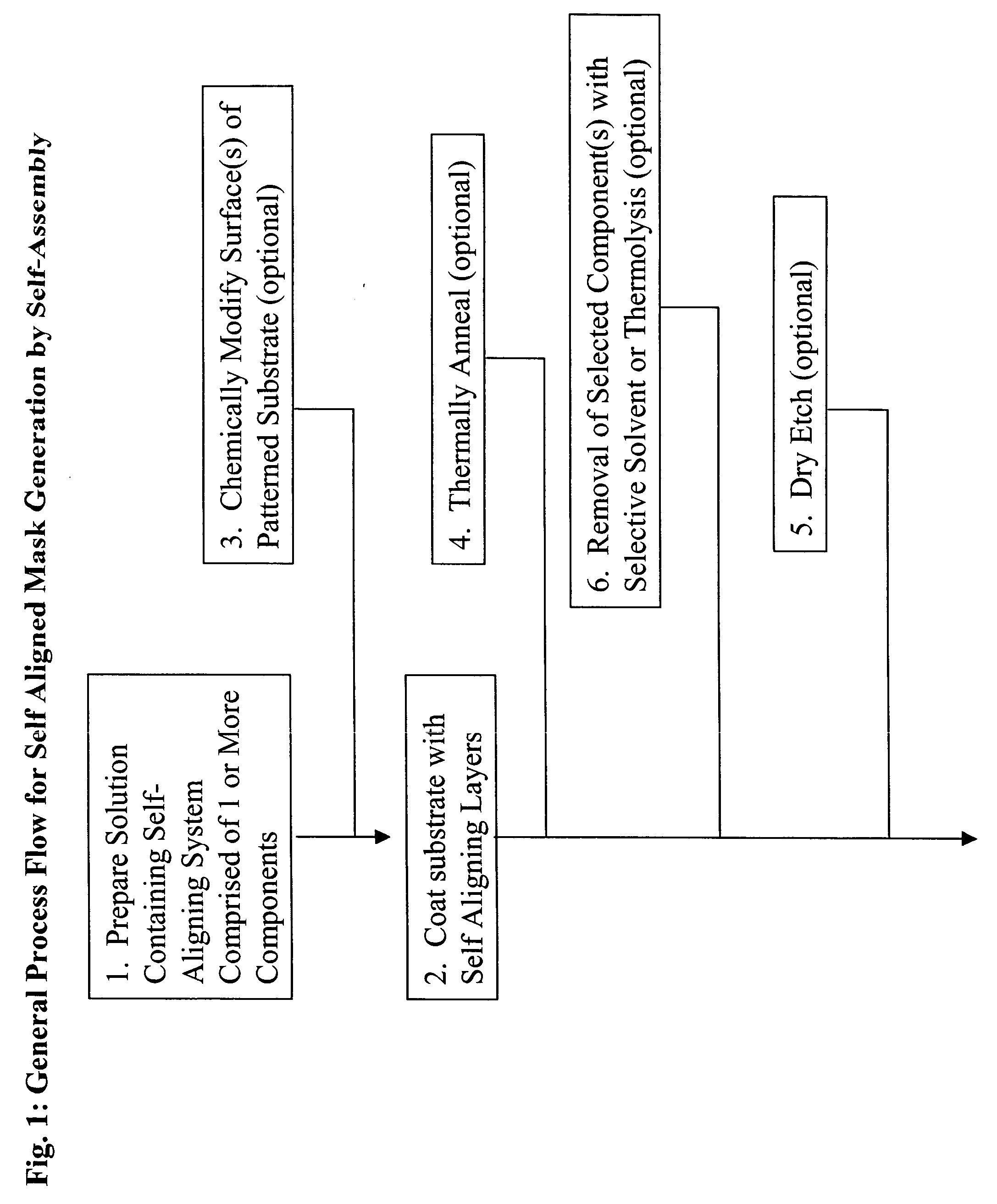

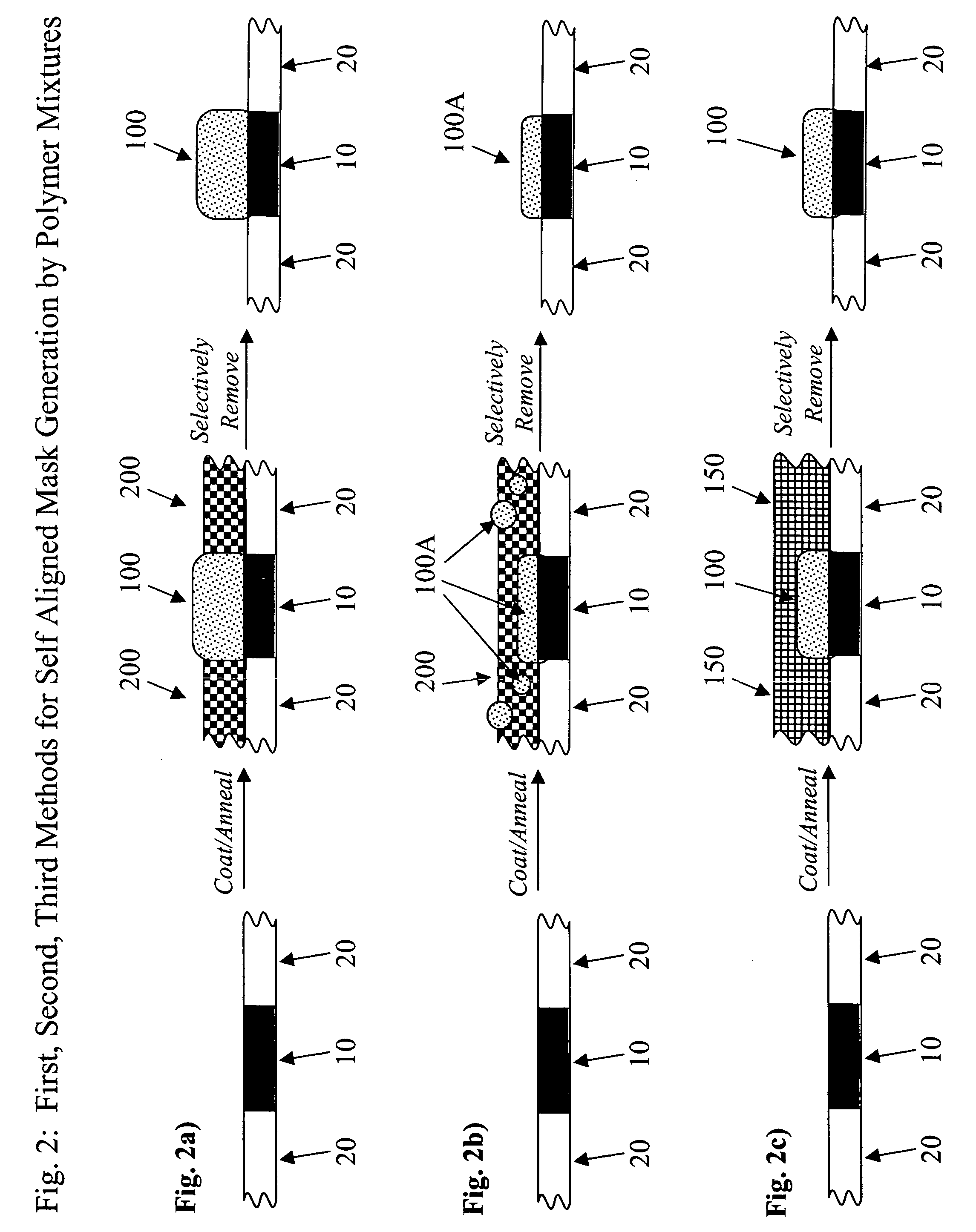

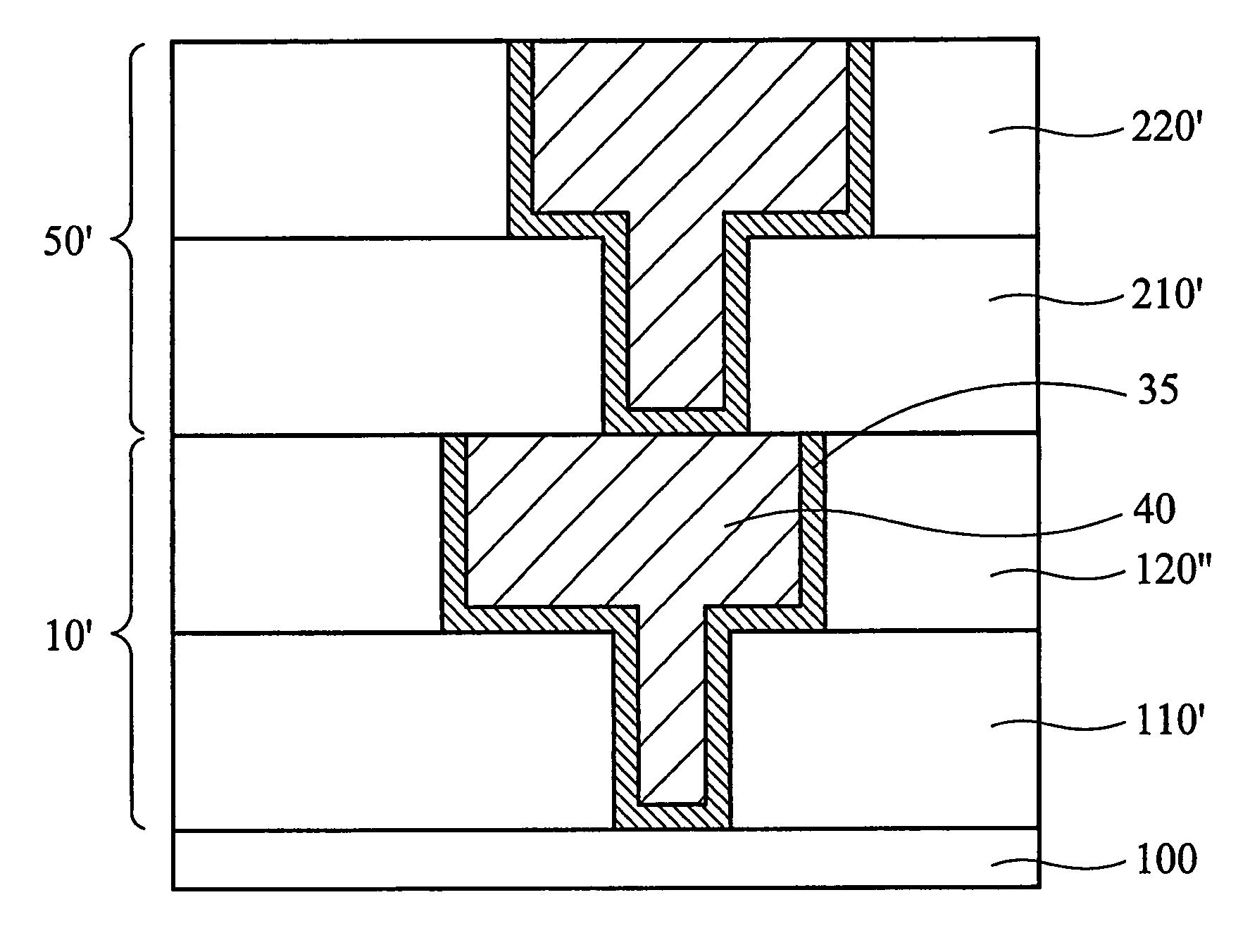

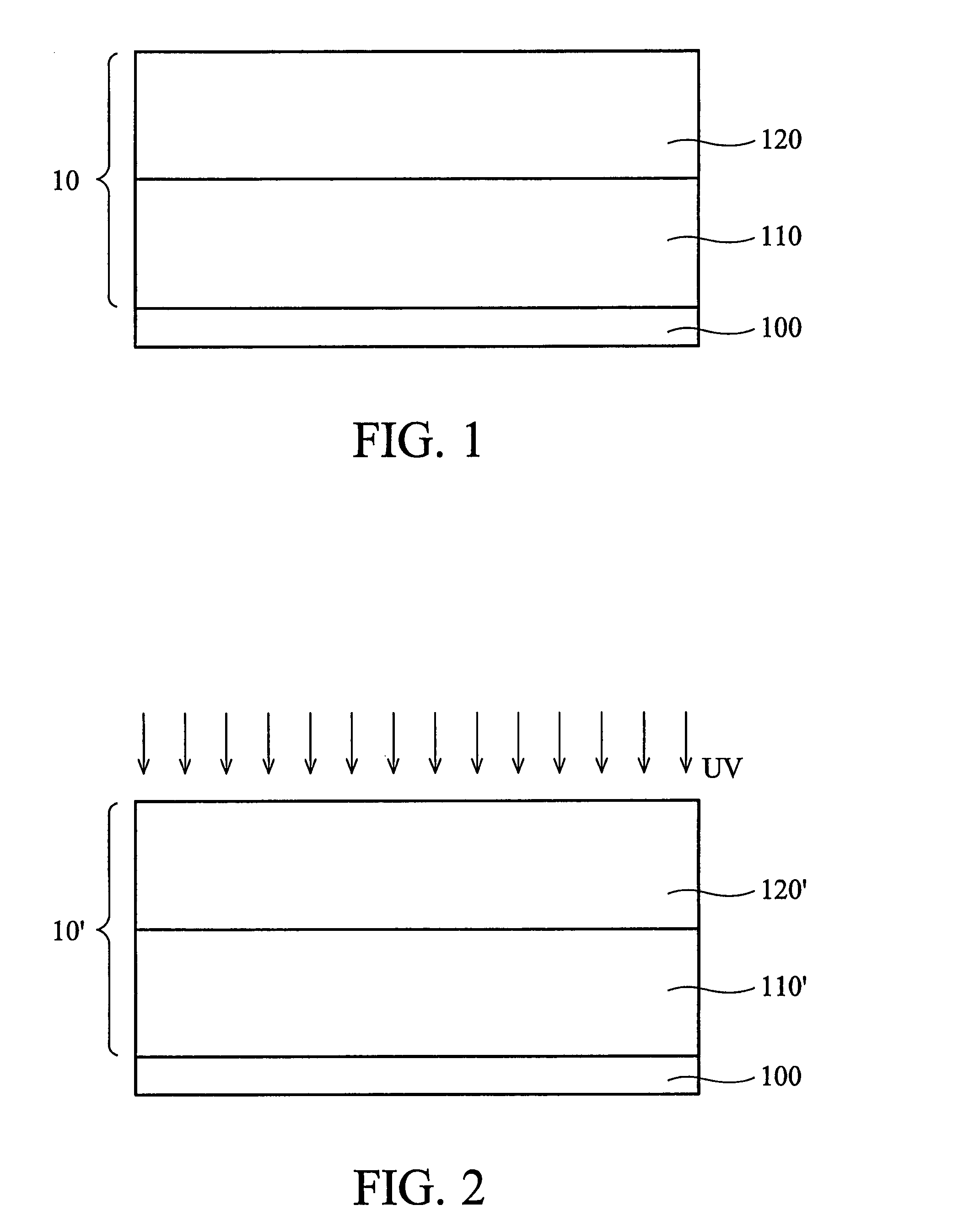

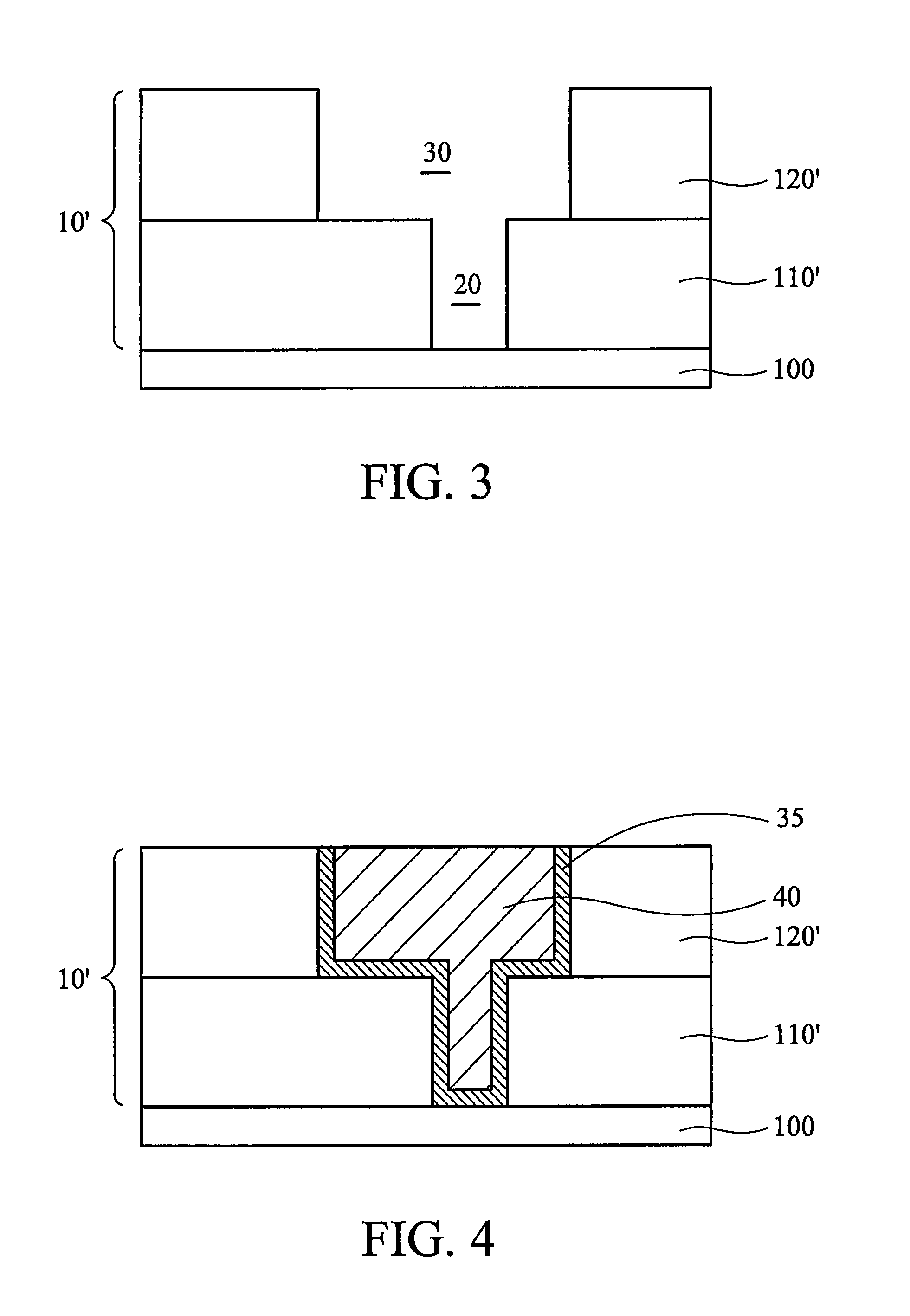

Nonlithographic method to produce self-aligned mask, articles produced by same and compositions for same

InactiveUS6911400B2Simple and robustSpeed maximizationLayered productsDecorative surface effectsAtomic compositionDielectric

A method for forming a self aligned pattern on an existing pattern on a substrate comprising applying a coating of a solution containing a masking material in a carrier, the masking material having an affinity for portions of the existing pattern; and allowing at least a portion of the masking material to preferentially assemble to the portions of the existing pattern. The pattern may be comprised of a first set of regions of the substrate having a first atomic composition and a second set of regions of the substrate having a second atomic composition different from the first composition. The first set of regions may include one or more metal elements and the second set of regions may include a dielectric. The first and second regions may be treated to have different surface properties. Structures made in accordance with the method. Compositions useful for practicing the method.

