Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

347 results about "Tape head" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tape head is a type of transducer used in tape recorders to convert electrical signals to magnetic fluctuations and vice versa. They can also be used to read credit/debit/gift cards because the strip of magnetic tape on the back of a credit card stores data the same way that other magnetic tapes do. Cassettes, reel-to-reel tapes, 8-tracks, VHS tapes, and even floppy disks and modern hard drive disks all use the same principle of physics to store and read back information. The medium is magnetized in a pattern. It then moves at a constant speed over an electromagnet. Since the moving tape is carrying a changing magnetic field with it, it induces a varying voltage across the head. That voltage can then be amplified and connected to speakers in the case of audio, or measured and sorted into '1's and zeroes in the case of digital data.

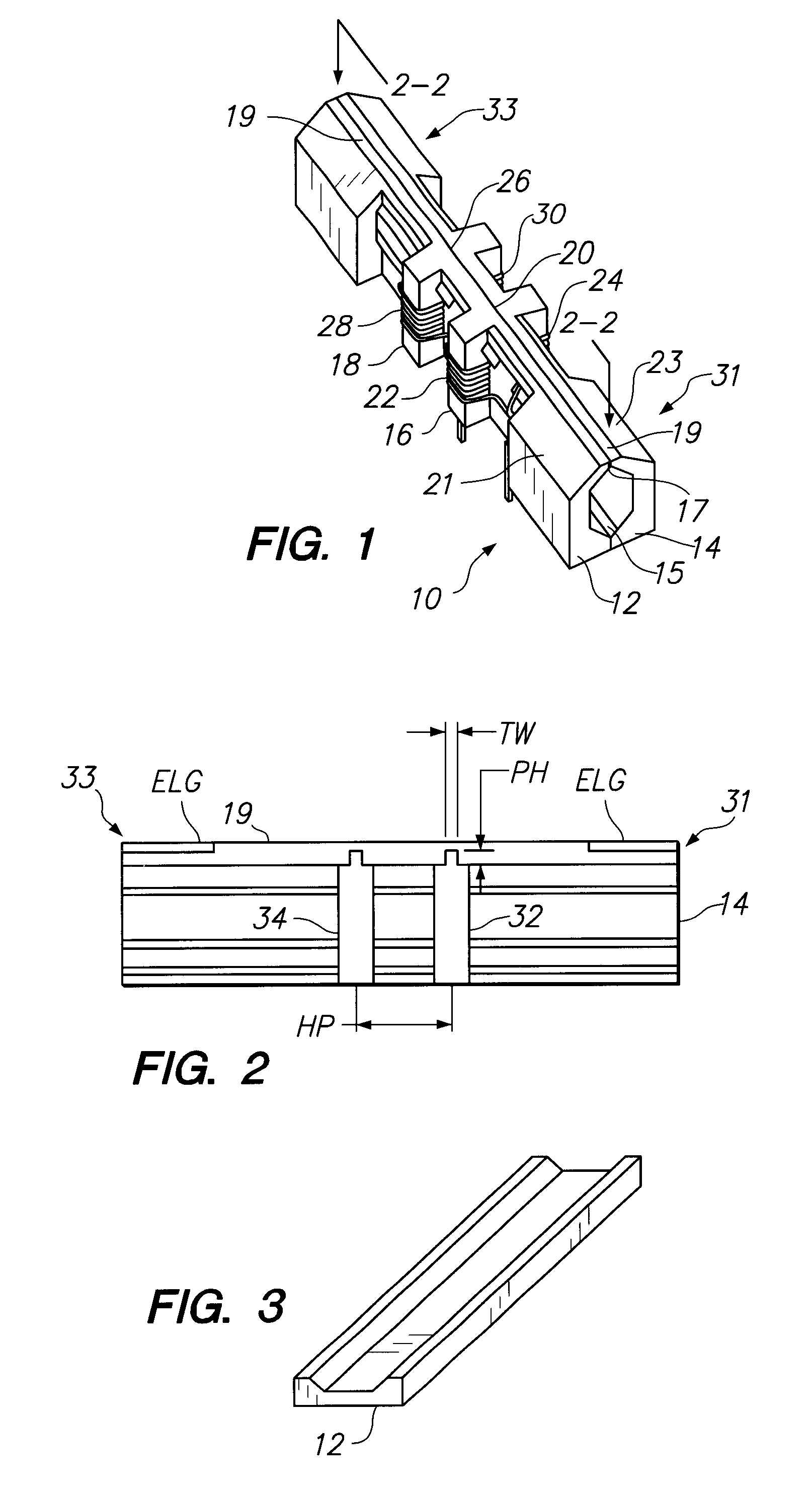

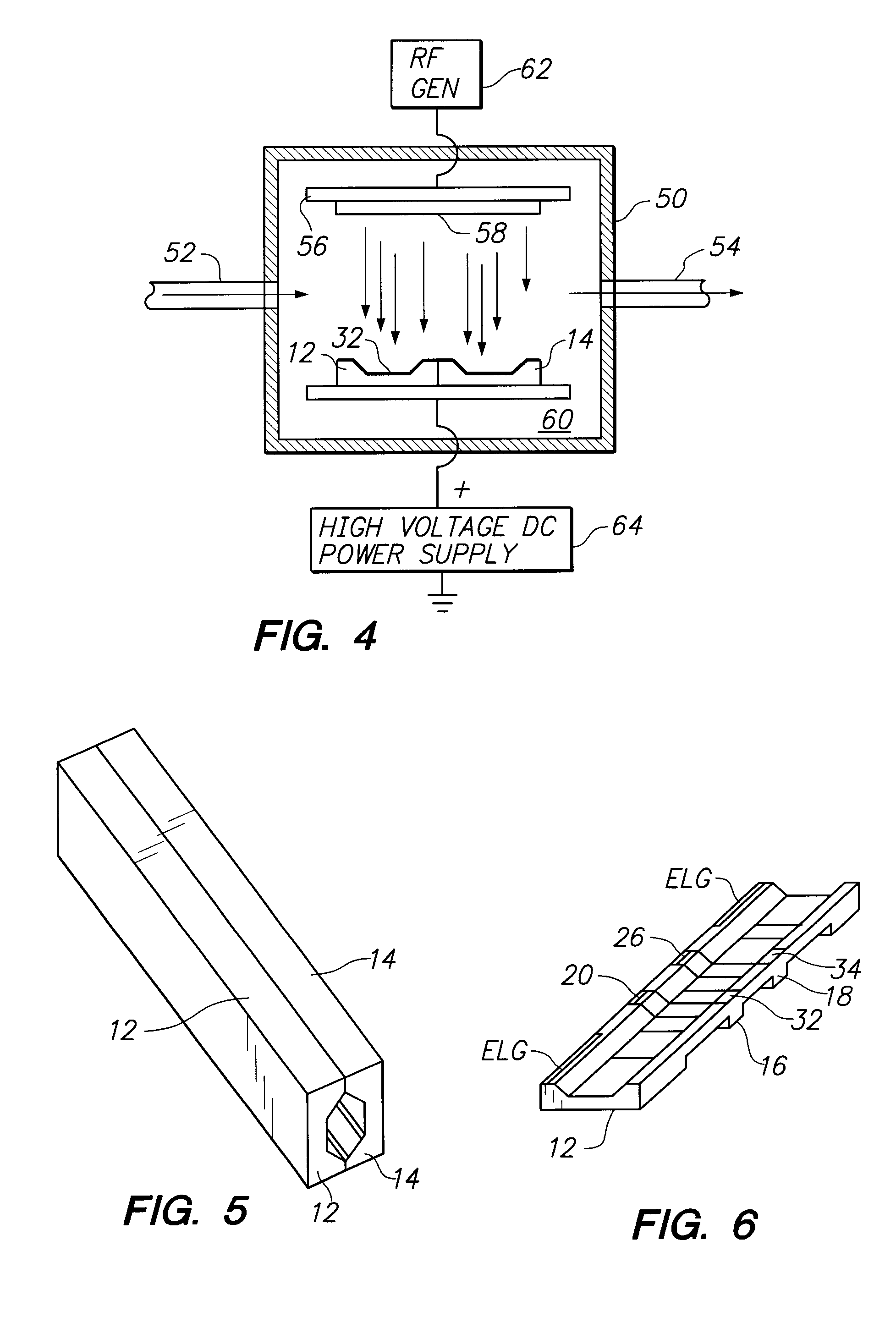

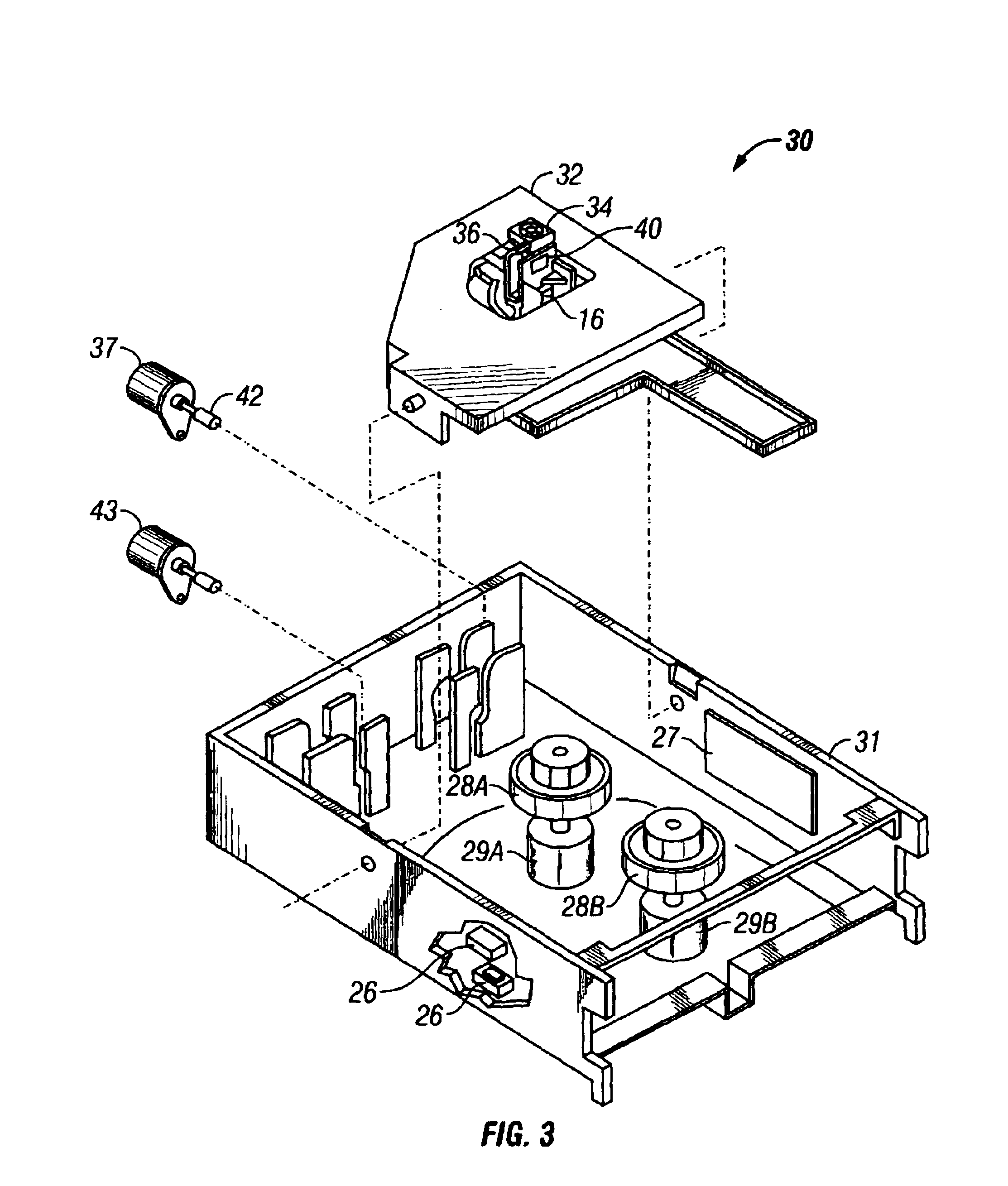

Pivoting lever cam guide tape head positioner

InactiveUS6075678AImprove mechanical rigidityHigh of resistance to vibrationTrack finding/aligningAlignment for track following on tapesLight beamEngineering

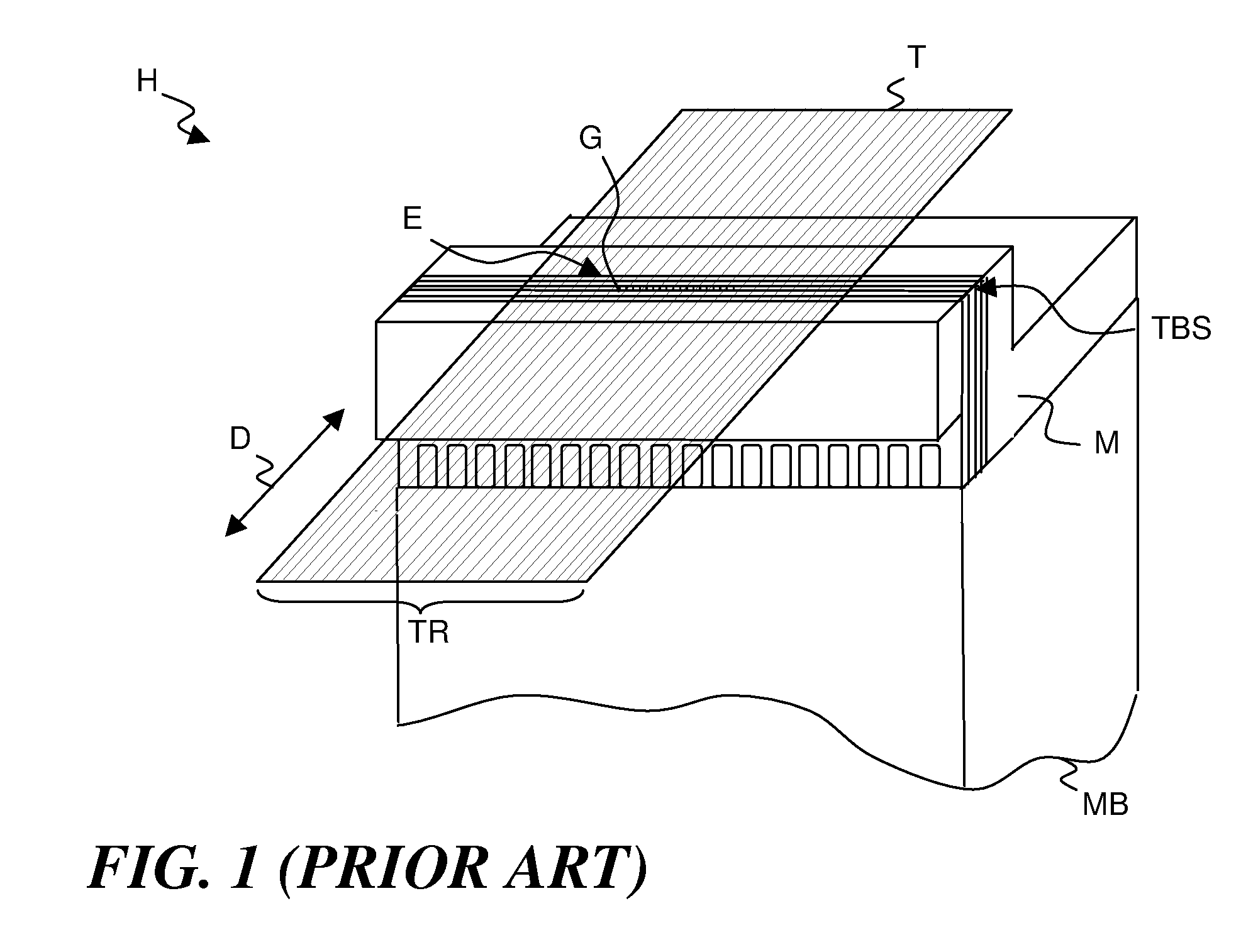

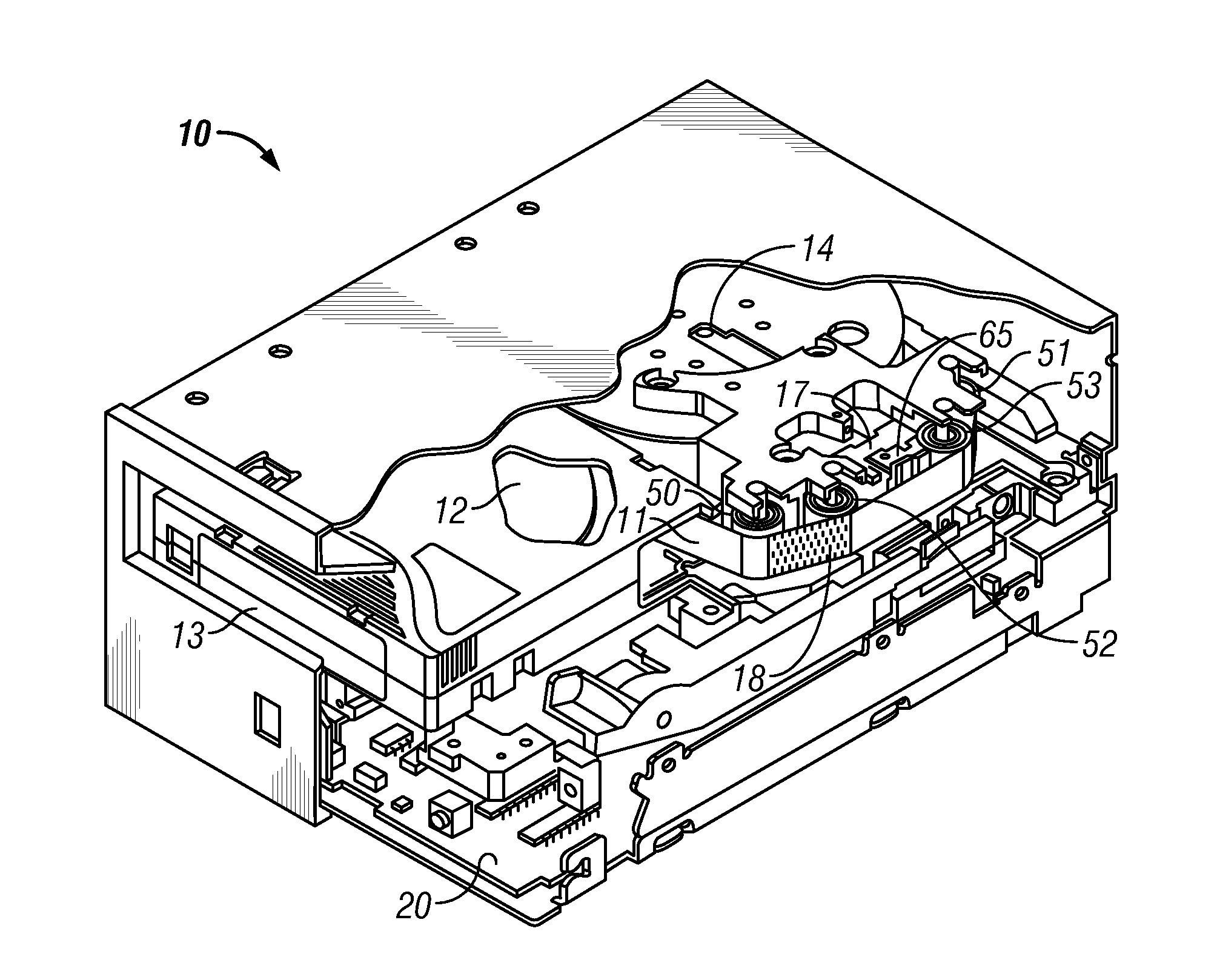

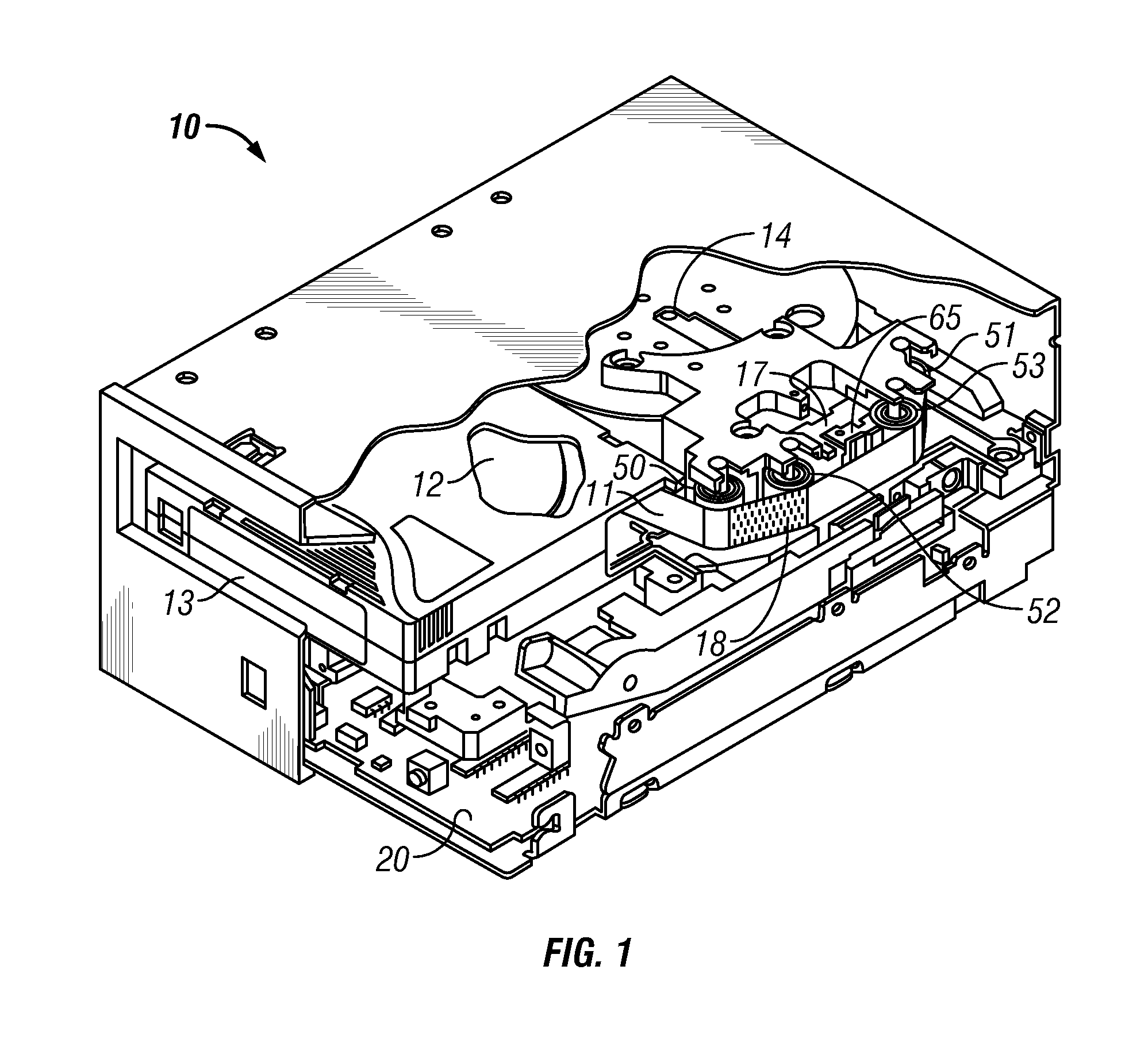

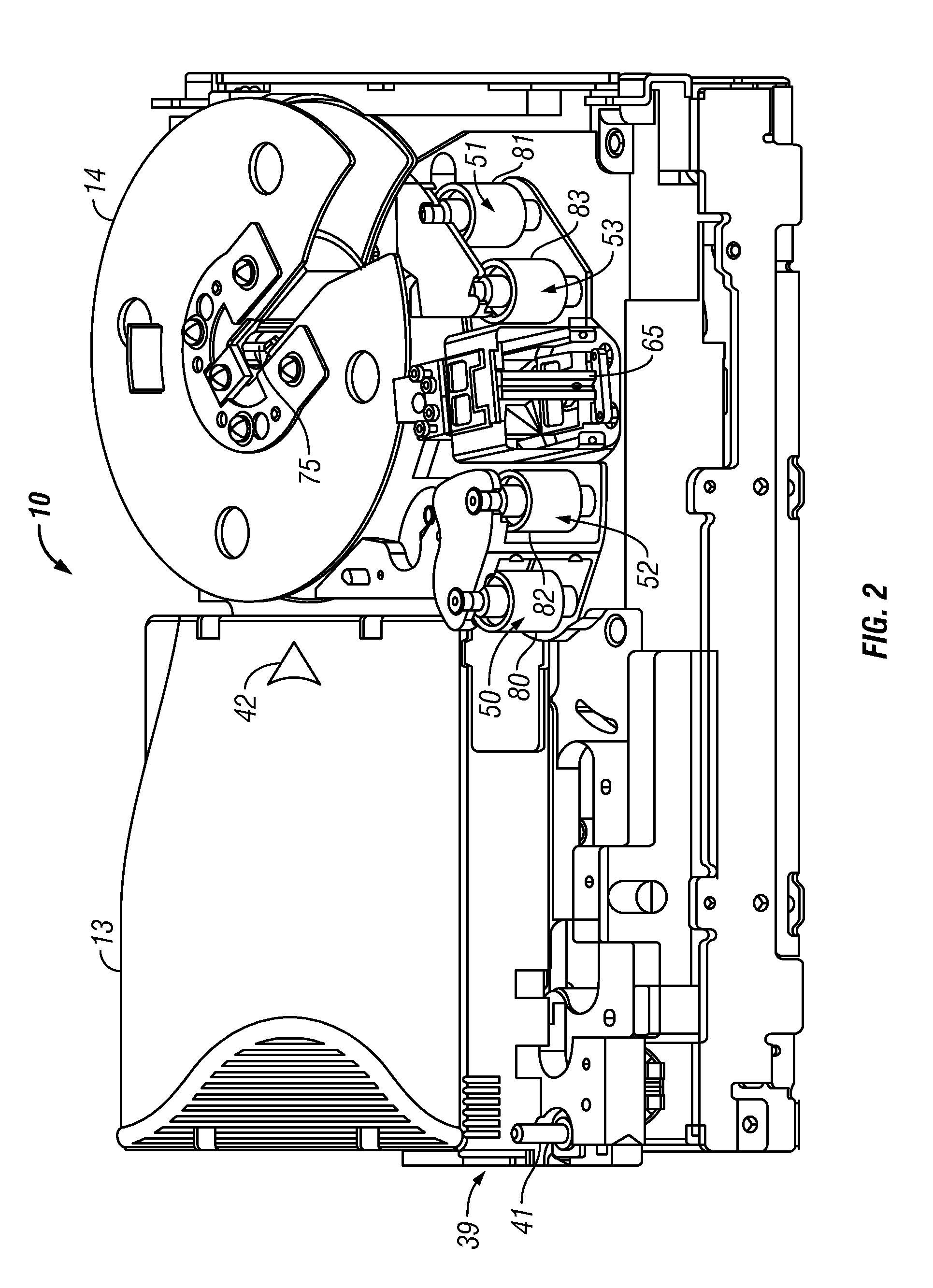

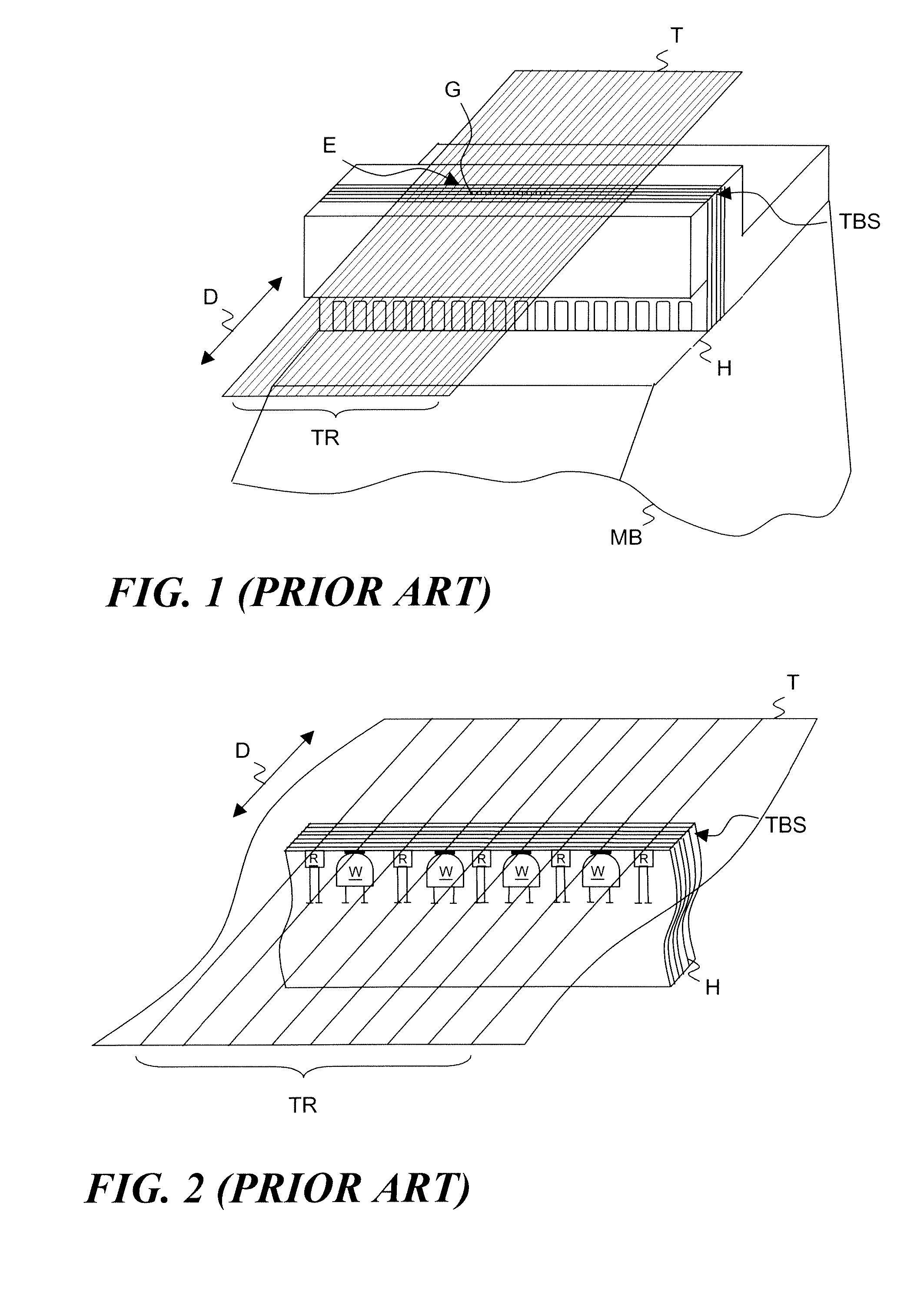

A fine lateral head positioner for a tape drive includes a frame mounted to a base of a tape transport. A tape head slides laterally along a head guide. A guide beam actuated by a fine position actuator applies limited transverse adjustments to the tape head relative to a tape transport path via a cam and cam-follower arrangement. A coarse positioner between the frame and the base provides coarse position adjustment of the tape head laterally among multiple sets of parallel tracks defined along a longitudinal direction of a magnetic tape moving along the tape transport path, and the guide beam provides fine position adjustment of the tape head enabling it to follow in real time a particular set of parallel tracks of the tape during each data writing or reading operation.

Owner:QUANTUM CORP

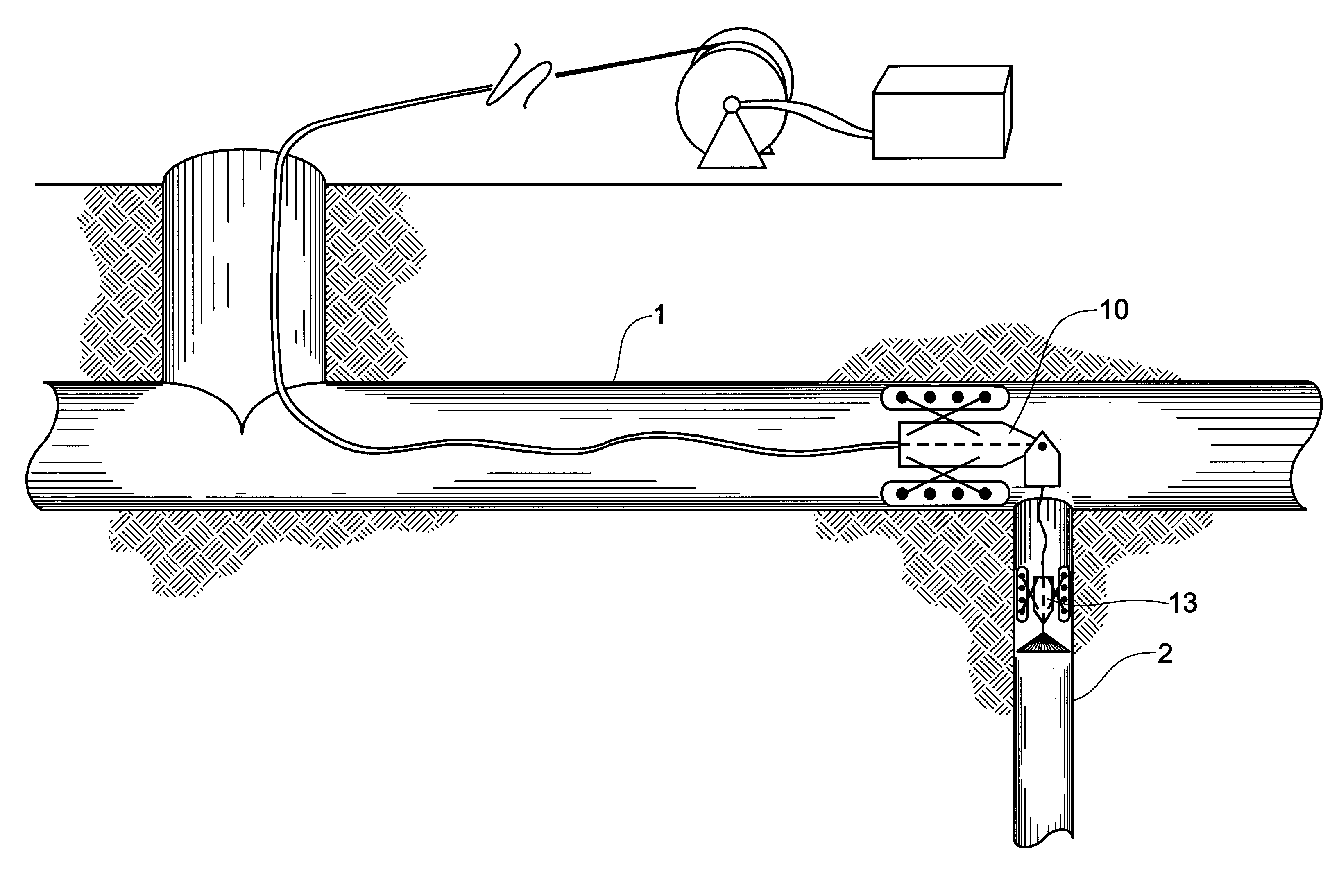

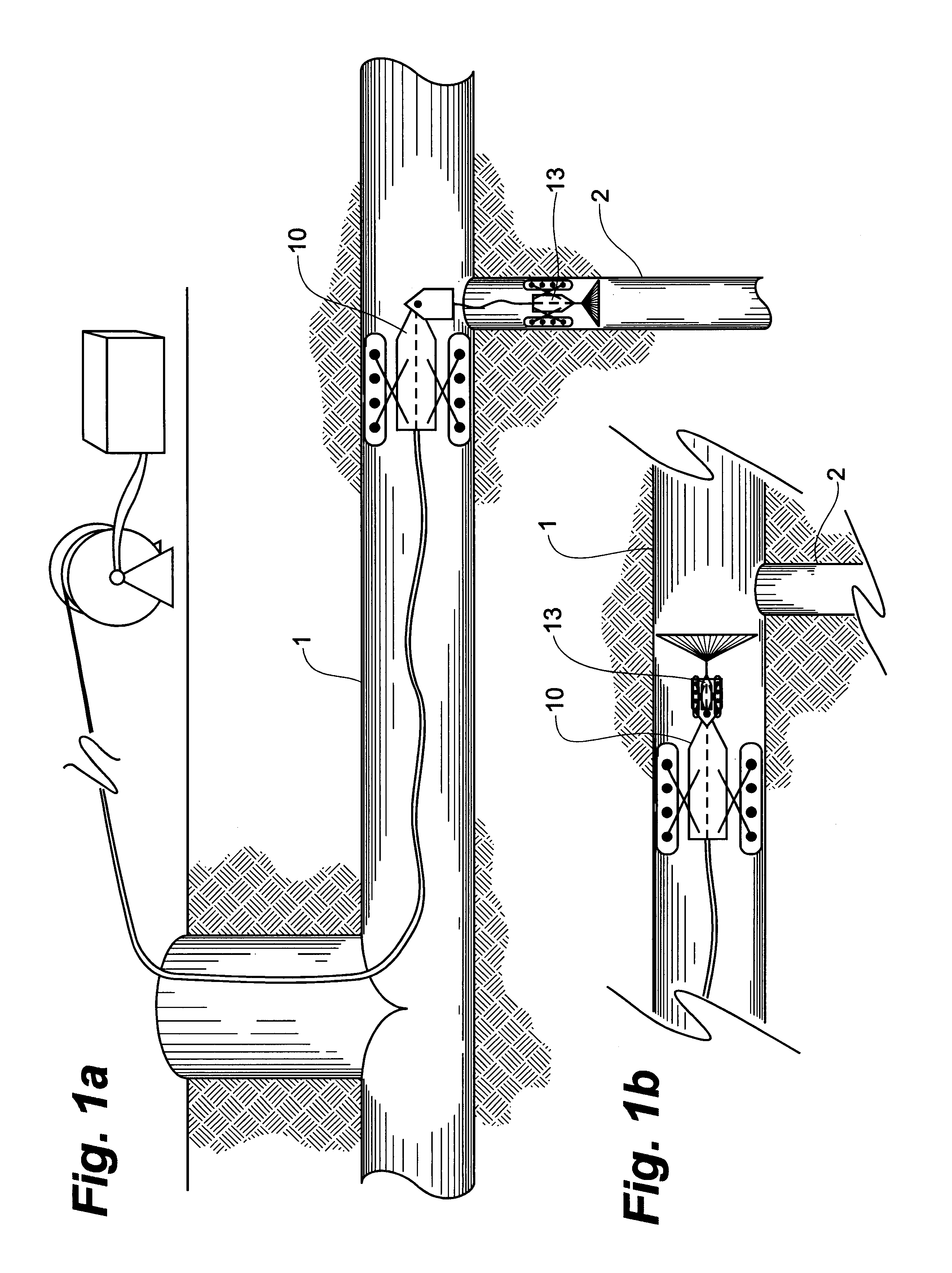

Robotic apparatus and method for treatment of conduits

InactiveUS6887014B2Novel methodMeasurement devicesRailway tunnelsElectrical conductorTeleoperated robot

A robotic apparatus and method for treatment of system of conduits and lateral sub-conduits comprising a remotely controlled robotic vehicle which navigates main conduits which delivers a series of tools to locations within the conduit. The mule's tools comprise a variety of devices including a tape head and a transport housing for a second remotely controlled robotic vehicle, or mouse which can be deployed for traversing and treating sub-conduits. Further, a method to install one or more small diameter flexible elongate members, such as conductors or sheathes to the inside of the system of conduits comprises advancing an elongate member through the conduit system with the mule or mouse, anchoring the elongate member and then taping the elongate member with the taping head while retreating out of the conduit. Preferably the tape is pre-shaped to minimize wrinkling upon application and more preferably, greater security and tape bonding strength is achieved by spraying over the tape and elongate member.

