Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Difference in level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

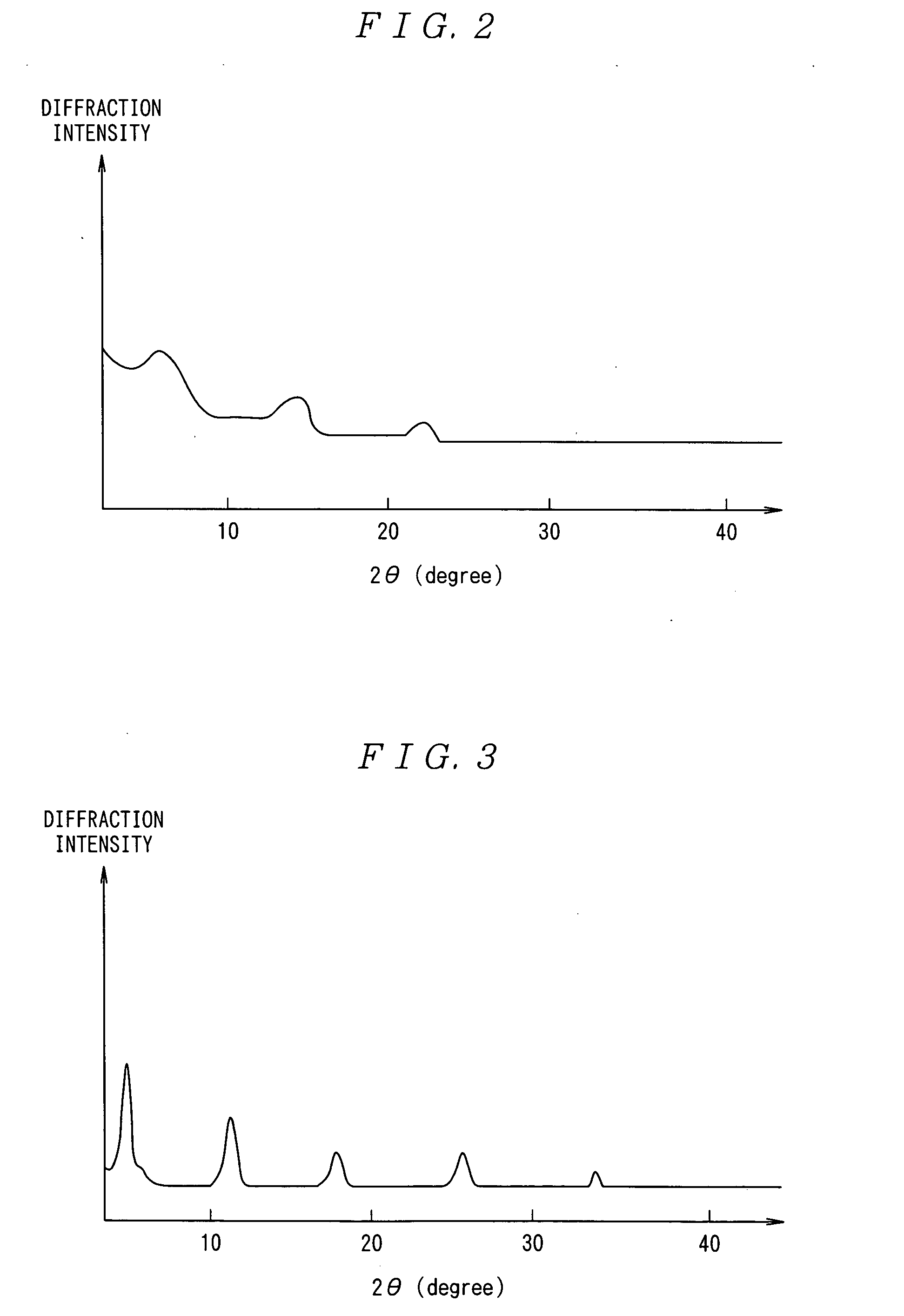

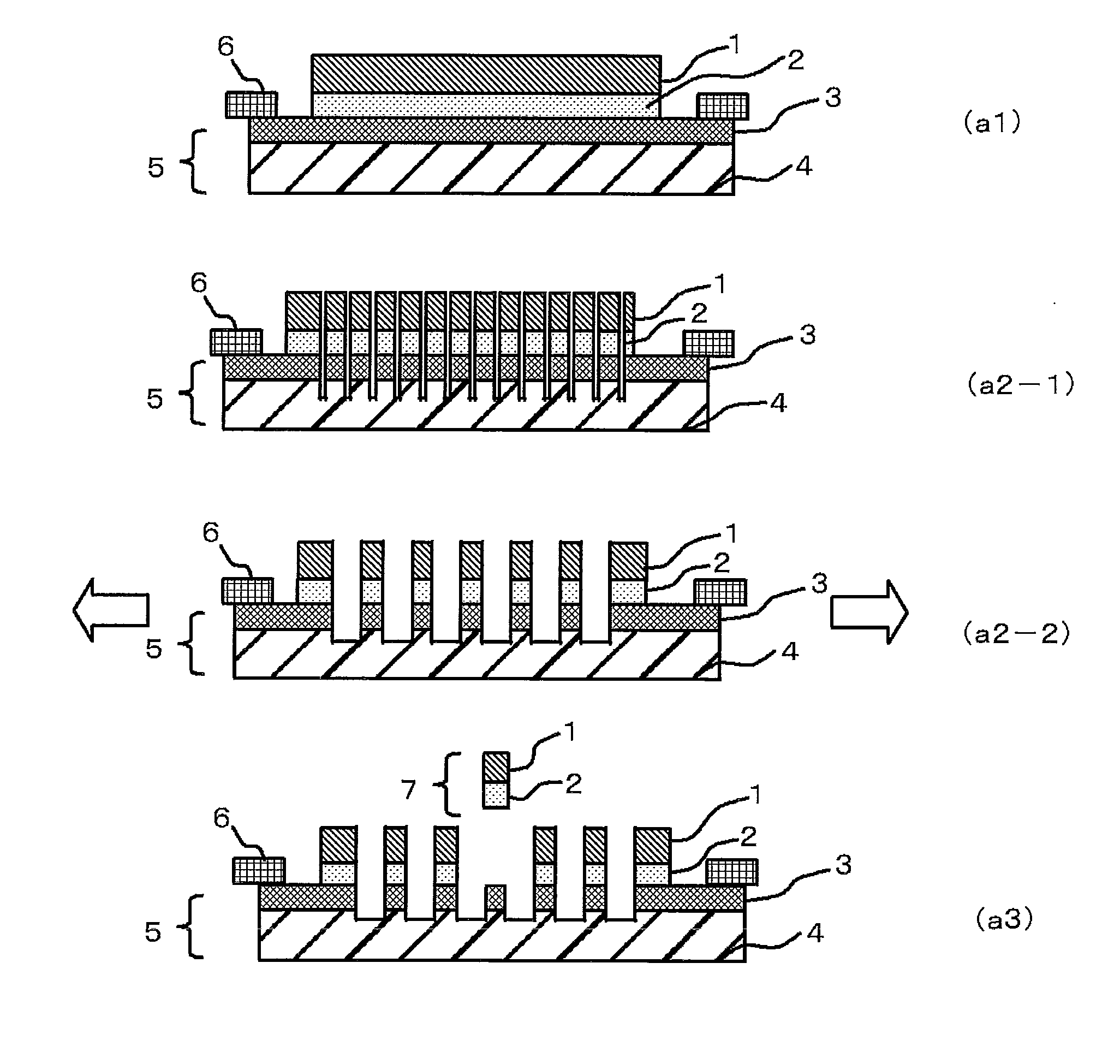

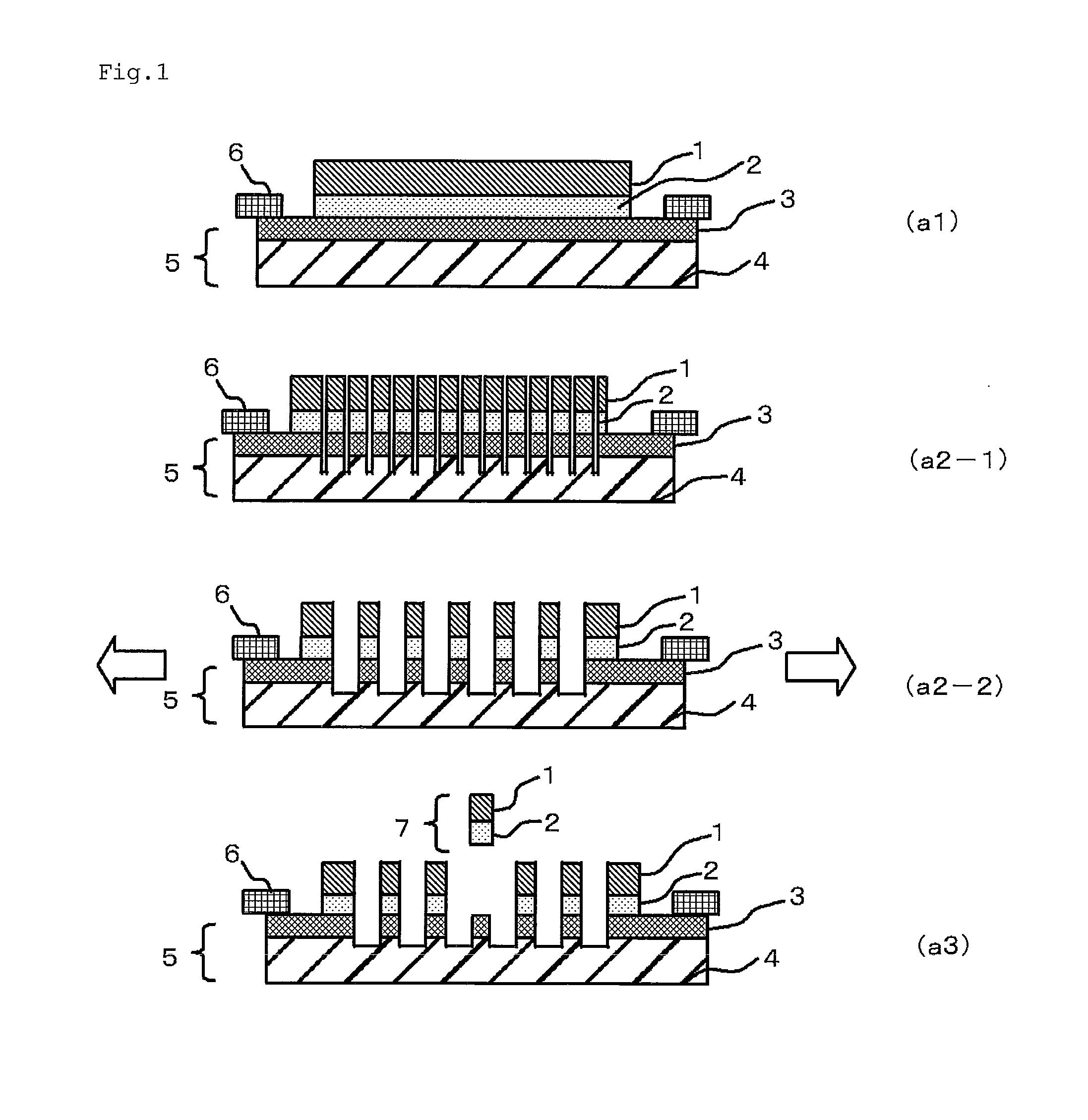

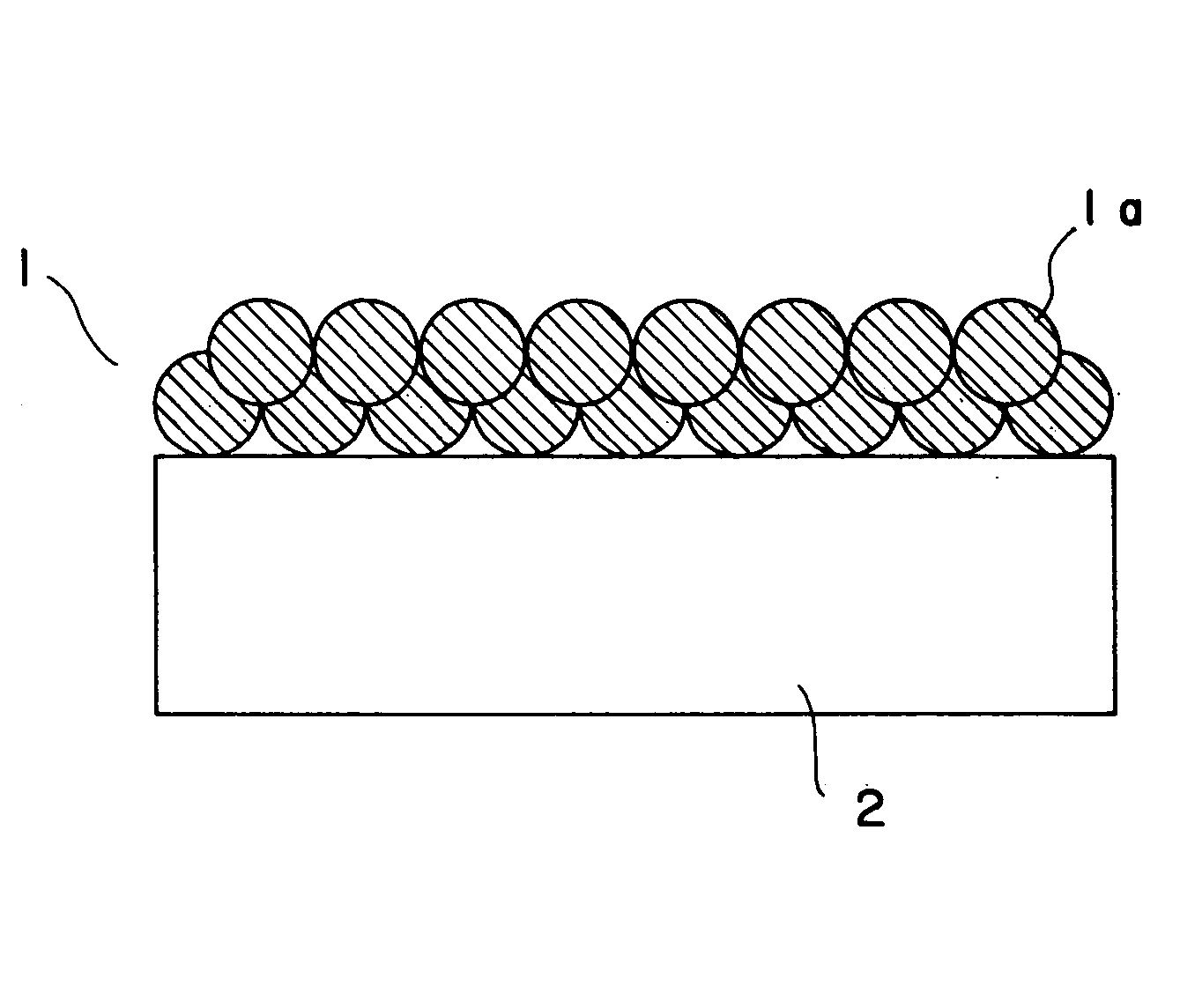

Organic semiconductor element

InactiveUS7061010B2Easy to produceLow costPolycrystalline material growthFrom normal temperature solutionsPhotonicsElectronic properties

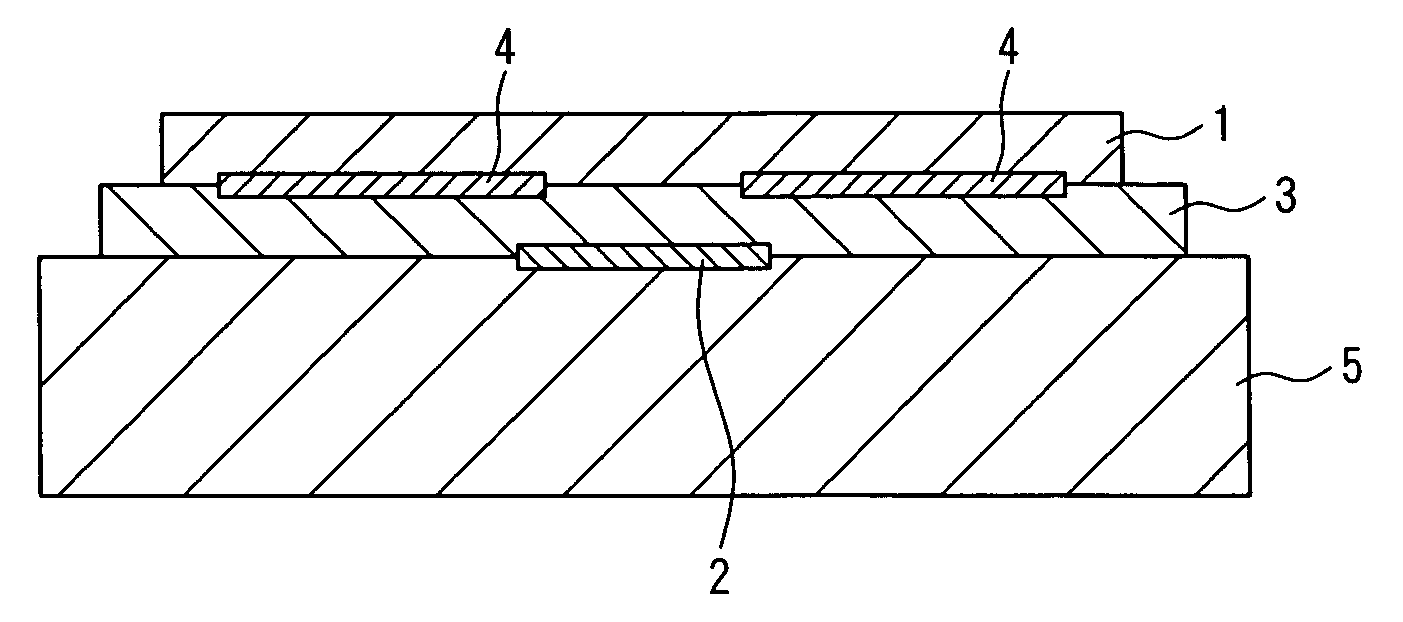

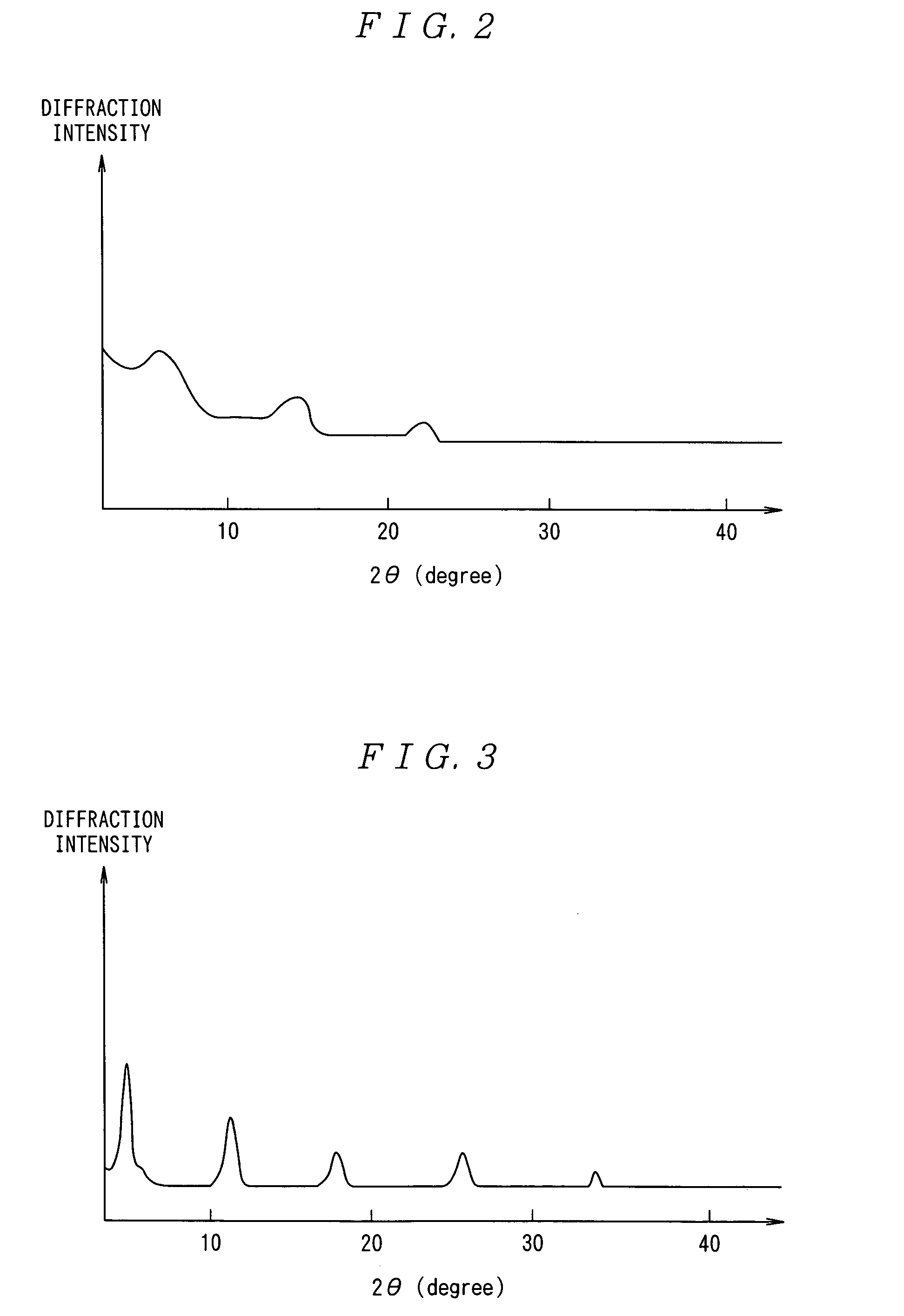

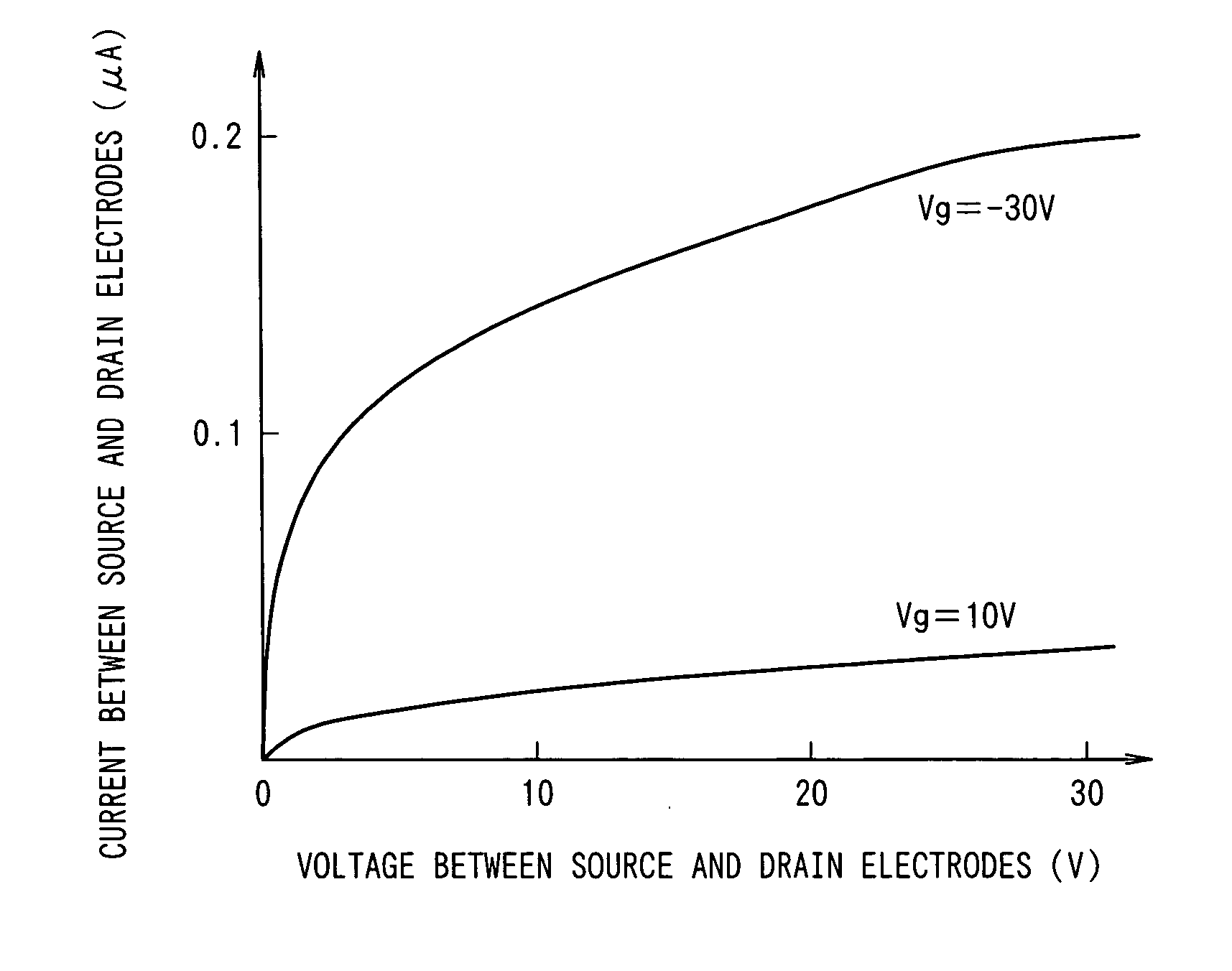

The present invention relates to an organic semiconductor thin film suitably employed in electronics, photonics, bioelectronics, or the like, and a method for forming the same. The present invention further relates to a solution for an organic semiconductor used to form the organic semiconductor thin film and an organic semiconductor device using the organic semiconductor thin film.The transistor of the present invention is manufactured by forming sequentially a gate electrode (2), an insulator layer (3), a source electrode and drain electrode (4, 4) on a glass substrate (5), applying thereto a 0.05% (by mass) solution of pentacene in o-dichlorobenzene and drying the solution to form an organic semiconductor thin film (1).The present invention provides a transistor with superior electronic characteristics because the organic semiconductor thin film (1), which can be formed easily at low cost, is almost free of defects.