Owner:GLOBALFOUNDRIES INC

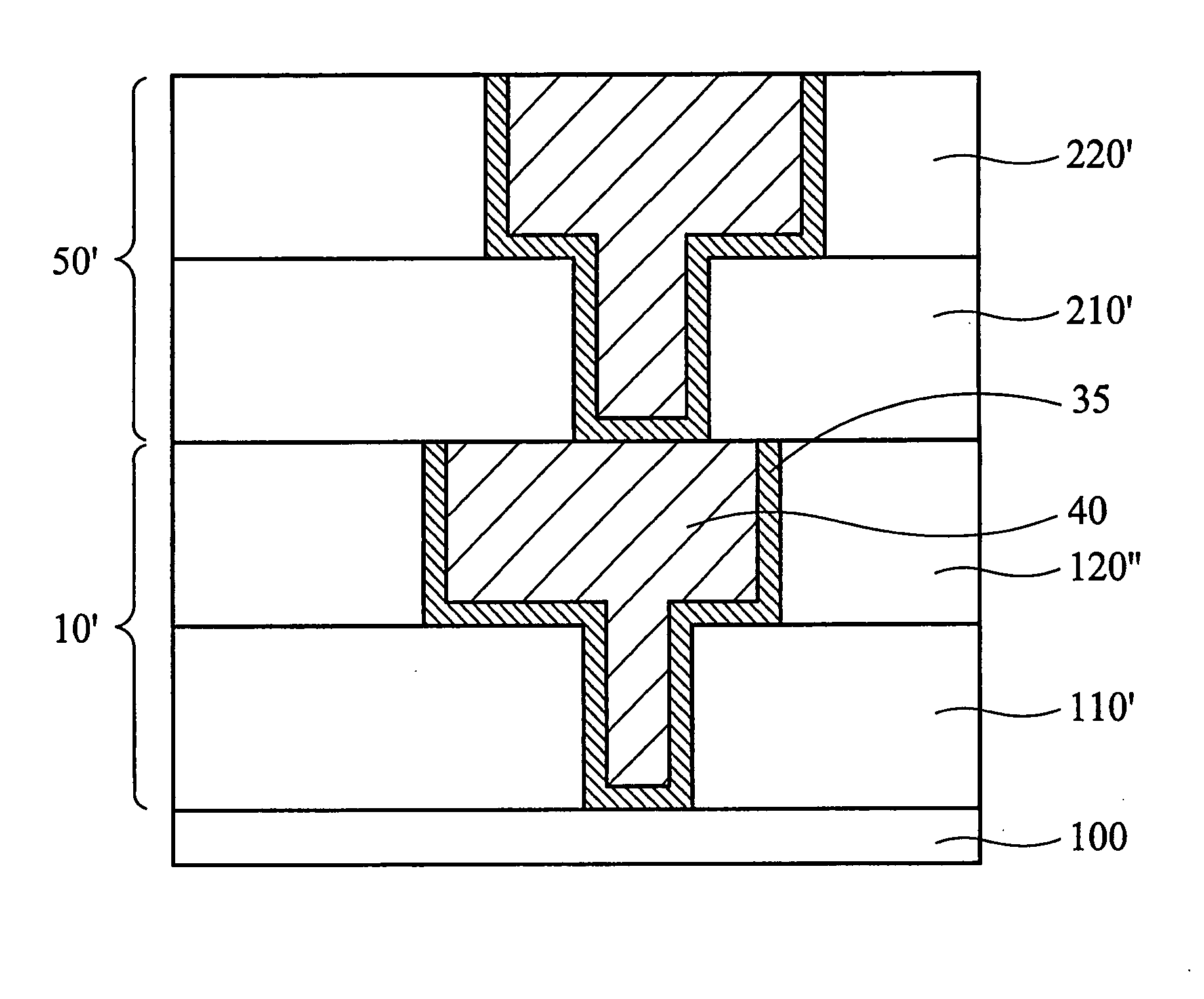

Interconnects containing bilayer porous low-k dielectrics using different porogen to structure former ratio

InactiveUS20080171431A1High strengthHigh hardnessRadiation applicationsSemiconductor/solid-state device detailsAtomic compositionDielectric permittivity

A bilayer porous low dielectric constant (low-k) interconnect structure and methods of fabricating the same are presented. A preferred embodiment having an effective dielectric constant of about 2.2 comprises a bottom deposited dielectric layer and a top deposited dielectric layer in direct contact with the former. The bottom layer and the top layer have same atomic compositions, but a higher dielectric constant value k. The bottom dielectric layer serves as an etch stop layer for the top dielectric layer, and the top dielectric layer can act as CMP stop layer. One embodiment of making the structure includes forming a bottom dielectric layer having a first porogen content and a top dielectric layer having a higher porogen content. A curing process leaves lower pore density in the bottom dielectric layer than that left in the top dielectric layer, which leads to higher dielectric value k in the bottom dielectric layer.

Owner:TAIWAN SEMICON MFG CO LTD

Method of manufacturing semiconductor active layer, method of manufacturing thin film transistor using the same and thin film transistor having semiconductor active layer

A method of manufacturing an IGZO active layer includes depositing ions including In, Ga, and Zn from a first target, and depositing ions including In from a second target having a different atomic composition from the first target. The deposition of ions from the second target may be controlled to adjust an atomic % of In in the IGZO layer to be about 45 atomic % to about 80 atomic %.

Owner:SAMSUNG DISPLAY CO LTD

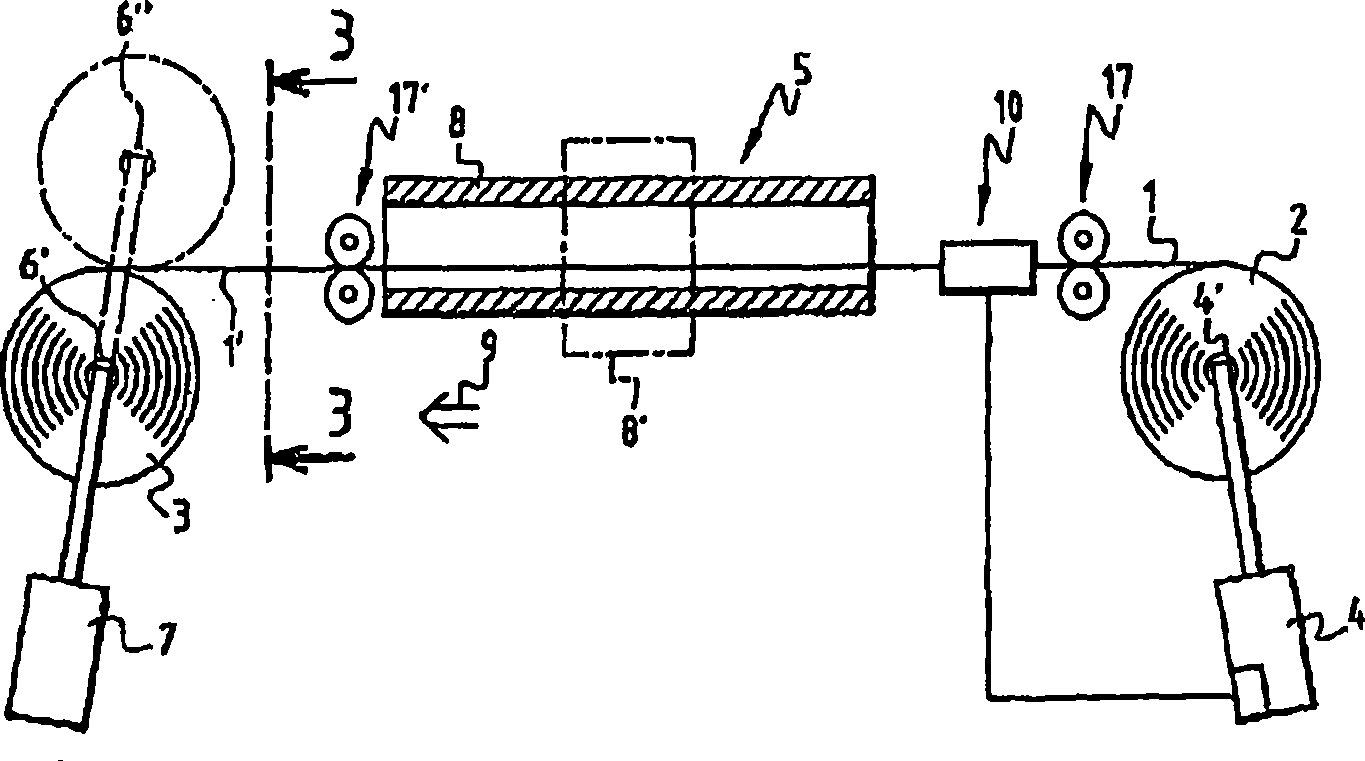

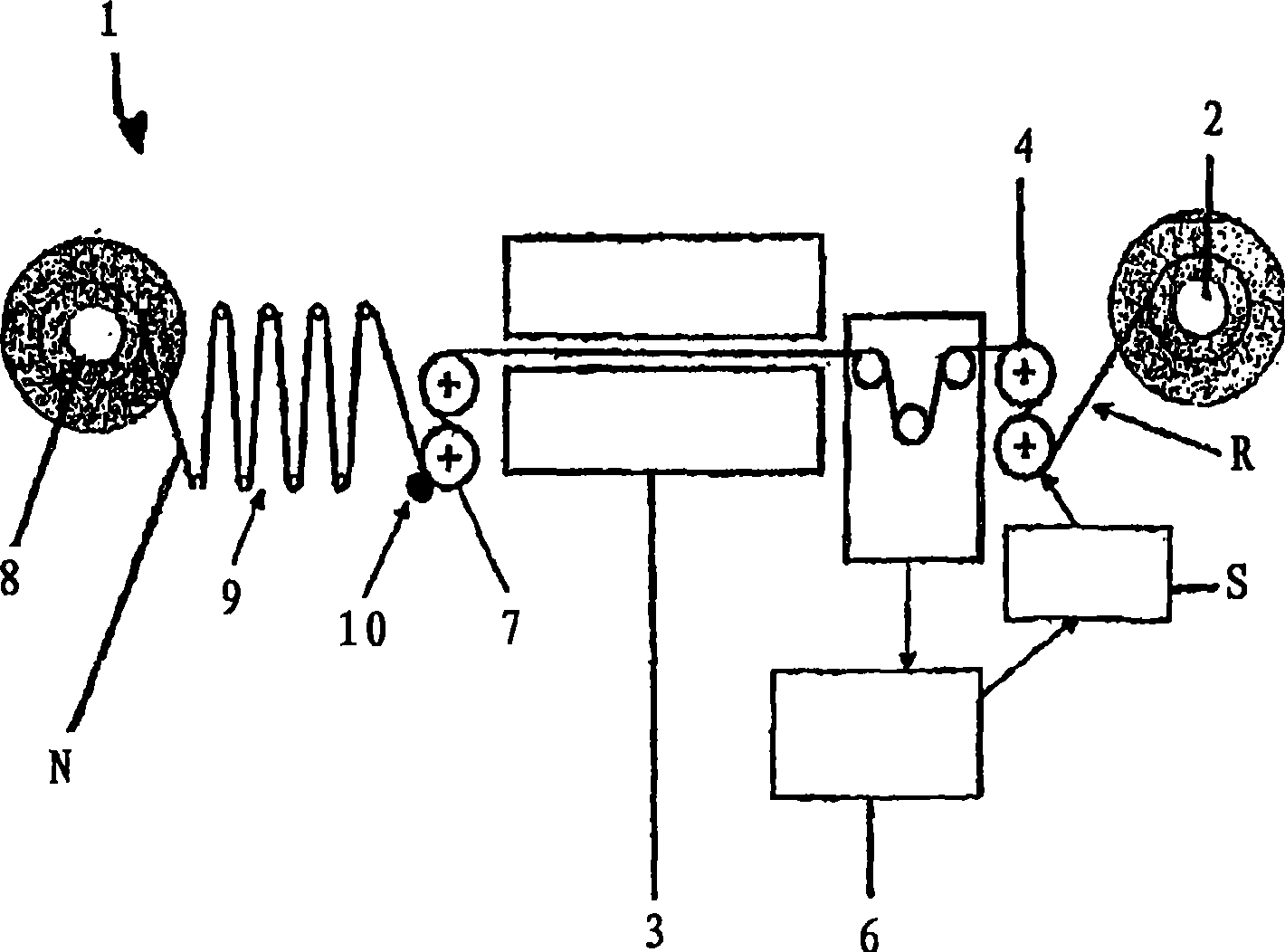

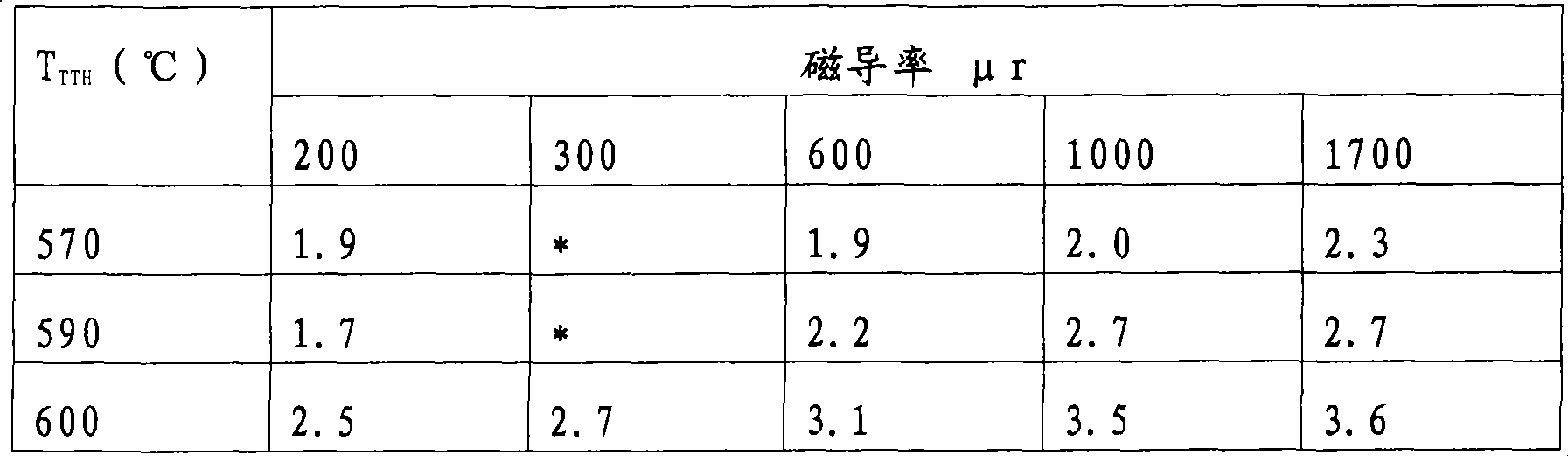

Method of producing a strip of nanocrystalline material and device for producing a wound core from said strip

The invention relates to a method of producing a strip of nanocrystalline material which is obtained from a wound ribbon that is cast in an amorphous state, having atomic composition [Fe1-a-bCoaNib]100-x-y-2-alpha-beta-gamma Cu<x>Si<y>BzNbalphaM'betaM''gamma, M' being at least one of elements V, Cr, Al and Zn, and M being at least one of elements C, Ge, P, Ga, Sb, In and Be, with: a <= 0.07 and b = 0.1, 0.5 <= x <=1.5 and 2 <= a <= 5, 10 <= y <= 16.9 and 5 <= z <= 8, beta <= 2 and gamma <= 2. According to the invention, the amorphous ribbon is subjected to crystallisation annealing, in which the ribbon undergoes annealing in the unwound state, passing through at least two S-shaped blocks under voltage along an essentially longitudinal axial direction of the ribbon, such that the ribbon is maintained at an annealing temperature of between 530 DEG C and 700 DEG C for between 5 and 120 seconds and under axial tensile stress of between 2 and 1000 Mpa. The tensile stress applied to the amorphous ribbon, the displacement speed of the ribbon during annealing and the annealing time and temperature are all selected such that the cross-section profile of the strip is not in the form of Omega and the maximum deflection of the cross-section of the strip is less than 3% of the width of the strip and preferably less than 1% of the width. The invention also relates to the strip and the core thus obtained and to the device used to implement the method.

Owner:IMPHY ALLOYS

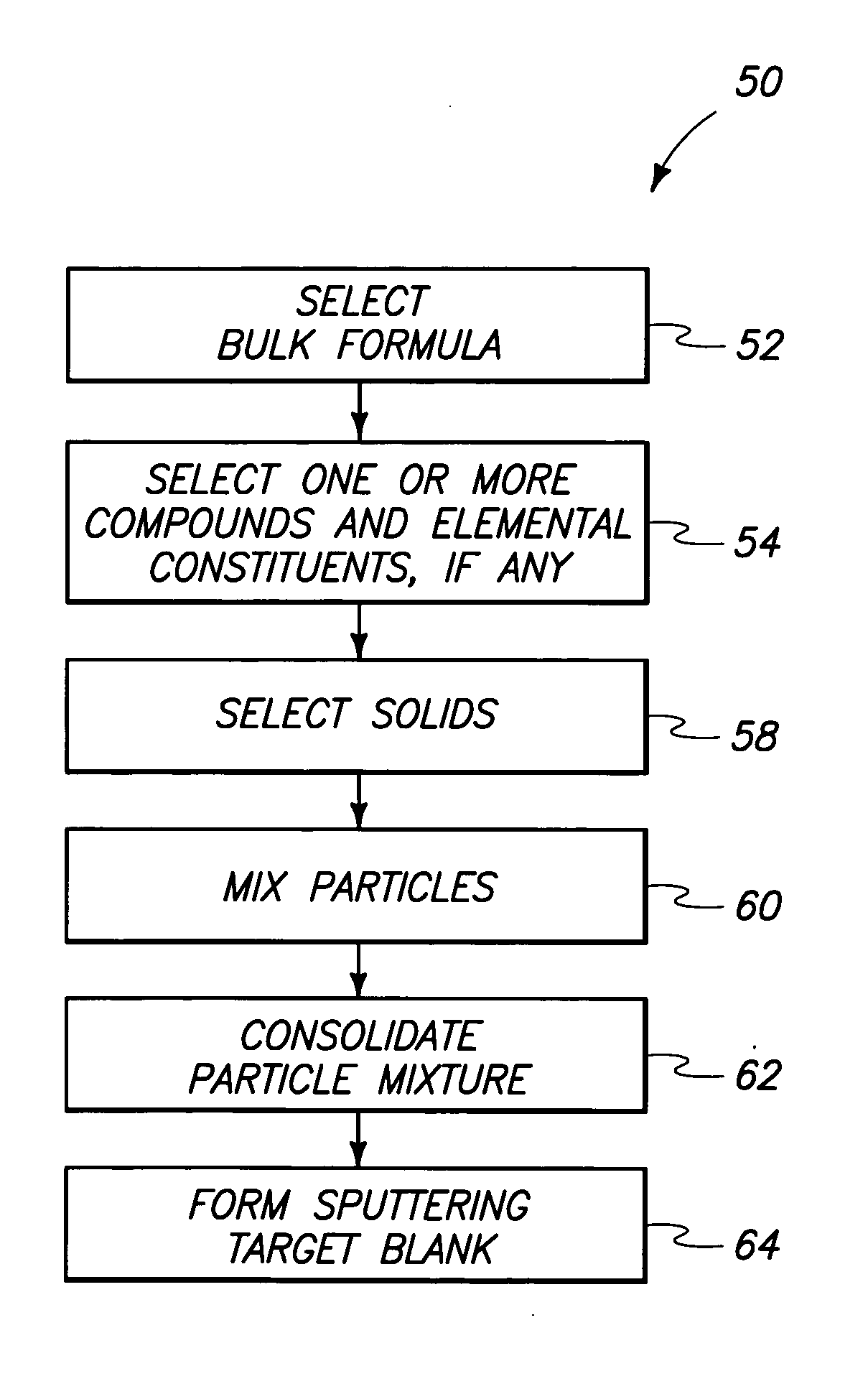

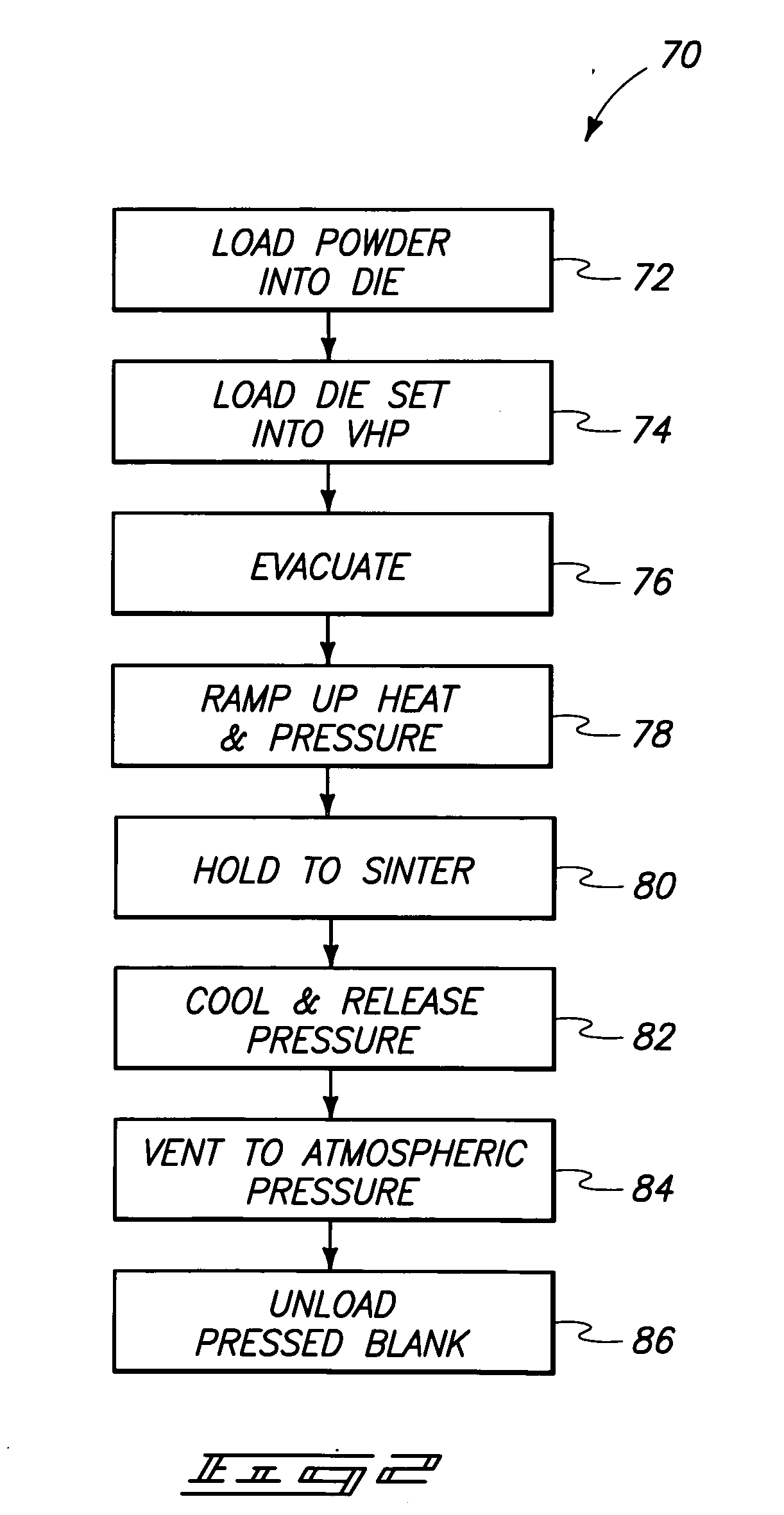

Chalcogenide PVD components and methods of formation

A PVD component forming method includes identifying two or more solids having different compositions, homogeneously mixing particles of the solids using proportions which yield a bulk formula, consolidating the homogeneous particle mixture to obtain a rigid mass while applying pressure and using a temperature below the minimum temperature of melting or sublimation of the solids, and forming a PVD component including the mass. A chalcogenide PVD component includes a rigid mass containing a bonded homogeneous mixture of particles of two or more solids having different compositions, the mass having a microcomposite structure exhibiting a maximum feature size of 500 μm or less, and one or more of the solids containing a compound of two or more bulk formula elements. An alternative PVD component exhibits a uniform composition with less than 10% difference in atomic compositions from feature to feature.