Owner:GEOLYN CONSULTANTS INC

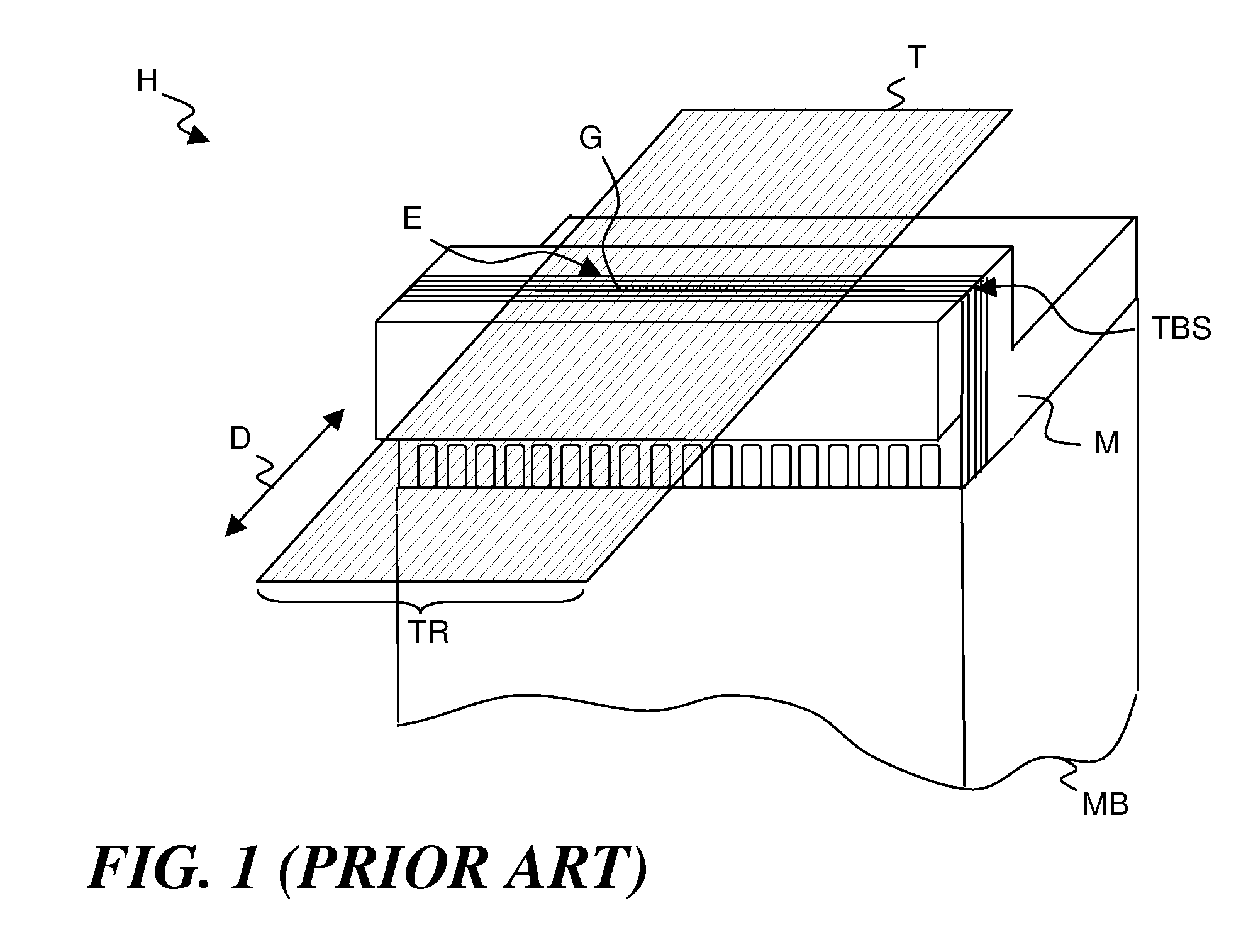

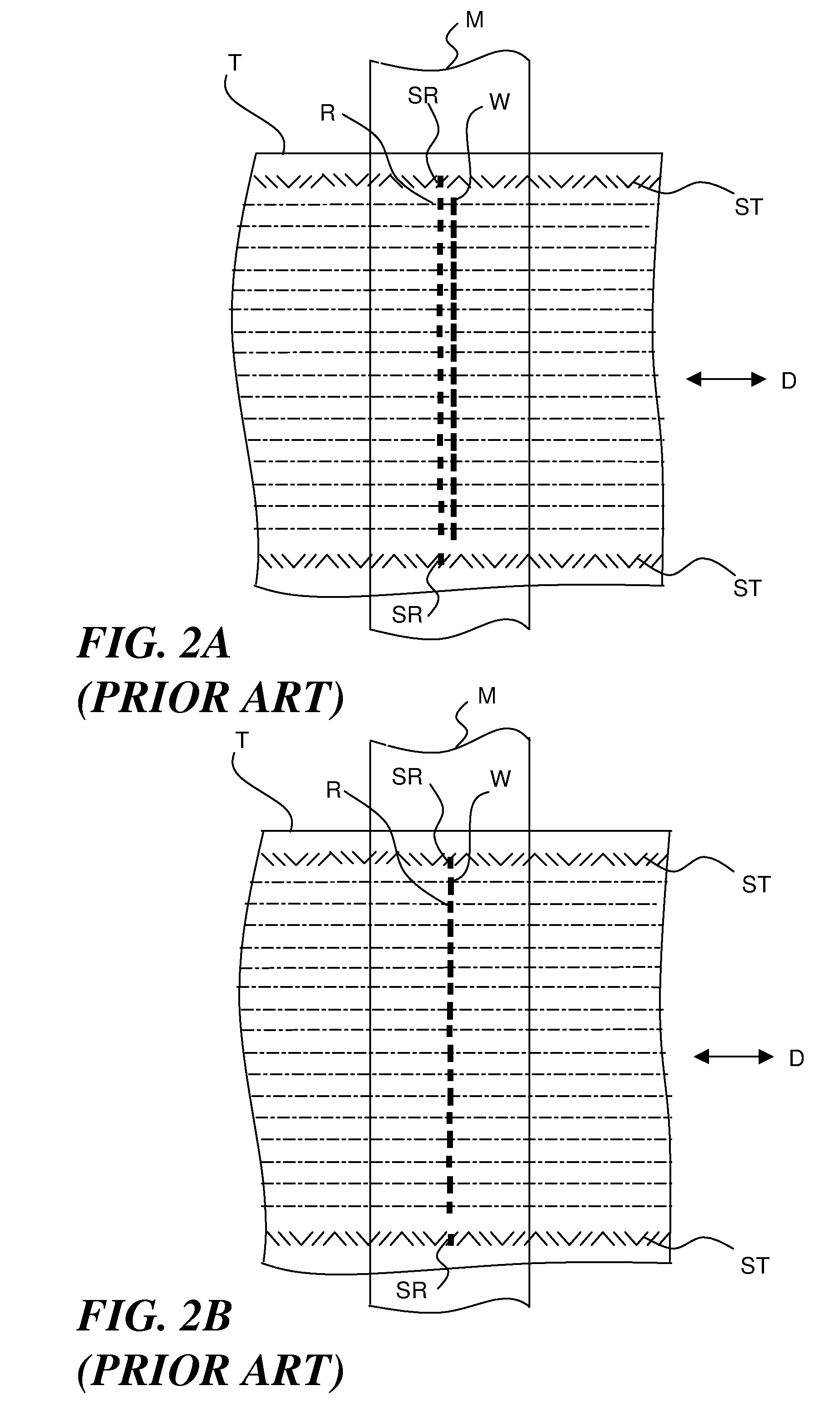

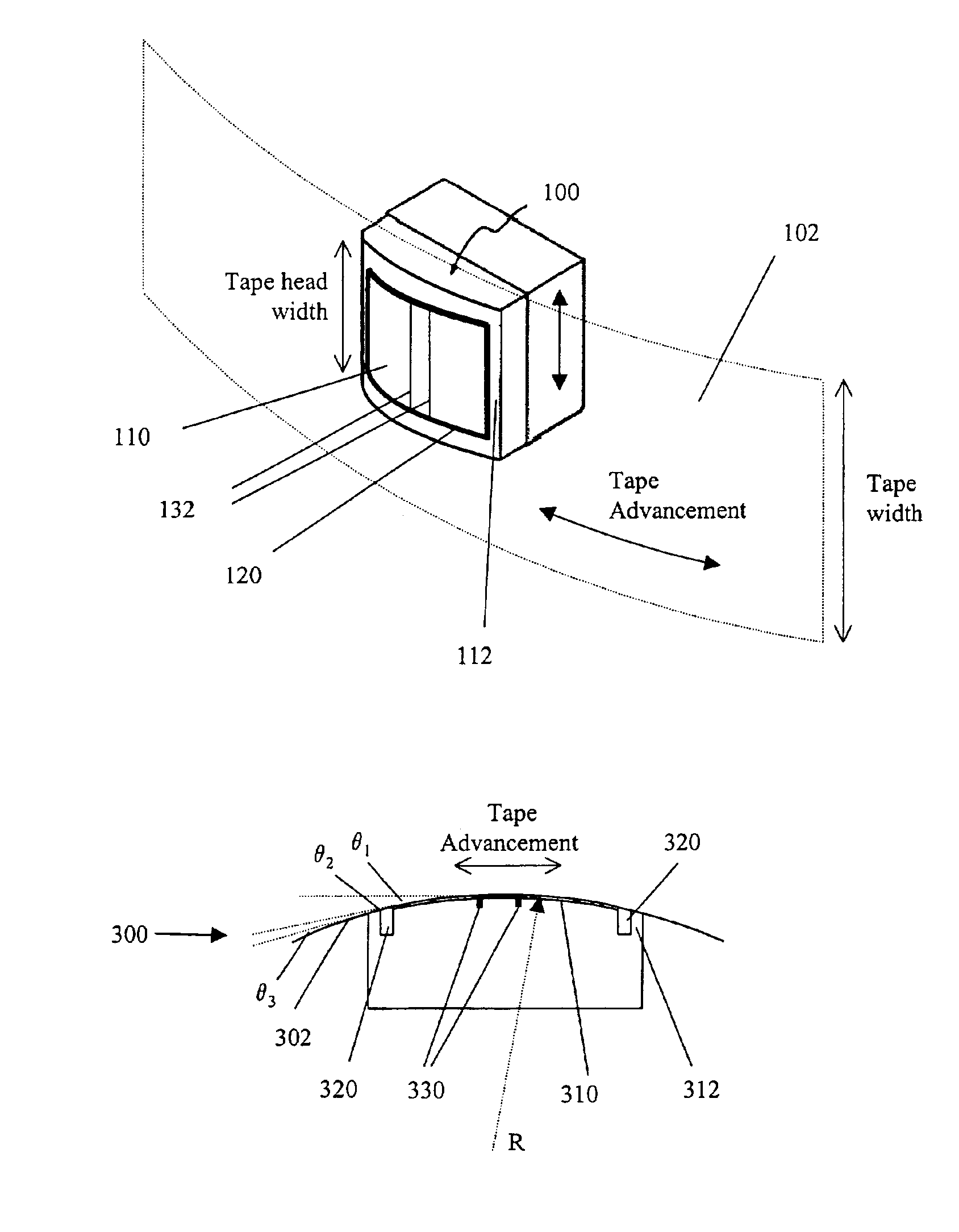

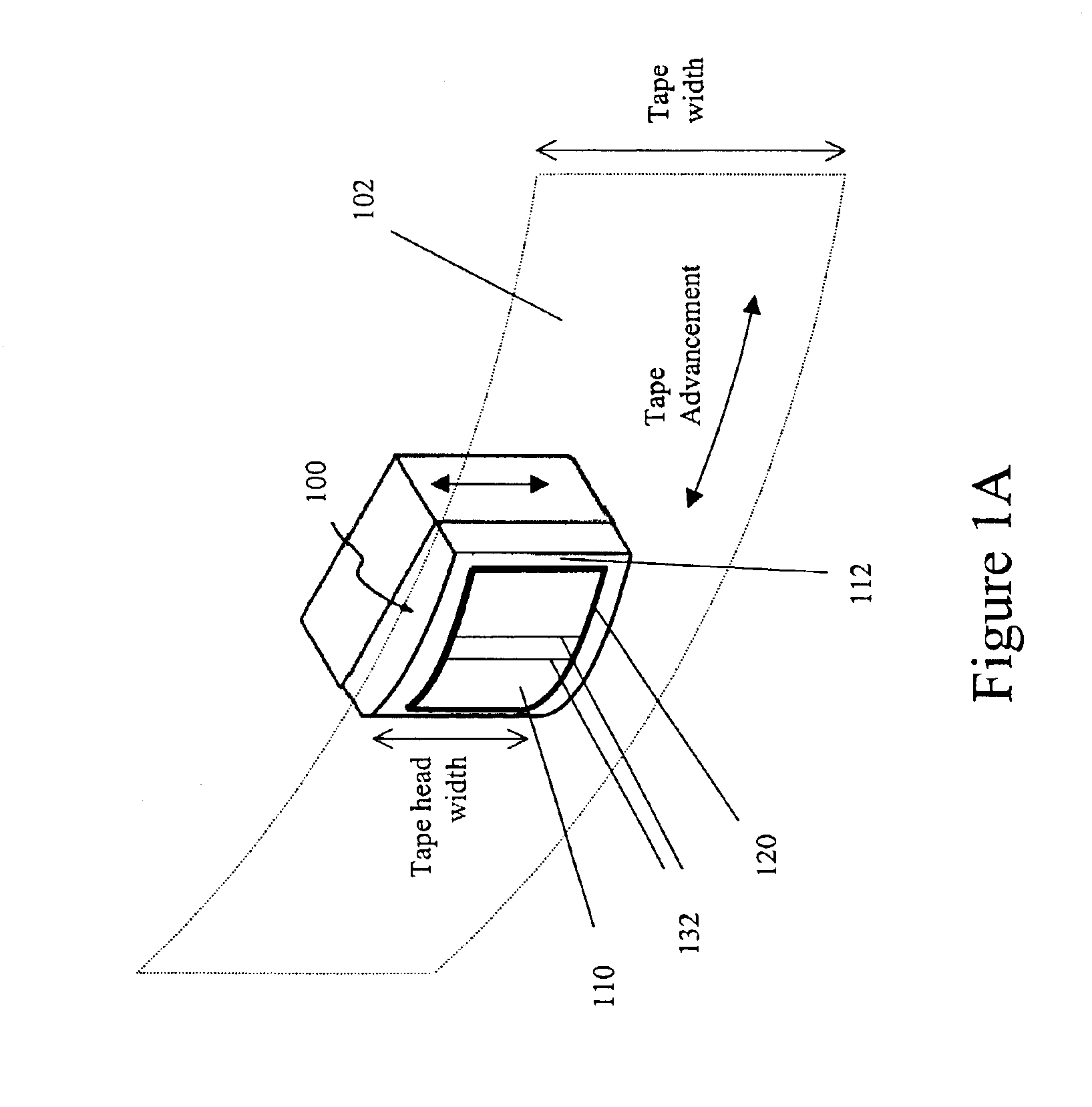

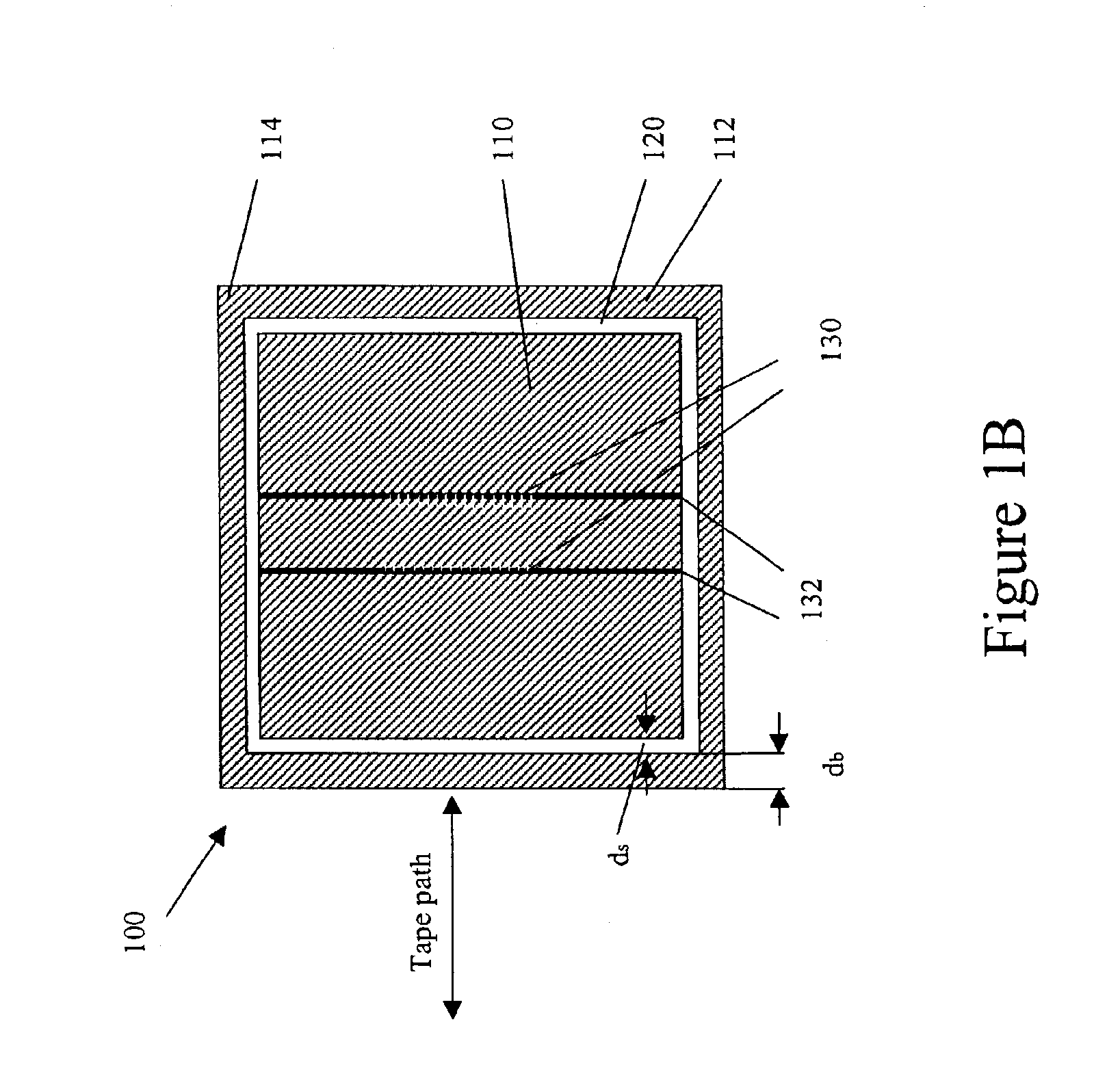

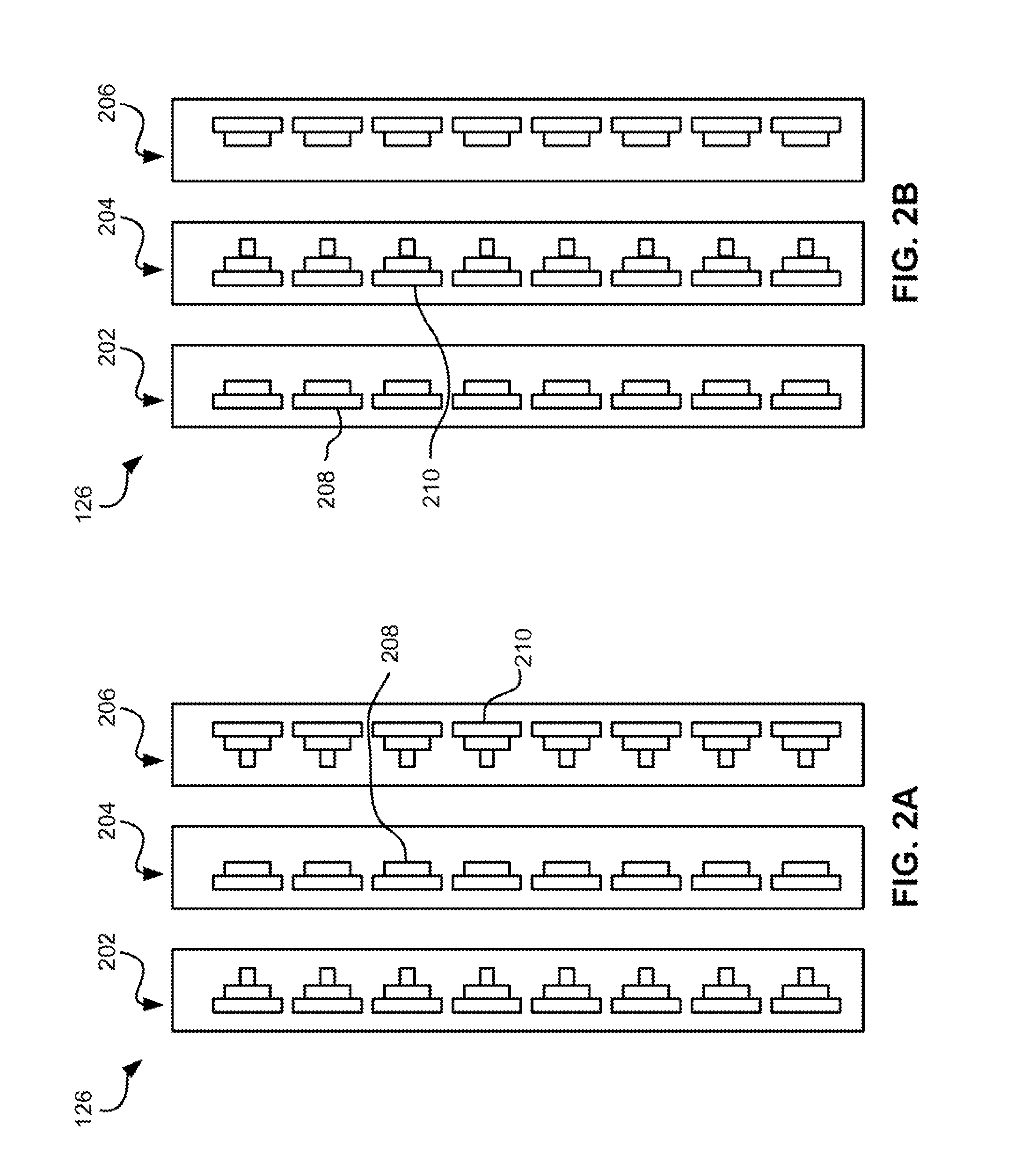

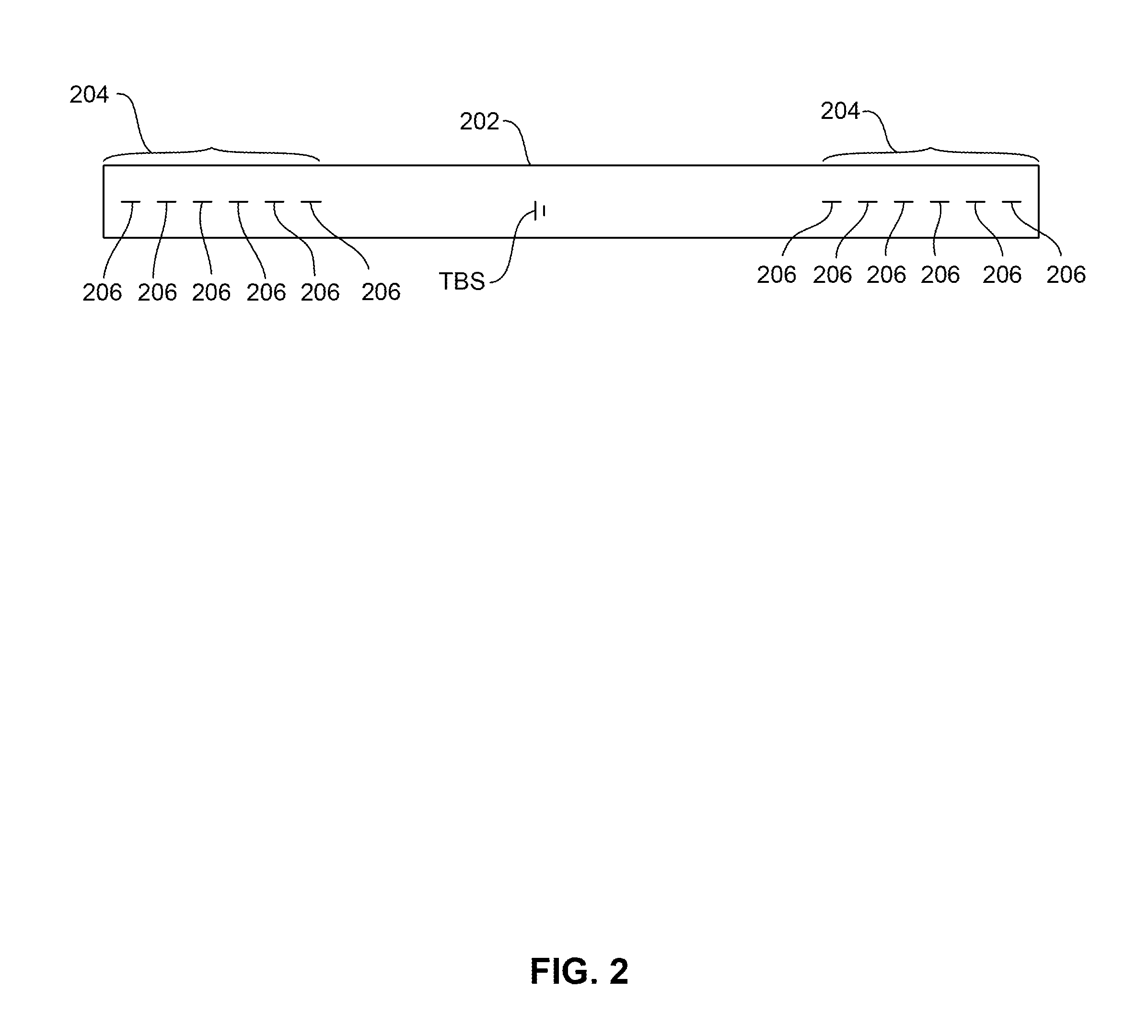

High Areal Density Tape Head

InactiveUS20080137235A1Tape track is reducedReduce tape trackFilamentary/web record carriersAlignment for track following on tapesAdhesive beltTransducer

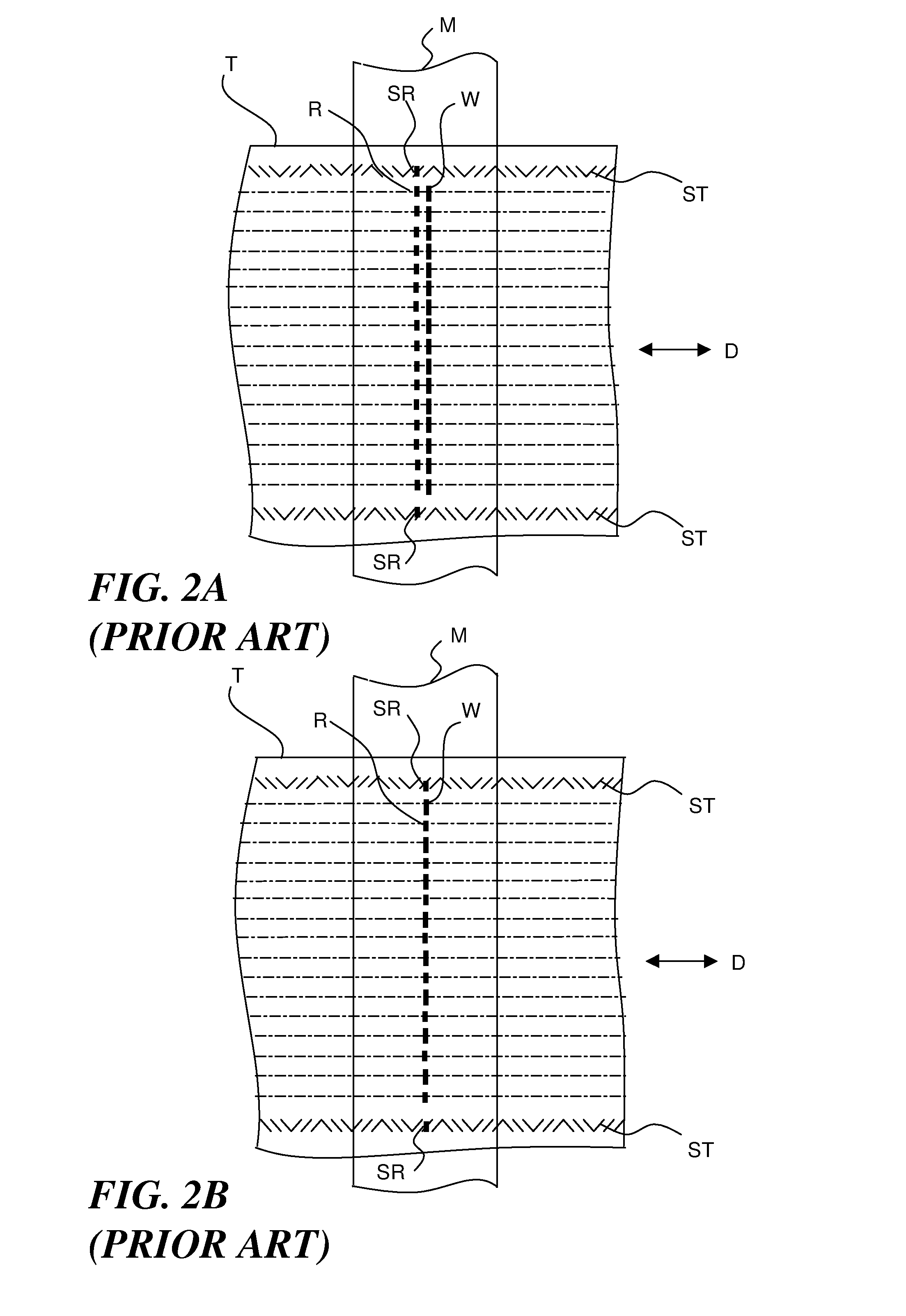

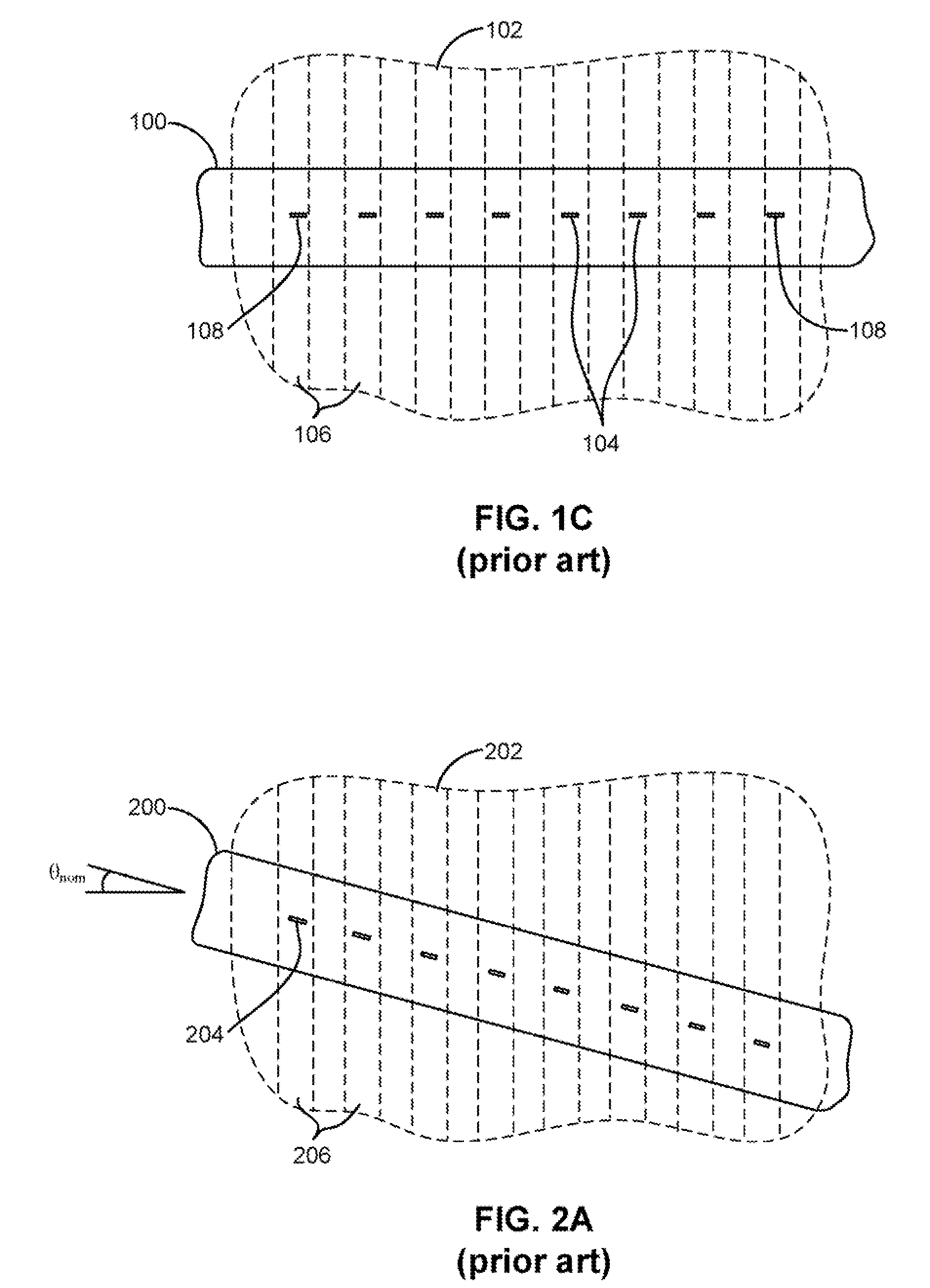

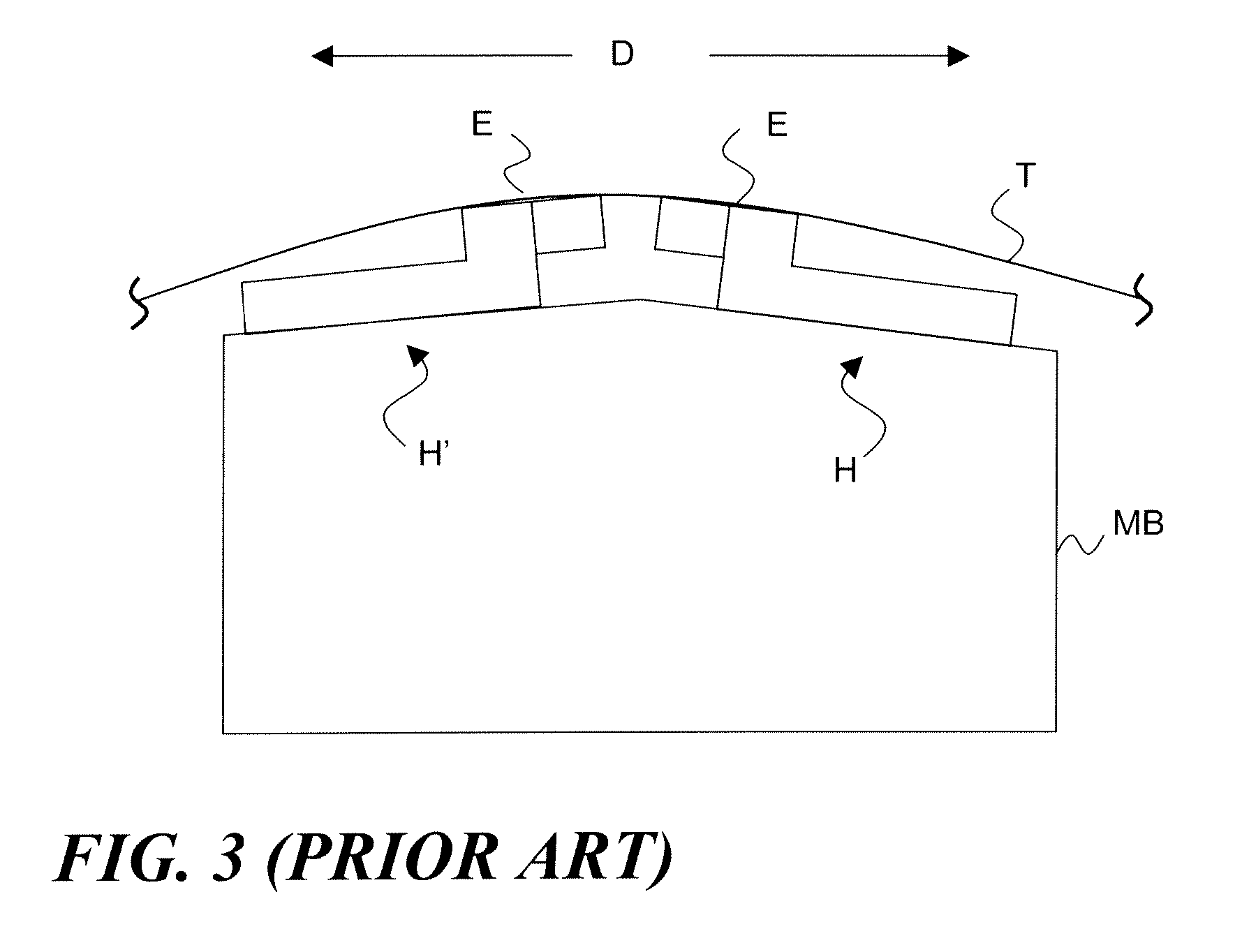

A tape head designed for transducing data on a magnetic recording tape that is subject to tape dimensional changes. The tape head includes two or more arrays of transducer elements having different transducer spacing distances corresponding to different track spacing distances to be transduced. One of the transducer arrays may be used for transducing the tape under nominal tape track spacing conditions. Another transducer array may be used for transducing the tape when the tape track spacing is reduced due to the tape shrinkage. Still another transducer array may be used for transducing the tape when the tape track spacing is enlarged due to tape expansion.

