Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

286results about How to "Improve electrical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric motors

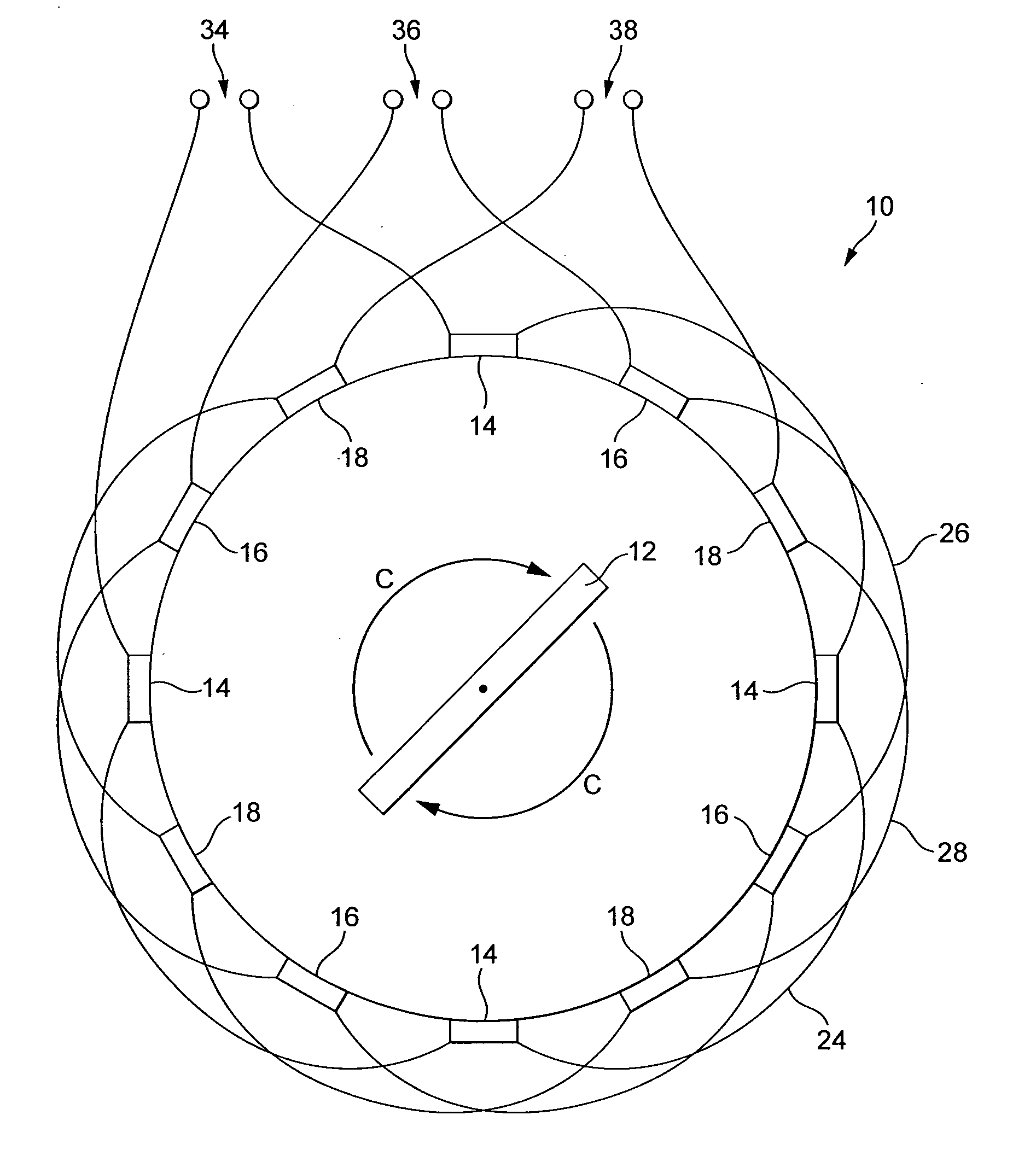

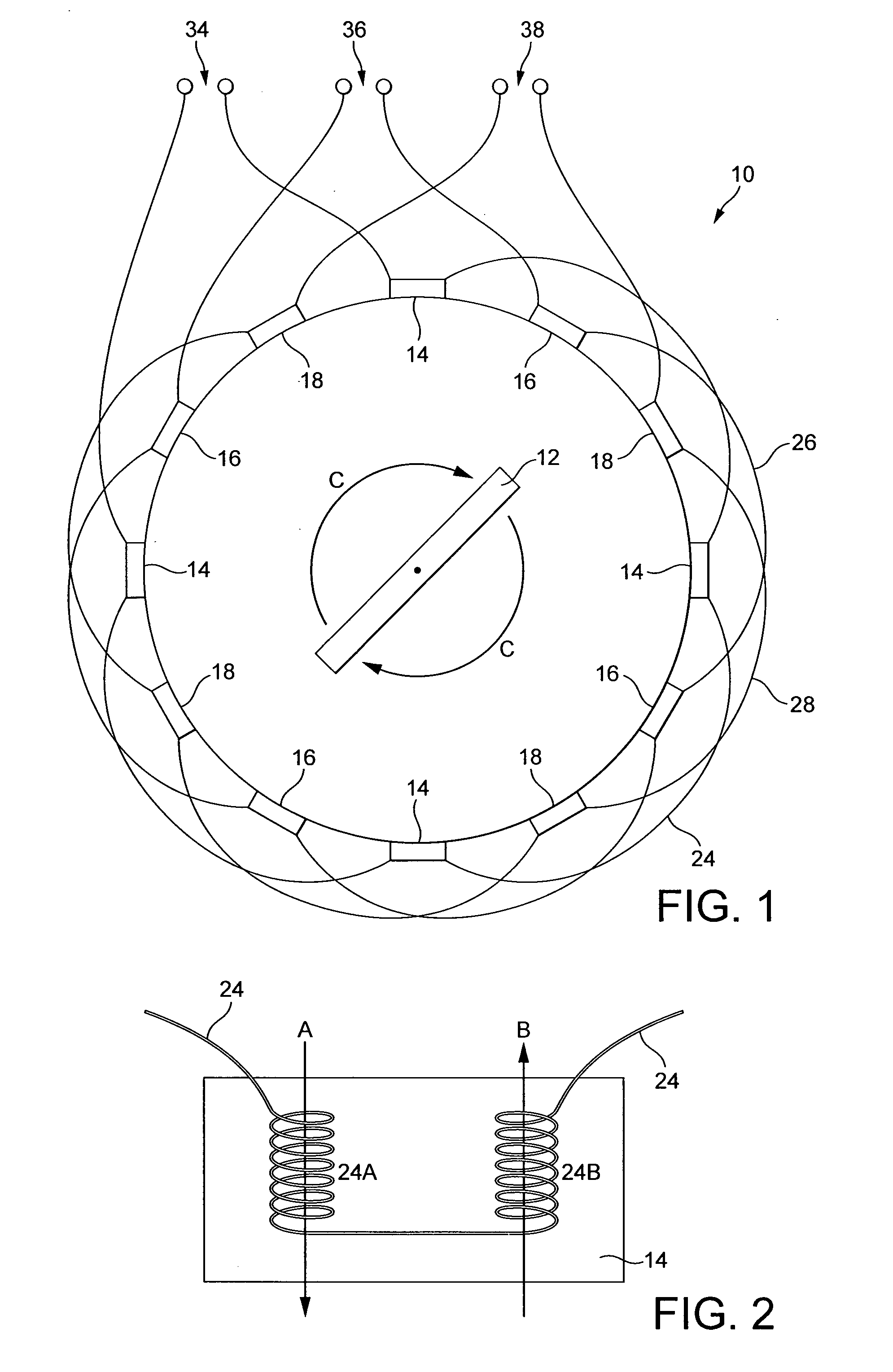

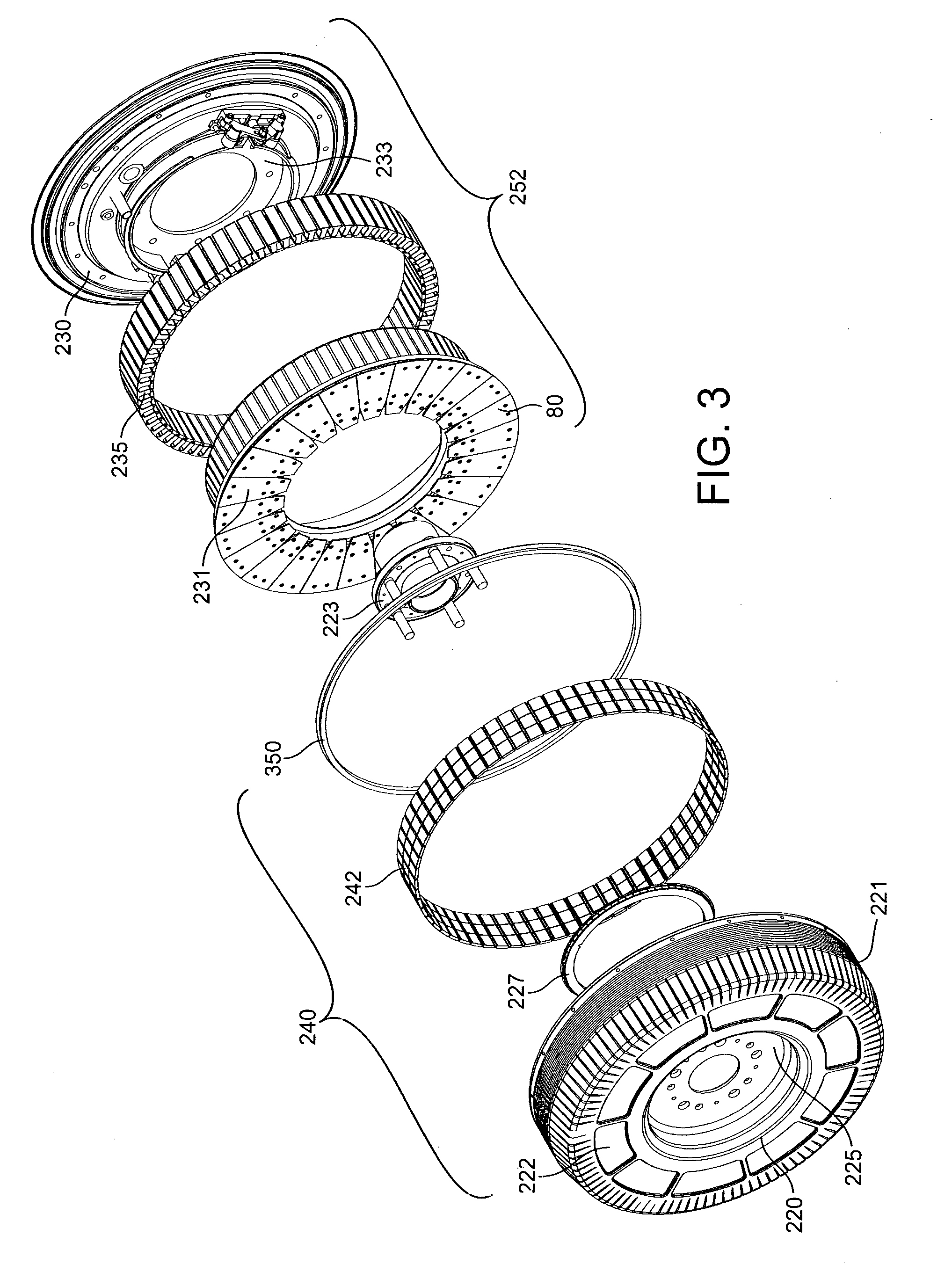

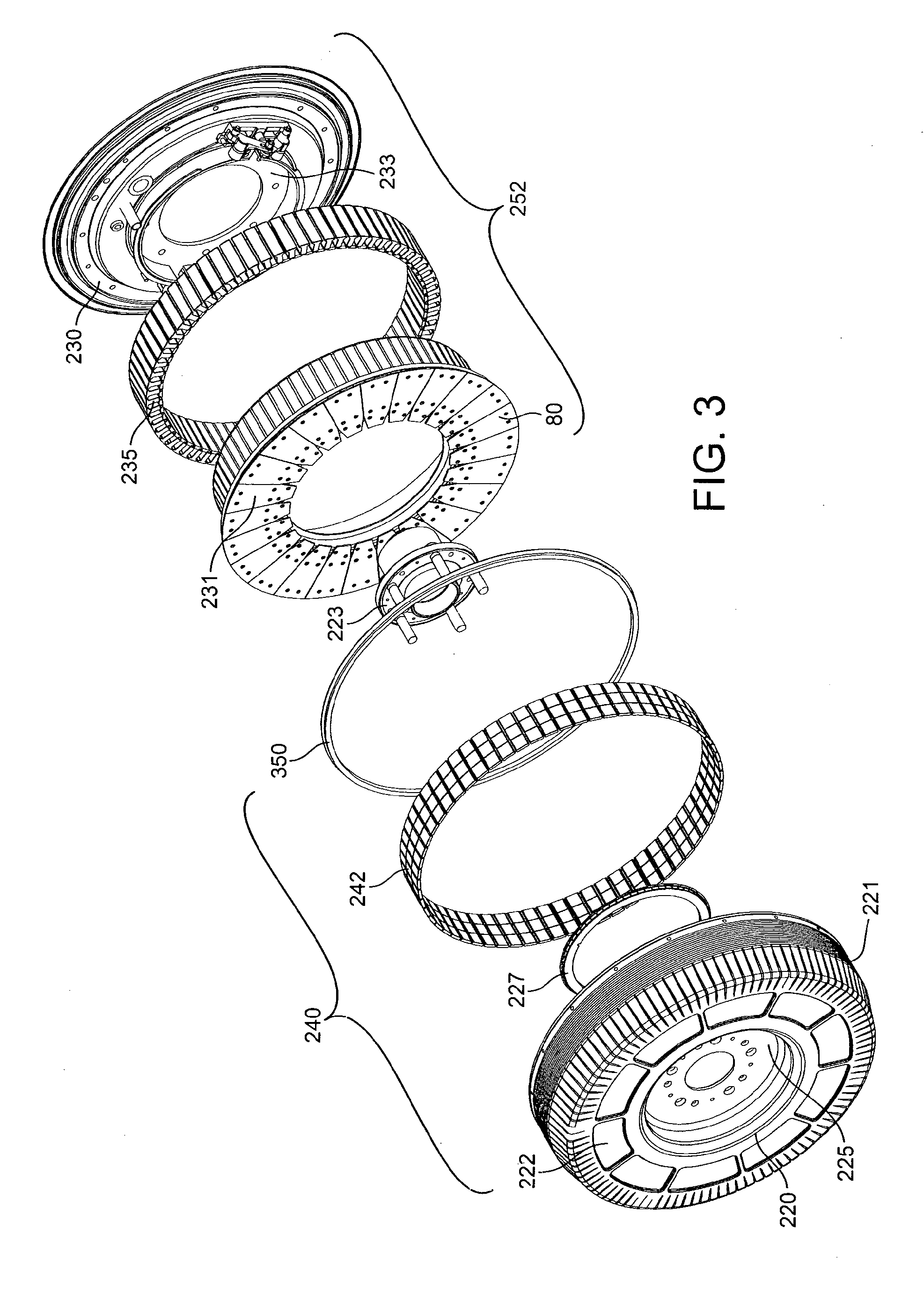

ActiveUS20100138127A1Increase inductanceEasy to controlSingle motor speed/torque controlMagnetic circuitControl systemTraction control system

An electric motor includes one or more separate coil sets arranged to produce a magnetic field of the motor. The electric motor also includes a plurality of control devices coupled to respective sub-sets of coils for current control. A similar arrangement is proposed for a generator. A coil mounting system for an electric motor or generator includes one or more coil teeth for windably receiving a coil for the motor and a back portion for attachably receiving a plurality of the coil teeth. A traction control system and method for a vehicle having a plurality of wheels independently powered by a respective motor. A suspension control system and method for a vehicle having a plurality of wheels, each wheel being mounted on a suspension arm of the vehicle and being independently powered by a respective motor.

Owner:PROTEAN ELECTRIC LIMITED

Insulating paint for variable frequency motor and preparation method thereof

ActiveCN101892006AImprove electrical strengthGood chemical resistanceChemical industryEpoxy resin coatingsChemistryChemical stability

The invention relates to an insulating paint for a variable frequency motor and a preparation method thereof. The insulating paint comprises the main components: unsaturated polyester resin, epoxy resin, cross-linking monomer, initiator, acid anhydride curing agent, polymerization inhibitor and filler. The preparation method comprises the steps of: preparing materials according to the components in part by weight, mixing base materials uniformly for later use, treating the filler and mixing and treating the base materials and the filler. The invention has the advantages that: the insulating paint is suitable for the variable frequency motor, in particular a high-power variable frequency motor; an insulating paint film has excellent mechanical property, good compatibility with electromagnetic wires, long pulse-resistant time, high electrical strength, low dielectric loss, good chemical stability resistance and high heat conductivity; and the preparation method for the insulating paint can ensure the quality of the produced insulating paint for the variable frequency motor.

