Extrusion molding die and method in semi-solid preparation method of aluminum-clad magnesium composite pipe

An extrusion forming and semi-solid technology, applied in the direction of metal extrusion dies, etc., can solve the problems of high production temperature, high cost, and difficult precise control of the production process, so as to improve strength and quality, reduce metal oxidation, and save processing cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

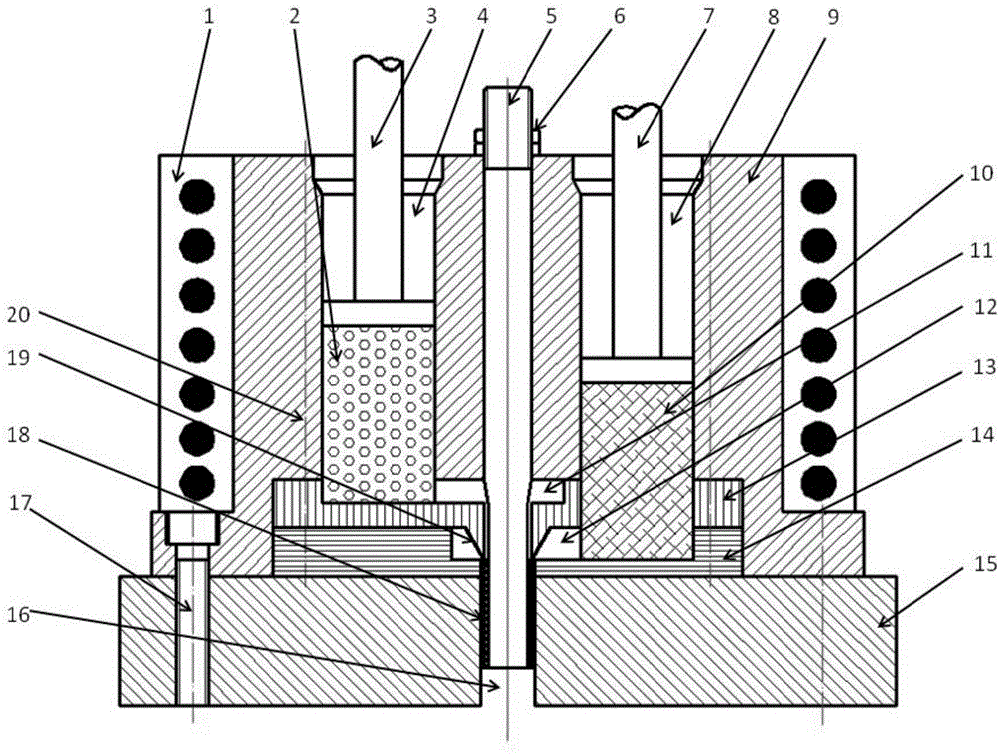

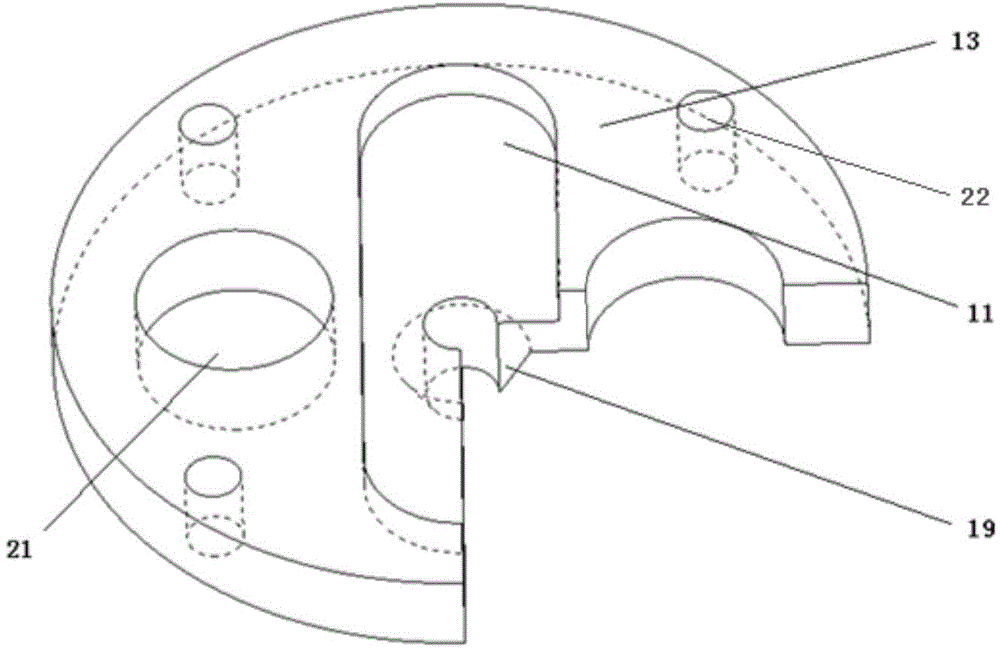

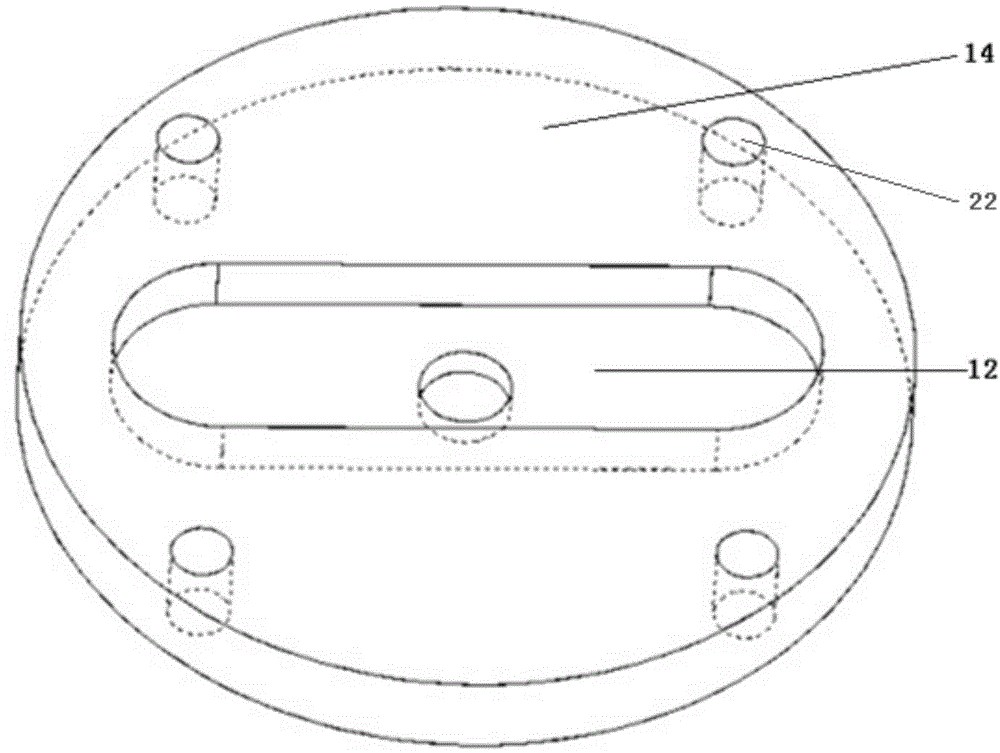

[0052] This embodiment relates to a semi-solid thixotropic extrusion forming process for an aluminum-clad magnesium composite pipe. Among them, thixotropic forming is to prepare a magnesium alloy or aluminum alloy ingot through heating (primary heating) and stirring steps to prepare a billet with a non-dendritic structure, and then cut it into a billet of a certain size after complete cooling. When forming, the blank can be directly heated (reheated) to the semi-solid temperature for extrusion forming. The prepared composite pipe has an inner diameter of 20 mm and a wall thickness of 4 mm, wherein the inner layer of magnesium alloy AZ91D has a wall thickness of 2.5 mm, and the outer layer of aluminum alloy 7075 has a wall thickness of 1.5 mm. The used magnesium alloy and aluminum alloy semi-solid billets are all rods with a diameter of 60 mm and a length of 90 mm. The heating resistance wire (1) ensures that the preheating temperature of the extrusion mold is 250°C. The semi...

Embodiment 2