Owner:ASAHI KASEI KK

Device and method for generating X-rays having different energy levels and material discrimination system

ActiveUS7646851B2Non-destructively inspectedDifference in levelMaterial analysis using wave/particle radiationX-ray tube with very high currentNon destructiveMicrowave

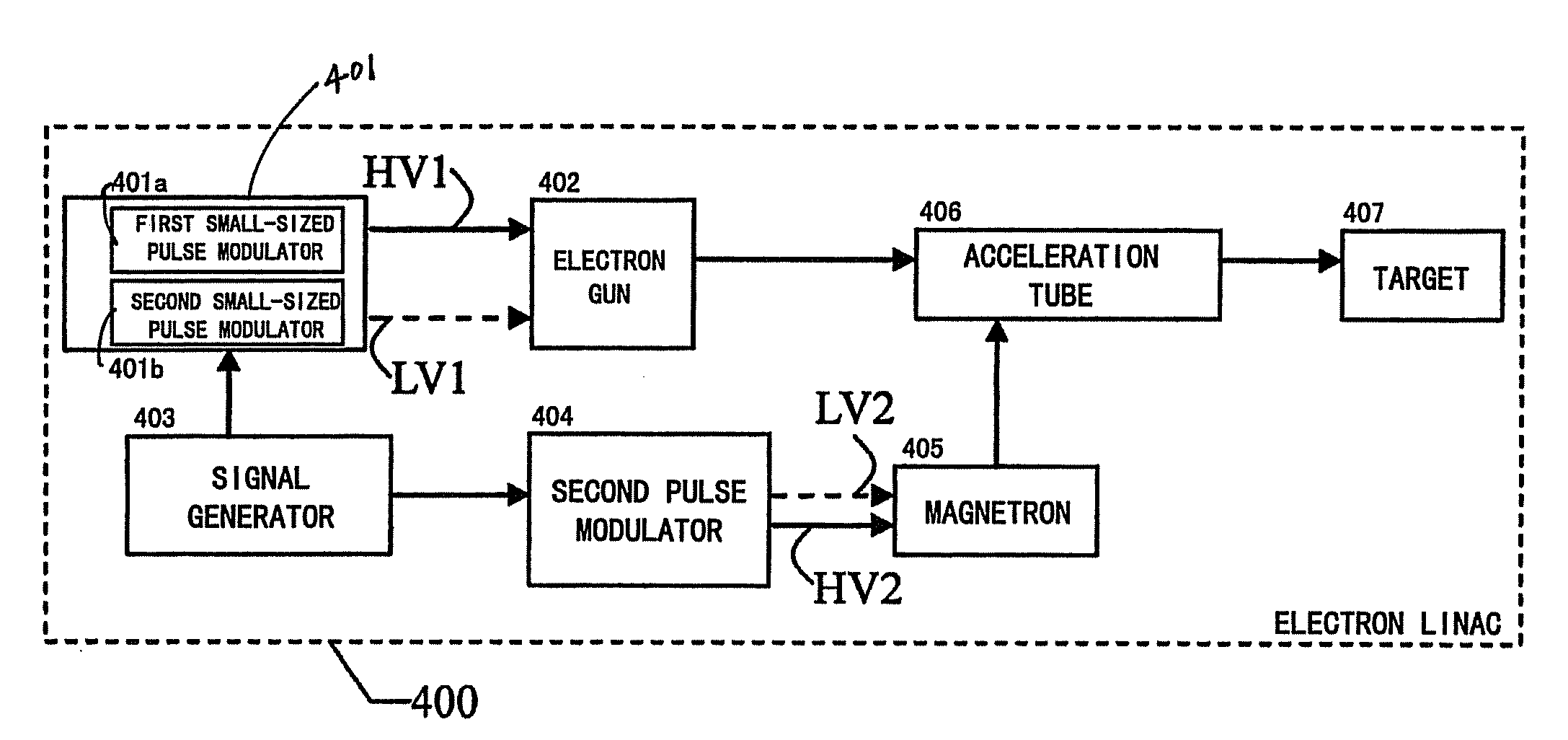

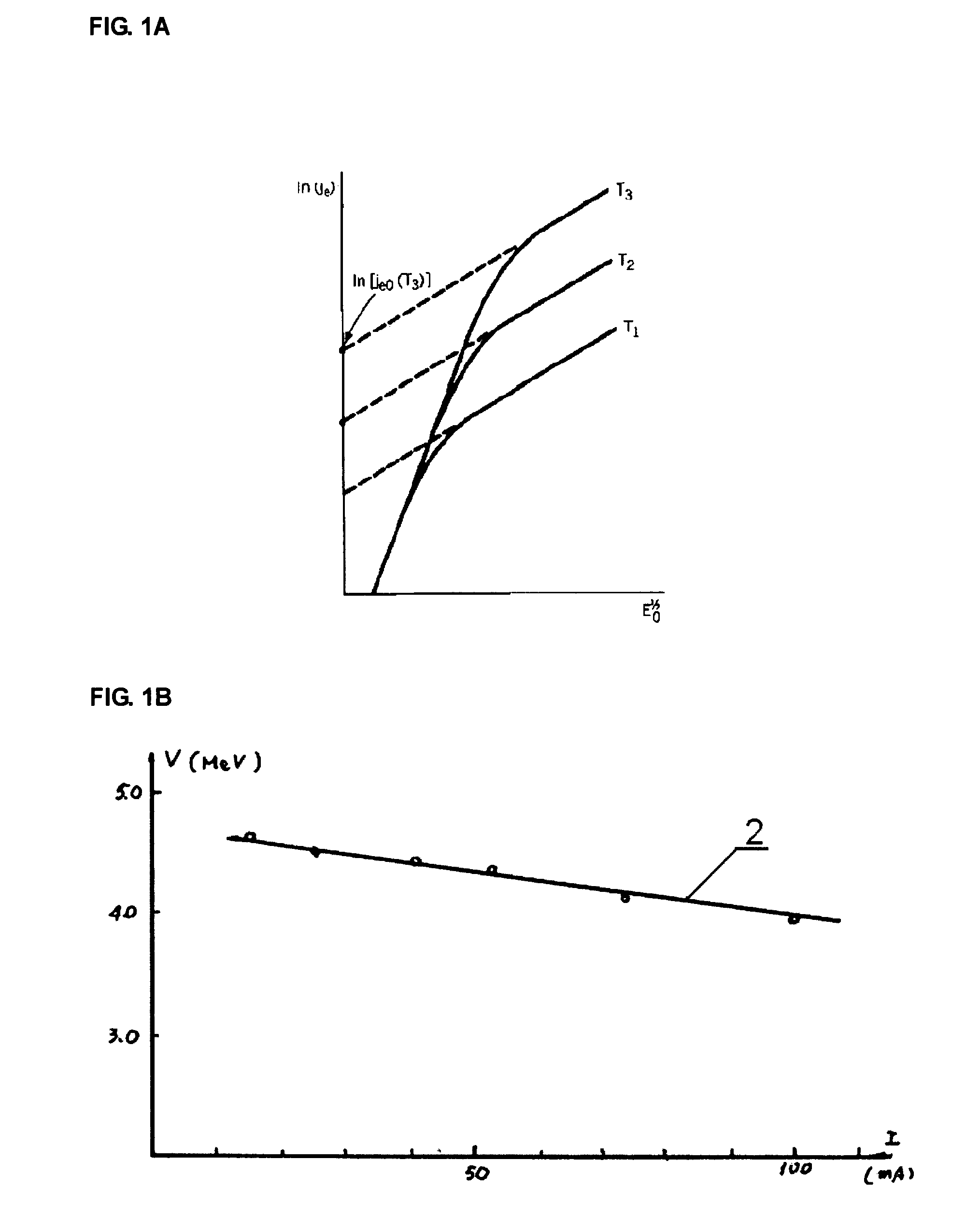

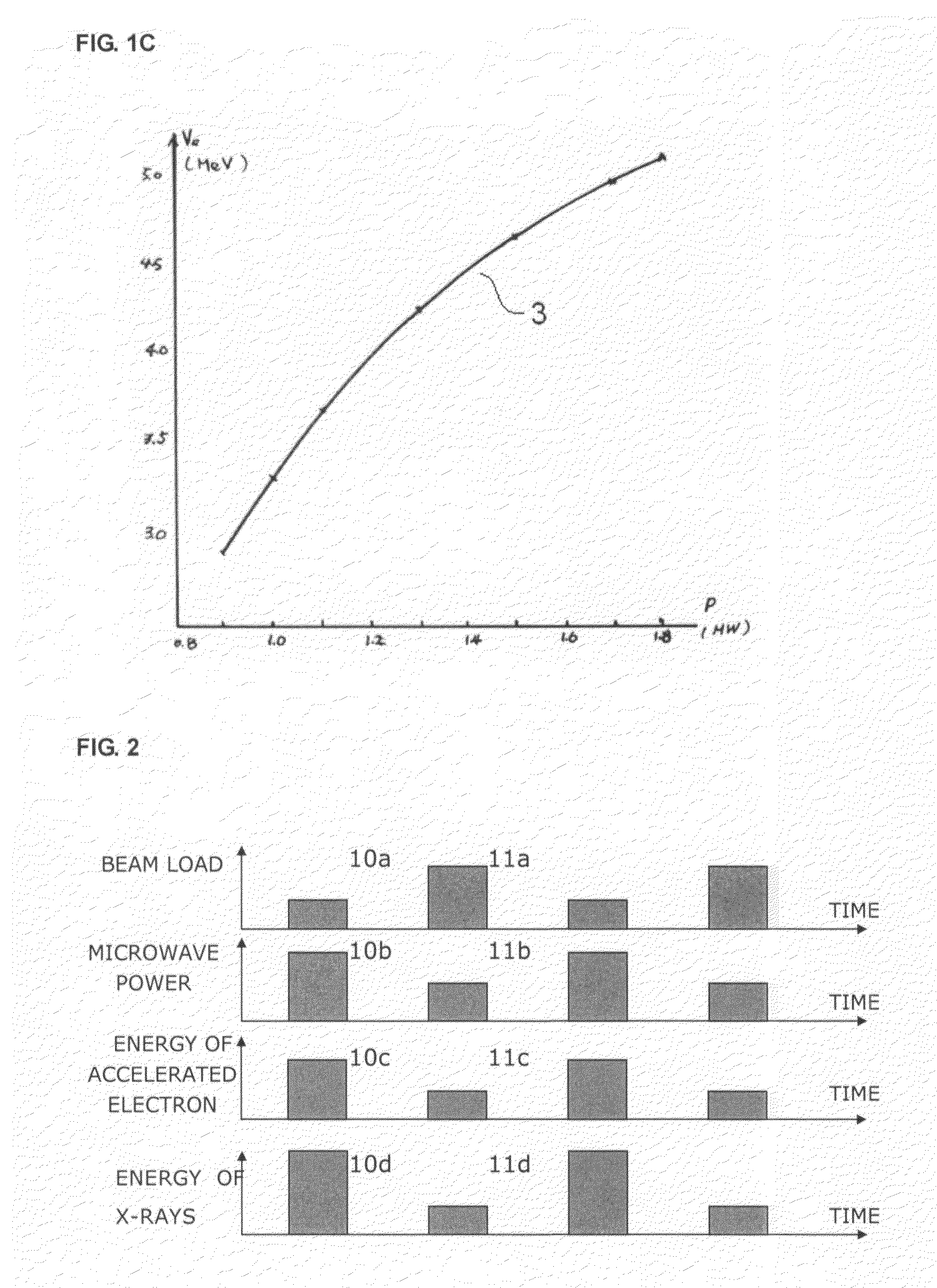

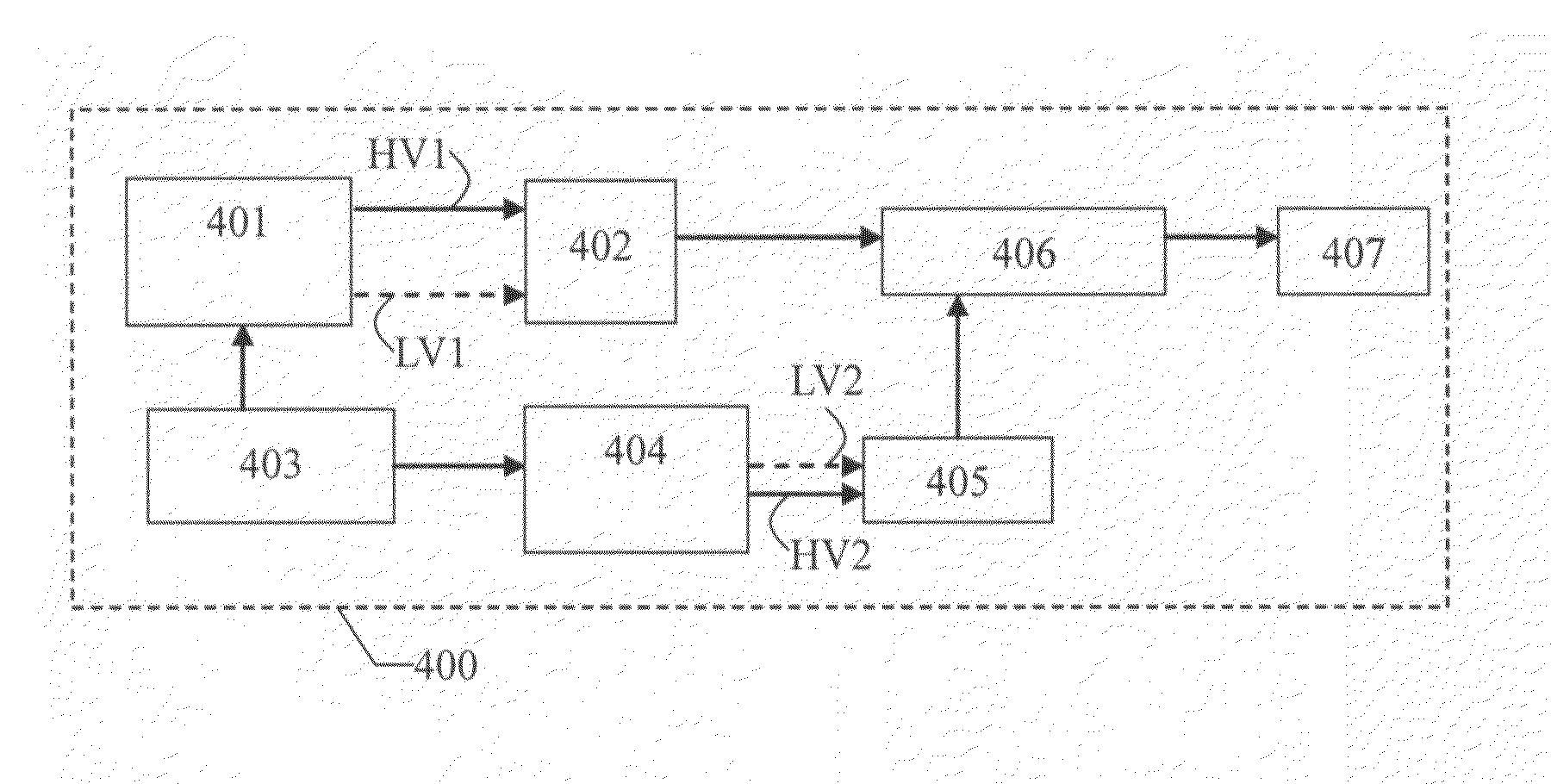

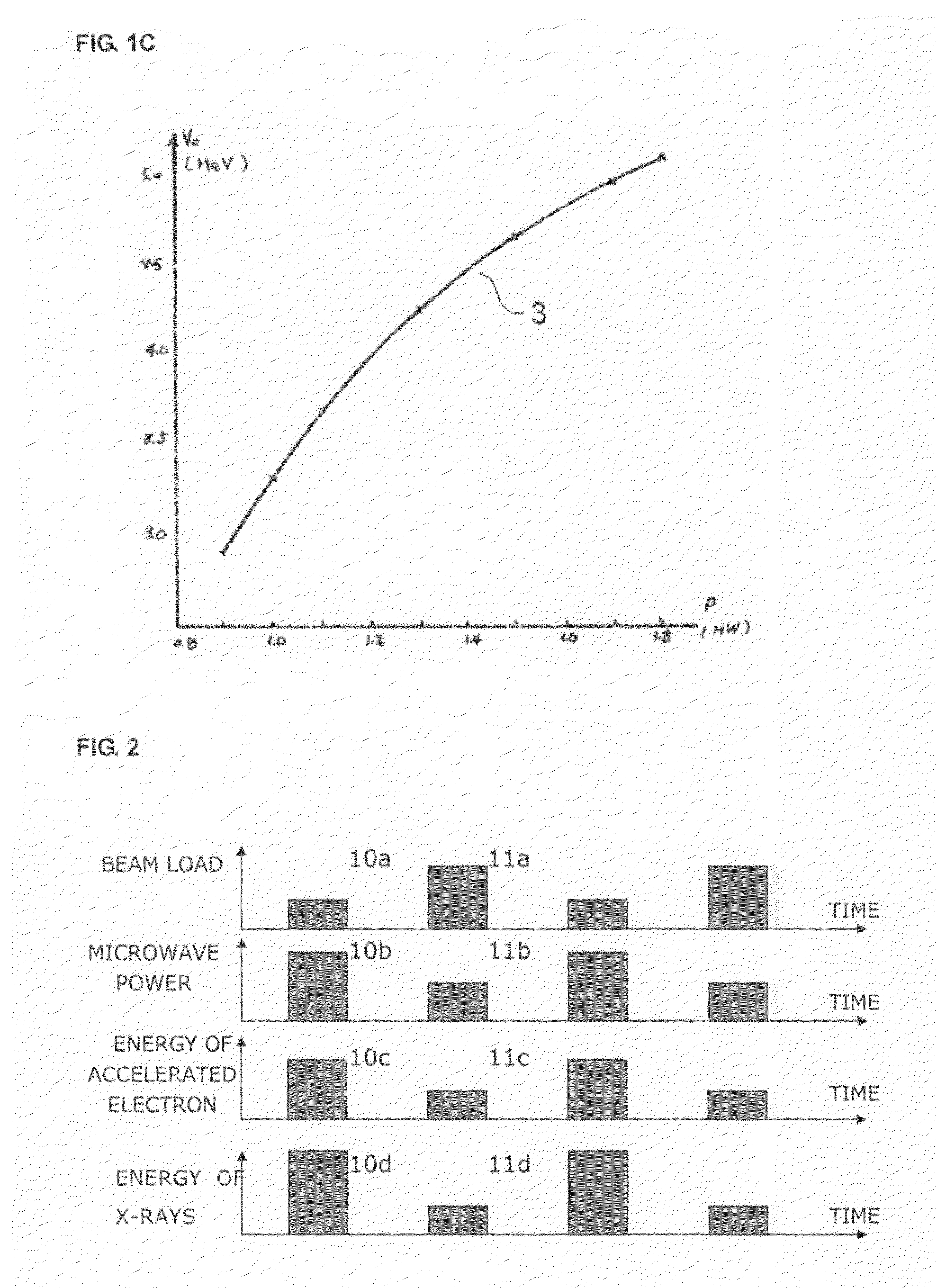

Disclosed is a device and method for generating X-rays having different energy levels as well as a material discrimination system thereof. The method comprises the steps of: generating a first pulse voltage, a second pulse voltage, a third pulse voltage and a fourth pulse voltage, generating a first electron beam having a first beam load and a second electron beam having a second beam load, respectively, based on the first pulse voltage and second pulse voltage, generating a first microwave having a first power and a second microwave having a second power, respectively, based on the third pulse voltage and the fourth pulse voltage, accelerating the first and second electron beams respectively using the first and second microwave to obtain the accelerated first electron beam and the second electron beam, hitting a target with the accelerated first electron beam and the second electron beam to generate a first X-ray and a second X-ray having different energy levels. The X-rays having different energy levels generated by the present invention can be used in the non-destructive inspection for large-sized container cargo at places such as Customs, ports and airports, and in realizing the material discrimination for the inspected object.