Owner:HONEYWELL INT INC

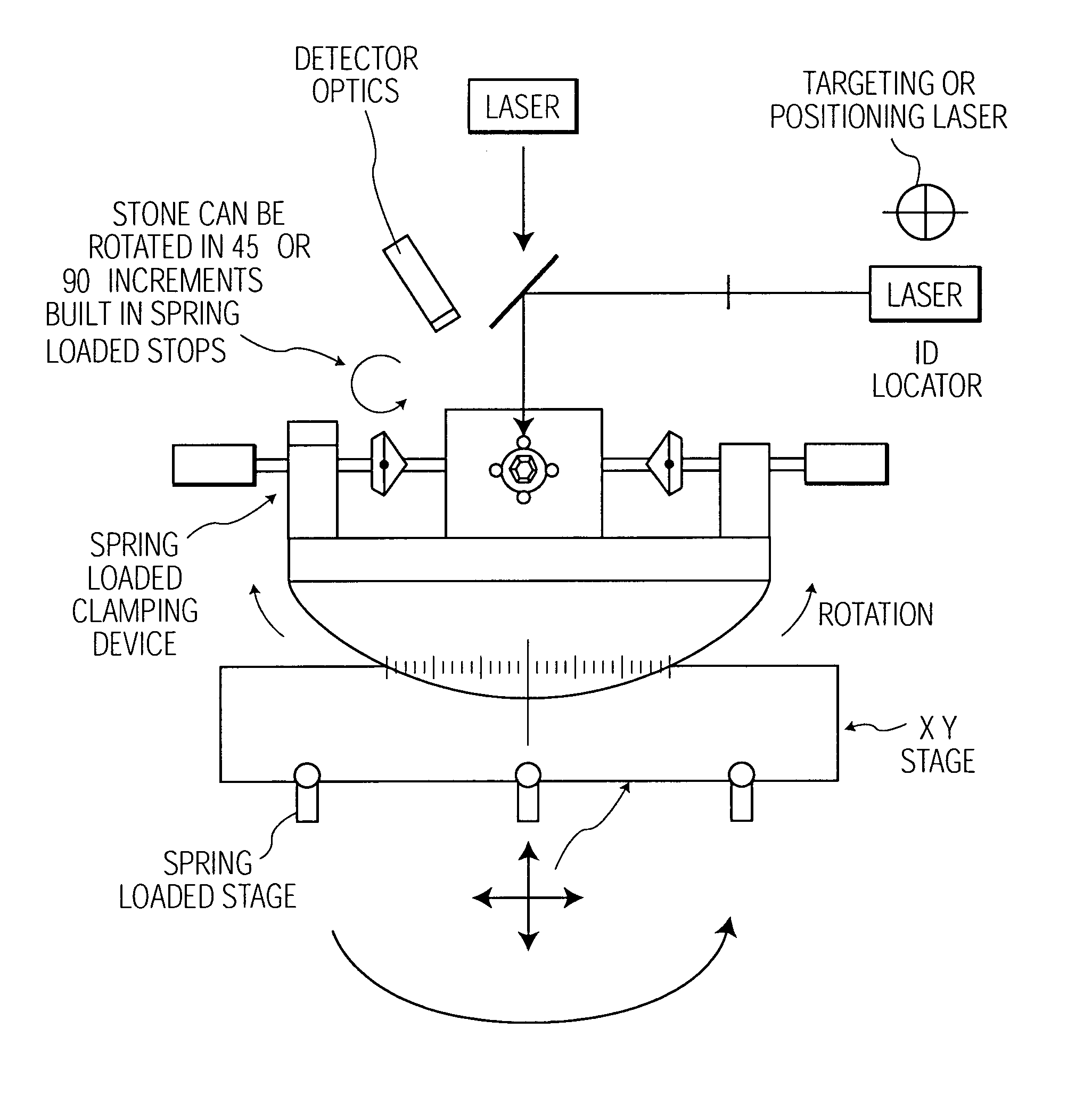

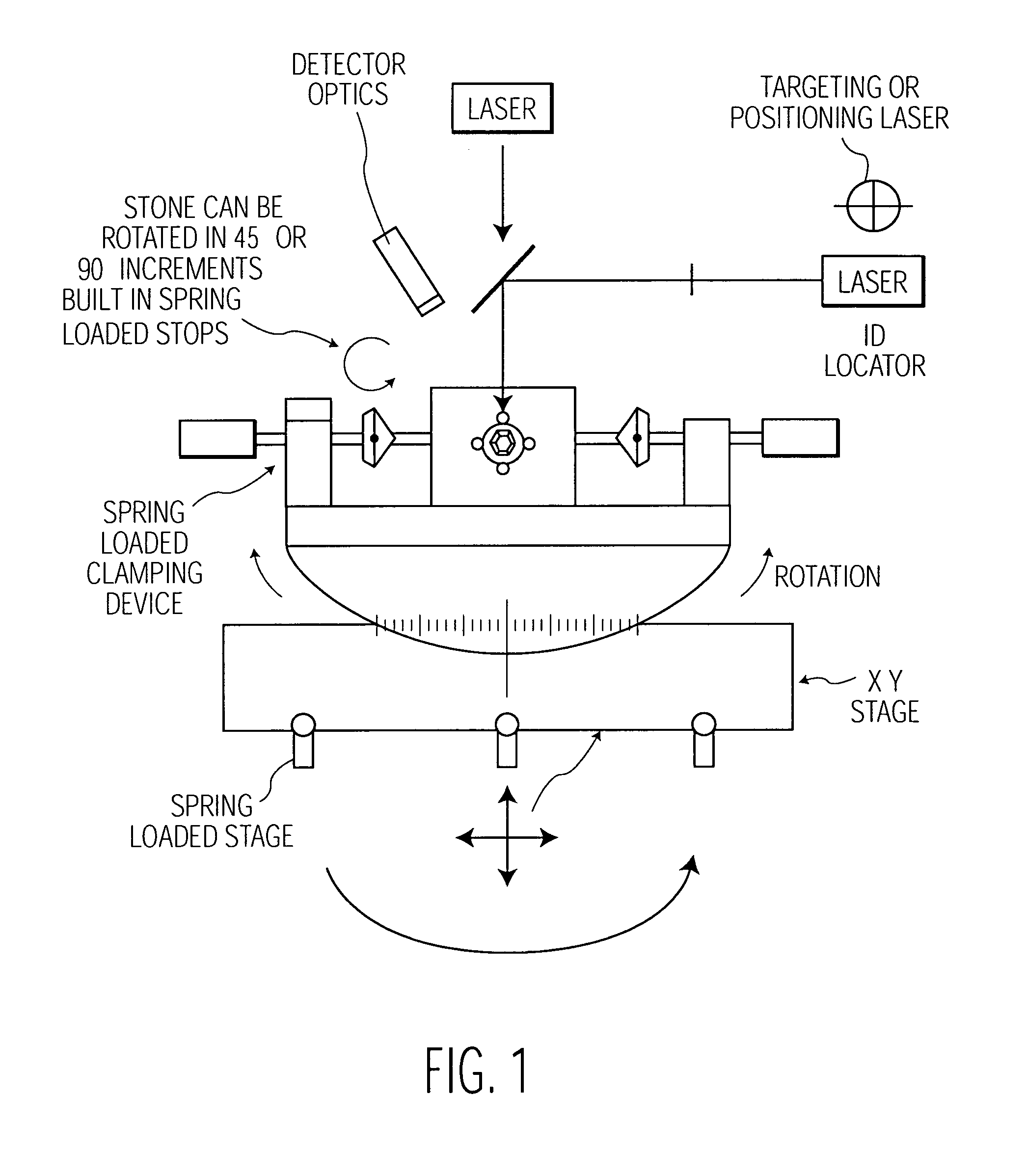

System and method for analysis of gemstones

InactiveUS7557917B1Reduce detection limitRapid analysis cycleRadiation pyrometrySpectrum investigationSpectral emissionChemical composition

A system for analyzing the chemical composition of a sample, comprising exciting a portion of the sample to generate atomic spectral emissions; a spectrometer for determining atomic emission characteristics; processor for receiving an output from the spectrometer, analyzing said output to determine atomic composition, said processor predicting at least one of (i) an origin of the sample, (ii) a treatment applied to said sample, (iii) a composition of the sample, and (iv) a feedback signal for controlling a process. Calibration samples are also provided for standardizing readings from the spectrometer.