[0054] This embodiment relates to a semi-solid thixotropic extrusion forming process for an aluminum-clad magnesium composite pipe. The prepared composite tube has an inner diameter of 20 mm and a thick wall of 5 mm, wherein the inner magnesium alloy AZ91D wall thickness is 3 mm, and the outer aluminum tube wall thickness is 2 mm. The used magnesium alloy and aluminum alloy semi-solid billets are rods with a diameter of 80 mm and a length of 110 mm. The heating resistance wire (1) ensures that the preheating temperature of the extrusion mold is 300°C. The semi-solid blanks of magnesium alloy and aluminum alloy are respectively heated in an induction heating furnace. The semi-solid temperature of the outer layer of 7075 aluminum alloy is 617°C, and the semi-solid temperature of the inner layer of AZ91D magnesium alloy is 584°C. Then quickly put the heated aluminum alloy and magnesium alloy blanks into the outer tube extrusion cavity (8) and inner tube extrusion cavity (4) of ...

Embodiment 3

[0056] The invention relates to a semi-solid rheological extrusion forming process of an aluminum-clad magnesium composite pipe. Among them, rheological deformation is a simplification of thixotropic deformation, that is, after the alloy ingot is heated and stirred directly to form a non-dendritic structure, it is cooled to a semi-solid temperature range (incomplete cooling), and then extruded immediately. The prepared composite pipe has an inner diameter of 20 mm and a wall thickness of 8 mm, wherein the inner layer of magnesium alloy AZ91D has a wall thickness of 5 mm, and the outer layer of aluminum alloy 7075 has a wall thickness of 3 mm. The heating resistance wire ensures that the preheating temperature of the extrusion mold is 280°C. After drying, the block-shaped commercial AZ91 magnesium alloy and 7075 aluminum alloy ingots were respectively heated to the complete melting temperature in a resistance heating furnace, and then kept for 20 minutes. After standing still,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com