Owner:TSINGHUA UNIV +1

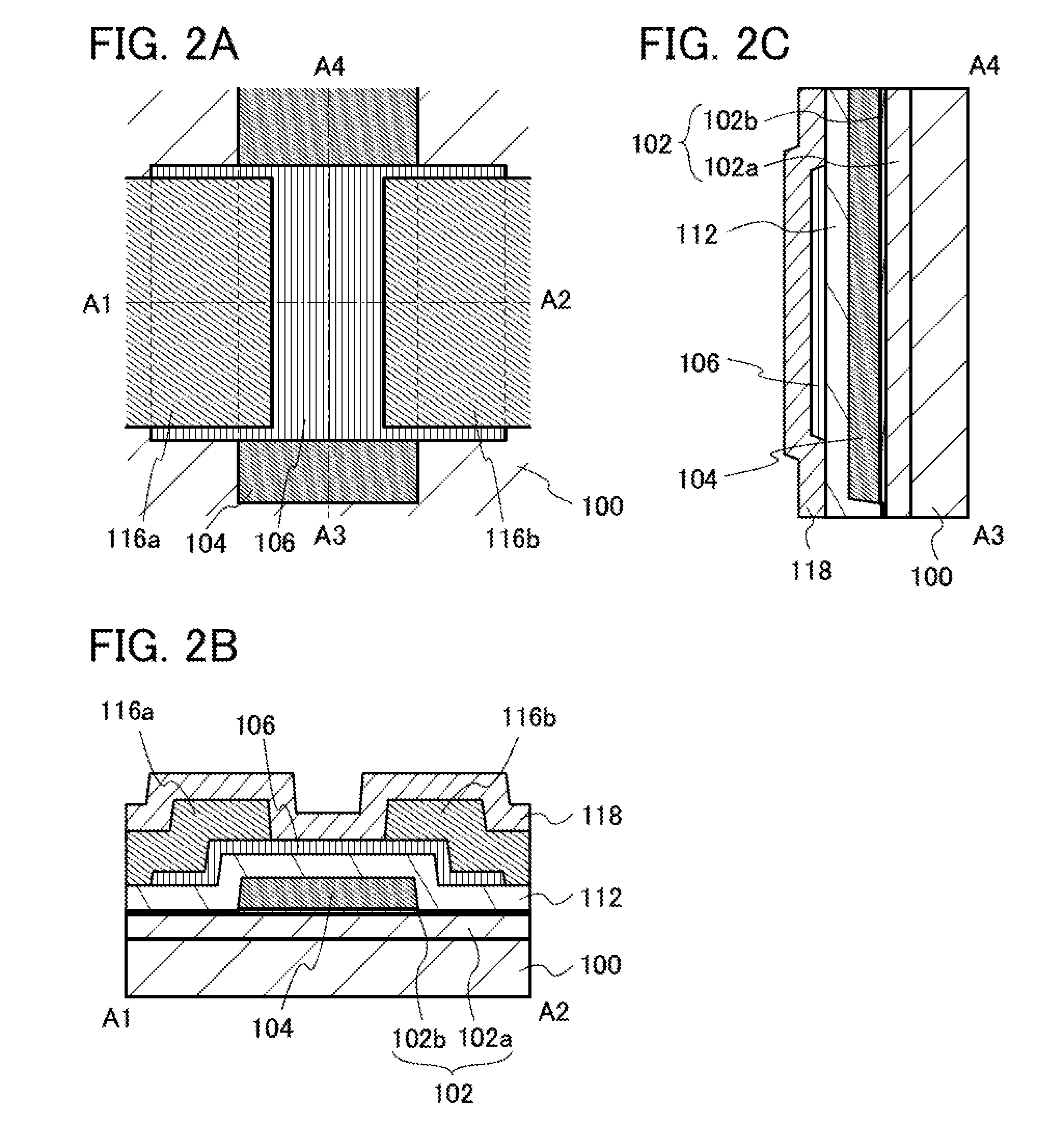

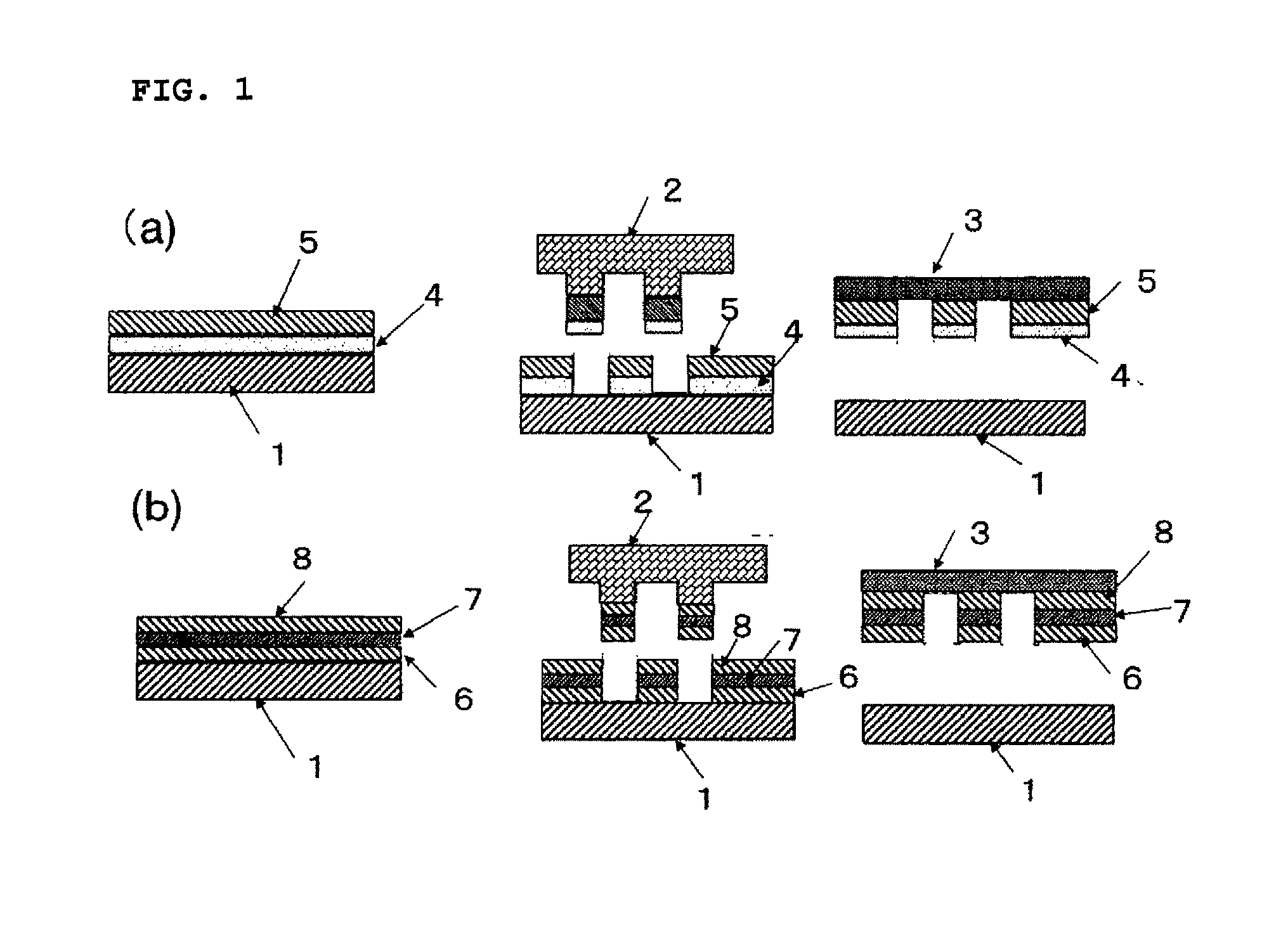

Processing method of stacked-layer film and manufacturing method of semiconductor device

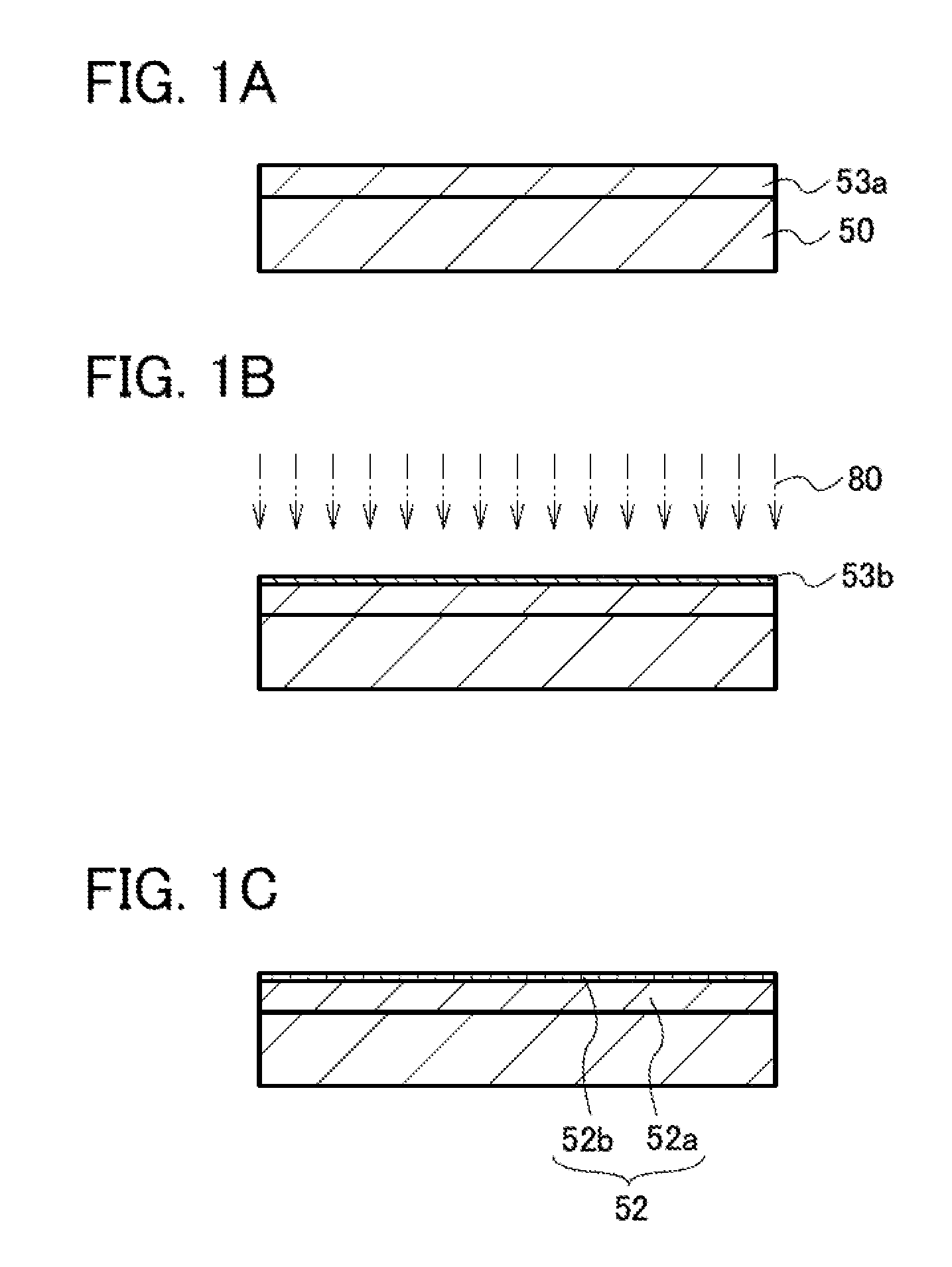

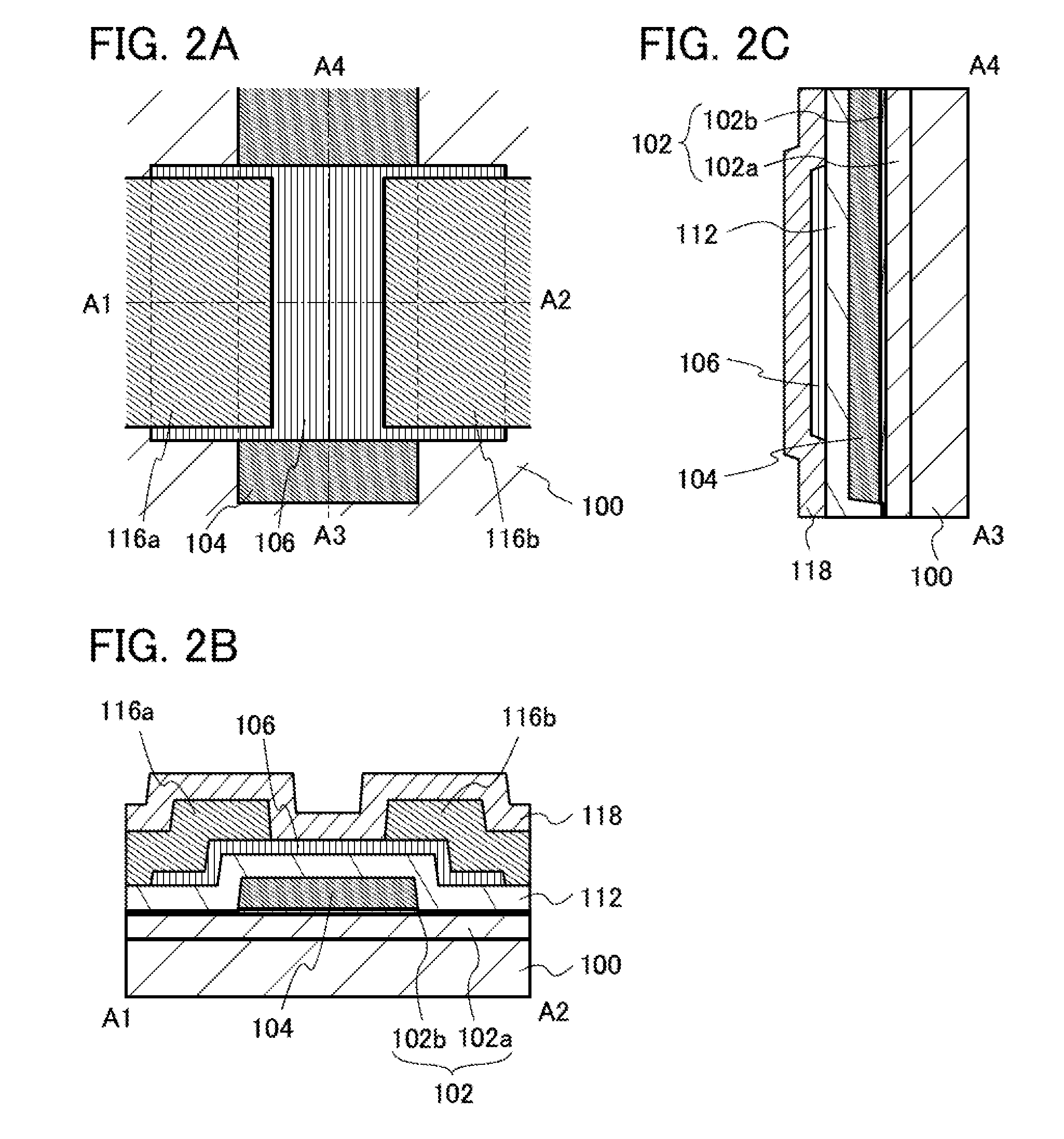

ActiveUS20130267068A1Reduce thicknessDecrease in yieldSolid-state devicesSemiconductor/solid-state device manufacturingPolymer chemistryOxide

In a processing method of a stacked-layer film in which a metal film is provided on an oxide insulating film, plasma containing an oxygen ion is generated by applying high-frequency power with power density greater than or equal to 0.59 W / cm2 and less than or equal to 1.18 W / cm2 to the stacked-layer film side under an atmosphere containing oxygen in which pressure is greater than or equal to 5 Pa and less than or equal to 15 Pa, the metal film is oxidized by the oxygen ion, and an oxide insulating film containing excess oxygen is formed by supplying oxygen to the oxide insulating film.

Owner:SEMICON ENERGY LAB CO LTD

Device and method for generating x-rays having different energy levels and material discrimination system

ActiveUS20070269013A1Improve accuracyShort lifeMaterial analysis using wave/particle radiationX-ray tube with very high currentNon destructiveMicrowave

Disclosed is a device and method for generating X-rays having different energy levels as well as a material discrimination system thereof. The method comprises the steps of: generating a first pulse voltage, a second pulse voltage, a third pulse voltage and a fourth pulse voltage, generating a first electron beam having a first beam load and a second electron beam having a second beam load, respectively, based on the first pulse voltage and second pulse voltage, generating a first microwave having a first power and a second microwave having a second power, respectively, based on the third pulse voltage and the fourth pulse voltage, accelerating the first and second electron beams respectively using the first and second microwave to obtain the accelerated first electron beam and the second electron beam, hitting a target with the accelerated first electron beam and the second electron beam to generate a first X-ray and a second X-ray having different energy levels. The X-rays having different energy levels generated by the present invention can be used in the non-destructive inspection for large-sized container cargo at places such as Customs, ports and airports, and in realizing the material discrimination for the inspected object.

Owner:TSINGHUA UNIV +1

Organic semicondutor element

InactiveUS20050258417A1Reduce spacingIncrease speedPolycrystalline material growthFrom normal temperature solutionsPhotonicsElectron

The present invention relates to an organic semiconductor thin film suitably employed in electronics, photonics, bioelectronics, or the like, and a method for forming the same. The present invention further relates to a solution for an organic semiconductor used to form the organic semiconductor thin film and an organic semiconductor device using the organic semiconductor thin film. The transistor of the present invention is manufactured by forming sequentially a gate electrode (2), an insulator layer (3), a source electrode and drain electrode (4, 4) on a glass substrate (5), applying thereto a 0.05% (by mass) solution of pentacene in o-dichlorobenzene and drying the solution to form an organic semiconductor thin film (1). The present invention provides a transistor with superior electronic characteristics because the organic semiconductor thin film (1), which can be formed easily at low cost, is almost free of defects.