Owner:武汉长海电力推进和化学电源有限公司

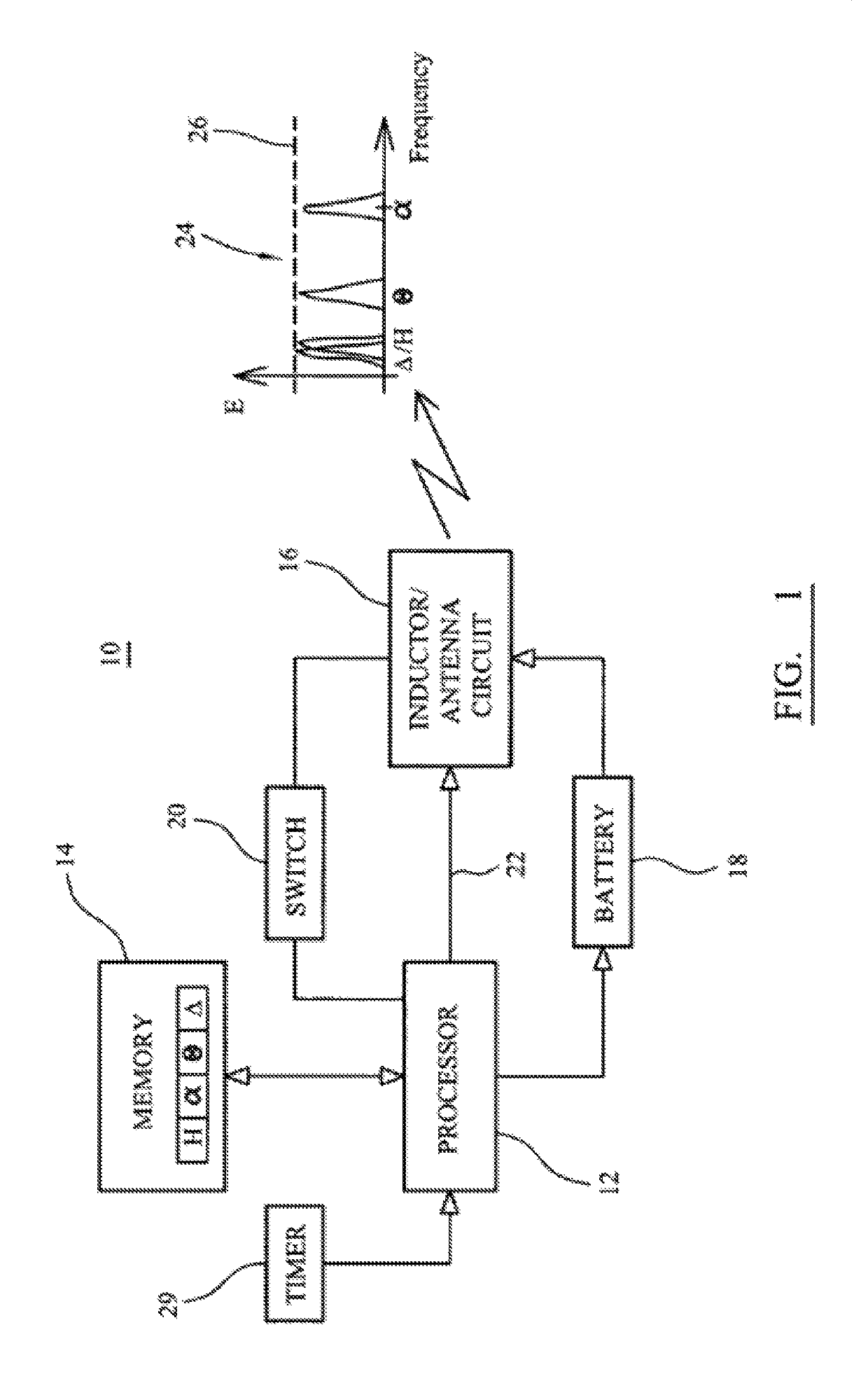

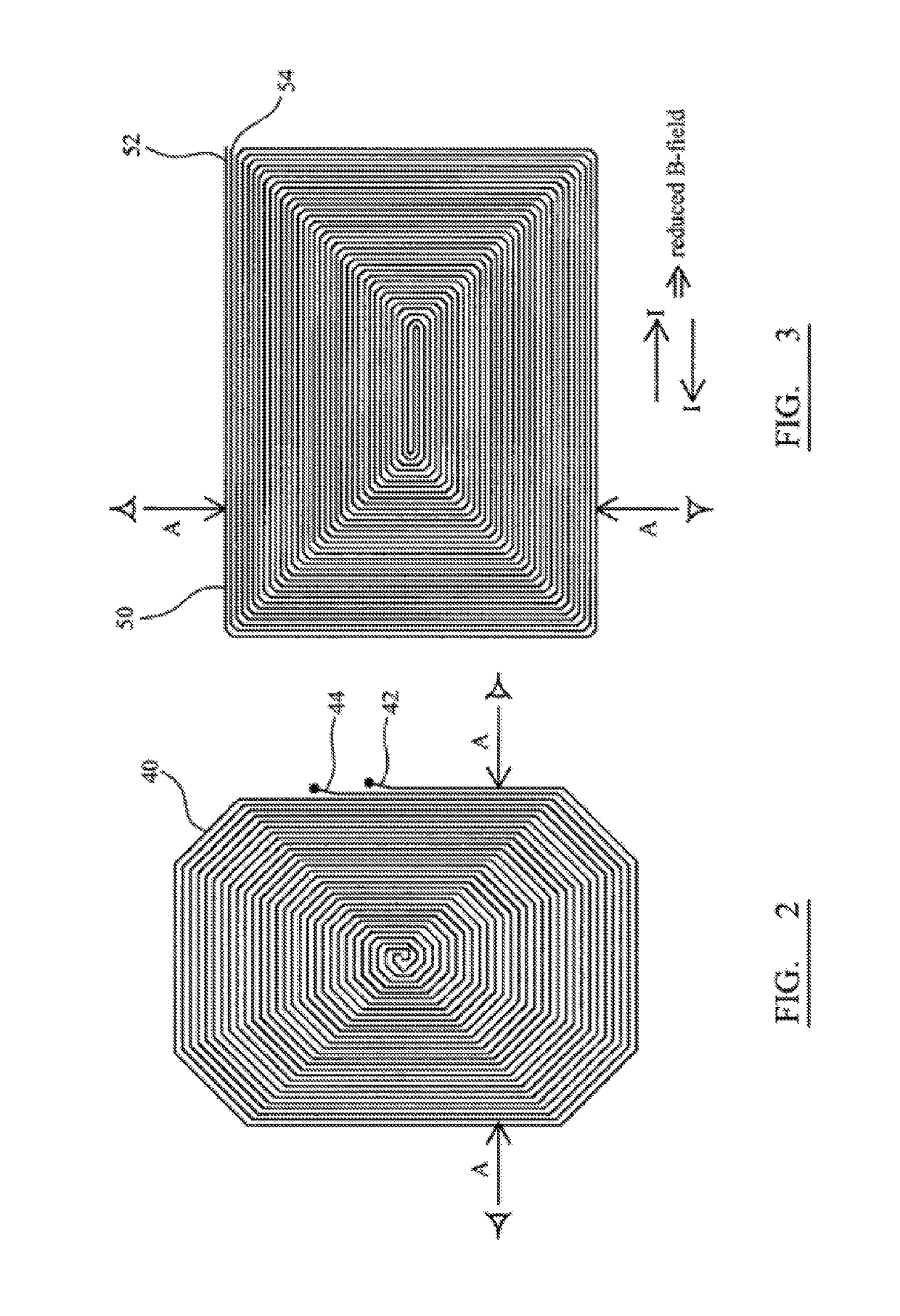

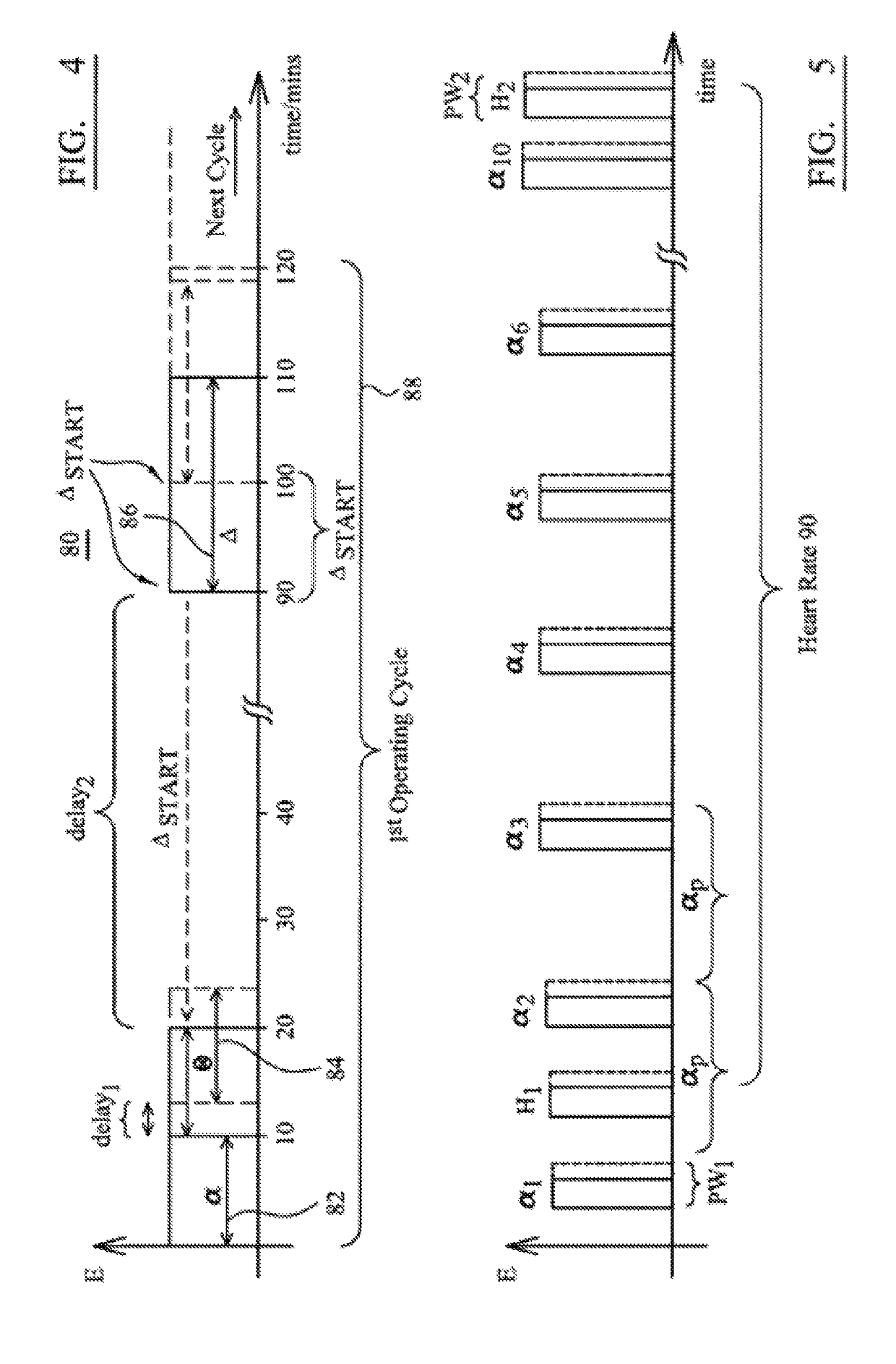

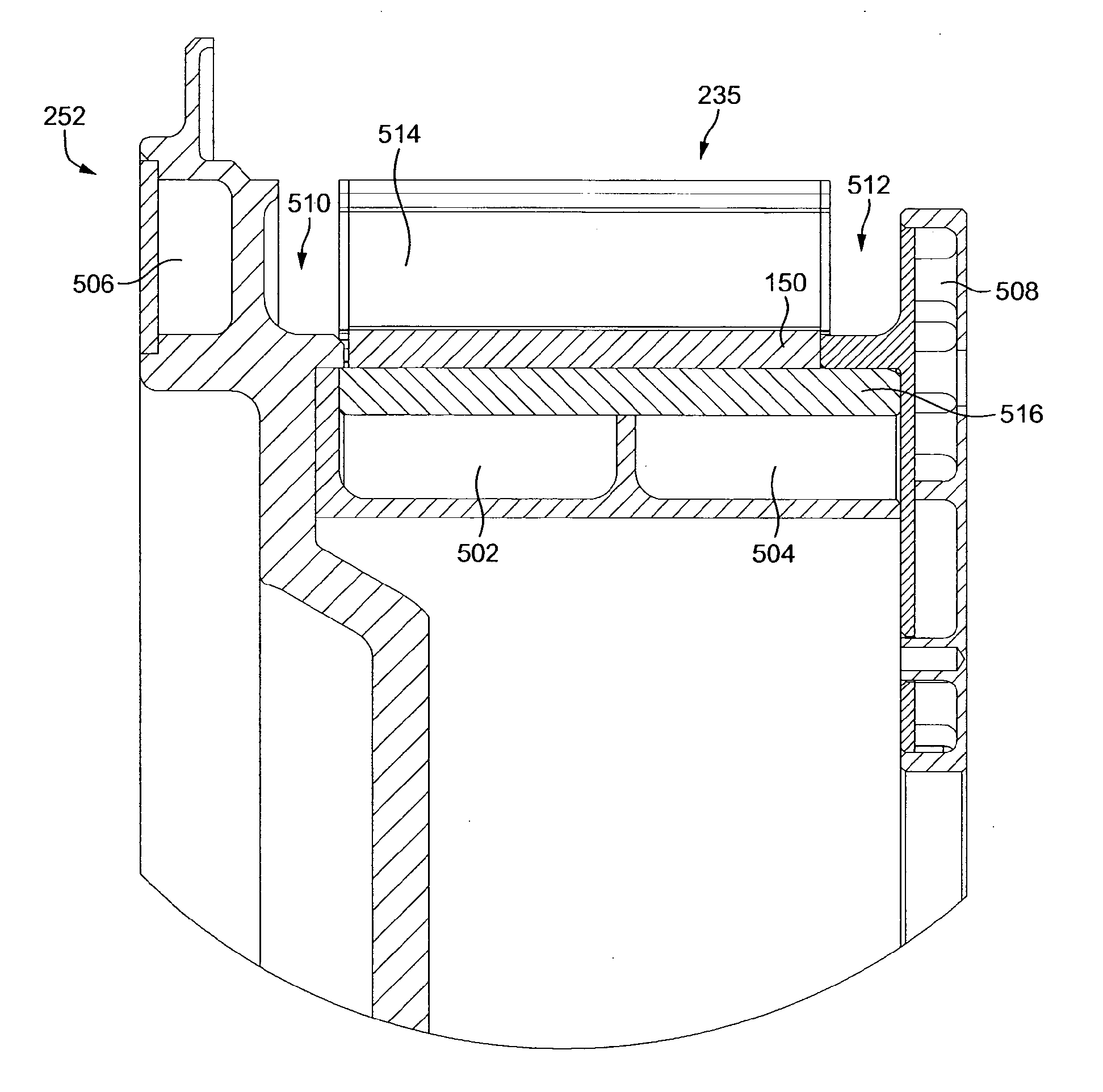

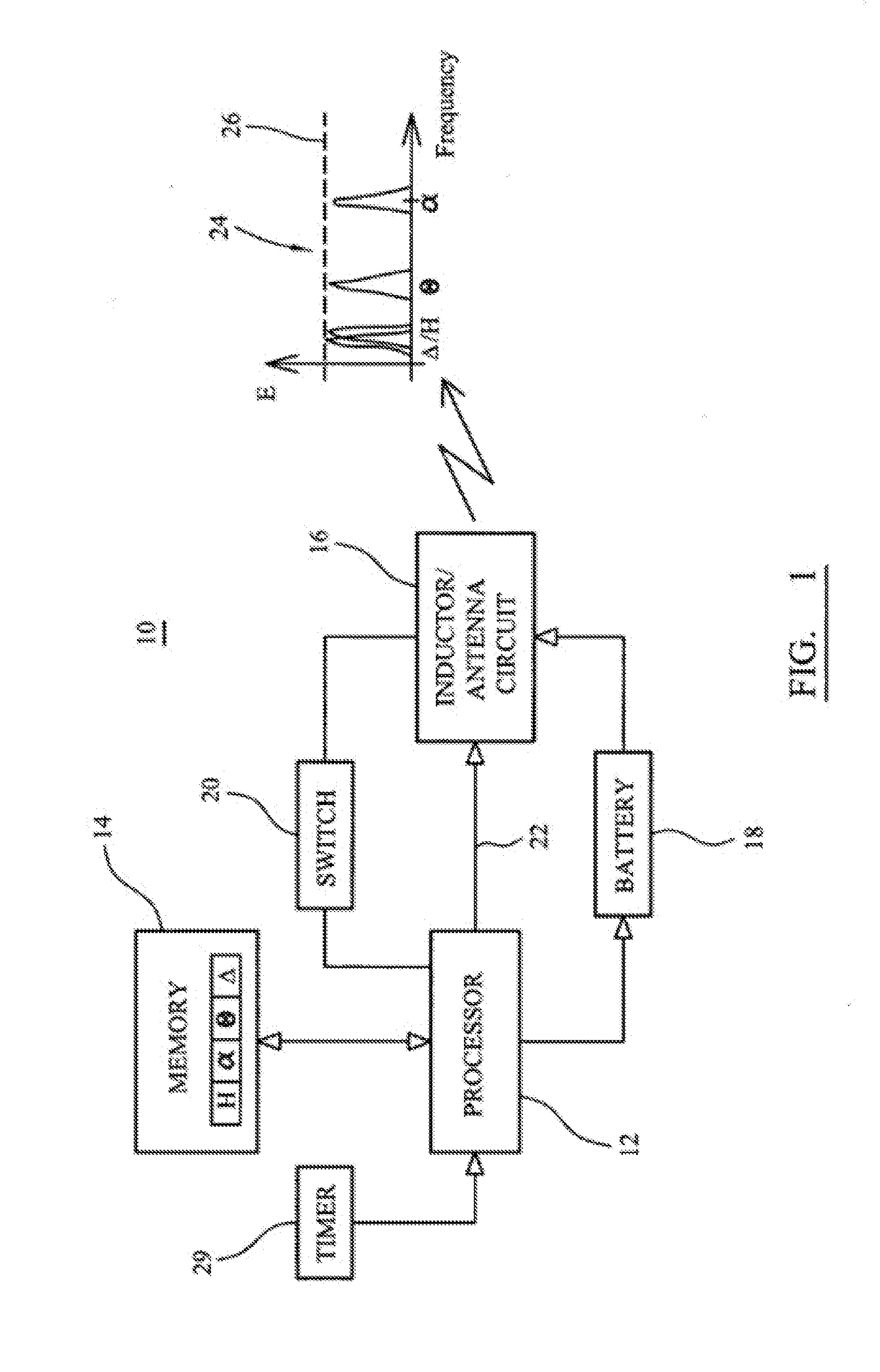

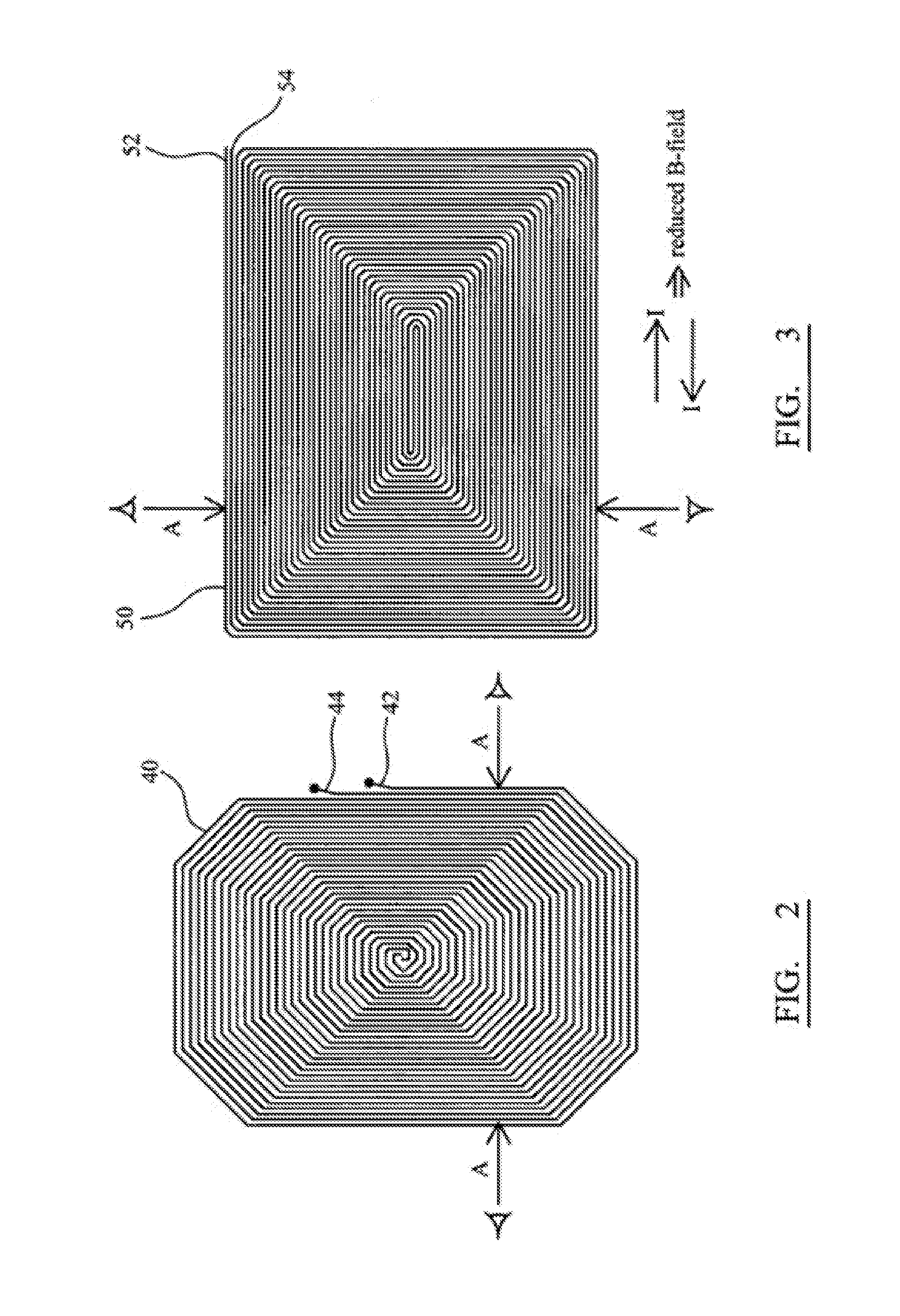

Therapeutic field generator device and method

ActiveUS10478588B2Improve electrical strengthReducing the magnetic field generatedElectrotherapyMagnetotherapy using coils/electromagnetsEngineeringOperation mode

Owner:ZEEZ TECH

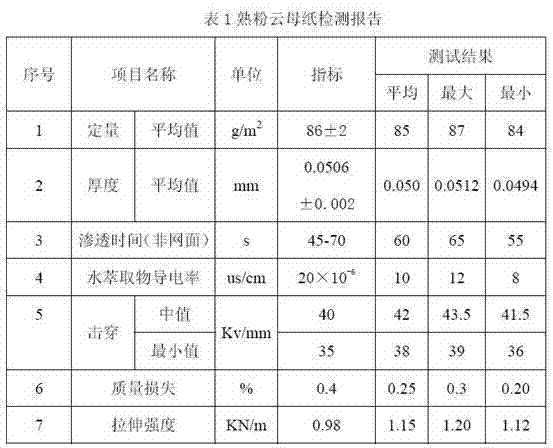

Manufacturing method of ultra-high voltage insulation cooked mica paper

InactiveCN102127882AImprove electrical strengthHigh tensile strengthPlastic/resin/waxes insulatorsUltra high voltagePulp and paper industry

The invention discloses a manufacturing method of ultra-high voltage insulation cooked mica paper, and aims to solve the problem that the mica paper prepared by the existing raw powder technique is not applicable to large-size power equipment. The method disclosed by the invention comprises the following steps: screening the mica raw material, calcining at high temperature, screening, dipping, making cooked mica pulp, manufacturing paper with the pulp, drying and the like. The mica paper produced by the method disclosed by the invention has the characteristics of high electric strength and high tensile strength.

