A kind of iron-based amorphous thin strip and its manufacturing method

An iron-based amorphous and thin strip technology, applied in the field of amorphous alloys, can solve the problem of high manufacturing cost, achieve the effects of good toughness, ultra-high saturation magnetic induction intensity, and reduce manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Fe, Si, boron iron (24%), C, Al are divided into Fe a Si b B c C d Al e Chemical composition ratio configuration, the manufacturing process adopts the following steps:

[0042] Step 1, configure the master alloy according to the chemical composition ratio,

[0043] Step 2, smelting the master alloy obtained in step 1,

[0044] Step 3, remelting the alloy obtained in step 2, and throwing the strip to make an amorphous thin strip,

[0045] Step 4, heat-treating the amorphous ribbon obtained in Step 3,

[0046] Step five, perform performance test on the product obtained in step four.

[0047] When operating the step 1, according to Fe a Si b B c C d Al e Calculate the number of atoms required for the target composition of the corresponding raw materials, and use a physical balance to weigh and prepare the Fe a Si b B c C d Al e master alloy;

[0048] When operating the step 2, put the master alloy obtained in the step 1 into an intermediate frequency vacuum...

Embodiment 2

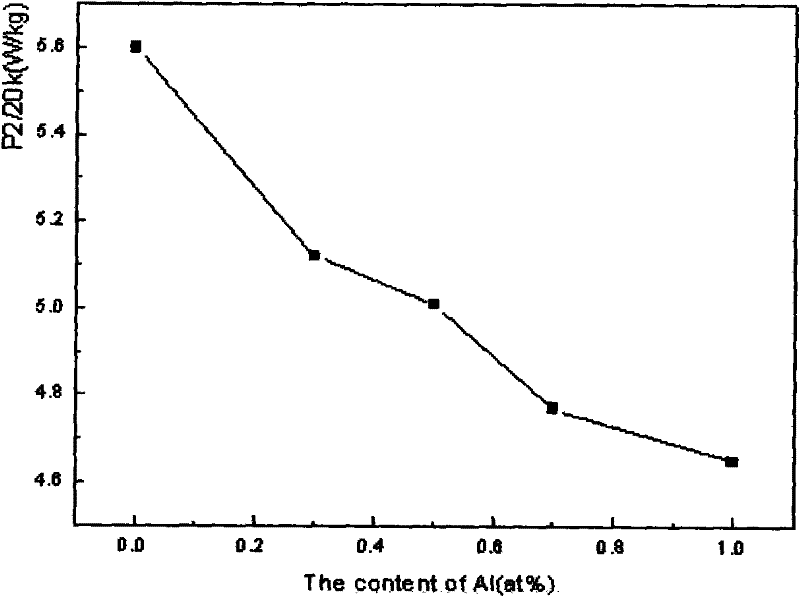

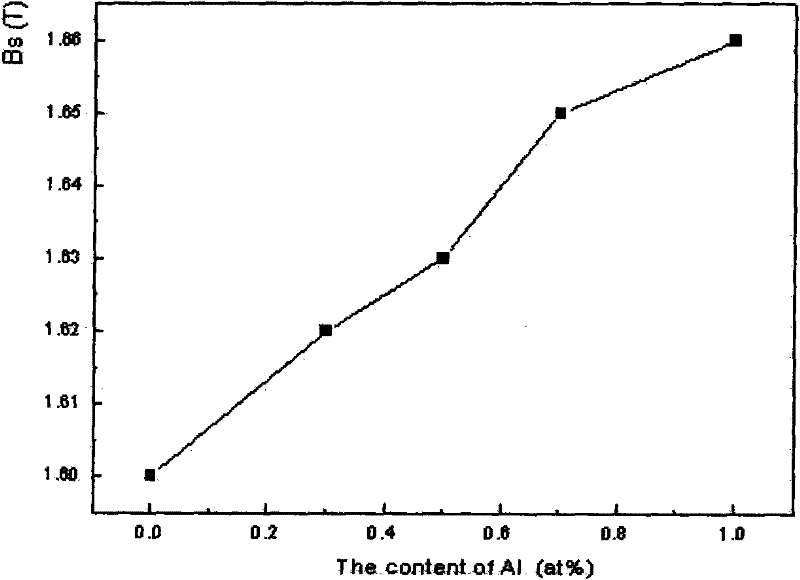

[0057] Iron-based amorphous ribbons according to chemical composition Fe 82 Si 5.5 B 11.5-e C 1 Al e (e≤1) Proportioning is carried out, and the obtained alloy is processed according to the method of Example 1, and its saturation magnetic induction Bs and iron loss P2 / 20k are measured. The saturation magnetic induction Bs varies with the Al content as figure 1 As shown, the change of iron loss with Al content is as figure 2 shown. from Figure 1 ~ Figure 2 It can be seen that it is appropriate to control the amount of Al addition within 1 atomic percent.

Embodiment 3

[0059] Iron-based amorphous ribbons according to chemical composition Fe 80 Si 7 B 11-e C 2 Al e (e≤1) Proportioning is carried out, and the obtained alloy is processed according to the method of Example 1, and its saturation magnetic induction Bs and iron loss P2 / 20k are measured. The saturation magnetic induction Bs varies with the Al content as image 3 As shown, the change of iron loss with Al content is as Figure 4 shown. from Figure 3 ~ Figure 4 It can be seen that the addition of Al significantly increases the saturation magnetic induction Bs, and Bs increases with the increase of Al content; the iron loss of the alloy with Al addition is significantly lower than that without Al addition, and decreases with the increase of Al content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com