Owner:ASAHI KASEI KK

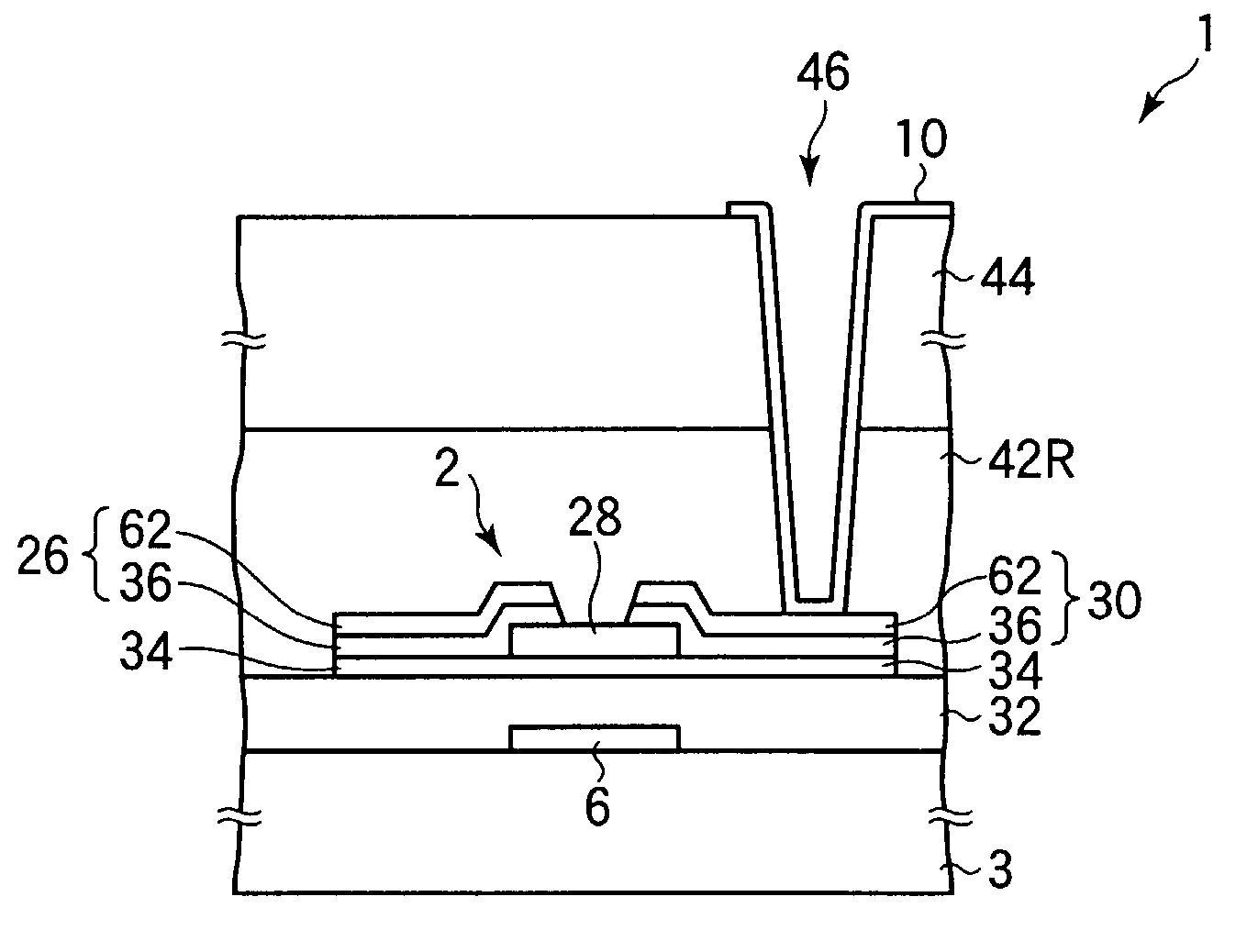

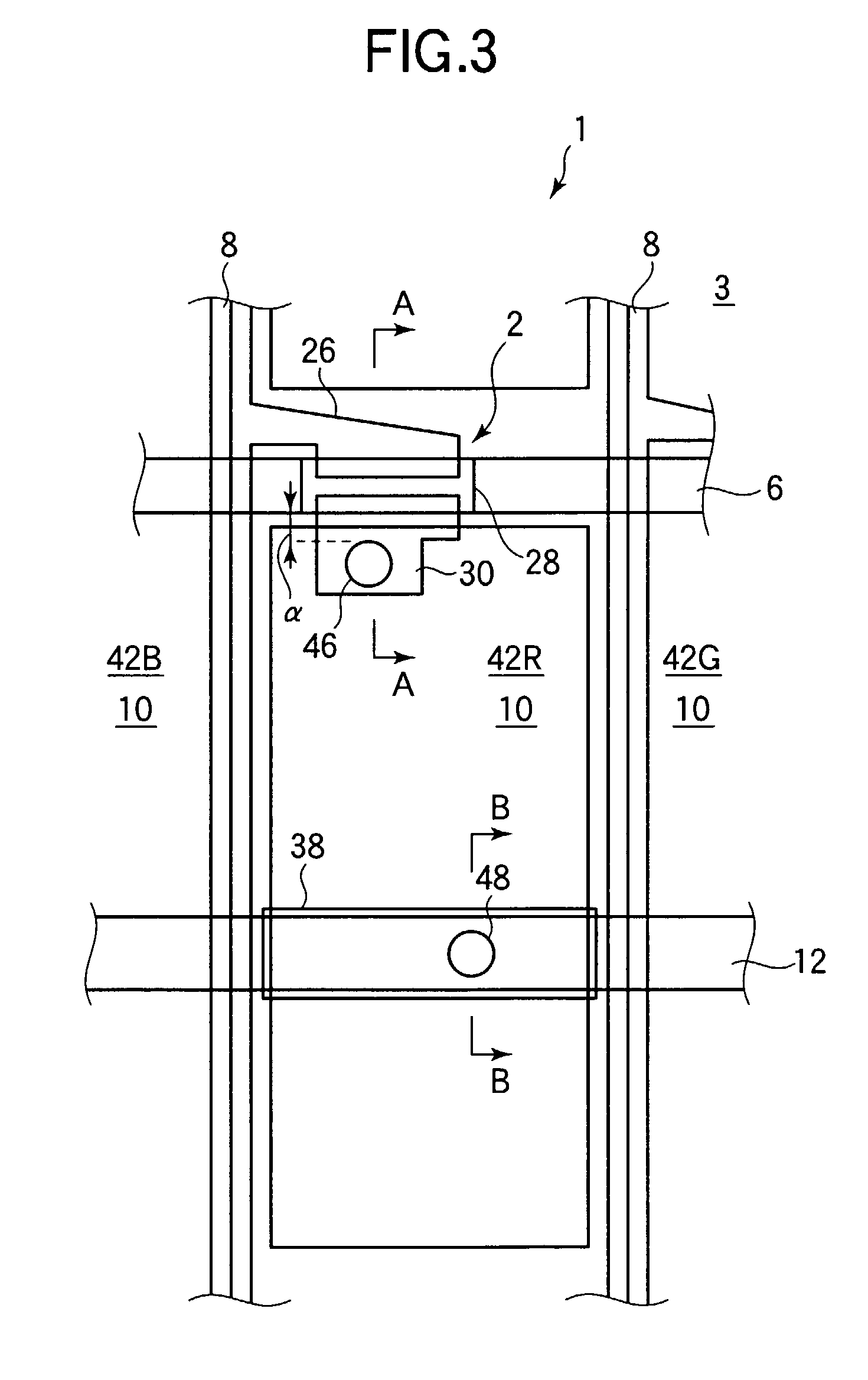

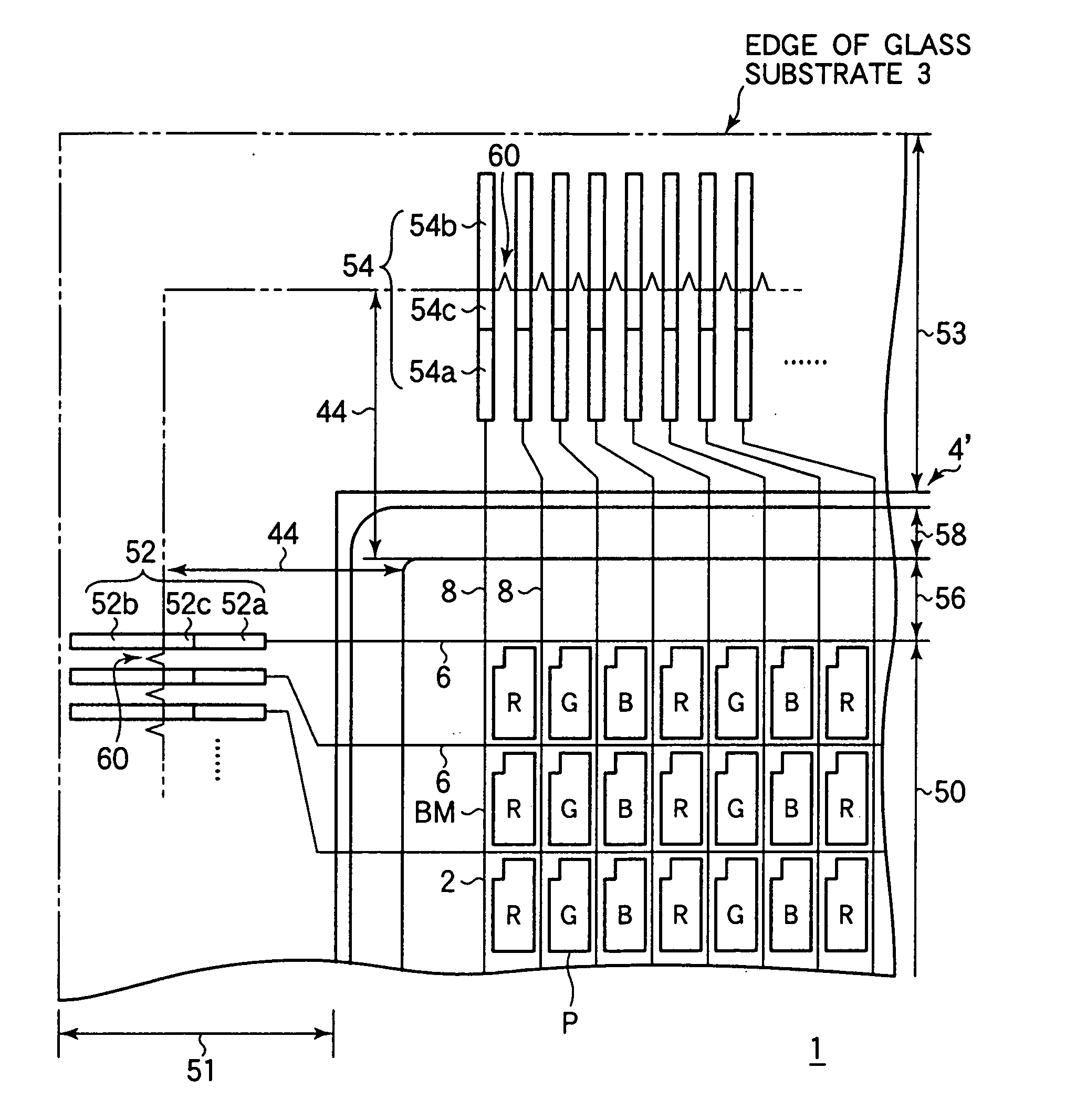

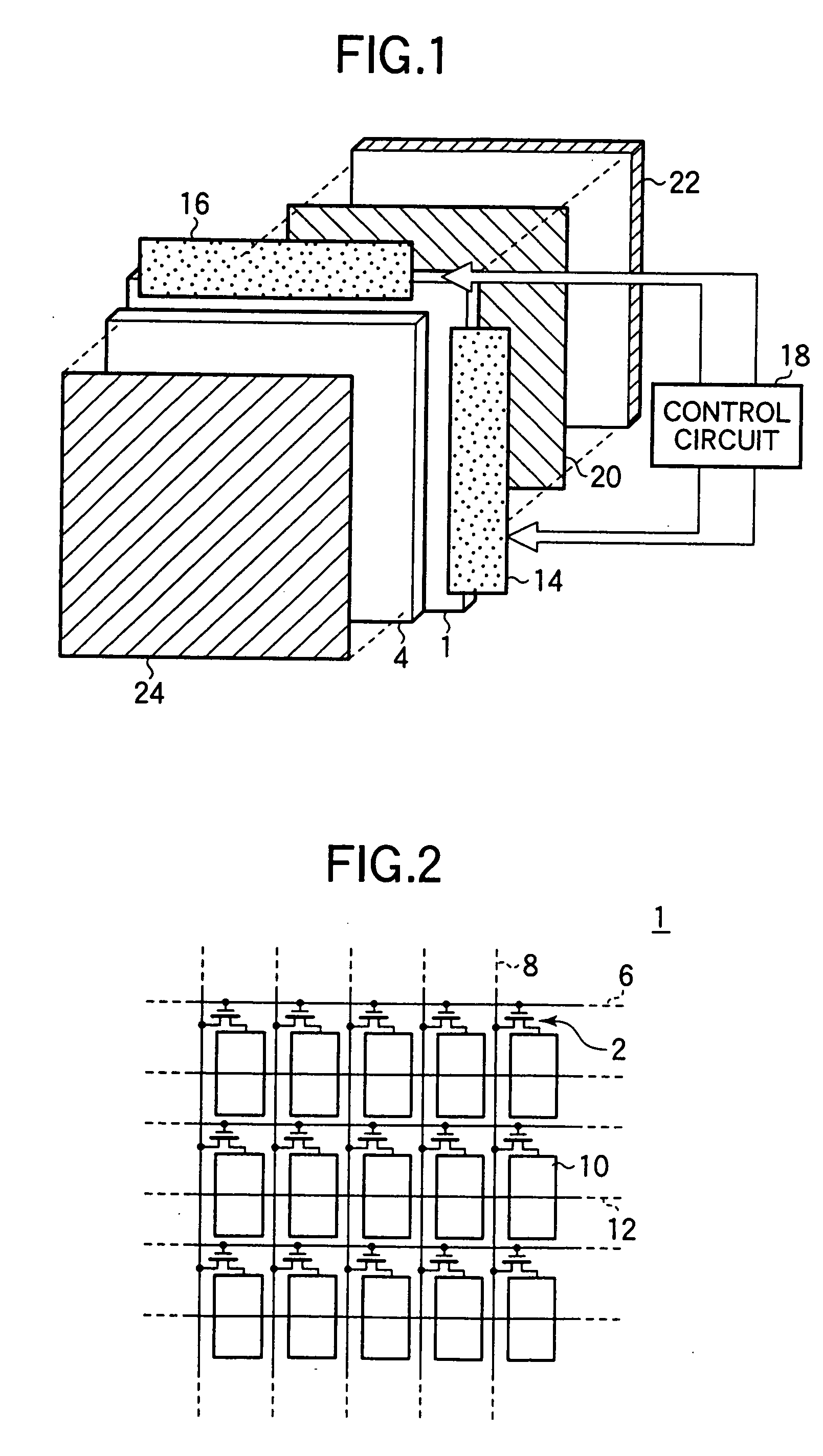

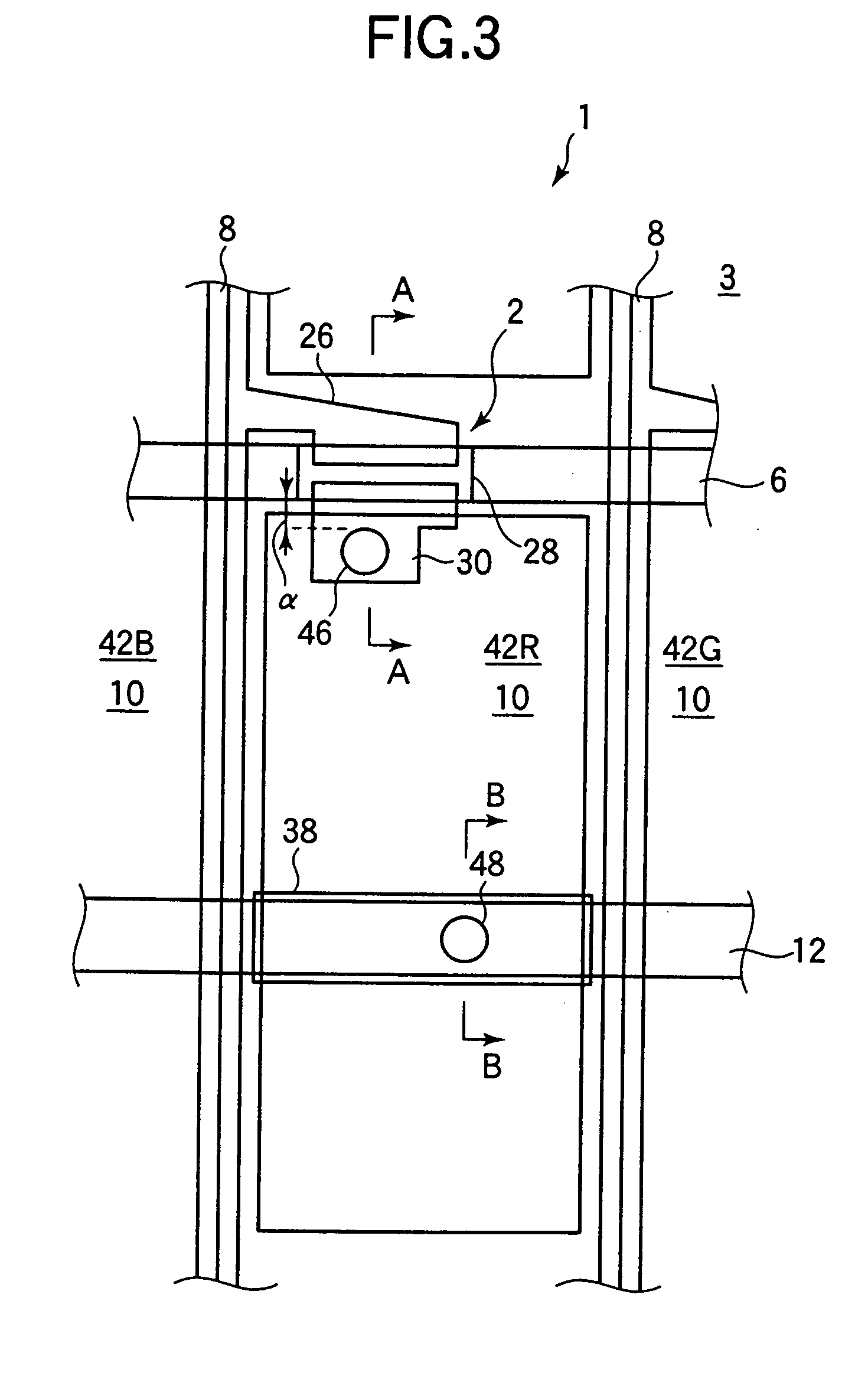

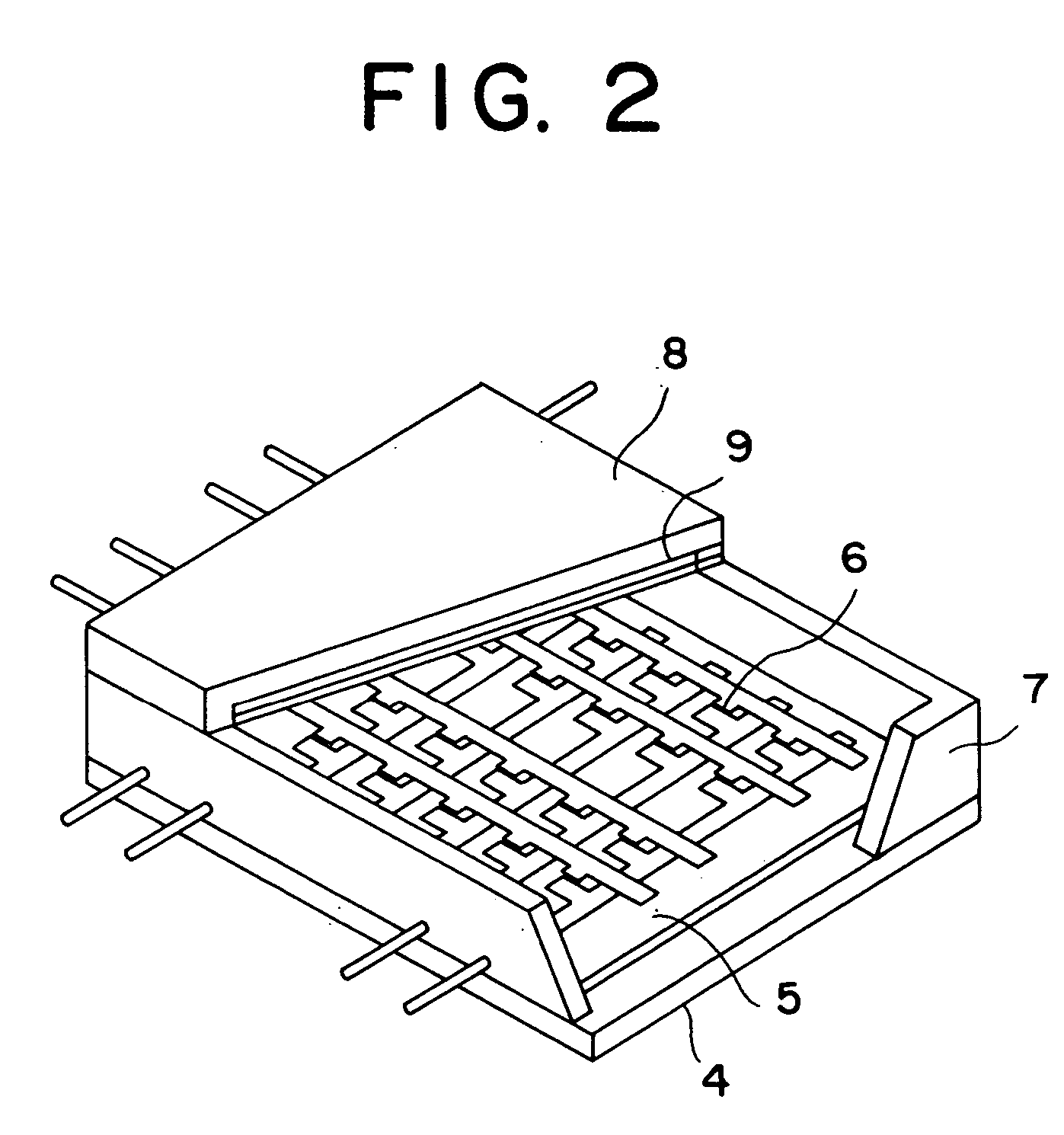

Substrate for use in a liquid crystal display and liquid crystal display using the same

InactiveUS7050137B2Occurrence of crack can be suppressedImprove reliabilityTransistorStatic indicating devicesLiquid-crystal displayExternal connection

The invention relates to a substrate for use in a liquid crystal display of a CF-on-TFT structure in which a color filter is formed on the side of an array substrate in which a switching element is formed, and has an object to provide a substrate for use in a liquid crystal display, which enables simplification of a manufacturing process typified by a photolithography process and has high reliability. The substrate for use in the liquid crystal display is constructed to include external connection terminals which include first terminal electrodes electrically connected to gate bus lines led out from a plurality of pixel regions arranged on a glass substrate in a matrix form, second terminal electrodes formed of forming material of a pixel electrode and directly on the glass substrate, and electrode coupling regions for electrically connecting the first and the second terminal electrodes, and which electrically connect an external circuit and the gate bus lines.

Owner:SHARP KK

Processing method of stacked-layer film and manufacturing method of semiconductor device

ActiveUS8999773B2Reduce thicknessEasy to shapeTransistorSolid-state devicesHigh frequency powerExcess oxygen

In a processing method of a stacked-layer film in which a metal film is provided on an oxide insulating film, plasma containing an oxygen ion is generated by applying high-frequency power with power density greater than or equal to 0.59 W / cm2 and less than or equal to 1.18 W / cm2 to the stacked-layer film side under an atmosphere containing oxygen in which pressure is greater than or equal to 5 Pa and less than or equal to 15 Pa, the metal film is oxidized by the oxygen ion, and an oxide insulating film containing excess oxygen is formed by supplying oxygen to the oxide insulating film.