Owner:IBM CORP

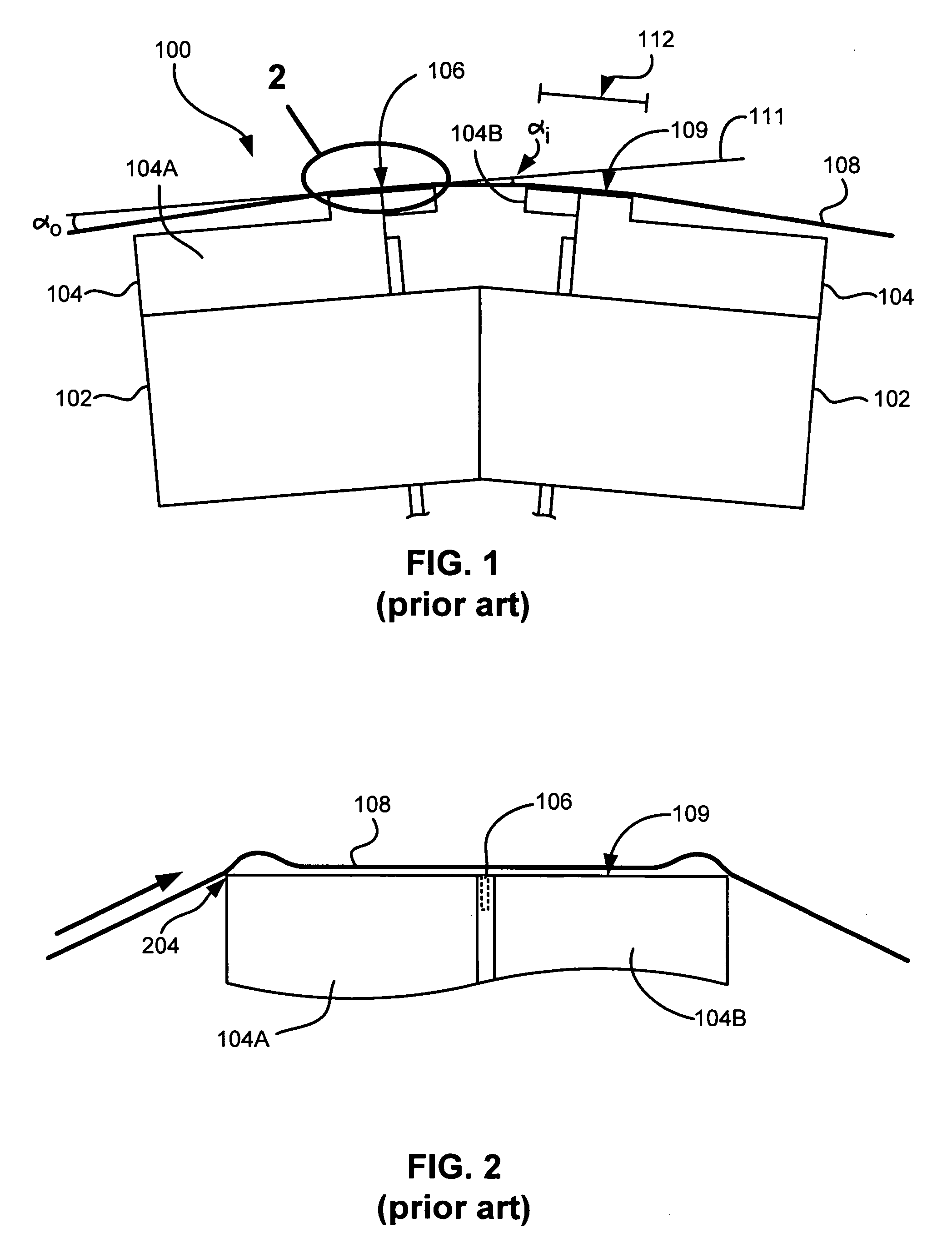

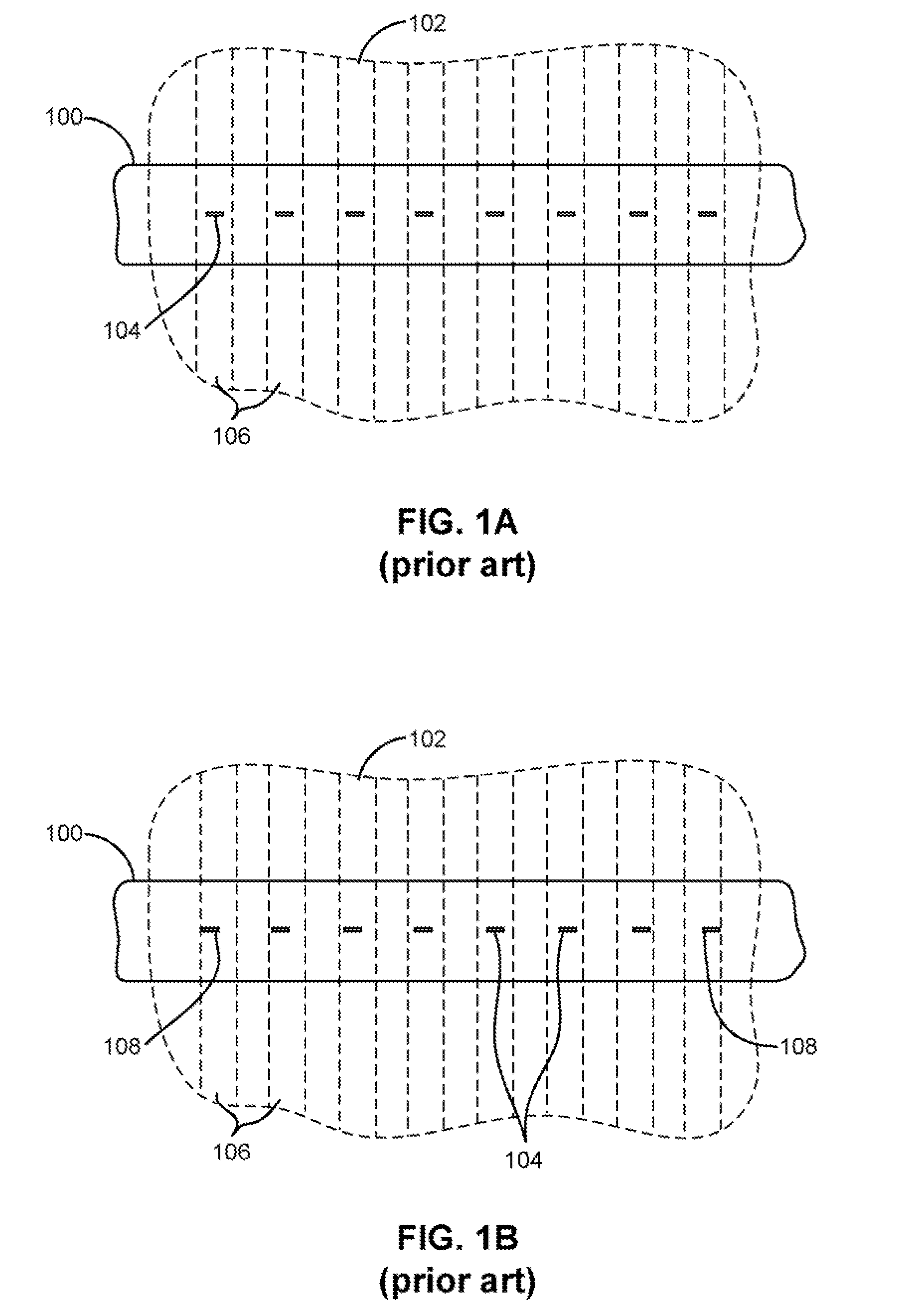

Low friction tape head and system implementing same

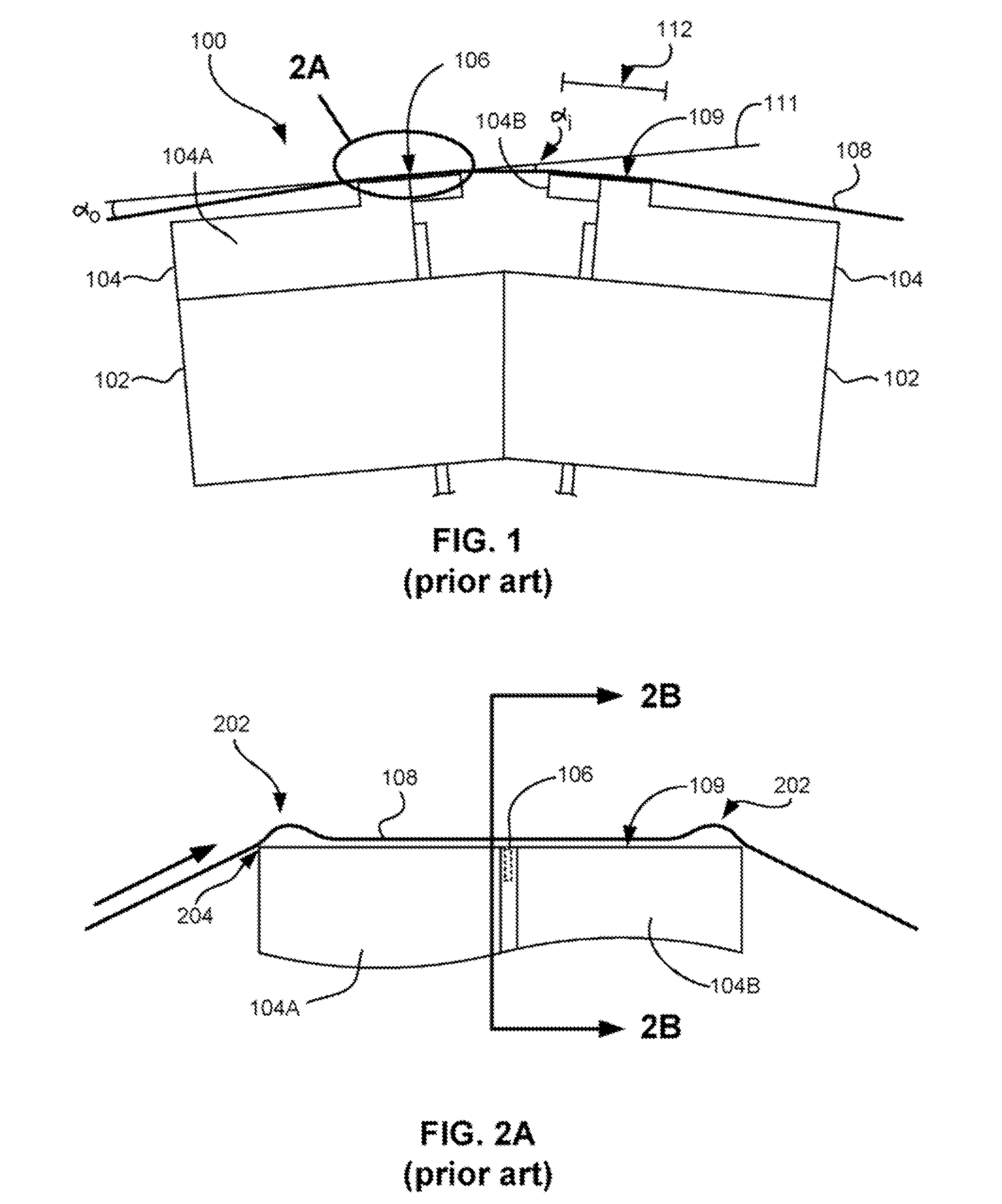

InactiveUS20120008234A1Manufacture head surfaceManufacturing heads with multiple gapsMagnetic mediaMechanical engineering

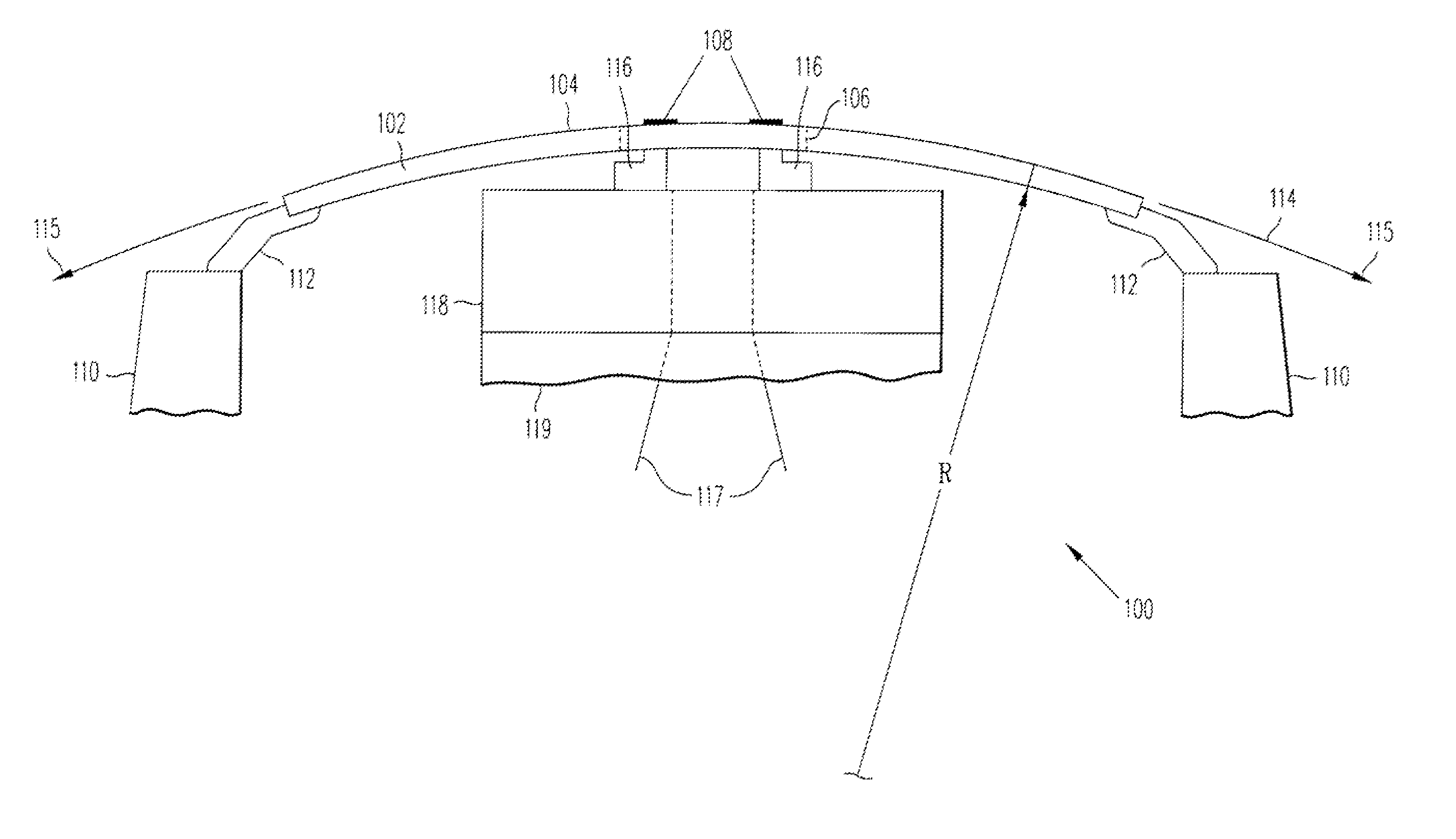

A magnetic data storage system according to one embodiment includes a magnetic head; and guides on opposite sides of the magnetic head for directing a magnetic medium over the magnetic head. The magnetic head includes: outer portions each having a tape bearing surface and an array of transducers selected from a group consisting of readers and writers; and a central portion positioned between the outer portions, the central portion having a tape bearing surface and an array of transducers selected from a group consisting of readers and writers. An inner edge of each of the tape bearing surfaces of the outer portions is adapted for skiving air from the magnetic medium when the magnetic medium travels in a direction from the central portion towards the respective outer portion. The guides are oriented to direct the magnetic medium to fly over a leading one of the outer portions, engage a leading edge of the tape bearing surface of the central portion, and engage an inner edge of the tape bearing surface of a trailing one of the outer portions.

Owner:IBM CORP

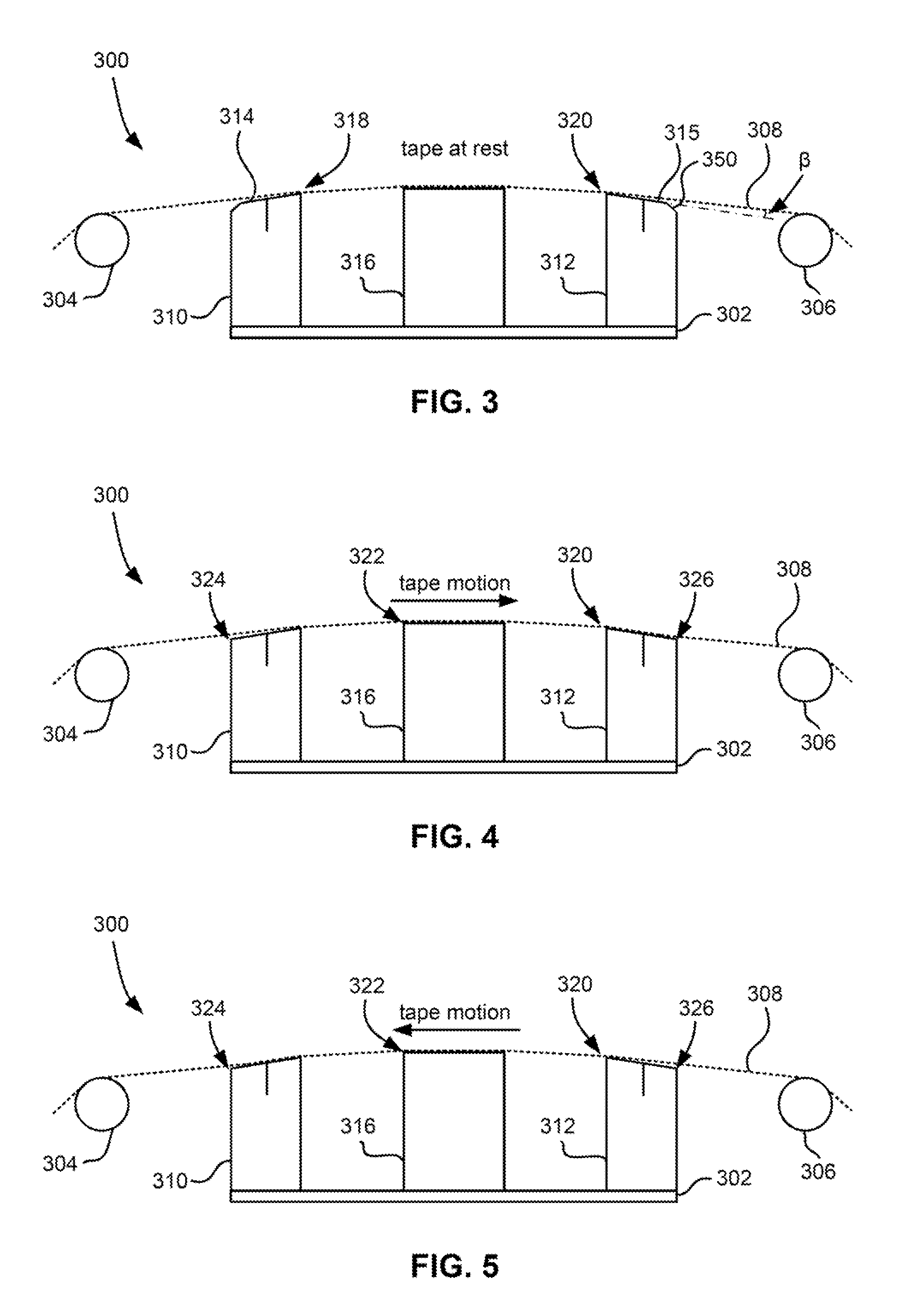

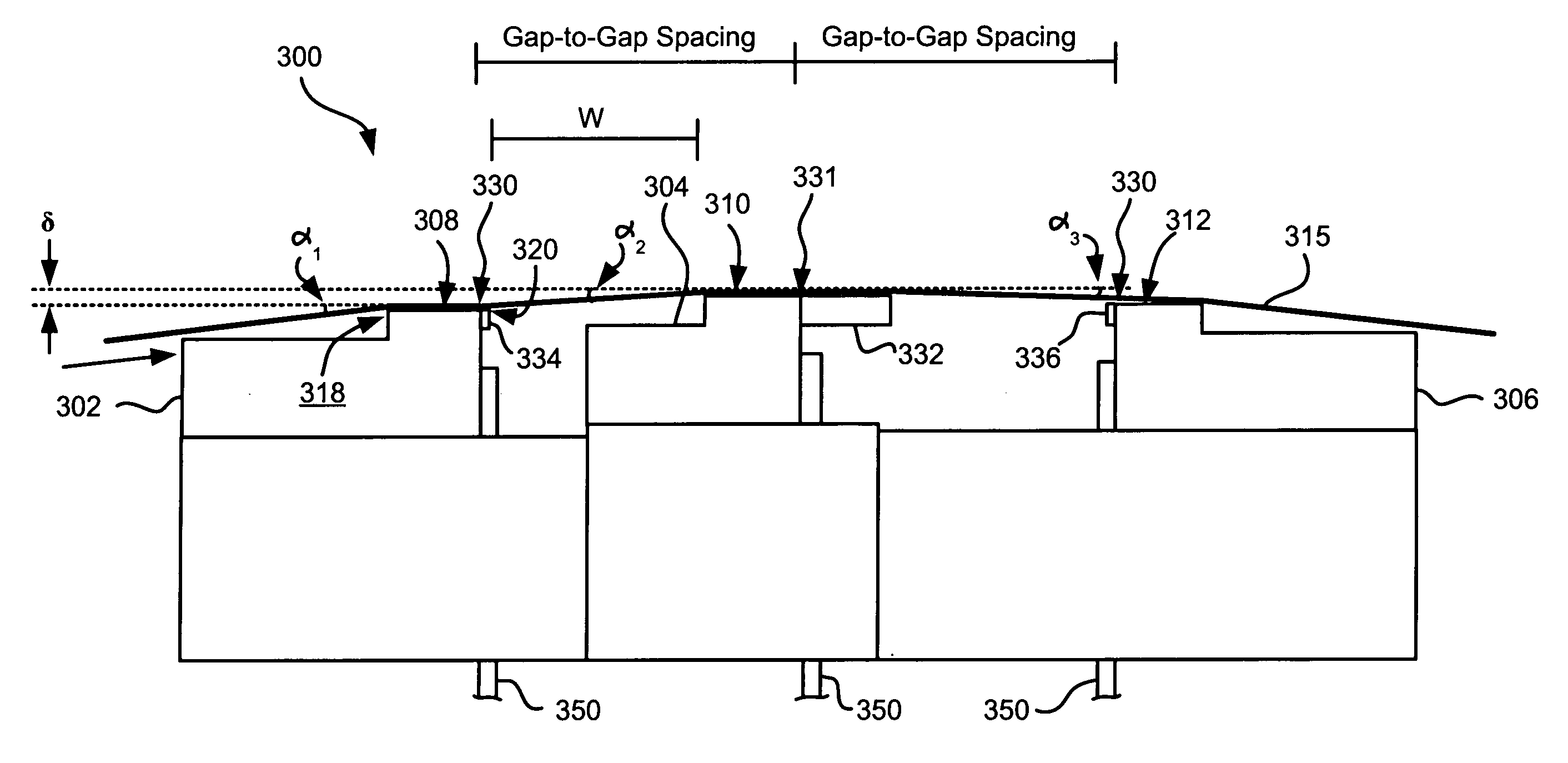

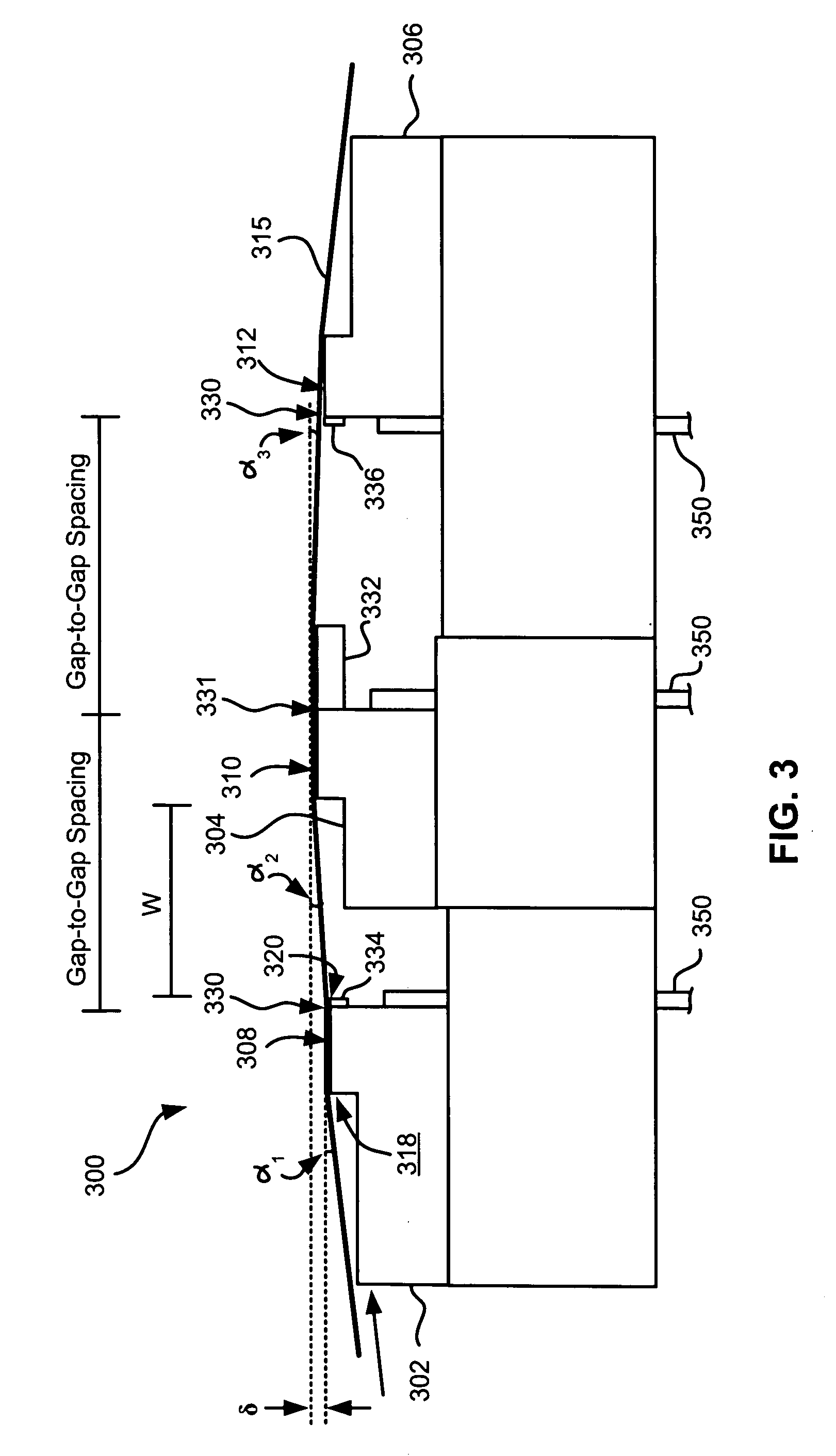

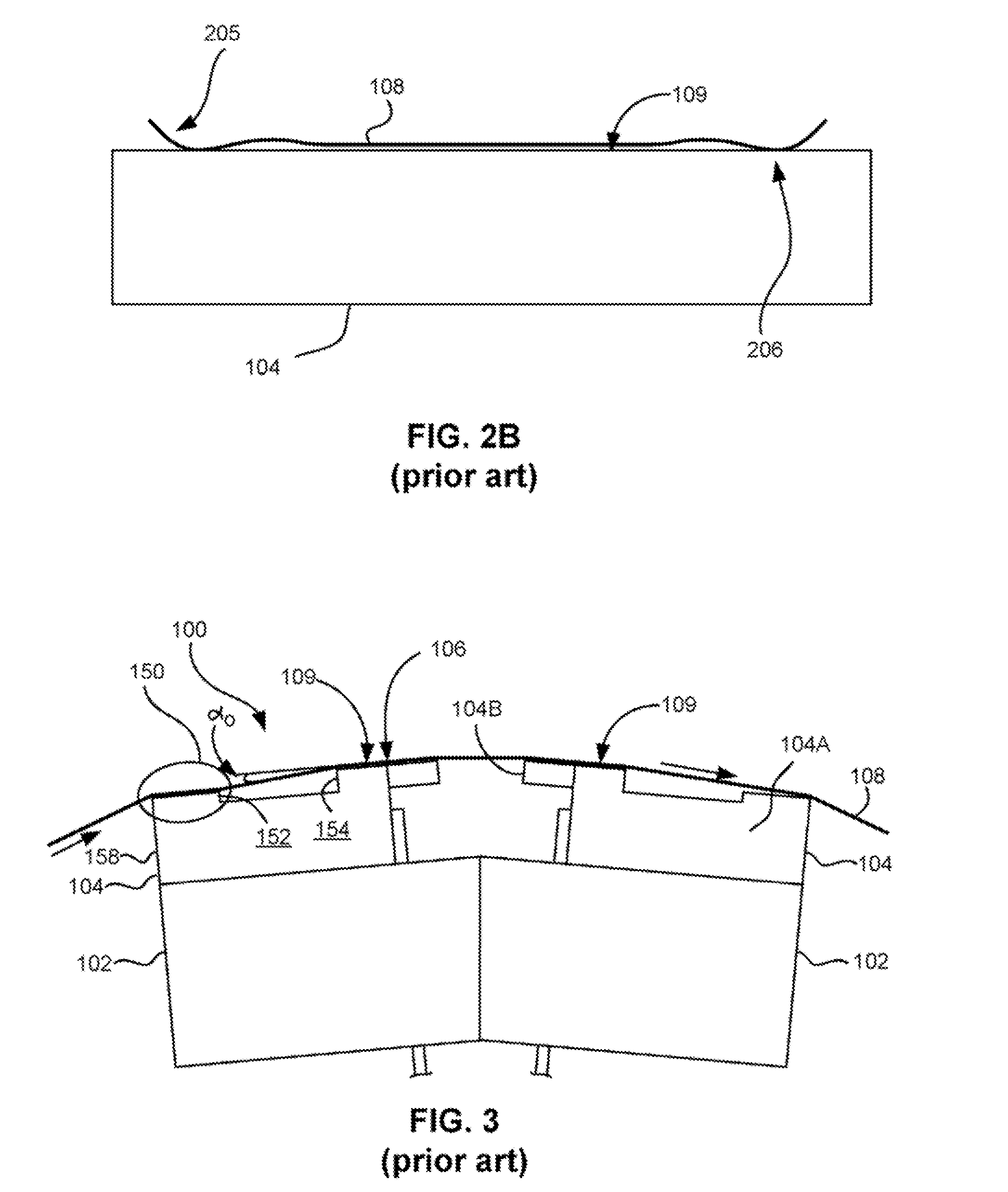

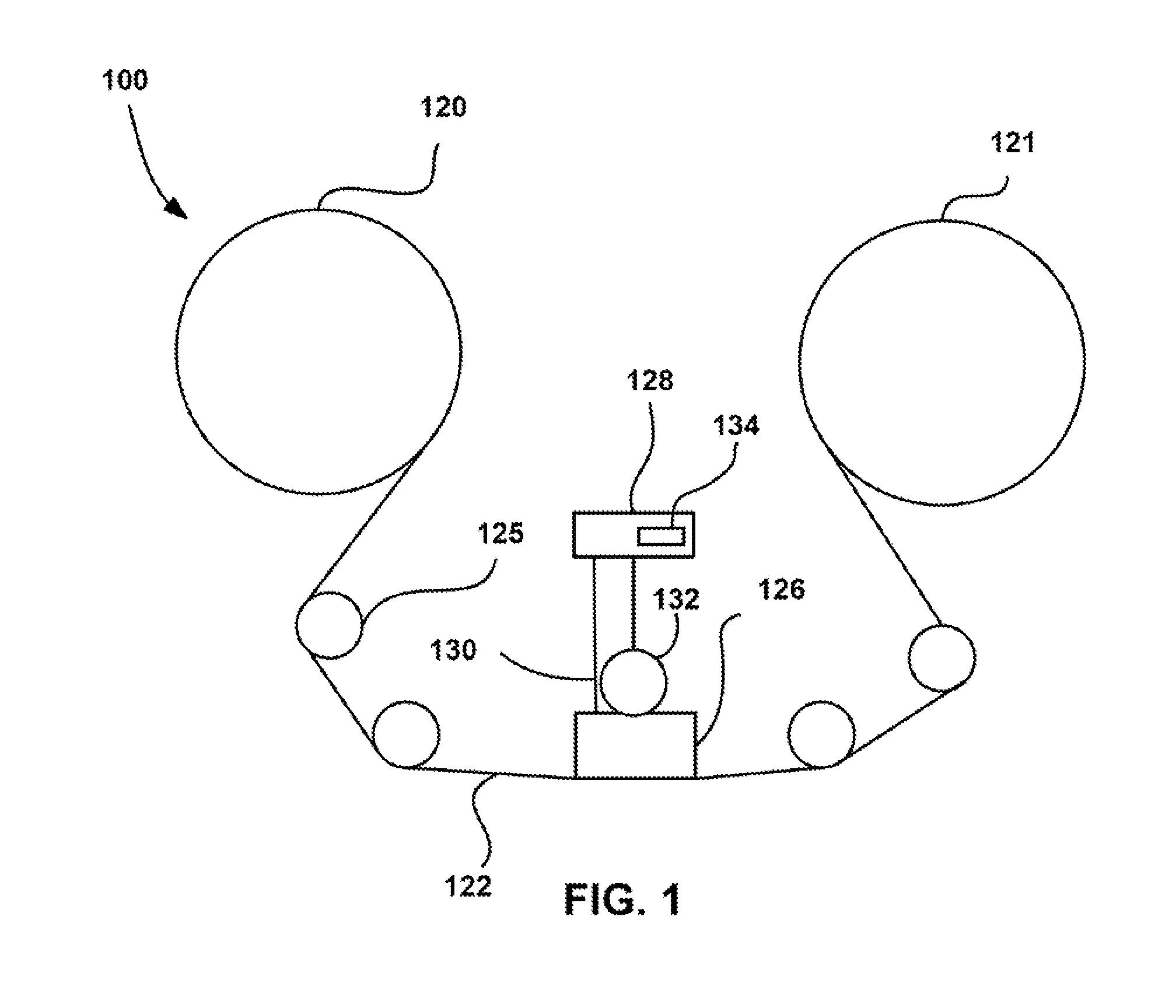

Flat profile tape head

InactiveUS20070047142A1Reduce wearAvoid excessive wearManufacture head surfaceRecord information storageEngineeringBearing surface

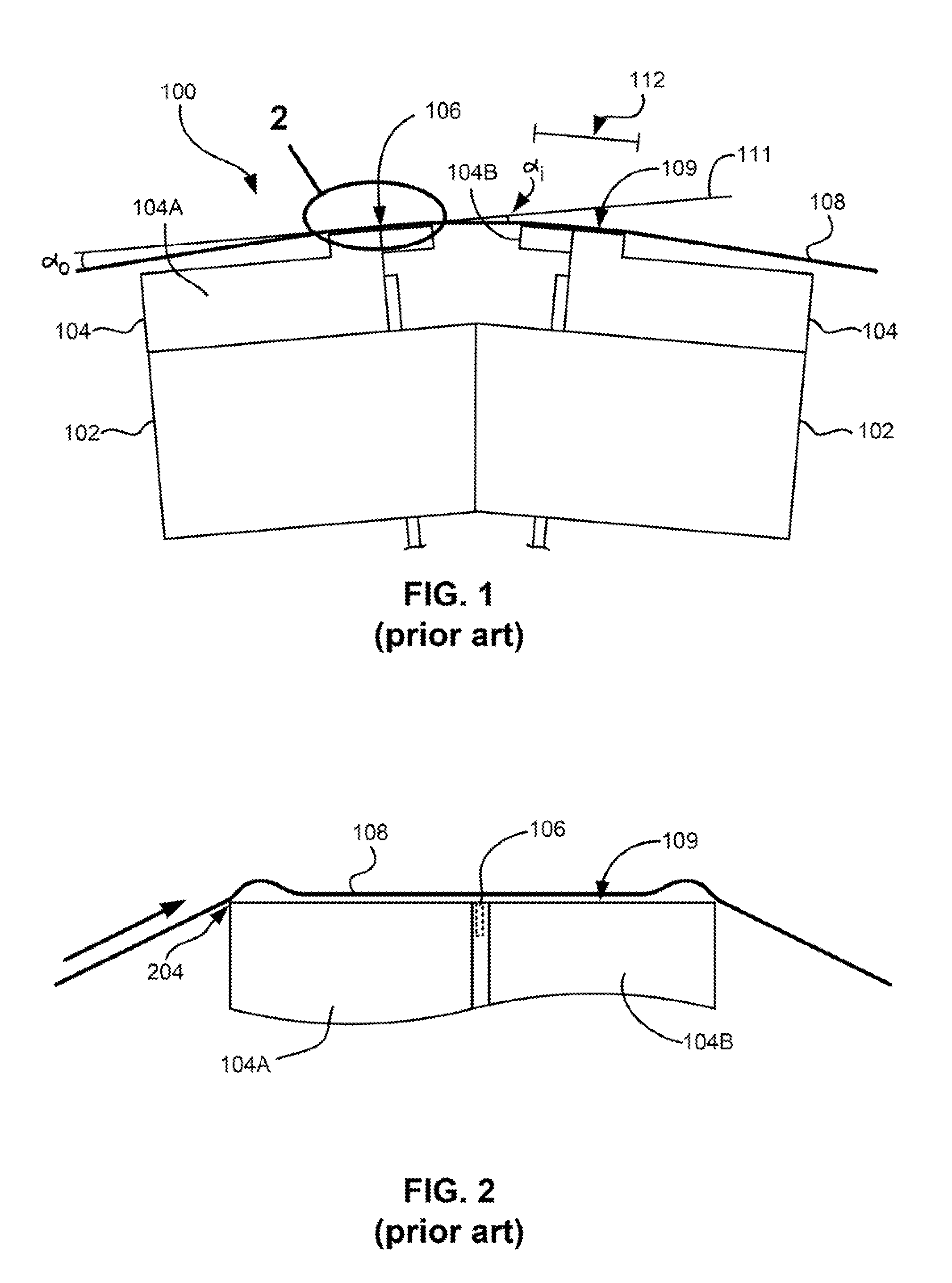

A magnetic head according to one embodiment includes a first module having a flat profile tape bearing surface, a second module having a flat profile tape bearing surface, and a third module having a flat profile tape bearing surface. The third module is positioned on an opposite side of the second module than the first module. The tape bearing surfaces of the first, second and third modules may lie along substantially parallel planes, may be configured in a tangent (angled) configuration, or may be configured in an overwrap configuration. Data writing and reading functions are usually performed by different modules at a given time.

Owner:IBM CORP

Tape heads for use with multiple tape formats

InactiveUS7570450B2Driving/moving recording headsAlignment for track following on tapesComputer hardwareTape head

A magnetic head according to one embodiment includes an array of elements, the elements being selected from a group consisting of data readers, data writers, and combinations thereof, wherein a first subset of the elements is operable for reading or writing data in a first tape format, wherein a second subset of the elements is operable for reading or writing data in a second tape format, at least some of the elements being present in both subsets, wherein a spacing of servo bands on a tape written in the first format is different than a spacing of servo bands on a tape written in the second format.