Owner:HANGZHOU KAIER MICA PROD

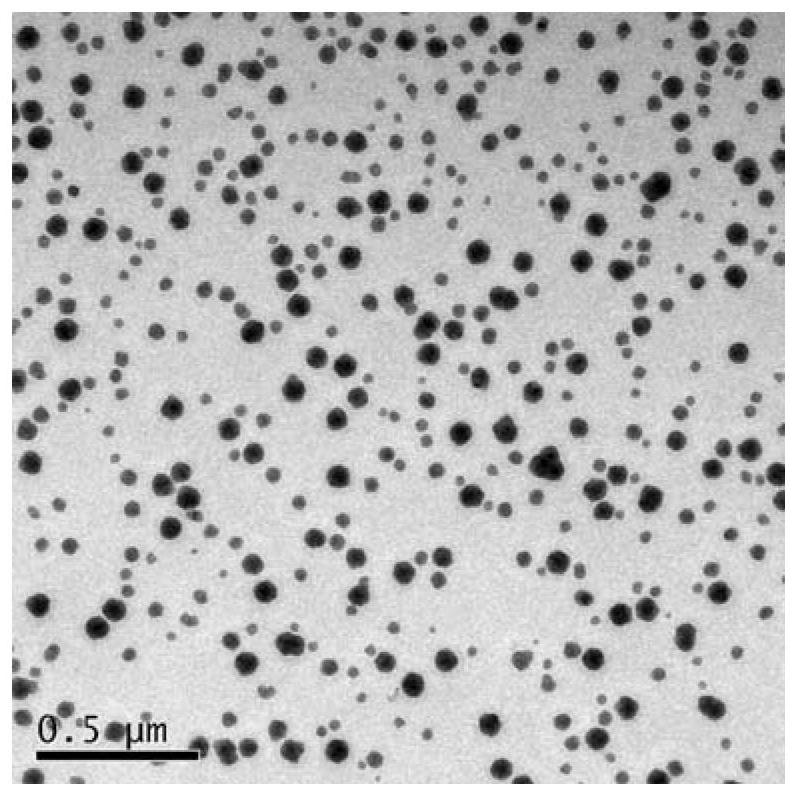

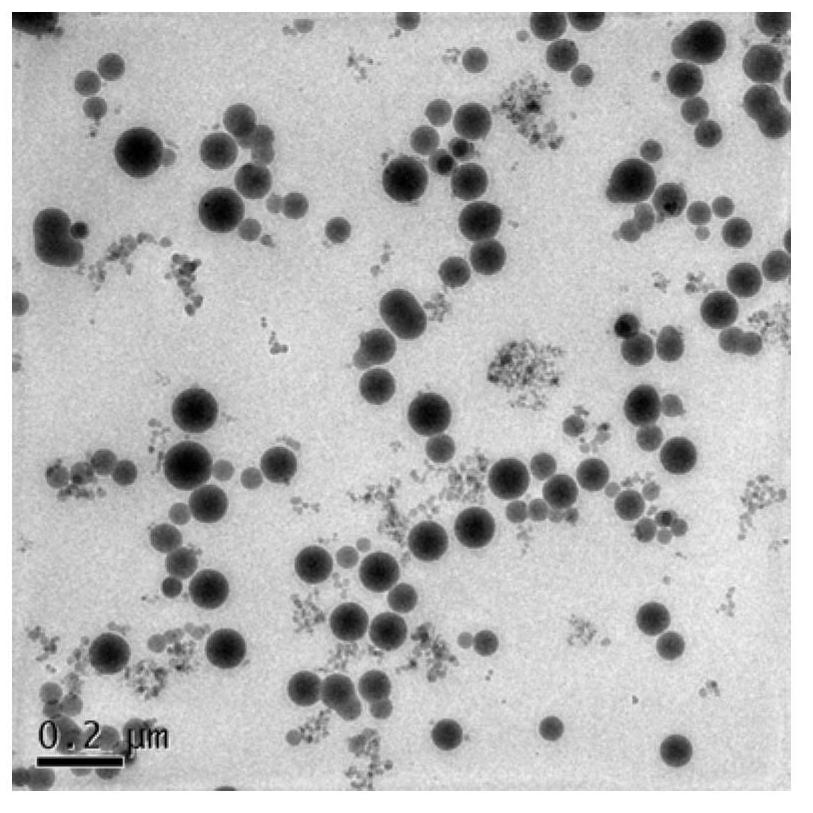

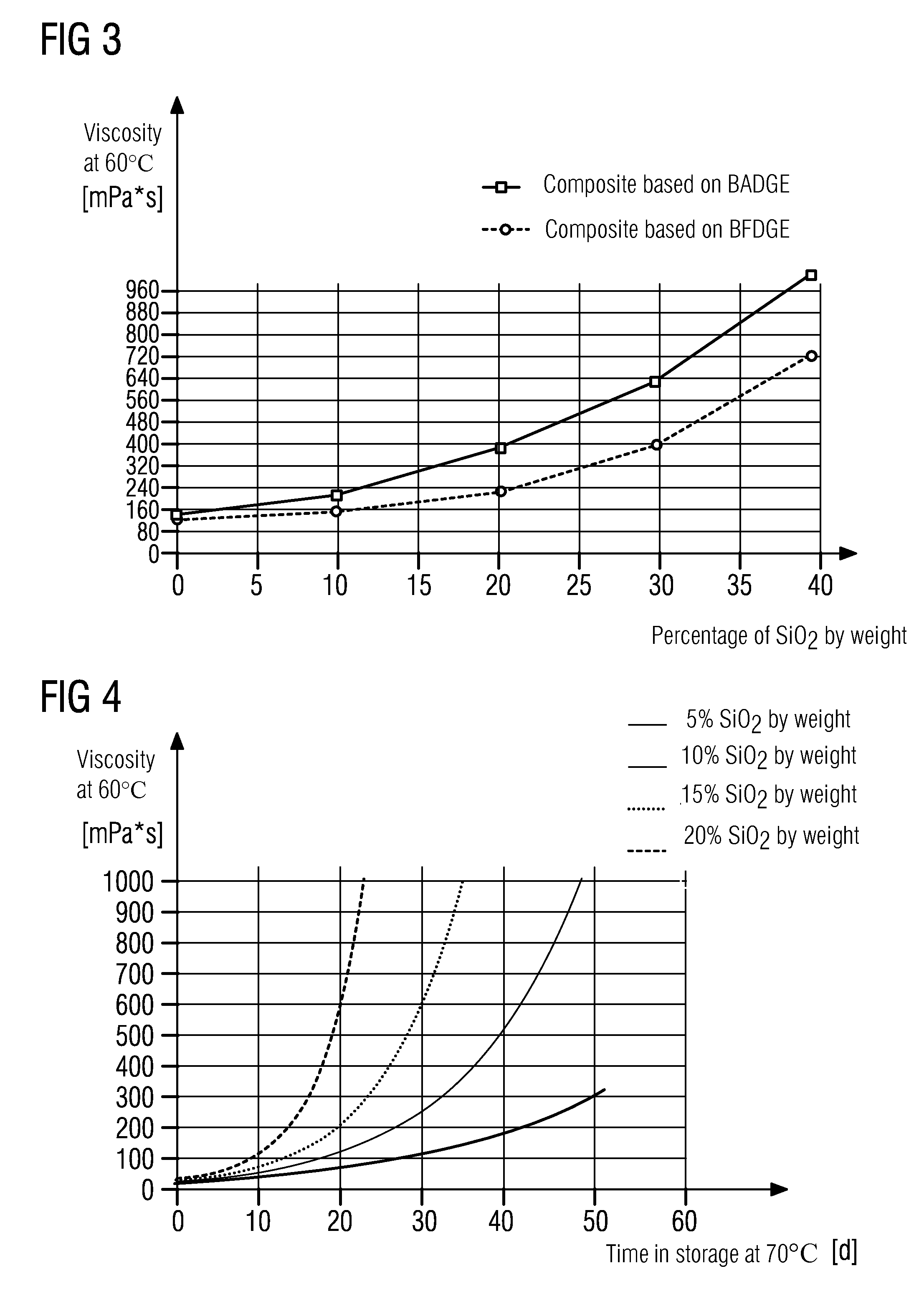

Nano modified epoxy vacuum pressure impregnation resin and preparation method thereof

ActiveCN102690496AImproved low temperature mechanical propertiesImprove thermal conductivityChemical industryEpoxy resin coatingsDefoaming AgentsMaterials science

The invention relates to a nano modified epoxy vacuum pressure impregnation resin, which comprises the following components in percentage by weight: 36 to 45 percent of bisphenol A epoxy resin, 5 to 20 percent of low-viscosity epoxy active diluent with the viscosity of 3-200mps, 40 to 50 percent of liquid anhydride, 1 to 8 percent of nanopowder with the grain size of 1-100nm, 0.2 to 2 percent of dispersing agent, 0.1 to 2 percent of silane coupling agent, and 0.1 to 1 percent of defoaming agent. Compared with the common epoxy vacuum pressure impregnation resin, the nano modified epoxy vacuum pressure impregnation resin has the advantages that the thermal conductivity and corona resistant performance are obviously improved, the heat resistance and electric strength are improved and the nano modified epoxy vacuum pressure impregnation resin can meet requirements in the fields such as high-power variable frequency motors and low temperature superconducting motors.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

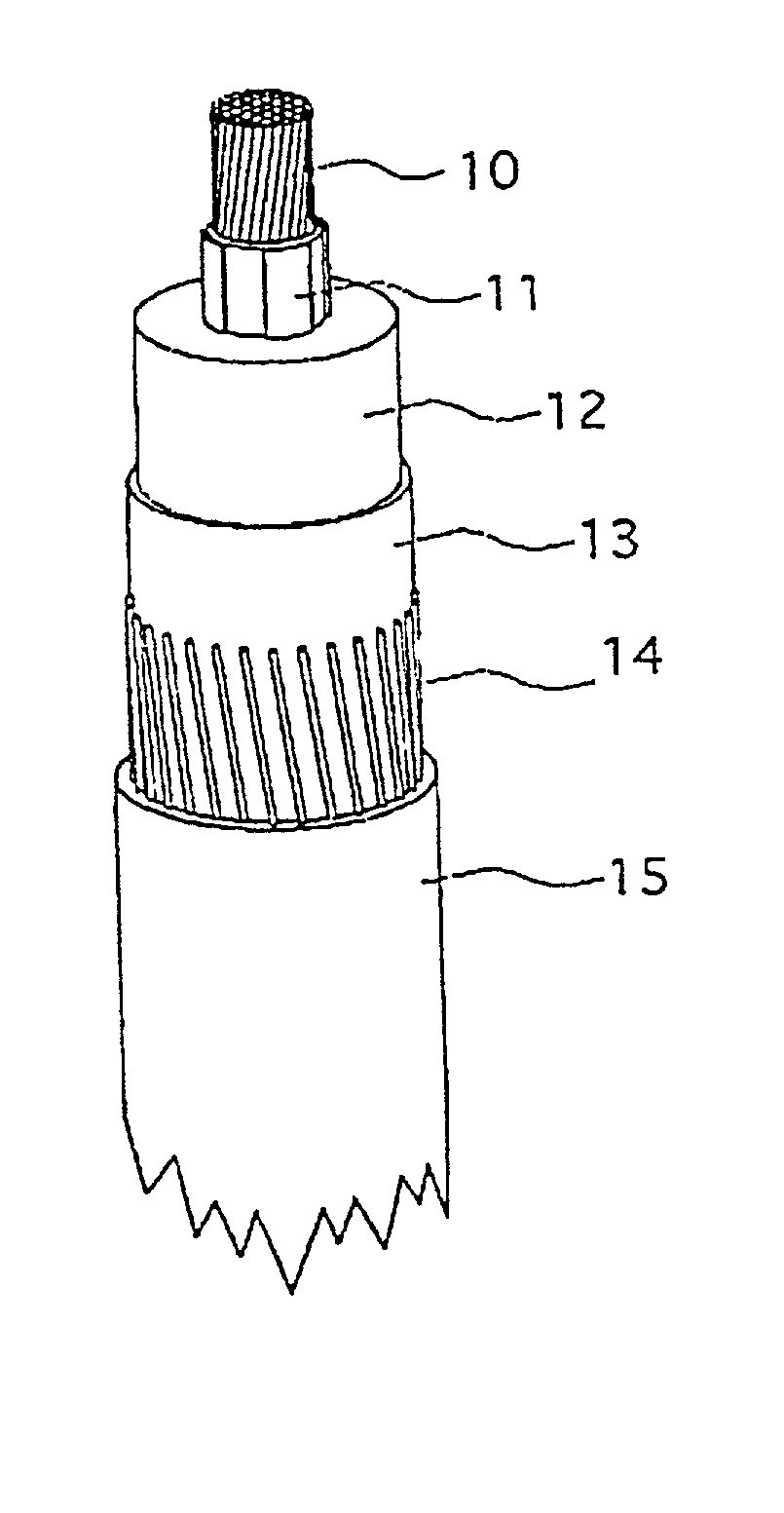

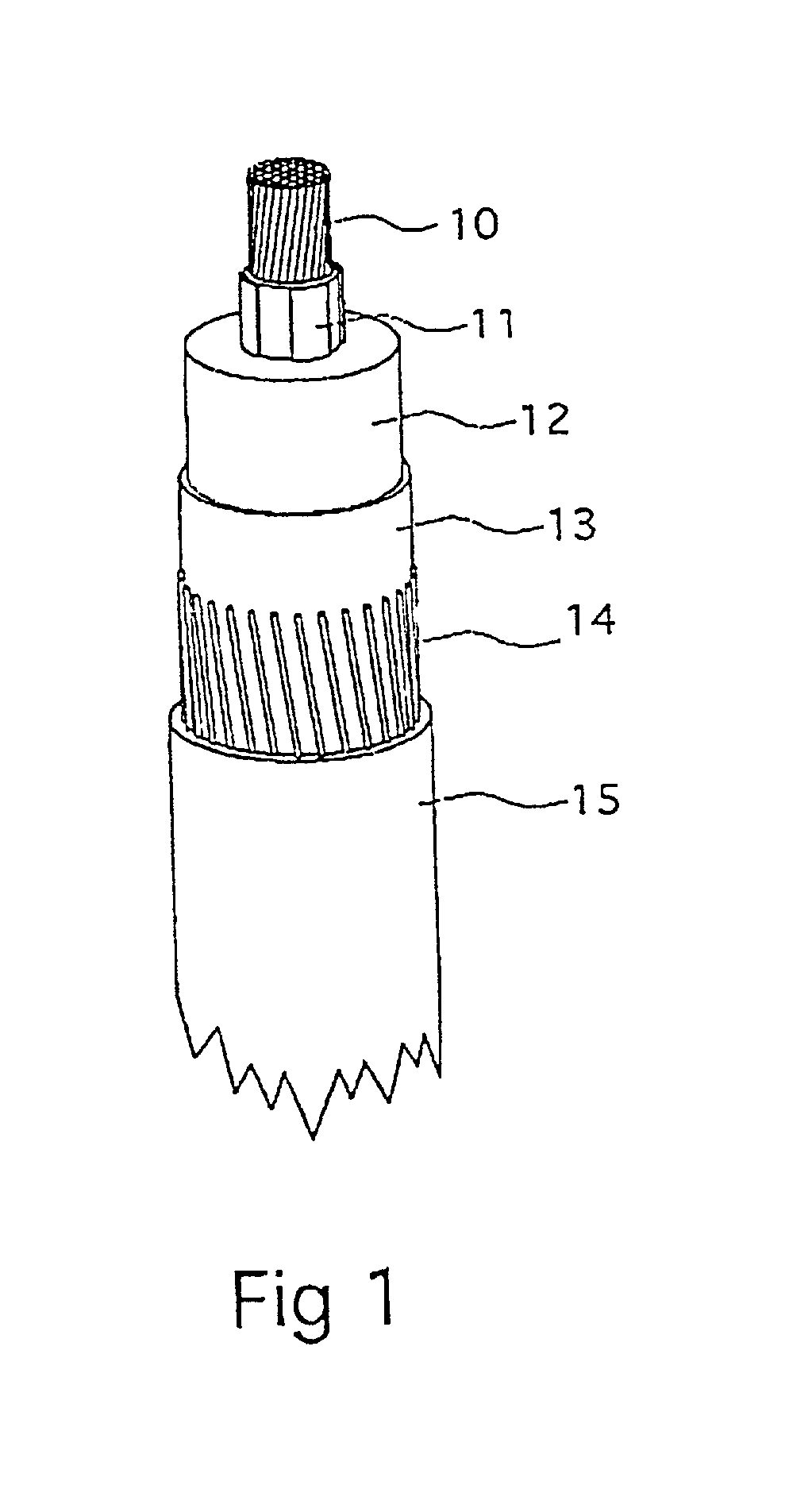

Electric DC-cable with an insulation system

InactiveUS20020039654A1Shorten production timeLow production costPlastic/resin/waxes insulatorsYarnCross-linkElectrical conductor

An insulated DC-cable and method for production of an insulated DC-cable with an insulating system comprising an extruded cross-linked polyethylene based insulation disposed around the conductor. The extruded polyethylene based compound comprises additives such as cross-linking agent, scorch retarding agent and antioxidant. The scorch retarding agent comprises a compound (D), 2,4-diphenyl-4-methyl-pentene-1 and the antioxidant comprises a compound (C), a diester of 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionicacid and thiodiglycol. The compounded polyethylene based resin composition is extruded and cross-linked at a temperature and for a period of time sufficient enough to cross link the insulation. The temperature and the period of time upon extrusion and cross-linking are limited so as to substantially suppress or essentially avoid undesired polar by-products being formed in the cross-linked composition.

Owner:GUSTAFSSON BILL +7

Electric Motors

ActiveUS20130049498A1Increase inductanceEasy to controlSingle motor speed/torque controlRailway vehiclesPower flowControl system

An electric motor includes one or more separate coil sets arranged to produce a magnetic field of the motor. The electric motor also includes a plurality of control devices coupled to respective sub-sets of coils for current control. A similar arrangement is proposed for a generator. A coil mounting system for an electric motor or generator includes one or more coil teeth for windably receiving a coil for the motor and a back portion for attachably receiving a plurality of the coil teeth. A traction control system and method for a vehicle having a plurality of wheels independently powered by a respective motor. A suspension control system and method for a vehicle having a plurality of wheels, each wheel being mounted on a suspension arm of the vehicle and being independently powered by a respective motor.

Owner:PROTEAN ELECTRIC LIMITED

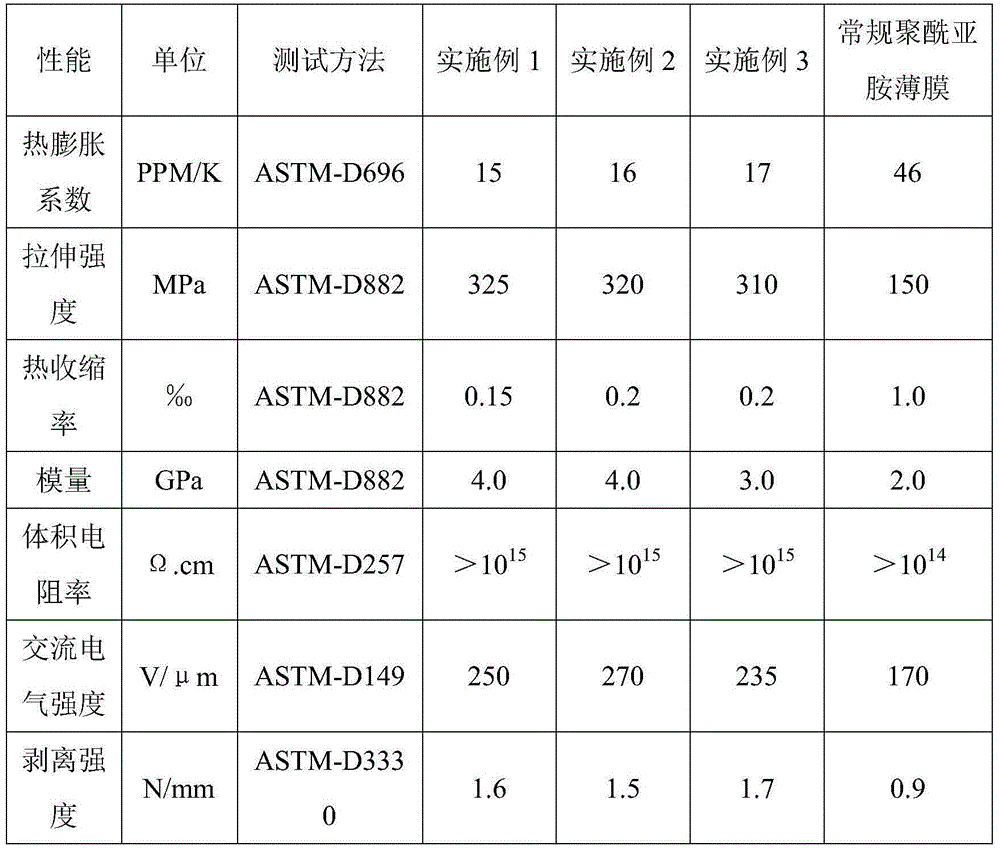

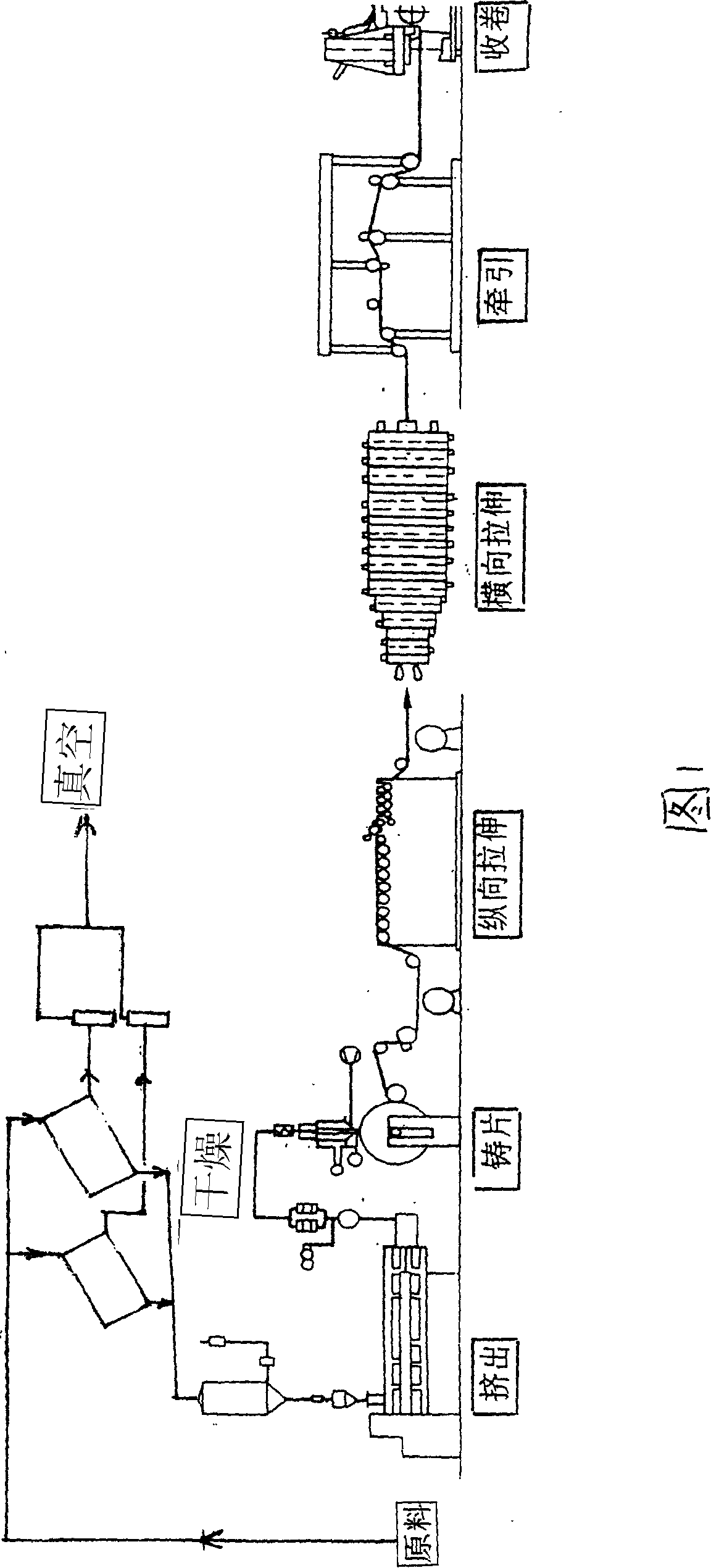

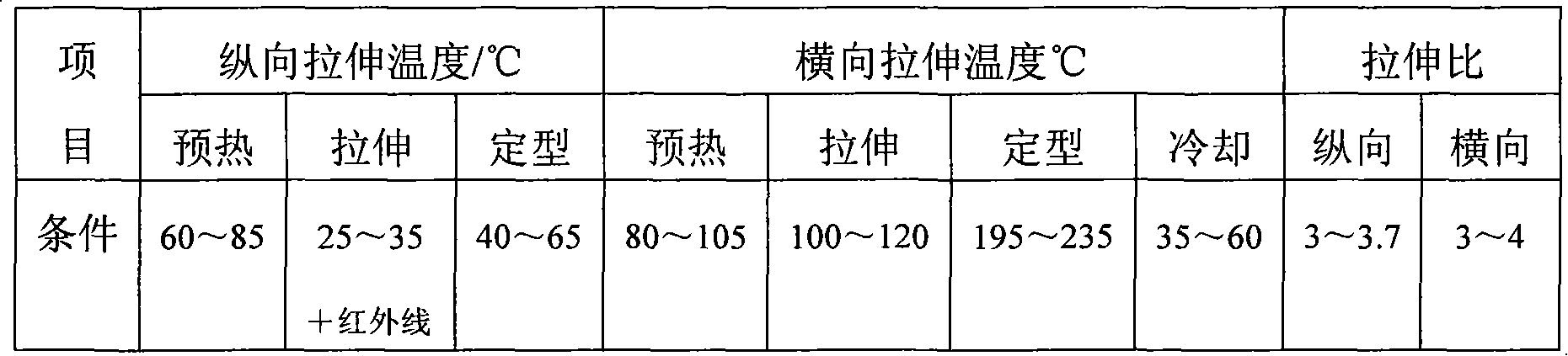

Preparation method for polymide film with low thermal expansion coefficient

The invention provides a preparation method for a polymide film with the low thermal expansion coefficient. The method comprises the following steps that 1, pyromellitic anhydride and ursol are placed into a dimethylacetamide solvent for condensation polymerization to obtain a polyamide acid glue solution A; 2, 2, 3',3,4'- biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether are placed into the dimethylacetamide solvent for condensation polymerization to obtain a polyamide acid glue solution B; 3, the polyamide acid glue solution A and the polyamide acid glue solution B are mixed for a high-speed stirring reaction to obtain a polyamide acid glue solution C; 4, the tape casting technology is adopted on the polyamide acid glue solution C to obtain a film, and finally the film is fed into an imidization furnace to be processed to obtain the polymide film with the low thermal expansion coefficient. The CTE of the polymide film with the low thermal expansion coefficient is 15-17 ppm / K, and the polymide film further has the advantages of being high in strength, stability, electrical strength and the like.