Owner:AMERICAN GEMOLOGICAL LAB

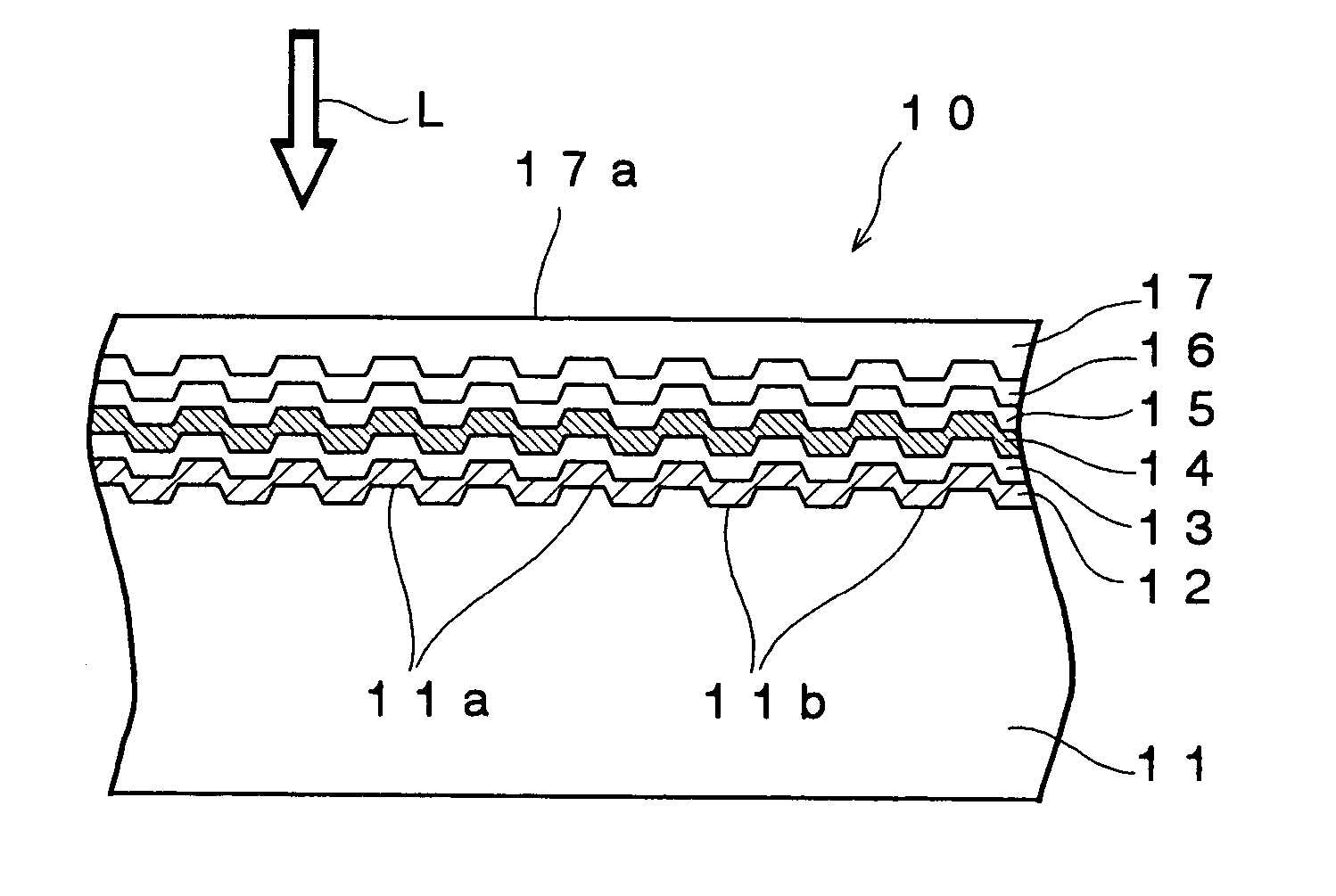

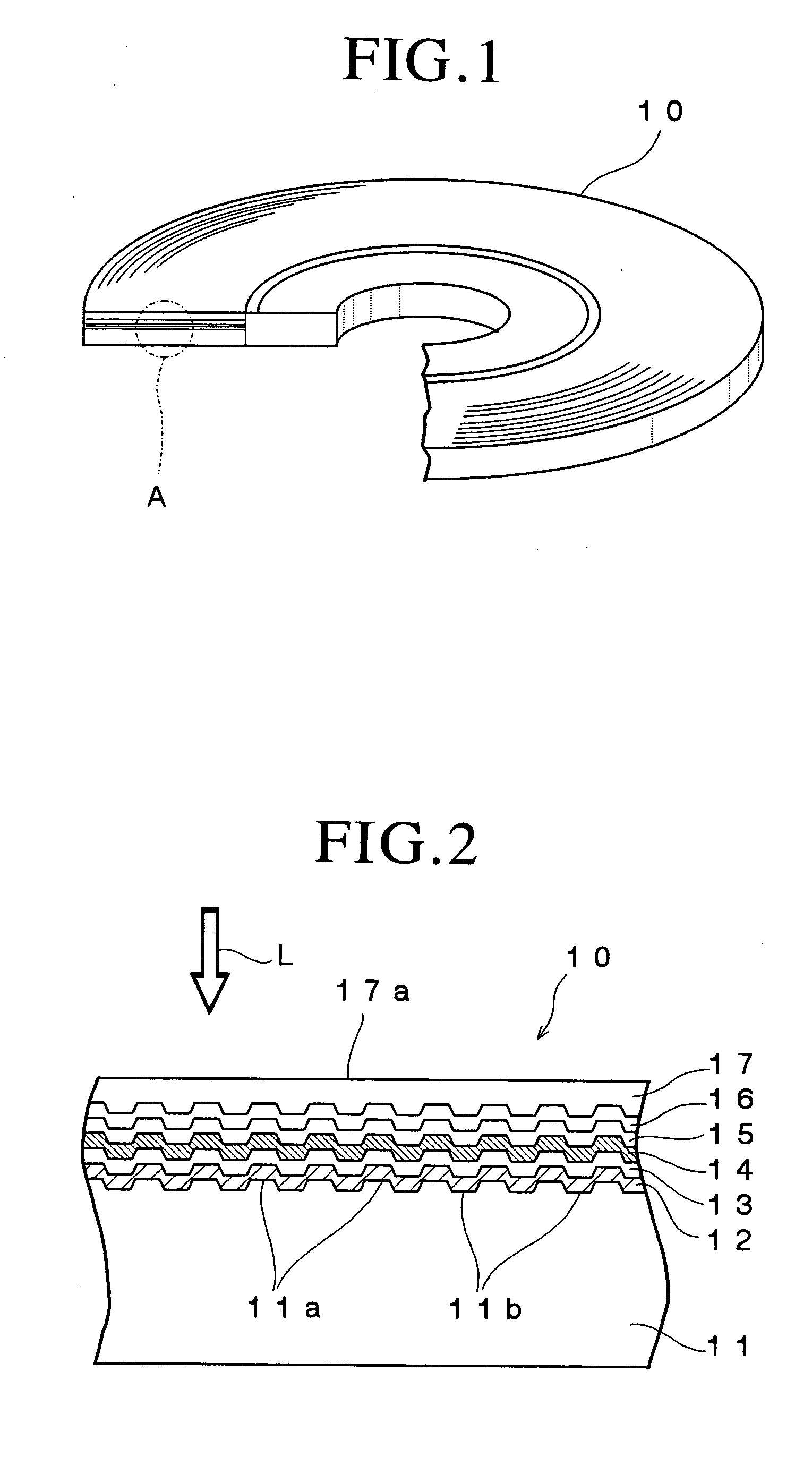

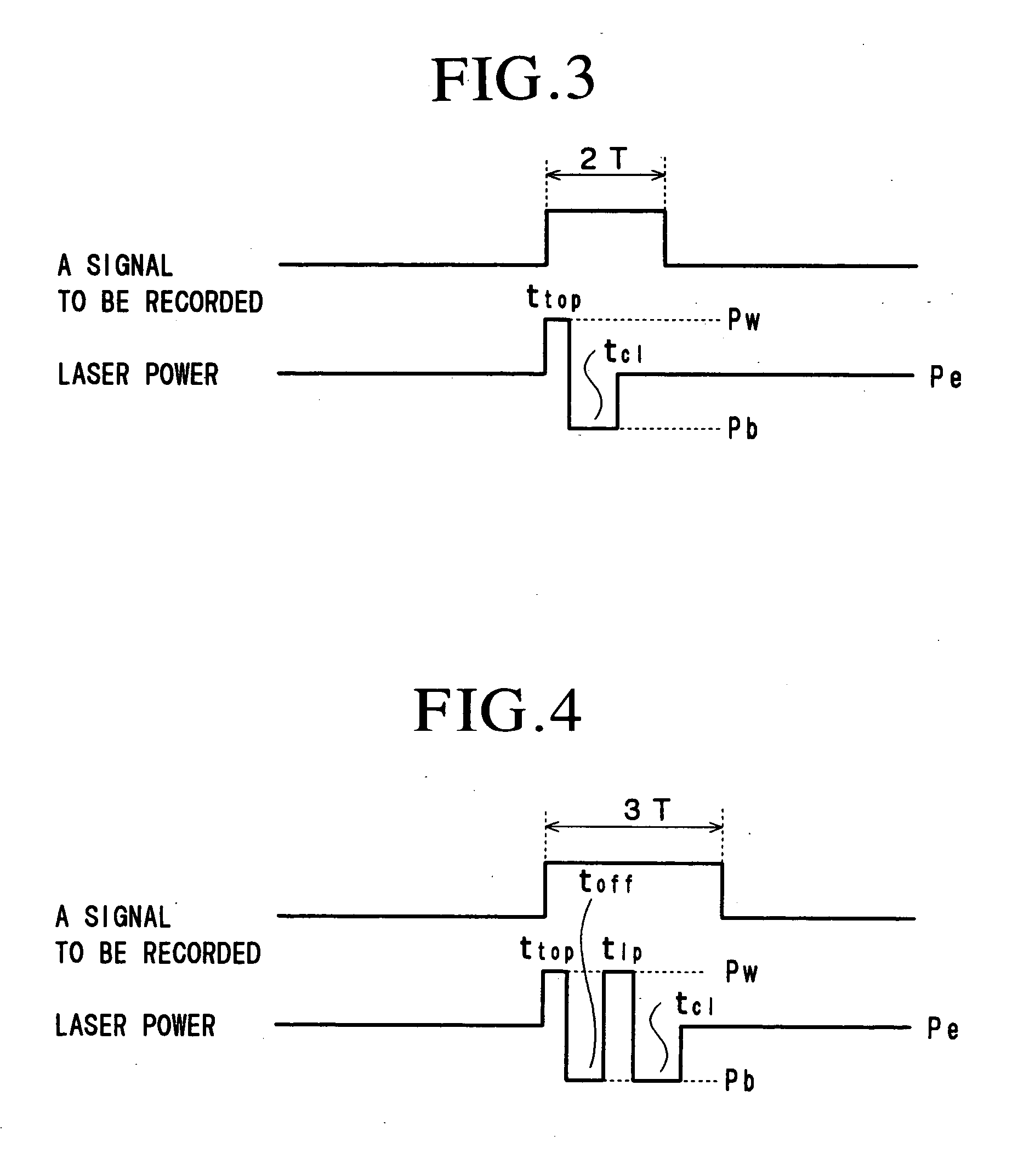

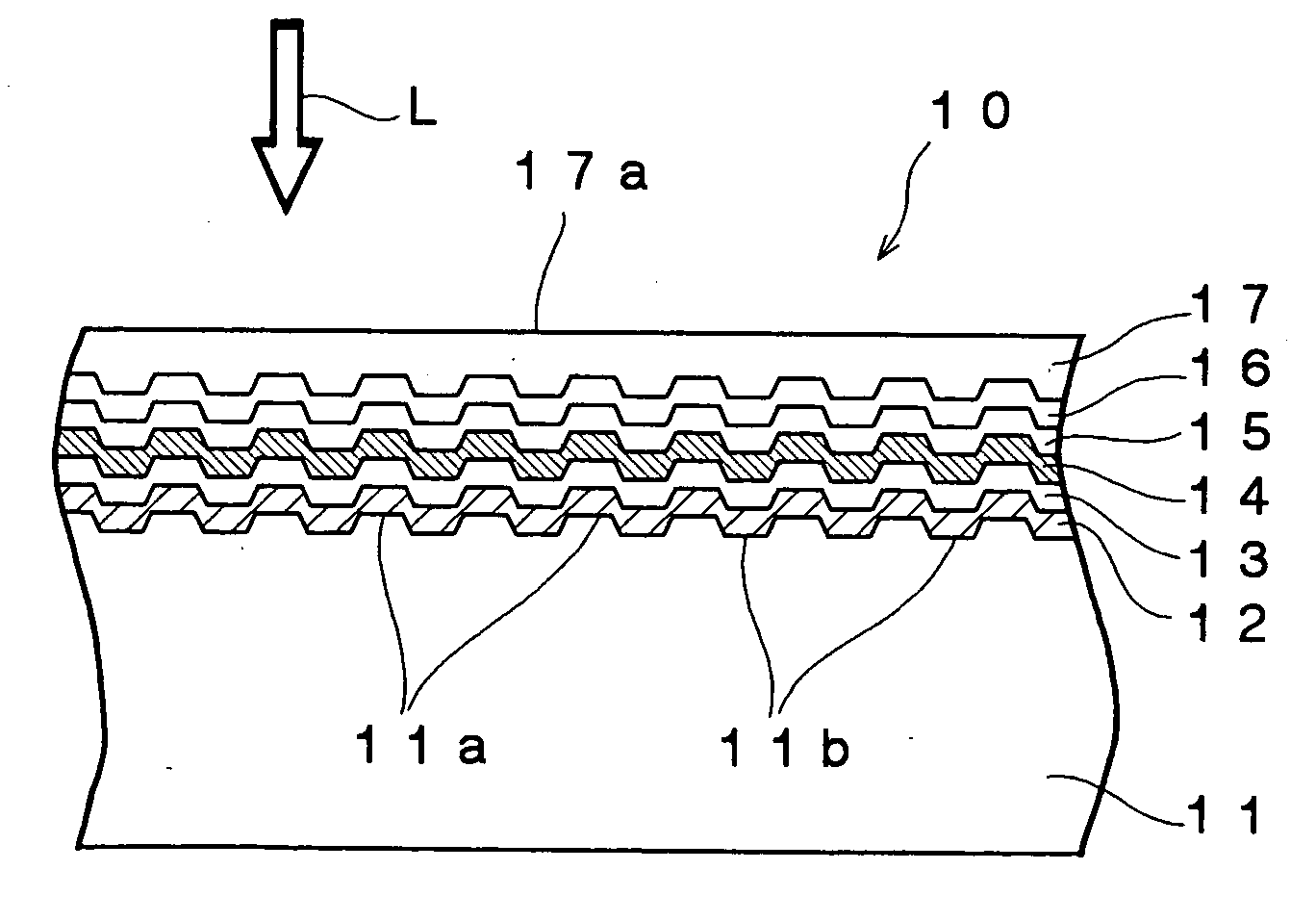

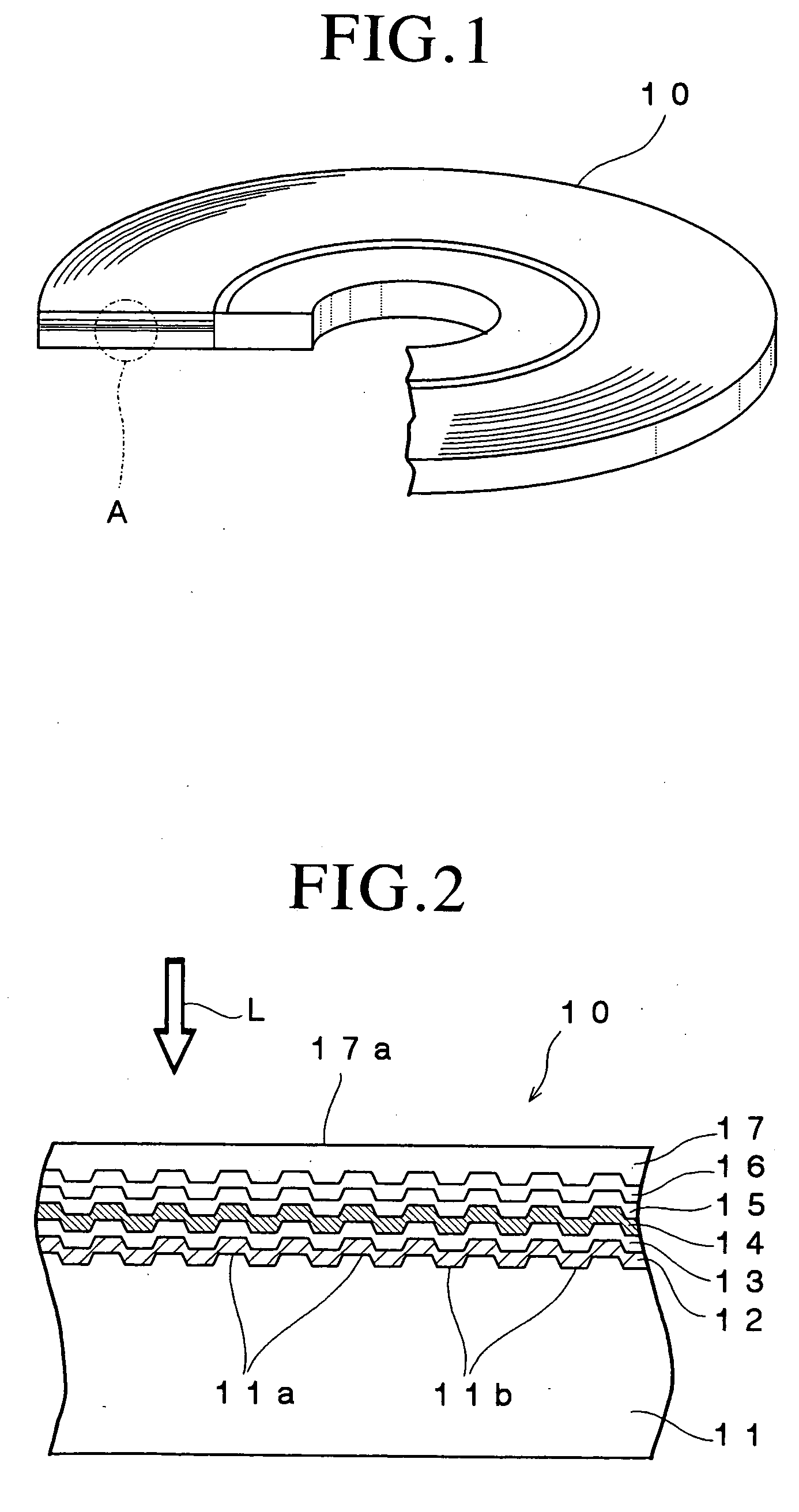

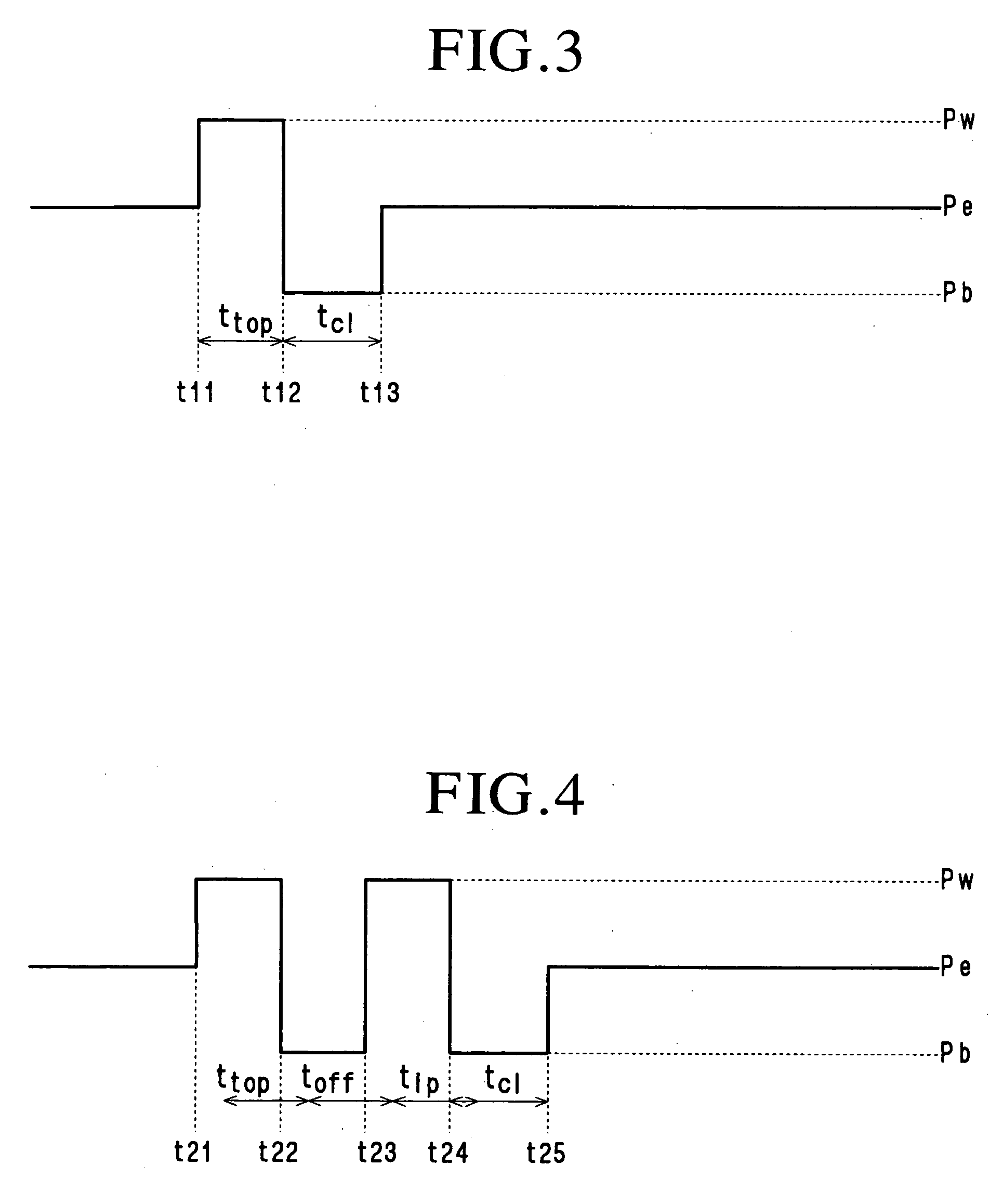

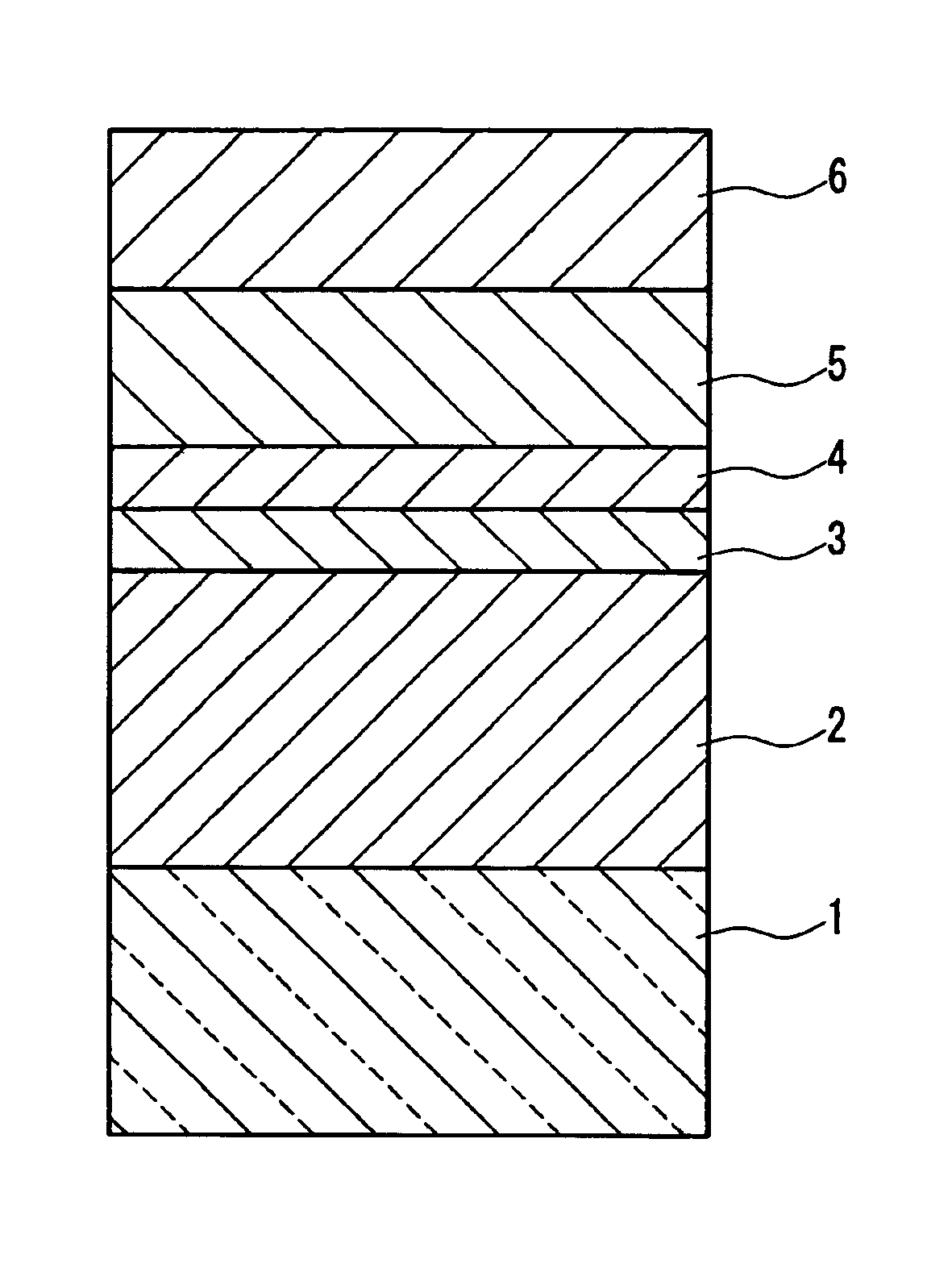

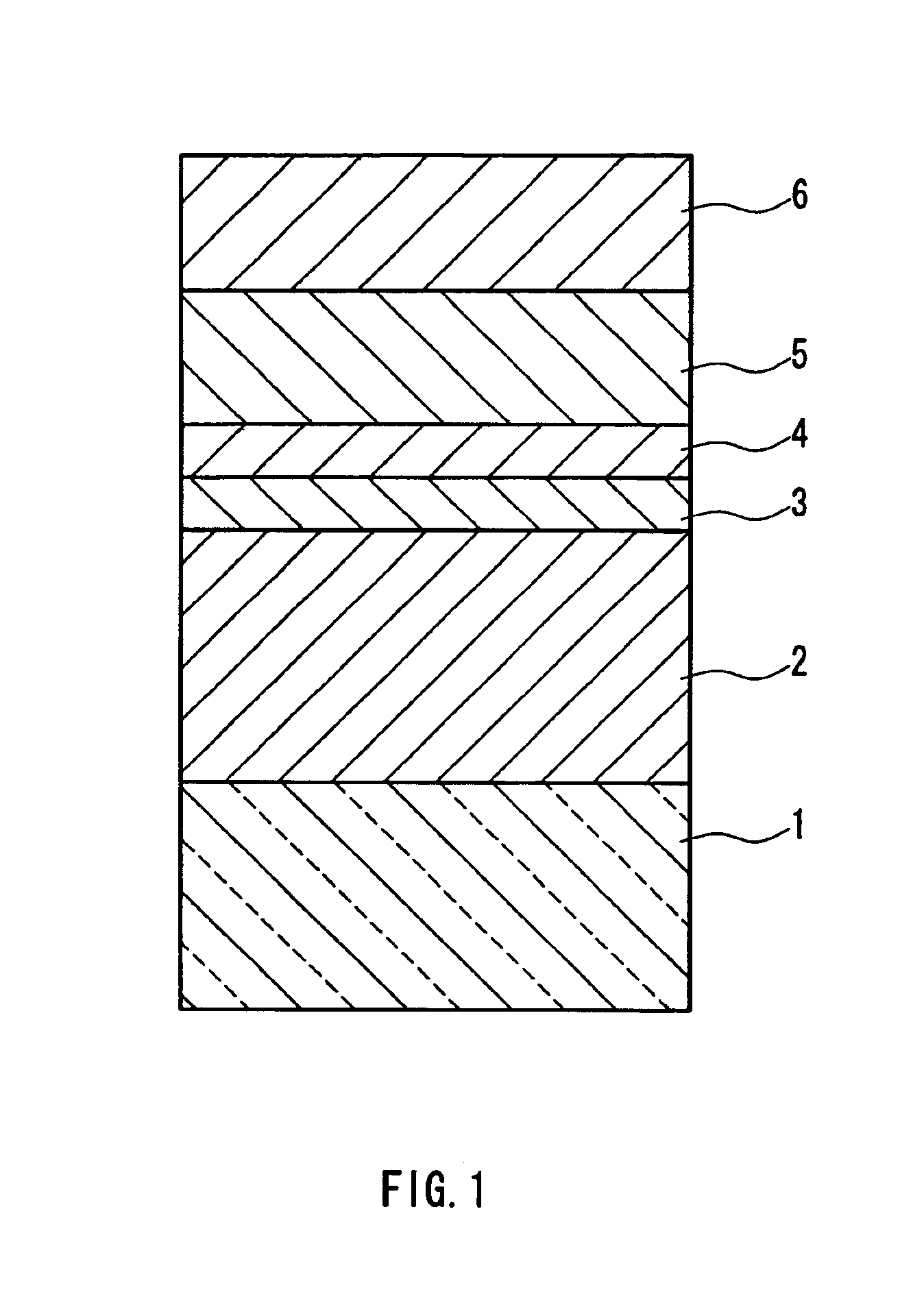

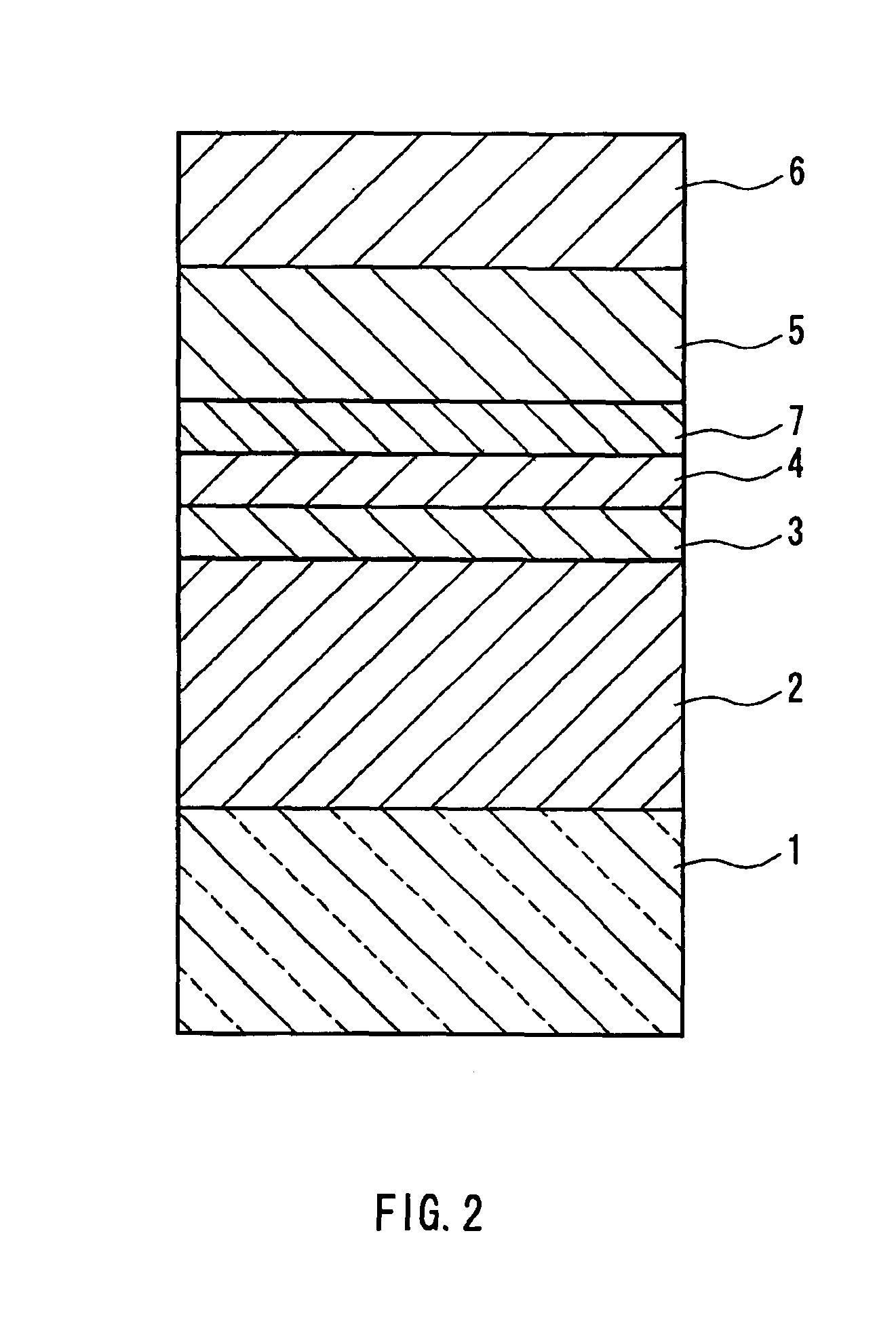

Optical recording medium

An optical recording medium includes a recording layer, a first dielectric layer disposed on the side of a light incidence plane through which the laser beam enters with respect to the recording layer, a second dielectric layer disposed on the side opposite to the light incidence plane with respect to the recording layer, a heat radiation layer disposed on the side of the light incidence plane with respect to the first dielectric layer and a reflective layer disposed on the side opposite to the light incidence plane with respect to the second dielectric layer, the recording layer containing a phase change material represented by an atomic composition formula: SbaTebGecMnd, where a is equal to or larger than 55 and equal to or smaller than 70, c is equal to or larger than 4 and equal to or smaller than 10, d is equal to or larger than 10 and equal to or smaller than 20, a / b is equal to or larger than 2.8 and equal to or smaller than 3.5 and a / d is equal to or larger than 3.0 and equal to or smaller than 6.0, in an amount equal to or more than 95 atomic %. According to the thus constituted optical recording medium, it is possible to simultaneously improve characteristics of recording data therein at a high linear velocity, data reproduction durability and storage reliability.