Owner:IBM CORP

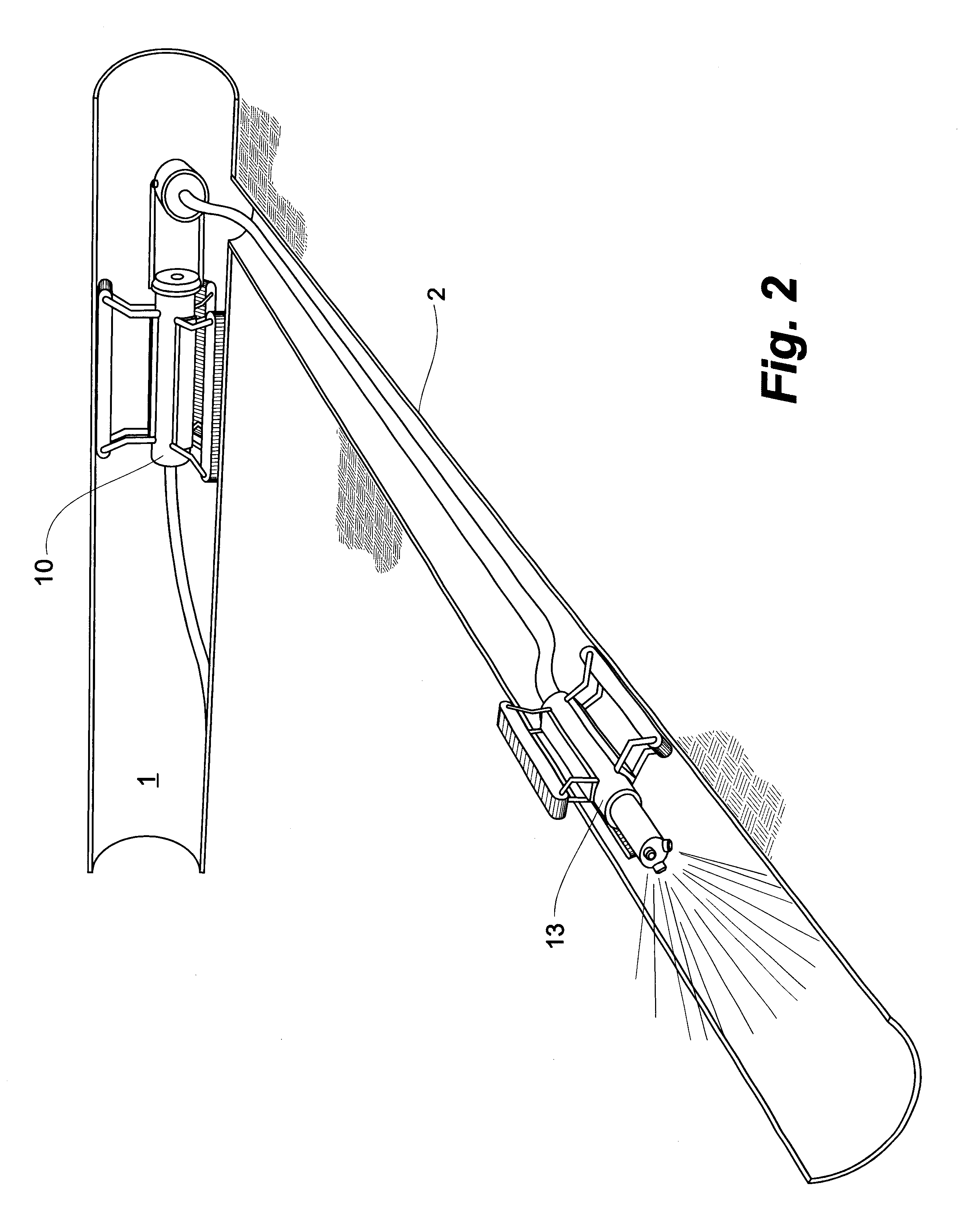

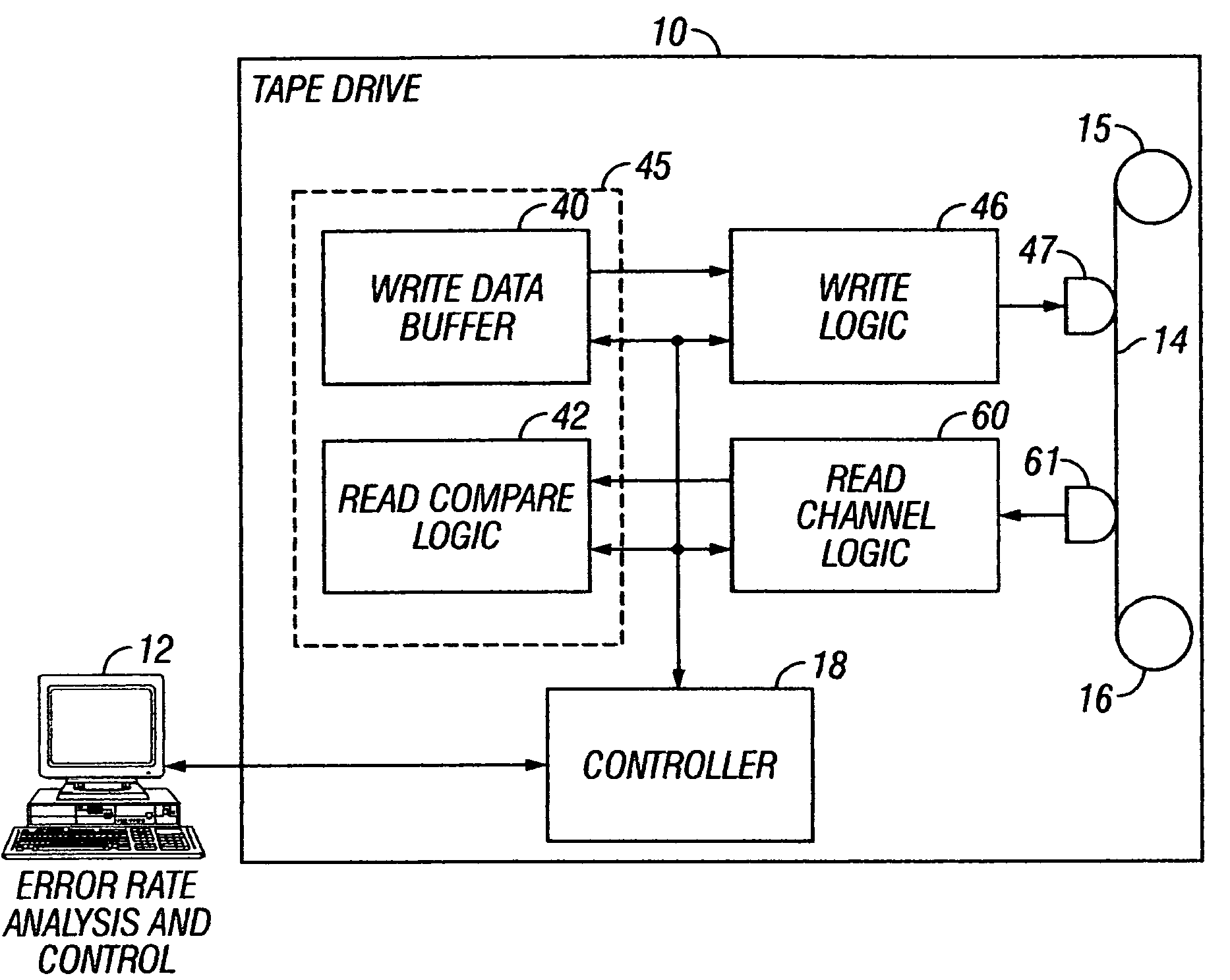

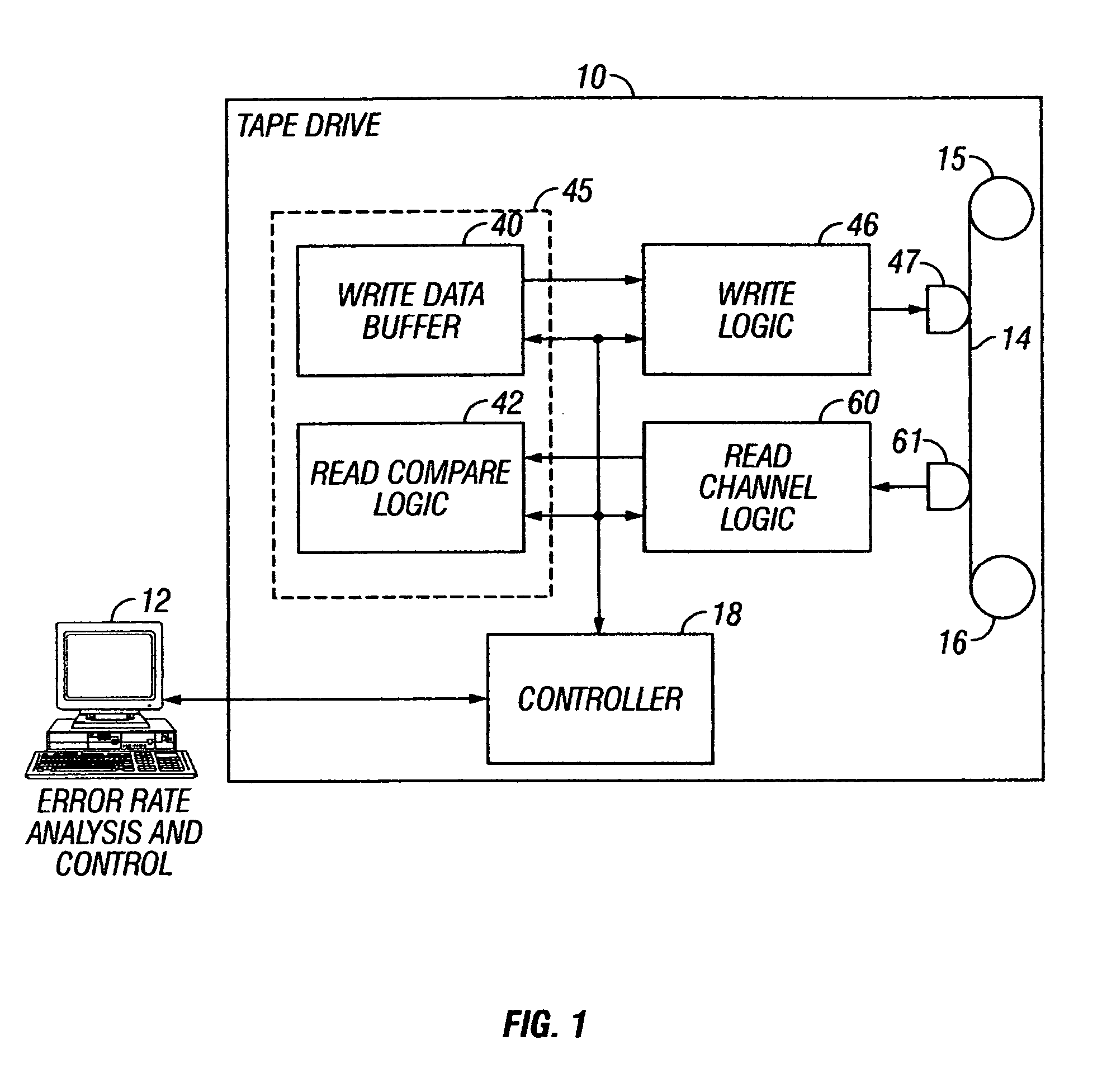

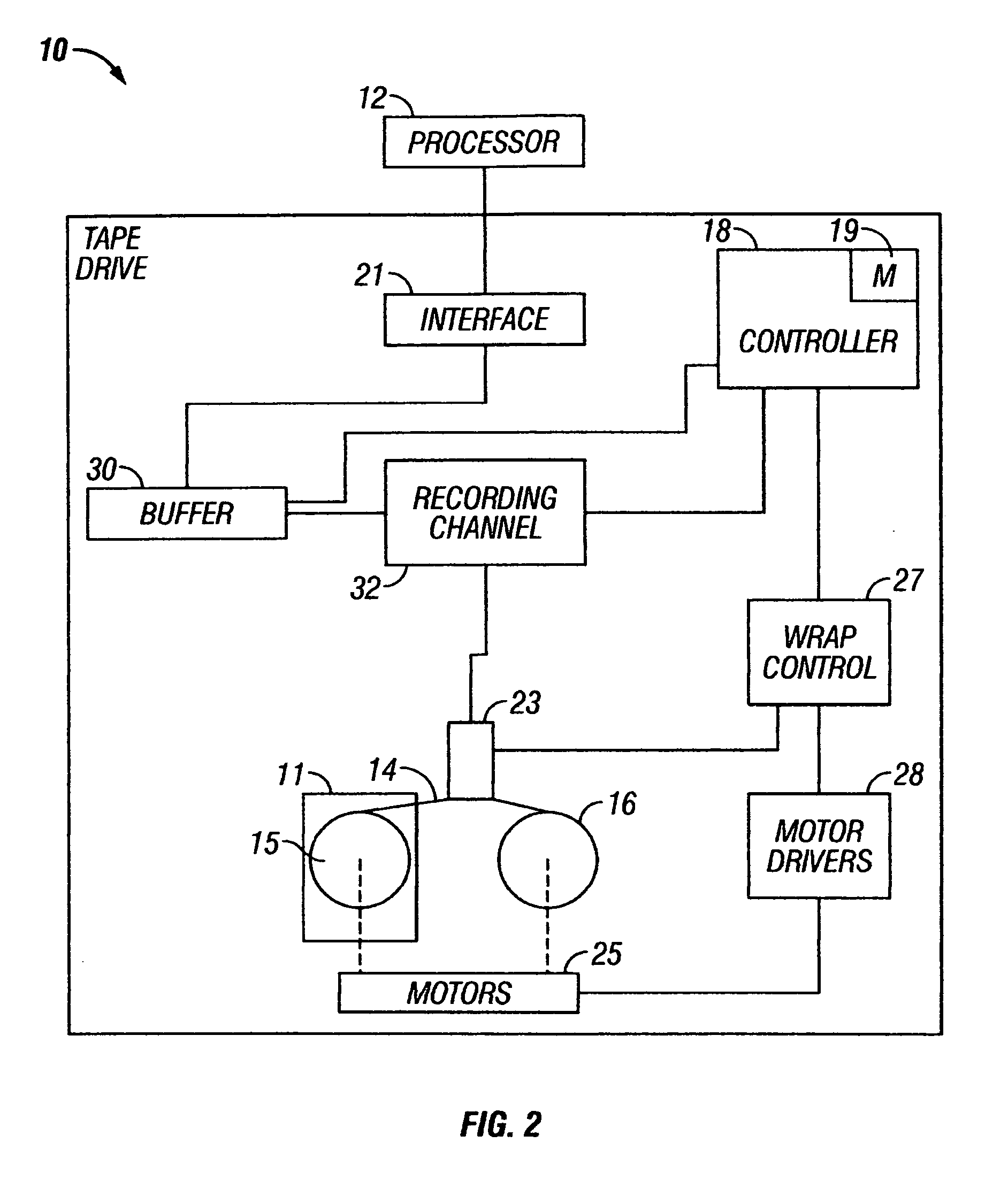

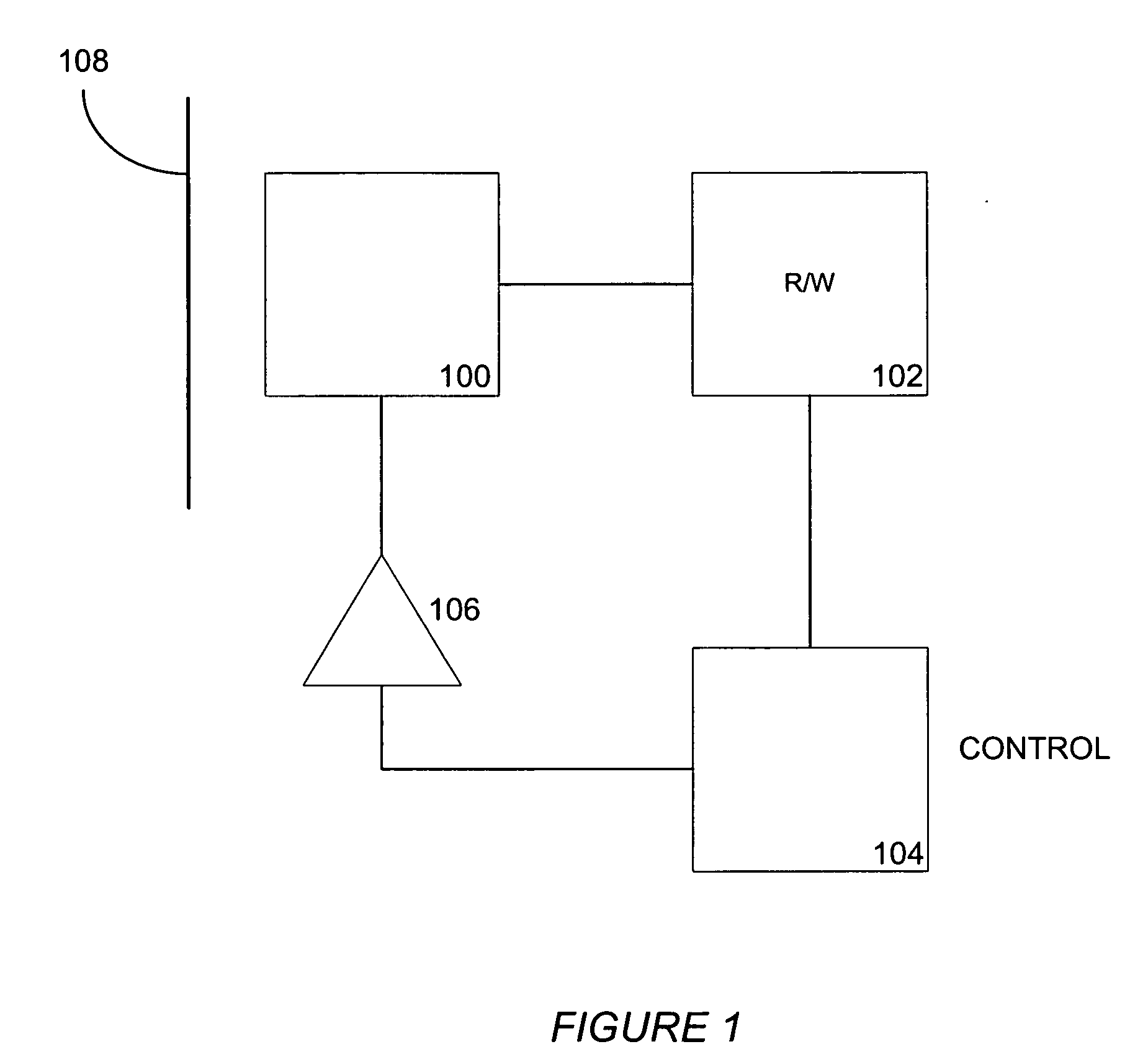

Integrated multiple channel data reliability testing for a magnetic tape drive

InactiveUS7573664B2Driving/moving recording headsFilamentary/web record carriersChannel dataComputer hardware

Data reliability testing for a magnetic tape drive is conducted separately for the channels of a magnetic tape drive which write and read tracks of a multiple track magnetic tape. Memory stores testing data representing data separately written to tracks of a multiple track magnetic tape; each of a plurality of read channels reads data sensed by a tape head from a separate track of a magnetic tape; and error processing logic detects differences between data from each of a plurality of the read channels, and stored testing data of the memory representing data written to the same separate tracks.