Owner:安徽统唯新材料科技股份有限公司

Full-dull colorful insulation polyester film and production technology thereof

The invention relates to a full-dull colorful insulation polyester membrane, which is prepared by matt film polyester chips, color master batches, and master batches containing silicon oxide, while the three materials are mass rationed as 20-30 accounts of matt film polyester chip, 2-6 accounts of color master batches, and 2-6 accounts of the master batches containing silicon oxide. The invention has the advantages that 1, the product is hard to lose color and be polluted in the insulation applications as electron, wire and electric fields, the membrane is easily to be sliced, with high electric strength and good insulation, 2, the membrane has flat and smooth surface, 3, the invention can prepare insulation polyester membranes with different colors.

Owner:TIANJIN SHIQI TECH DEV

Insulation for rotating electrical machines

InactiveUS20130131218A1Increase heightExtended service lifePlastic/resin/waxes insulatorsNanoparticleElectric machinery

A mica-based insulation based on impregnating resin for rotating electrical machines is provided. The mica-based impregnating resin includes an epoxy resin / anhydride mixture and a nanoparticulate filler, wherein the nanoparticulate filler is a nanoparticulate silicon dioxide and / or aluminum oxide modified by a silanizing reagent. Further, a method of producing the mica-based impregnating resin is provided.

Owner:SIEMENS AG

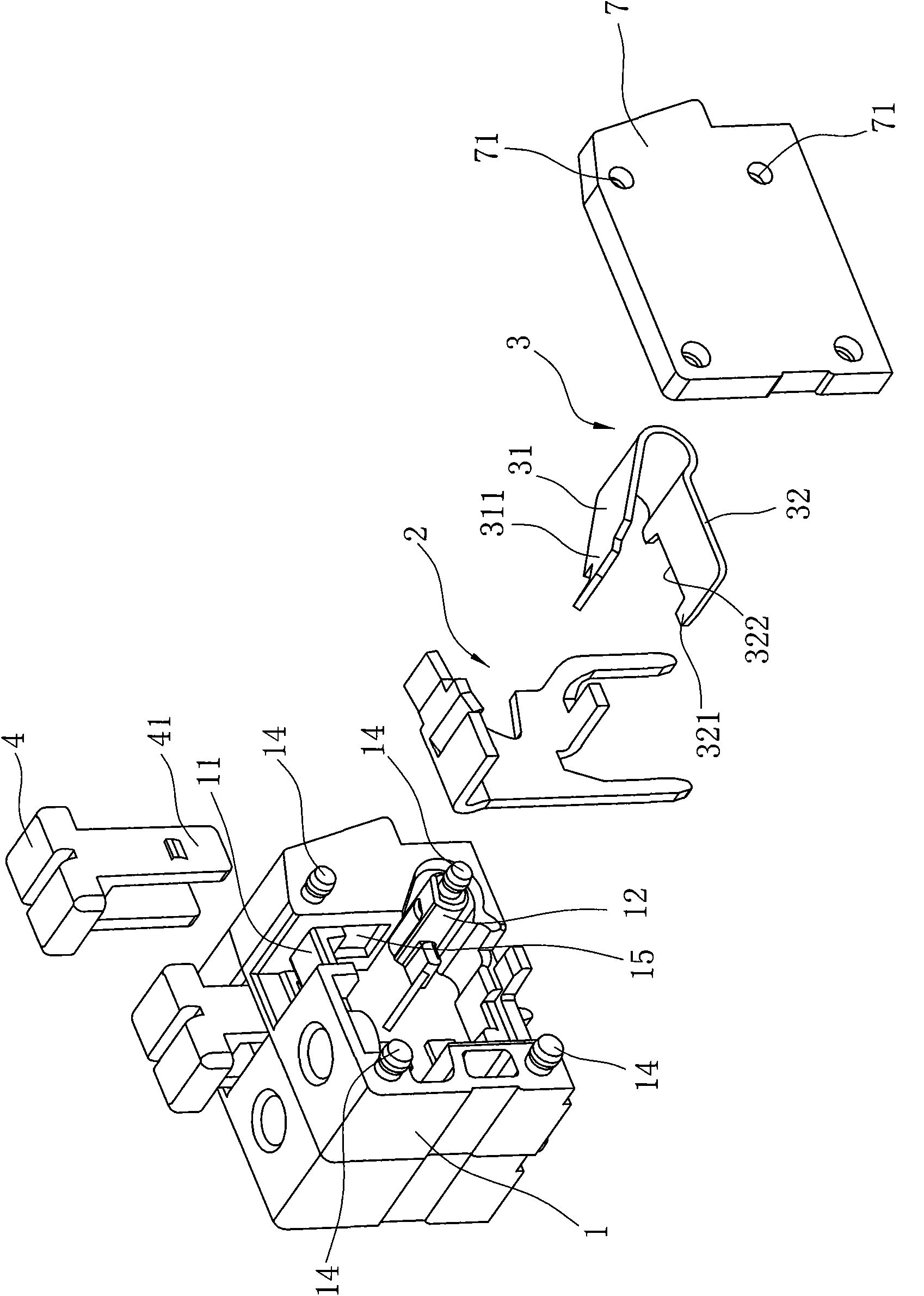

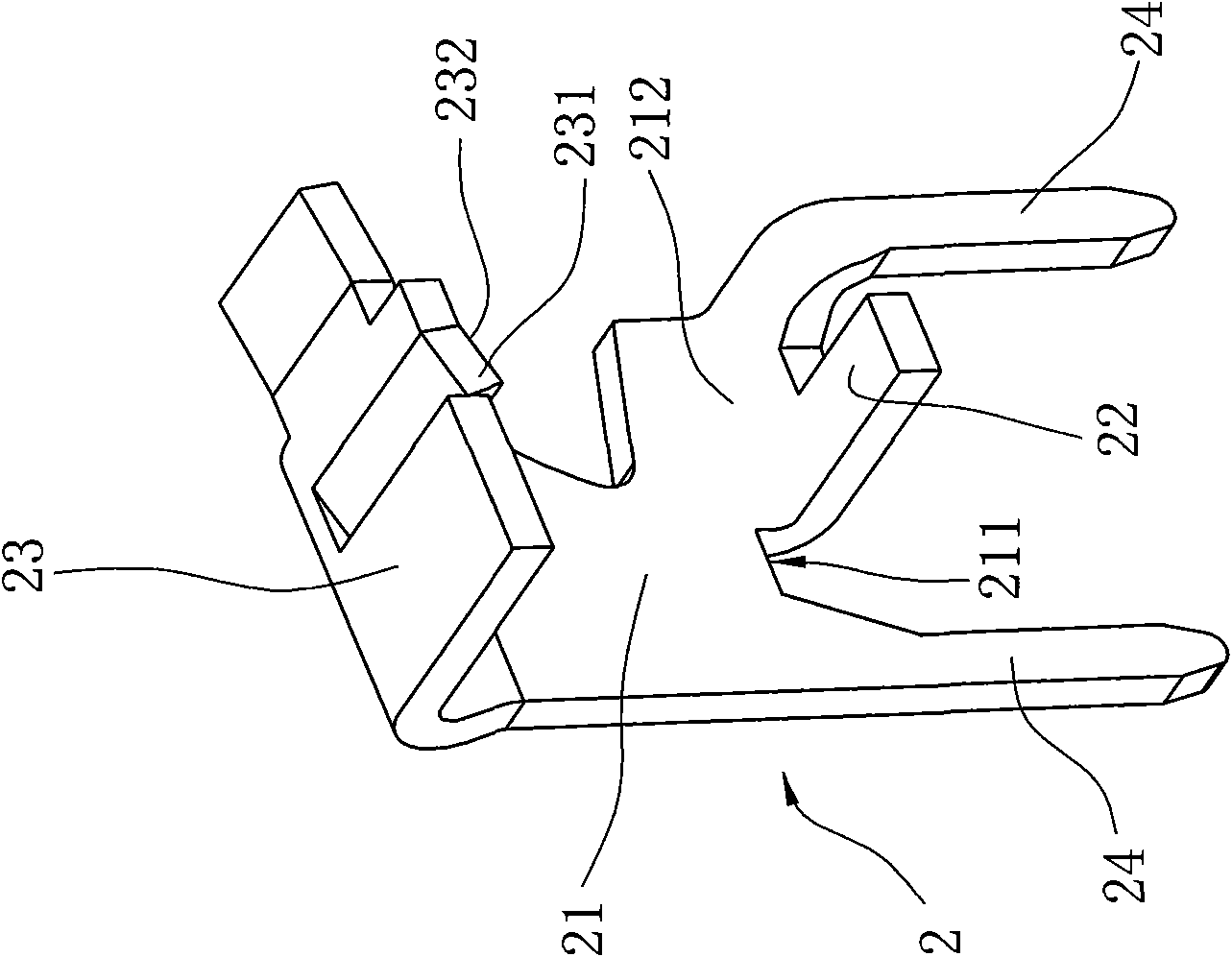

Electric connector

ActiveCN101562282AIncreased current carrying areaImprove conductivityCoupling device connectionsContact member manufacturingElectricityState of art

The invention provides an electric connector. The electric connector comprises an insulating base, a solder terminal fixedly arranged in the insulating base and an elastic plate comprising a free end and a fixed end, wherein the free end always keeps the trend of pressing against the solder terminal; the fixed end is fixedly connected with the solder terminal; and the bottom end of a button connected with the upper part of the base is pressed against the free end of the elastic plate. The electric connector is characterized in that the solder terminal comprises a current carrying main board, and a support plate pressed against the bottom of the fixed end extends out of the lower part of the current carrying main board and the upper edge of the current carrying main board is bended outwards to form a capped edge pressed against the top of the free end; the current carrying main board, the support plate and the capped edge of the solder terminal form a C-shaped cross section; and the bottom of the solder terminal is also provided with two solder legs which are one-piece formed, arranged on both sides of the support plate respectively and staggered front and back. Compared with the prior art, the electric connector has the advantages that the current carrying area of the solder terminal is larger, and the conductivity of the solder terminal is improved; and because the solder legs are staggered front and back, the creepage distance is increased, the withstand voltage value of the electric connector is improved, and the electric strength of the product is further improved.

