Slitting-free non-winding amorphous ribbon preparation method and preparation system

A preparation system and thin strip technology, applied in the field of preparation method and preparation system of non-slitting and non-coiled amorphous thin strips, to achieve the effects of avoiding performance degradation, reducing equipment investment, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

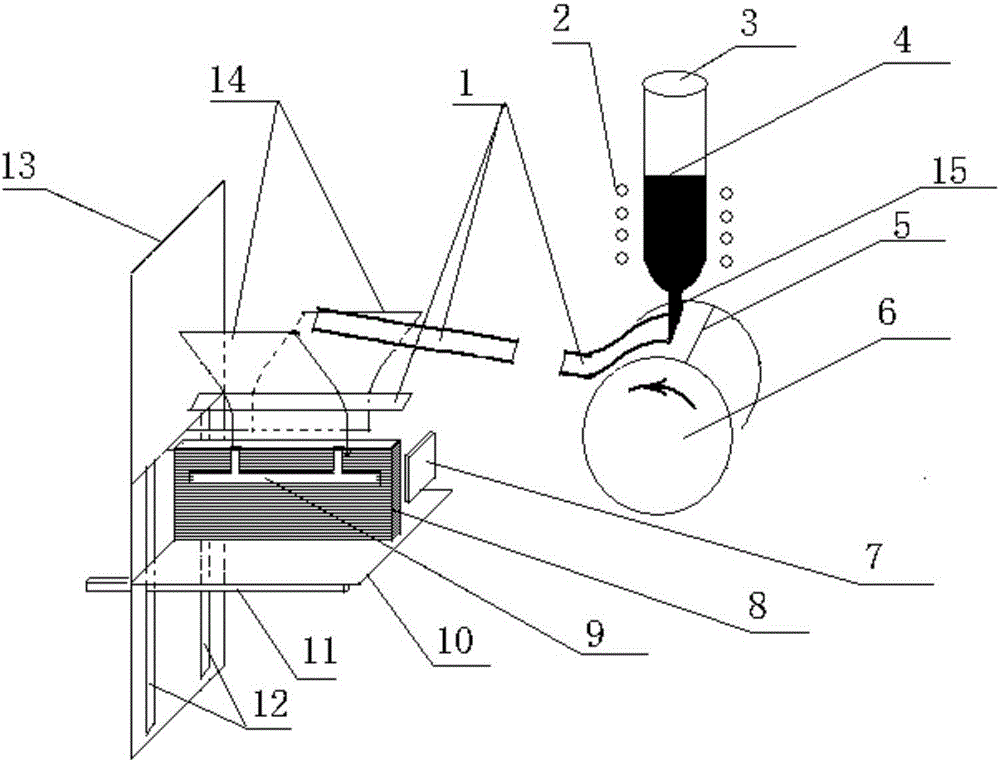

[0075] Further, the preparation method of the non-slitting non-coiling amorphous ribbon specifically includes:

[0076] Configure the master batch according to the target required components, and configure the master alloy by the AC arc melting method or the high frequency induction heating method;

[0077] Set grooves on the cooling roll surface according to the target requirements;

[0078] Configure amorphous ribbon collection device according to target requirements;

[0079] Configure the melt nozzle and melt the master alloy according to the target requirements;

[0080] According to the target requirements, a single-roll rapid quenching method is used to prepare stacks of amorphous ribbons.