Owner:IBM CORP

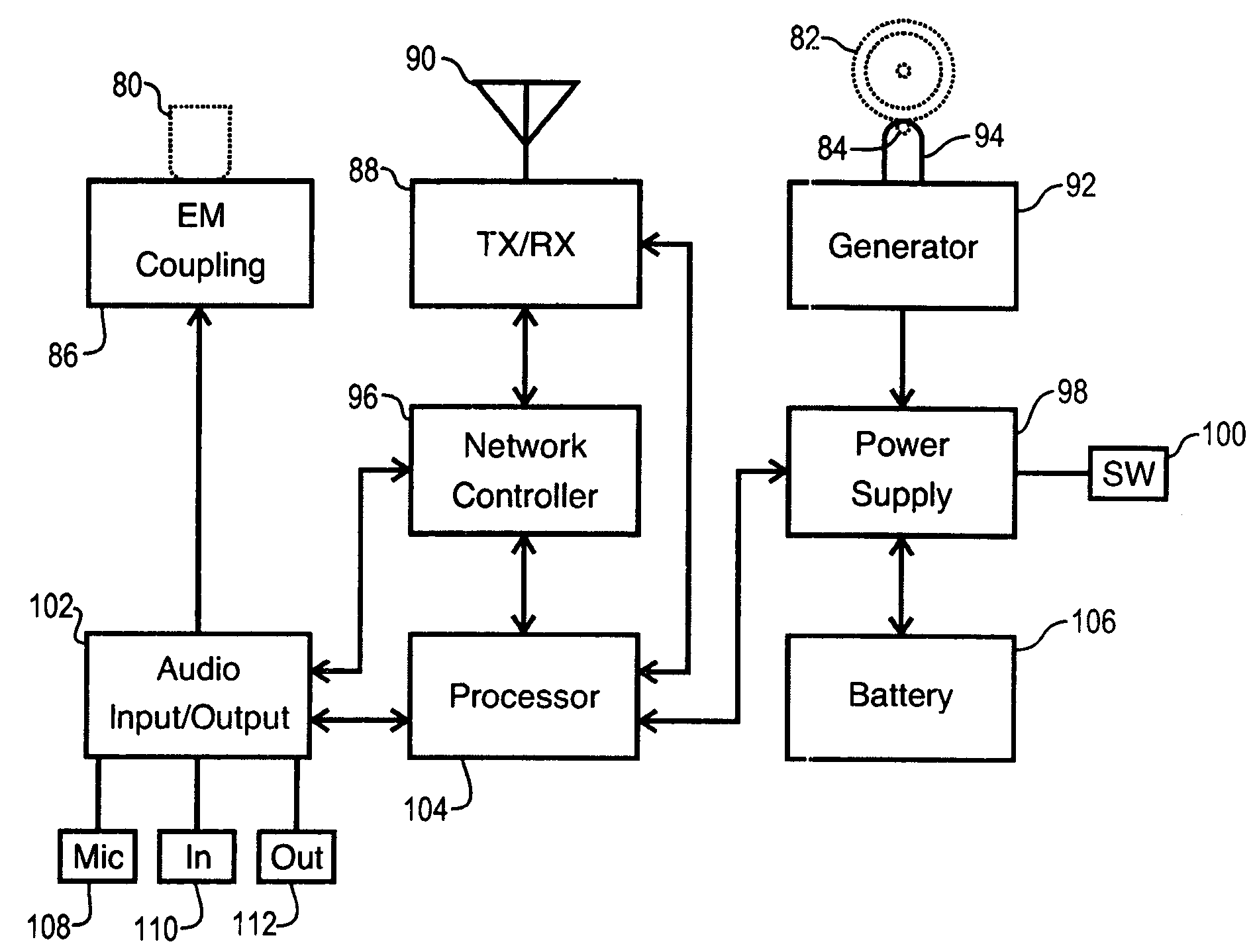

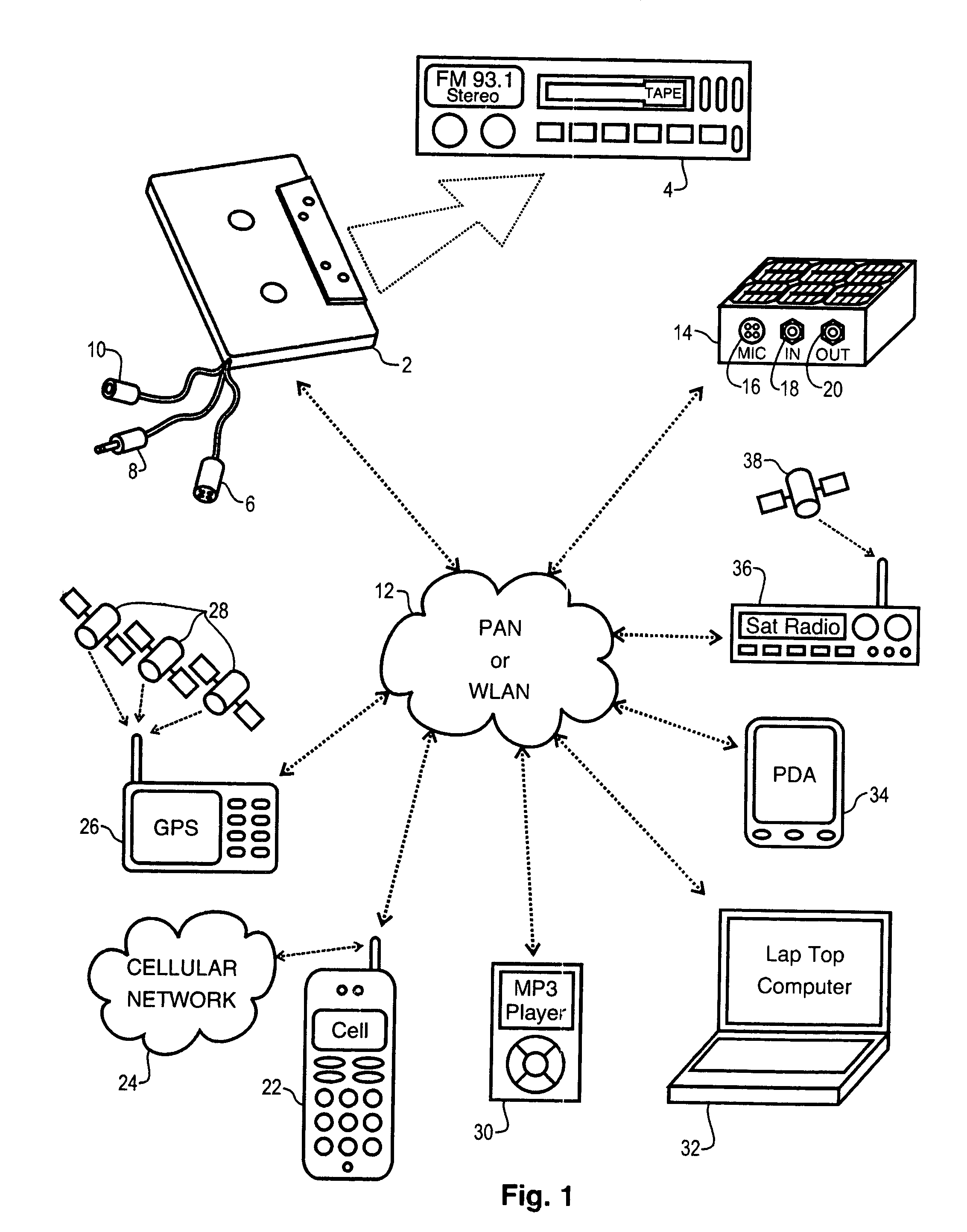

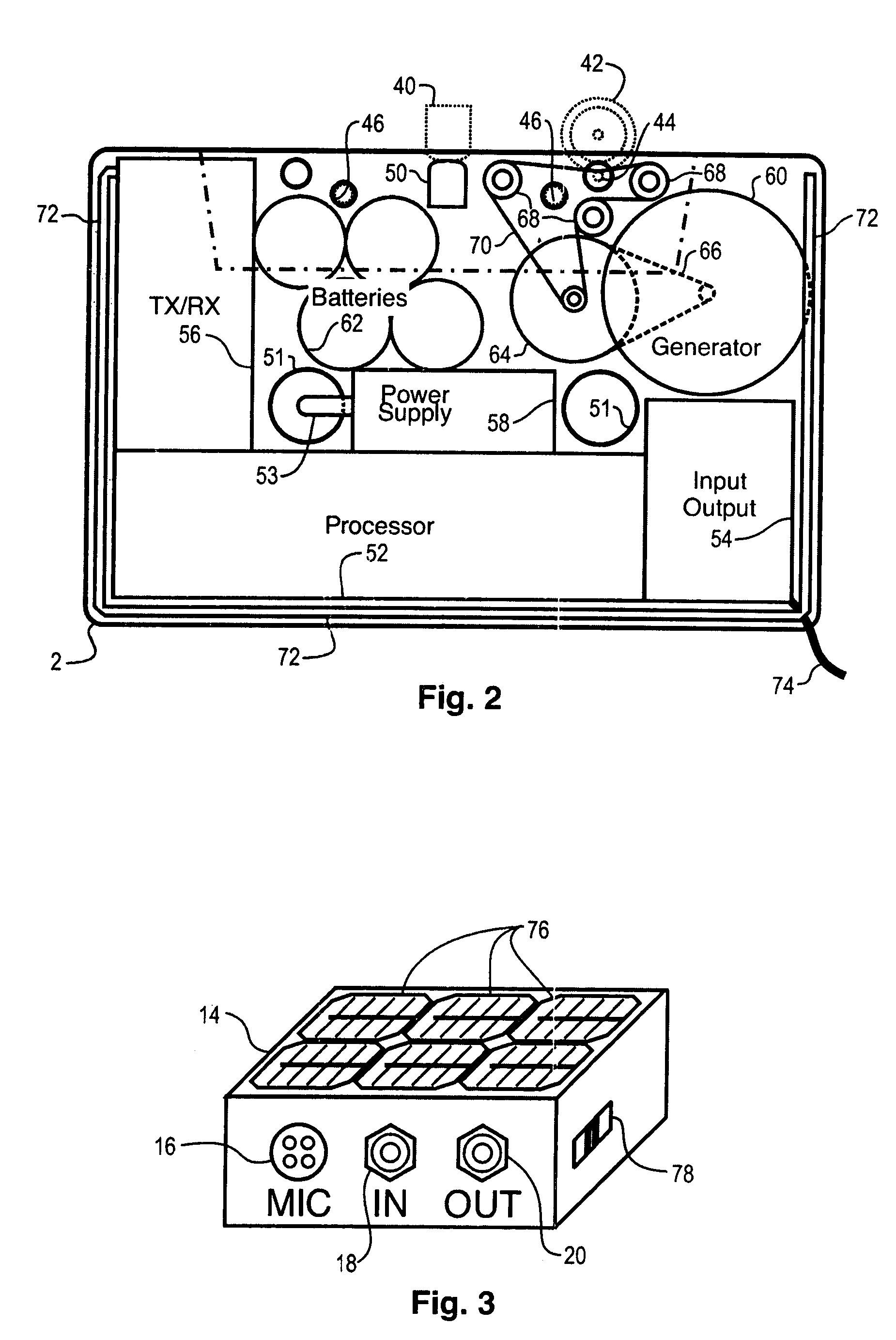

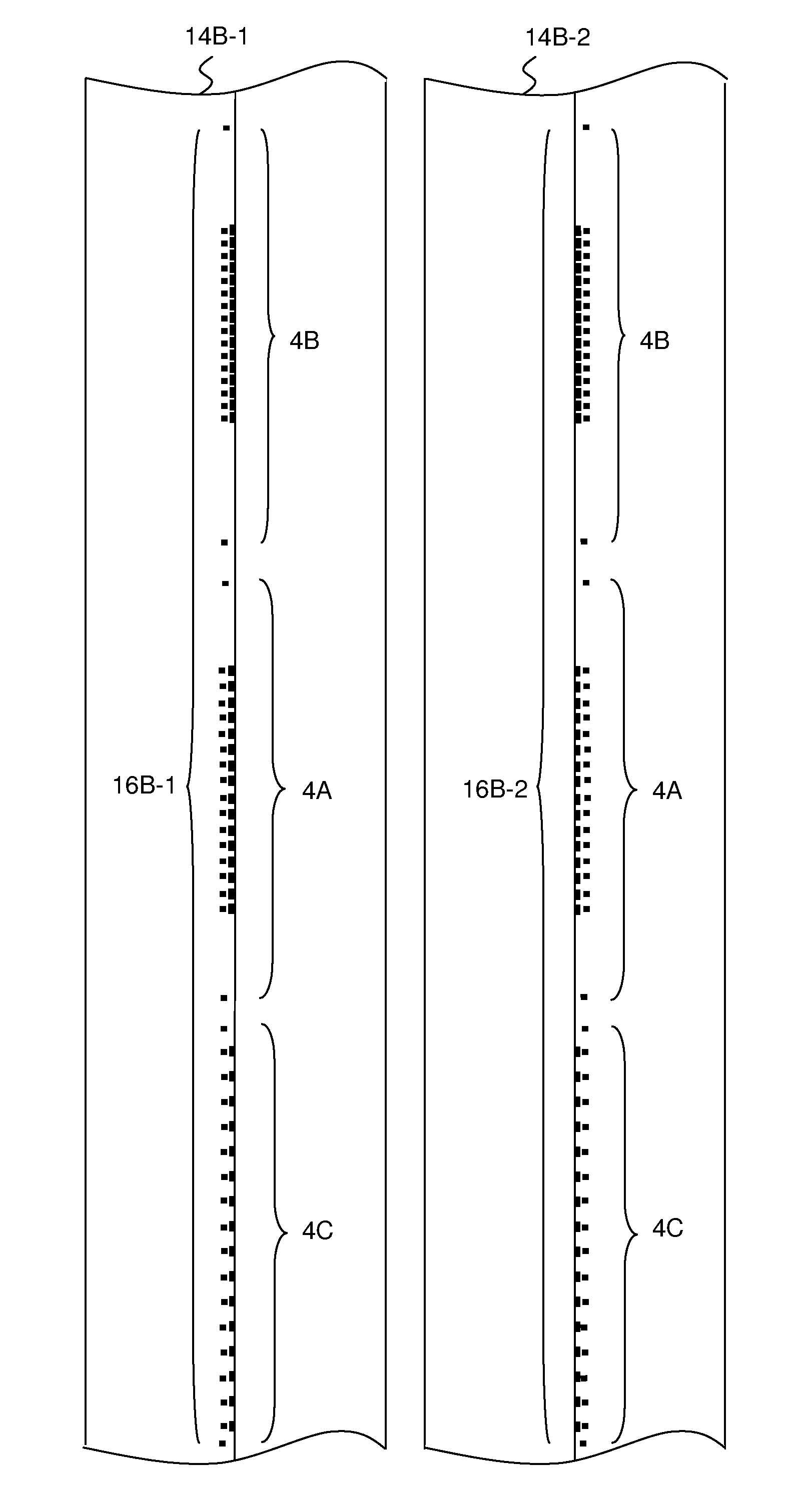

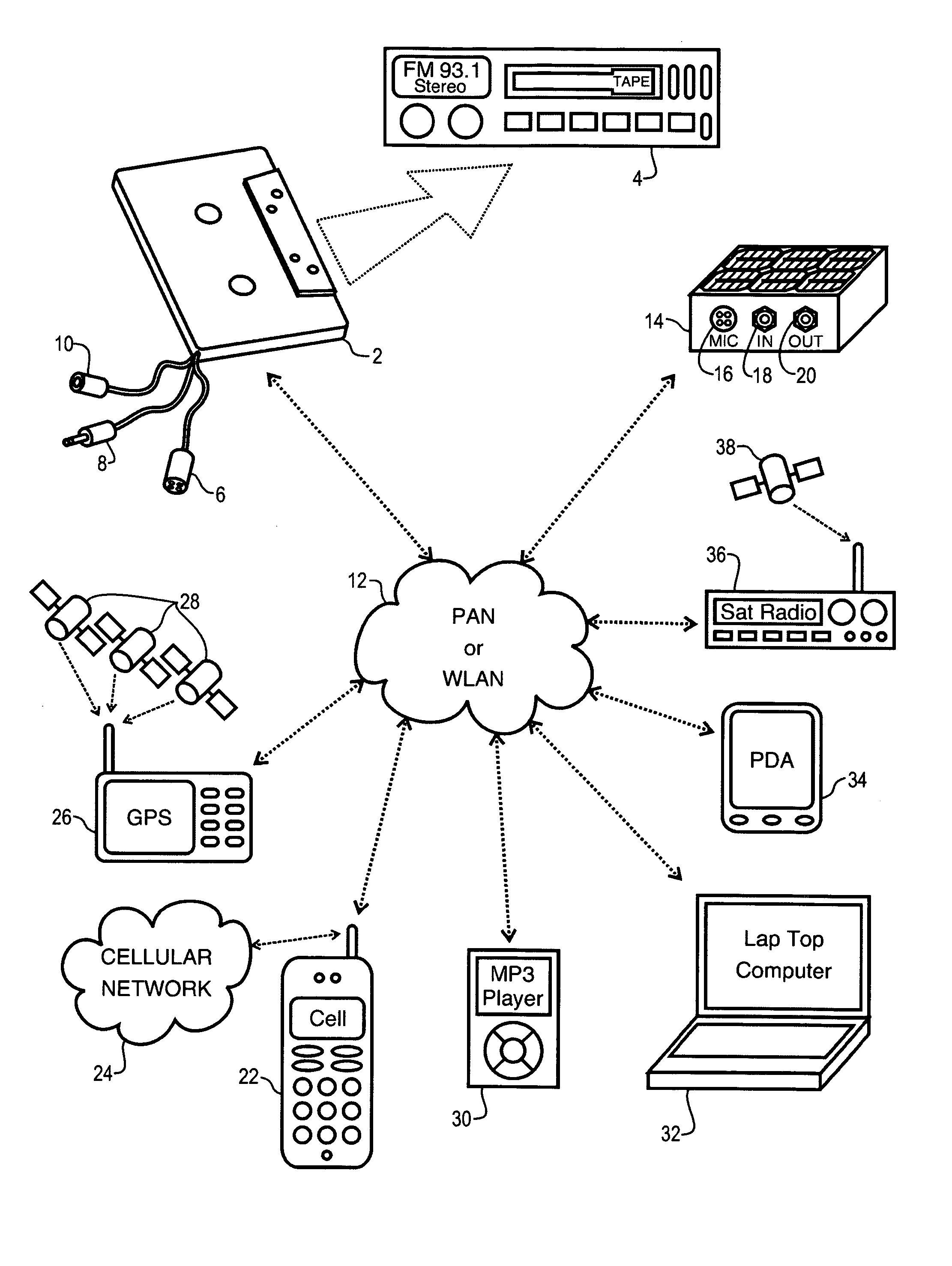

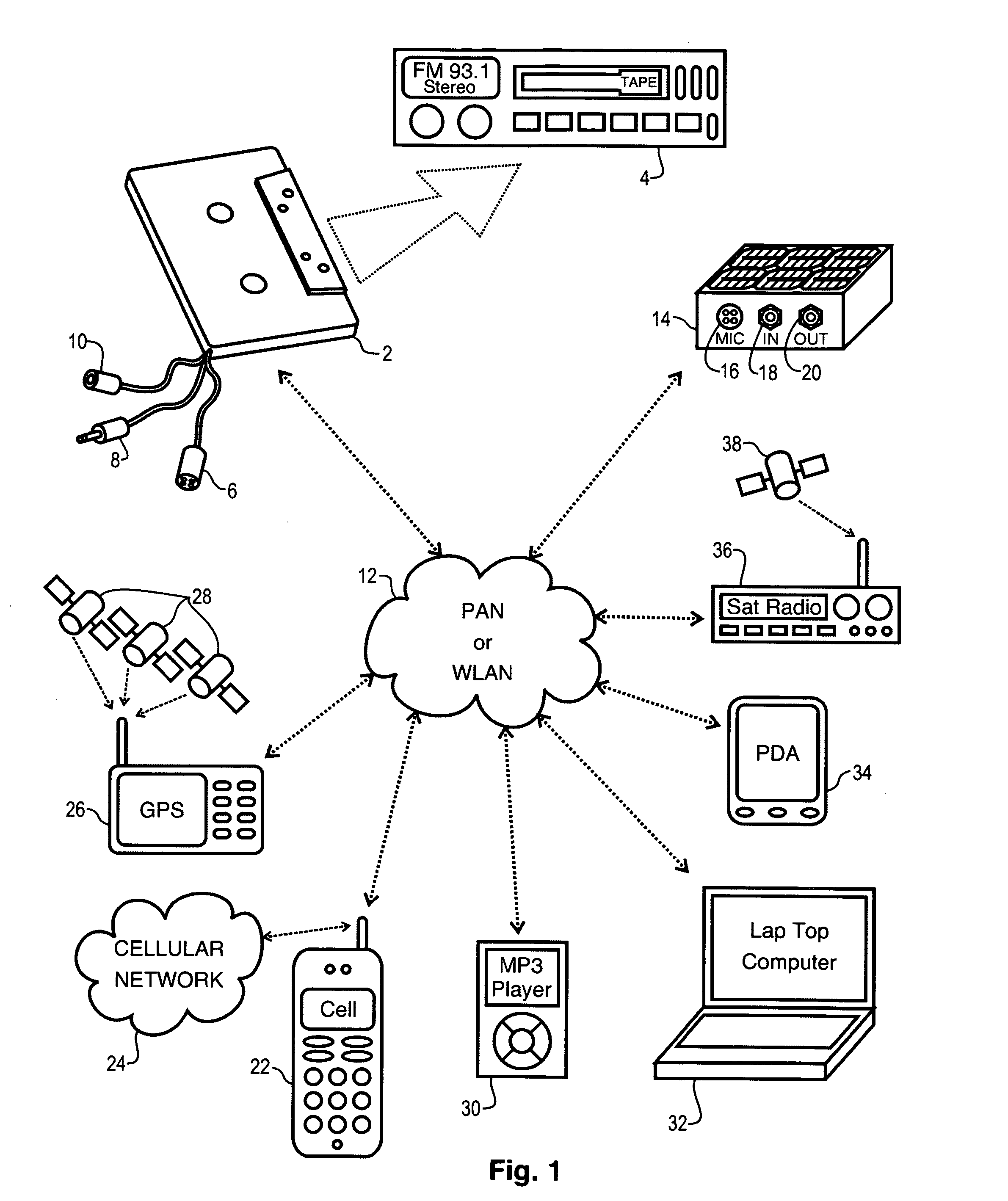

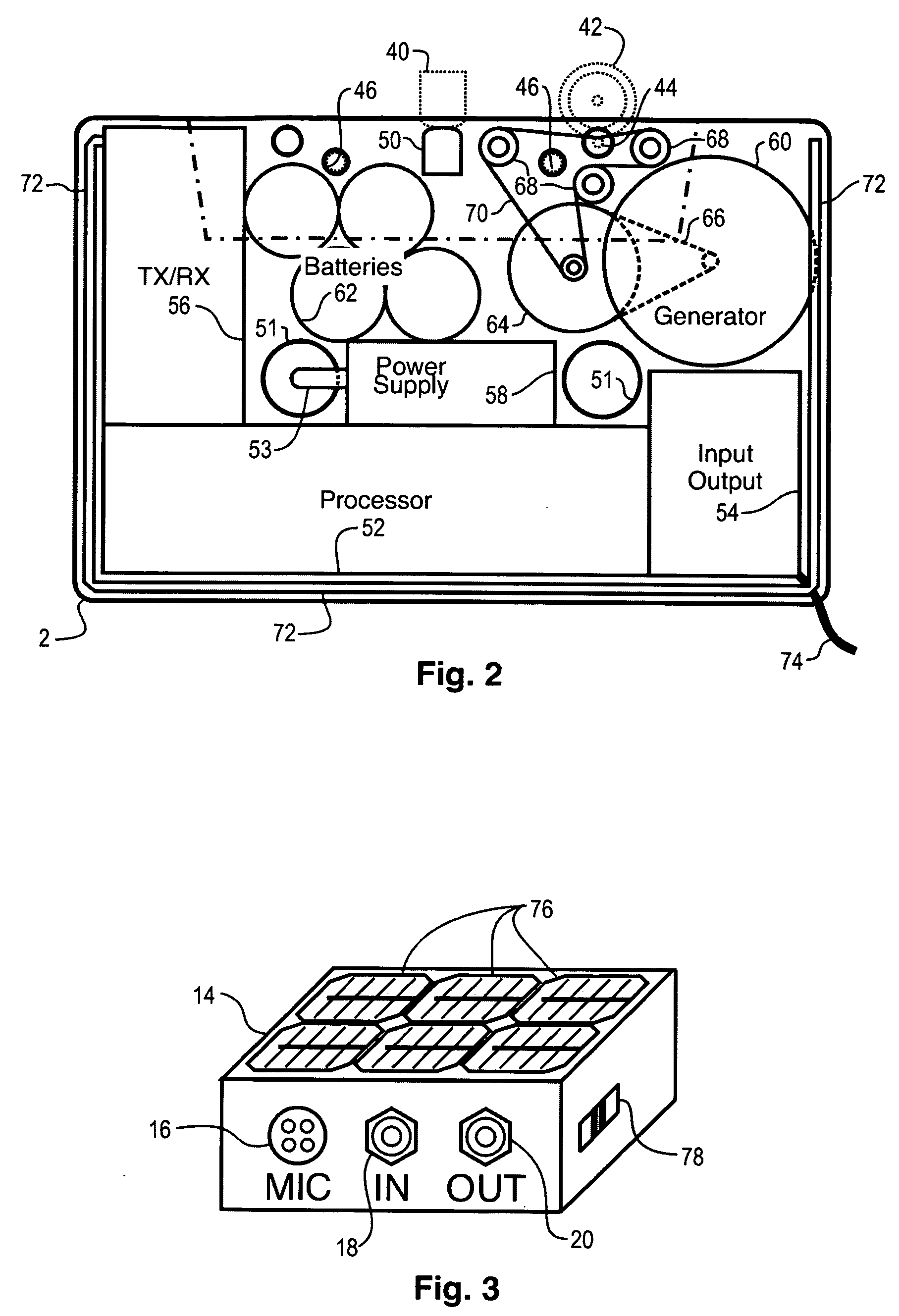

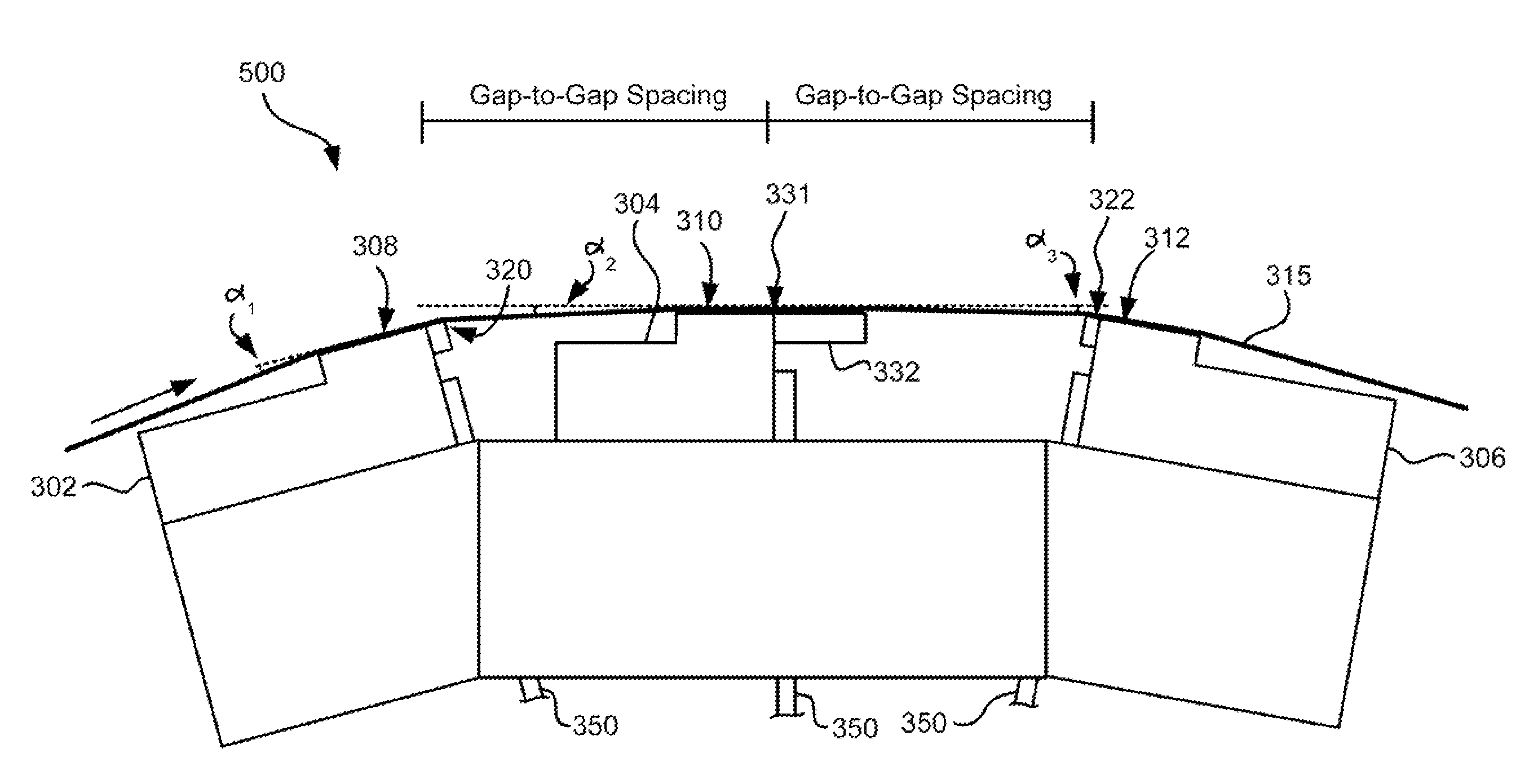

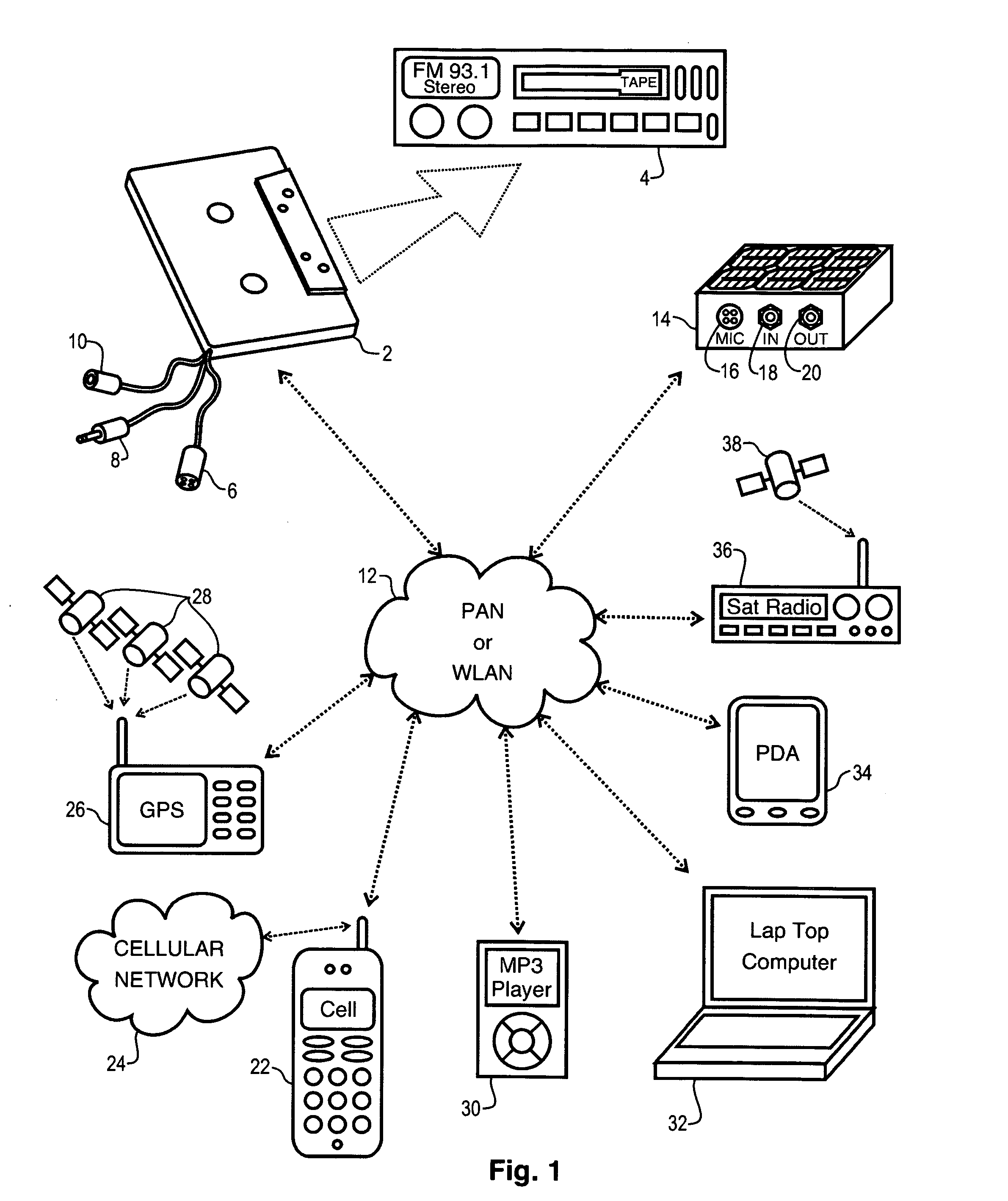

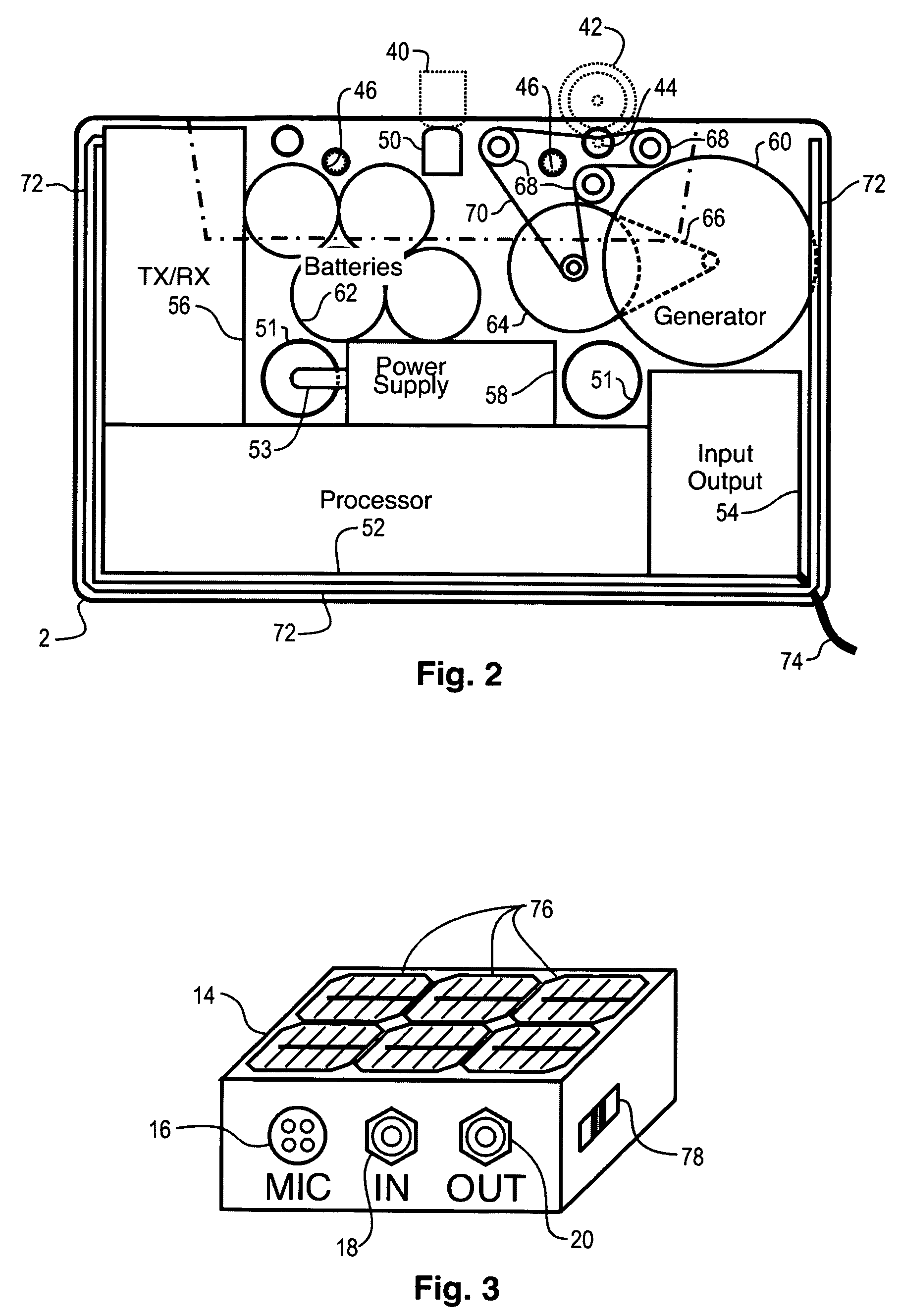

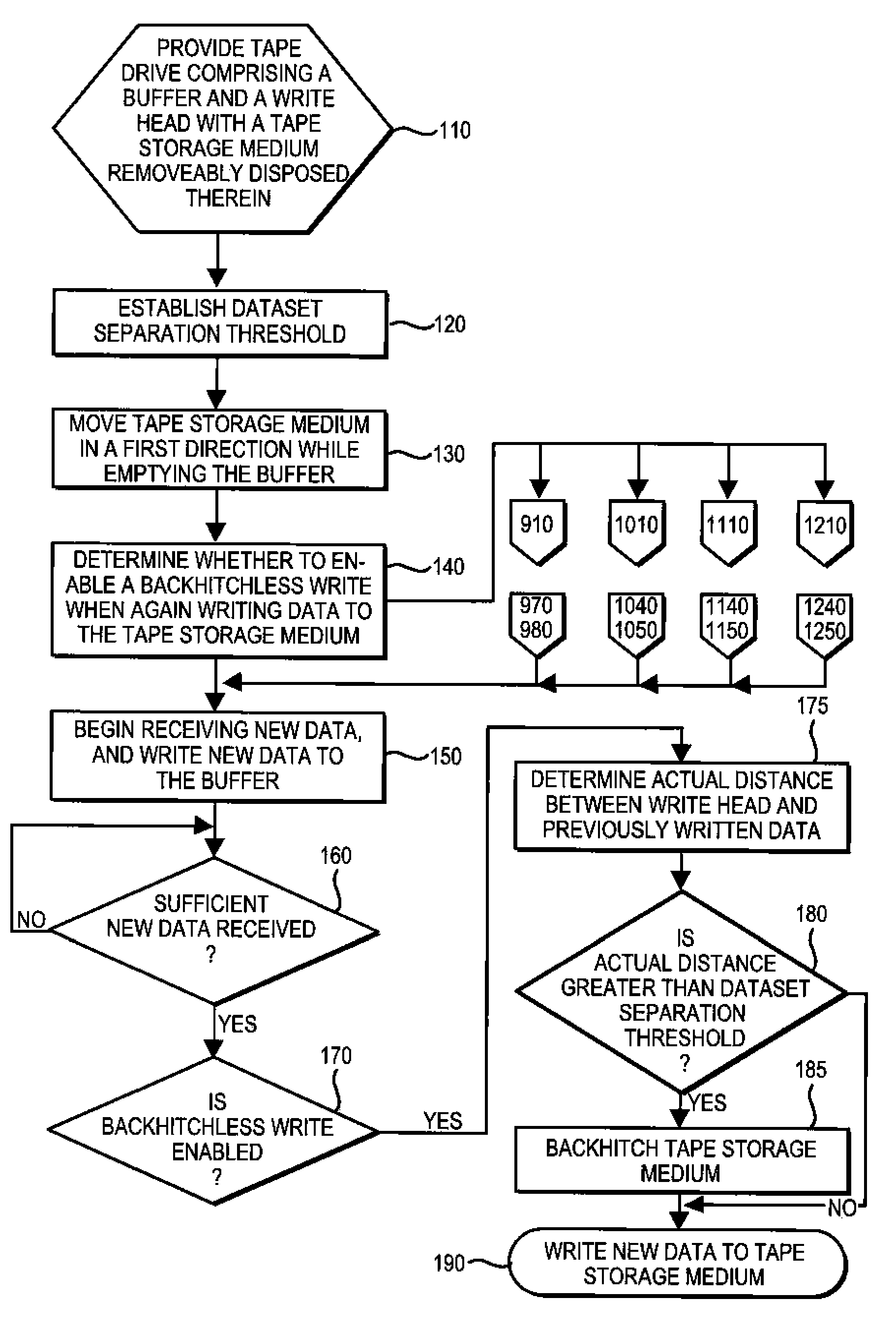

Network interface cassette adapter and method

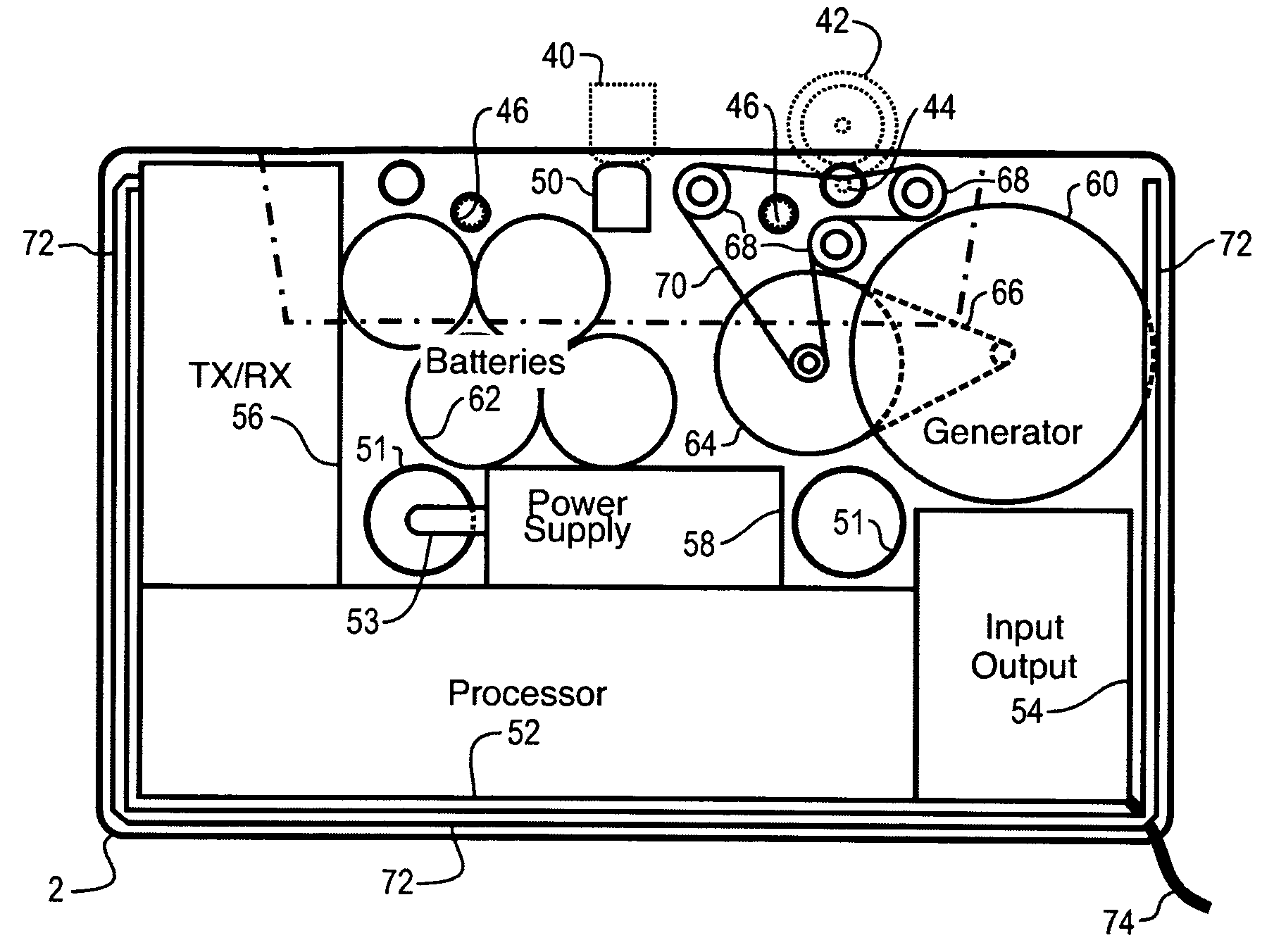

A network interface cassette for coupling signals between a wireless network and a tape head in a cassette tape player. The network interface cassette includes an enclosure that is conformed to the cassette tape form factor. It contains a transceiver that converts base band signals for radio frequency communications within the wireless network. It also contains a network controller that is coupled to communicate the base band signals with the transceiver. The network controller converts digital audio signals to and from the base band signals. There is an audio processor that converts the digital audio signals to analog audio signals. A coupling means converts the analog audio signals to magnetic audio signals. The coupling means is aligned to couple the magnetic audio signals to the tape head. A power supply with batteries and a generator driven from the cassette player capstan are provided. A wireless user interface adapter is provided to couple microphone and audio signals to the apparatus. Plural communications requests are processed, and include a priority scheme to manage resource contention.

Owner:THE SOURCE

High areal density tape head

InactiveUS7480117B2Shorten the trackFilamentary/web record carriersAlignment for track following on tapesAdhesive beltTransducer

A tape head designed for transducing data on a magnetic recording tape that is subject to tape dimensional changes. The tape head includes two or more arrays of transducer elements having different transducer spacing distances corresponding to different track spacing distances to be transduced. One of the transducer arrays may be used for transducing the tape under nominal tape track spacing conditions. Another transducer array may be used for transducing the tape when the tape track spacing is reduced due to the tape shrinkage. Still another transducer array may be used for transducing the tape when the tape track spacing is enlarged due to tape expansion.

Owner:INT BUSINESS MASCH CORP

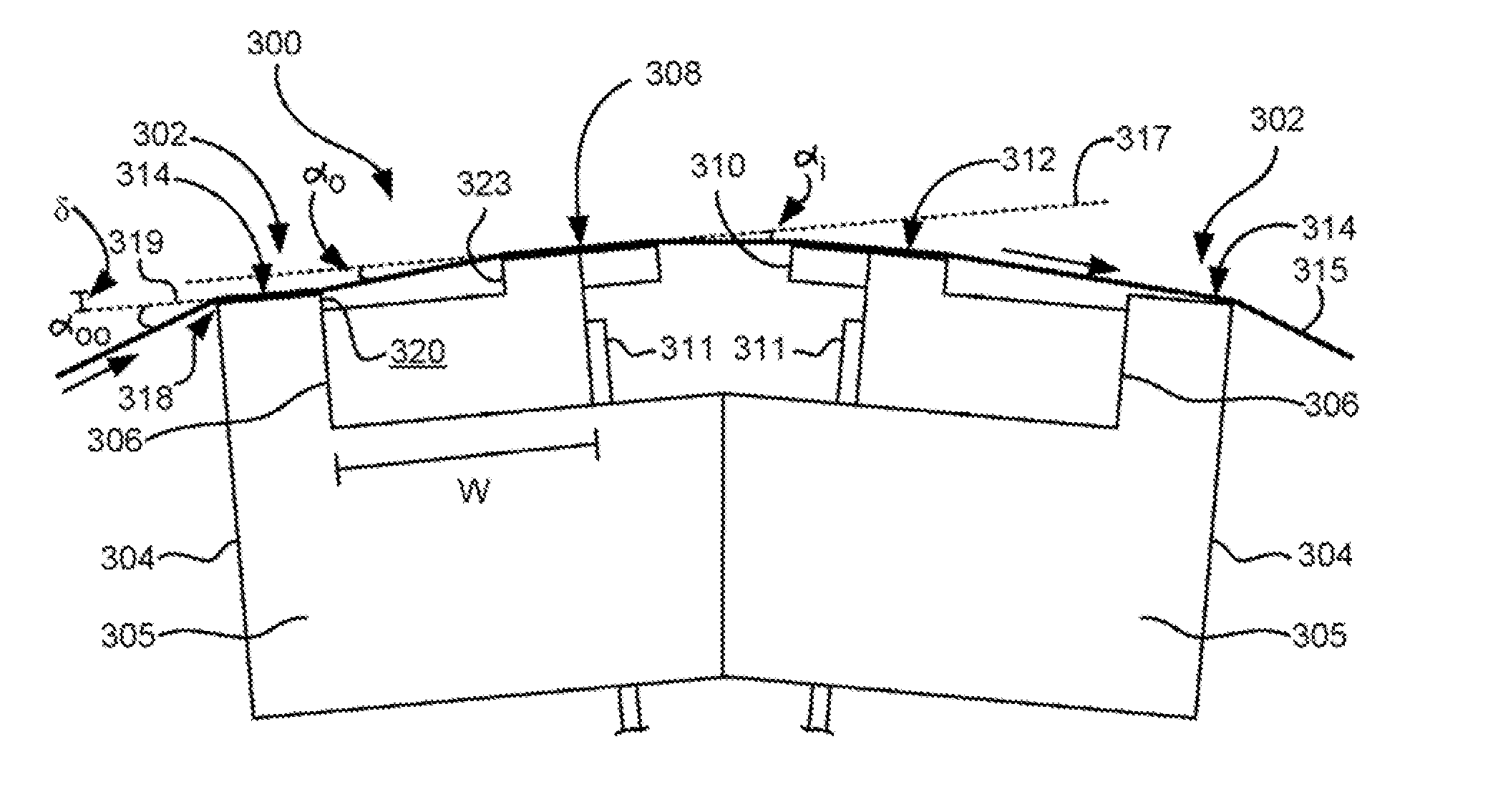

Tape head with thin support surface and method of manufacture

According to one aspect, an exemplary method of manufacturing a magnetic head assembly with a predetermined wrap angle is described. The method includes removing a portion of a magnetic head support surface to create a slot transverse to a direction the media advances and at least partially separating a major support surface having an active device region and a thin support surface. The method further includes removing a portion of the thin support surface such that the height of at least a portion of the thin support surface is reduced relative to the major support surface. The height may be reduced to achieve a predetermined wrap angle between the media and the major support surface of the head assembly.

Owner:QUANTUM CORP

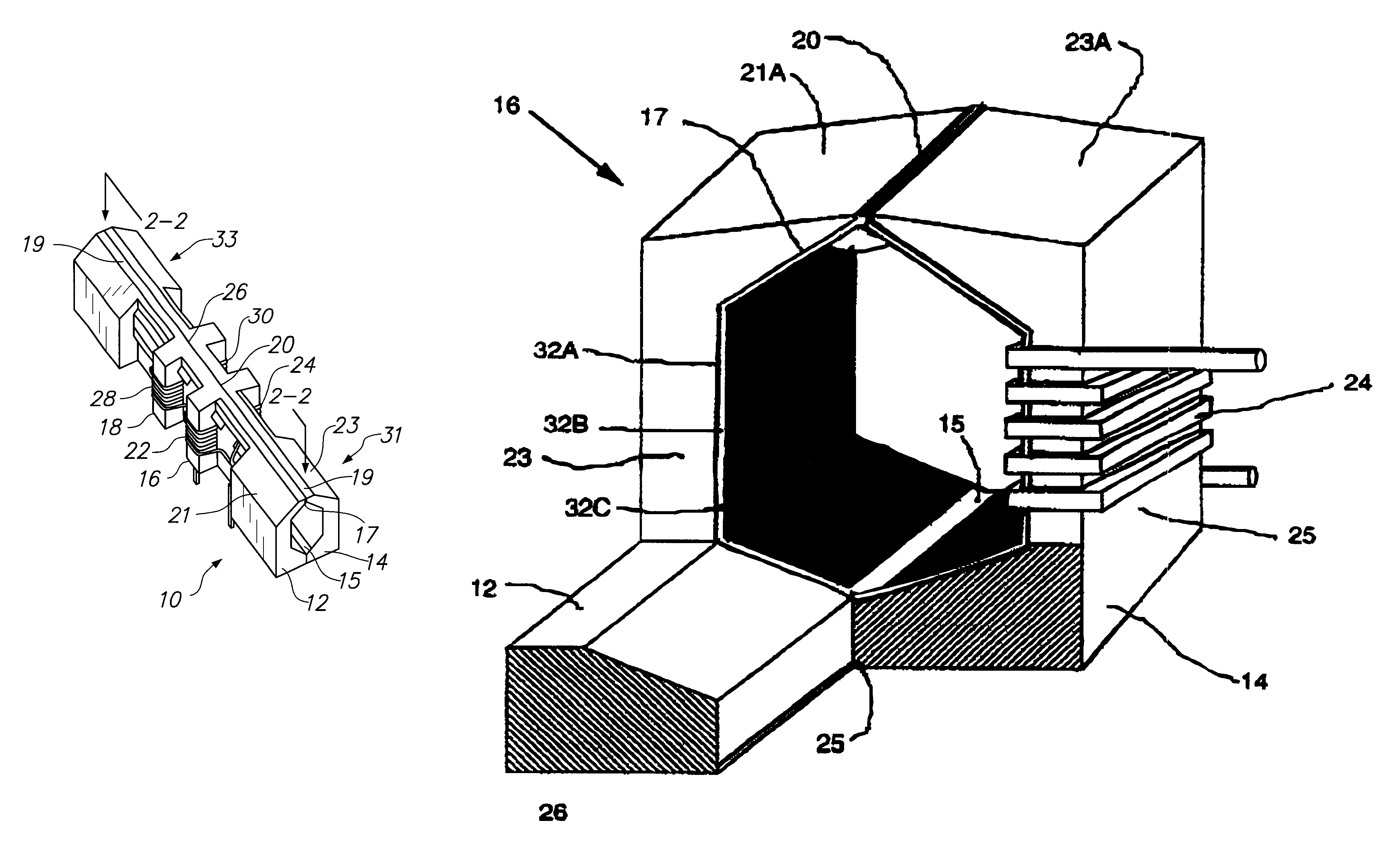

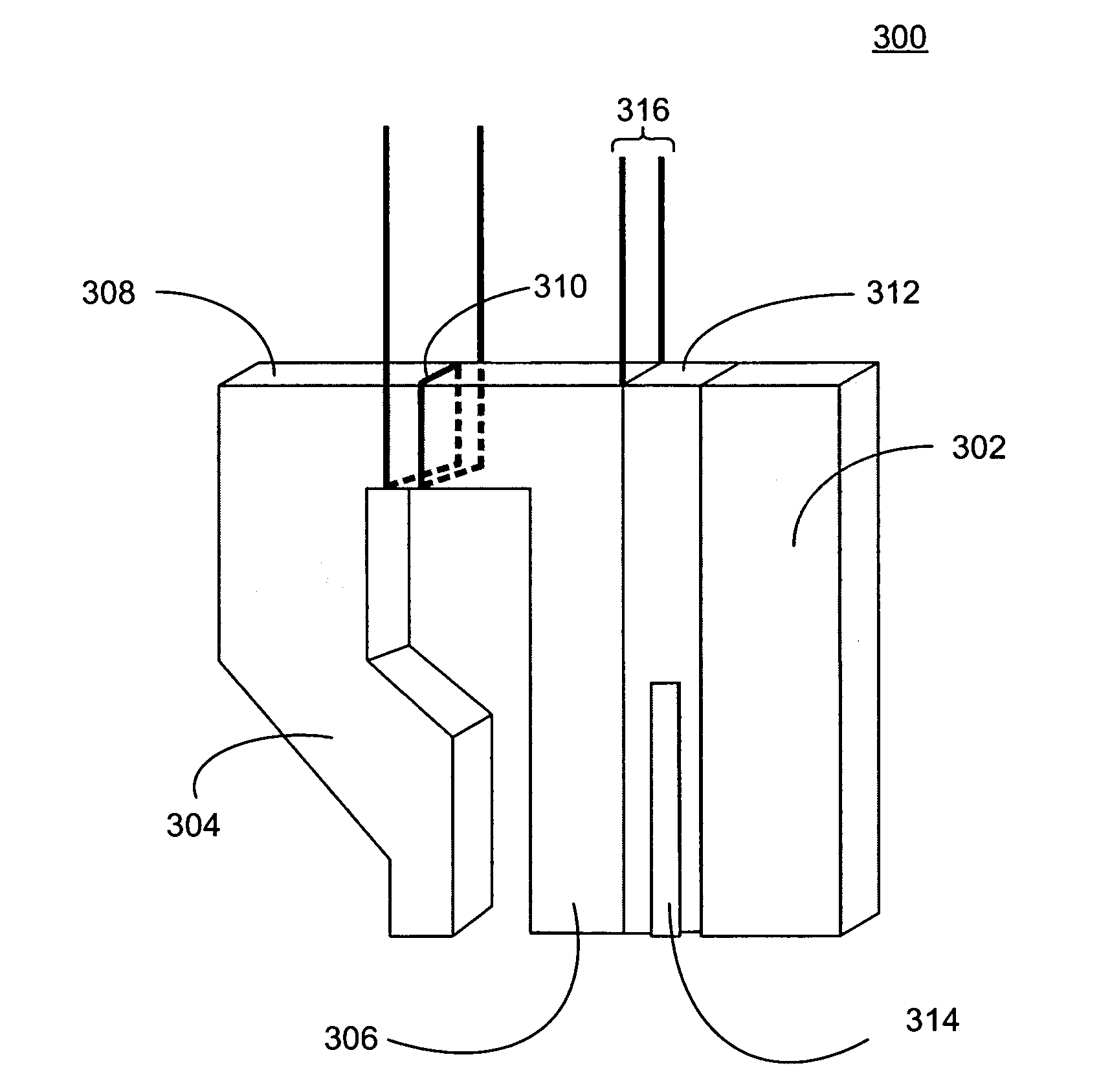

Self-aligned metal film core multi-channel recording head for tape drives

InactiveUS6288870B1Improve high frequency performanceManufacture head surfaceManufacturing heads with multiple gapsMagnetic transducersEngineering

A self-aligned multi-channel tape head structure has a non-magnetic ceramic substrate defining an interior longitudinal channel and a plurality of head regions. At least one head leg at each region defines lateral openings to the interior longitudinal channel. Each head region has a thin-film metal magnetic core deposited on an inside wall surface of the ceramic substrate and a magnetic gap in a longitudinal face of the ceramic substrate. A coil of wire is wound around each head leg to provide a magnetic transducer head at each head region.

Owner:QUANTUM CORP

Progressive track width head and method

InactiveUS20080088963A1Manufacture head surfaceManufacturing heads with multiple gapsEngineeringTape head

A tape head according to one embodiment includes an array of readers, each of the readers having a track width, wherein the track width of an inner reader of the array is greater than a track width of an outer reader relative thereto. A tape head according to another embodiment includes an array of readers, each of the readers having a track width, wherein the track width of at least some of the readers progressively decrease in a direction along the array from a middle of the array towards an end of the array.

Owner:IBM CORP

Tape head with outrigger

InactiveUS20080049358A1Manufacture head surfaceManufacturing heads with multiple gapsBearing surfaceTape head

A magnetic head assembly according to one embodiment of the present invention includes a substrate having a tape bearing surface. A plurality of elements are coupled to the substrate and positioned towards the tape bearing surface. The elements selected from a group consisting of readers, writers, and combinations thereof. A base is coupled to the substrate. The base has an outrigger formed integrally therewith. The outrigger causes a tape passing thereacross to approach the substrate at a first wrap angle relative to a plane of the tape bearing surface of the substrate.

Owner:IBM CORP

Low friction tape head and system implementing same

InactiveUS20120300338A1Manufacture head surfaceDriving/moving recording headsMagnetic mediaTransducer

A magnetic head according to one embodiment includes outer modules each having a tape bearing surface and an array of transducers selected from a group consisting of readers and writers; and an inner module positioned between the outer modules, the inner module having a tape bearing surface and an array of transducers selected from a group consisting of readers and writers, wherein portions of edges of the tape bearing surface of the inner module are non-skiving in regions not aligned with the array of transducers in a direction of media travel thereacross, wherein an outer edge of the tape bearing surface of each of the outer modules are adapted for skiving air from the magnetic medium when the magnetic medium travels in a direction from the respective outer module towards the inner module.