Owner:NINGBO DEGSON ELECTRONICS CO LTD

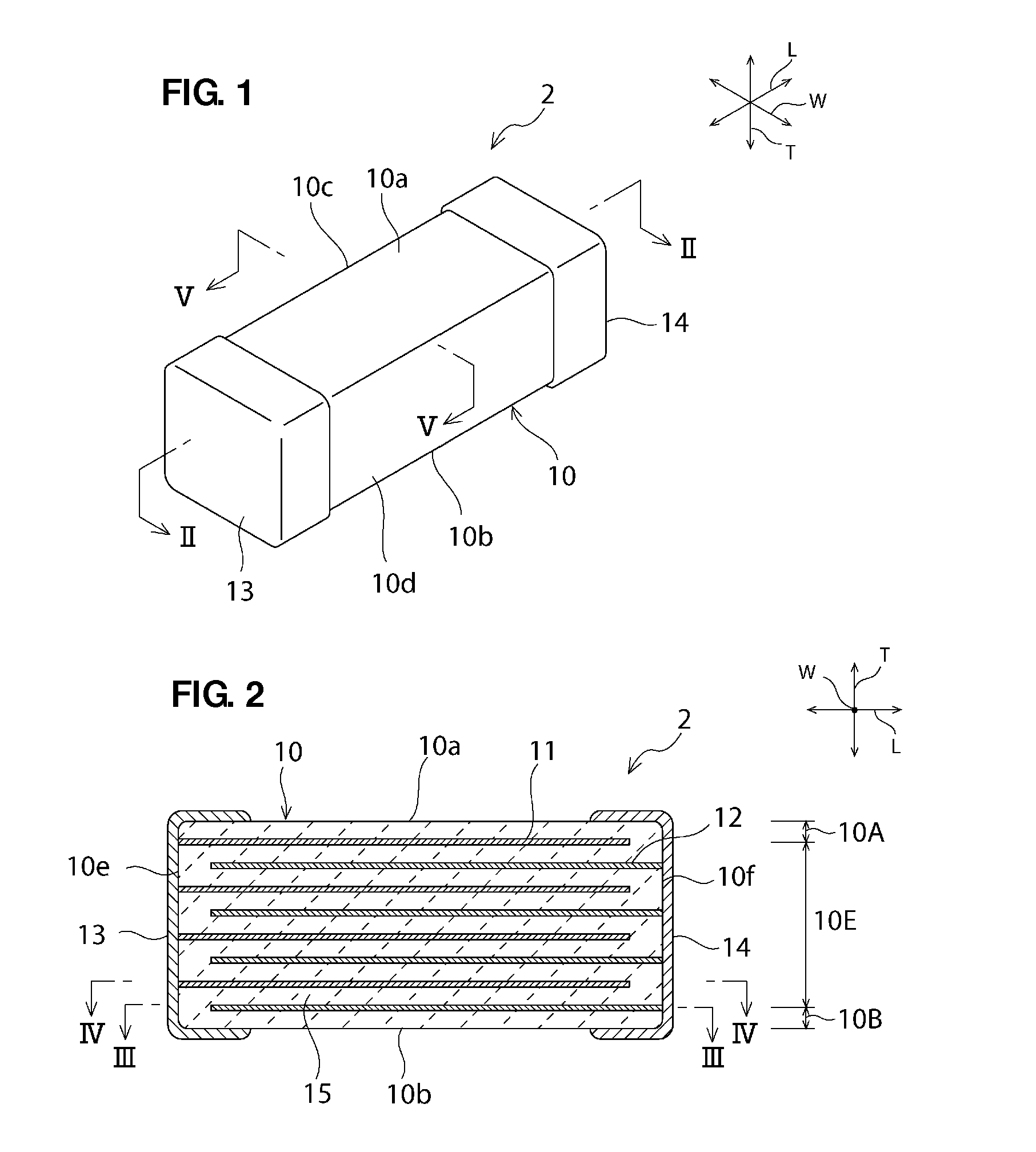

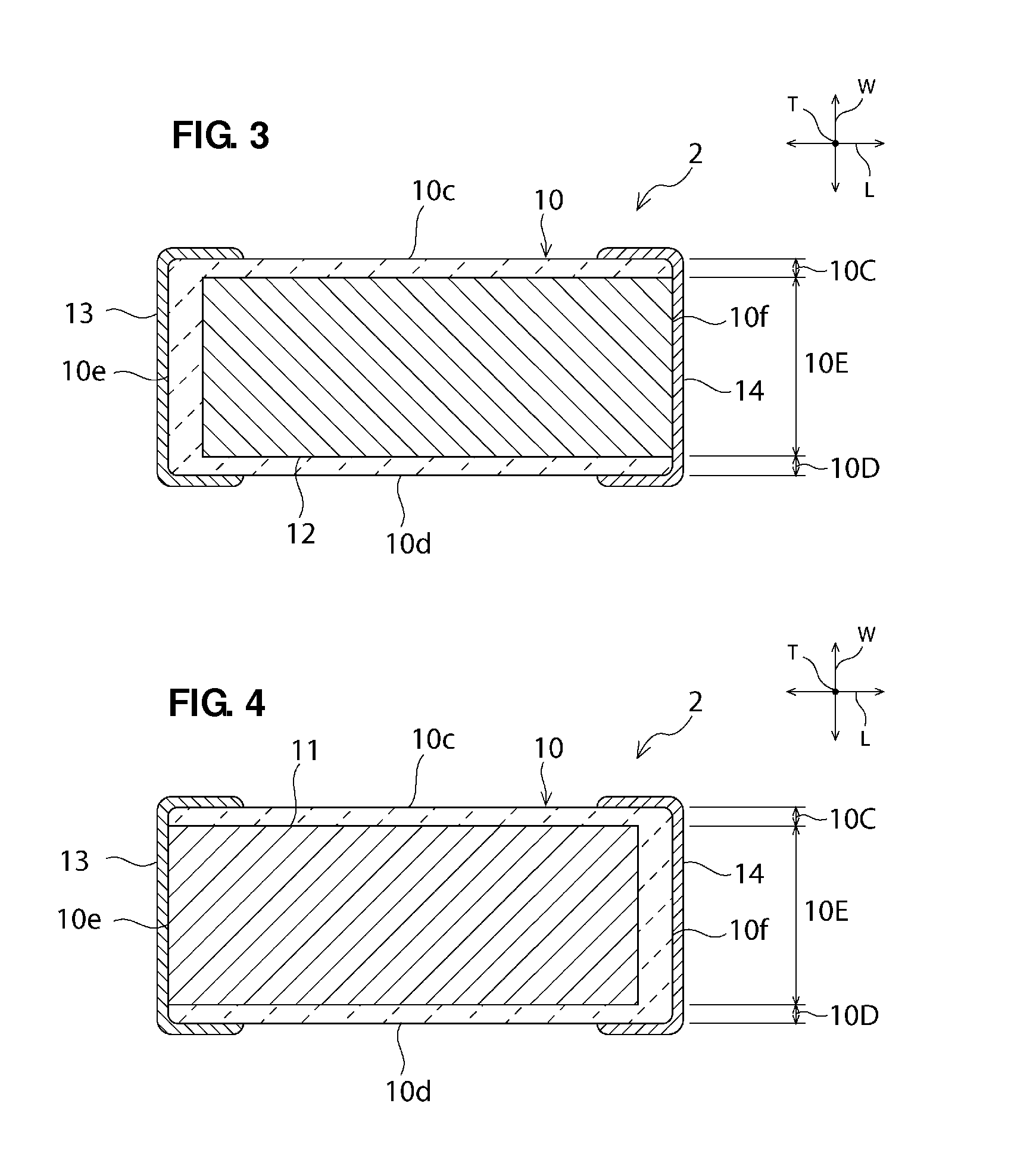

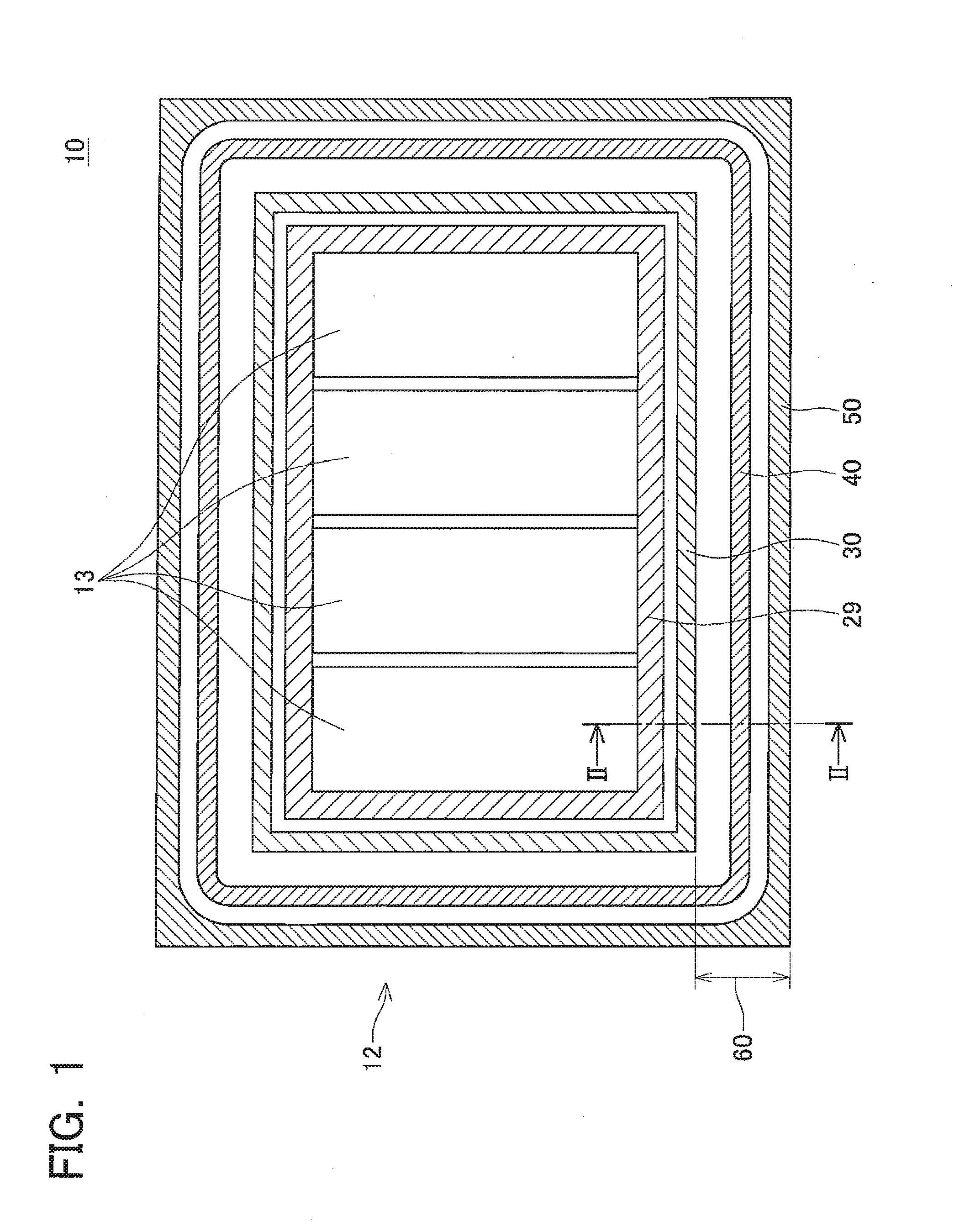

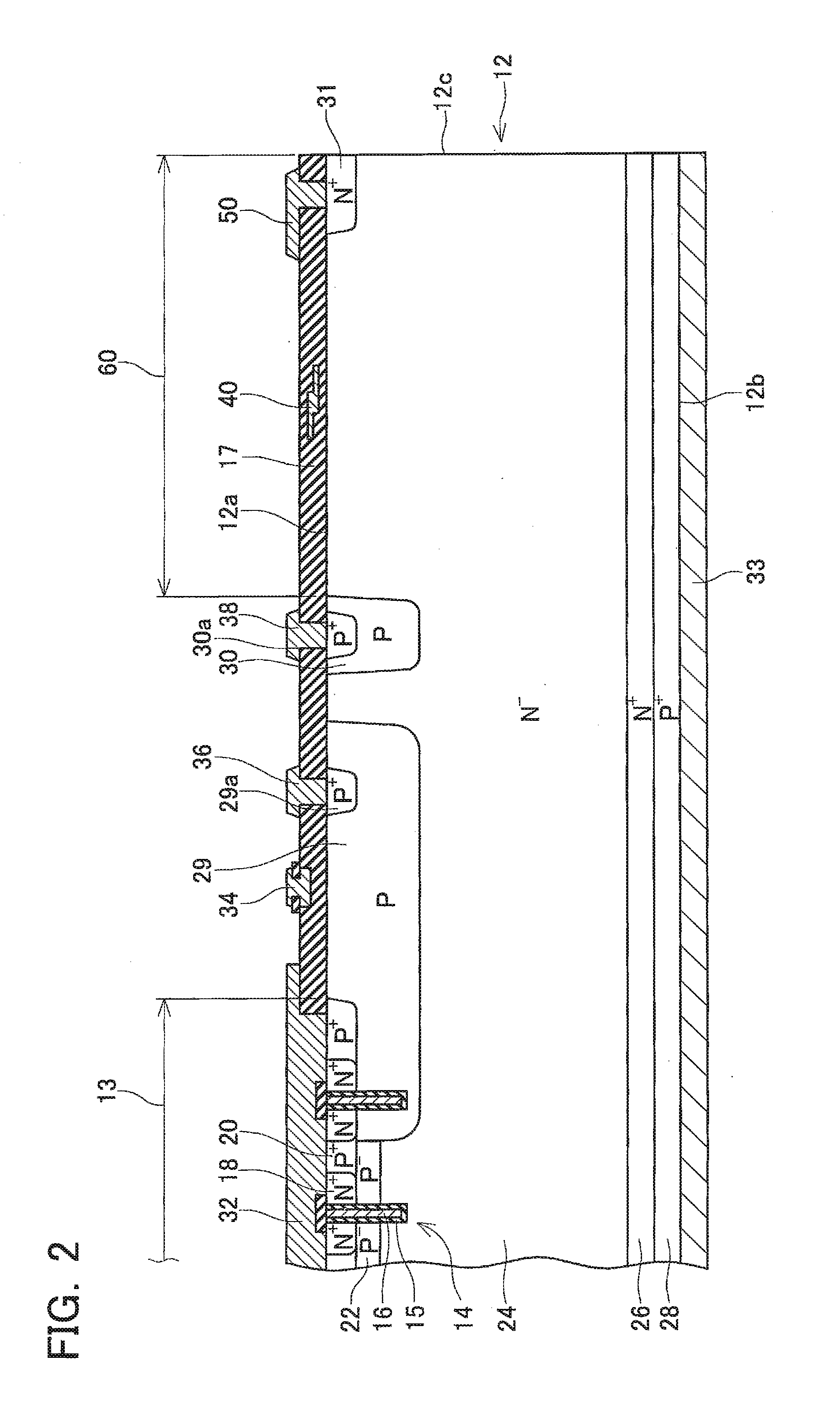

Multilayer ceramic electronic component

ActiveUS20120250220A1Improve electrical strengthDifference in levelFixed capacitor electrodesFixed capacitor dielectricElectronic componentUltimate tensile strength

A multilayer ceramic electronic component that is small, that has high electrical strength, and that is resistant to separation between ceramic layers includes a ceramic sintered body having a substantially rectangular parallelepiped shape and a plurality of first and second internal electrodes. The plurality of first and second internal electrodes are alternately arranged so as to face each other. The first and second internal electrodes are parallel or substantially parallel to first and second major surfaces. The first and second internal electrodes are exposed to at least one of the fifth and sixth surfaces and are not exposed to the third or fourth surface. No bends exist in any of the ends of each of the first and second internal electrodes adjacent to the third and fourth surfaces.

Owner:MURATA MFG CO LTD

Vacuum glue-dipping insulation pipe without air gaps and manufacturing method thereof

InactiveCN101615455AImprove electrical performanceImprove mechanical propertiesInsulating bodiesEngineeringMechanical property

The invention discloses a vacuum glue-dipping insulation pipe without air gaps and a manufacturing method thereof, relates to an insulation pipe and a manufacturing method thereof, and solves the problems of poor electrical property and mechanical property of the insulation pipe caused by air bubbles, gaps and local layering produced easily among layers of glass fabrics in the prior manufacturing process of the insulation pipe. The insulation pipe is formed by winding the glass fabrics, resin glue is dipped in the glass fabrics, and the resin glue is prepared by stirring the following components in portion by weight at the temperature of between 50 and 80 DEG C: 100 portions of modified epoxy resin, 85 portions of curing agent, 10 portions of toughening agent and 3 portions of accelerating agent. The method comprises the following steps: first, designing a core die; second, winding the glass fabrics; third, glue dipping; fourth, primary curing; five, demoulding; six, secondary curing; and seven, removing burrs to obtain the vacuum glue-dipping insulation pipe without the air gaps. The insulation pipe is formed by glue dipping under a vacuum state, and the air bubbles, the gaps and the local layering are not produced among layers of the glass fabrics, so the electrical property and the mechanical property of the insulation pipe are improved.

Owner:朱笑梅

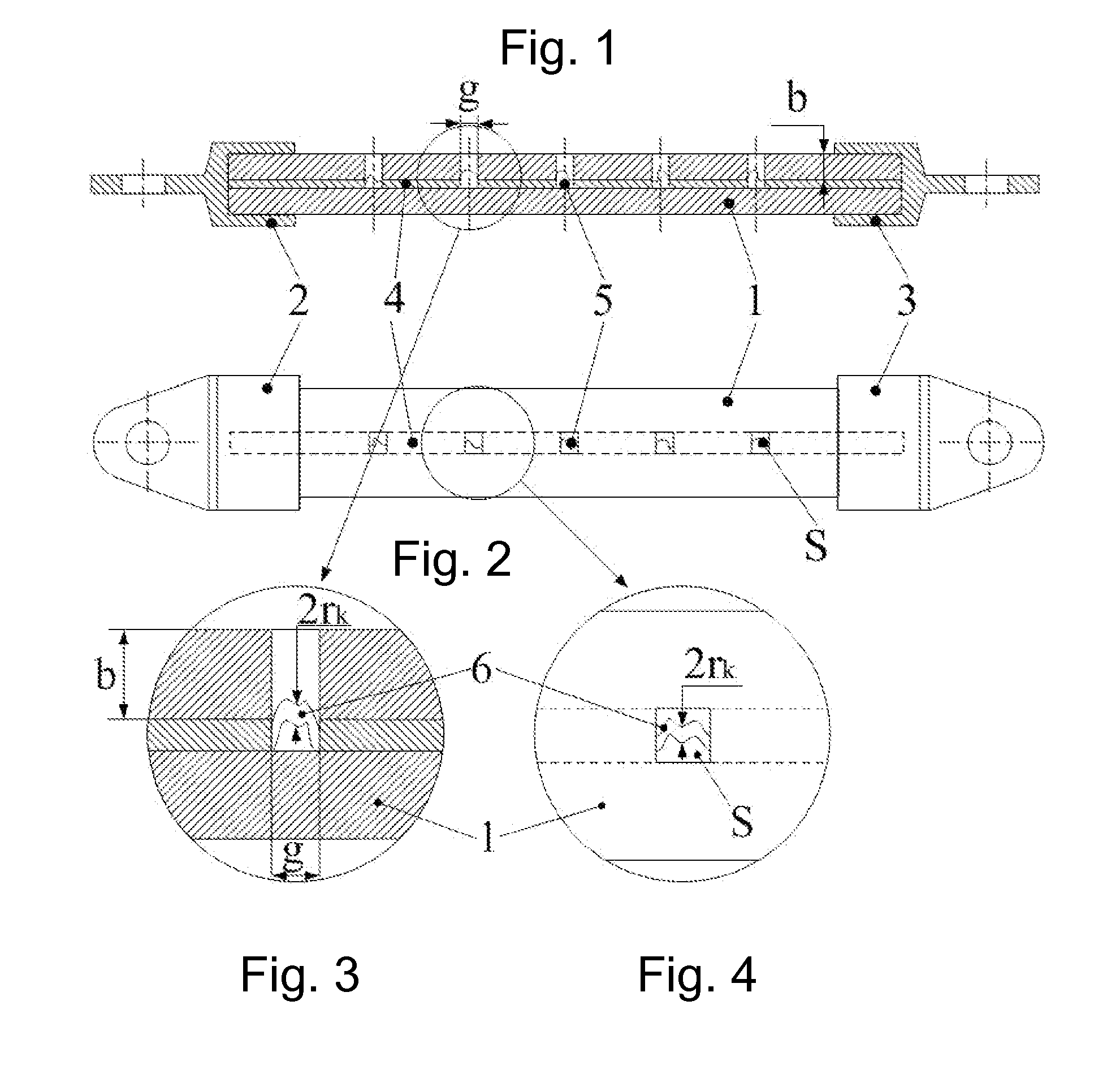

Lightning arrester and a power transmission line provided with such an arrester

ActiveUS20110304945A1Improve reliabilityReduce maintenance costsInstallation of lighting conductorsEmergency protective arrangement detailsElectric power transmissionDielectric

A lightning arrester for protecting elements of electrical facilities or a power transmission line comprises an insulating body which is made of a solid dielectric, preferably in the form of a bar, a strip or a cylinder, two main electrodes that are mechanically coupled to the insulating body and two or more intermediate electrodes. The intermediate electrodes, preferably made in the form of bars or cylinders, are arranged between the main electrodes so that said intermediate electrodes are mutually shifted along the longitudinal axis of the insulating body or along a spiral line. Such design makes it possible to form a discharge channel between the adjacent electrodes. Furthermore, said electrodes are located inside the insulating body and are separated from the surface of the body by an insulation layer. Discharge chambers formed as cavities or through bores opened to the surface of the insulating body are arranged between the pairs of the adjacent electrodes. Dimensions of the chambers are selected such that a discharge is easily blown out from the chambers to the surface of the insulating body, thereby increasing the efficiency of the discharge current quenching. In the preferred embodiments, the arrester is provided with an additional electrode for reducing a flashover voltage. Various embodiments of a power transmission line using the arrester of the invention are also disclosed.

Owner:OTKRYTOE AKTSIONERNOE OBSCHESTVO NPO STREAMER

Manufacturing method of corona-resistant polyimide film sintered enamelled copper strap wires

ActiveCN102800423AHigh corona resistance strengthHigh temperature resistanceInsulating conductors/cablesPolyesterCopper conductor

The invention relates to a manufacturing process of enamelled copper strap wires, and particularly relates to a manufacturing method of corona-resistant polyimide film sintered enamelled copper strap wires. The manufacturing method comprises the following steps of: processing a copper conductor into a copper strap wire; making the copper strap wire to a 200-grade polyester-imine / polyamide-imide compound type enamelled copper strap wire; and covering a corona-resistant polyimide film on the enamelled copper strap wire and then heating, baking and sintering the enamelled copper strap wire. The manufacturing method combines an enameling process and a glass-coating process, overcomes the limitation of the conventional process, makes up single performance of the existing process, and well combines the enameling process and the glass-coating process; and the product has high corona resistance strength and reaches a high temperature resistance level.

