Preparation method of ultrahigh power multilayer composite membrane capacitor

A multi-layer composite film and capacitor technology, applied in capacitor manufacturing, multilayer capacitors, capacitors, etc., can solve the problems of low qualification rate and high cost, and achieve the effect of reducing process cost, improving energy storage density and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

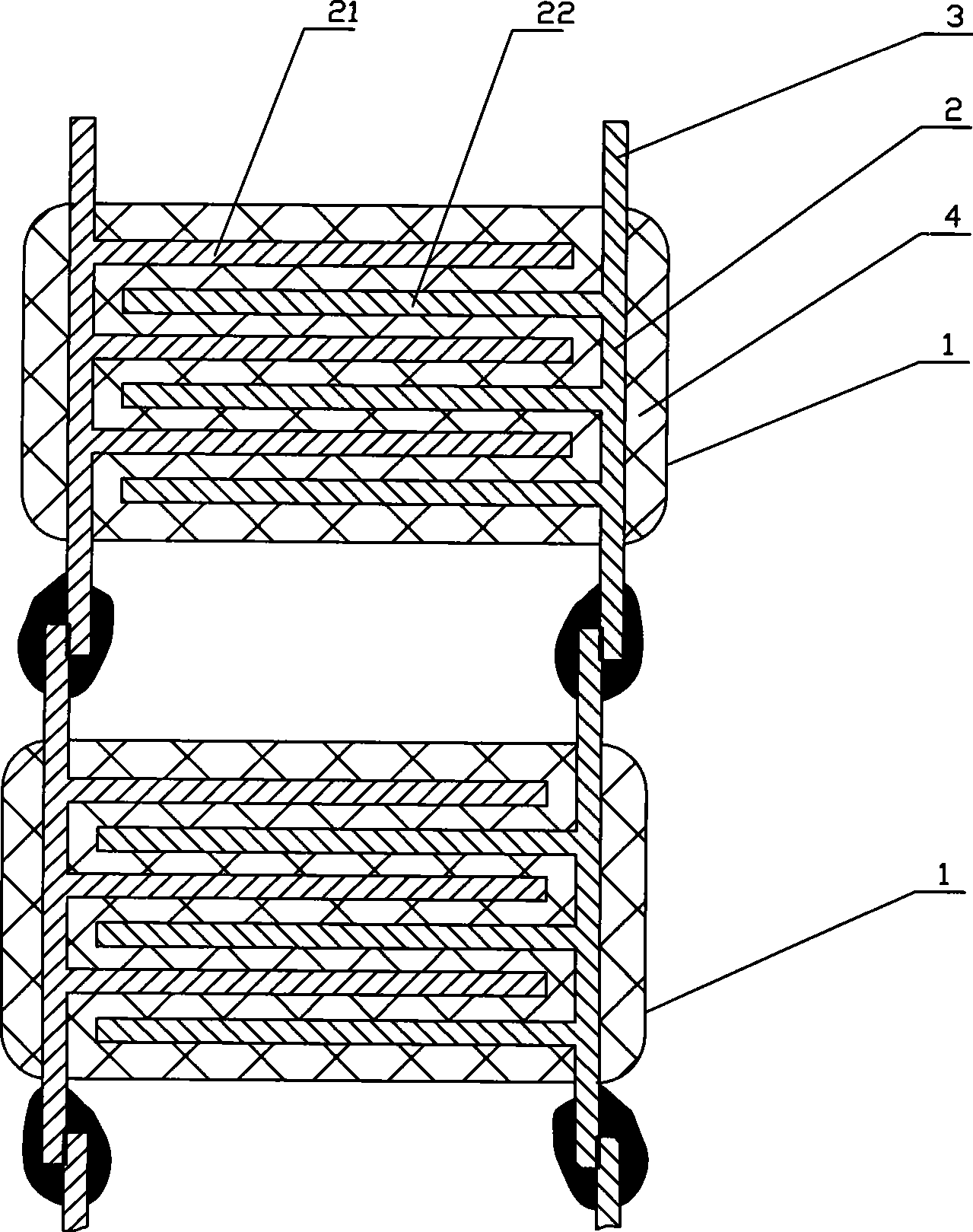

Image

Examples

Embodiment Construction

[0020] The preparation process of the present invention:

[0021] First, mixing ceramic powder and polyvinylidene fluoride nano-powder, because the polyvinylidene fluoride content is very low, and adding a certain amount of dimethylformamide as the polyvinylidene fluoride solvent to make the mixing more uniform. The ball milling process is used to make the powder uniformly mixed, and the polyvinylidene fluoride powder is evenly coated on the surface of the barium titanate powder, which is beneficial to the formation of a uniform and dense composite film. After the composite powder is uniformly mixed, add terpineol and other organic solvents to configure the dielectric slurry. The slurry is required to have good stability and a certain fluidity, and the various components in the mixed solvent can be maintained at 160°C. It is completely volatilized and will not adversely affect the dielectric layer.

[0022] Then, a multilayer film is prepared. Due to the use of ceramic / organic com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com