Hot isostatic pressing forming equipment

A molding equipment and hot isostatic pressing technology, which is applied in the field of high-performance material preparation and cleaning, can solve the problems of high production cost, no scale, low penetration rate, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

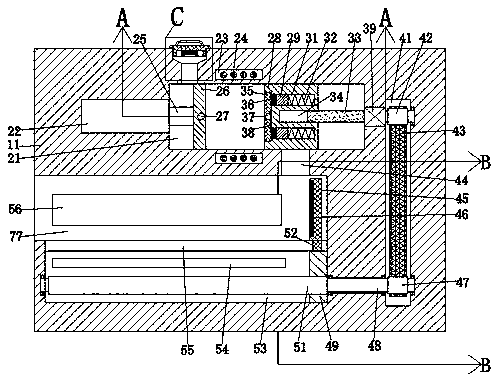

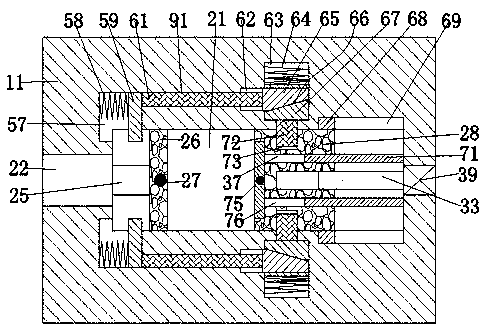

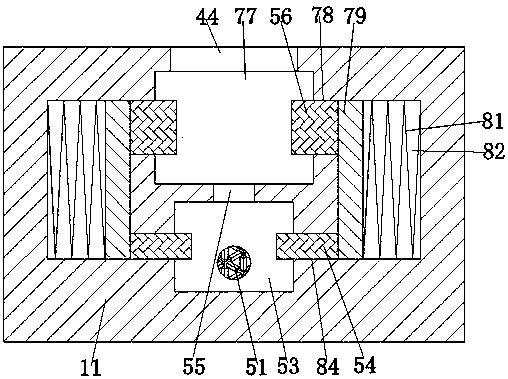

[0018] Such as Figure 1-Figure 4As shown, a hot isostatic pressing molding equipment of the present invention includes a device body 11 and a molding device disposed in the device body 11, and the molding device includes a first cavity disposed in the device body 11 21. Locking devices are symmetrically arranged in the front and rear inner walls of the first cavity 21, a hydraulic cylinder 22 is fixed in the left inner wall of the first cavity 21, and a hydraulic cylinder 22 is fixed in the first cavity 21. The first slider 26 that can slide left and right, the hydraulic inner column 25 is connected between the left end surface of the first slider 25 and the hydraulic cylinder 22, the right side of the first slider 26 is located on the The first cavity 21 is provided with a second slider 28 that can slide left and right, the second slider 28 is provided with an ejection assembly, and the second slider is provided with a third cavity 34 that opens to the right , the first mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com