Owner:SICHUAN JINRUI ELECTRIC

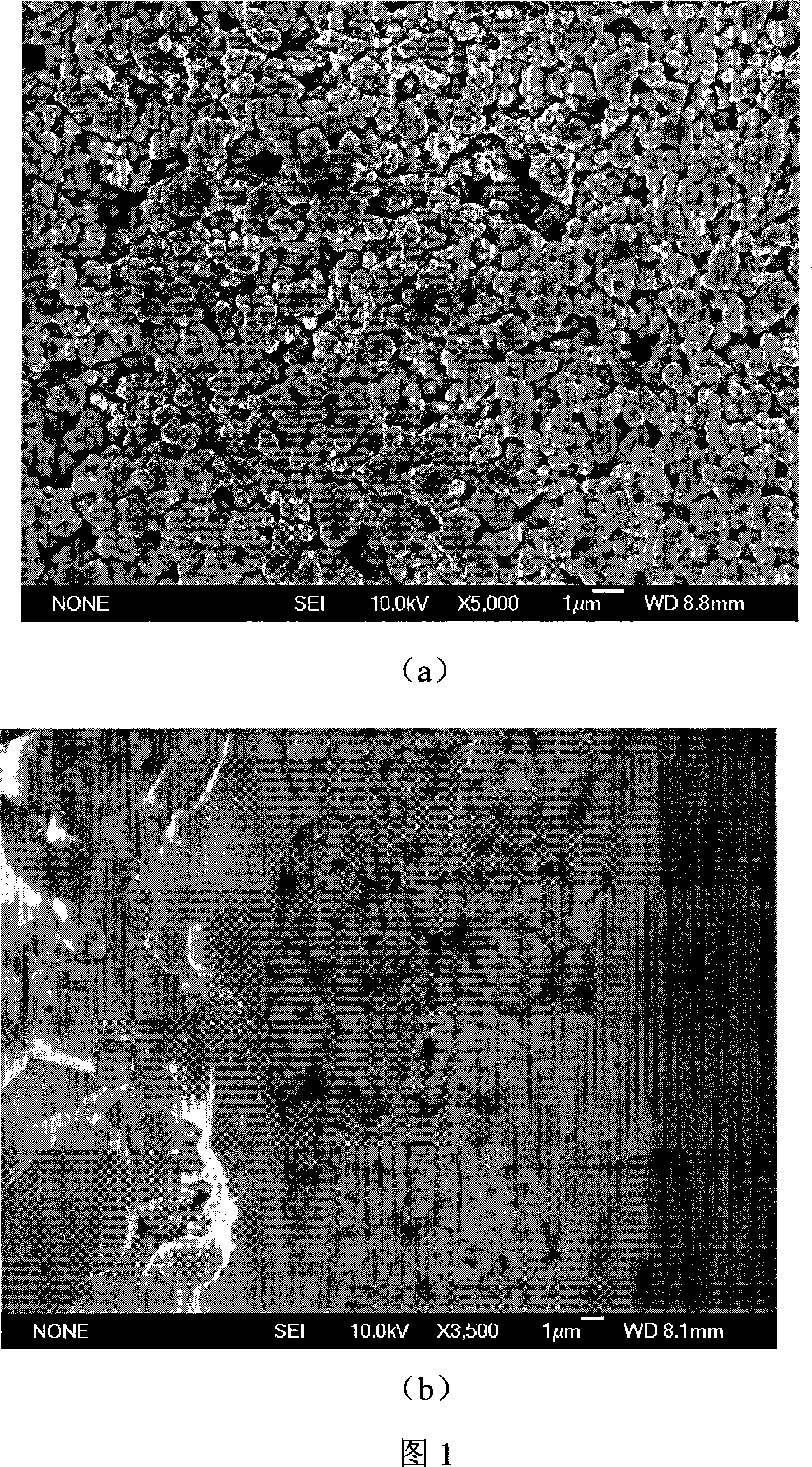

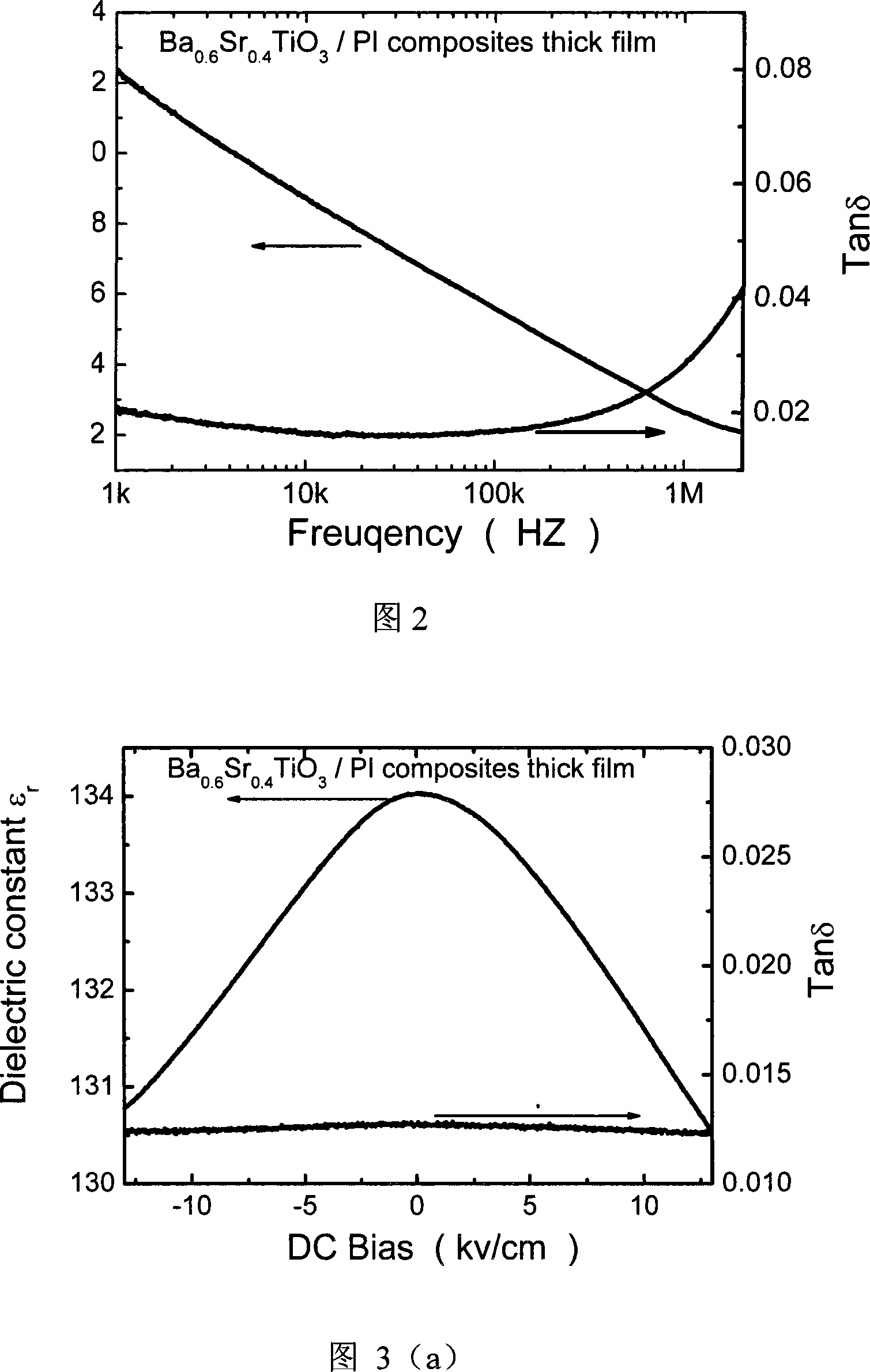

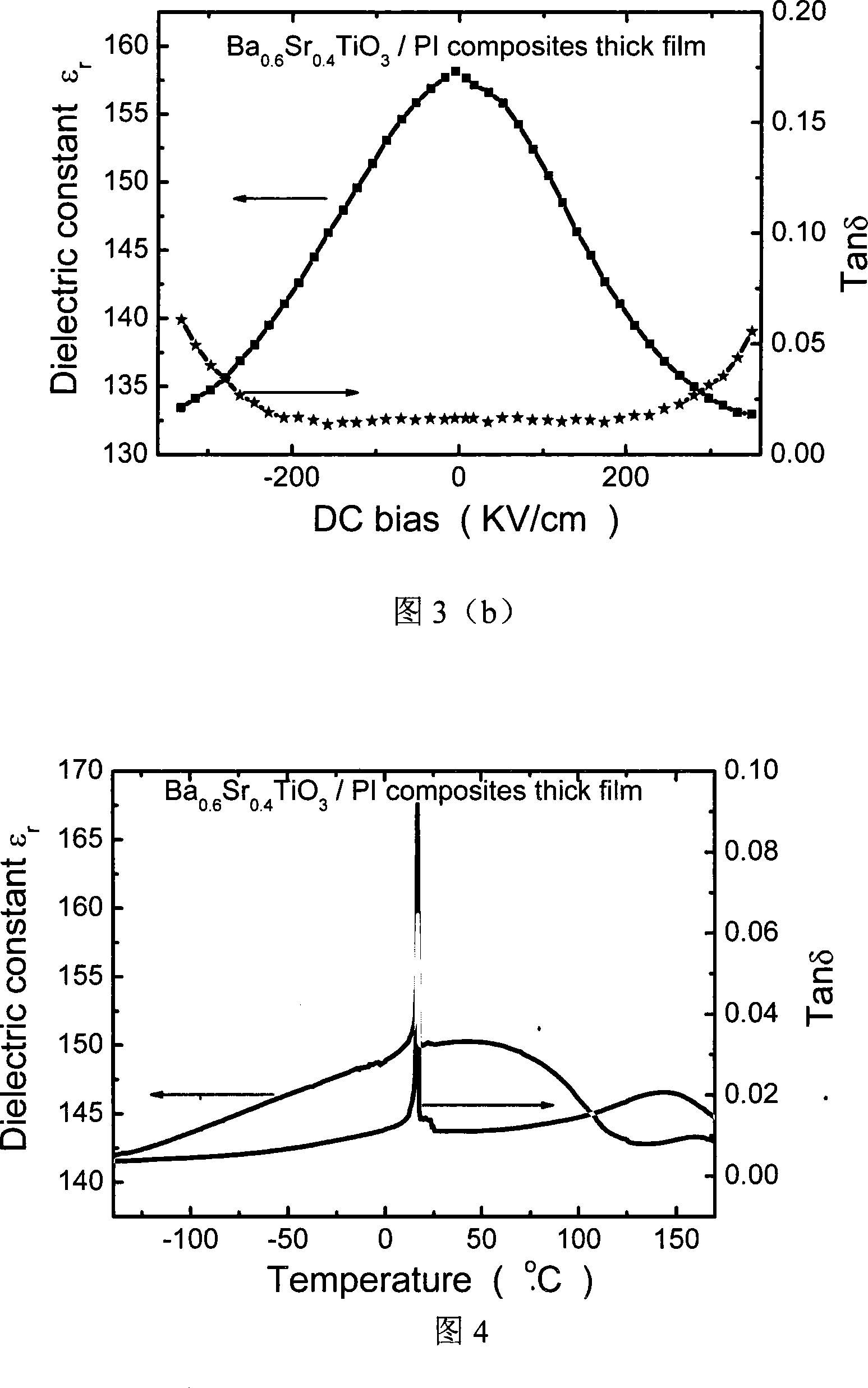

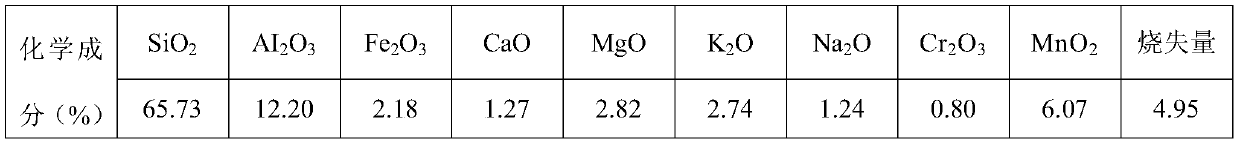

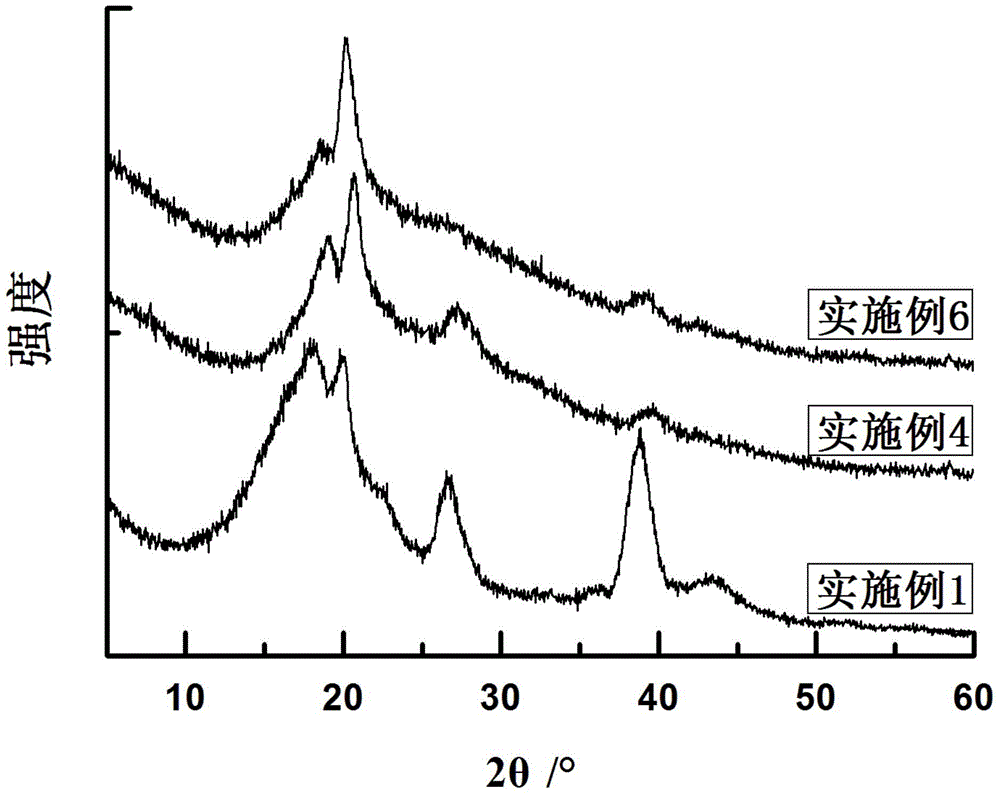

Method for preparing strontium-barium titanate/polymide dielectric adjustable composite material thick film

InactiveCN101070427ALow heat treatment temperatureImprove electric strengthCoatingsInsulation resistancePre treatment

The invention discloses the preparation methods of a barium strontium titanate / polyimide dielectric with the materials of adjustable thick composite, uses polyimide as a precursor; Selecting the barium strontium titanate powder dielectric ceramics (Ba1-xSrx) TiO3 as dielectric adjustable phase, polyimide precursors and the surface treatment of barium strontium titanate dielectric ceramic powder mixed in proportion, by using a high-energy or ordinary ball milling way to make them adequately scattered and get mixed thick-film paste;Using conventional spin-coating process, dipping - carrying process or extension of thick slurry will be mixed in the pre-treatment of the coating material on the substrate, and then coating on the substrate material after the heat treatment process and follow-up process can be get Barium strontium titanate / polyimide dielectric adjustable thick composite materials. This invention need a low processing temperature (=< 350 degree C), the minimum curing temperature is less than 160 degree C.

Owner:XI AN JIAOTONG UNIV

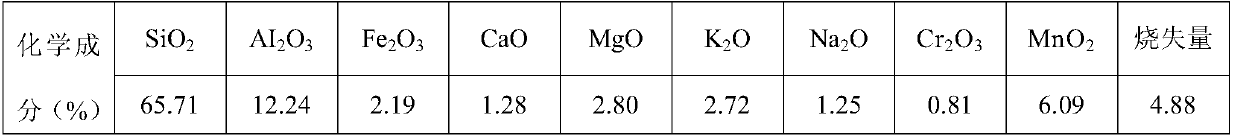

Brown glaze and production method thereof

The invention belongs to the technical field of electric porcelain brown glaze toner, and particularly discloses brown glaze. The brown glaze comprises the following raw materials of, in parts by mass, 18-26 parts of potassium feldspar, 6-14 parts of albite, 2-8 parts of Inner Mongolia soil, 10-18 parts of Shaanxi kaolin, 7-12 parts of calcined talc, 0-3 parts of limestone, 25-33 parts of quartz powder, 1-1.6 parts of iron oxide red, 0.4-1.2 parts of chromium oxide and 7-12 parts of manganese oxide. The invention furthermore discloses a production method of the brown glaze. The production method of the brown glaze comprises the following steps of (1) raw material preparation, (2) ball-milling, (3) deironing treatment and (4) aging. According to the brown glaze produced by using the production method, the product yield is improved, the brown glaze has good comprehensive performance, and the production cost is effectively reduced so that the market requirements can be well met.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

High frequency dielectric ceramic material sintered under low temp and its preparation

InactiveCN1431166AWide sintering temperature rangeLower sintering temperatureCeramicsDielectric ceramicsIon

A high-frequency dielectric ceramics sintered at low temp has a structure expressing formula: (Bi3xZn2-3x)(Znx-y / 3Nb2-x-2y / 3May)O7 and (Bi3xZn2-3x)(ZnxNb2-x-yMby)O7, where Ma=Sn or Zn, Mb=Sb, Ta, or Mo, x=0.45-0.67 and y=0-1.5. Its advantages are high dielectric coefficient (25-8), low medium loss, low sintering temp (840-1060 deg.C), high insulating resistance, and wide range of temp coefficients.

Owner:XI AN JIAOTONG UNIV

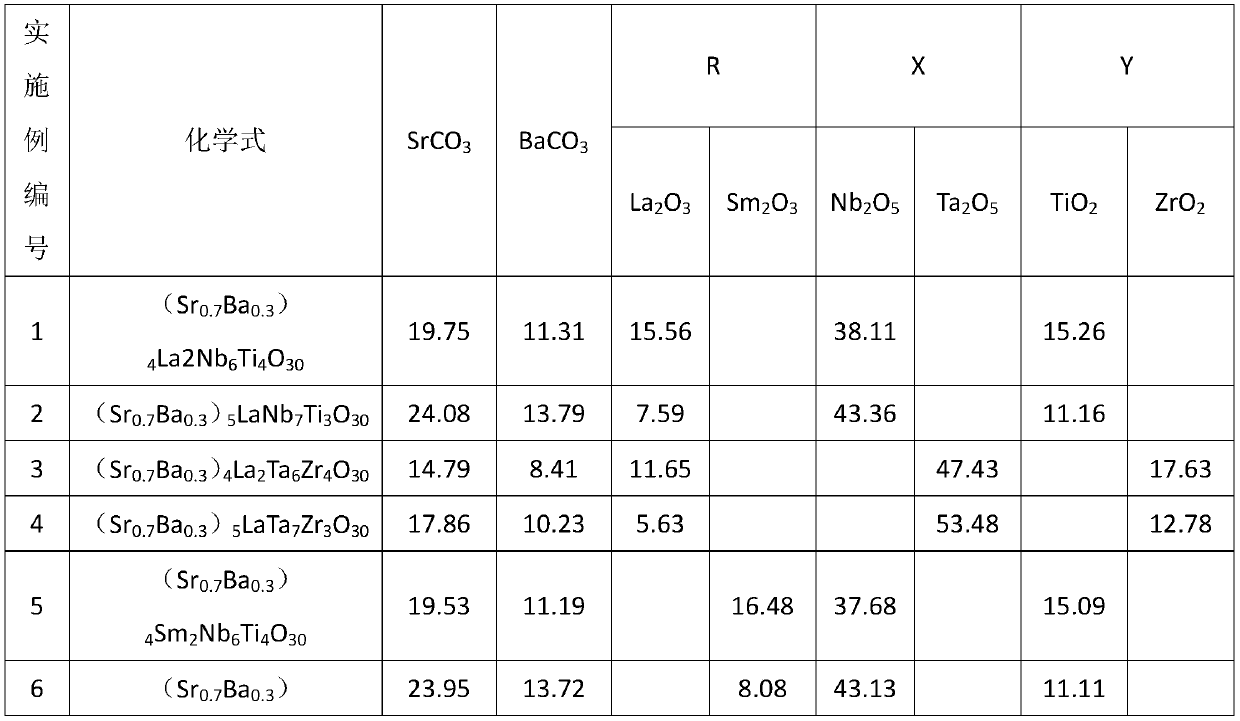

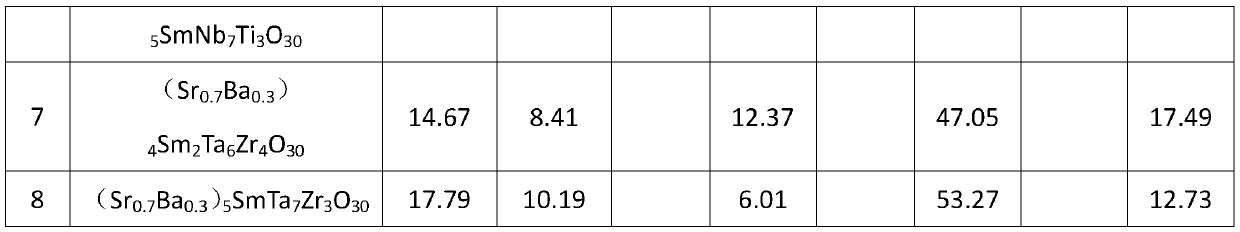

High-dielectric strength leadless energy storage dielectric ceramic material and preparation method thereof

A high-dielectric strength leadless energy storage dielectric ceramic material and a preparation method thereof belong to the technical fields of electronic information functional materials and devices. The high-dielectric strength leadless energy storage dielectric ceramic material is characterized in that the composition formula of the material is (Sr0.7Ba0.3)aR6-aX2+aY8-aO30, wherein X is Nb<5+> or Ta<5+>, Y is Ti<4+> or Zr<4+>, R is a trivalent rare earth element, and the value of a is 4 or 5. The material achieves a high dielectric strength, realizes a high energy storage efficiency, saves the energy cost, and has a wide application prospect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

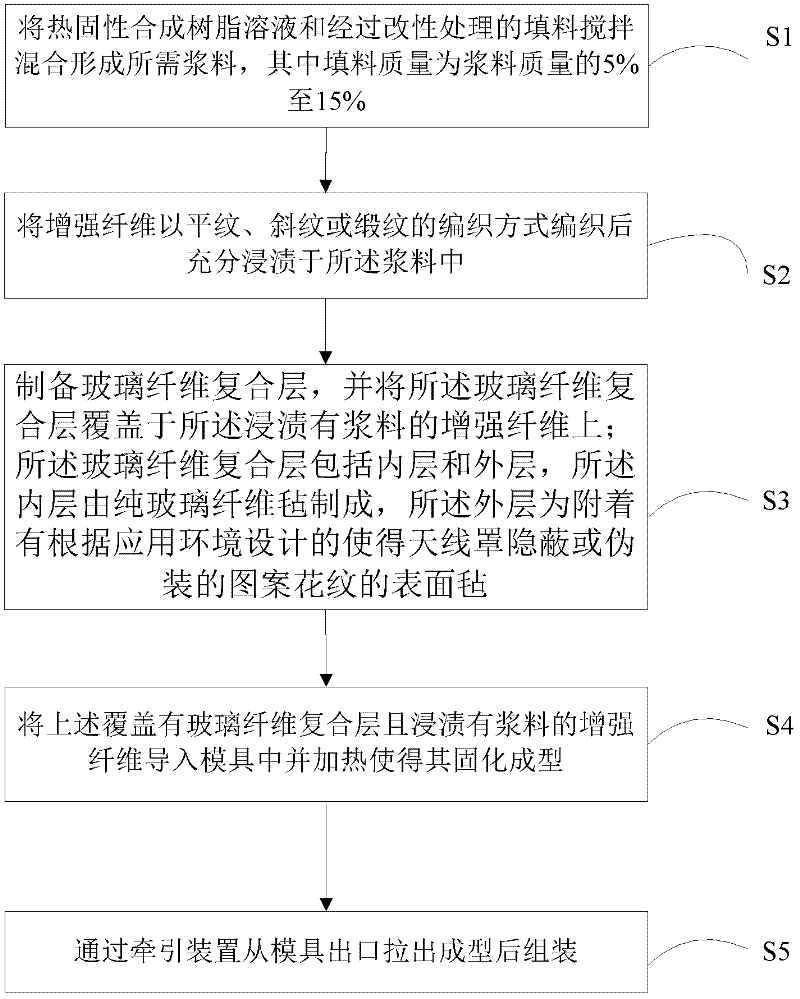

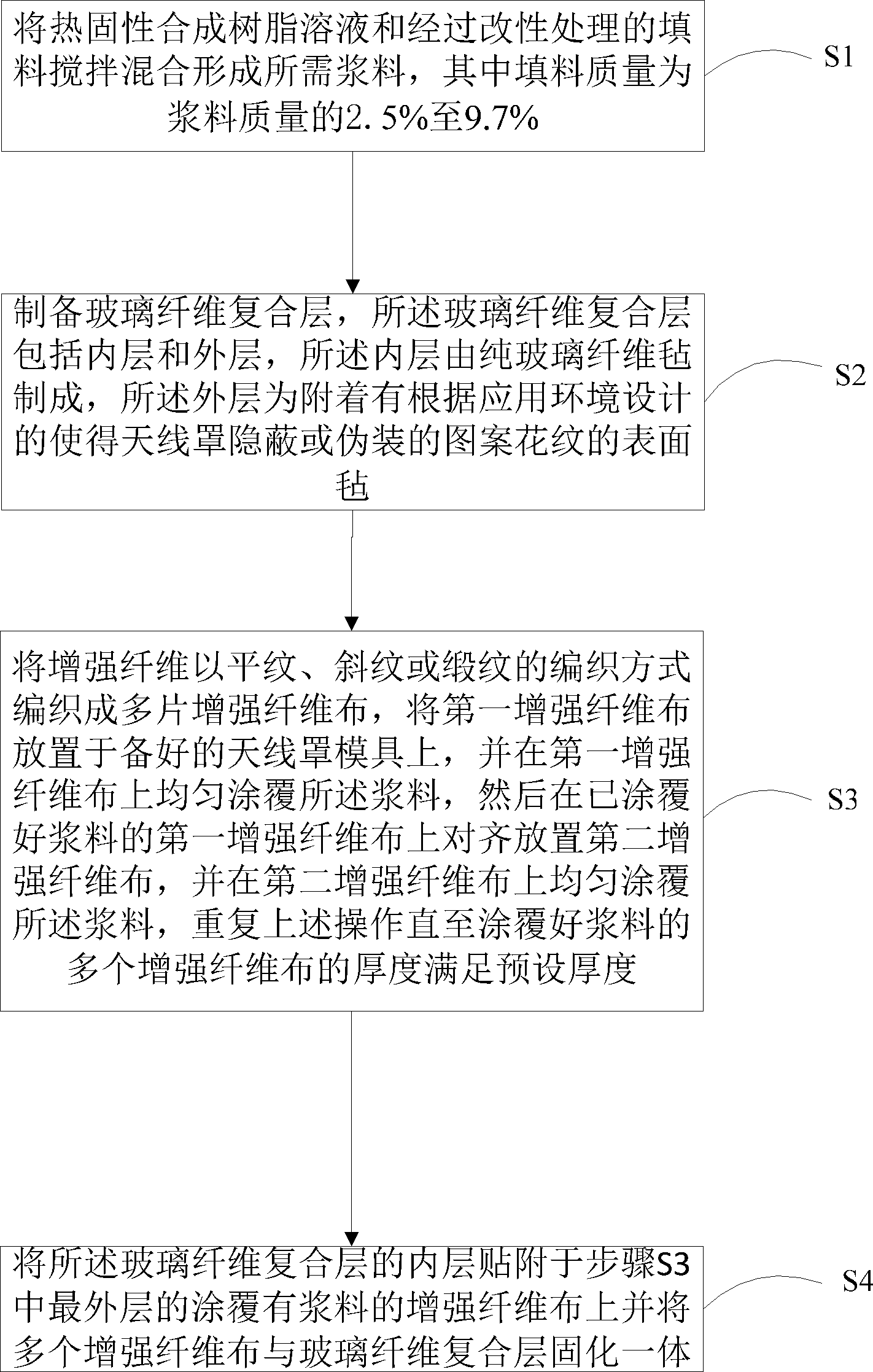

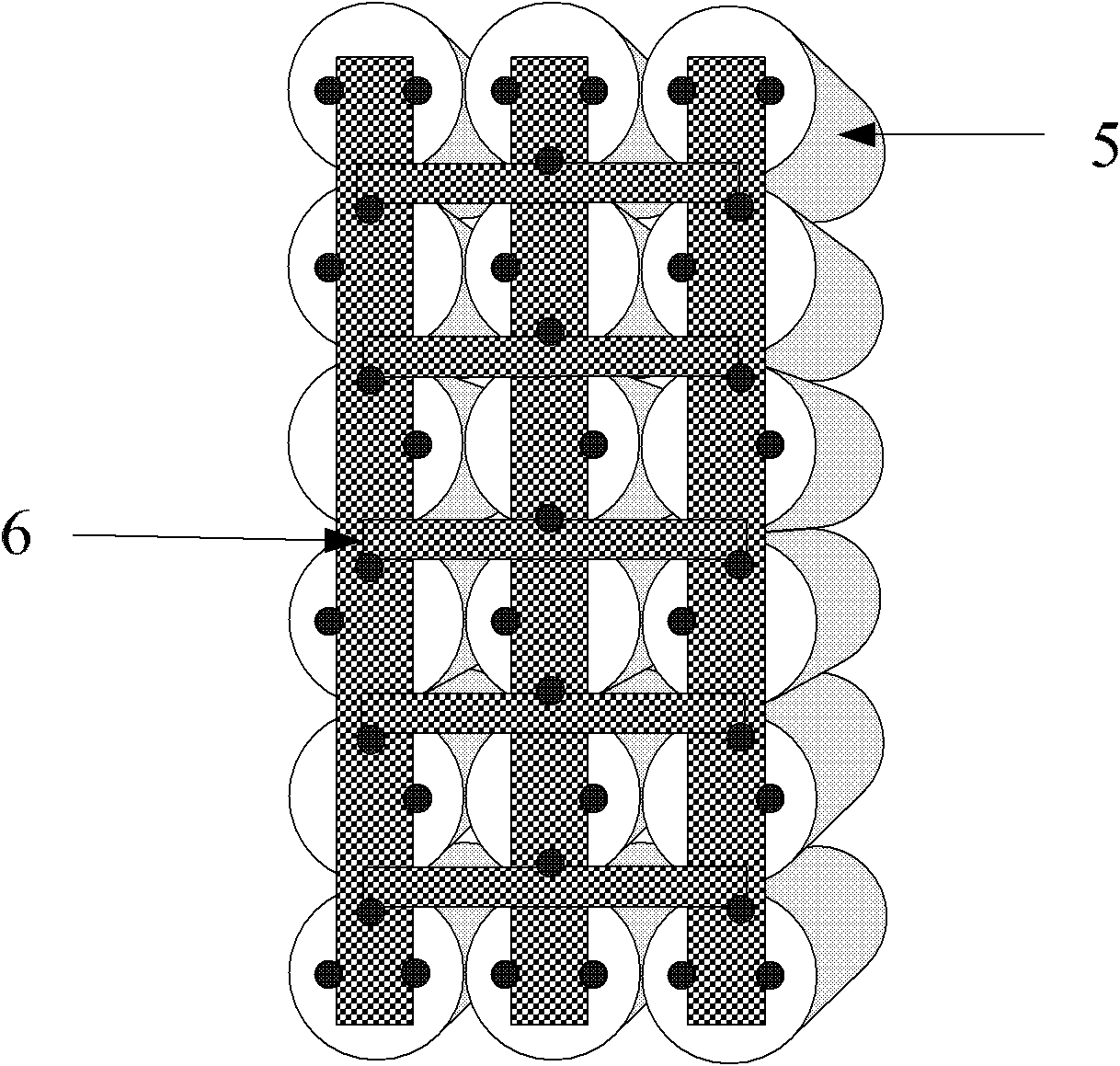

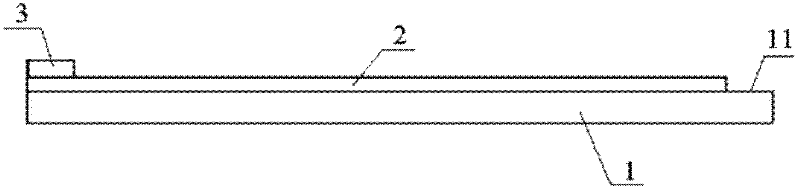

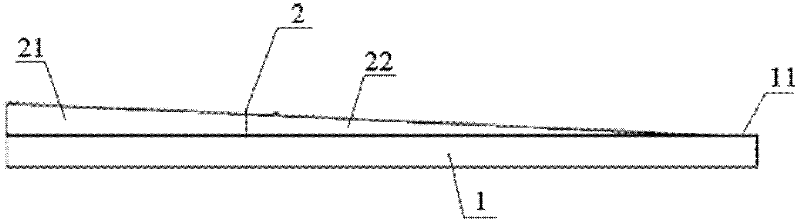

Beautified radome and preparation method thereof

ActiveCN102694257AHigh mechanical strengthImprove electrical strengthRadiating element housingsFiberGlass fiber

The invention discloses a beautified radome and a preparation method thereof. The method comprises steps: stirring and mixing a thermosetting synthetic resin solution and a modified filling material to form a required slurry, wherein the mass of the filling material is 5% to 15% of that of the slurry; fully dipping reinforced fiber in the slurry after the reinforced fiber is braided in a plain, a twill, or a satin braiding mode; preparing a glass fiber composite layer, and coating the glass fiber composite layer on the reinforced fiber dipped with the slurry; introducing the reinforced fiber dipped with the slurry and covered with the glass fiber composite layer into a mold, and heating the mold to make the reinforced fiber solidified; and pulling out the solidified reinforced fiber from a mold outlet to be shaped, and assembling the shaped reinforced fiber. With the method of the invention, a pattern layer for beautifying the radome, and a radome body are integrally molded, a repeated painting beautification technology in a late stage is reduced, the resource is saved, and the defect of the present spraying technology is overcome.