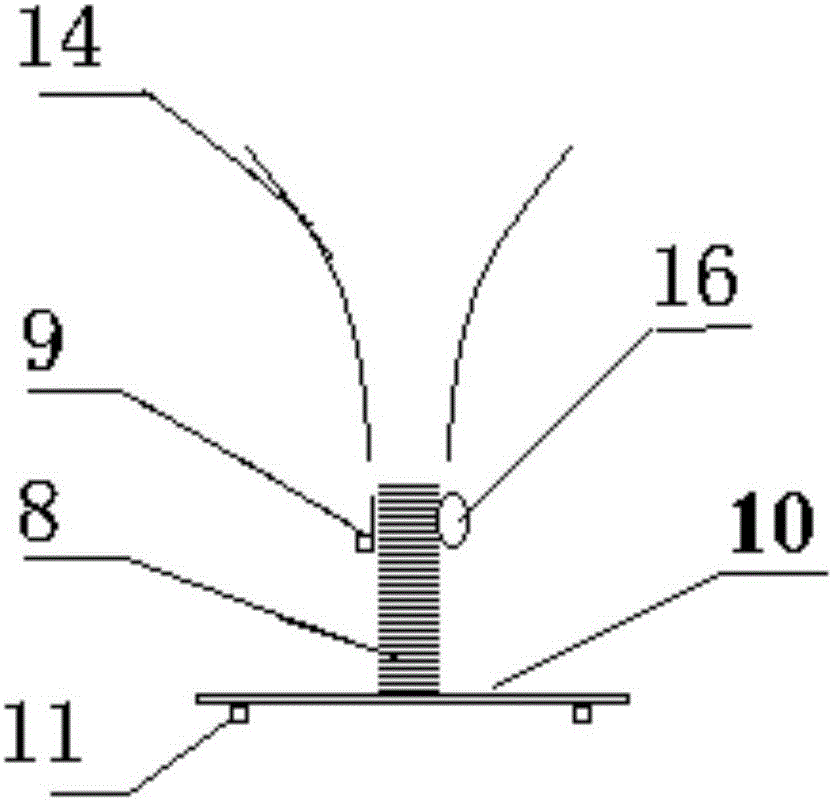

[0081] Furthermore, a strip-shaped amorphous thin ribbon automatic collector is arranged in front of the cooling roller to automatically collect and neatly stack the strip-shaped amorphous thin ribbon from the cooling roller.

[0082] Further, the segment-shaped amorphous thin ribbon automatic ...

Embodiment 1

[0088] Complete the first embodiment of the present invention according to the following steps:

[0089] 1. Preparation of master alloy: A mixture of 78% Fe, 9% Si and 13% B is prepared by atomic ratio. Under the protection of argon, it is heated and melted by high-frequency induction method and cooled to obtain a master alloy.

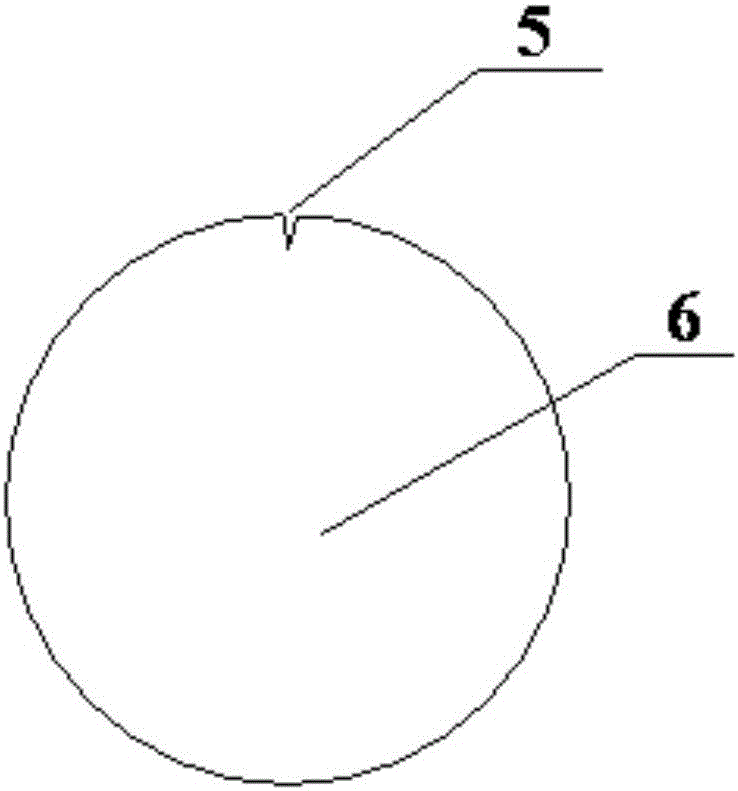

[0090] 2. Set a groove of 0.3mm wide and 0.2mm deep on the surface of the cooling roll with a diameter of 45cm perpendicular to the direction of rotation, and then polish the cooling roll surface.

[0091] 3. The amorphous alloy ribbon of the present invention is prepared by the single-roll rapid quenching technology including the following sub-steps.

[0092] (a) Put the master alloy composed of the above atomic ratio in a crucible with a softening temperature higher than 1400°C.

[0093] (b) Under the protection of argon, heat the master alloy by high-frequency induction until it melts, and continue to heat it until it is overheated into an alloy melt.

[0094...

Embodiment 2

[0099] Complete embodiment 2 of the present invention according to the following steps:

[0100] 1. Master alloy preparation: according to the atomic ratio including 73.5% Fe, 1.0% Cu, 3.0% Nb, 13.5% atomic ratio Si and 9.0% atomic ratio B preparation and mixing, under the protection of argon, use high frequency After heating and melting by induction method, it is cooled to obtain a master alloy.

[0101] 2. Set 0.15mm wide and 0.2mm deep grooves perpendicular to the rotation direction at 3 equal points on the surface of the cooling roll with a diameter of 45cm, and then polish the cooling roll surface.

[0102] 3. The amorphous alloy ribbon of the present invention is prepared by the single-roll rapid quenching technology including the following sub-steps.

[0103] (a) Put the master alloy composed of the above atomic ratio in a crucible with a softening temperature higher than 1400°C.

[0104] (b) Under the protection of argon, heat the master alloy by high-frequency induction until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com