Owner:IBM CORP

Tape head having a support plate with contoured surface

ActiveUS20060232884A1Disposition/mounting of recording headsManufacturing heads with multiple gapsEngineeringActuator

Owner:META PLATFORMS INC

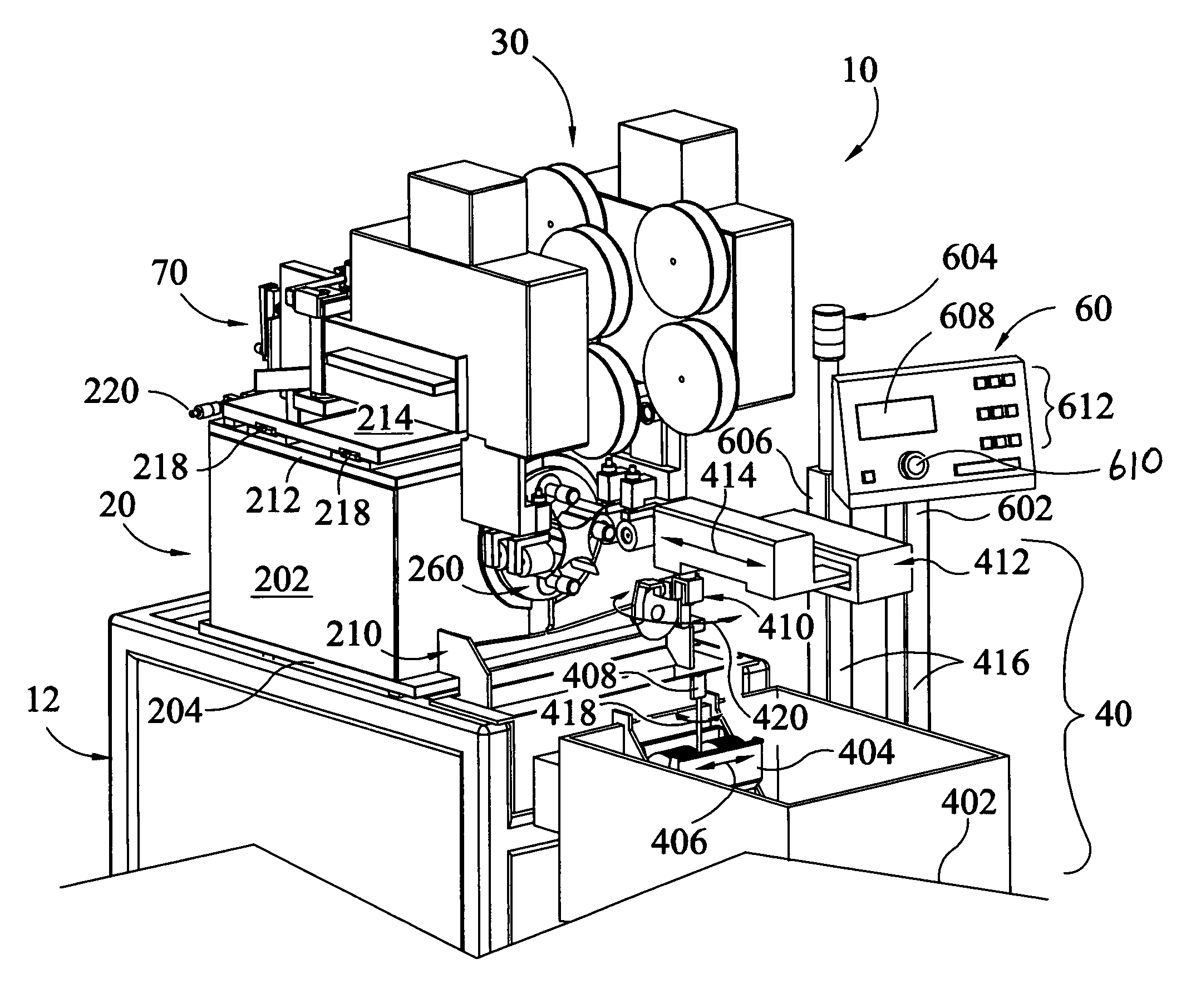

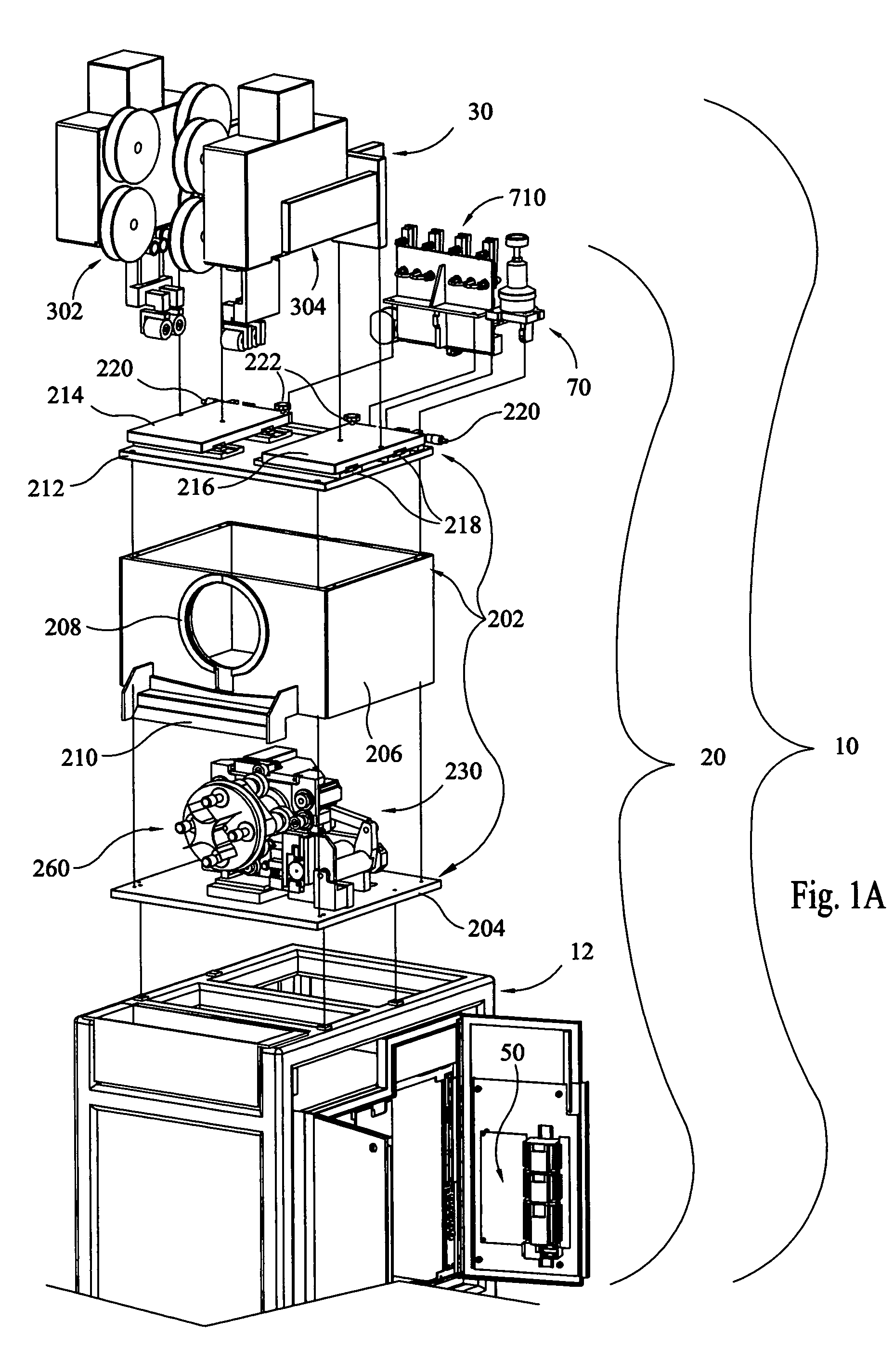

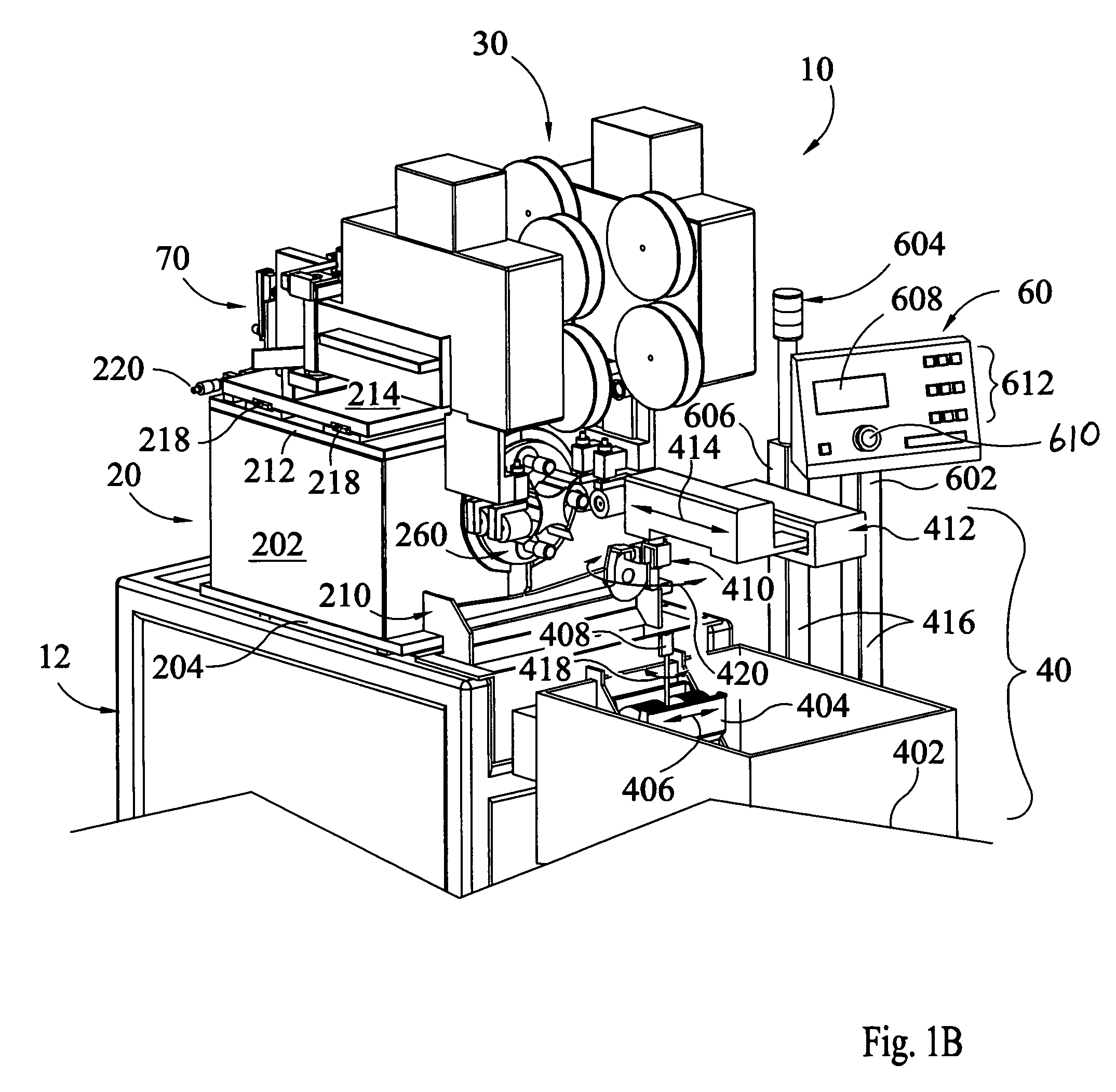

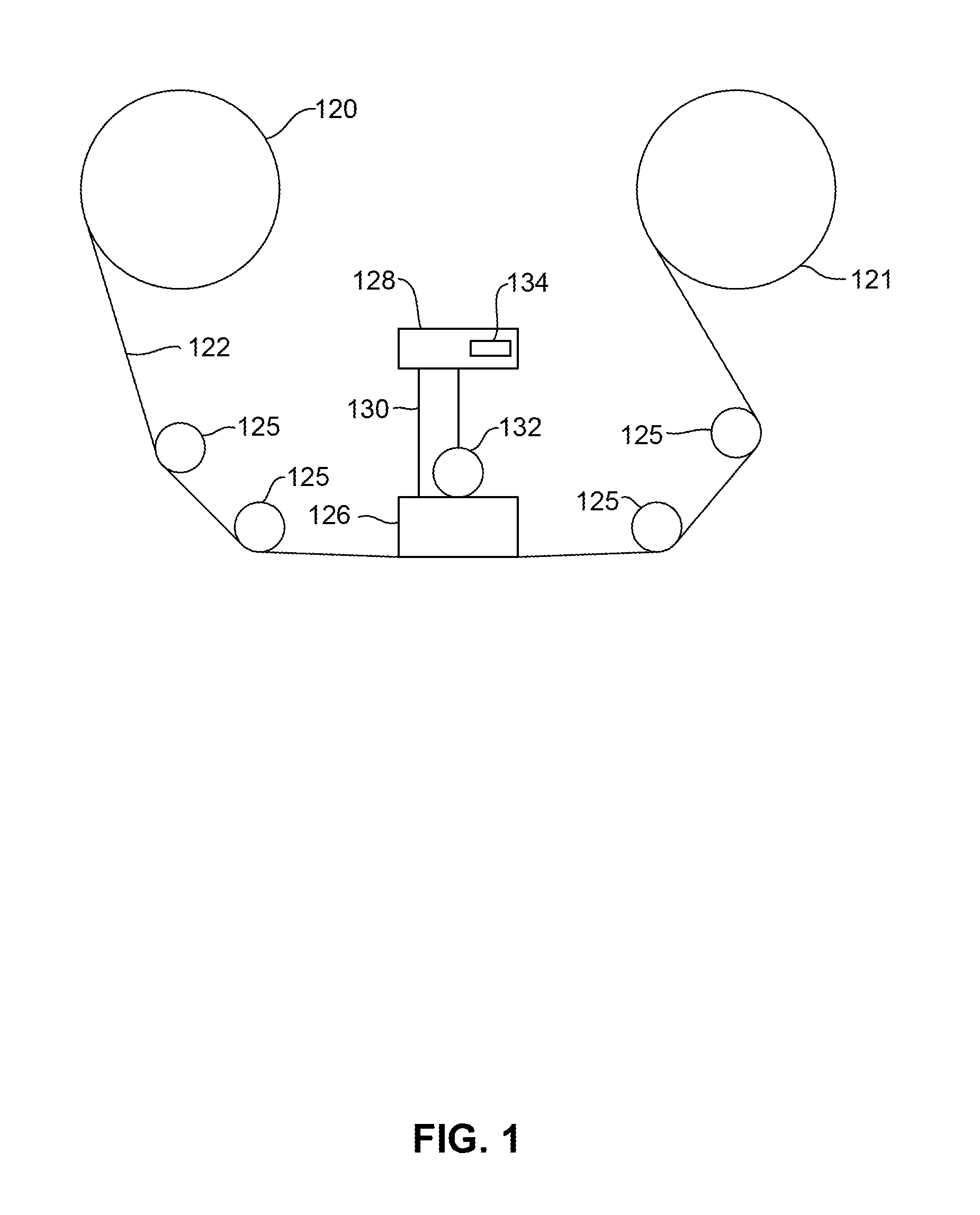

Multi-station disk finishing apparatus and method

InactiveUS20060135042A1Easy to adaptQuality improvementConveyorsGrinding drivesMagnetic memoryEngineering

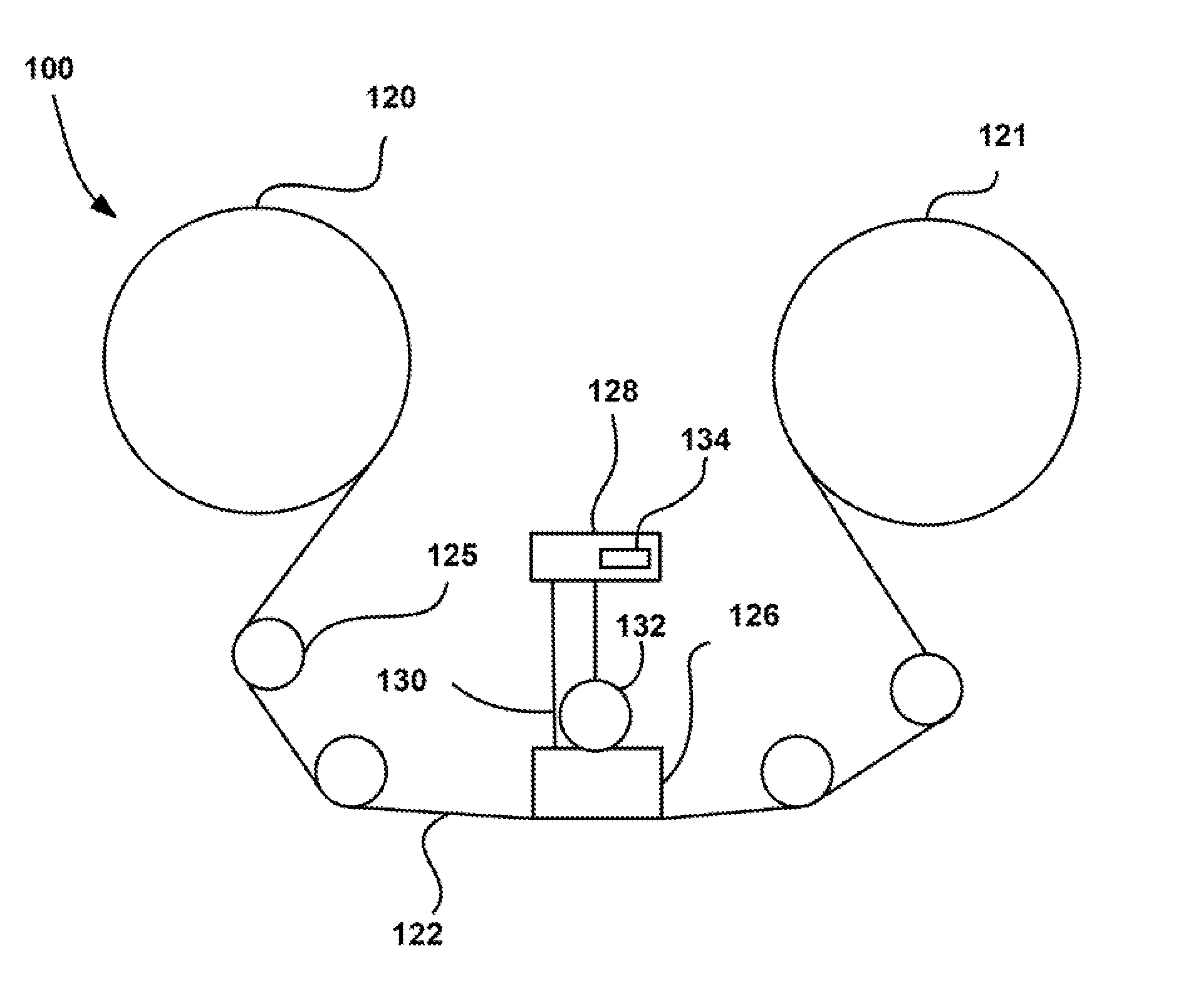

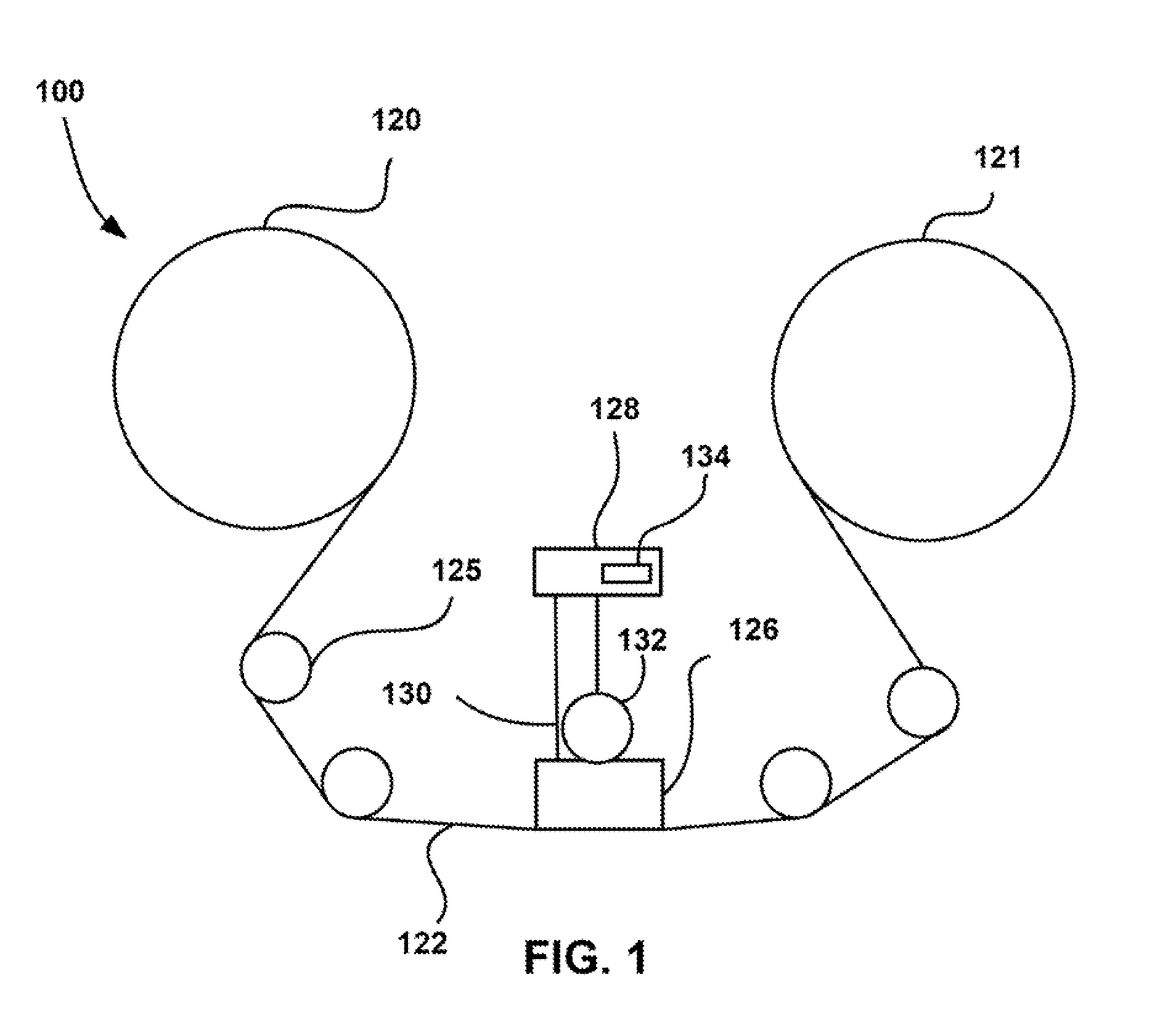

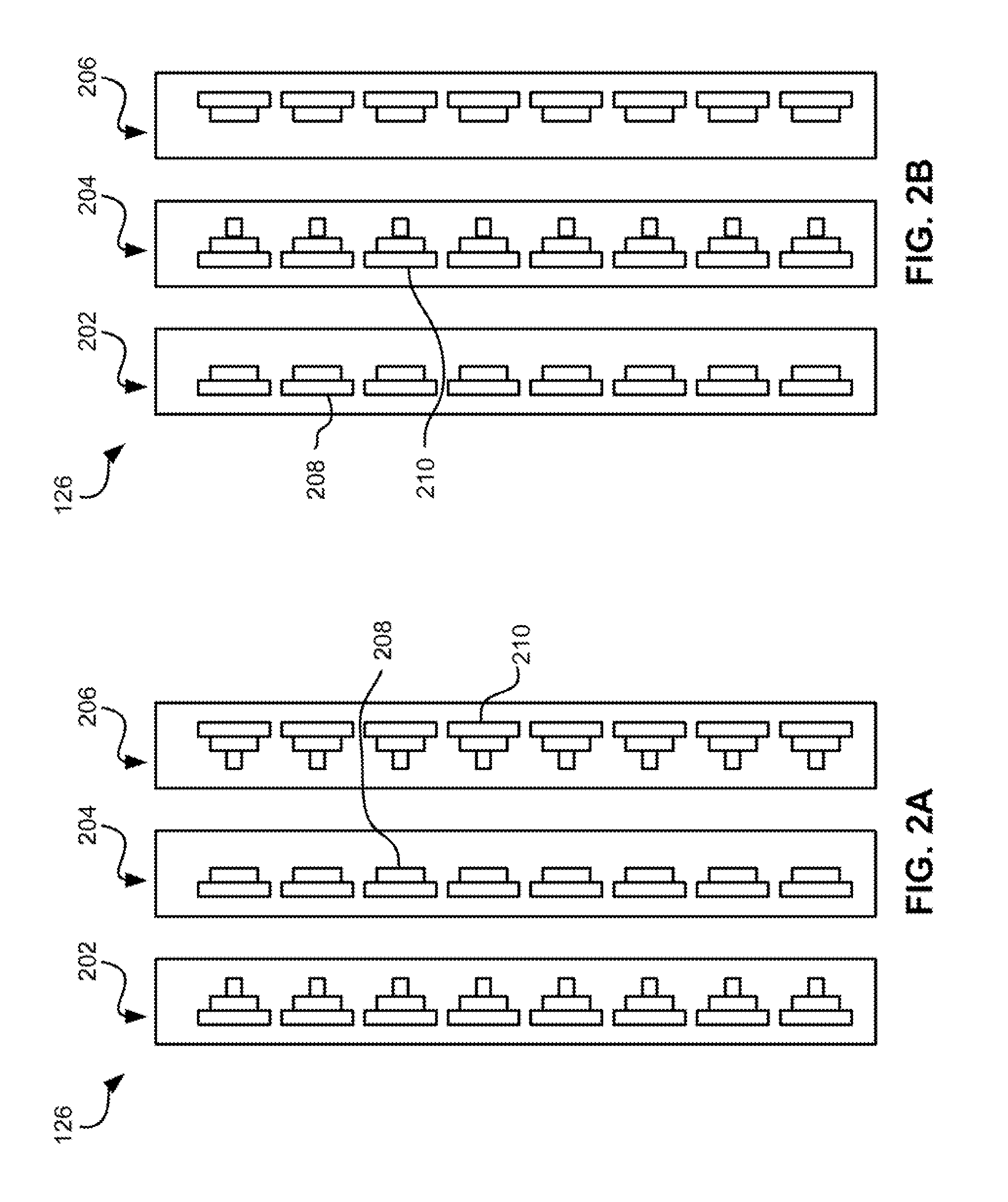

Multi-disk processing system and method of continuous finishing of memory media disks for digital data storage systems in preparation for magnetic memory coating, comprising four main sub-systems: 1) multiple driven spindles mounted on a chassis, at 3, 6, 9 and 12 o'clock positions; 2) finishing tape head units mounted on a base; 3) a robotic handler for loading and unloading disks onto / off at least one of the spindles; and 4) a programmable system controller that controls the sub-system operations and loading / unloading. The tape head sub-system includes its own programmable controller and sensors for control of the finishing tape advance. The multiple spindles and handler rotate relative to each other. In a preferred embodiment, the spindles are mounted on a rotating turntable that also oscillates. Alternately, the spindles are fixed in position and a rotating handler with multiple grippers for simultaneously loading / unloading disks from all spindles at once is used.