Owner:KUANG CHI INST OF ADVANCED TECH

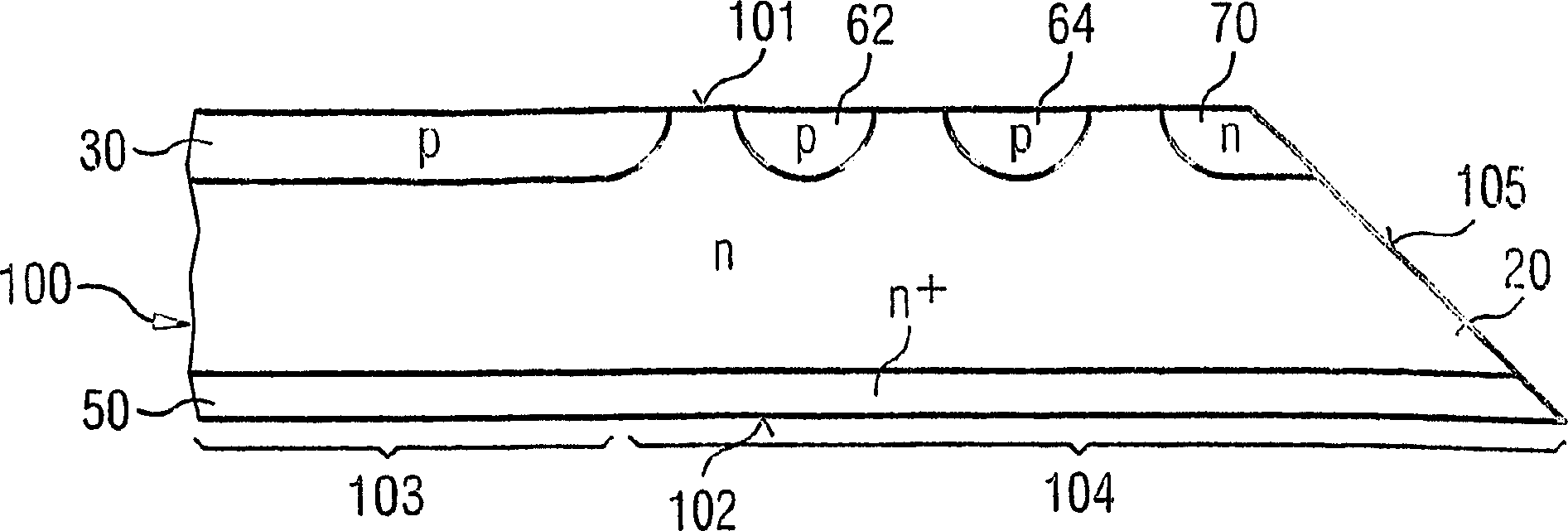

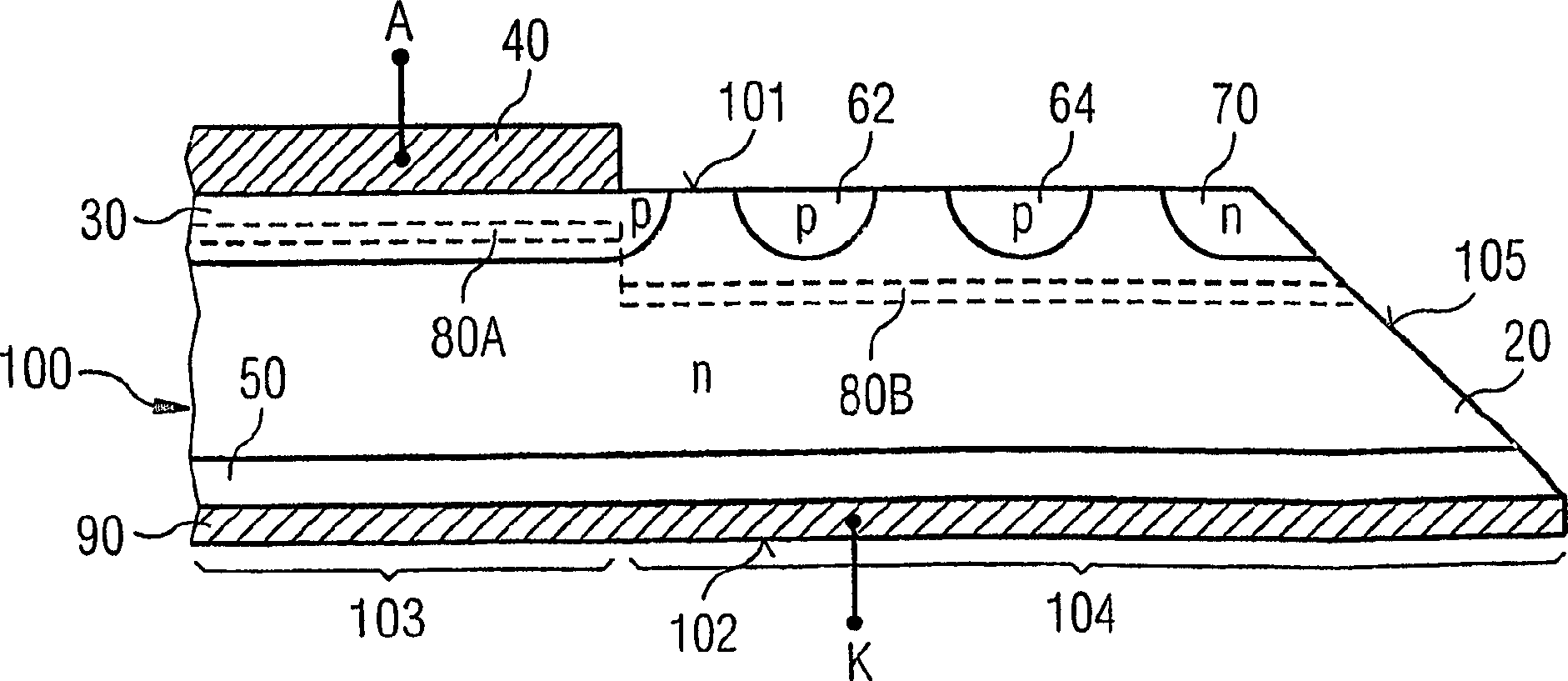

Semiconductor device

ActiveUS20110079870A1Improve electrical strengthSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSemiconductor device

This specification discloses a semiconductor device having higher electric strength.The semiconductor device disclosed in this specification has a semiconductor element region, a peripheral termination region, a peripheral electrode, an insulating film, and an intermediate electrode. A semiconductor element is formed within the semiconductor element region. The peripheral termination region is formed around the semiconductor element region and formed of a single conductive type semiconductor. The semiconductor element region and the peripheral termination region are exposed at one surface of a semiconductor substrate. The peripheral electrode is formed on a surface of the peripheral termination region and along a circumference of the semiconductor substrate. The insulating film is formed on the surface of the peripheral termination region and between the semiconductor element region and the peripheral electrode. The intermediate electrode is formed on the insulating film. A thickness of the insulating film under the intermediate electrode is larger at a side of the peripheral electrode than at a side of the semiconductor element region.

Owner:TOYOTA JIDOSHA KK

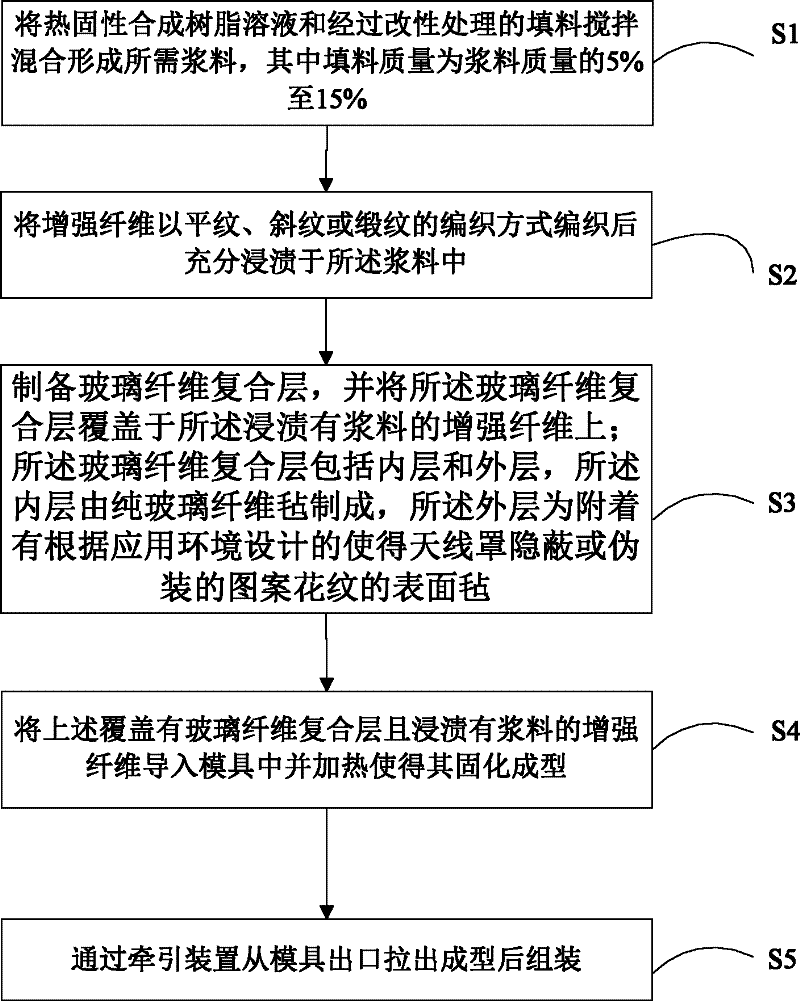

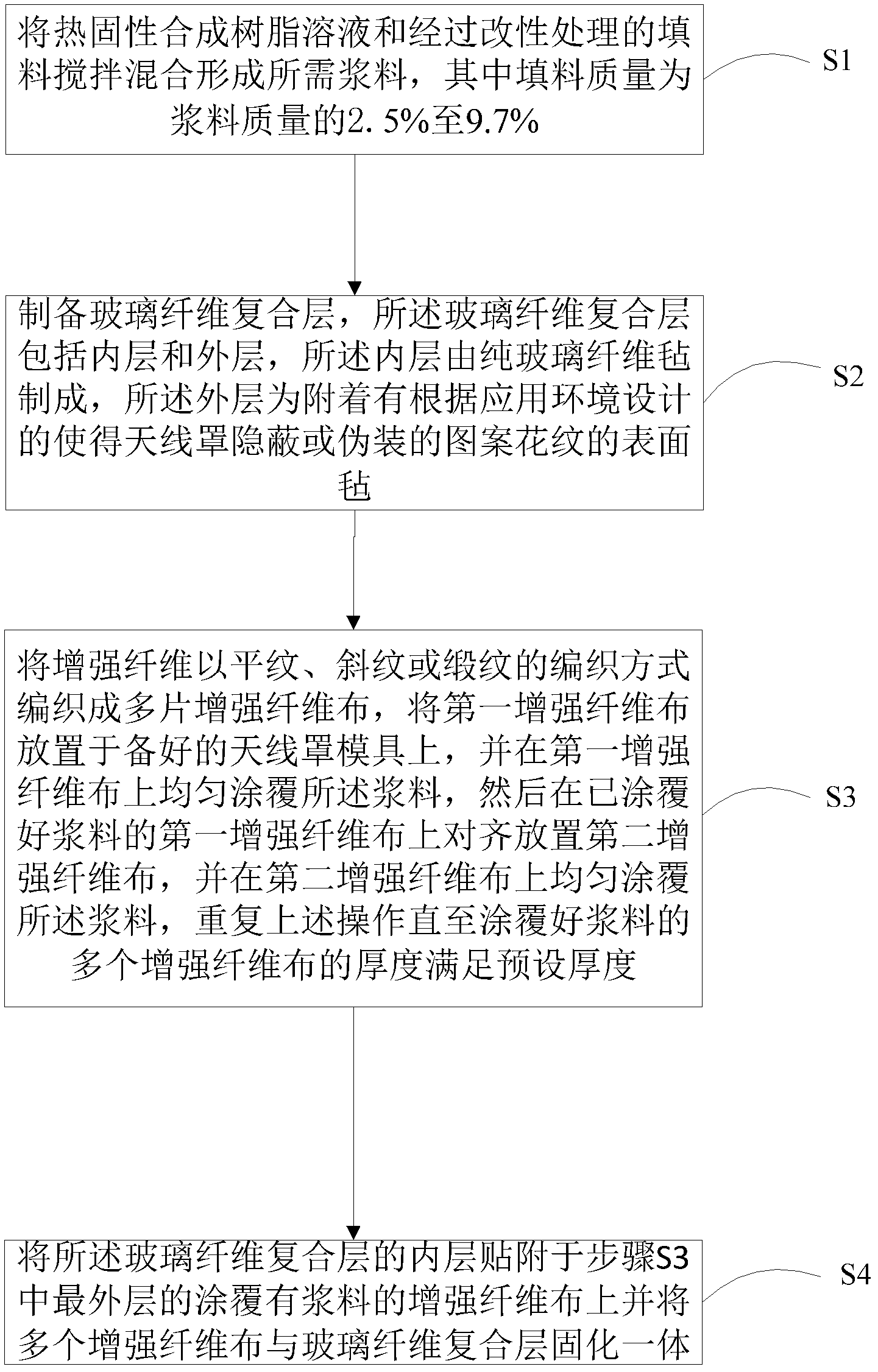

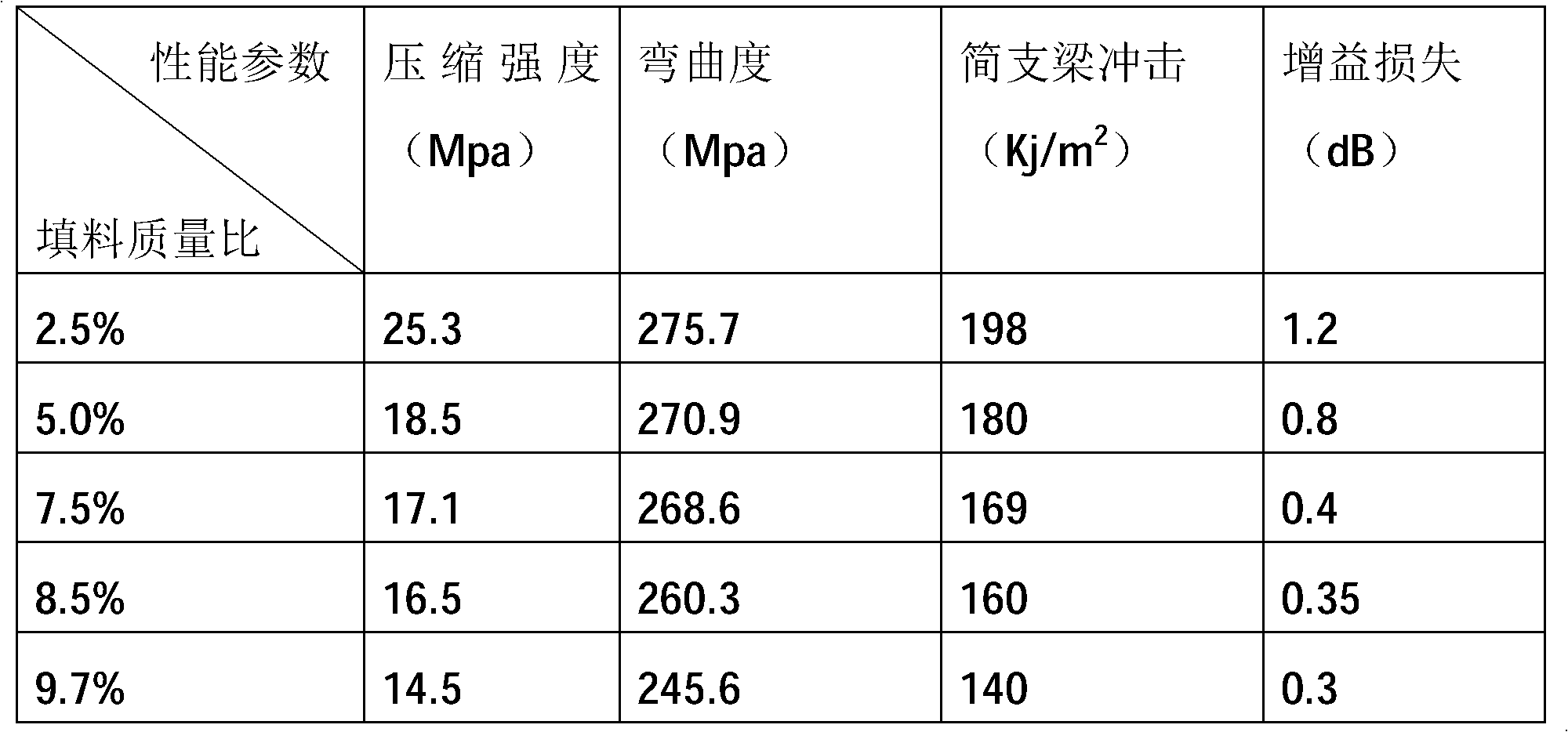

Beautification antenna housing and preparation method thereof

ActiveCN102683844AHigh mechanical strengthImprove electrical strengthRadiating element housingsFiberGlass fiber

The invention discloses a beautification antenna housing and a preparation method thereof. The preparation method comprises the steps of: stirring and mixing thermosetting synthetic resin solution and modified filler to form required slurry, wherein the mass of the filler is 2.5-9.7% the mass of the slurry; preparing a fiberglass composite layer, wherein the fiberglass composite layer comprises an inner layer and an outer layer, the inner layer is made of pure fiberglass felt and the outer layer is a surface felt adhered with patterns which are designed according to the application environment and used for hiding or deceiving the antenna housing; sequentially coating the slurry on multiple pieces of reinforcing fiber cloth; and adhering the inner layer of the fiberglass composite layer to the outmost reinforcing fiber cloth coated with the slurry, and integrally curing the multiple pieces of reinforcing fiber cloth and the fiberglass composite layer. According to the invention, the pattern layer of the beautification antenna housing and an antenna housing body are integrally formed by a hand pasting process, so that the late-stage repeated spray painting beautification process is reduced, the resources are saved and the defects of the traditional spray coating process are overcome.

Owner:KUANG CHI INST OF ADVANCED TECH

Metallized membrane capacitor assembly

ActiveCN102522198AClosely arrangedReduce self-healing noiseMultiple fixed capacitorsFixed capacitor electrodesCapacitanceLow voltage

The invention discloses a metallized membrane capacitor assembly, which belongs to a capacitor used in the pulse power field and solves the problem that the traditional high-voltage metallized membrane capacitor is readily explosive when used in atmospheric or low pressure environment. The metallized membrane capacitor assembly comprises capacitor cores, DMD (Digital Micromirror Device) insulating papers, a high-voltage extraction electrode and a low-voltage extraction electrode, wherein M capacitor cores achieve the purpose of connecting capacitors in parallel to form capacitor stacks; N capacitor stacks achieve the purpose of connecting capacitors in series to form capacitor assemblies; the DMD insulating papers are arranged among the capacitor stacks; and the capacitor assemblies, the DMD insulation papers, the high-voltage extraction electrode and the low-voltage extraction electrode are integrally encapsulated by polyurethane pouring sealant to form the metallized membrane capacitor assembly. The metallized membrane capacitor assembly has higher energy storage density and electric strength, good insulation reliability in atmospheric or low pressure environment, and better mechanical performance and longer service life under a heavy-current discharging condition.