Owner:SEMICON ENERGY LAB CO LTD

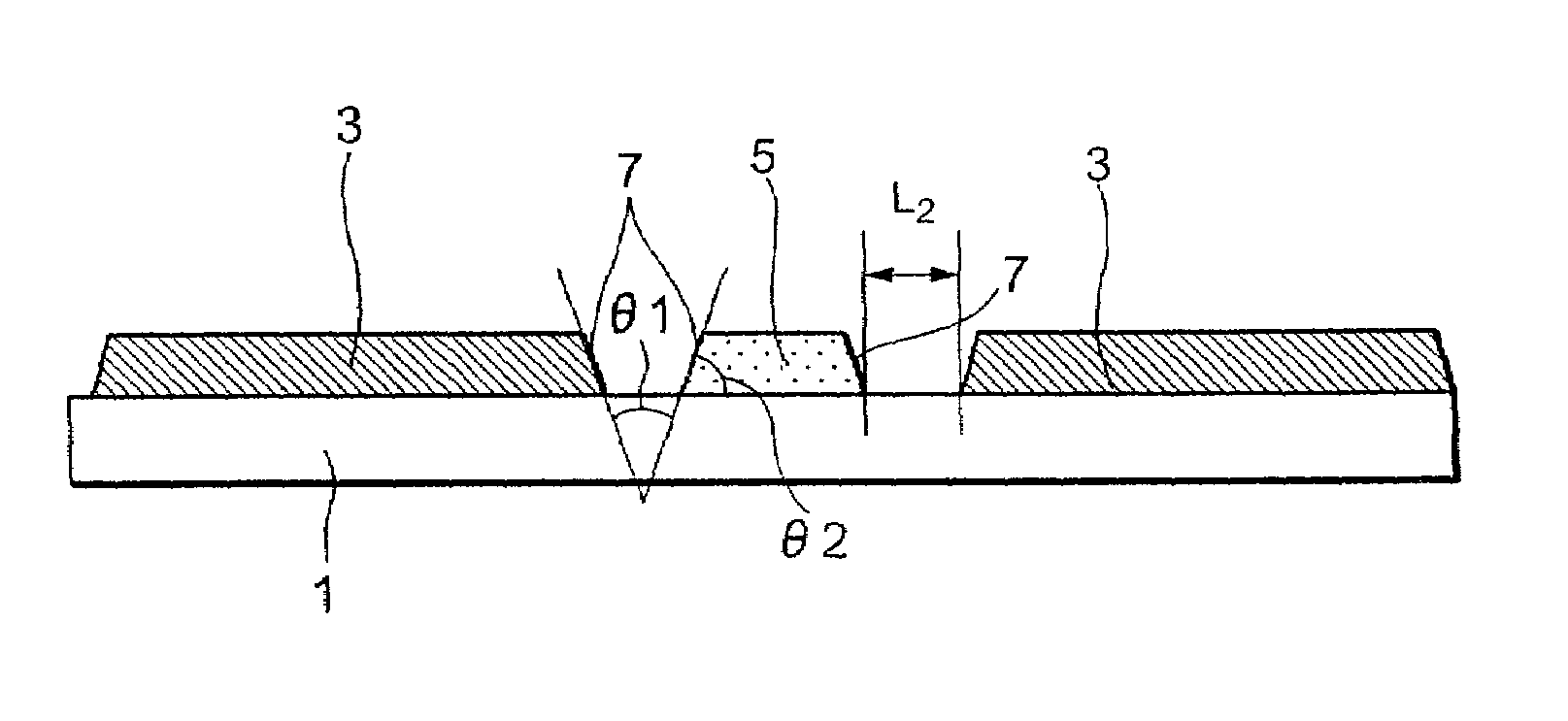

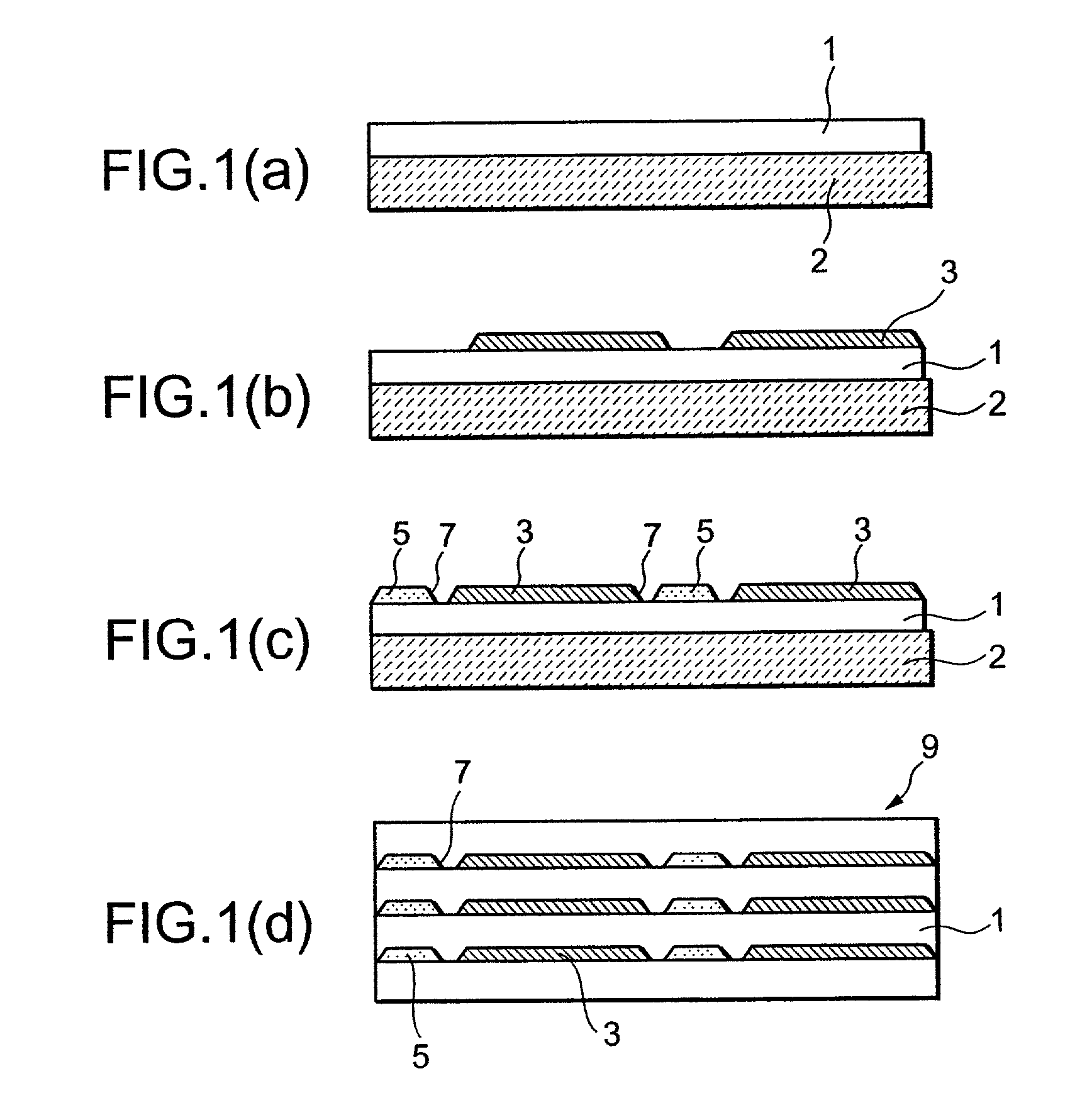

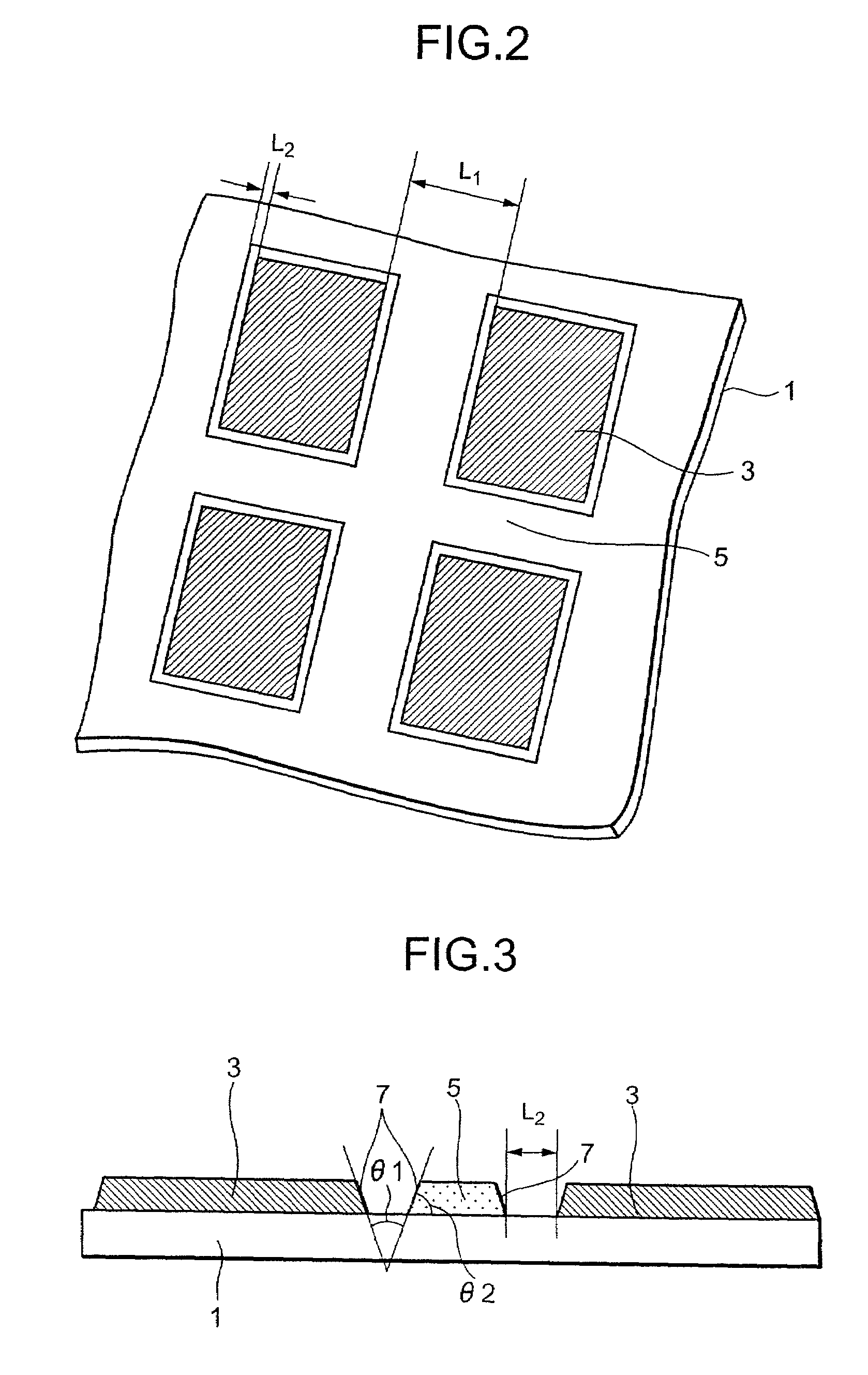

Method of producing ceramic laminates

InactiveUS7089659B2Suppress cracksSuppressing occurrenceCeramic layered productsCircuit susbtrate materialsMetallurgySlurry

A method of producing ceramic laminates includes forming a ceramic green sheet by applying a ceramic slurry on a carrier film; forming, maintaining a predetermined gap, a plurality of electrically conducting patterns having inclined surfaces at the ends by printing an electrically conducting paste on the main surface of the ceramic green sheet; forming ceramic patterns having inclined surfaces at the ends among the electrically conducting patterns by printing a ceramic paste with a distance of not smaller than 10μm from the electrically conducting patterns; and laminating ceramic green sheets on which are formed the electrically conducting and ceramic patterns.

Owner:KYOCERA CORP

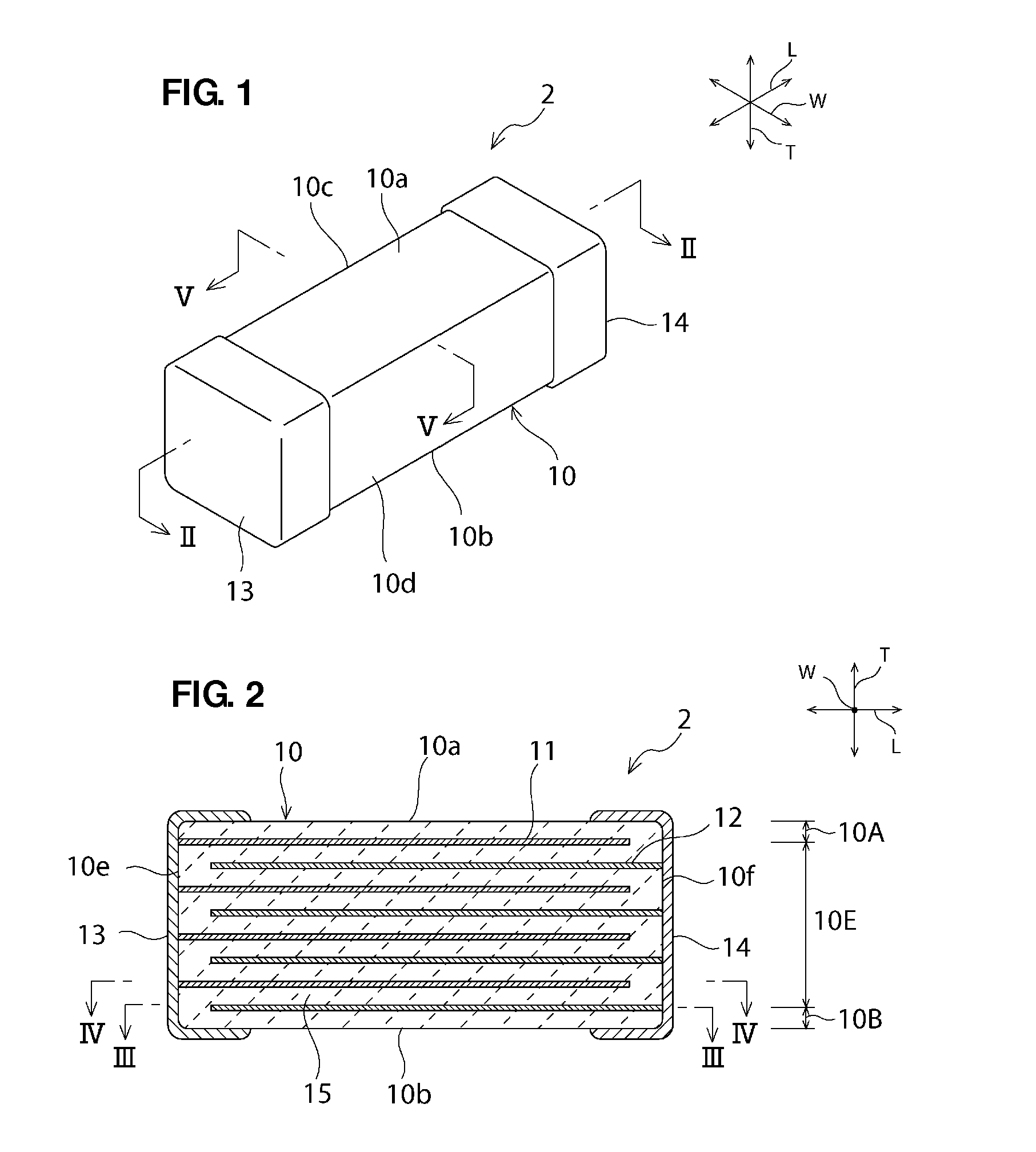

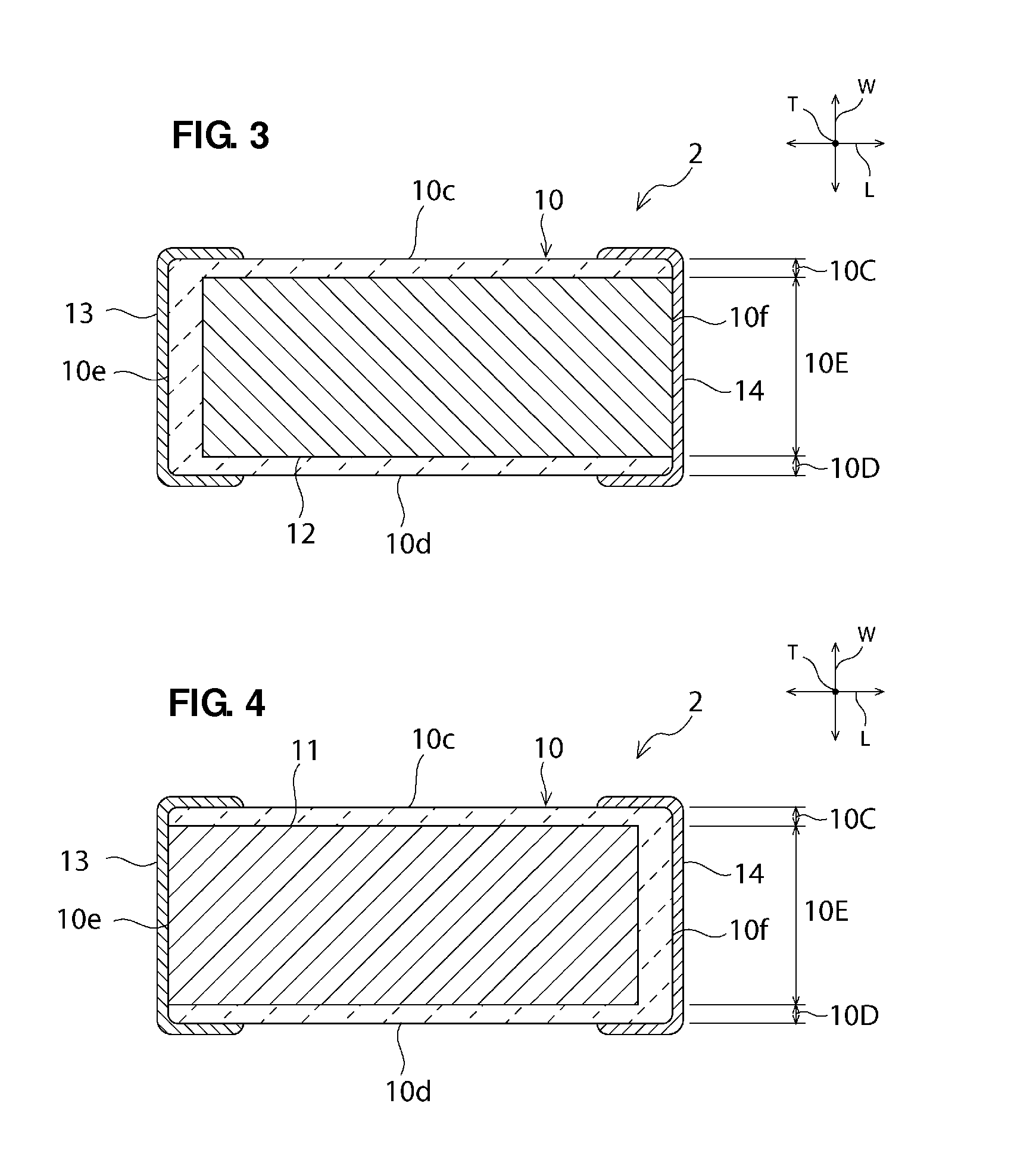

Multilayer ceramic electronic component

ActiveUS20120250220A1Improve electrical strengthDifference in levelFixed capacitor electrodesFixed capacitor dielectricElectronic componentUltimate tensile strength

A multilayer ceramic electronic component that is small, that has high electrical strength, and that is resistant to separation between ceramic layers includes a ceramic sintered body having a substantially rectangular parallelepiped shape and a plurality of first and second internal electrodes. The plurality of first and second internal electrodes are alternately arranged so as to face each other. The first and second internal electrodes are parallel or substantially parallel to first and second major surfaces. The first and second internal electrodes are exposed to at least one of the fifth and sixth surfaces and are not exposed to the third or fourth surface. No bends exist in any of the ends of each of the first and second internal electrodes adjacent to the third and fourth surfaces.

Owner:MURATA MFG CO LTD

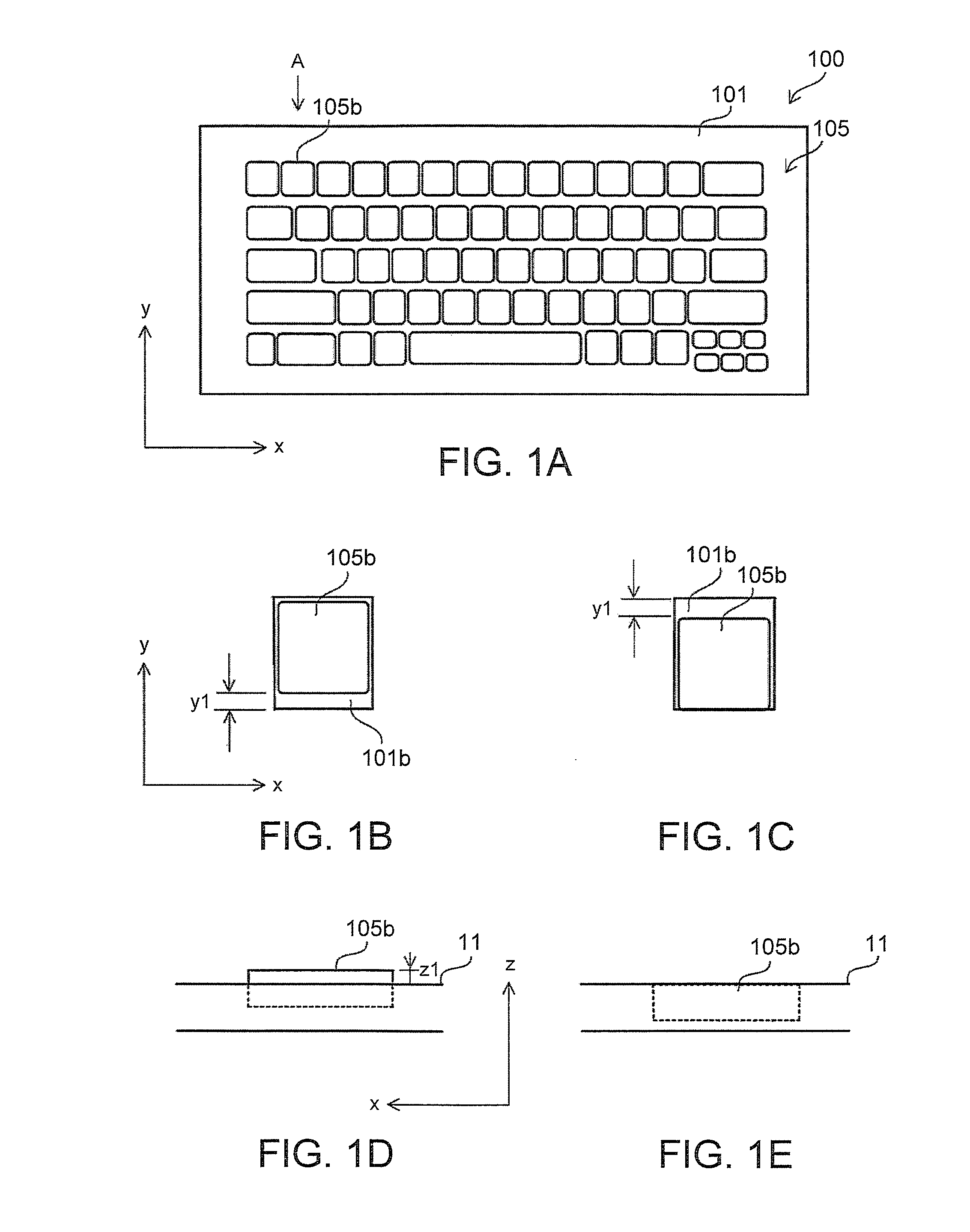

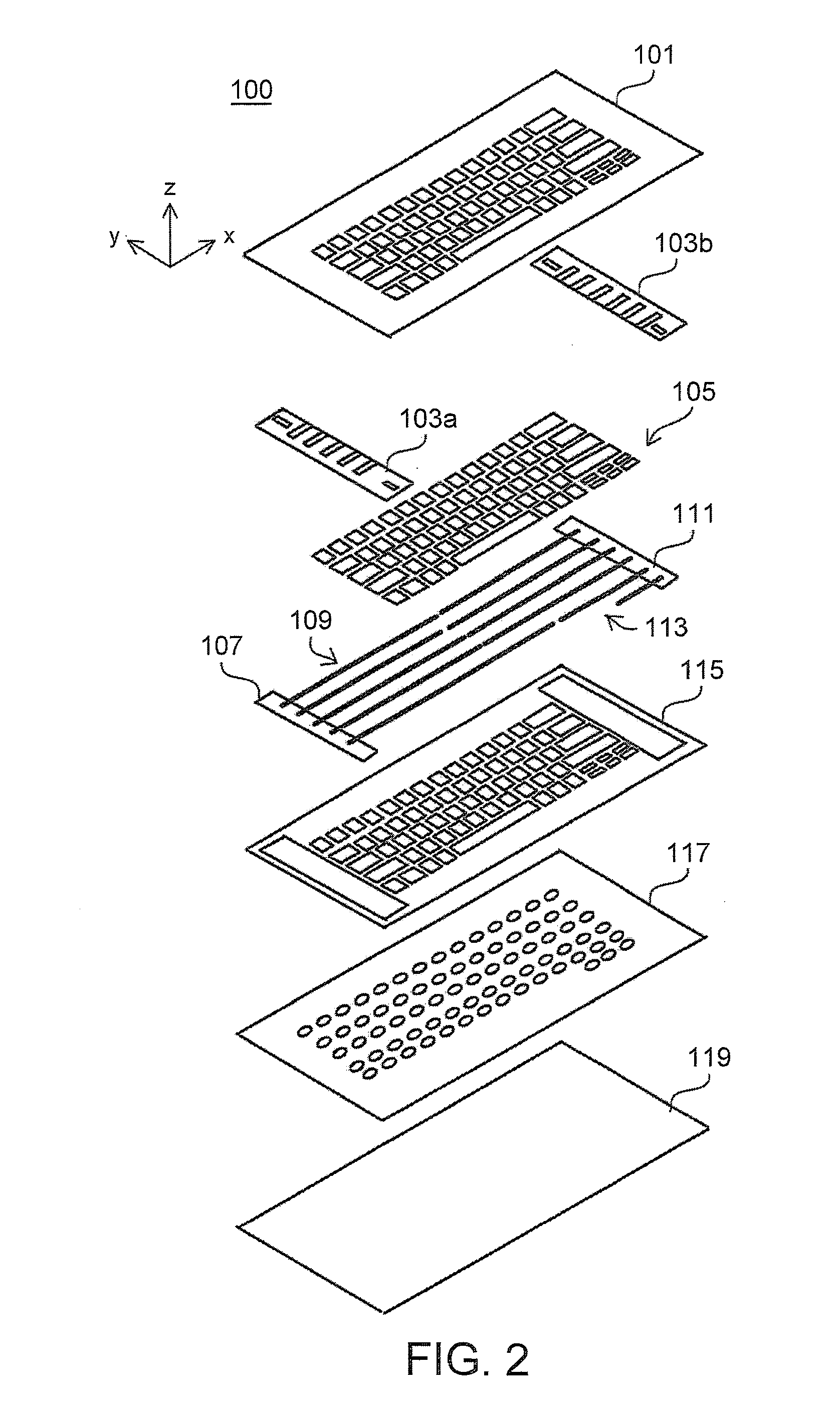

Thin Keyboard

ActiveUS20140168875A1Increase distanceInput thinnerEmergency actuatorsDigital data processing detailsLeft directionMagnet

A thin keyboard having multiple keys is disclosed. At least one of the keys includes a key magnet, and a holding magnet is mounted on a transverse slider. The key is located in a ready position by a magnetic attraction of the holding magnet to the key magnet. When the transverse slider is slid, a separating protrusion pushes a chamfer to widen the distance between the holding magnet and the key magnet. The distance between both magnets is also widened in a right and left direction, and when the magnetic attraction drops, the key is located by gravity in a release position.