Owner:XYRATEX TECH LTD

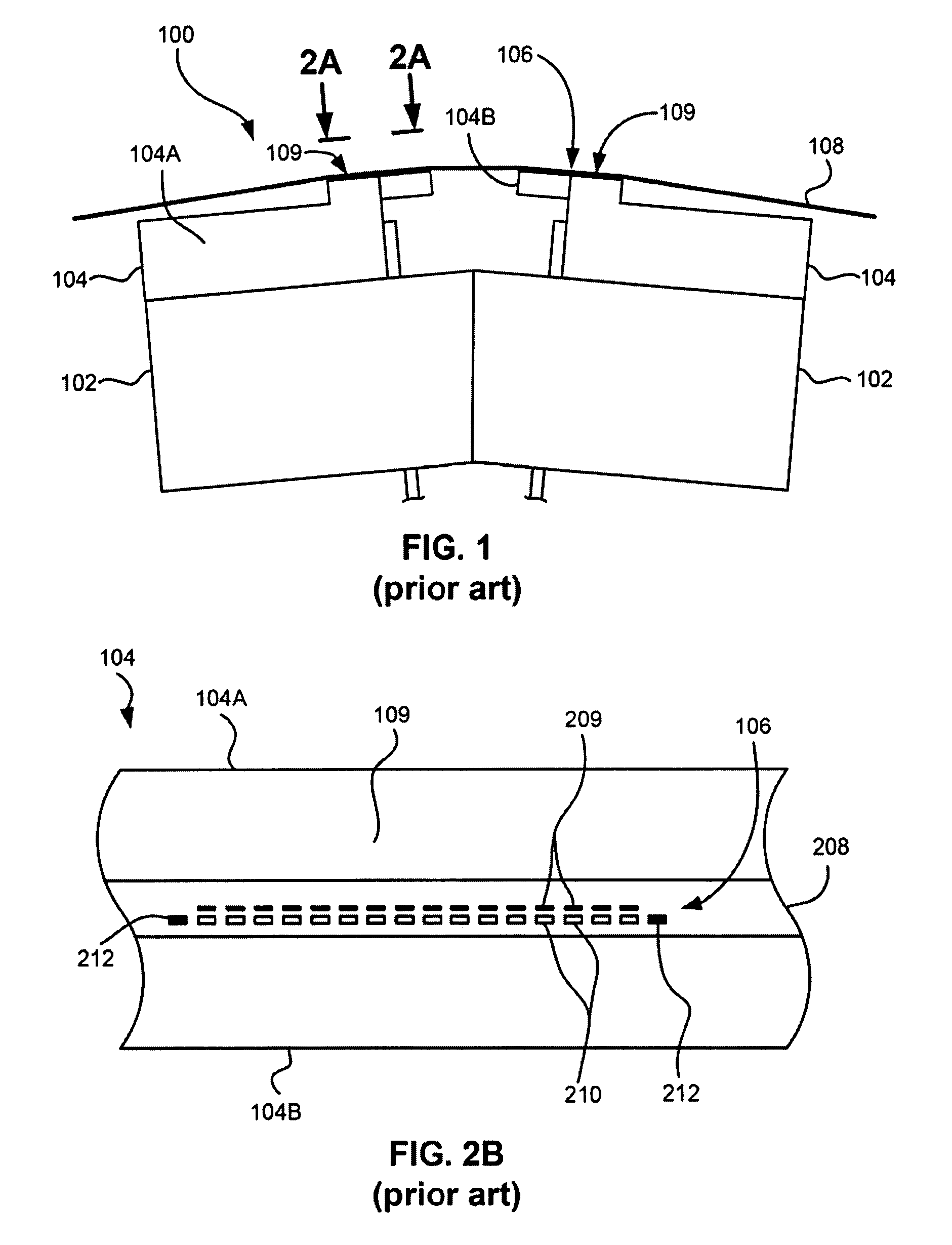

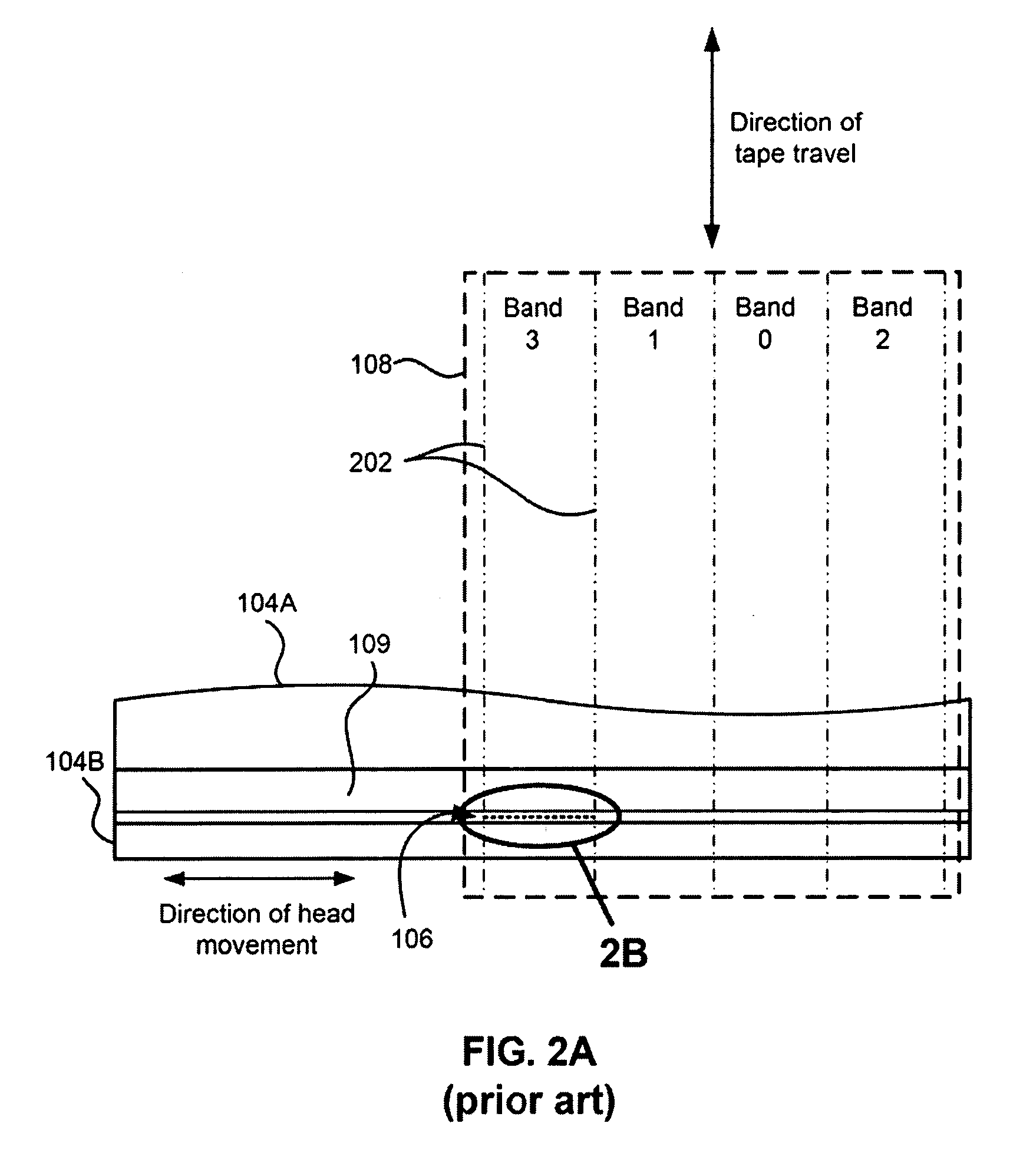

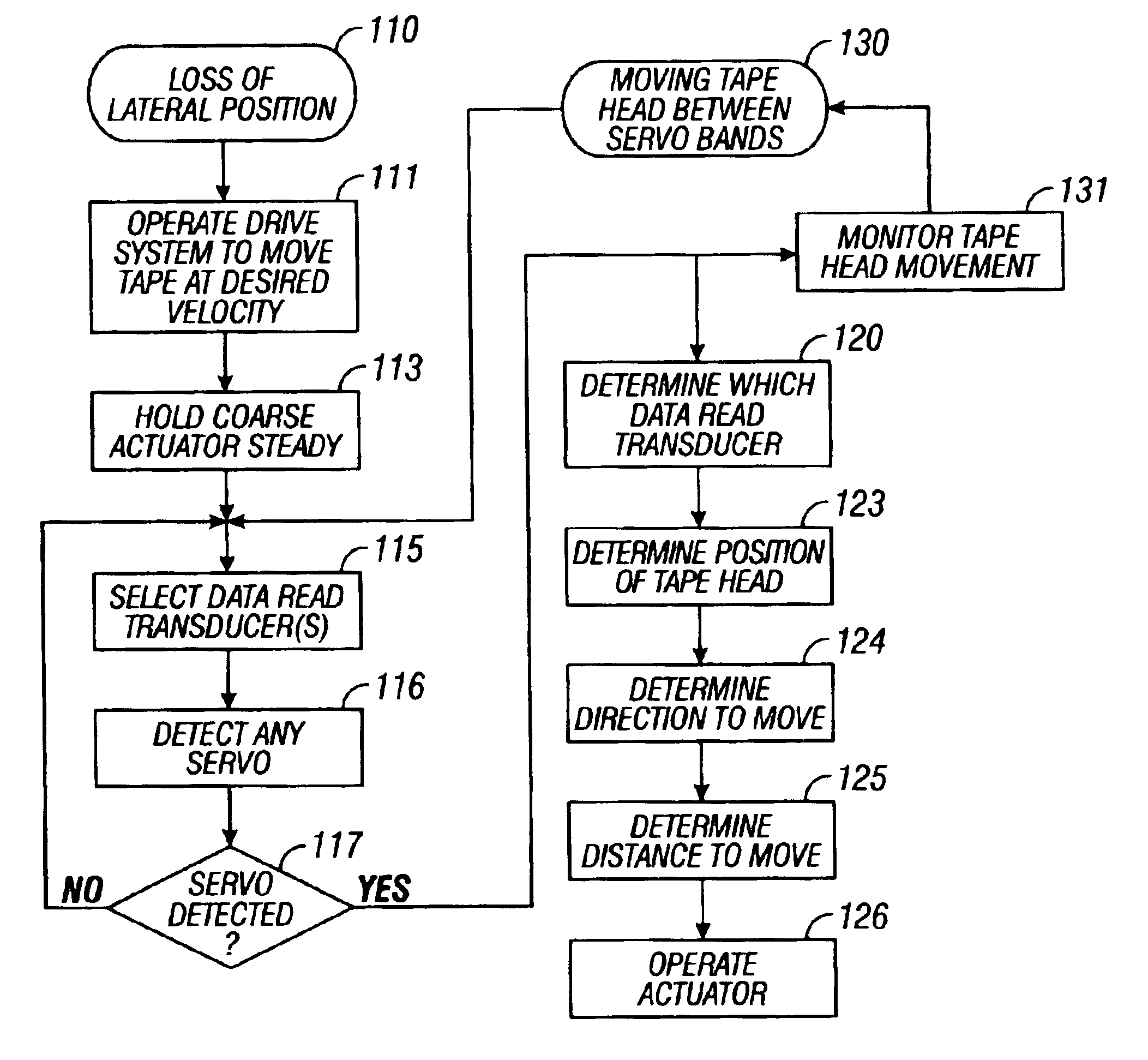

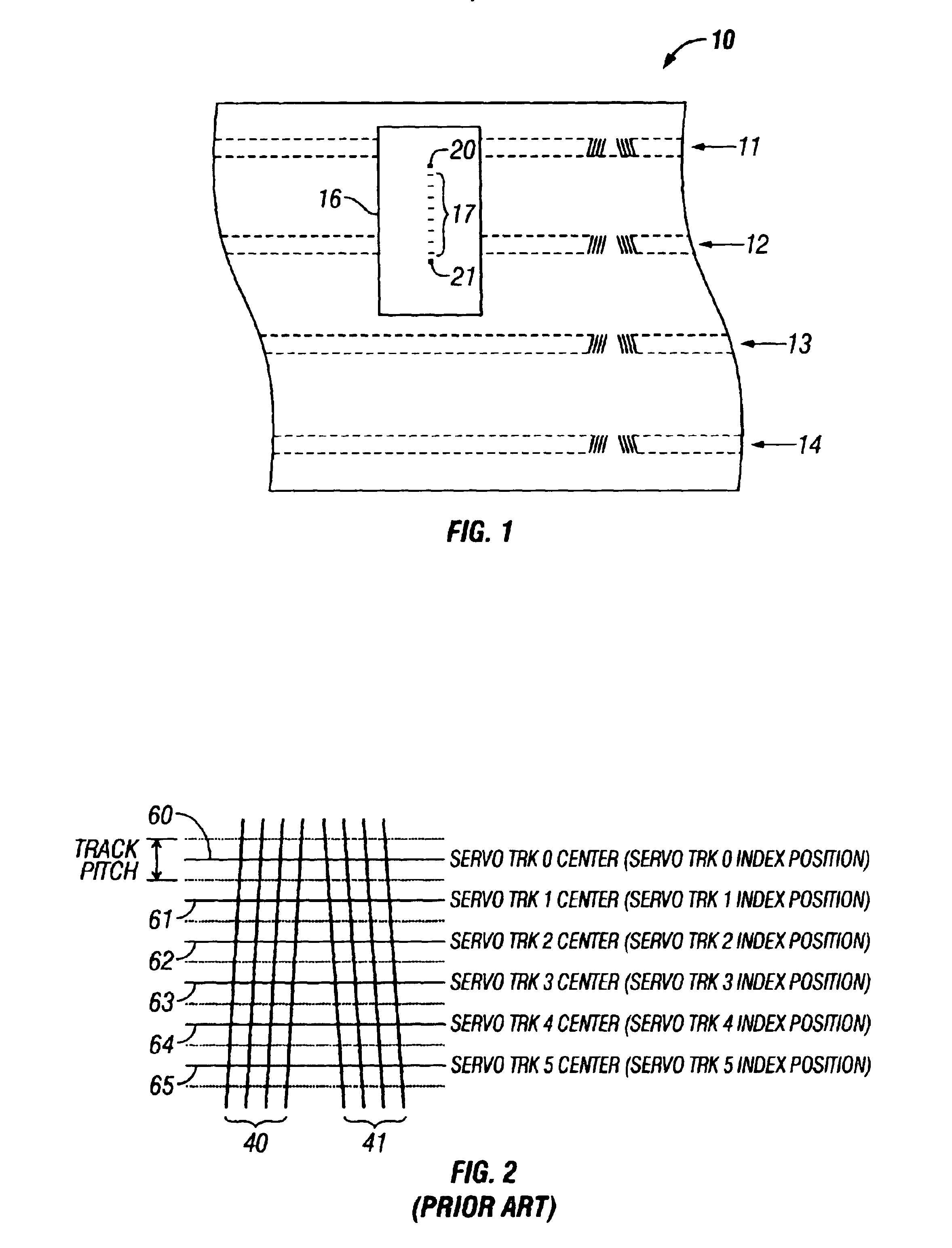

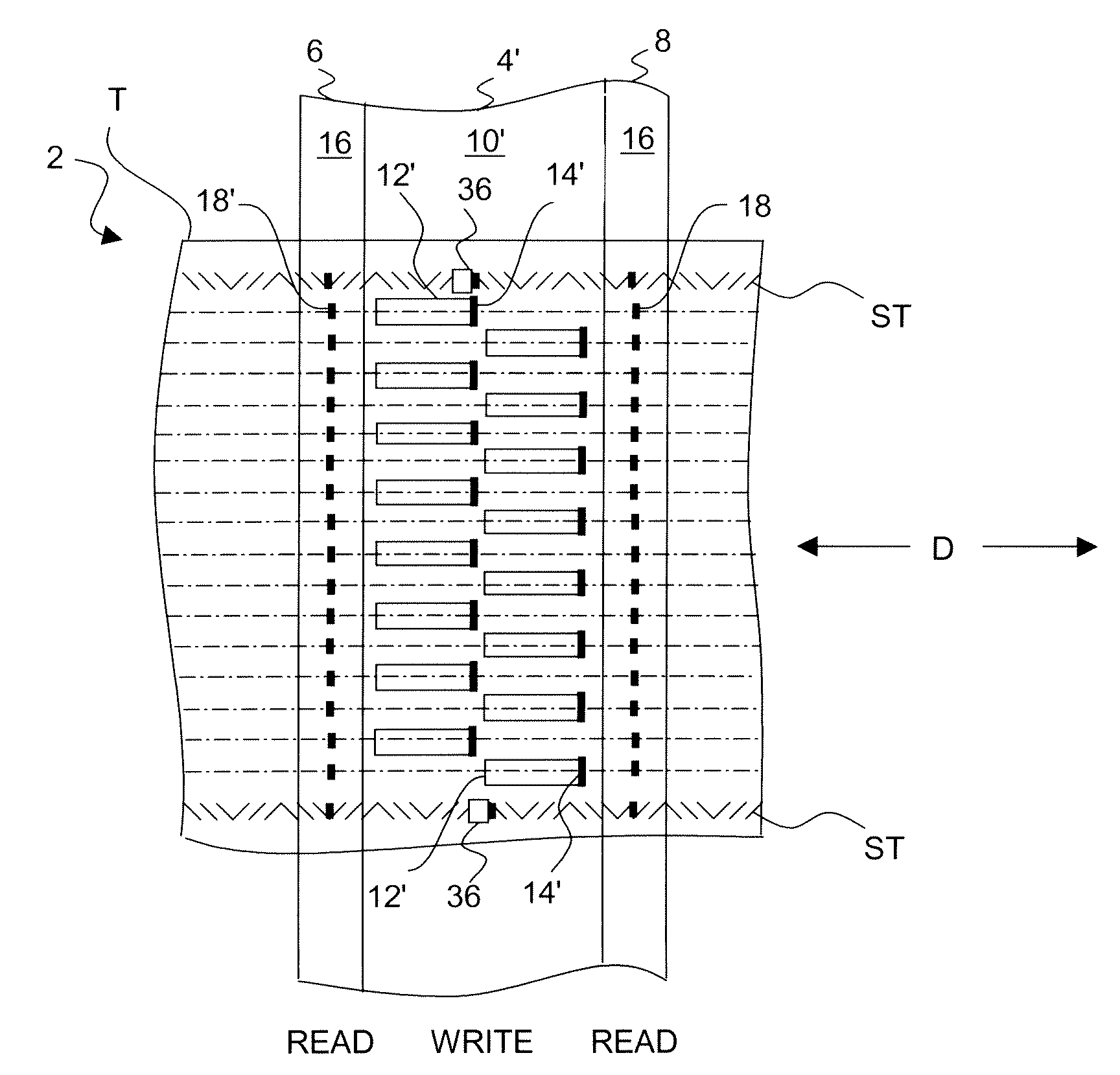

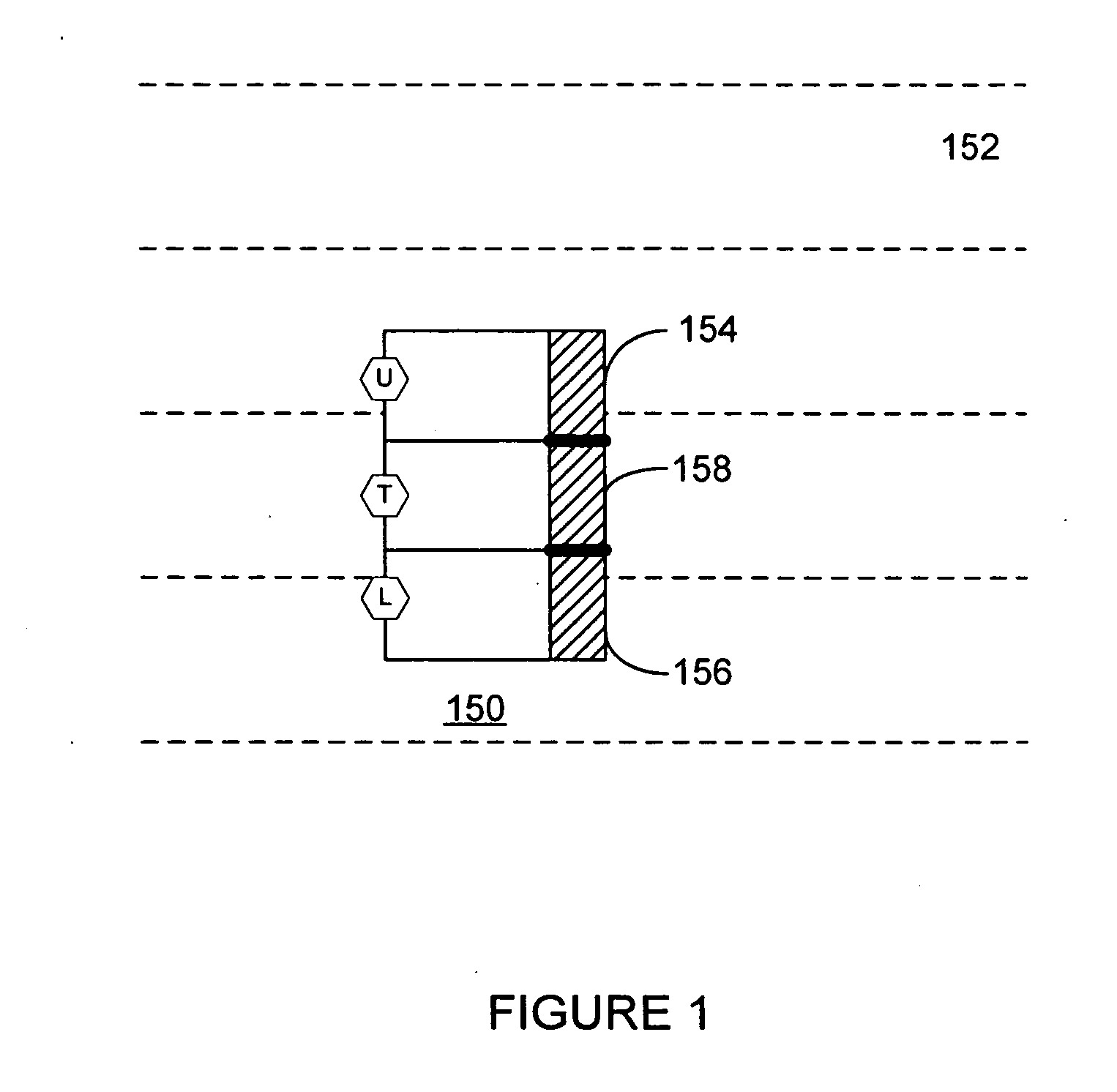

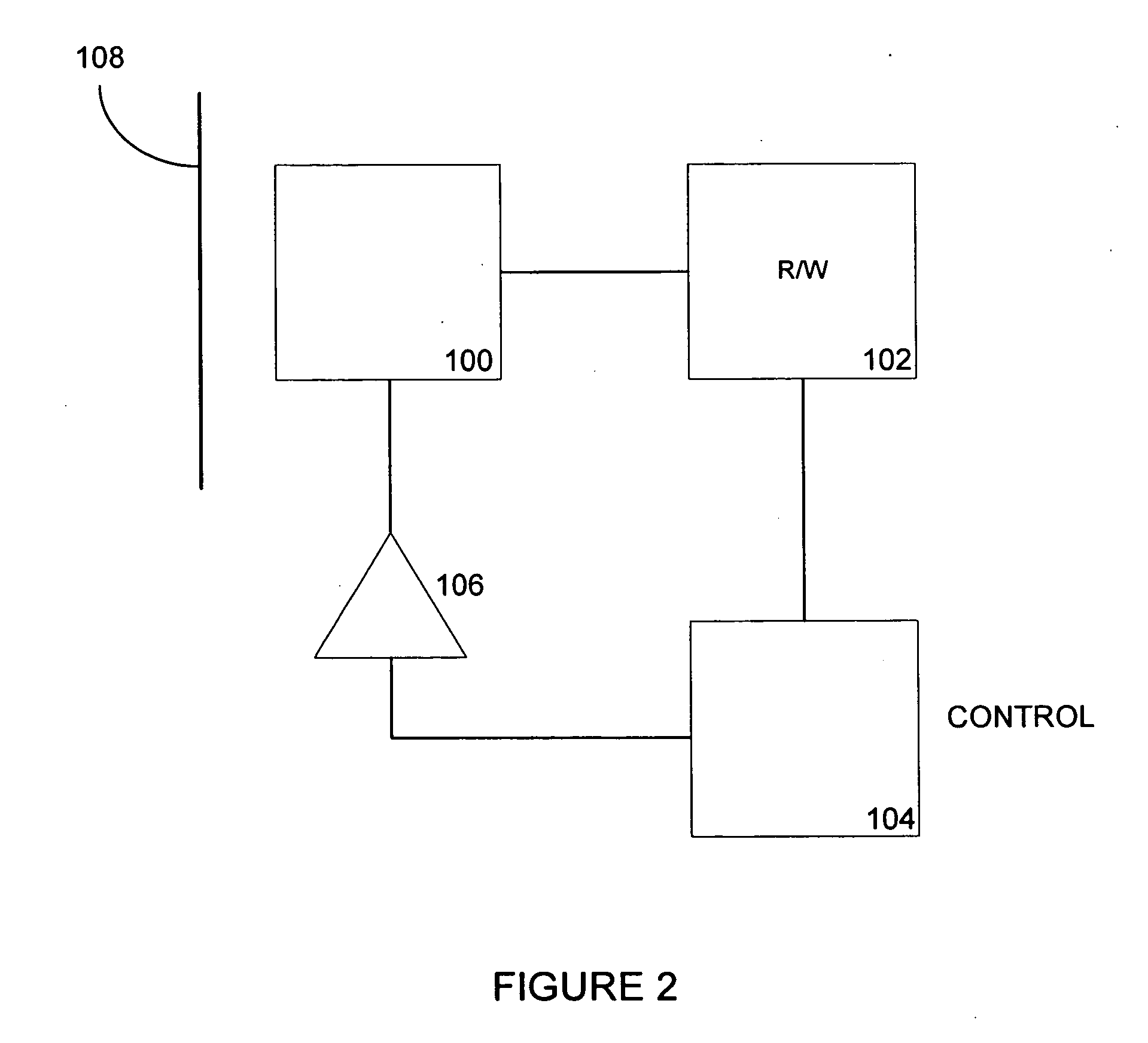

Data read transducers for determining lateral position of a tape head with respect to longitudinal servo bands of magnetic tape

InactiveUS6940682B2Alignment for track following on tapesRecord information storageSensing dataControl system

In a magnetic tape system, during lateral repositioning of a tape head between servo bands, the servo head is not on a servo band and is unable to provide servo position information. Hence, information about the lateral position may be lost. A control system selectively senses data read transducers of the tape head; and, upon detecting a servo signal of a servo band from a sensed data read transducer, determines the lateral position of the tape head with respect to the detected servo band based upon the position of the data read transducer that sensed the detected servo signal.

Owner:INT BUSINESS MASCH CORP

Network interface cassette adapter and method

A network interface cassette for coupling signals between a wireless network and a tape head in a cassette tape player. The network interface cassette includes an enclosure that is conformed to the cassette tape form factor. It contains a transceiver that converts base band signals for radio frequency communications within the wireless network. It also contains a network controller that is coupled to communicate the base band signals with the transceiver. The network controller converts digital audio signals to and from the base band signals. There is an audio processor that converts the digital audio signals to analog audio signals. A coupling means converts the analog audio signals to magnetic audio signals. The coupling means is aligned to couple the magnetic audio signals to the tape head. A power supply with batteries incorporates a spindle driven sensor means to control power and function selection within the device. A wireless user interface adapter is provided to couple microphone and audio signals to the apparatus. Plural communications requests are processed, and include a priority scheme to manage resource contention.

Owner:GENERAL WIRELESS OPERATIONS +1

Low friction tape head and system implementing same

A magnetic head according to one embodiment includes outer modules each having a tape bearing surface and an array of transducers selected from a group consisting of readers and writers; and an inner module positioned between the outer modules, the inner module having a tape bearing surface and an array of transducers selected from a group consisting of readers and writers, wherein portions of edges of the tape bearing surface of the inner module are non-skiving in regions not aligned with the array of transducers in a direction of media travel thereacross, wherein an outer edge of the tape bearing surface of each of the outer modules are adapted for skiving air from the magnetic medium when the magnetic medium travels in a direction from the respective outer module towards the inner module.

Owner:INT BUSINESS MASCH CORP

Highly aligned thin film tape head

InactiveUS6496329B2Improved tape head element alignmentEasy alignmentManufacturing heads with multiple gapsManufacture unitary devices of plural headsComputer hardwareData density

Reducing alignment errors between a read element and corresponding write elements permits narrower data tracks and, hence, greater data density on magnetic tape. A method for manufacturing a thin film tape head having multiple write elements and at least one read element corresponding to each write element is provided. Excess material is trimmed from each write element to align the write element with corresponding read elements. The excess material may be track trimmed using a focused ion beam.

Owner:STORAGE TECHNOLOGY CORPORATION

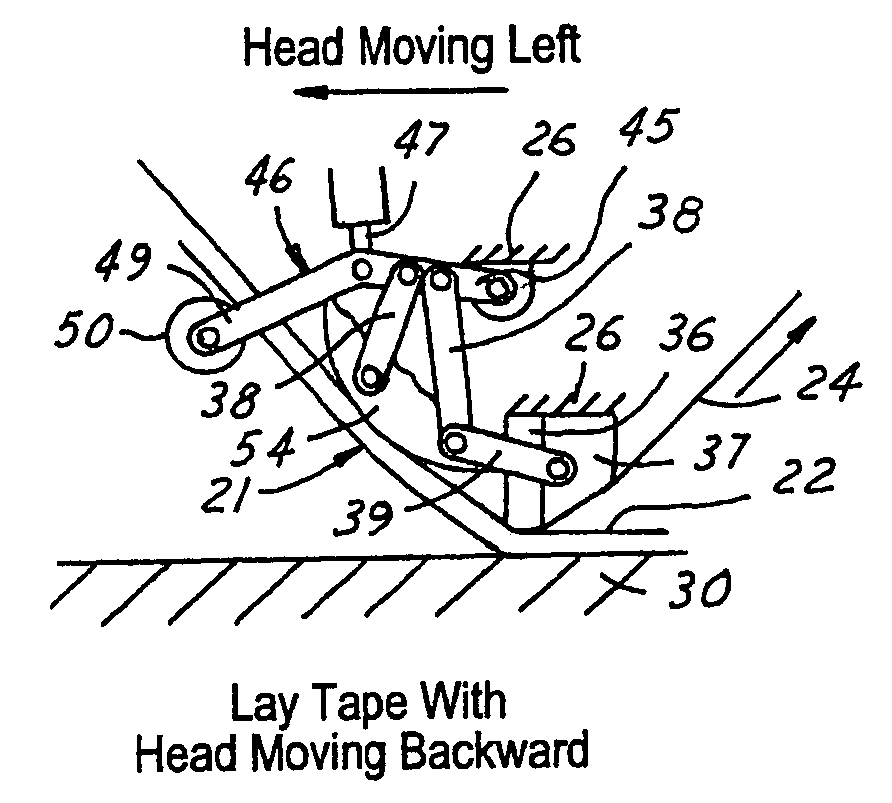

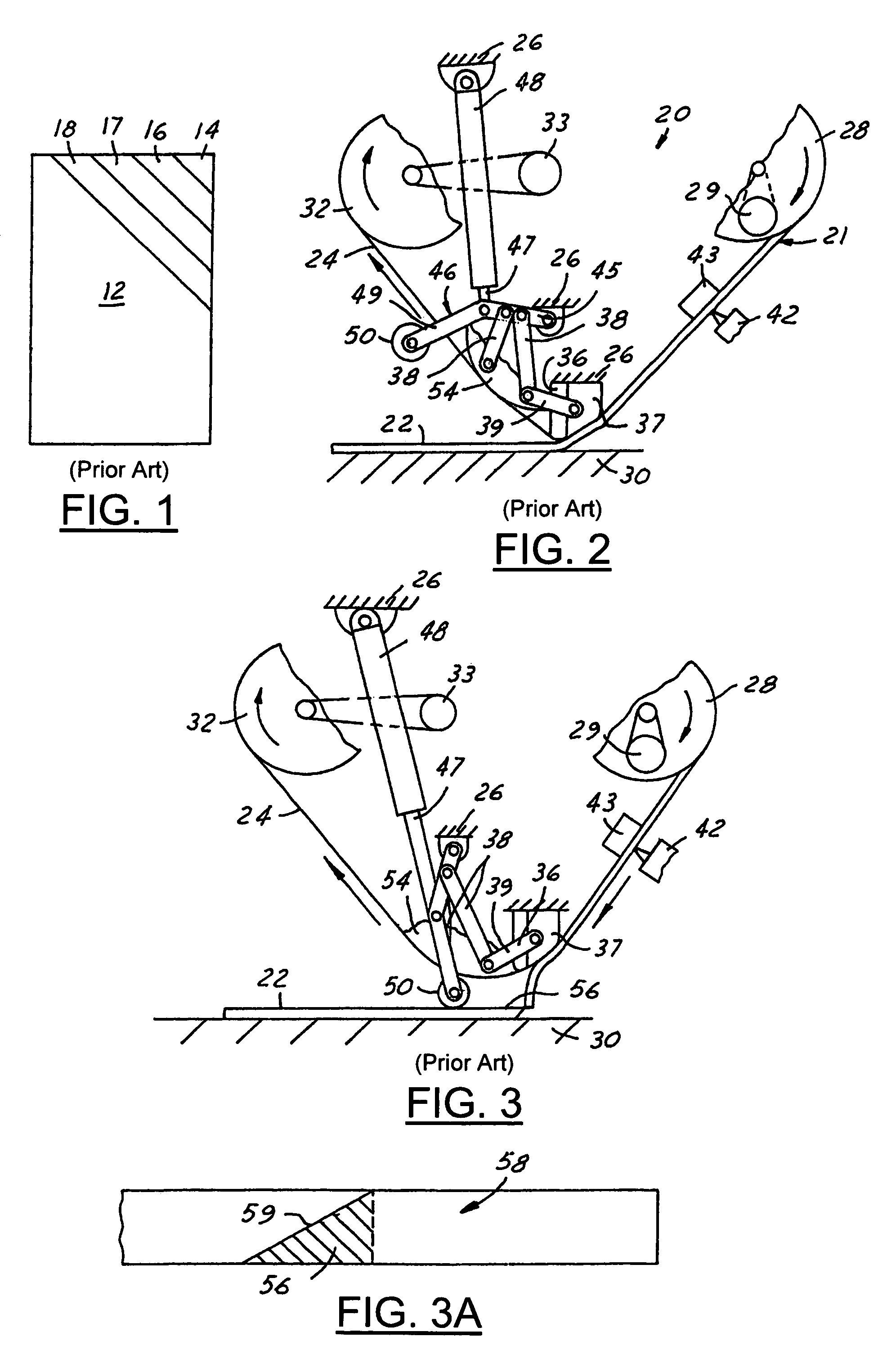

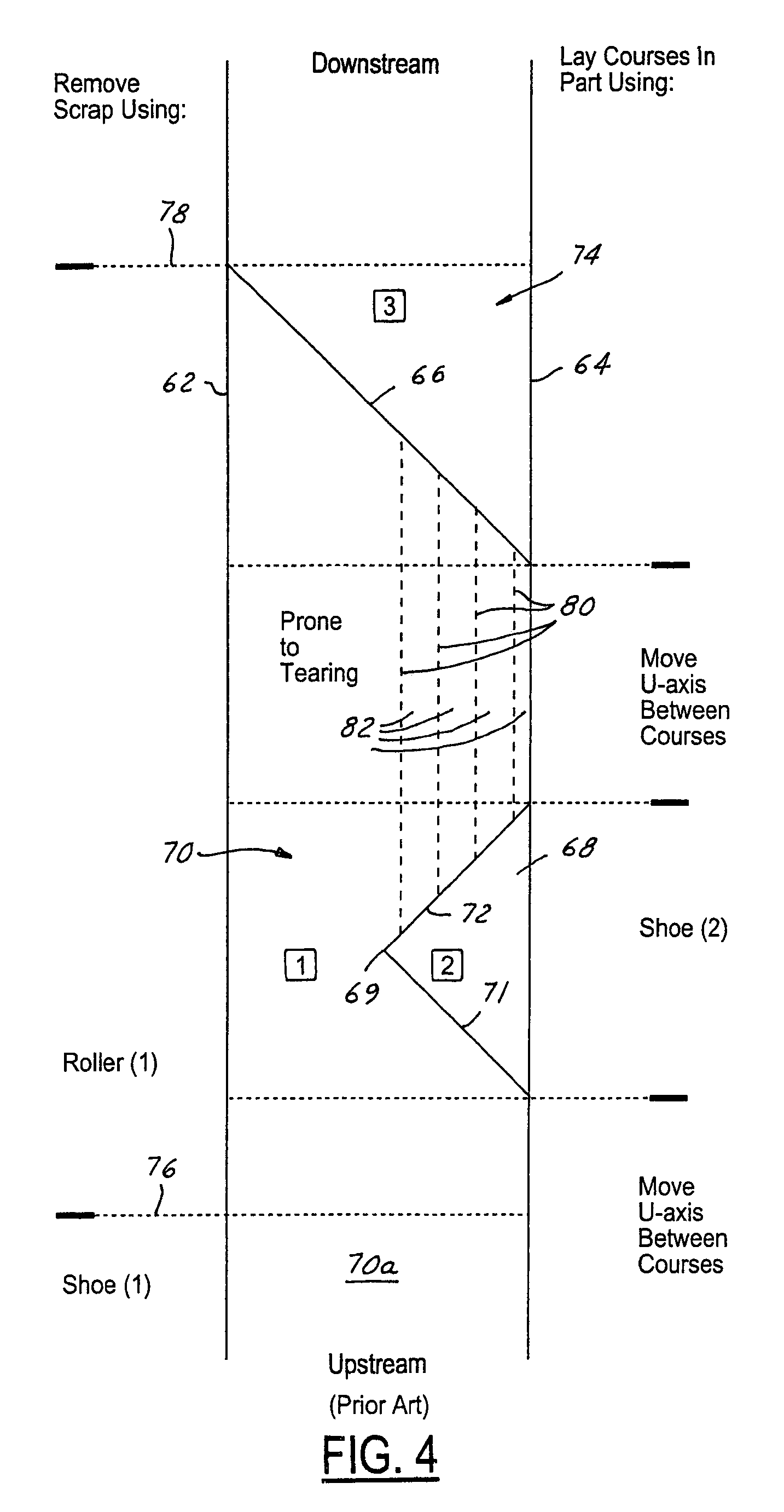

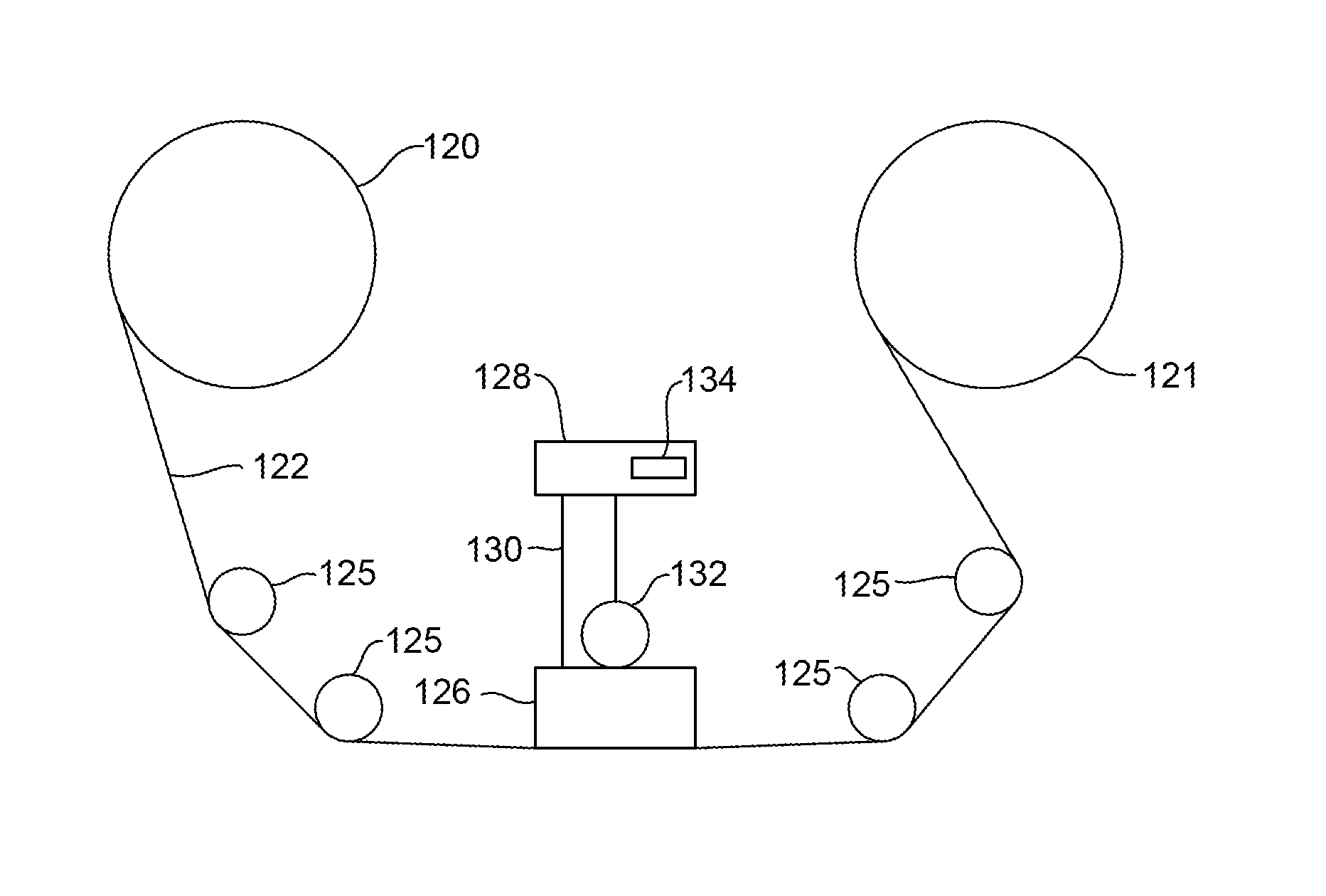

Process for laying fiber tape

ActiveUS7326312B1Reliable removalLamination ancillary operationsPaper/cardboard articlesFiberEngineering

The process for laying a non-full width course of fiber composite tape in a part is designed to ensure that all of the scrap portion of the tape surrounding the non-full width course is deposited in the scrap area and not in the part. An extra cut is made in tape downstream of the non-full width course, between the non-full width course and next course. After the tape head attempts to lay the scrap in the scrap area in the forward direction, the tape head makes a pass in the scrap area with the tape feed and the tape head moving in the reverse direction, and the scrap is laid beginning from the portion of the tape having the extra cut, and progressing to the non-full width course. The method may be used to remove scrap from around non-full width courses having any shape.

Owner:WELLS FARGO BANK NAT ASSOC +1

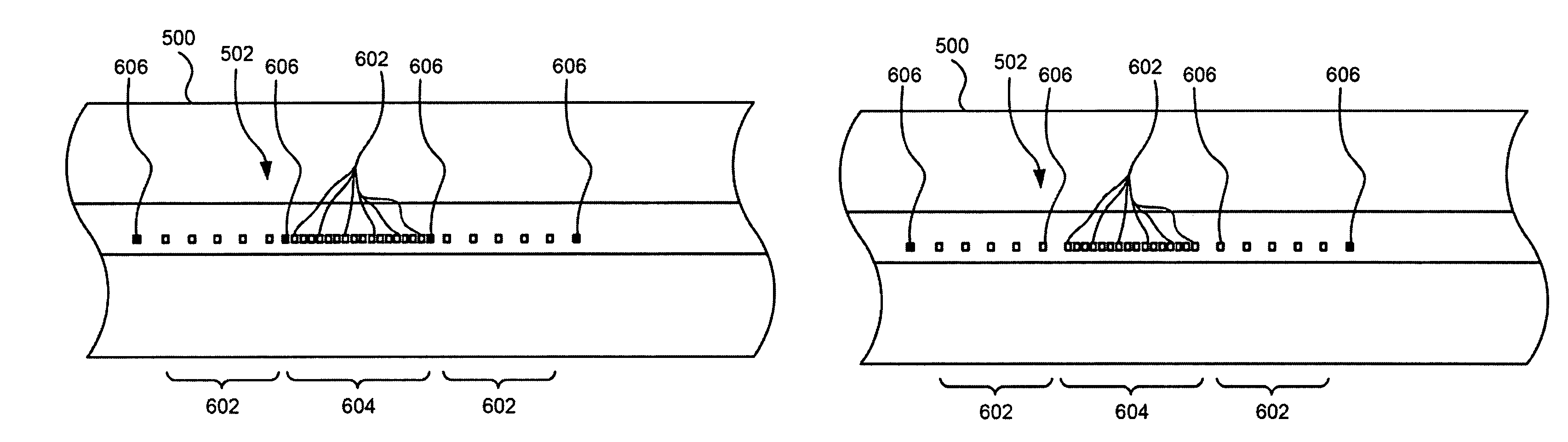

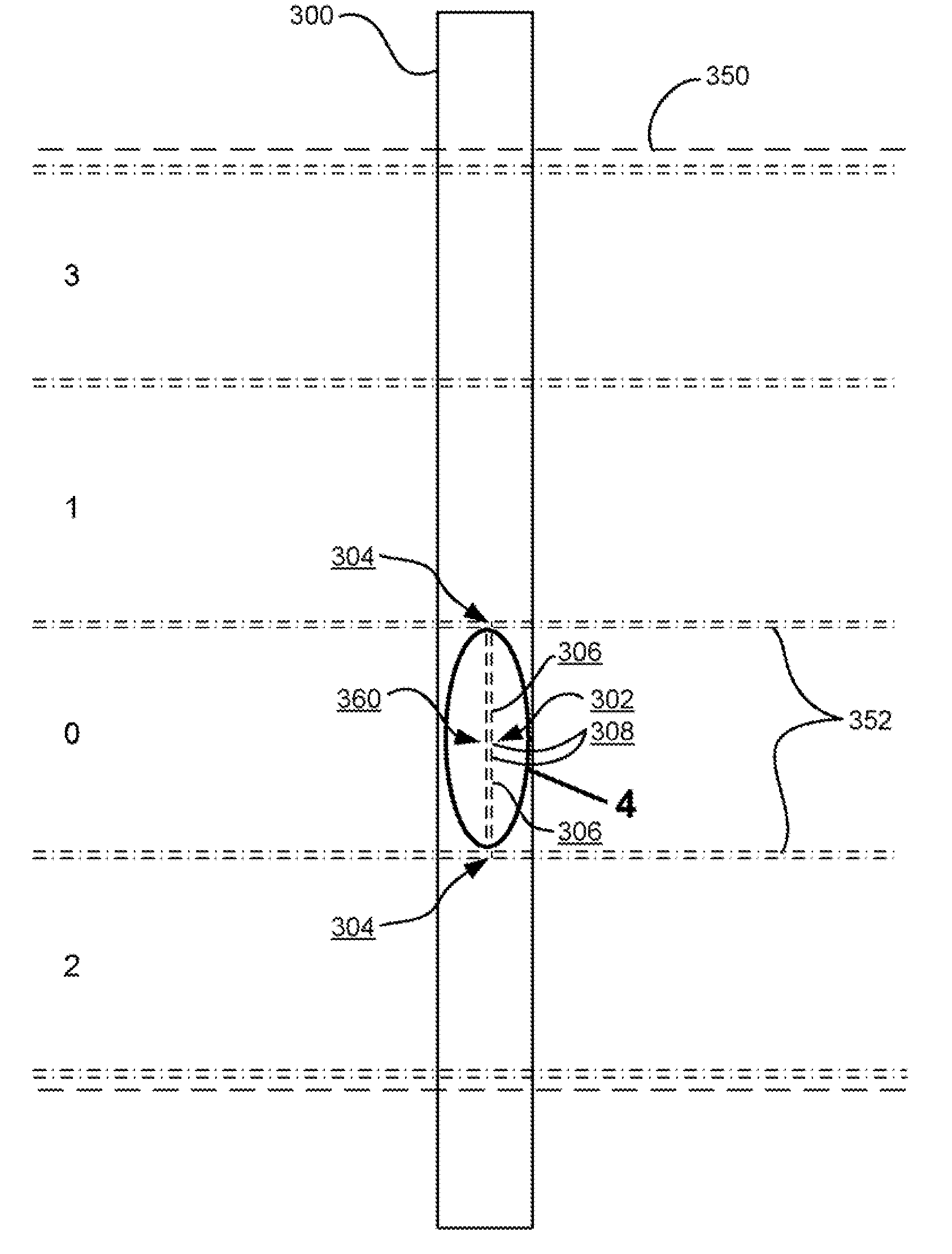

Positioning coarse servo actuator of tape servo system to allow fine servo actuator to follow tape shift excursions

ActiveUS20110102937A1Reduce the determined position errorReduce positioningAlignment for track following on tapesRecord information storageServo actuatorPosition error

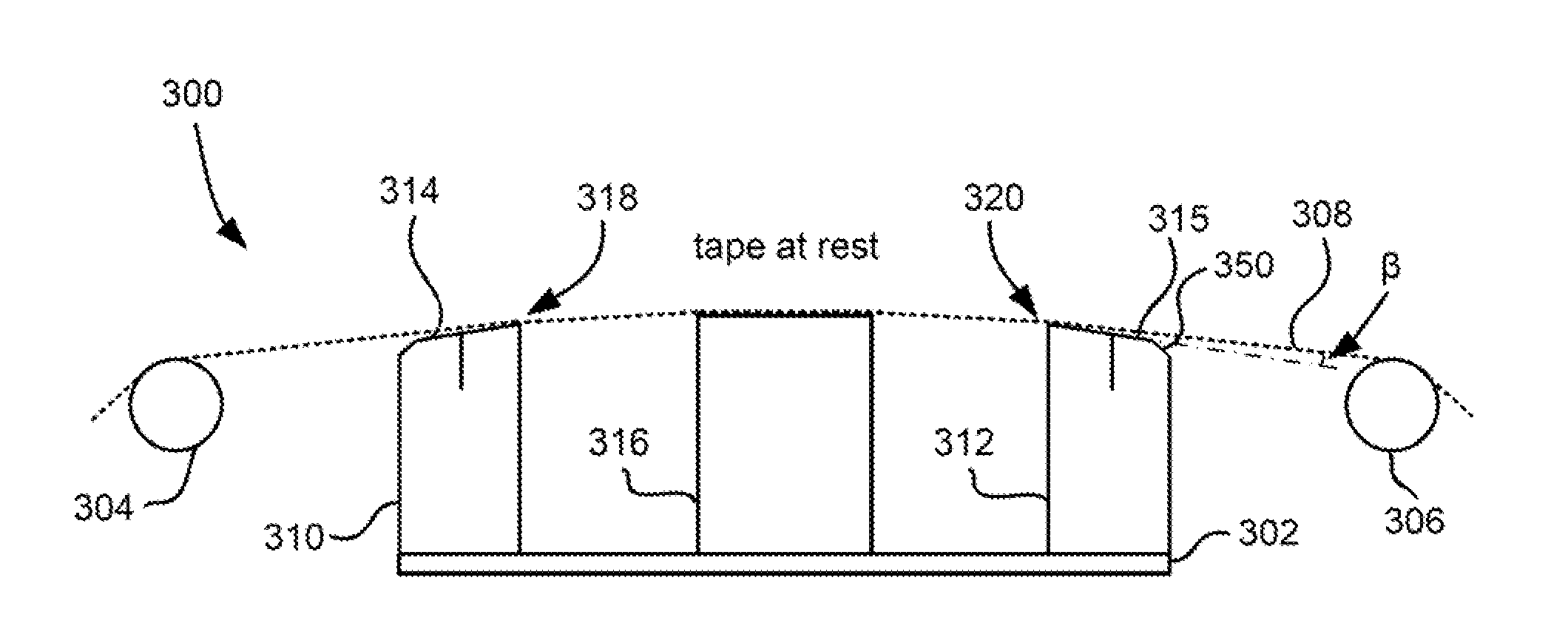

Methods, servo systems, and data storage drives follow the lateral shift excursions of longitudinal tape, for example, from flangeless tape guides. A servo sensor is configured to sense lateral position of a tape head with respect to longitudinal servo tracks of the tape, a fine actuator is configured to translate the head laterally, and a coarse actuator is configured to translate the fine actuator laterally. Position error is determined between the head and a desired position related to the servo track, and the fine actuator operated to translate the head laterally to reduce the position error. In the embodiment, lateral shift excursion is sensed from the position error, and the coarse actuator is positioned substantially at a midpoint of the lateral shift excursion. Thus, the fine actuator follows the lateral shift excursions, while the coarse actuator remains at the midpoint.

Owner:IBM CORP

Network interface cassette adapter and method

ActiveUS7120463B2Television system detailsSubstation speech amplifiersTransceiverDigital audio signals

A network interface cassette for coupling signals between a wireless network and a tape head in a cassette tape player. The network interface cassette includes an enclosure that is conformed to the cassette tape form factor. It contains a transceiver that converts base band signals for radio frequency communications within the wireless network. It also contains a network controller that is coupled to communicate the base band signals with the transceiver. The network controller converts digital audio signals to and from the base band signals. There is an audio processor that converts the digital audio signals to analog audio signals. A coupling means converts the analog audio signals to magnetic audio signals. The coupling means is aligned to couple the magnetic audio signals to the tape head. A power supply with batteries incorporates a spindle driven sensor means to control power and function selection within the device. A wireless user interface adapter is provided to couple microphone and audio signals to the apparatus. Plural communications requests are processed, and include a priority scheme to manage resource contention.