Owner:TDK CORPARATION

Optical recording medium and data recording apparatus for recording data in the same

An optical recording medium includes a recording layer, a first dielectric layer disposed on the side of a light incidence plane through which the laser beam enters with respect to the recording layer, a second dielectric layer disposed on the side opposite to the light incidence plane with respect to the recording layer, a heat radiation layer disposed on the side of the light incidence plane with respect to the first dielectric layer and a reflective layer disposed on the side opposite to the light incidence plane with respect to the second dielectric layer, the recording layer containing a phase change material represented by an atomic composition formula: SbaTebGecTbd, where a is equal to or larger than 63 and equal to or smaller than 78, c is equal to or larger than 2 and equal to or smaller than 10, d is equal to or larger than 3 and equal to or smaller than 15, (a+d) is equal to or larger than 75 and equal to or smaller than 82 and a / b is equal to or larger than 3.3 and equal to or smaller than 4.9, in an amount equal to or more than 95 atomic %. According to the thus constituted optical recording medium, it is possible to simultaneously improve characteristics of recording data therein at a high linear velocity, data reproduction durability and storage reliability.

Owner:TDK CORPARATION

Target with metal glass coating and composite material prepared from target

InactiveCN101768718AUniform compositionVacuum evaporation coatingSputtering coatingAtomic compositionMetal

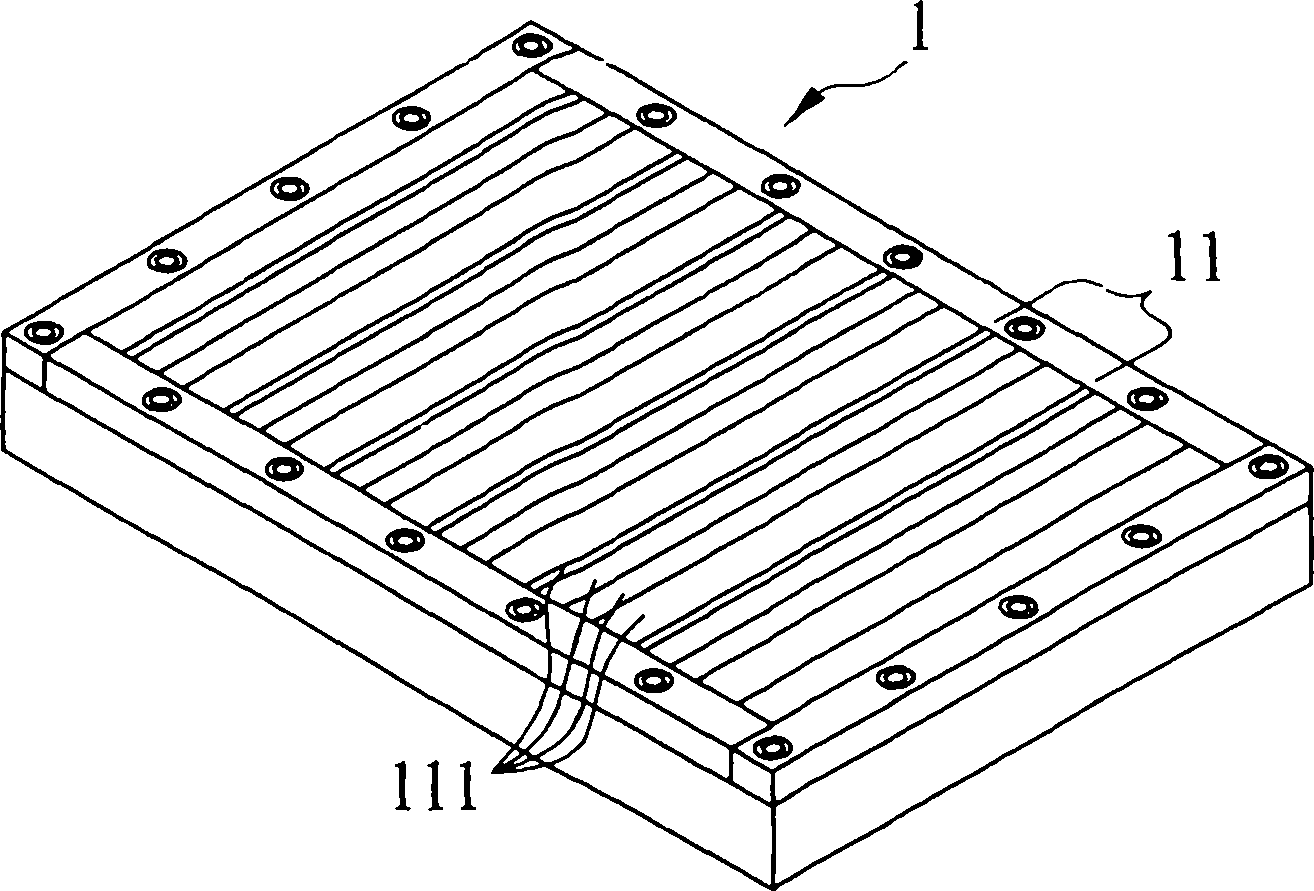

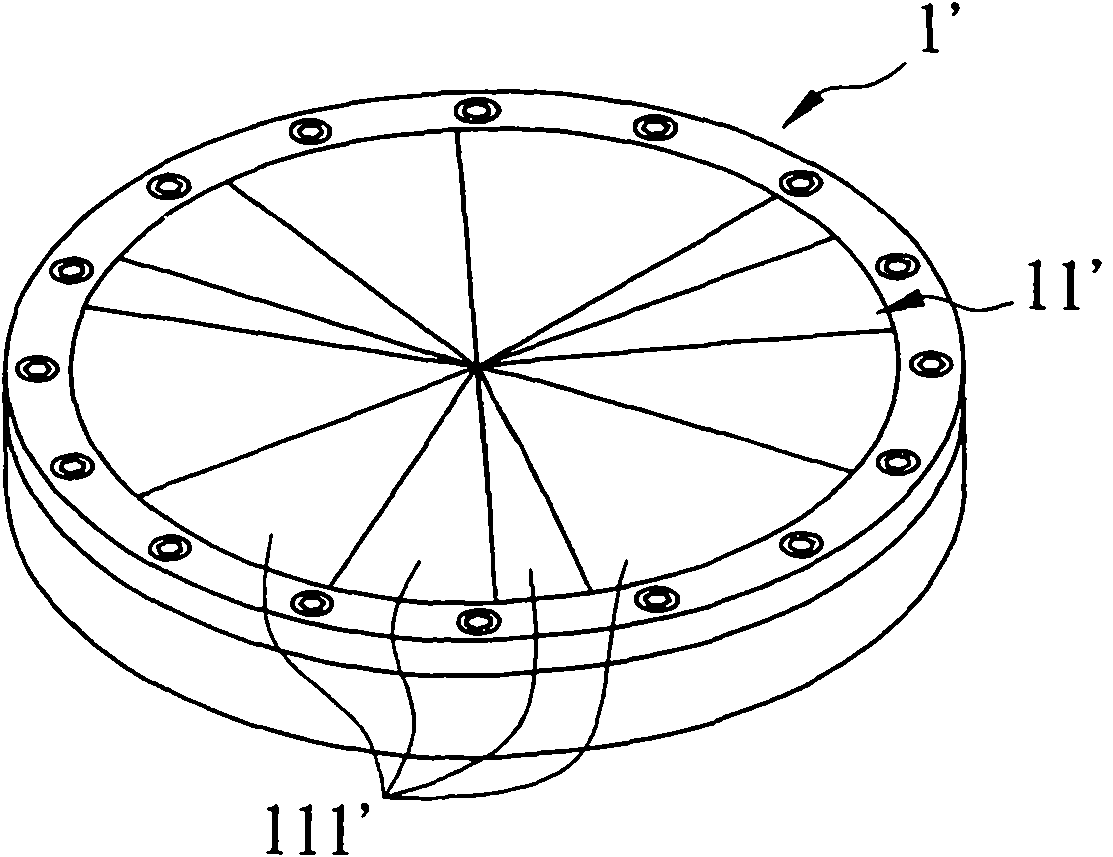

The invention discloses a target with a metal glass coating. The ZraKbMcNd metal glass coating is formed on a substrate by sputtering, wherein K, M and N are selected from elements in VB group, VIB group, VIIIA group, IB group, IIIA group and IVA group; the atomic radius percentage of any two of K, M and N is not less than 15 percent; and a, b, c and d represent atomic composition percentage, wherein a is more than or equal to 30 percent and less than or equal to 77 percent, b is more than or equal to 11 percent and less than or equal to 50 percent, c is more than or equal to 4 percent and less than or equal to 15 percent, and d is more than or equal to 4 percent and less than or equal to 10 percent. The target is provided with a plurality of fan-shaped coating material units which are spliced into a disc or arranged continuously in a rectangular shape, wherein each coating material unit is provided with four element strips which consist of four metal elements, namely zirconium, K, M and N, and the number ratio of zirconium, K, M and N of all the element strips and the metal glass coating are in a sputtering generation proportional relationship.

Owner:METAL INDS RES & DEV CENT

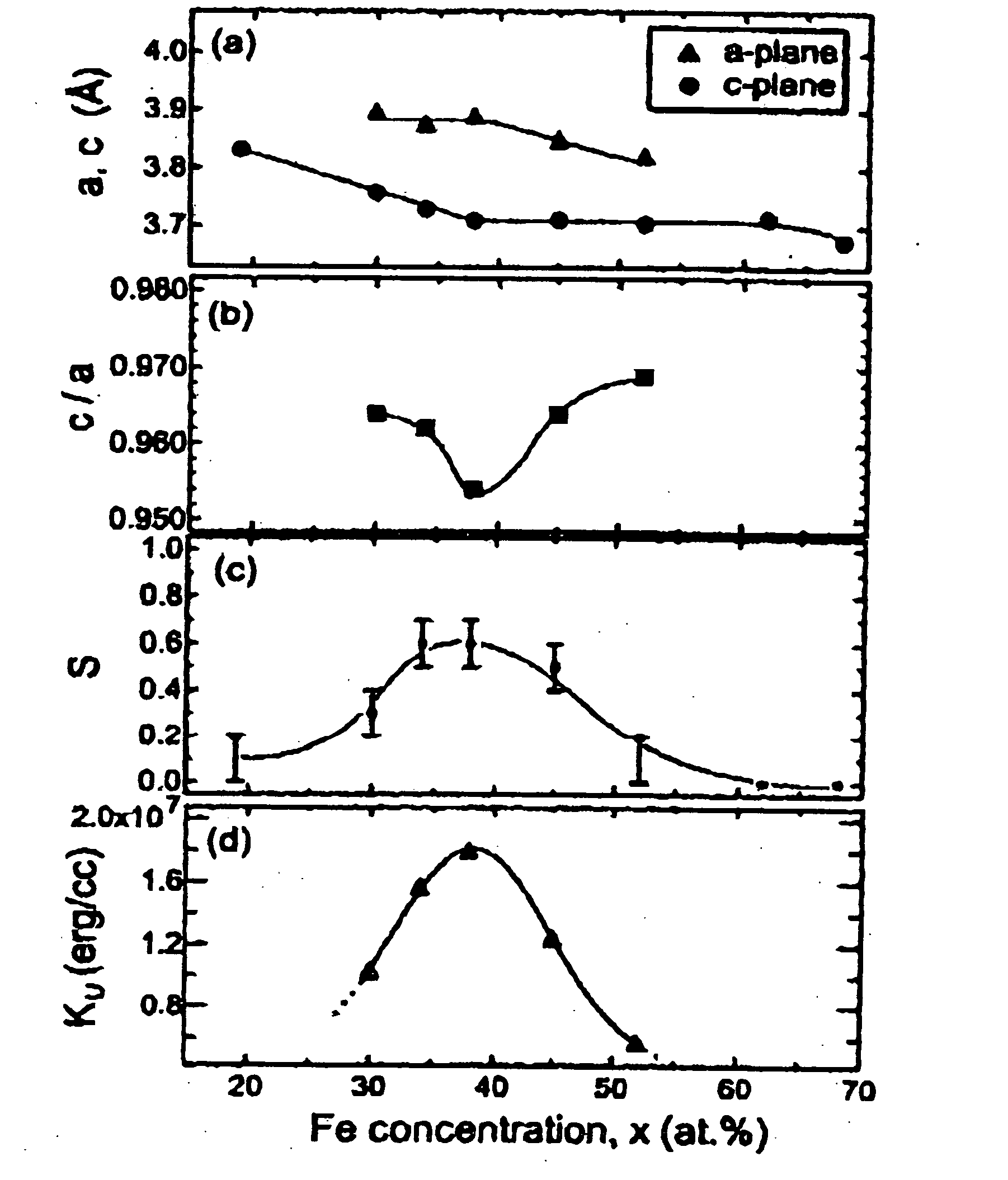

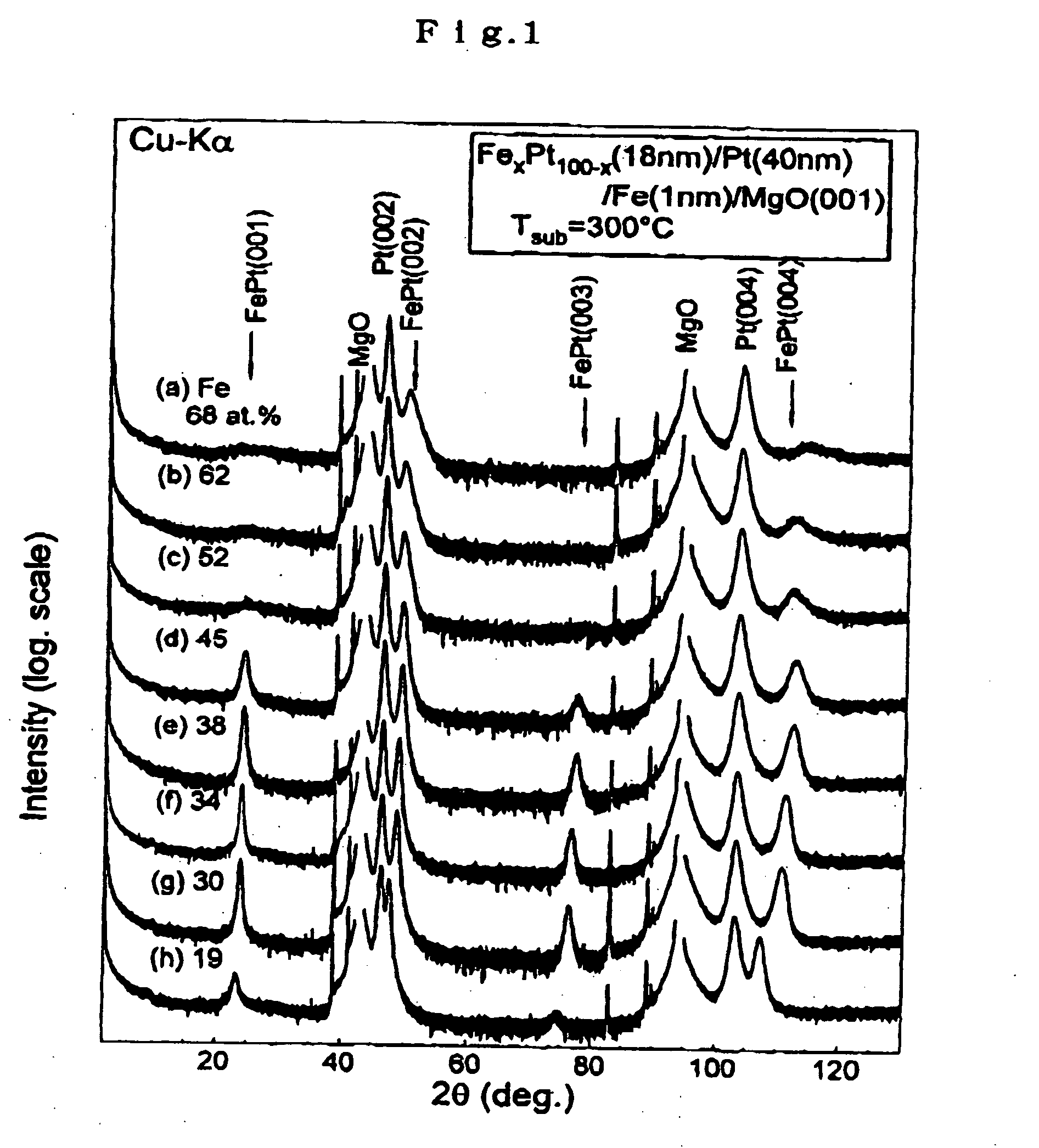

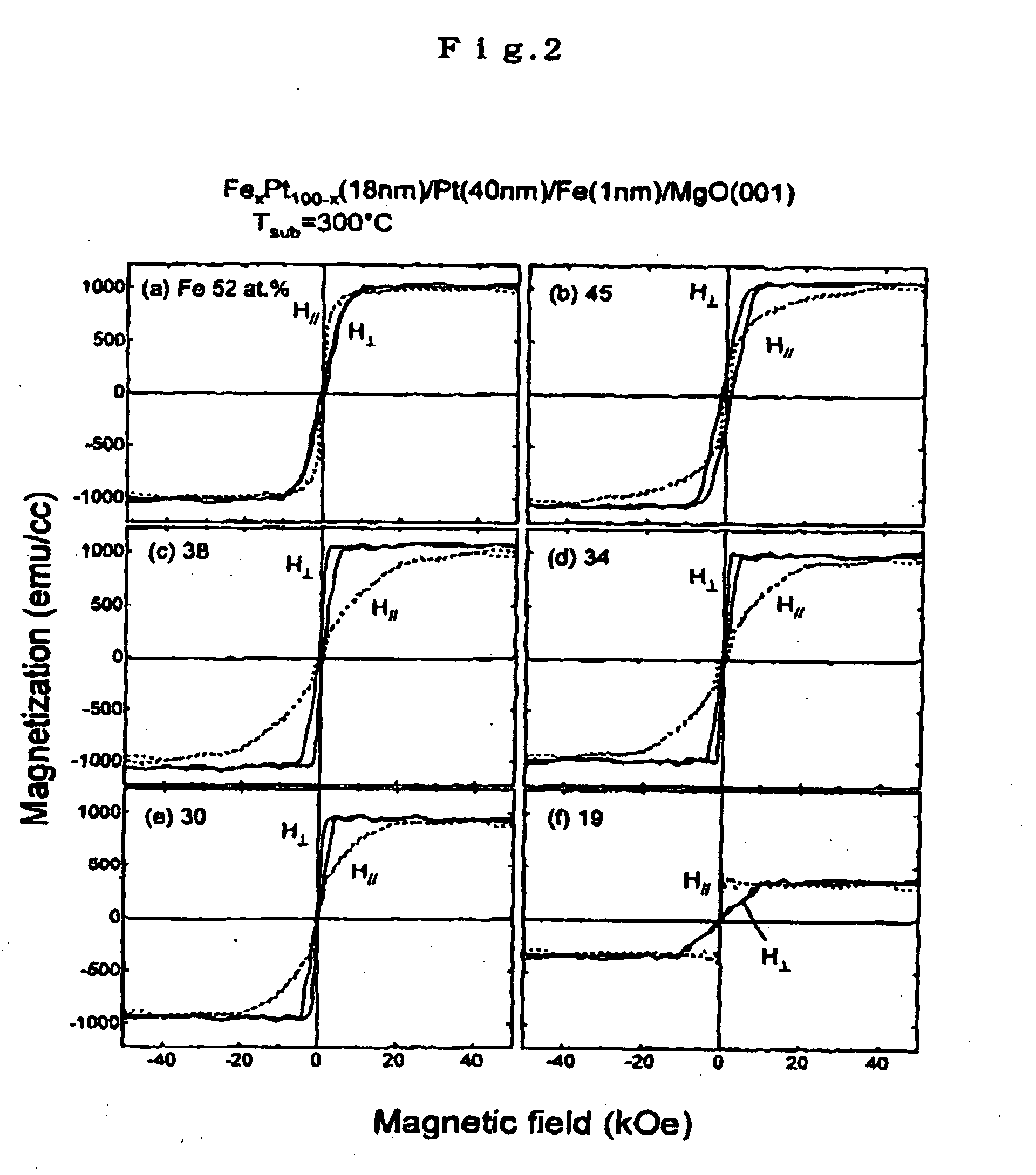

Fept magnetic thin film having perpendicular magnetic anisotropy and method for preparation thereof

InactiveUS20060188743A1Not be restrictHigh magnetic fieldBase layers for recording layersVacuum evaporation coatingAtomic compositionMaterials science

An FePt magnetic thin film, characterized in that it has an atomic composition represented by the following formula: FexPt100-x wherein 19<x<52; and a method for manufacturing the FePt magnetic thin film. The FePt magnetic thin film is novel, can be formed at a lowered temperature, and further, has perpendicular magnetic anisotropy.