Owner:LENOVO PC INT

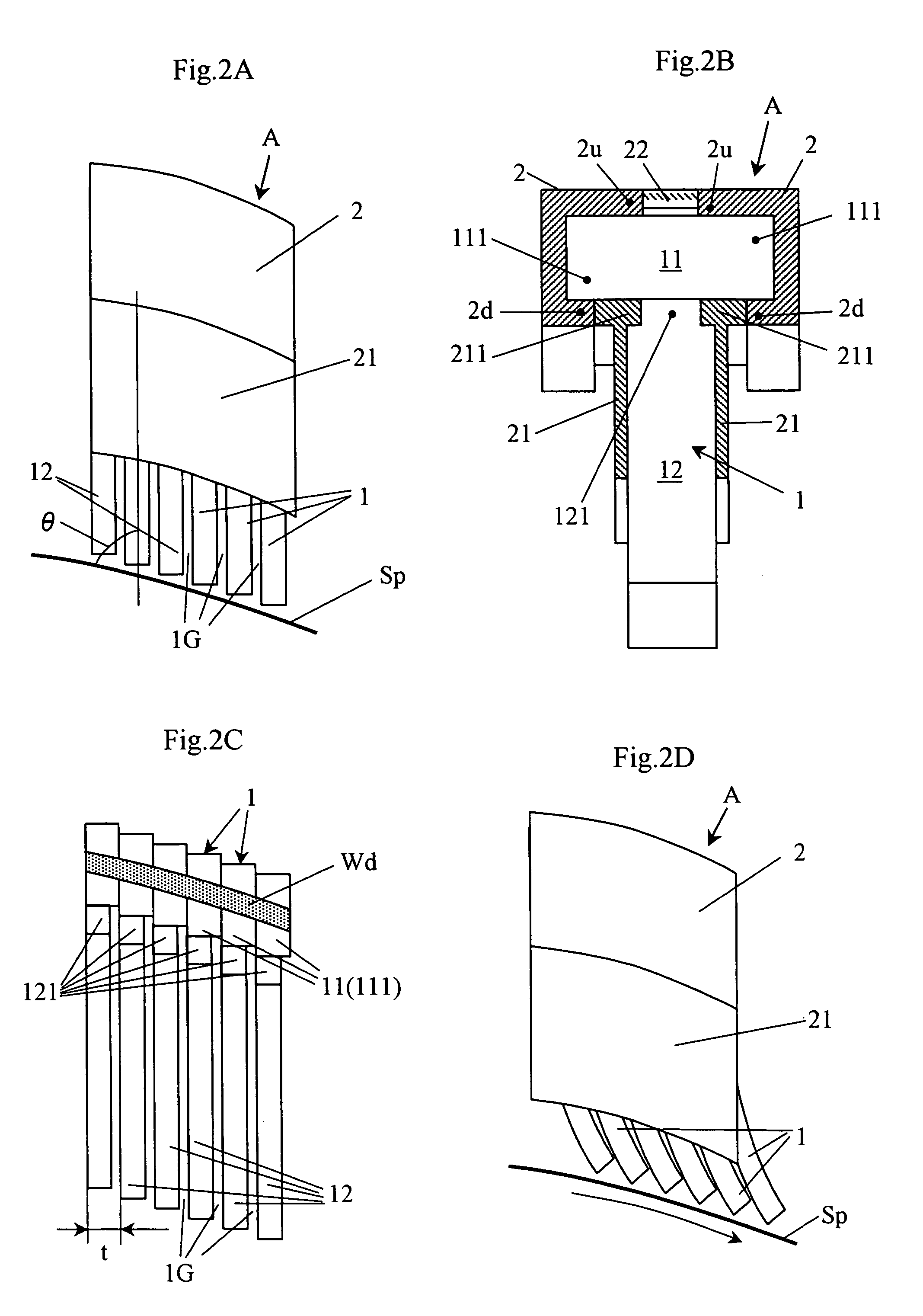

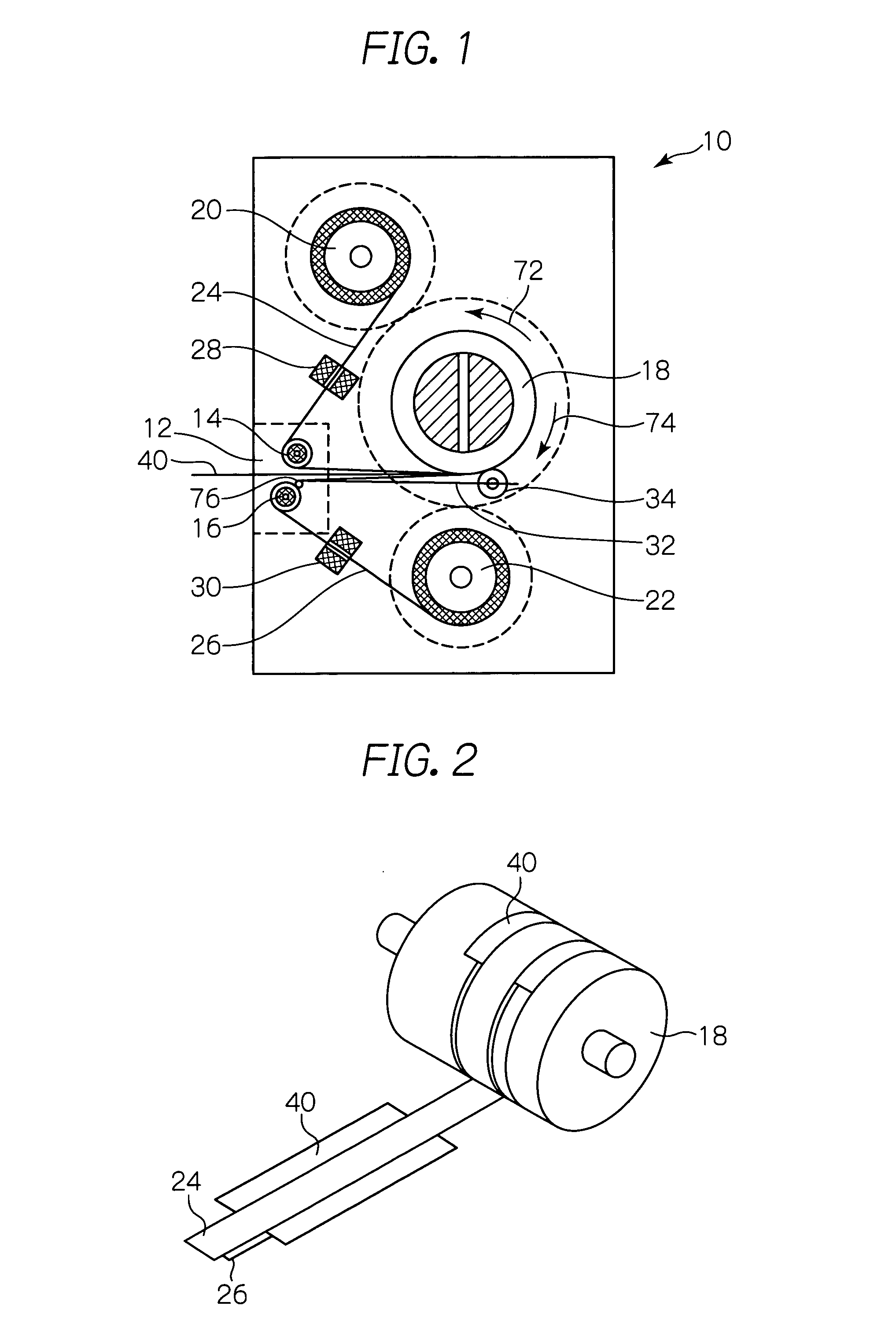

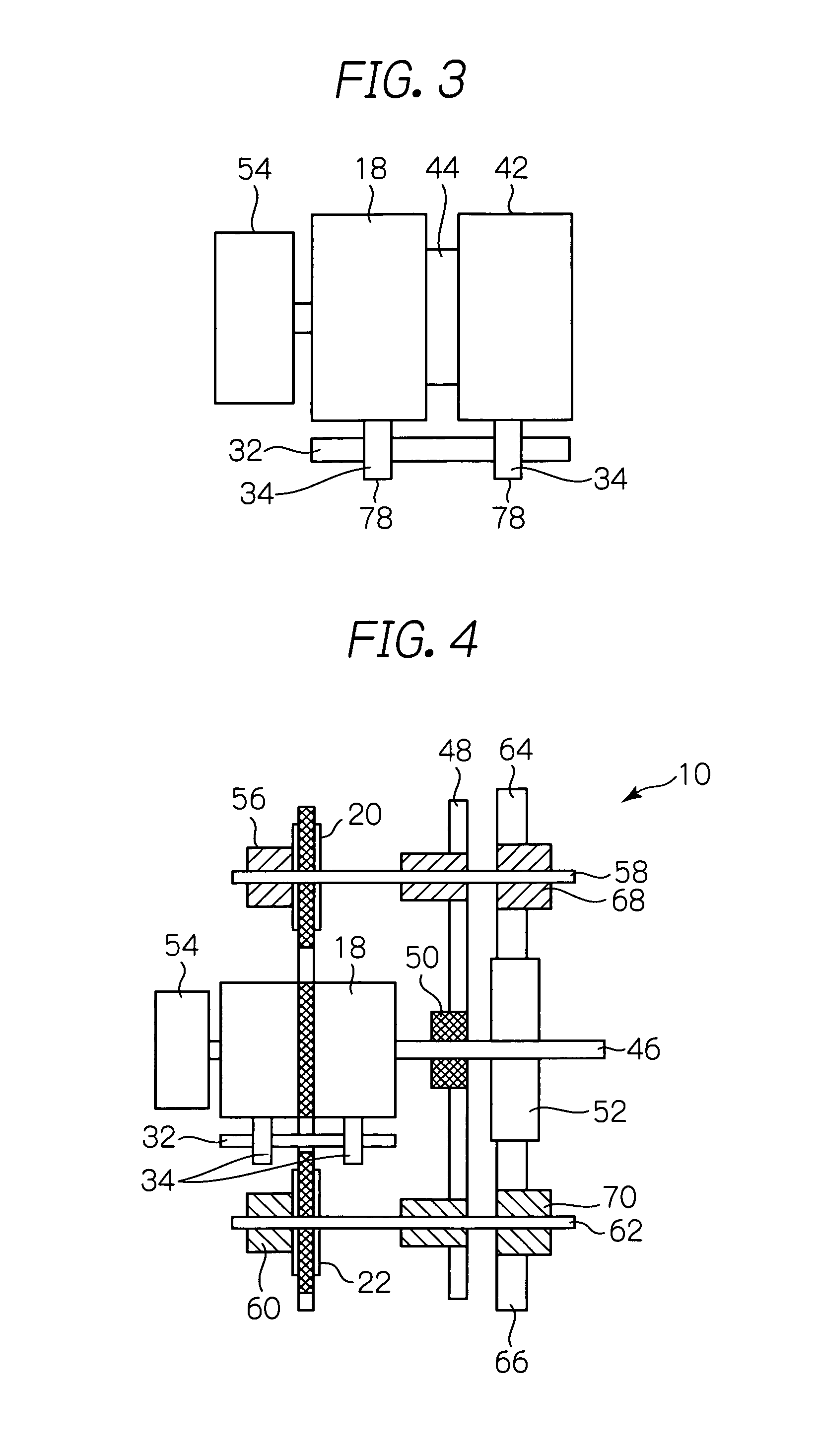

Method of manufacturing axis seals having reduced gas leakage properties and a rotary machine using axis seals

ActiveUS7334328B2Reduce the amount requiredImprove sealingEngine sealsPump componentsThin metalMetallic materials

In a method of manufacturing an axis seal, first, a roll of rolled metal material is cut into metal material plates of a predetermined size. Next, metal material plates are etched from both sides so as to form a predetermined size. Subsequently, the thin metal plates are arranged so as to be in a ring shape, oriented in the same direction, and are welded so as to be fixed. Additionally, during these processes, heat treatment is performed by heating rolls of rolled metal materials or metal material plates or thin metal plates at a predetermined timing, thereby eliminating residual stress (strain).

Owner:MITSUBISHI HEAVY IND LTD

Substrate for use in a liquid crystal display and liquid crystal display using the same

InactiveUS20060125994A1Improve reliabilitySimple manufacturing processTransistorNon-linear opticsElectricityLiquid-crystal display

Owner:SHARP KK

Semiconductor device and method of manufacturing the same

InactiveUS7557401B2Difference in levelReduce contact resistanceTransistorSolid-state devicesEngineeringSemiconductor

A semiconductor device includes an element isolation insulating film adjacent to an active area, a gate insulating film formed on a semiconductor substrate in the active area, paired gate electrodes located on the gate insulating film, a contact plug located on the active area between the gate electrodes, a pair of first upper lines located on the gate electrodes, a second upper line located on the gate electrodes, and a stopper film above upper surfaces of the gate electrodes and side surfaces of the gate electrodes. The element isolation insulating film has a first height of an upper surface thereof with reference to an upper surface of the semiconductor substrate and a second height of another upper surface thereof with reference to another upper surface of the semiconductor substrate. The first height is smaller than the second height.

Owner:KK TOSHIBA

Method of manufacturing semiconductor device and semiconductor device

InactiveUS20110180939A1InhibitionImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

Provided is a method of manufacturing a semiconductor device capable of adhering semiconductor elements and a support member for mounting semiconductor elements, such as lead frames, organic substrates or the like, even in a relatively low temperature range without damaging adhesion property and workability and of suppressing the occurrence of voids. The method of manufacturing a semiconductor device according to the invention is a method of manufacturing a semiconductor device comprising a semiconductor element and a support member adhered to the semiconductor element through a cured material of an adhesive film, wherein the method comprises the steps (a) to (d) in this order;(a) preparing adhesive film-attached semiconductor elements;(b) thermocompression-bonding said adhesive film-attached semiconductor elements to said support member so as to obtain a semiconductor part made of said adhesive film-attached semiconductor elements and said support member;(c) heating and pressurizing said semiconductor part made of said adhesive film-attached semiconductor elements and said support member using a pressurized fluid so as to proceed with curing of adhesive film; and(d) electrically connecting said adhesive film-attached semiconductor elements and said support member.

Owner:SUMITOMO BAKELITE CO LTD

Semiconductor device formed on insulating layer and method of manufacturing the same

InactiveUS20060086934A1Avoid concentrationPrevent movementTransistorSolid-state devicesEngineeringSemiconductor

Owner:RENESAS TECH CORP

Transparent type liquid crystal display device

A first conductive layer in which a first electrode film is formed, a first protective layer on the first conductive layer, a first hole penetrating through the first protective layer to reach the first electrode film, a second conductive layer including a second electrode film which is disposed on the first protective layer and in contact with a portion of the first electrode film at the bottom of the first hole and the lower electrode, a second protective layer disposed on the second conductive layer and including the insulating film, a second hole disposed on the second protective layer and penetrating through the second protective layer to reach the second electrode film, and a third conductive layer including a third electrode film which is in contact with a portion of the second electrode film at the bottom of the second hole and the upper electrode.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Semiconductor device and method of manufacturing the same

InactiveUS20060234448A1Reduce difference in levelReduce contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorDevice material

A semiconductor device includes an element isolation insulating film, memory cell transistors formed in an element isolation region and having respective gate electrodes, and a stopper film for forming a contact, formed both on a sidewall of the gate electrode of each transistor and on the element isolation insulating film between the gate electrodes. A level difference is set between the upper surface of the element isolation insulating film and the upper surface of the semiconductor substrate in the element isolation region. The level difference is set so that a level difference between the gate electrodes is smaller than a level difference in the gate electrode. Furthermore, the surface of the semiconductor substrate in the drain contact formation region is located lower than the surface of the semiconductor substrate corresponding to the gate electrode.

Owner:KK TOSHIBA

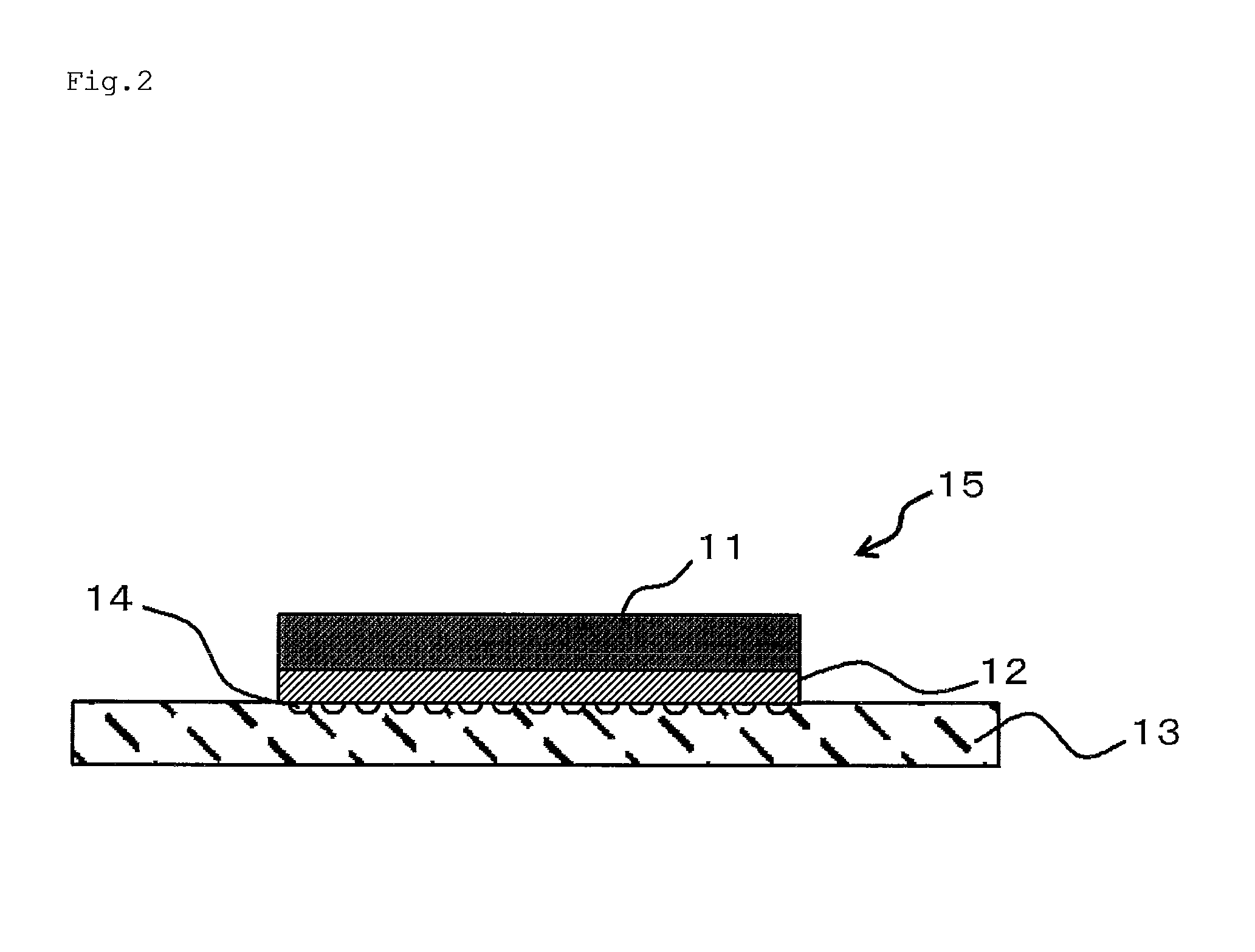

Polishing compound and polishing method

InactiveUS20090140199A1High removal rateDifference in levelOther chemical processesPrinted circuit aspectsIonTriethylenetetramine

To provide a polishing compound which can satisfy both high removal rate of an object to be polished and excellent property to eliminate the difference in level, and to provide a polishing method which can polish a wiring metal fast while suppressing increase of a wiring metal resistance and is excellent in the property to eliminate the difference in level.A polishing compound which comprises abrasive particles, an oxidizing agent, ammonium ions, polyvalent carboxylate ions, at least one chelating agent selected from the group consisting of pentaethylenehexamine, triethylenetetramine and tetraethylenepentamine, and an aqueous medium. Further, a polishing method of polishing a wiring metal 3 by using the polishing compound, after providing a wiring trench 2 on a resin substrate 1 and embedding the wiring metal 3 in the wiring trench 2.

Owner:ASAHI GLASS CO LTD +1

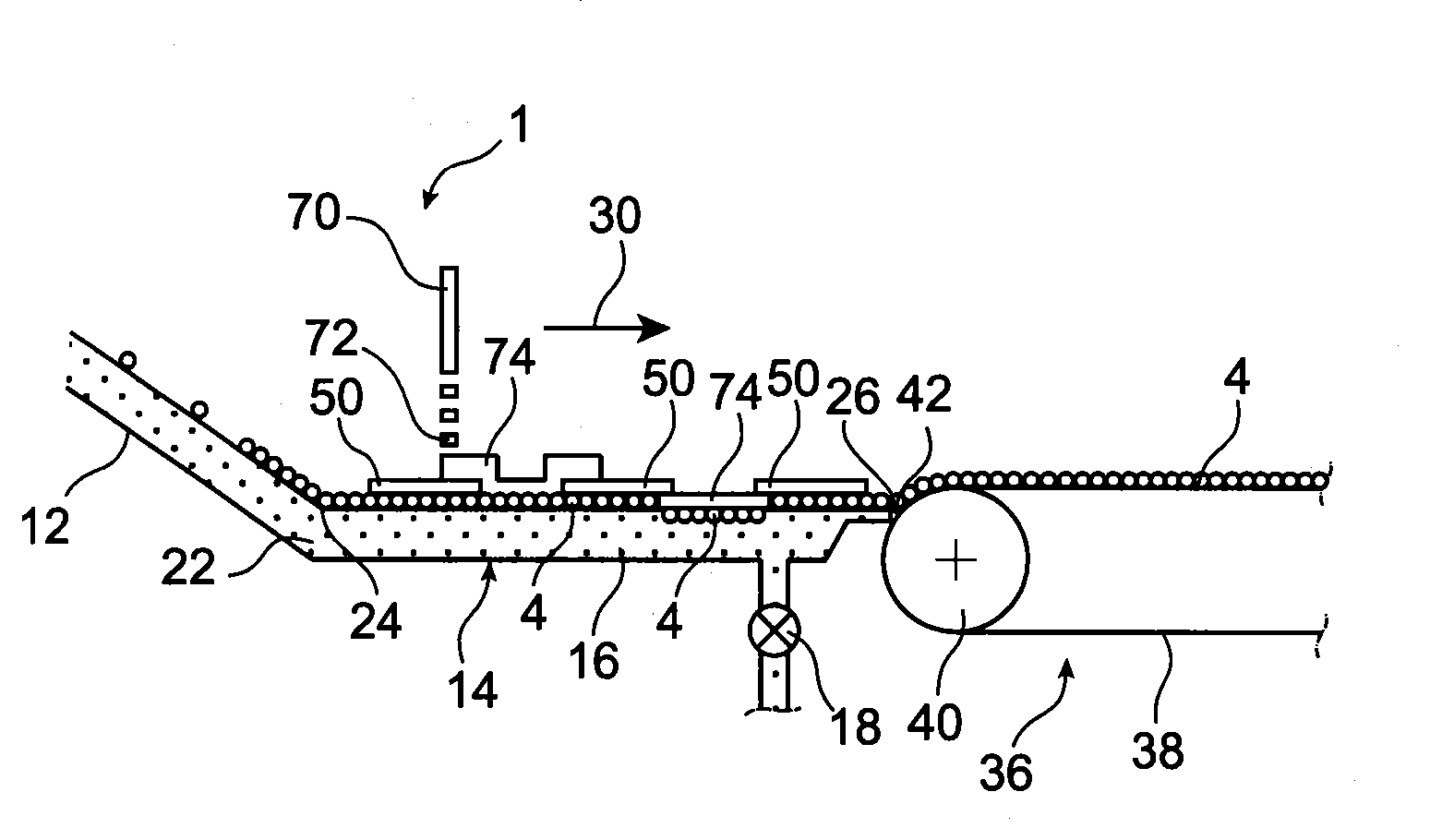

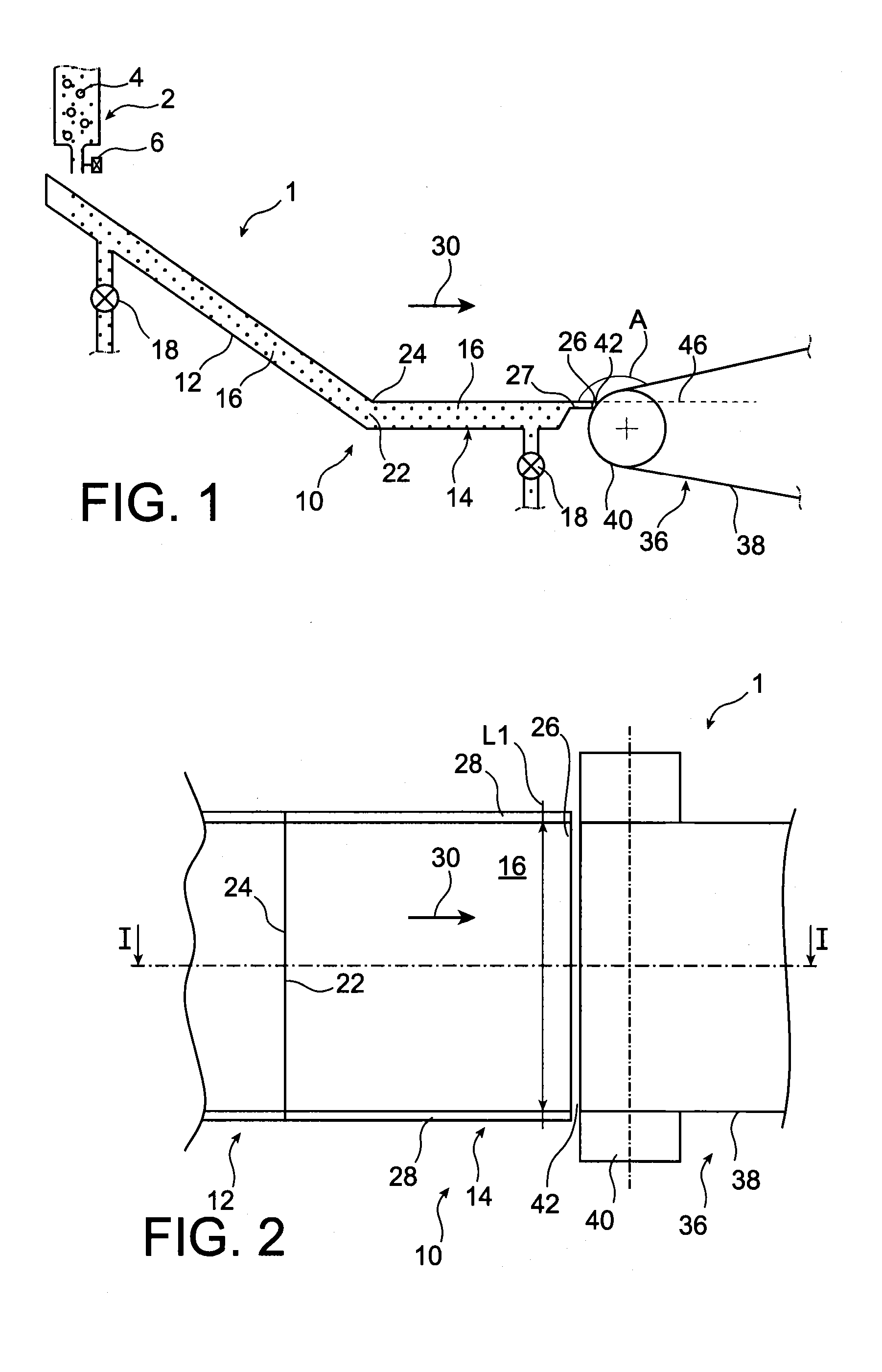

Method for transferring objects onto a substrate using a compact particle film, including a step of producing connectors on the objects