Owner:HUAZHONG UNIV OF SCI & TECH

Metallized film for film capacitor and manufacturing method thereof

InactiveCN102290232ASmall end face resistanceReduce contact resistanceThin/thick film capacitorFixed capacitor electrodesMetallic materialsOptoelectronics

The invention relates to a metallized film for a thin film capacitor, comprising a dielectric layer and a metallized film layer, the metallized film layer and the dielectric layer are combined with each other, and a misaligned edge is left at one end of the dielectric layer. The metallized film layer is in a triangular shape; the thicker side of the metallized film layer is located at the metallized edge after the metallized film layer is combined with the dielectric layer. The present invention also relates to a method for making a metallized film for a film capacitor of the present invention, comprising the following steps: coating a metal material on a dielectric layer, leaving a wrong edge at one end of the dielectric layer to form a metallized film layer, and The metallized film layer is in a triangular shape, wherein the thicker side of the metallized film layer is located at the metallized edge after the metallized film layer is combined with the dielectric layer. The processing technology of the invention is simple, and the contact resistance of the thin film capacitor made by it is small, so that the characteristics of the product are good.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

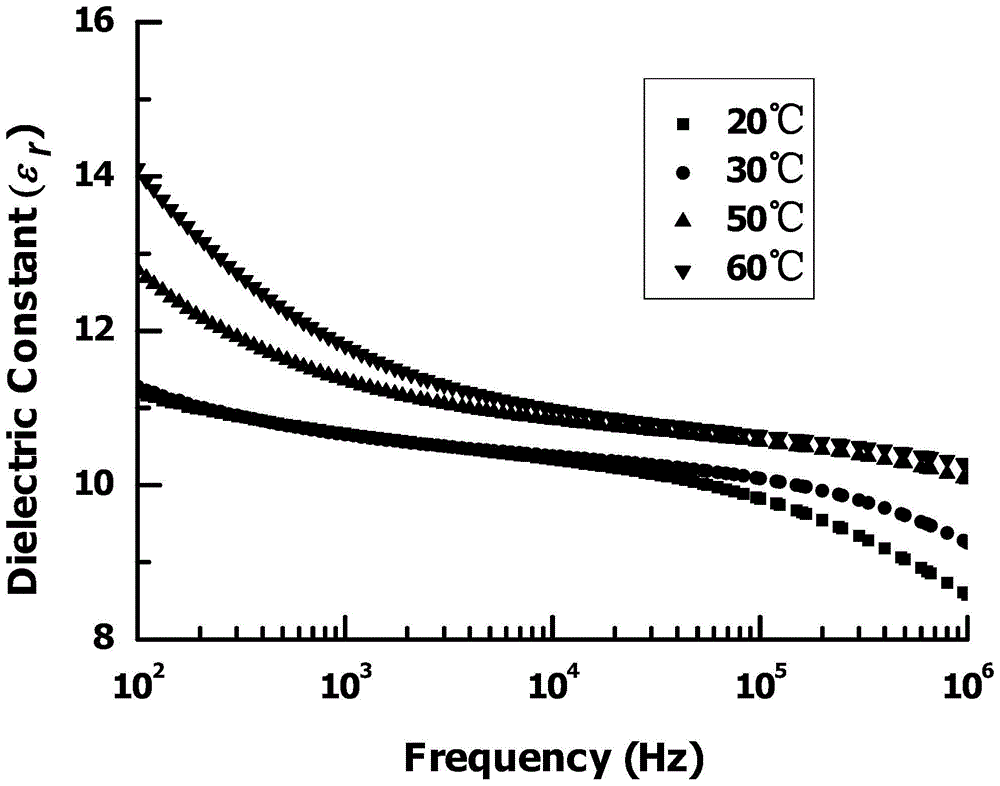

Preparation method of PVDF (polyvinylidene fluoride) film and PVDF film

The invention relates to a fluorine-containing polymer, particularly a preparation method of a PVDF (polyvinylidene fluoride) film and a PVDF film. The preparation method of the high-beta-phase-content PVDF film comprises the following steps: dissolving PVDF raw powder in a mixed solvent composed of a good solvent and a poor solvent, regulating the width of a flow casting scraper slit, carrying out flow casting on a clean glass plate or polyester film strip, and carrying out bottom plate heat drying to prepare the high-beta-phase-crystal-content PVDF film. The method can adopt the mixed solvent to control the crystalline state of the PVDF. The obtained PVDF film has the advantages of high beta-phase crystal content, high compactness, no pore, high dielectric strength and high dielectric constant, and can be used for preparing high-energy-density capacitors.

Owner:NORTHWEST INST OF NUCLEAR TECH +1

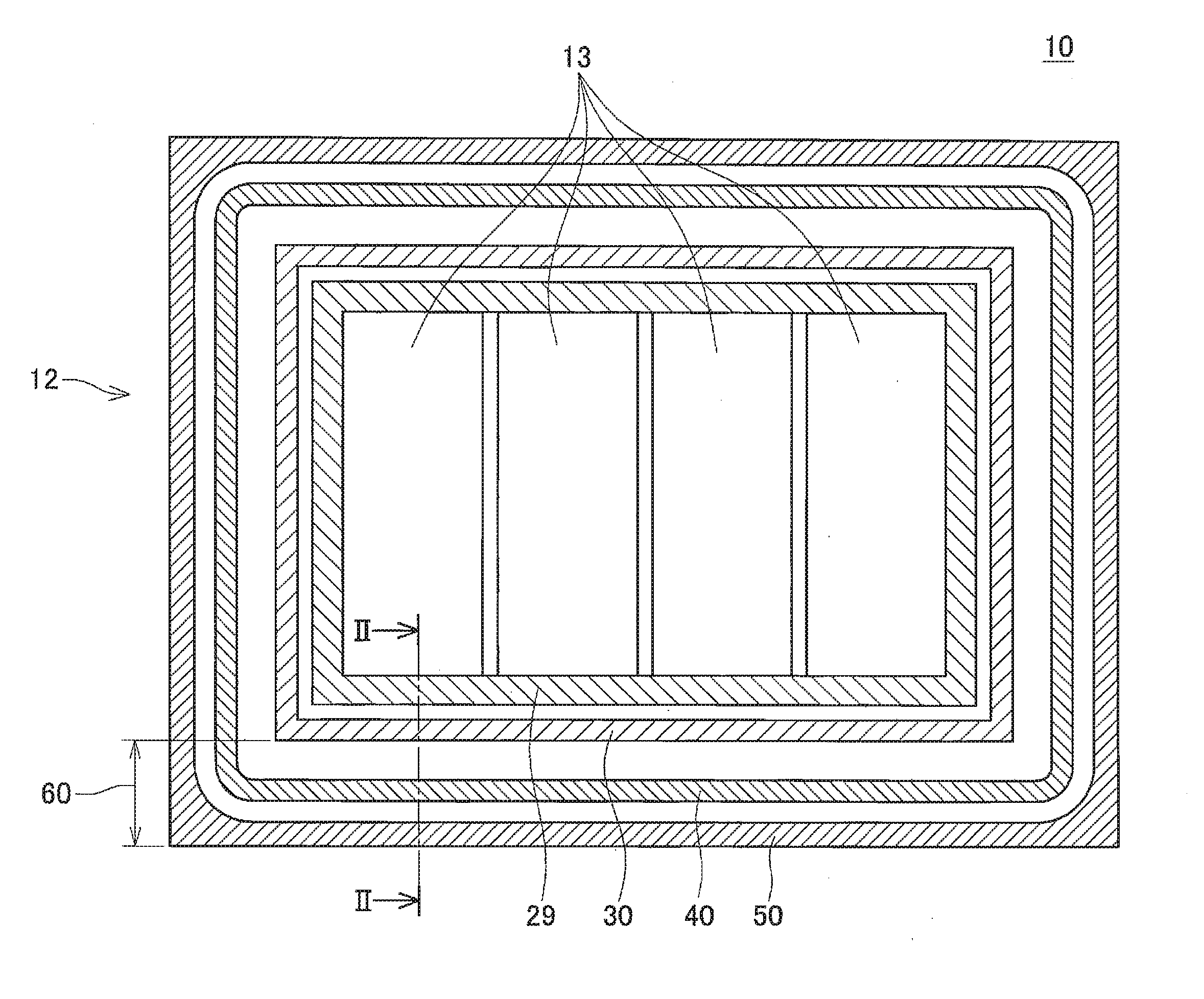

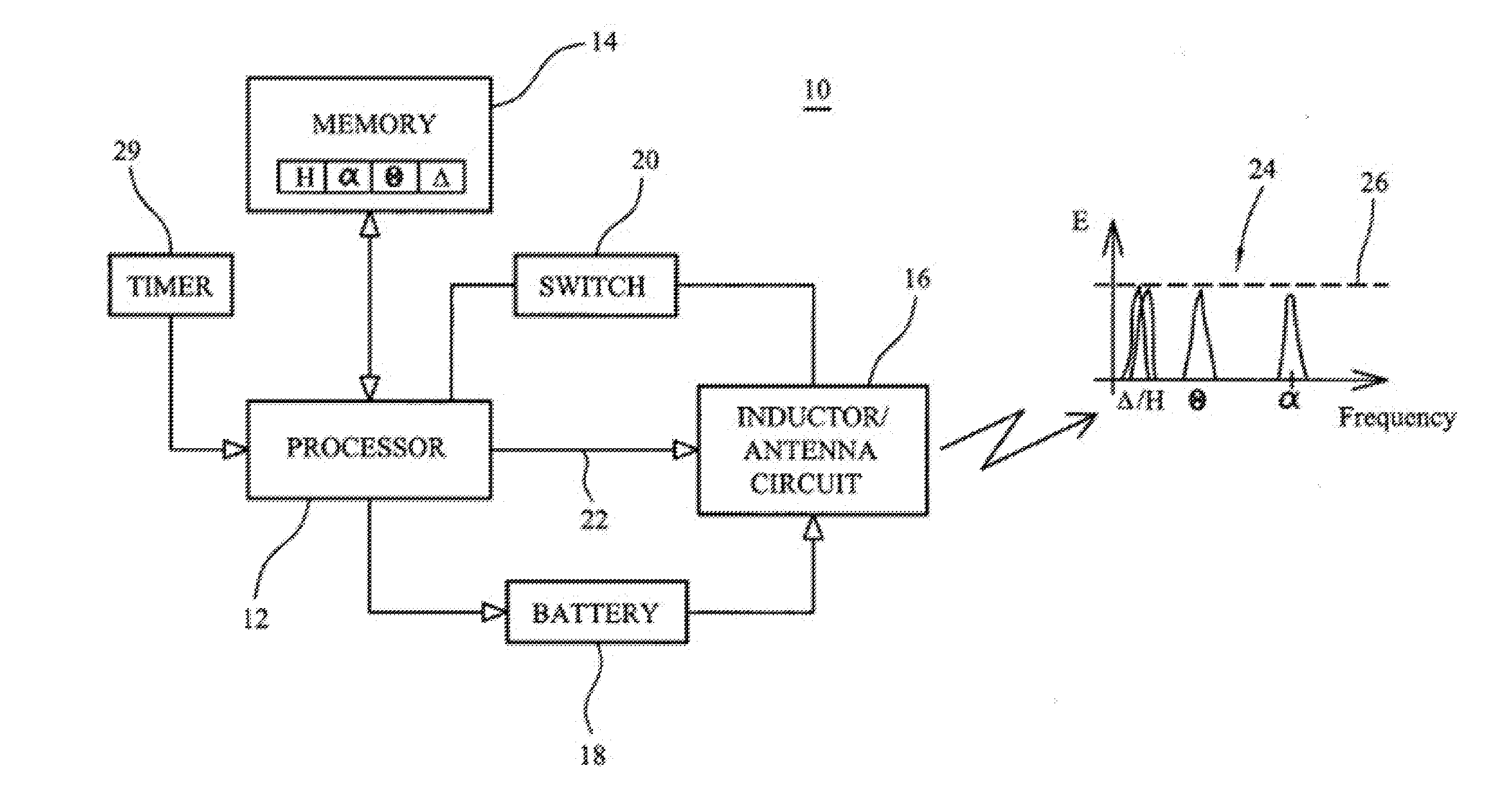

Therapeutic field generator device and method

ActiveUS20170028166A1High rate of acceptancePromote resultsElectrotherapyMagnetotherapy using coils/electromagnetsEngineeringOperation mode

A portable therapeutic field generator device (10) generates a reduced magnetic field component for a relatively large electric field by virtue that adjacent conductive tracks in a radiating element (40, 50) conduct electrical current in opposing directions. The device (10) includes a processor (12) that, in response to a control algorithm stored in memory (14), supplies a pulse wave (22) to a circuit containing the radiating element (40, 50). The pulse establishes generation of a base heartbeat reference having a frequency around a nominal heart rate. At periodic times, the base heart beat reference is supplemented by mutually exclusive periods of alpha wave, theta wave and delta wave generation (or other selected frequencies below about 200 Hz) based on selected brainwave frequencies for these waves, with the pulses having a duration generally corresponding to that ascribed to neuron depolarisation pulses. The device (10) cycles through multiple cycles (88) and, dependent upon the effect that is desired, may see delta wave frequencies follow theta wave frequencies that follow alpha wave frequencies. Delays may exist between transitions between the generated waves, with delta wave generation occurring no later than sixty minutes from commencement of alpha wave production for a mode that induces sleep. Delta waves production has, typically, a duration that is twice that of either the alpha or theta wave production. A second mode of operation sees longer pulse times for higher frequencies—between about 100 Hz and 500 Hz—associated with muscle stimulation.

Owner:ZEEZ TECH

Semiconductor component and method for producing the same

ActiveCN1771604AHigh recombination effectImprove electrical strengthSemiconductor/solid-state device manufacturingSemiconductor devicesCharge carrierIrradiation

The invention relates to a method for producing a semiconductor component, the method comprising the method steps of irradiating the front side (101) of a semiconductor body (100) with energetic particles using a connecting electrode (40) as a mask in order to Recombination centers (80A, 80B) for recombining charge carriers of the first and second conductivity type are generated in the semiconductor body (100).

Owner:INFINEON TECH AG

Insulated medium size for thick-firm circuit

InactiveCN1508812AReduce the presence of air bubblesImprove electrical strengthSolid-state devicesInsulatorsElectrically conductiveSpray coating

Dispersing glass powder possessing insulation property on organic medium evenly with or without inorganic pigment being added forms the invented pulp. Viscosity and rheological property of the pulp can be adjusted to suit specific coating method such as silkscreen printing and spray coating. Feasible manufacturability of the pulp is obtained by designing formulation of glass and organic medium reasonably. Technical parameters of the pulp are: sintering temperature 540-600 deg.C, average thermal expansion coefficient of insulated medium layer (73 minus or plus 3)*10 to the power -7 / C. The invented pulp is applicable to Al2O3 ceramic wafer or general conduction film substrate glass. Using method of silkscreen printing and spray coating makes wet film through drying and sintering processes etc. forming insulation layer in thick film circuit. The insulation layer provides high electrical intensity.

Owner:张来斌

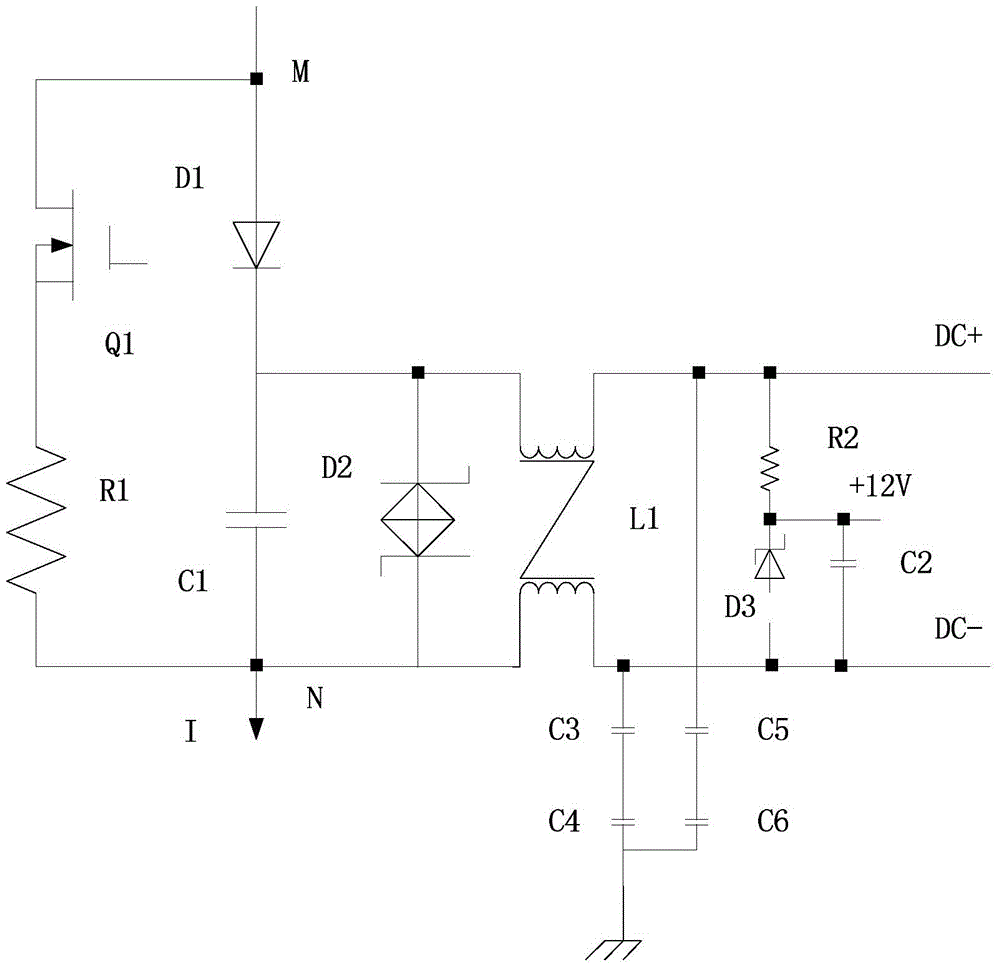

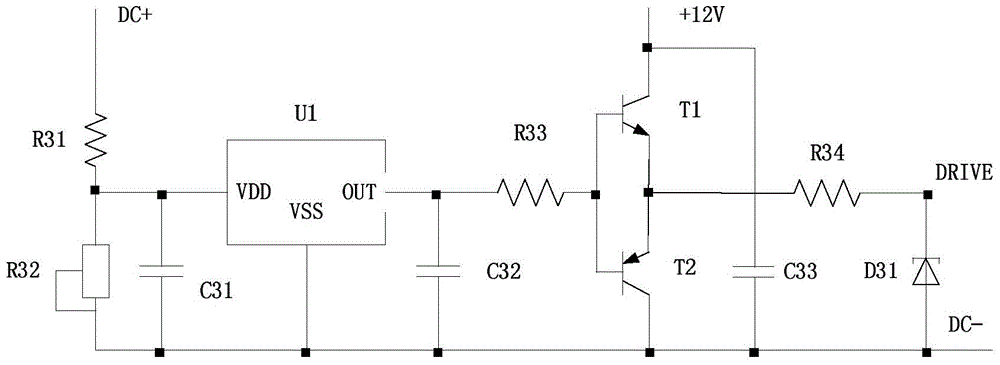

Single-line constant-current to constant-voltage electric energy conversion circuit

ActiveCN104967326AOutput power is easy to adjustWith electromagnetic compatibility (EMC) functionDc-dc conversionConstant-current supply dc circuitCapacitanceEngineering

The invention discloses a single-line constant-current to constant-voltage electric energy conversion circuit. The circuit comprises a current bypass, a CC / CV main circuit and a MOS pipe driving circuit. The CC / CV main circuit and the current bypass are connected in parallel and then are connected in series in the single-line constant current output channel. The current bypass comprises a NMOS pipe Q1 and a resistor R1. The CC / CV main circuit comprises a diode D1, capacitors C1and C2, a resistor R2 and a voltage-regulator tube D3. An anode of the diode D1 is connected to an input terminal of the current bypass. A cathode of the diode D1 is connected to an output terminal of the current bypass through a capacitor C1. The resistor R2, the capacitor C2 and the voltage-regulator tube D3 form an output branch. The output branch provides power for a MOS pipe driving circuit and the driving circuit is used for providing a trigger pulse for the NMOS pipe Q1. The single-line constant-current to constant-voltage electric energy conversion circuit is easy to carry out. A conception is ingenious and the circuit is especially suitable for being applied to a single line power supply occasion.

Owner:HUNAN HAIDUN OPTICAL FIBER SENSING TECH ENG LAB

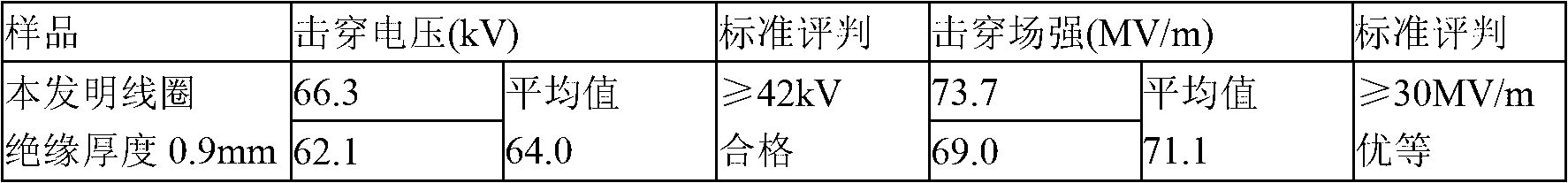

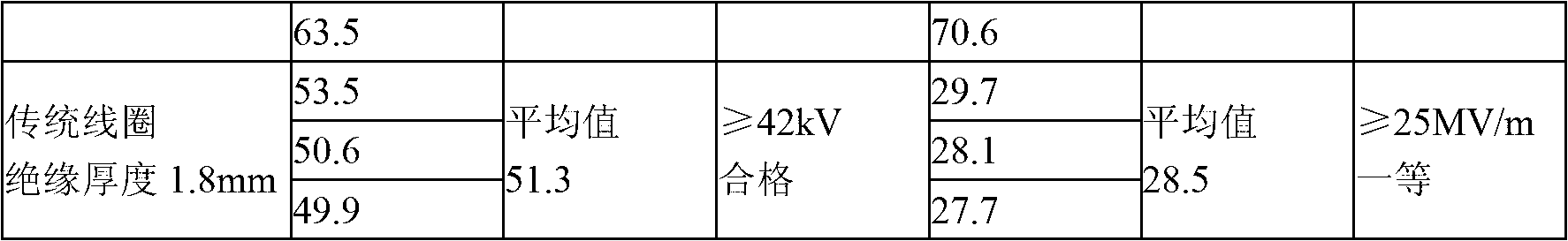

6 kilovolt level high-voltage motor insulation structure and manufacturing method thereof

InactiveCN102983654AHigh dielectric strengthReduce insulation thicknessWindings insulation shape/form/constructionApplying solid insulationMotor insulationEngineering

The invention discloses a 6 kilovolt level high-voltage motor insulation structure and a manufacturing method of the insulation structure. The insulation structure comprises an electromagnetic coil provided with a guide line insulating layer, and a main insulating layer manufactured on the electromagnetic coil in a winding mode. Epoxy acid anhydride type impregnating resin condensates are arranged in a gap between the guide line insulating layer on the electromagnetic coil and the main insulating layer. The 6 kilovolt level high-voltage motor insulation structure and the manufacturing method of the insulation structure have the advantages that insulating strength of the guide line insulating layer and the main insulating layer are both greatly promoted, but insulating thickness of the guide line insulating layer and the main insulating layer are obviously thinned.

Owner:上海同立电工材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com