Owner:NAT INST FOR MATERIALS SCI

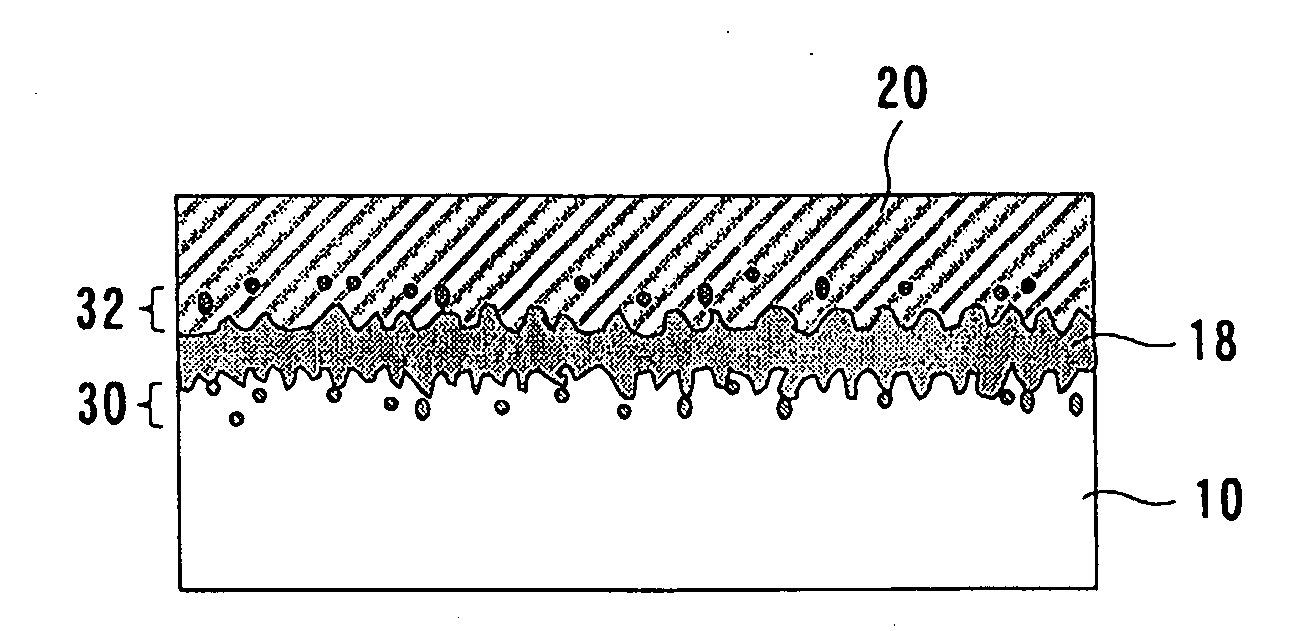

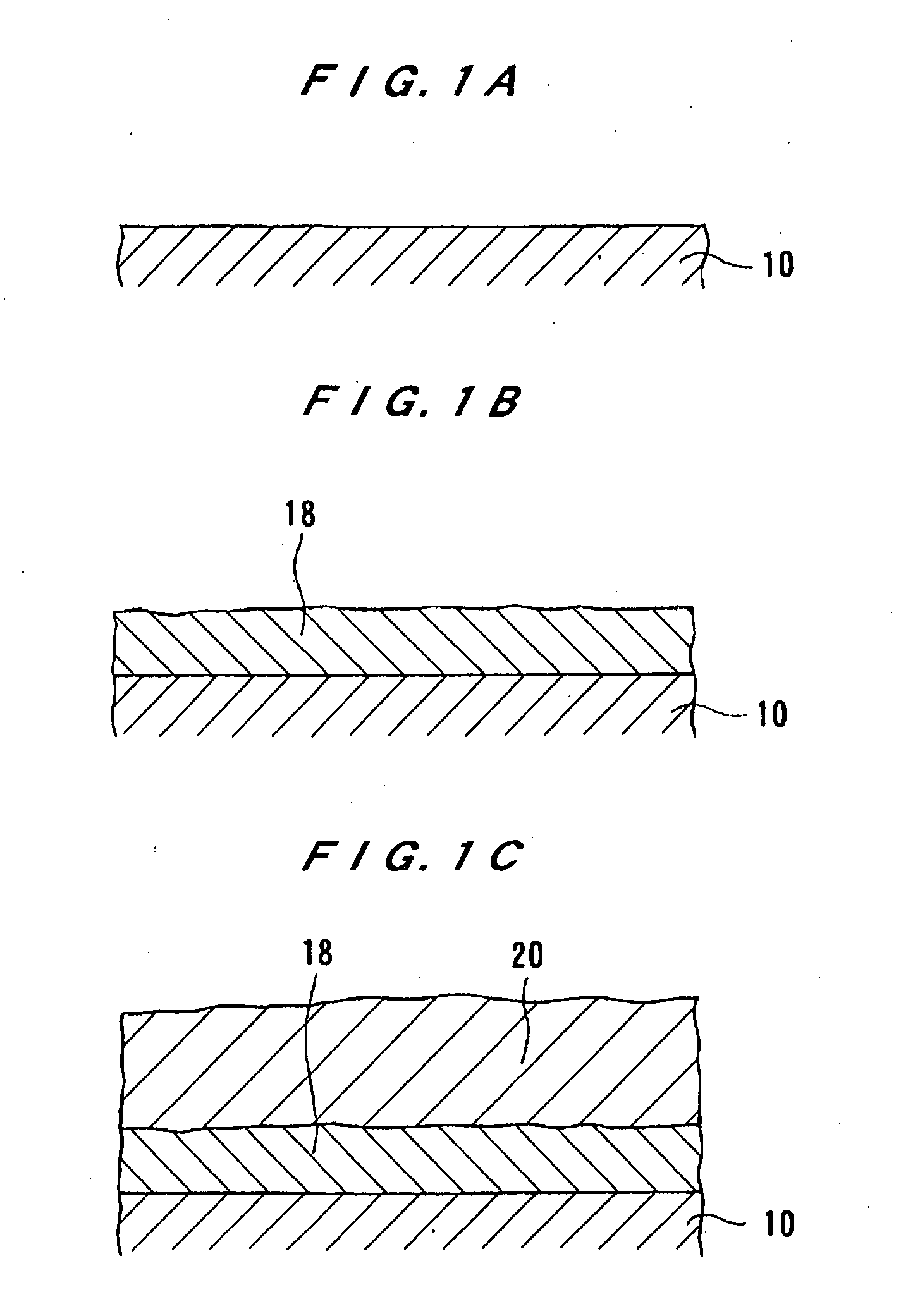

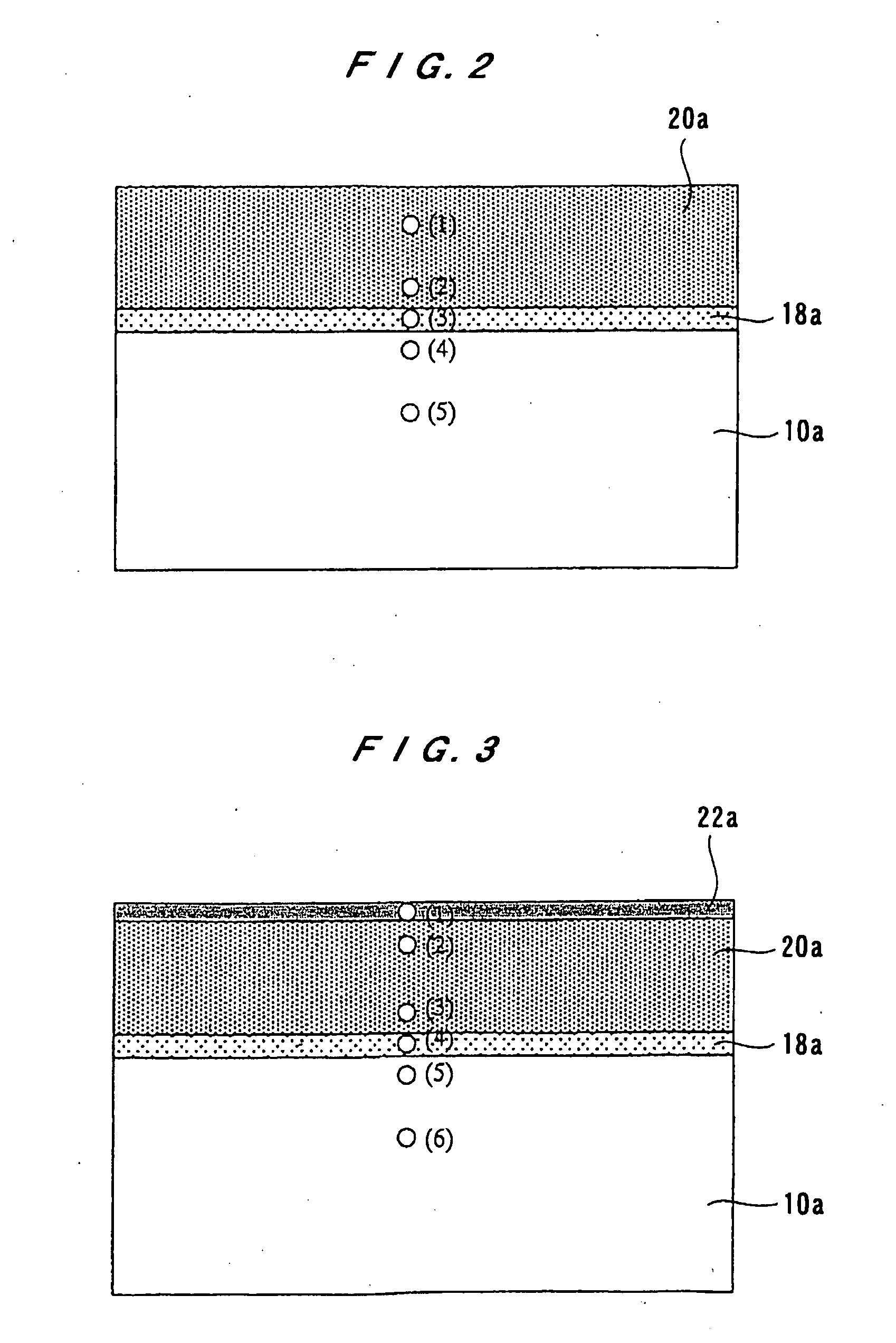

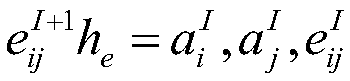

Diffusion Barrier Alloy Film, Method Of Manufacturing The Same, And High-Temperature Apparatus Member

InactiveUS20080081214A1Sufficient barrier propertyLow melting pointPretreated surfacesThin material handlingAlloy thin filmDiffusion barrier

A diffusion barrier alloy film has a diffusion barrier layer which has more excellent diffusion barrier properties than an Re—Cr alloy film, and can stand usage at higher temperatures (e.g., 1150° C. or higher). The diffusion barrier layer 18 is made of an Re—W alloy σ phase containing 12.5 to 56.5% of. W in terms of atomic composition and the remainder of Re excluding unavoidable impurities. A metal base 10 has a surface coated with a diffusion barrier layer 18. If required, the diffusion barrier layer 18 has a surface coated with a diffusion alloy layer 20 containing 10% or greater and less than 50% of Al, Cr, or Si in terms of atomic composition, providing a high-temperature apparatus member.

Owner:HOKKAIDO UNIVERSITY

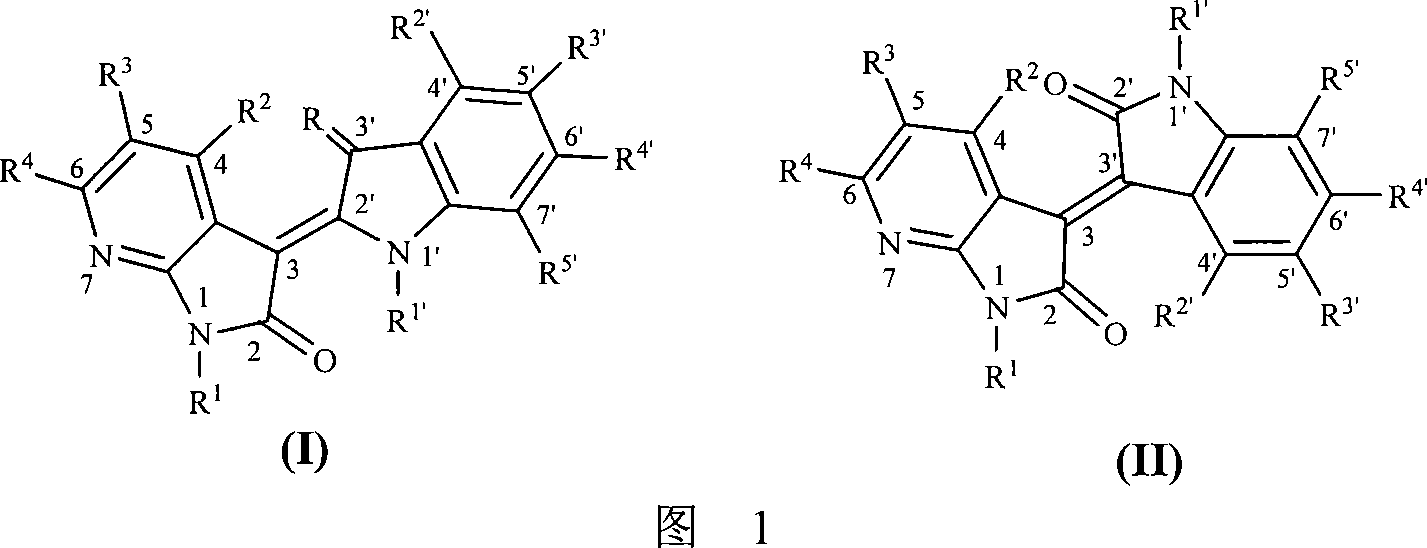

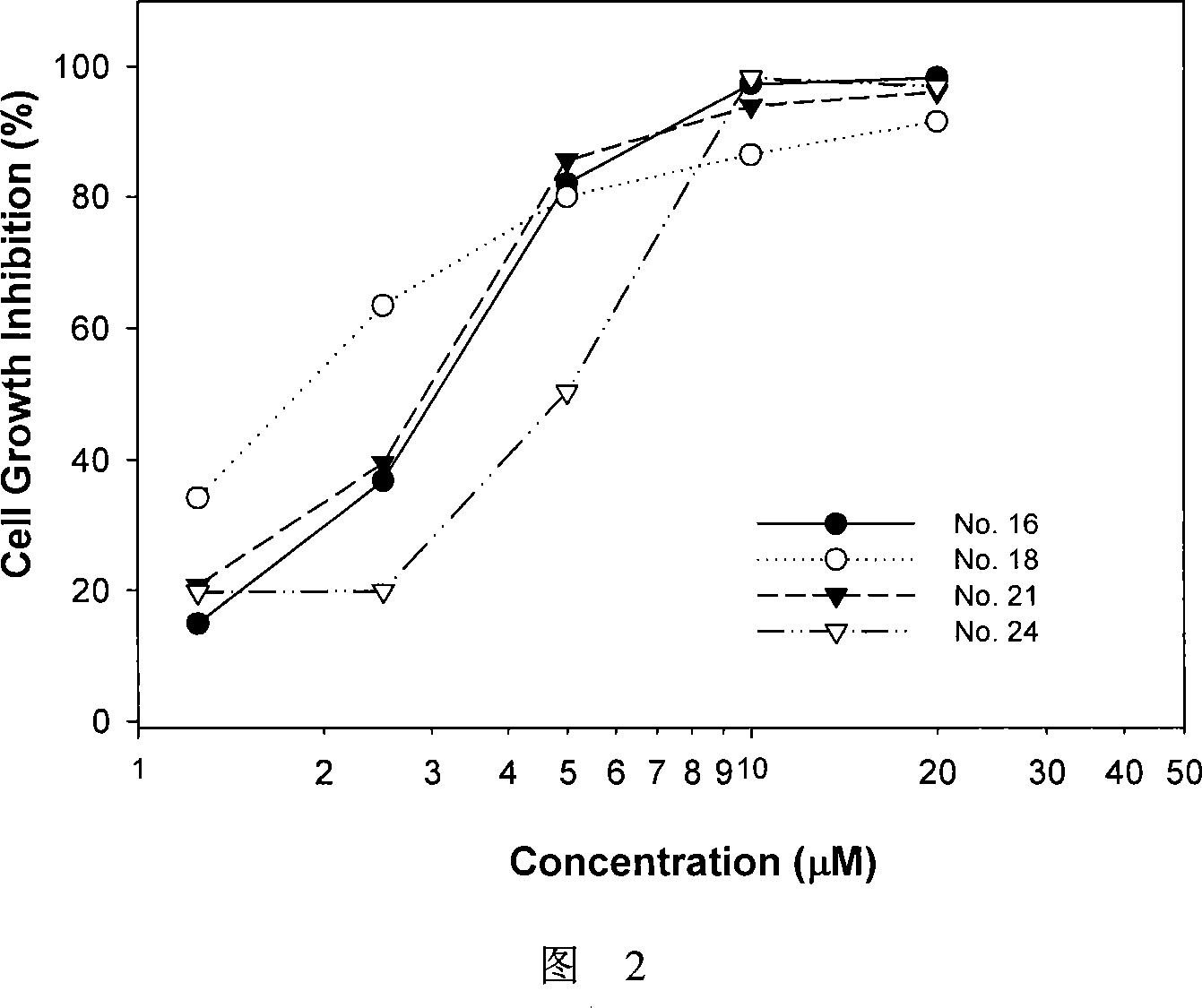

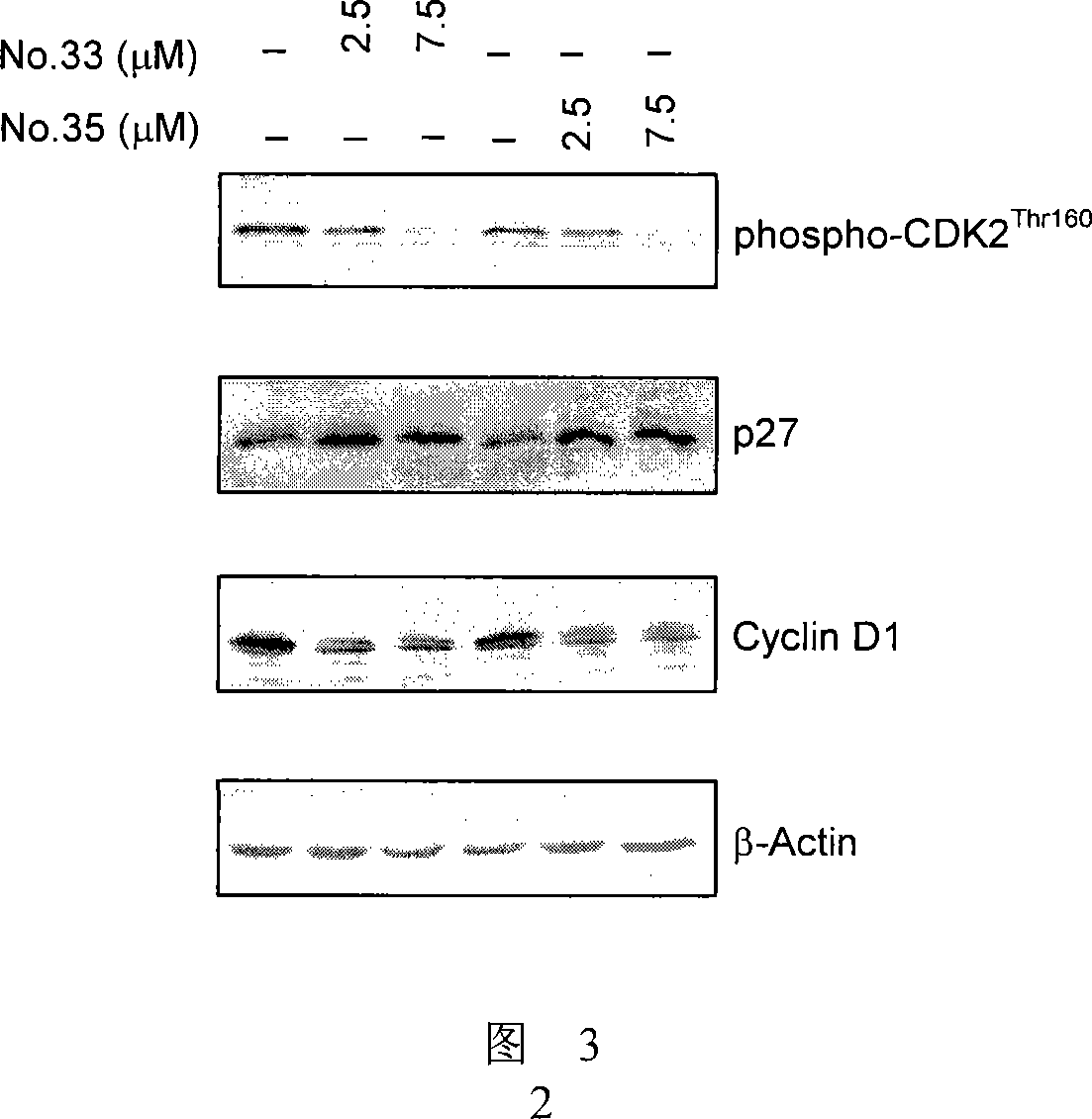

7-azaindirubin and 7-azaisoindigo derivative, its production and pharmaceutical use

ActiveCN101074229AImprove permeabilityImprove physical and chemical propertiesOrganic active ingredientsNervous disorderViral skin diseasesErythema induratum

A method for designing and synthesizing 7-azaindirubin and 7-azaisoindigo derivative and its medicinal use are disclosed. It changes indirubin and isoindigo nuclear-parent molecule atomic composition to form into compound. It also changes original molecule electric property. The process is carried out by coupling at different position by 7-azaindole and indole bi-molecule, inhibiting CDKs and CDKIs growth and breed and inducing CDKIs biological function. It can be used to treat malignant tumor, HIV and nervous system diseases.