InactiveUS20140374930A1Easy adhesionEasy to depositMaterial nanotechnologyLiquid surface applicatorsEngineeringPolymerization

A method for transferring objects onto a substrate, or running substrate, the objects to be transferred being placed in a transfer area containing a carrier liquid forming a conveyor, the objects being held by a compact film of particles floating on the carrier liquid of the transfer area, within which the objects are displaced with the film of particles to be transferred onto the substrate, making at least one connector on at least one of the objects, the connector being made by a substance comprising a polymerizable compound, put in contact with the object arranged within the transfer area, and then by polymerization of the substance.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method of Forming Fluorescent Surface and Image Display Unit

InactiveUS20040150324A1High metal back effectImprove featuresDischarge tube luminescnet screensLamp detailsPhosphorFluorescence

A method for forming a phosphor screen comprising the step of forming a phosphor layer containing a thermoplastic resin on the inner surface of a face plate, the step of pressurizing the phosphor layer being heated to plasticate the thermoplastic resin and smooth the surface of the phosphor layer, and the step of forming a metal film on the surface-smoothed phosphor layer and heating the face plate. Thermoplastic resin having a softening temperature of 50-350° C. can be used in the phosphor layer, and 0.05-50 wt % of such a thermoplastic resin in solid content ratio is contained in the layer. Heating / pressurizing conditions preferably involve temperatures of 50-350° C. and pressures of 10-10000 N / cm<2>. This method enhances the film forming property of a metal back layer and prevents cracks and pinholes in the metal back layer.

Owner:KK TOSHIBA

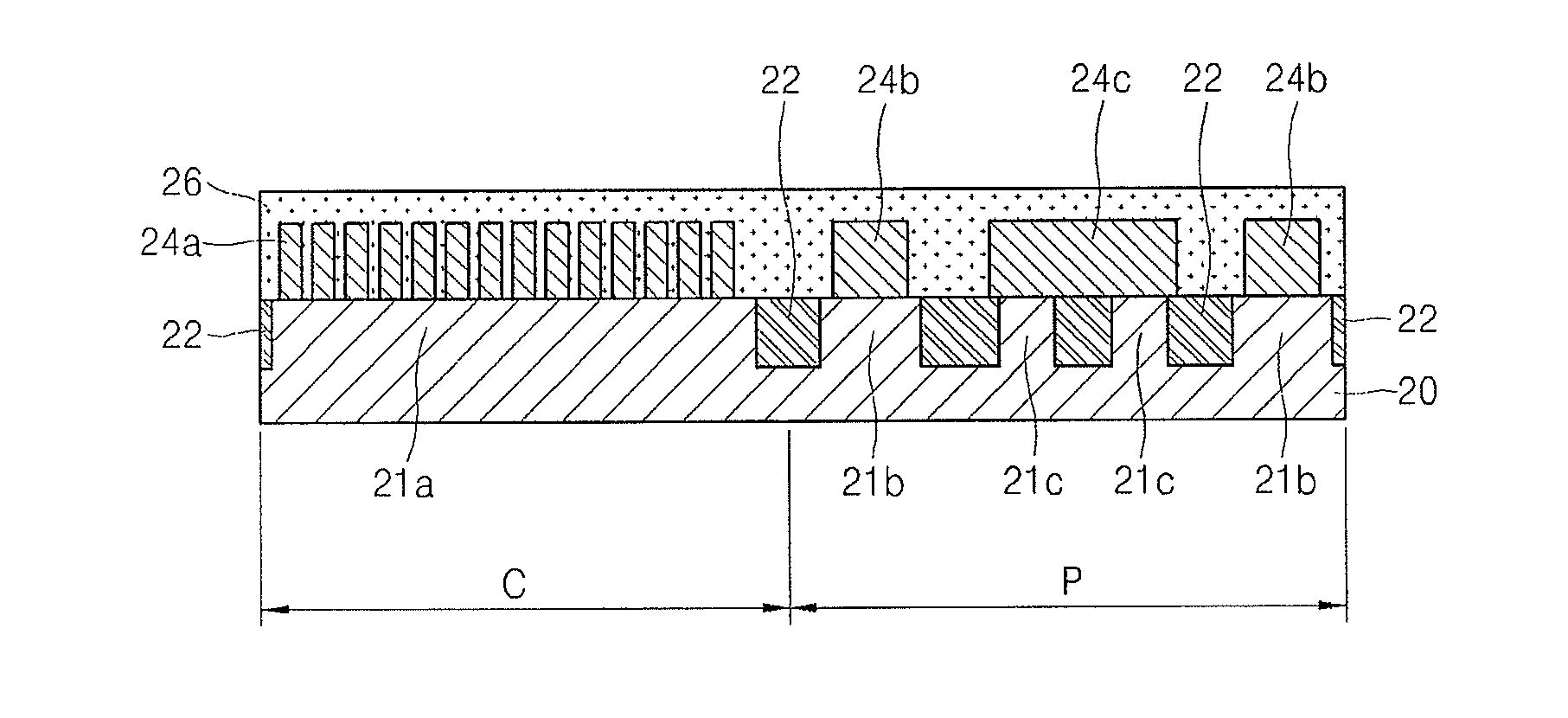

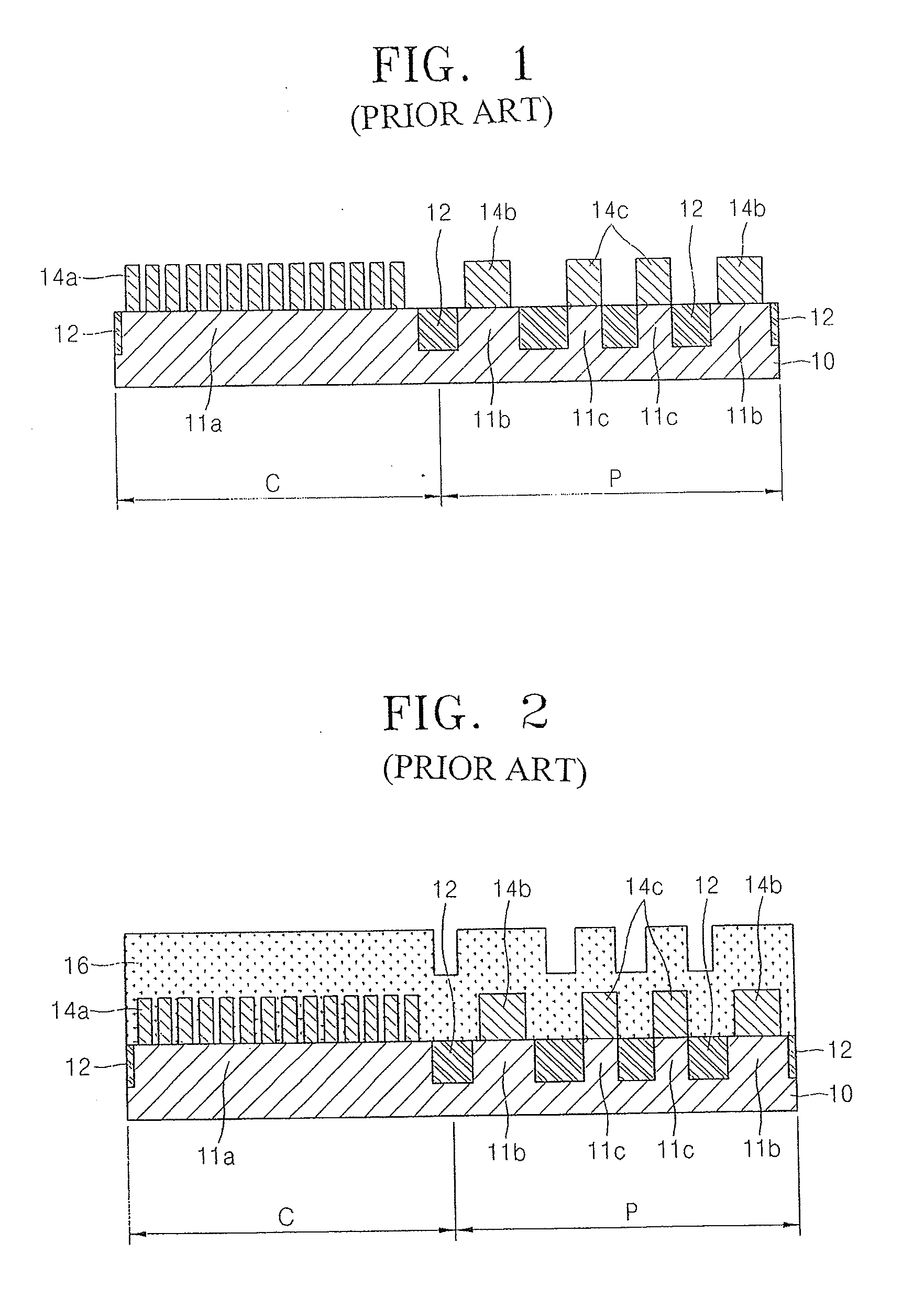

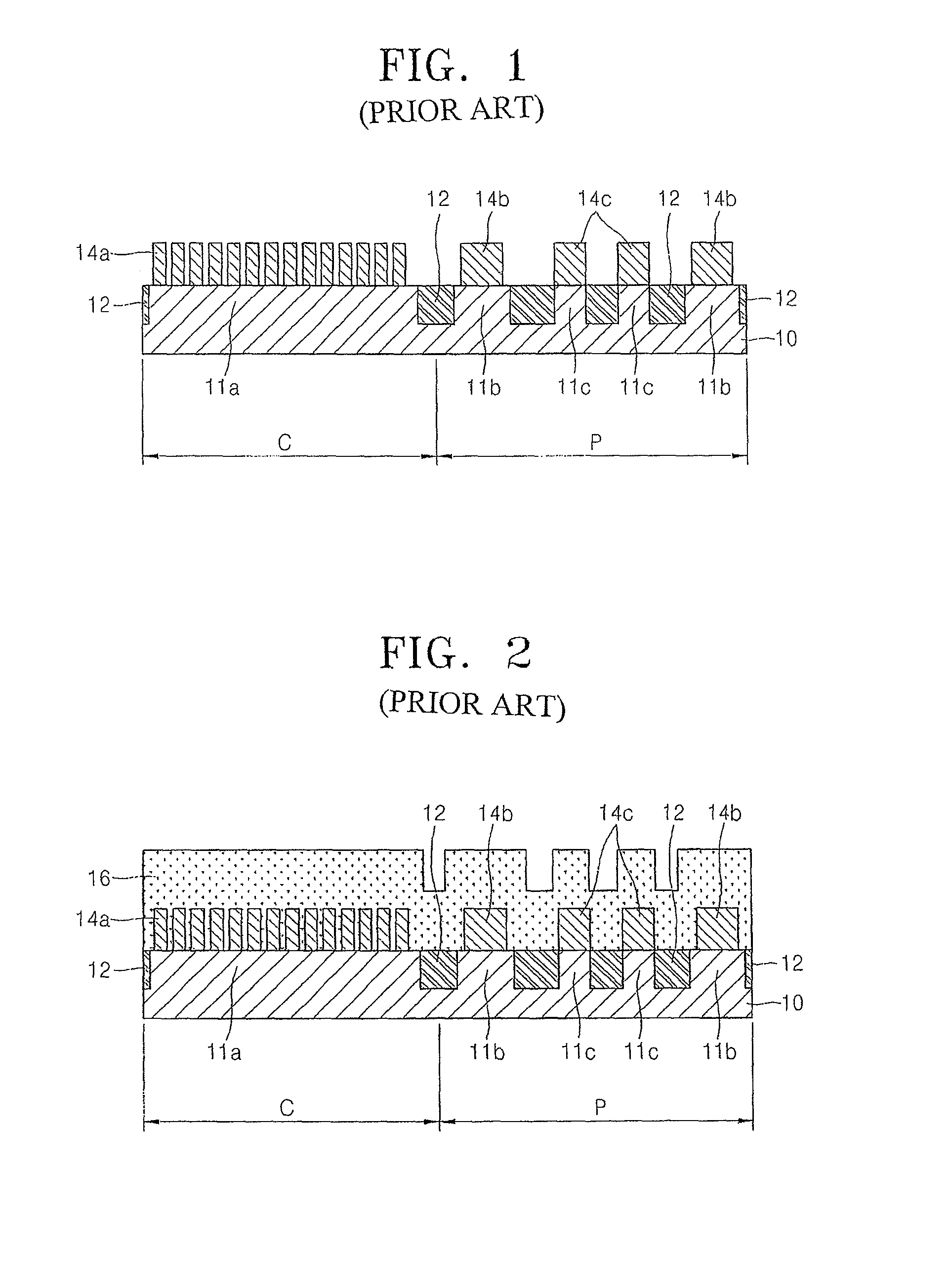

Semiconductor device including dummy gate part and method of fabricating the same

ActiveUS20120028435A1Reduce the differenceDifference in levelSolid-state devicesSemiconductor/solid-state device manufacturingCell regionDevice material

In a reliable semiconductor device and a method of fabricating the semiconductor device, a difference in height between upper surfaces of a cell region and a peripheral region (also referred to as a level difference) is minimized by optimizing dummy gate parts. The semiconductor device includes a semiconductor substrate including a cell region and a peripheral region surrounding the cell region, a plurality of dummy active regions surrounded by a device isolating region and formed apart from each other, and a plurality of dummy gate parts formed on the dummy active regions and on the device isolating regions located between the dummy active regions, wherein each of the dummy gate parts covers two or more of the dummy active regions.

Owner:SAMSUNG ELECTRONICS CO LTD

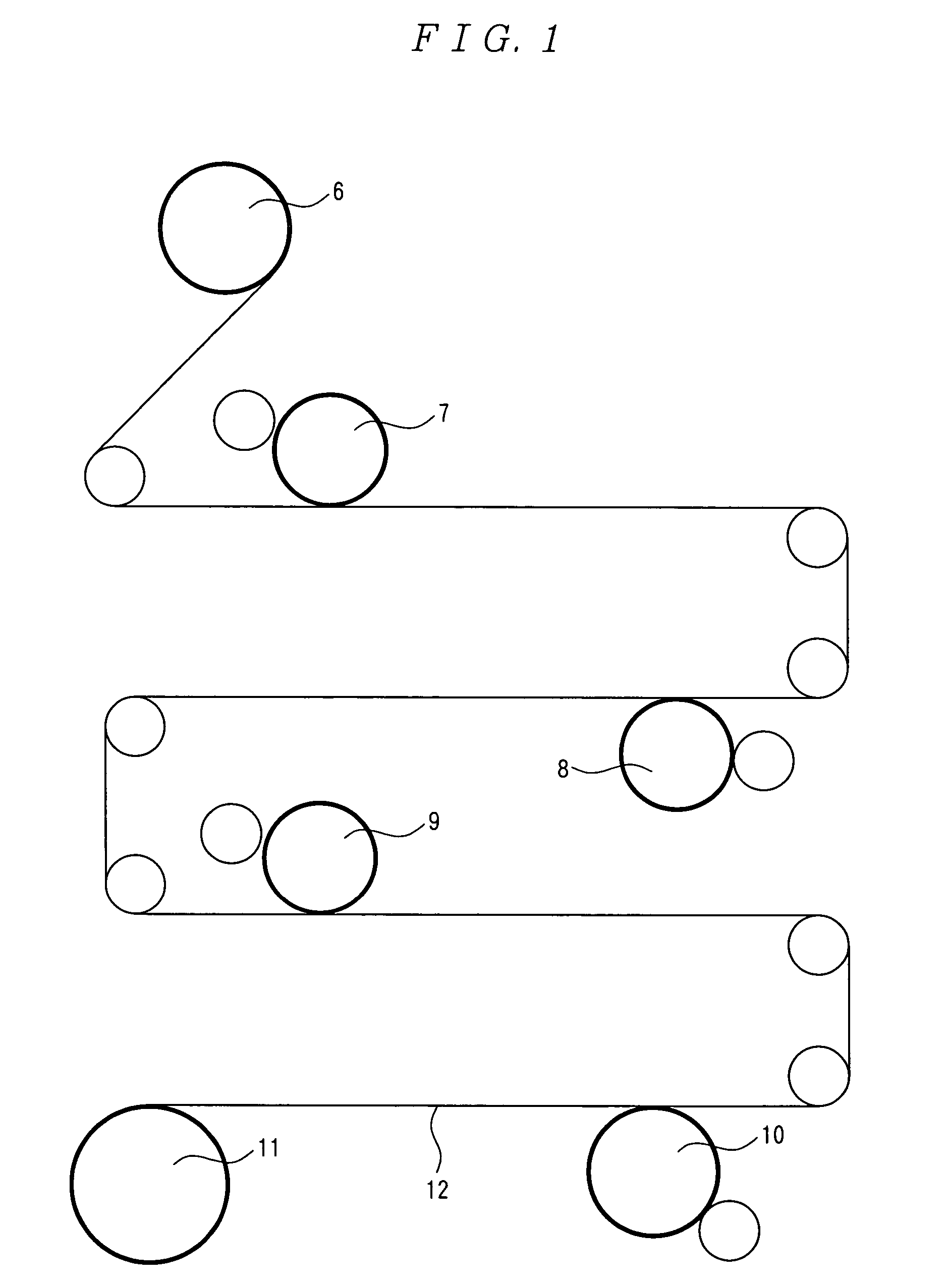

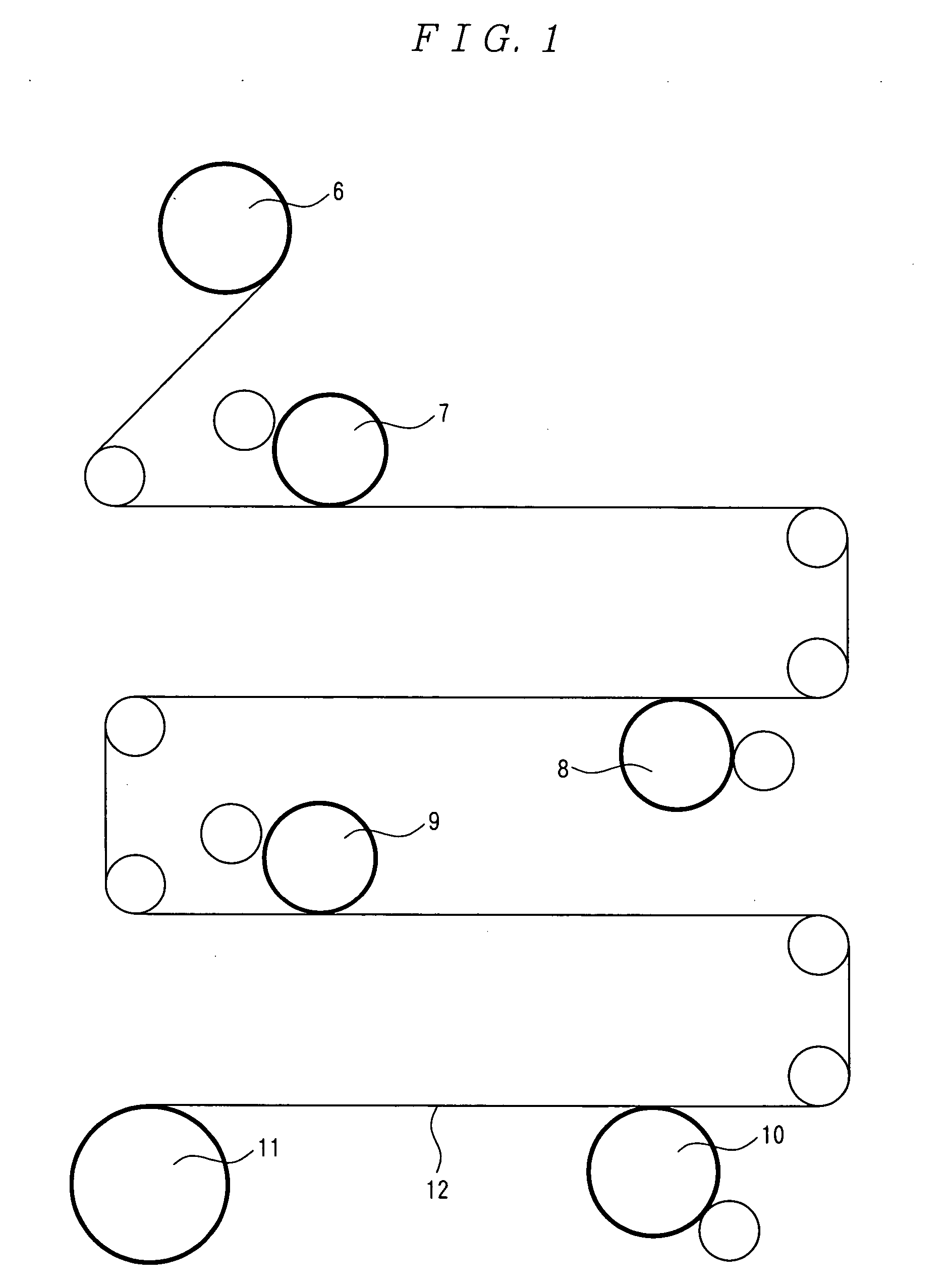

Medium storing and advancing apparatus

ActiveUS8360223B2Avoid deformationDifference in levelFilament handlingCoin/currency accepting devicesMechanical engineering

A medium storing and advancing apparatus is provided which prevents, when a medium sandwiched between two tapes is wound on a drum to be stored, that the medium could not be wound due to the thickness of the tapes wound previously on the drum. The medium storing and advancing apparatus includes reels which supply and wind up the tapes, and a drum which winds up the tapes, wherein the drum is provided with a drum groove portion over the circumferentially entire periphery substantially in a middle way of the outer peripheral surface of the drum so that the tapes are wound in the drum groove portion.

