Method of producing a strip of nanocrystalline material and device for producing a wound core from said strip

A technology of nano crystallization and material strips, which is applied in the direction of magnetic materials, nanotechnology, metal processing equipment, etc., and can solve problems such as uneven performance, difficulty in absorbing the tape head, and high fracture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

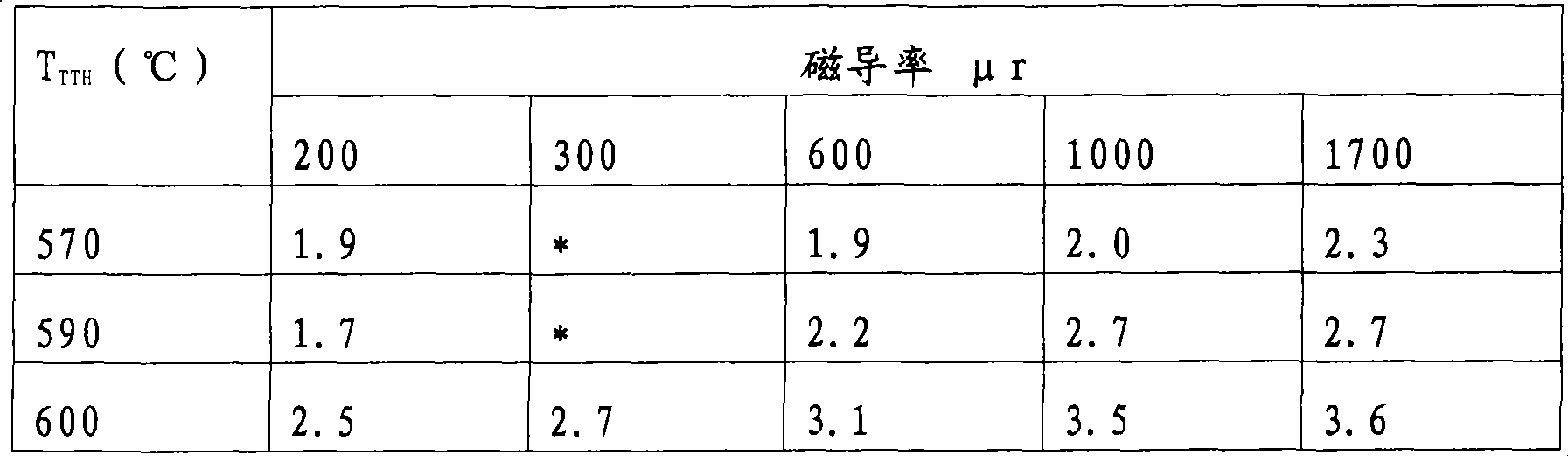

[0172] Example 1-Influence of grade composition

[0173] Influence of boron content

[0174] Examples V, W, and X with a boron content of 8.4% have a suitable level of brittleness, and the fracture rate is less than 5 fractures / km.

[0175] However, with such a high boron percentage, it becomes difficult to feed the crystallization under stress, especially slower than all industrially operable tests, such as C, D, E, and F, which requires reducing the feed speed To less than 4 cm / sec, and this will limit the available permeability range to permeability greater than 300. Therefore, the maximum boron content must be limited to 8%.

[0176] Moreover, Example N shows that the partial replacement of boron by 1.22% of carbon has very little damage to the product performance.

[0177] Effect of niobium content

[0178] Example J shows that if the percentage of niobium used is about 3.9%, the overall magnetic properties can be maintained, but the saturation induction B (200 Oe) will...

Embodiment 2

[0199] Example 2-Expansion

[0200] In order to study the effect of applied stress (on the tape) on the expansion of the nanocrystalline core, a series of amorphous tapes were prepared, the composition of which was consistent with casting 1 in Table 1, and the amorphous tapes were subjected to increasing tensile stress. The test conditions and the obtained results on the thickness reduction (ΔEp / Ep) and the degree of expansion are listed in Table 3:

[0201] table 3

[0202] Stress (MPa) Thickness (μm) ΔEp / Ep Expansion degree (%) 0 17.9 87.1% 19.9 17.8 -0.6% 86.7% 39.8 17.7 -1.2% 87.7% 79.5 17.4 -2.8% 87% 119 17.2 -4.1% 86.2% 171 16.8 -6.4% 84.6% 200 16.6 -8.4% 85.3% 300 16.1 -11% 85.7% 500 14.9 -16.8% 84.5%

[0203] It has been found that the method according to the present invention makes it possible to reduce the thickness of the nanocrystalline tape without significantly impairing the degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com