Owner:JC (WUXI) CO INC

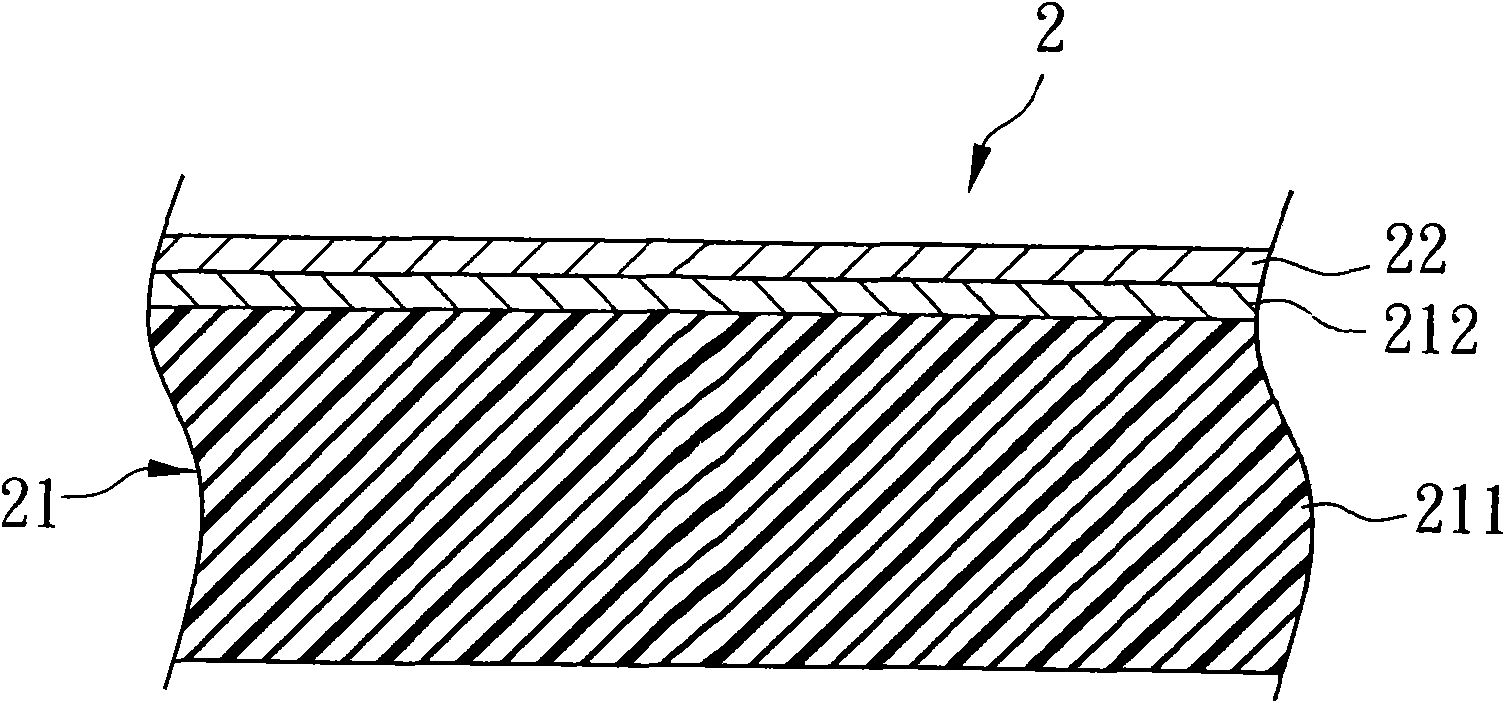

Optical information recording medium and its manufacturing method

An optical information recording medium of the present invention includes a protective layer; an interface layer; and a recording layer, the optical characteristics of which are changed reversibly when irradiated by a laser beam, layered in this order on a substrate. The protective layer contains at least Zn, S, and Si atoms, and an atomic composition ratio of O to Si is at least 0 and smaller than 2. A refractive index of the interface layer is smaller than a refractive index of the protective layer.

Owner:PANASONIC CORP

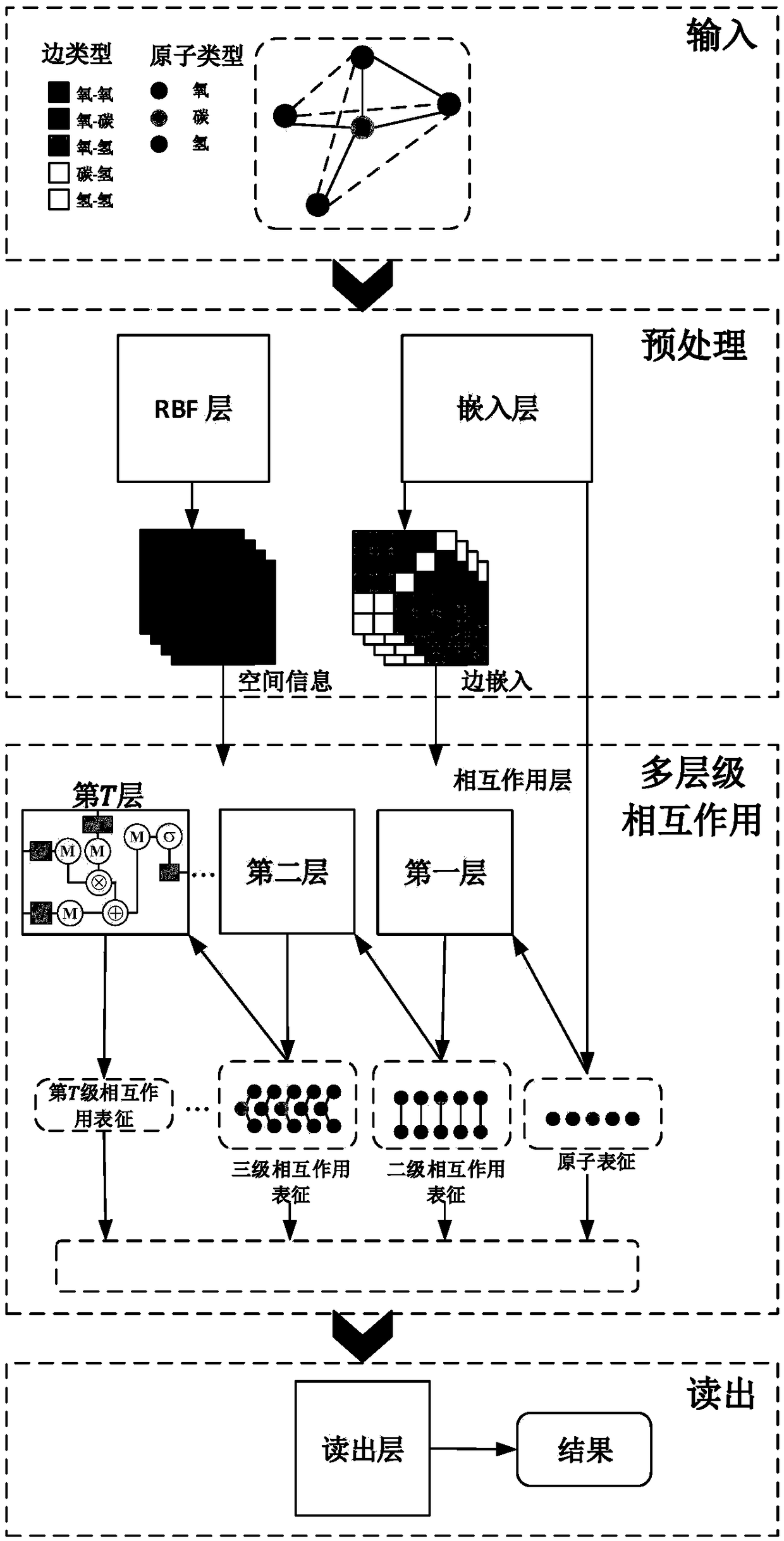

Molecule attribute prediction method based on artificial neural network

ActiveCN109461475AHigh speedHigh precisionChemical property predictionMolecular designNerve networkPredictive methods

The invention provides a molecule attribute prediction method based on an artificial neural network. The molecule attribute prediction method based on the artificial neural network comprises the following steps: S1) preprocessing of molecule data: acquiring atomic space representation and atomic composition representation through a method for data structure representation of graphs; S2) model establishment: acquiring representation of different stages of molecules from the atomic space representation and the atomic composition representation through a multilayered convolutional neural network,and combining the representations of the different stages of the molecules to obtain a model; and S3) predicting the molecule attribute according to the model. Compared with the prior art, the molecule attribute prediction method based on the artificial neural network has the advantages that the multistage convolutional neural network is used, the relation between the molecule attribute and spacecomposition can be learnt from information of known data and the multistage structure of the molecules, and is used for predicting the related attributes of unknown molecules, and therefore, the speed and the precision are good.

Owner:UNIV OF SCI & TECH OF CHINA

Low-k interconnect structure comprised of a multilayer of spin-on porous dielectrics

InactiveCN1505834APrecise and Uniform ControlImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSpins

A low-k dielectric metal conductor interconnect structure having no micro-trenches present therein and a method of forming such a structure are provided. Specifically, the above structure is achieved by providing an interconnect structure which includes at least a multilayer of dielectric materials which are applied sequentially in a single spin apply tool and then cured in a single step and a plurality of patterned metal conductors within the multilayer of spun-on dielectrics. The control over the conductor resistance is obtained using a buried etch stop layer having a second atomic composition located between the line and via dielectric layers of porous low-k dielectrics having a first atomic composition. The inventive interconnect structure also includes a hard mask which assists in forming the interconnect structure of the dual damascene-type. The first and second composition are selected to obtain etch selectivity of at least 10 to 1 or higher, and are selected from specific groups of porous low-k organic or inorganic materials with specific atomic compositions and other discoverable quantities.

Owner:GLOBALFOUNDRIES INC

High energy gasification/atomization of Fe#-[3]B/R#-[2]Fe#-[14]B nanometer composite permanent magnet powder and its preparation method

InactiveCN1593820AHigh B contentStrong Amorphous Formation AbilityMagnetic materialsHigh energyAlloy

The invention makes public a kind of composite nanometer Fe3B / R2Fe14B permanent magnetism powder by high-energy gas atomizing and the method of making it. Transform the alloy fluid, whose atomic composition formulary is Rx(Fel-wCow)100-x-y-xByTz, into ball powder by high-energy gas atomizing. Then dispose it and get composite nanometer Fe3B / R2Fe14B powder based on Fe3B by hot crystallization. The R is at least one component as following: Nd, Pr, Dy, and Tb. The T is at least one of the following components: Zr, Nb, Cr, Ga, Ti, V and Si. And the proportion should be:3.0<=x<=6.0,8<=y<=22,0<=z<=5,0<=w<=0.5. The powder made by this method has advantages such as glaze, ball shape, good fluidity and low cost, and is especially fit for adhesive binding magnet by injection molding.

Owner:ZHEJIANG UNIV

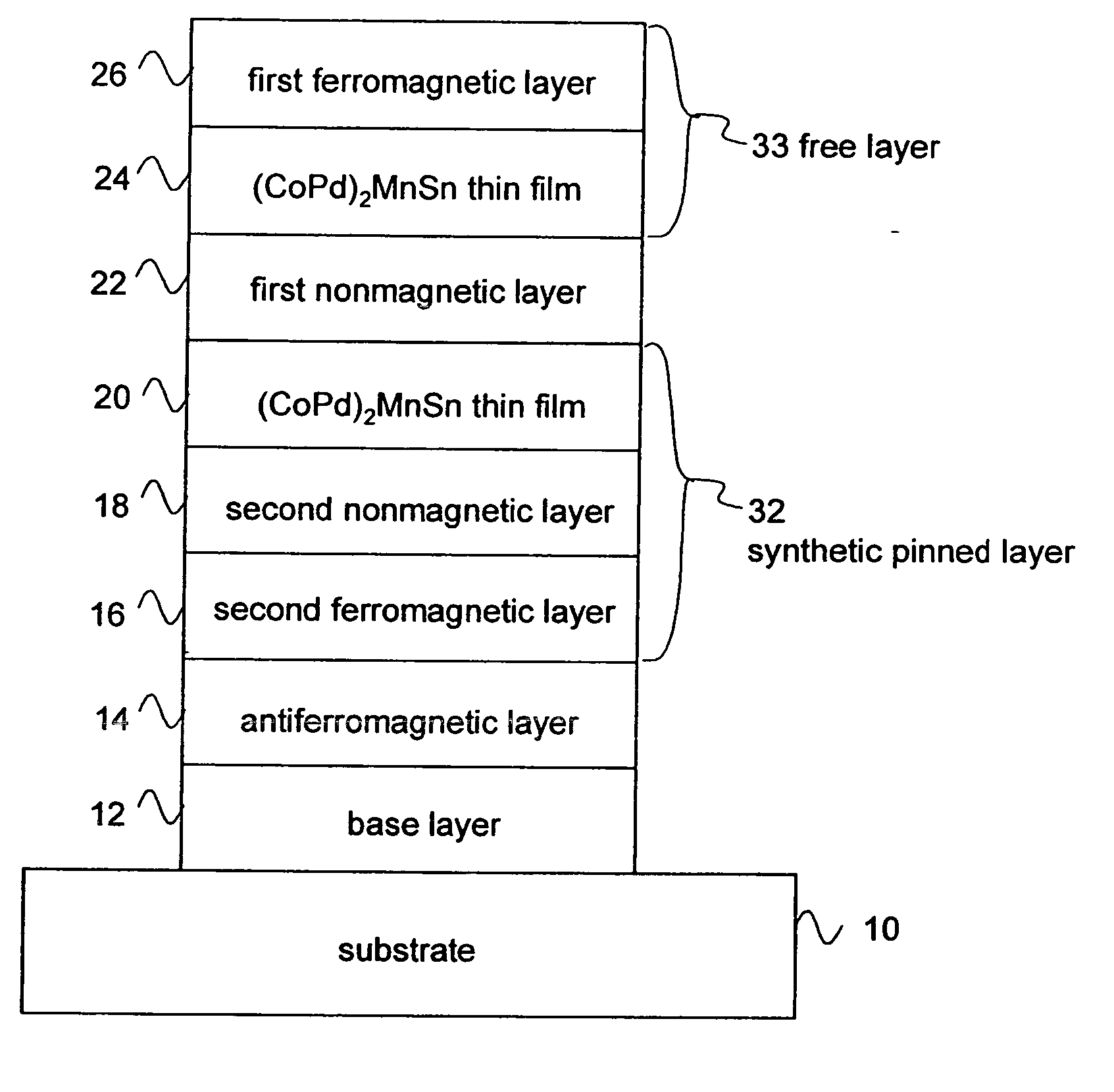

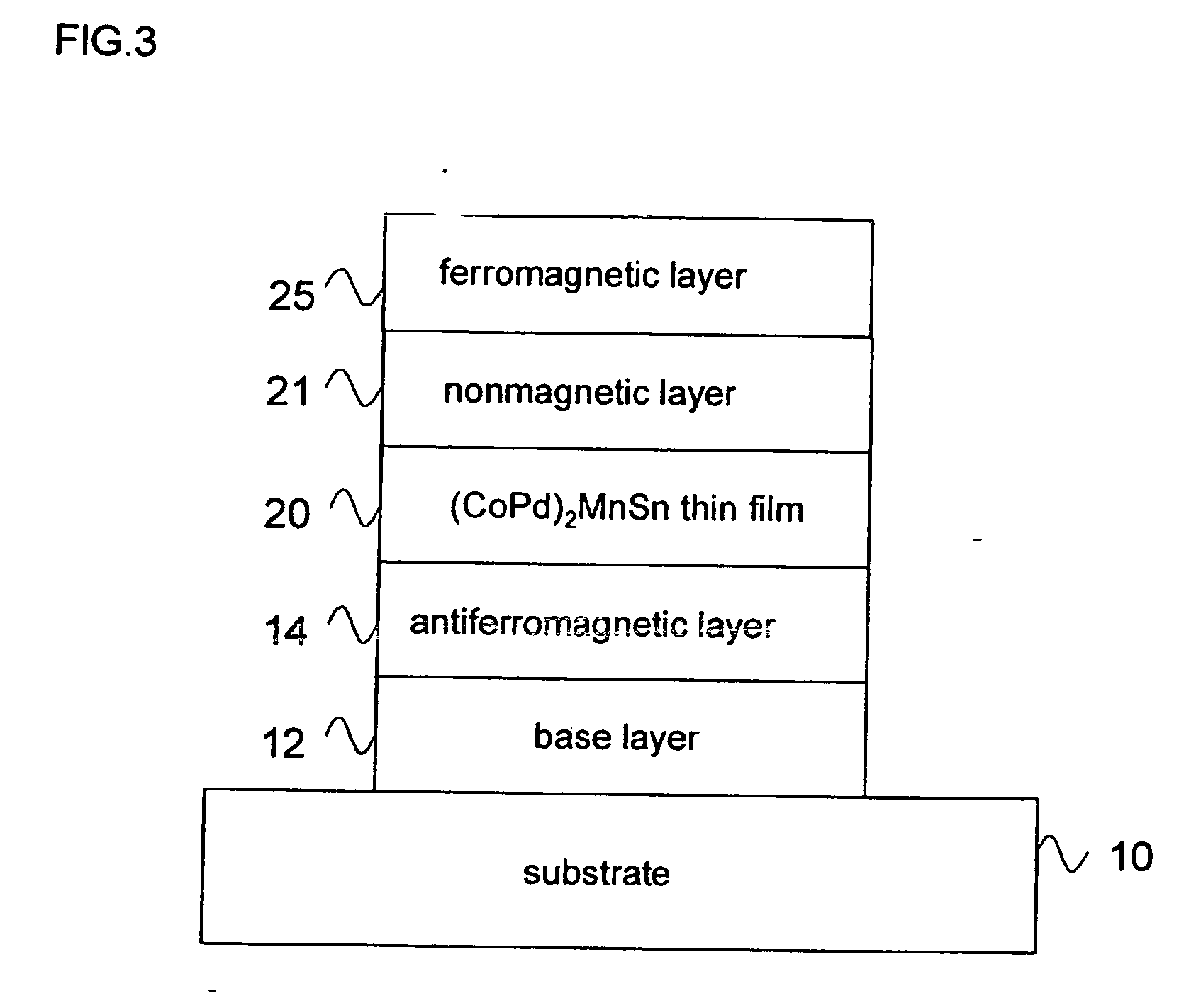

Magneto-resistance element and thin film magnetic head with improved heat reliability

ActiveUS20070058301A1Increase rate of changeImprove thermal reliabilityNanomagnetismMagnetic measurementsMagnetizationAlloy

A magneto-resistance element according to the present invention has a pinned layer whose magnetization direction is fixed; a free layer whose magnetization direction varies in accordance with an external magnetic field; and a nonmagnetic spacer layer that is arranged between the pinned layer and the free layer, at least the pinned layer or the free layer includes a layer having Heusler alloy represented by composition formula X2YZ (where X is a precious metal element, Y is a transition metal of Mn, V, or Ti group, Z is an element from group III to group V), and a part of composition X is replaced with Co, and an atomic composition ratio of Co in composition X is from 0.5 to 0.85.

Owner:TDK CORPARATION

Nonlithographic method to produce self-aligned mask, articles produced by same and compositions for same

InactiveUS20050233597A1Simple and robustSpeed maximizationLayered productsSemiconductor/solid-state device manufacturingDielectricAtomic composition

Owner:GLOBALFOUNDRIES INC

Interconnects containing bilayer porous low-k dielectrics using different porogen to structure former ratio

InactiveUS7723226B2High strengthHigh hardnessRadiation applicationsSemiconductor/solid-state device detailsAtomic compositionDielectric permittivity

A bilayer porous low dielectric constant (low-k) interconnect structure and methods of fabricating the same are presented. A preferred embodiment having an effective dielectric constant of about 2.2 comprises a bottom deposited dielectric layer and a top deposited dielectric layer in direct contact with the former. The bottom layer and the top layer have same atomic compositions, but a higher dielectric constant value k. The bottom dielectric layer serves as an etch stop layer for the top dielectric layer, and the top dielectric layer can act as CMP stop layer. One embodiment of making the structure includes forming a bottom dielectric layer having a first porogen content and a top dielectric layer having a higher porogen content. A curing process leaves lower pore density in the bottom dielectric layer than that left in the top dielectric layer, which leads to higher dielectric value k in the bottom dielectric layer.

Owner:TAIWAN SEMICON MFG CO LTD

Preparation method of platiniridium/carbon-electro catalyst by using microwave synthesis

InactiveCN101716507ASmall particle sizeNarrow particle size distributionCell electrodesCatalyst activation/preparationSodium acetrizoateSodium acetate

The invention discloses a preparation method of a platiniridium / carbon-electro catalyst by using microwave synthesis. The preparation method comprises the following steps of: evenly distributing nanometer carbon carriers in ethylene glycol solution containing both platinum metal salt and iridium metal salt at the same time, wherein the concentration of the platinum salt and the iridium salt is 0.001 to 0.01 mol / L; adding sodium acetate as a stabilizer, wherein the concentration of the sodium acetate in the resulting solution is 0.005 to 0.03 mol / L; then heating the well-distributed mixture of the nanometer carbon carriers and the metal salt ethylene glycol solution for 2 to 4 minutes by microwave radiation, and then filtering, washing and drying to obtain the platiniridium / carbon-electro catalysts. The atomic composition ratio of a platinum iridium alloy is PtxIry, wherein x is 0.1 to 1, and y is 0.1 to 1. The invention has the advantages that the nano-particles of the platinum iridium alloy, which are loaded on the surfaces of the carbon carriers, have small grain diameter averagely from 3 to 4 nm, and the grain diameter distribution is narrow, and the loading capacity of the alloy nano particles on the surface of the carbon carrier is 5% to 30%. The invention also has the advantages of high speed, simple process, high efficiency and energy saving. The platiniridium / carbon-electro catalyst is widely used in the field of electrochemical energy conversion.