Owner:GENERAL WIRELESS OPERATIONS +1

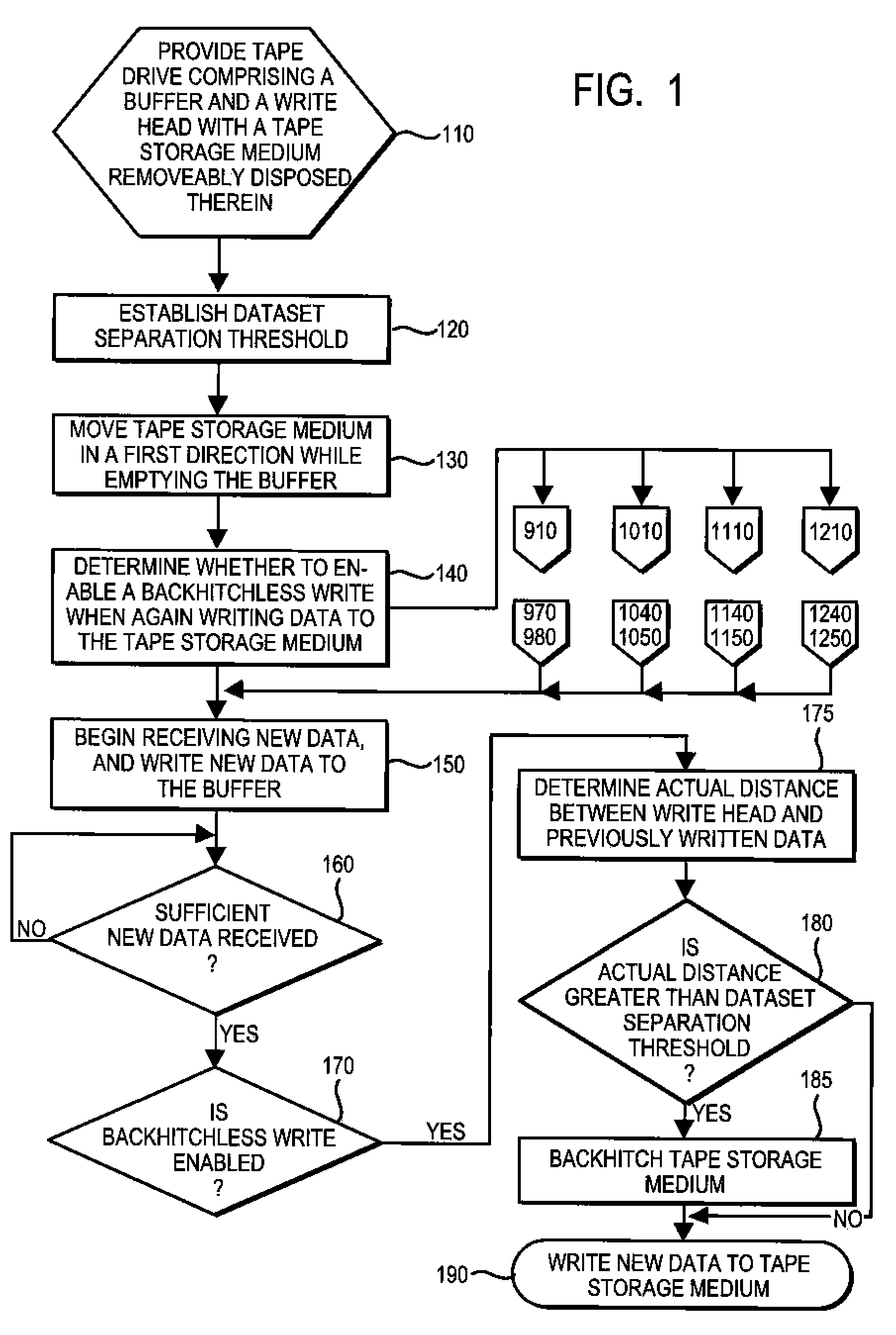

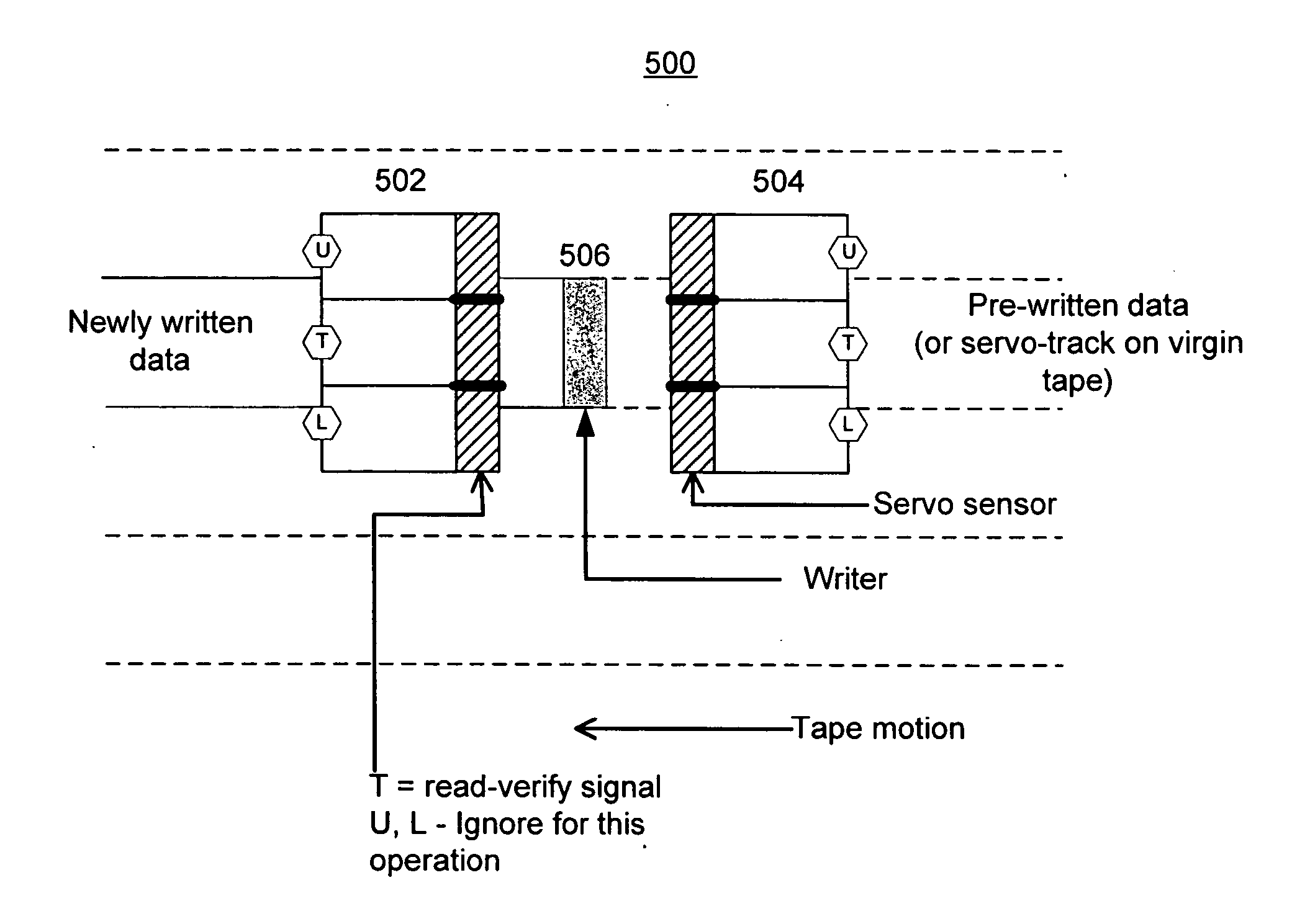

Same Wrap backhitchless write method to encode data on a tape storage medium

InactiveUS7903363B2Decrease nominal storage capacityEliminate time overheadAlignment for track following on tapesRecord information storageThumb oppositionTape drive

A method to write information to a tape storage medium by disposing a tape storage medium in a tape drive apparatus comprising a write head. The method moves the tape storage medium in a first direction, writes data from a buffer to the tape storage medium, and thereby empties the buffer while the tape storage medium is moving in the first direction. The method determines, while the tape storage medium is moving in the first direction, whether to enable a backhitchless write wherein the tape storage medium is not stopped and moved in a second and opposition direction, prior to writing new data to the tape storage medium. By not stopping the movement of the tape storage medium, and by not moving the tape storage medium in a reverse direction to reposition the write head, the method eliminates the time overhead required to stop the tape and reposition the tape head. Applicants' method achieves this time efficiency without adverse impact to the nominal storage capacity of the tape information medium.

Owner:IBM CORP

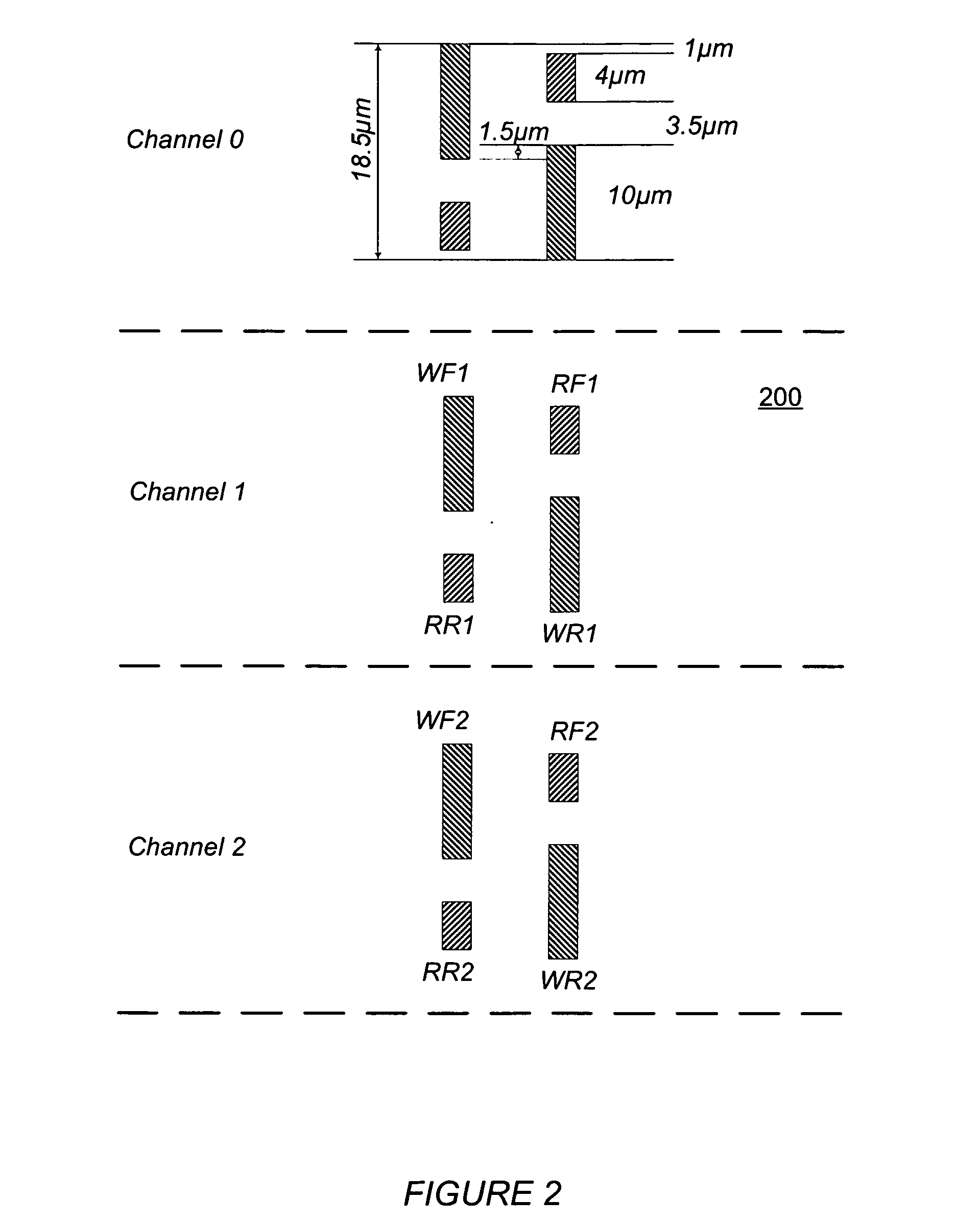

Auto-servo tape system and associated recording head

ActiveUS20060209450A1Driving/moving recording headsAlignment for track following on tapesComputer hardwareTape head

A recording head comprises a first tape-head contact area including a first write element and a first read element, which itself may include an MR sensor element. The first read element is laterally offset as to the first write element, and no portion of the first read element lies in a region laterally overlapped by the first write element. A second tape-head contact area includes a second write element and a second read element, which also may include an MR sensor element. The second read element is laterally offset as to the second write element, and no portion of the second read element lies in a region laterally overlapped by the second write element. The first read and write elements of the first tape-head contact area are aligned with the second write and read elements of the second tape-head contact area so that an end portion of the second write element lies in a region that laterally overlaps only an end portion of the first write element. Data track widths less than one micron are achievable with this head design.

Owner:QUANTUM CORP

Planar write module and hybrid planar write-vertical read bidirectional tape head

InactiveUS8130467B2Manufacturing heads with multiple gapsManufacture unitary devices of plural headsComputer hardwareBearing surface

A planar write module and a hybrid planar write-vertical read bidirectional tape head comprising the write module and one or more vertical read modules. The write module has a write module tape bearing surface for engaging the magnetic recording tape. Plural write elements in the write module each comprise plural thin film layers oriented in generally parallel planar relationship with the write module tape bearing surface. The write elements are arranged so that the transducing gaps (write gaps) of adjacent write elements are generally aligned in a direction that is transverse to a streaming direction of the magnetic recording tape. Each read module has a read module tape bearing surface for engaging the magnetic recording tape. Plural read elements in the one or more read modules each comprise plural thin film layers oriented in generally perpendicular relationship with the read module tape bearing surface.

Owner:INT BUSINESS MASCH CORP

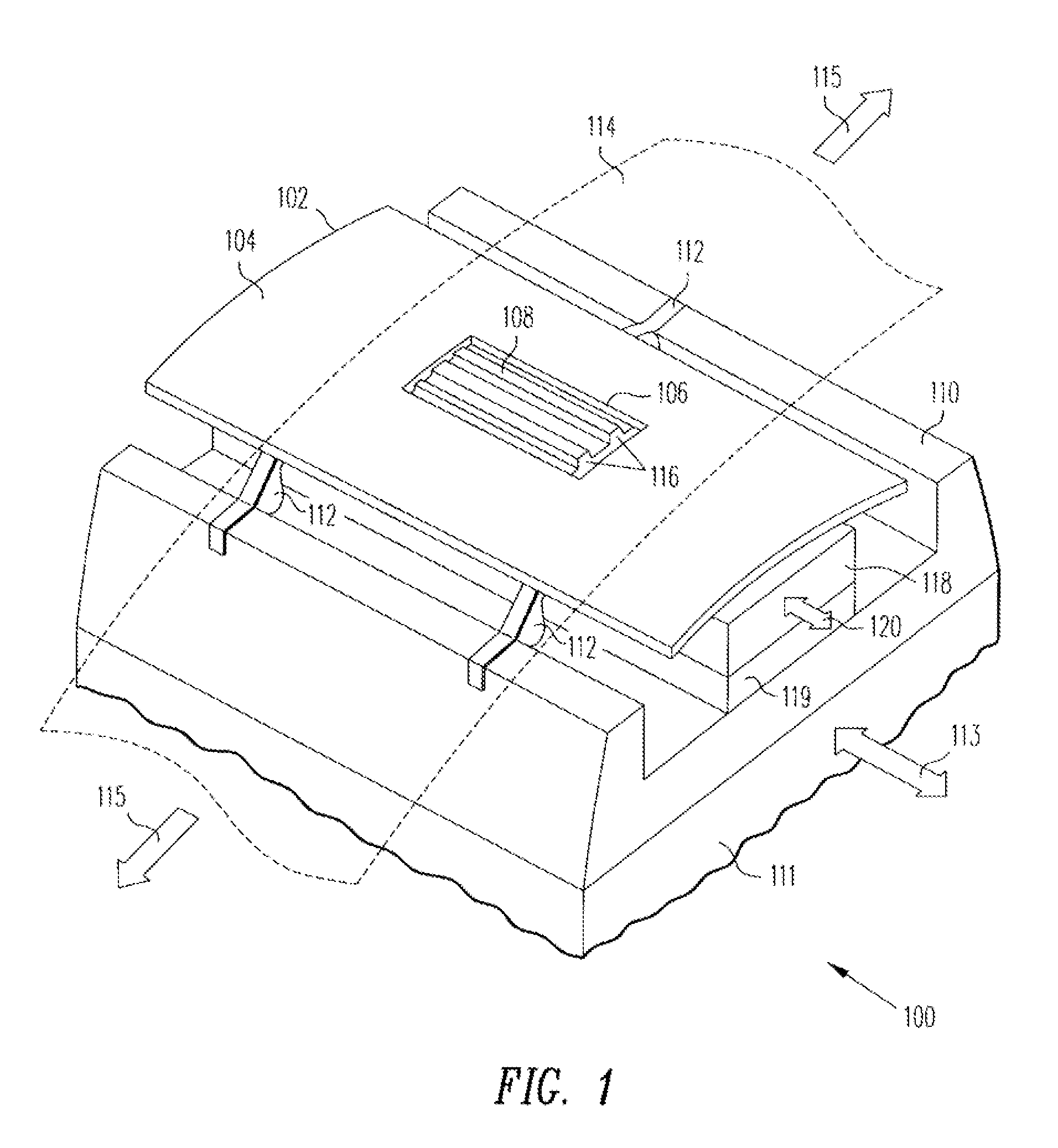

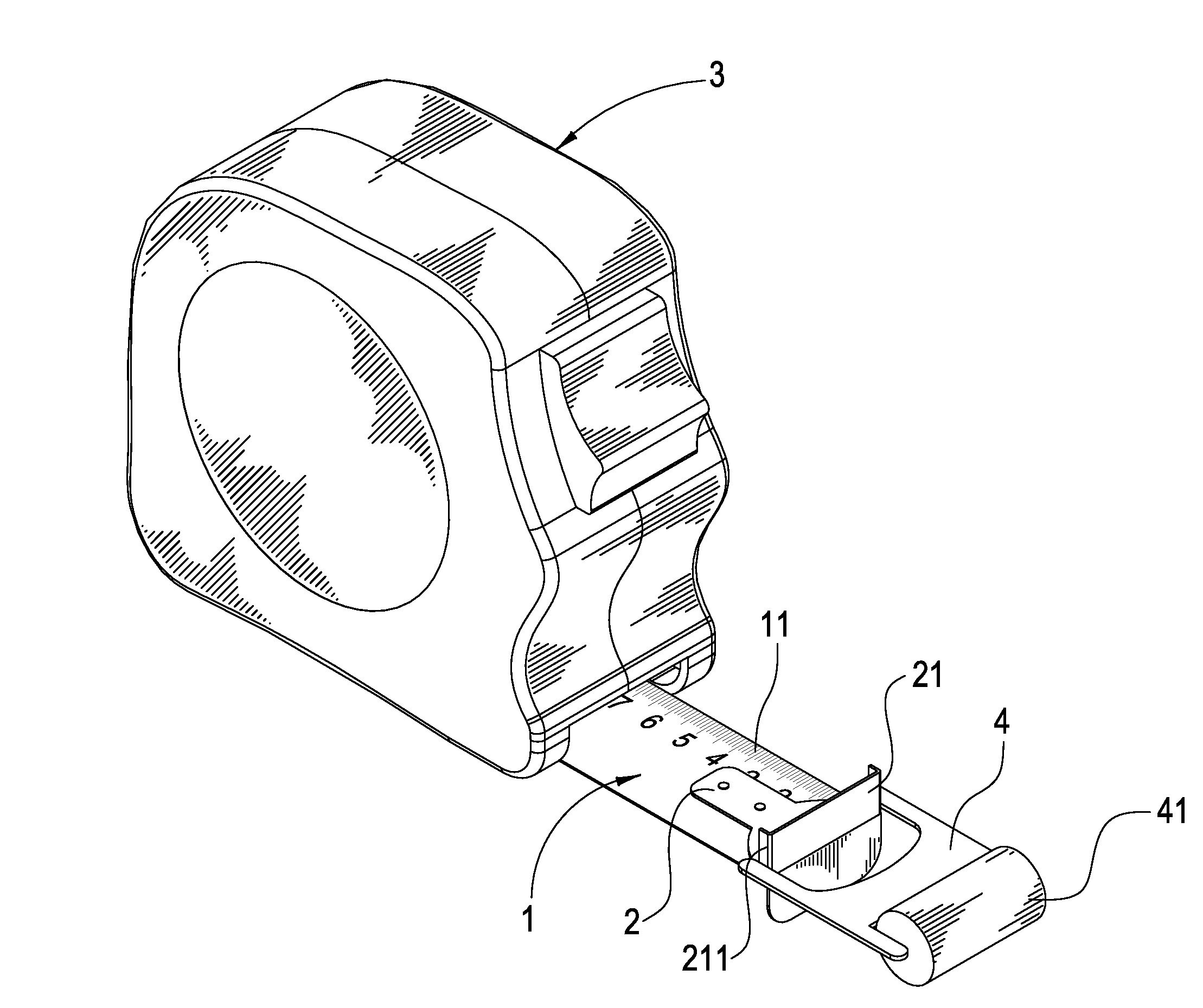

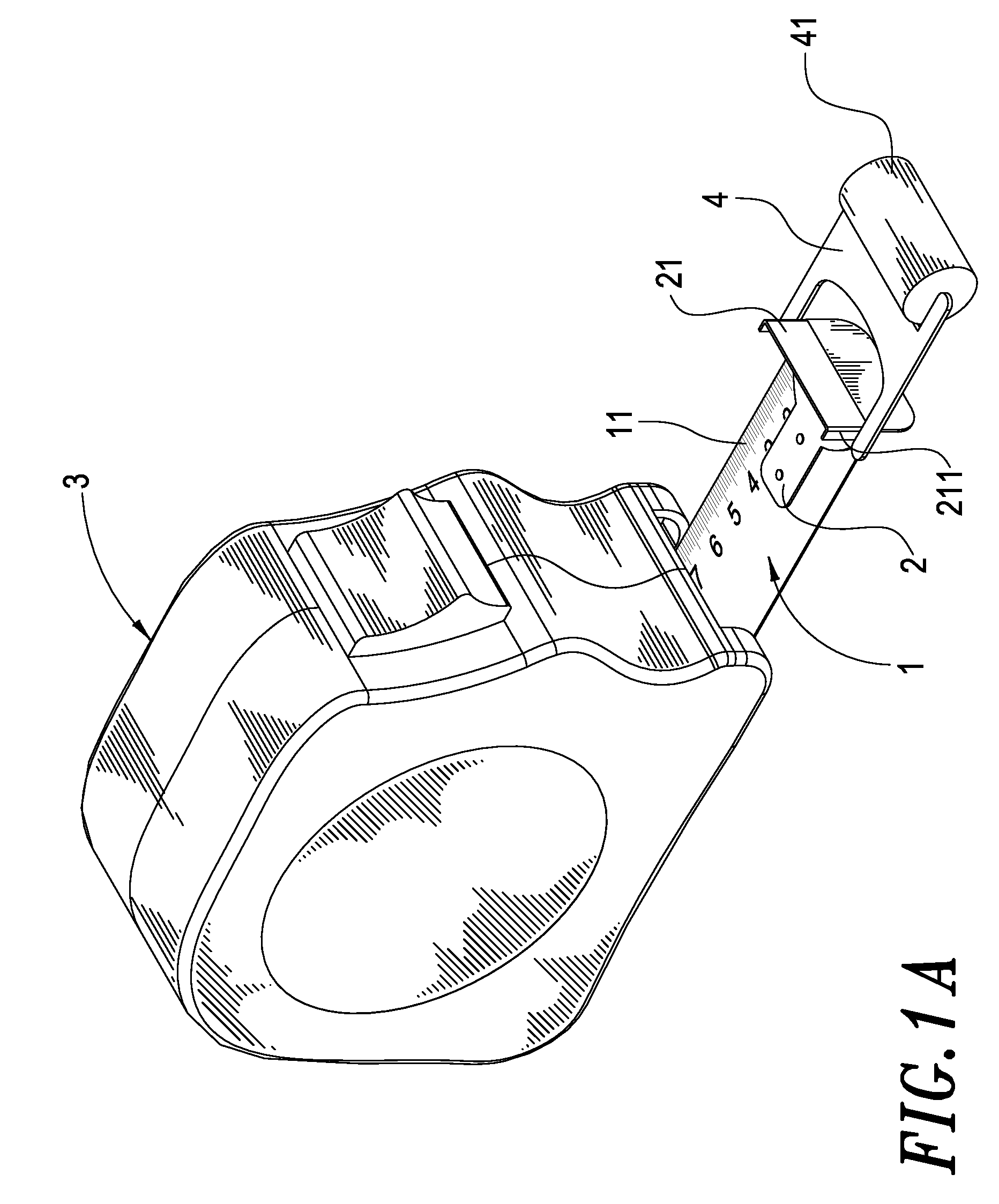

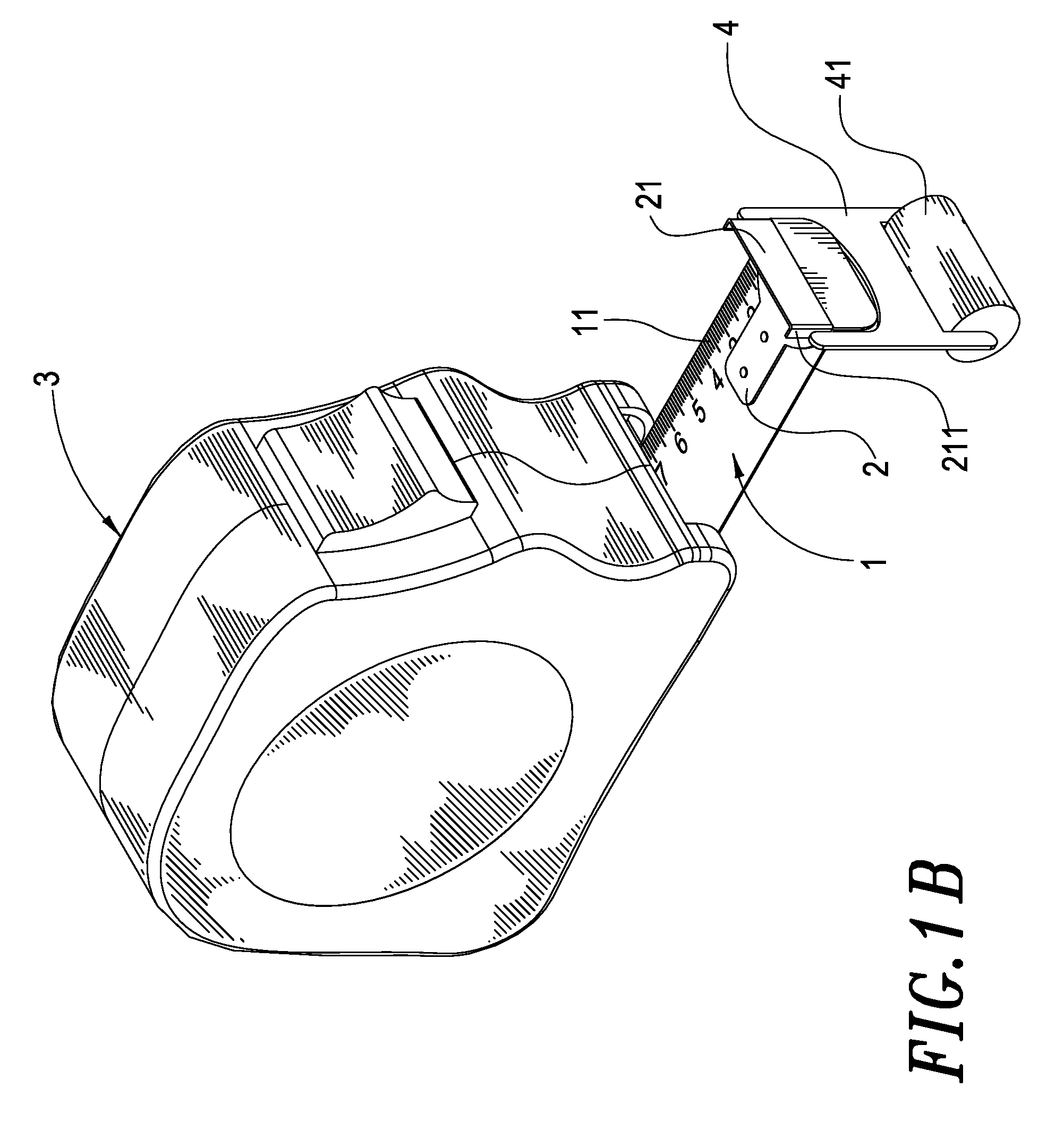

Structure for the head of measuring tape

A structure of head for the measuring tapes includes a moving part pivoted on a tape hook of the tape head, such that the moving part can overturn upwards and downwards on the tape hook and has the front portion thereof pivoting a wheel, wherein the wheel contacts with the object to measure or other contact areas as the tape is to be output and the output of the tape is facilitated through the rotation of the wheel.

Owner:LEE SHIH LIN

Correlation servo for positioning recording head

InactiveUS20070041121A1Error minimizationDriving/moving recording headsAlignment for track following on tapesTape driveComputer science

Tape heads and controllers for controlling such heads in a tape drive are described. A controller may determine a first parameter corresponding to the similarity between data read by a first pair of read elements of a head, a second parameter corresponding to the similarity between data read by another pair of read elements having one read element in common with the first pair, and a position of the head with respect to a data track based upon a relationship between the first and second parameters. The controller may adjust the head to a proper lateral position based upon the determined position.

Owner:QUANTUM CORP

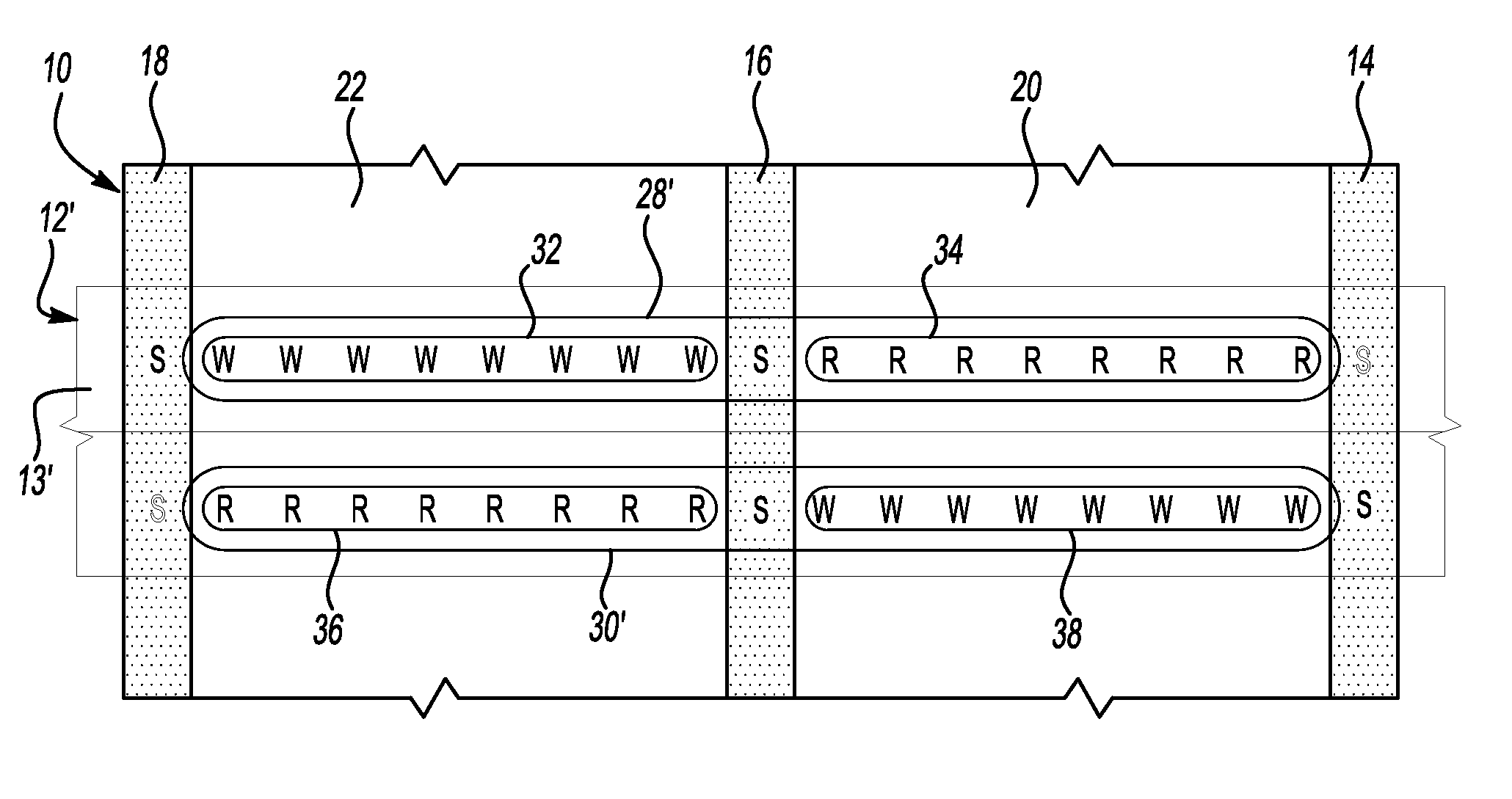

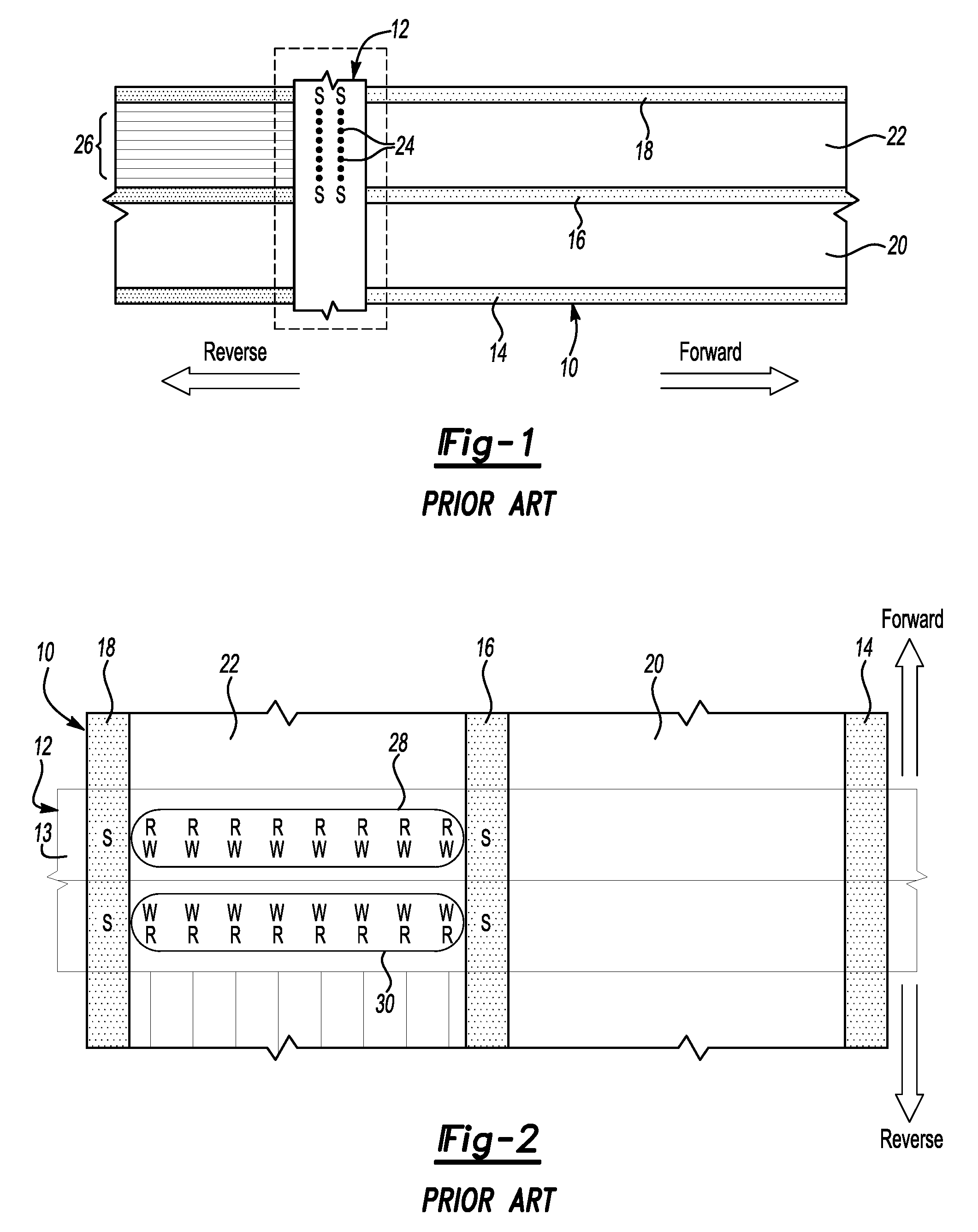

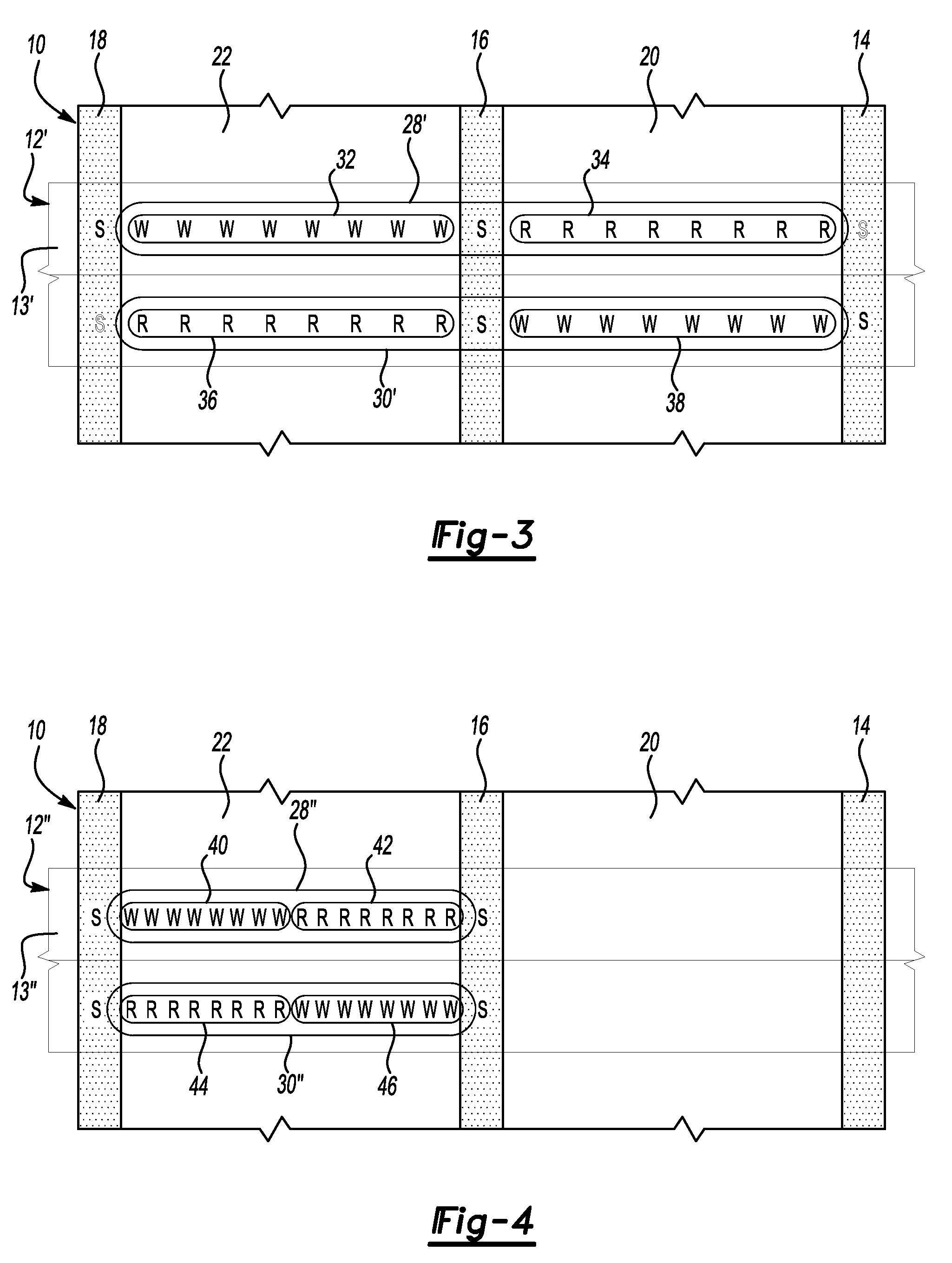

Tape head layout having offset read and write element arrays

ActiveUS8045290B2Driving/moving recording headsManufacturing heads with multiple gapsComputer hardwareComputer science

A tape head assembly for writing data to and reading data from a tape includes a tape head member having an engagement surface that is configured to engage the tape as the tape moves past the tape head member. A plurality of arrays of interactive elements are supported on the engagement surface. Each array is longitudinally offset from each other array. Each individual array includes a read group having only read elements and a write group having only write elements. Each read group is laterally offset from each write group within each array.

Owner:ORACLE INT CORP

Method for manufacturing a magnetic tape head using an ink mask formed by printing

InactiveUS20150138673A1Well definedNegatively impact performanceDecorative surface effectsFluid-dynamic spacing of headsEtchingMagnetic transducers

A method for forming a protective overcoat onto a tape bearing surface of a tape head used for magnetic tape recording. In order to ensure optimal surface tension and liftoff properties of the ink mask, the tape bearing surface is treated with a first application of ethanol, followed by an application of polydimethylsiloxane, followed by a second application of ethanol. After this treatment an ink mask can be printed onto the tape bearing surface so as to form a mask having an opening over the location of the magnetic transducer. An etching can then be performed followed by the deposition of a protective coating such as alumina.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com