Owner:赵杰 +1

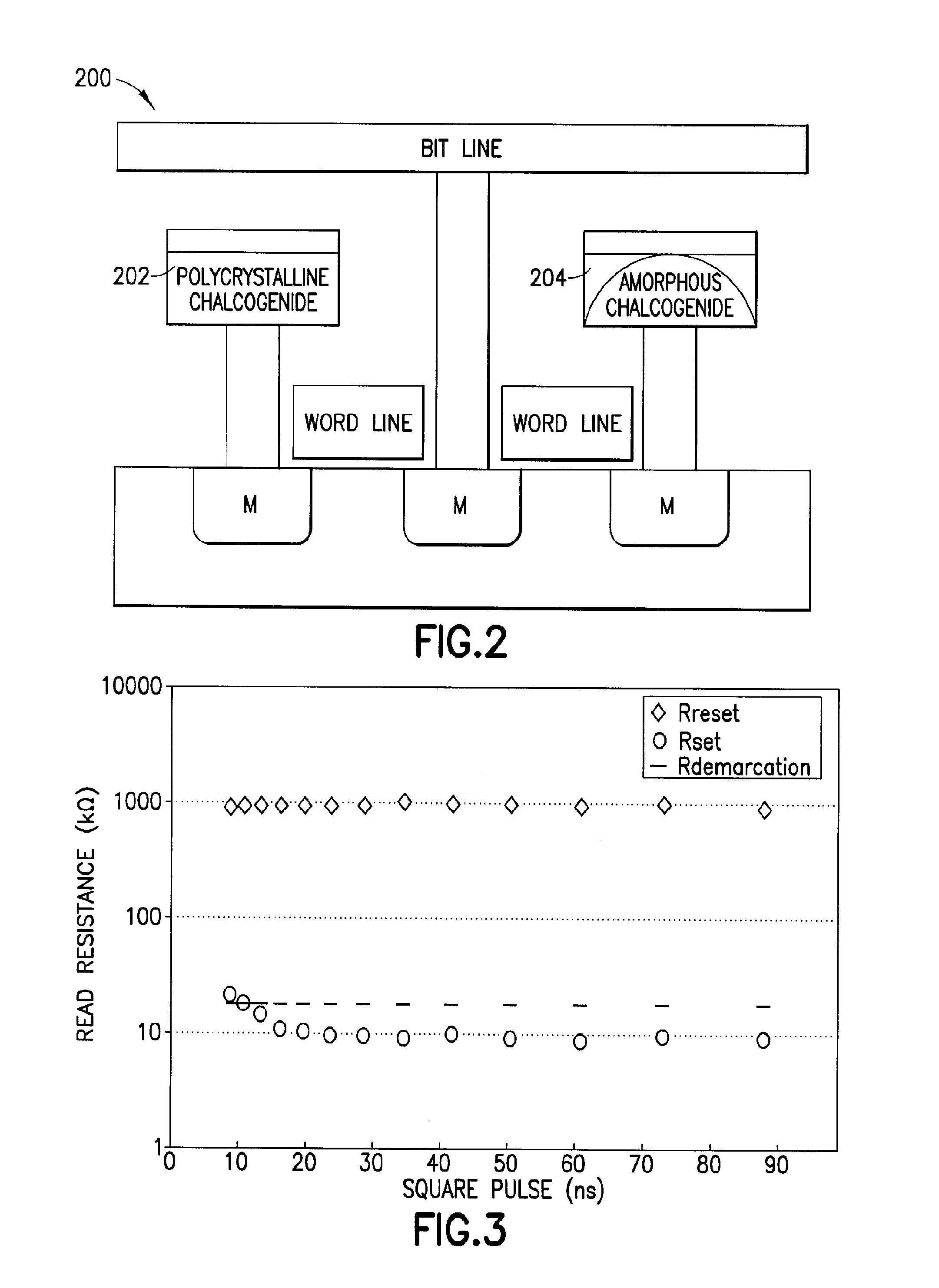

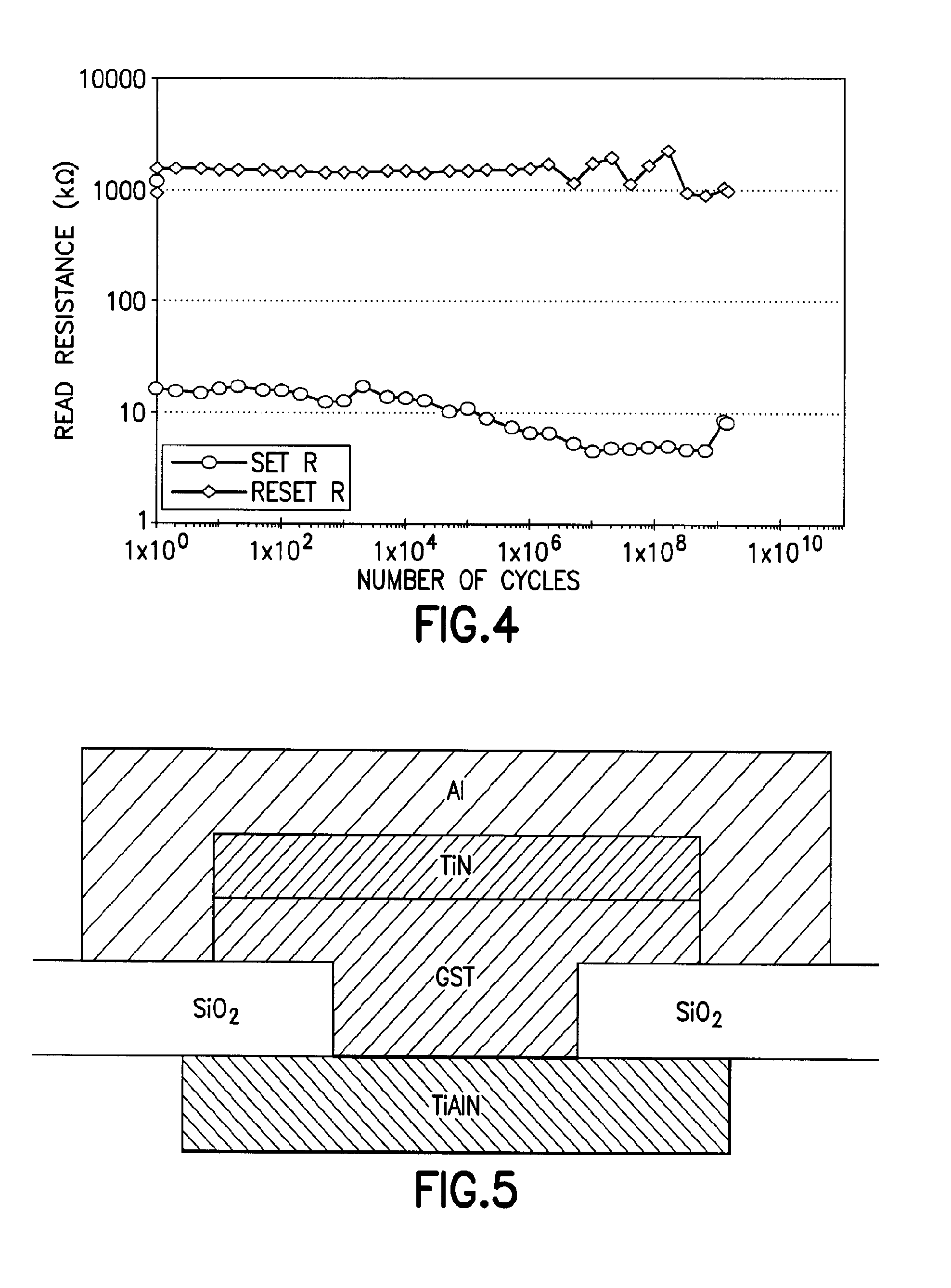

Germanium antimony telluride materials and devices incorporating same

ActiveUS20130112933A1Increase setting speedAdd settingsSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesPhase-change memoryRandom access memory

A chalcogenide alloy composition, having an atomic composition comprising from 34 to 45 Ge, from 2 to 16% Sb, from 48 to 55% Te, from 3 to 15% carbon and from 1 to 10% nitrogen, wherein all atomic percentages of all components of the film total to 100 atomic %. Material of such composition is useful to form phase change films, e.g., as conformally coated on a phase change memory device substrate to fabricate a phase change random access memory cell.

Owner:SAMSUNG ELECTRONICS CO LTD

Field-effect transistor, method for manufacturing same, and sputtering target

ActiveUS20160201187A1Easy to produceEliminate the effects ofCellsSolid-state devicesField-effect transistorAtomic composition

A field effect transistor including: a substrate, and at least gate electrode, a gate insulating film, a semiconductor layer, a protective layer for the semiconductor layer, a source electrode and a drain electrode provided on the substrate, wherein the source electrode and the drain electrode are connected with the semiconductor layer therebetween, the gate insulating film is between the gate electrode and the semiconductor layer, the protective layer is on at least one surface of the semiconductor layer, the semiconductor layer includes an oxide containing In atoms, Sn atoms and Zn atoms, the atomic composition ratio of Zn / (In+Sn+Zn) is 25 atom % or more and 75 atom % or less, and the atomic composition ratio of Sn / (In+Sn+Zn) is less than 50 atom %.

Owner:IDEMITSU KOSAN CO LTD

Method of manufacturing semiconductor active layer, method of manufacturing thin film transistor using the same and thin film transistor having semiconductor active layer

ActiveUS8017513B2Vacuum evaporation coatingSemiconductor/solid-state device manufacturingActive layerAtomic composition

A method of manufacturing an IGZO active layer includes depositing ions including In, Ga, and Zn from a first target, and depositing ions including In from a second target having a different atomic composition from the first target. The deposition of ions from the second target may be controlled to adjust an atomic % of In in the IGZO layer to be about 45 atomic % to about 80 atomic %.

Owner:SAMSUNG DISPLAY CO LTD

Semiconductor photocatalyst for the photocatalytic reforming of biomass derivatives for hydrogen generation, and preparation and use thereof

ActiveUS20130224105A1Easy to operateInexpensively appliedCatalyst protectionCatalyst activation/preparationIridiumCobalt

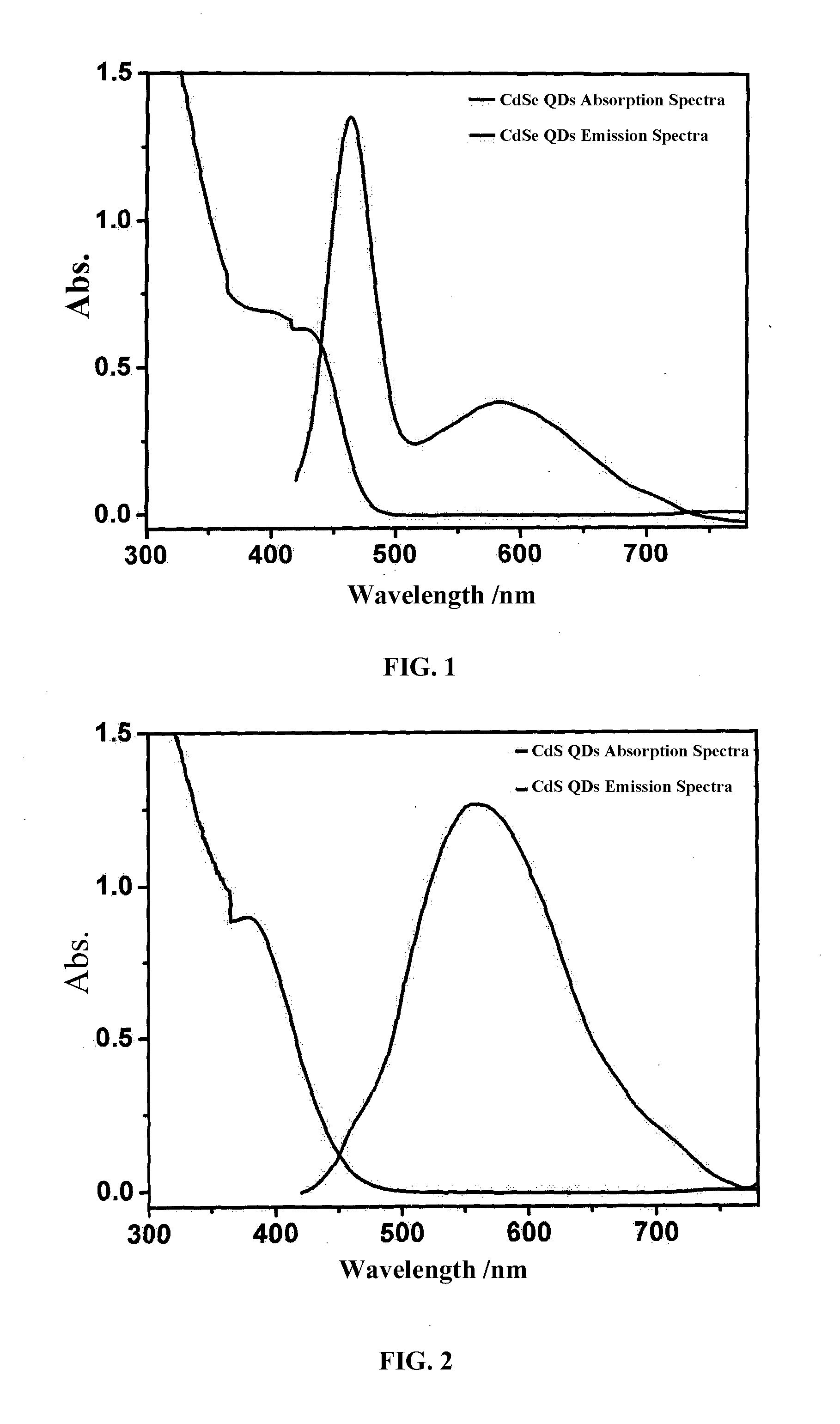

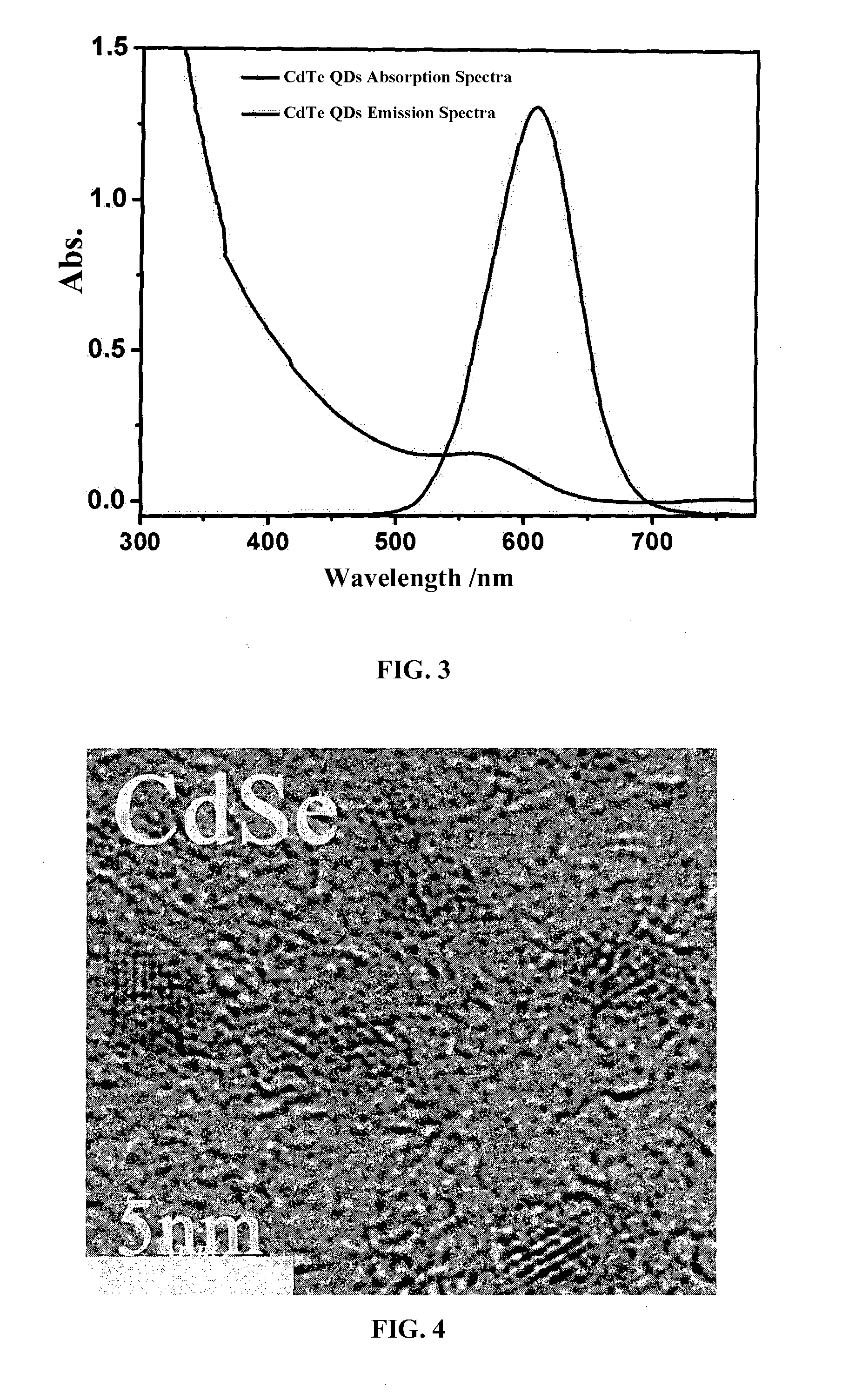

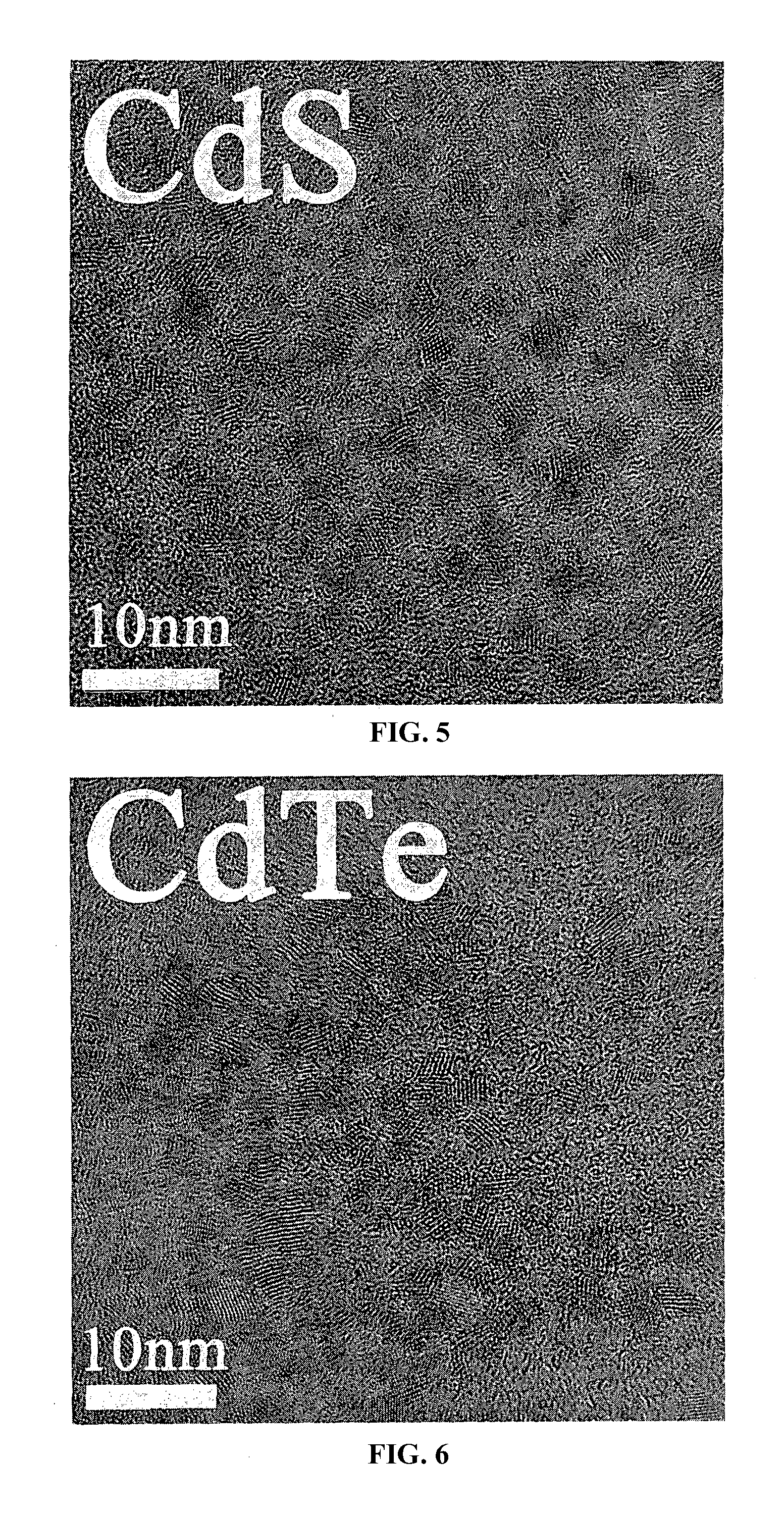

Disclosed are a semiconductor photocatalyst for the photocatalytic reforming of biomass derivatives for hydrogen generation, and preparation and use thereof. The semiconductor photocatalyst has the atomic composition ratio of M˜N-Ax; wherein M˜N are IIB group elements to VIA group elements, or IIIA group elements to VA group elements, A being one element or more than two elements selected from the group consisting of cobalt, nickel, iron, copper, chromium, palladium, platinum, ruthenium, rhodium, iridium and silver; and 0.02%≦x≦1.0%. The method of in-situ preparation of the highly effective semiconductor photocatalyst and catalytically reforming biomass derivatives for hydrogen generation by driving photoreaction with visible light via quantum dots is simple, fast, highly effective, inexpensive and practical. The in situ reaction can occur in sunlight without the need of harsh conditions such as calcination.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com