Owner:OKI ELECTRIC IND CO LTD

Semiconductor device including dummy gate part and method of fabricating the same

ActiveUS8053845B2Reduce the differenceDifference in levelSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialCell region

In a reliable semiconductor device and a method of fabricating the semiconductor device, a difference in height between upper surfaces of a cell region and a peripheral region (also referred to as a level difference) is minimized by optimizing dummy gate parts. The semiconductor device includes a semiconductor substrate including a cell region and a peripheral region surrounding the cell region, a plurality of dummy active regions surrounded by a device isolating region and formed apart from each other, and a plurality of dummy gate parts formed on the dummy active regions and on the device isolating regions located between the dummy active regions, wherein each of the dummy gate parts covers two or more of the dummy active regions.

Owner:SAMSUNG ELECTRONICS CO LTD

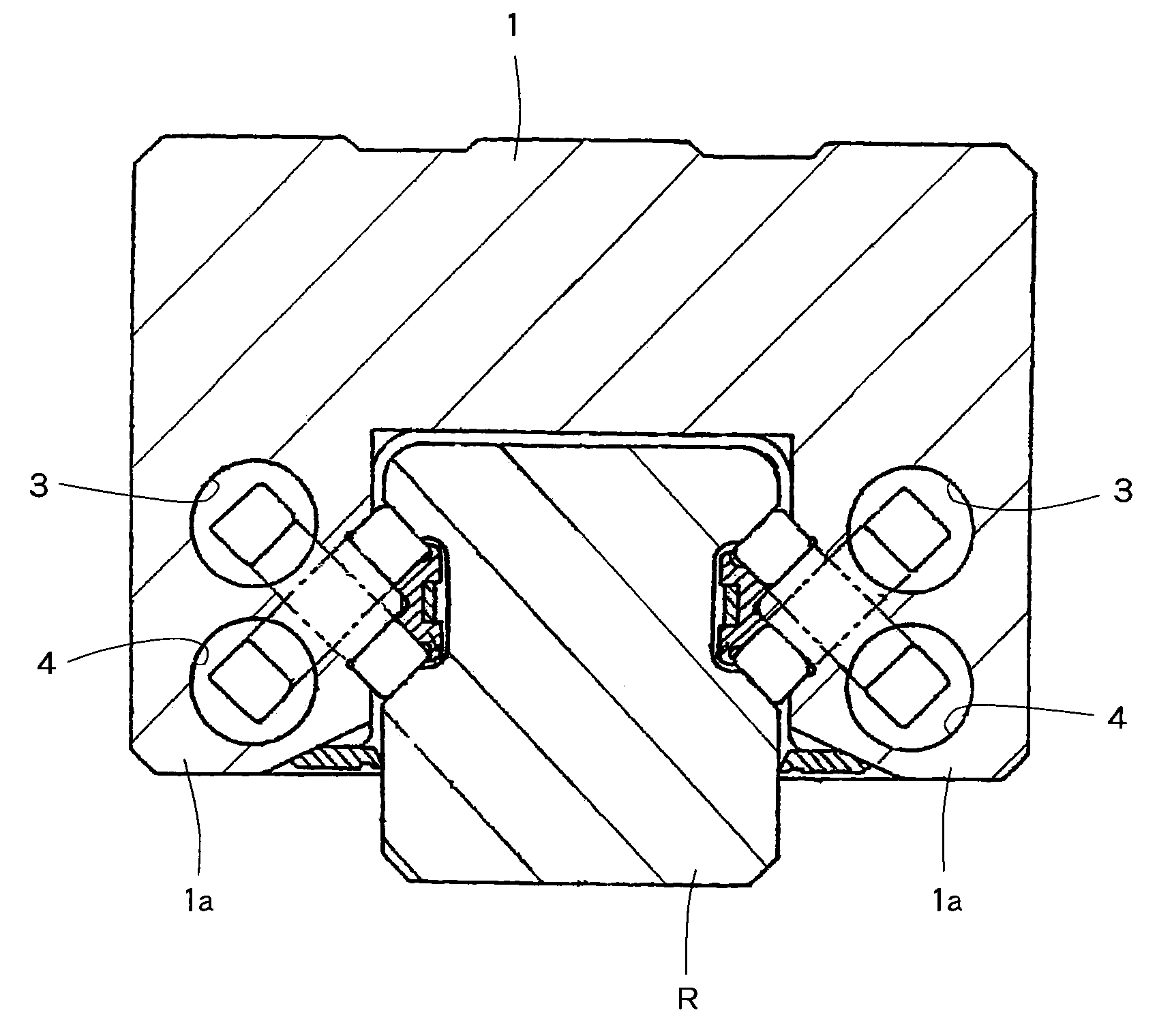

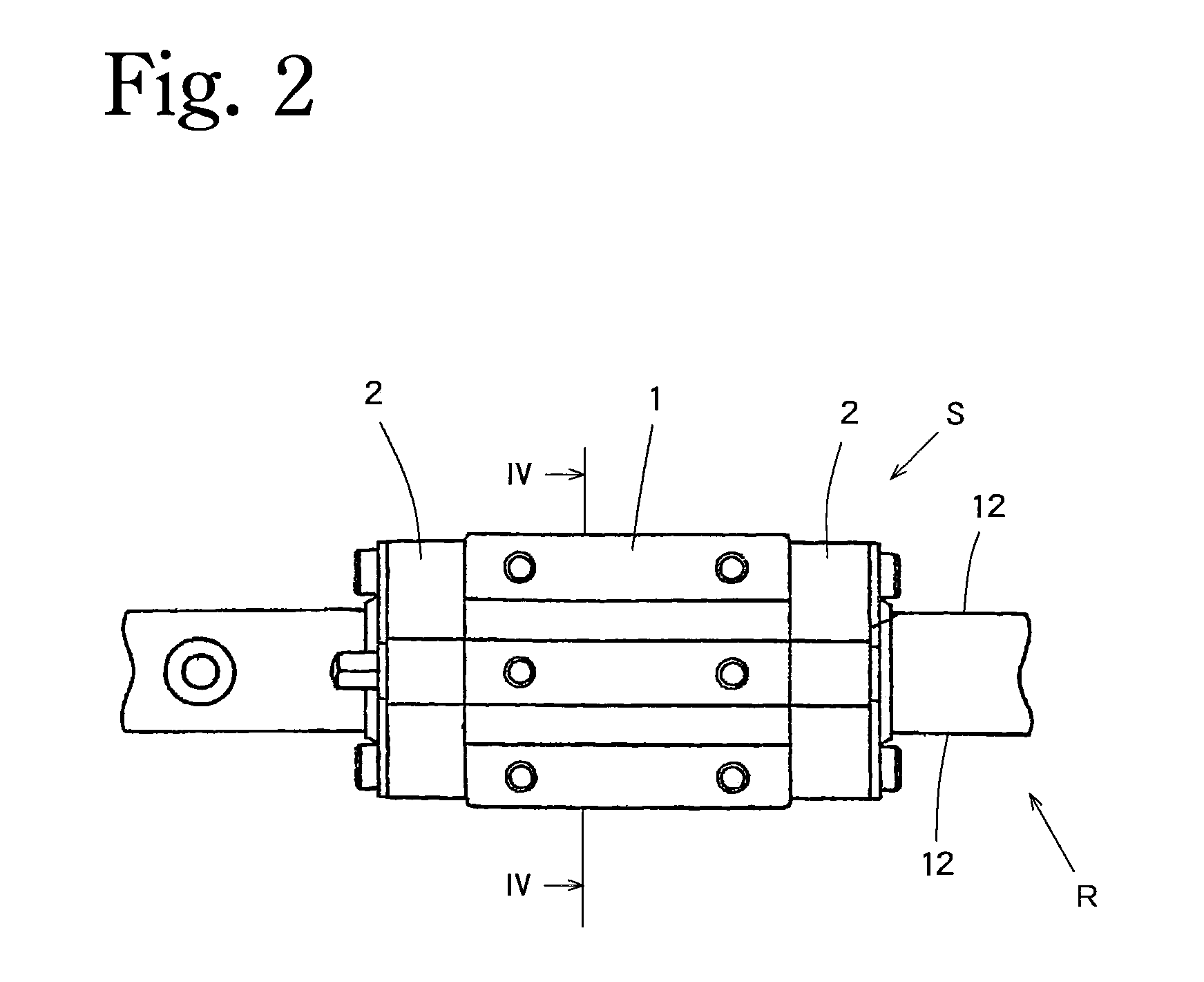

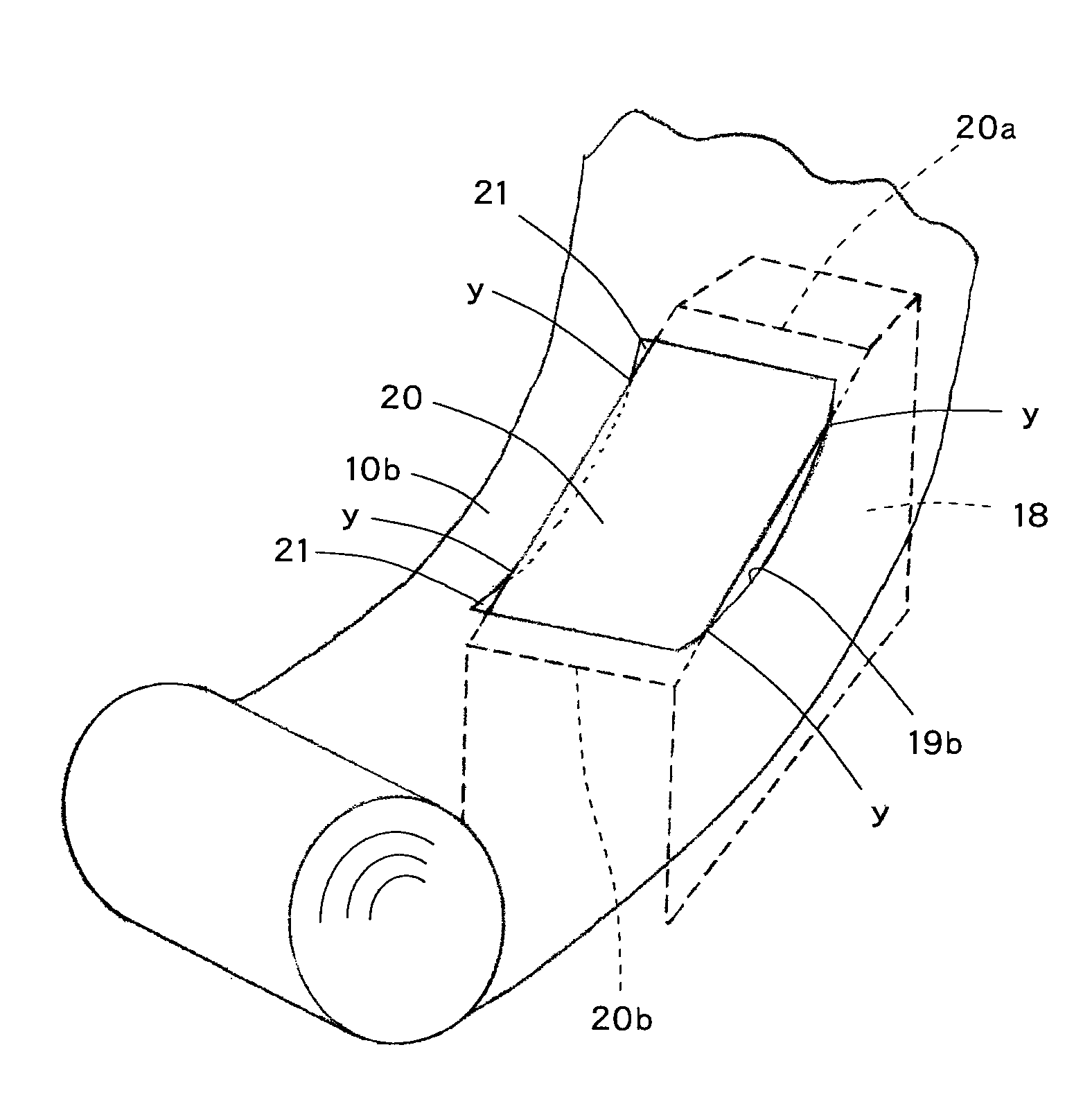

Slider For Linear Motion Rolling Guide Unit

ActiveUS20090060400A1Smooth rolling movementImprove the lubrication effectLinear bearingsShaftsLinear motionManufacturing cost reduction

A slider for a linear motion rolling guide unit can ensure a smooth rolling movement and a reliable lubricating capability and eliminate the need for accurate dimension control to reduce the manufacturing costs. A lubricating member A has a lubricating face 20 exposed on an outer peripheral face of a turning corner 10 in an end cap 2. The rolling elements 11 are lubricated by making contact with the lubricating face 20 while rolling through the turning corner. The lubricating face 20, exposed on the arced face 10b of the turning corner, and the outer peripheral face of the turning corner maintain the relation of crossing each other at two intersections. The lubricating face 20 is longer than the distance between the two intersections. Recessed areas 21 are formed between the outer peripheral face of the turning corner 10 and the lubricating face 20 in the surplus length regions.

Owner:NIPPON THOMPSON

Thin keyboard

ActiveUS9299513B2Increase distanceInput thinnerEmergency actuatorsDigital data processing detailsLeft directionMagnet

A thin keyboard having multiple keys is disclosed. At least one of the keys includes a key magnet, and a holding magnet is mounted on a transverse slider. The key is located in a ready position by a magnetic attraction of the holding magnet to the key magnet. When the transverse slider is slid, a separating protrusion pushes a chamfer to widen the distance between the holding magnet and the key magnet. The distance between both magnets is also widened in a right and left direction, and when the magnetic attraction drops, the key is located by gravity in a release position.

Owner:LENOVO PC INT

Electronic part manufacturing method and electronic part manufactured by the method

InactiveUS20120052259A1Reduce in quantityReduce defectsDecorative surface effectsTransfer patterningProduction rateEngineering

The present invention provides a new method for manufacturing an electronic part, which is capable of reducing the number of steps of superpose-printing, achieving positional accuracy (alignment accuracy) of precise superposed patterns, and layering with substantially no difference in level, thereby improving productivity and dimensional accuracy and eliminating defects. The method for manufacturing an electronic part includes the steps of forming a composite ink pattern layer on a releasing surface of a transfer plate using a relief offset method, and then simultaneously reversely transferring the composite ink pattern layer to a printing object. Various organic transistor elements are formed by combining a conductive ink, an insulating ink, and an ink containing a semiconductor.

Owner:DAINIPPON INK & CHEM INC

Semiconductor device having a chip bonding using a resin adhesive film and method of manufacturing the same

InactiveUS8436479B2Improve wettabilityDifference in levelSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

Provided is a method of manufacturing a semiconductor device capable of adhering semiconductor elements and a support member for mounting semiconductor elements, such as lead frames, organic substrates or the like, even in a relatively low temperature range without damaging adhesion property and workability and of suppressing the occurrence of voids. The method of manufacturing a semiconductor device according to the invention is a method of manufacturing a semiconductor device comprising a semiconductor element and a support member adhered to the semiconductor element through a cured material of an adhesive film, wherein the method comprises the steps (a) to (d) in this order;(a) preparing adhesive film-attached semiconductor elements;(b) thermocompression-bonding said adhesive film-attached semiconductor elements to said support member so as to obtain a semiconductor part made of said adhesive film-attached semiconductor elements and said support member;(c) heating and pressurizing said semiconductor part made of said adhesive film-attached semiconductor elements and said support member using a pressurized fluid so as to proceed with curing of adhesive film; and(d) electrically connecting said adhesive film-attached semiconductor elements and said support member.

Owner:SUMITOMO BAKELITE CO LTD

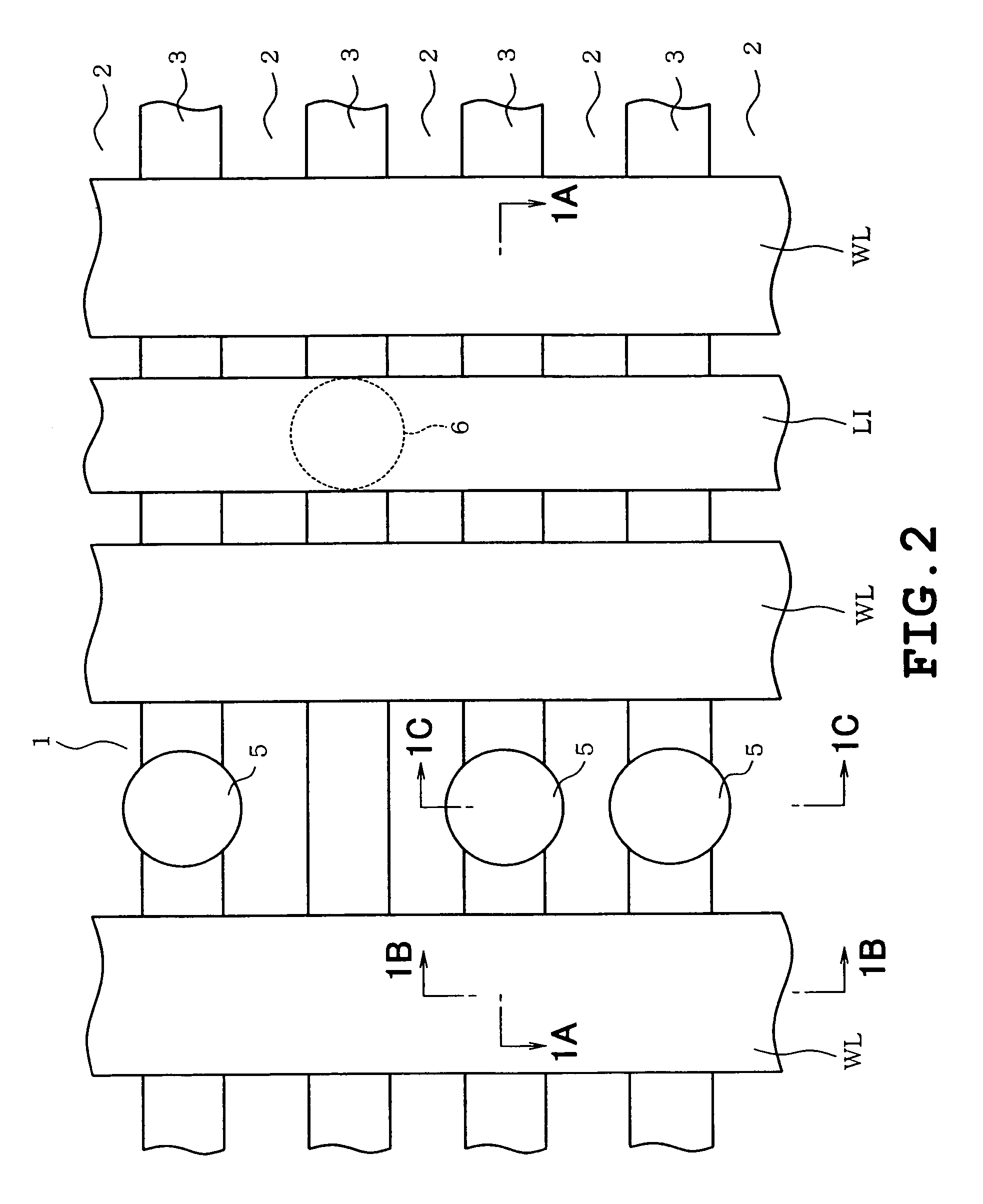

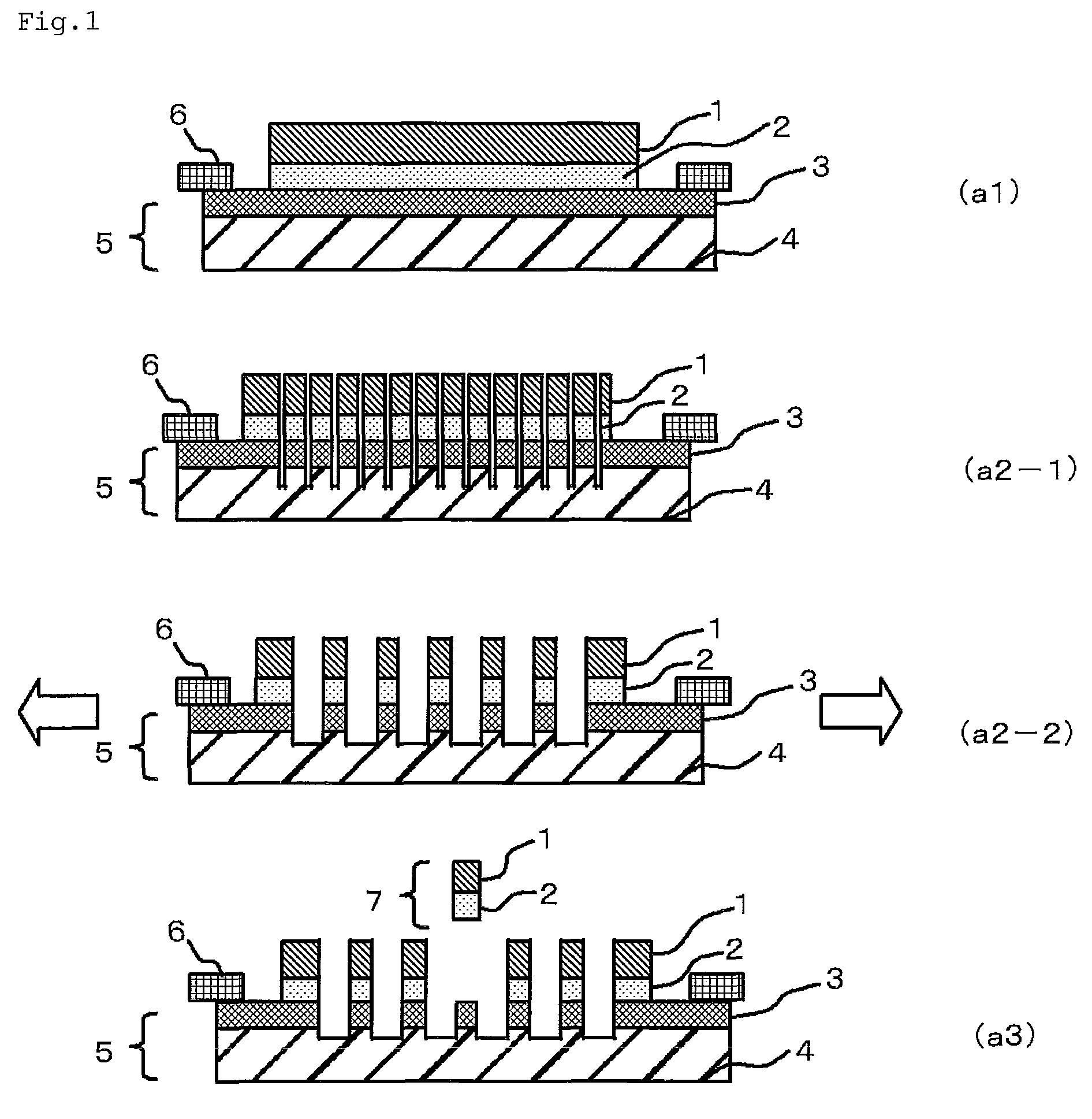

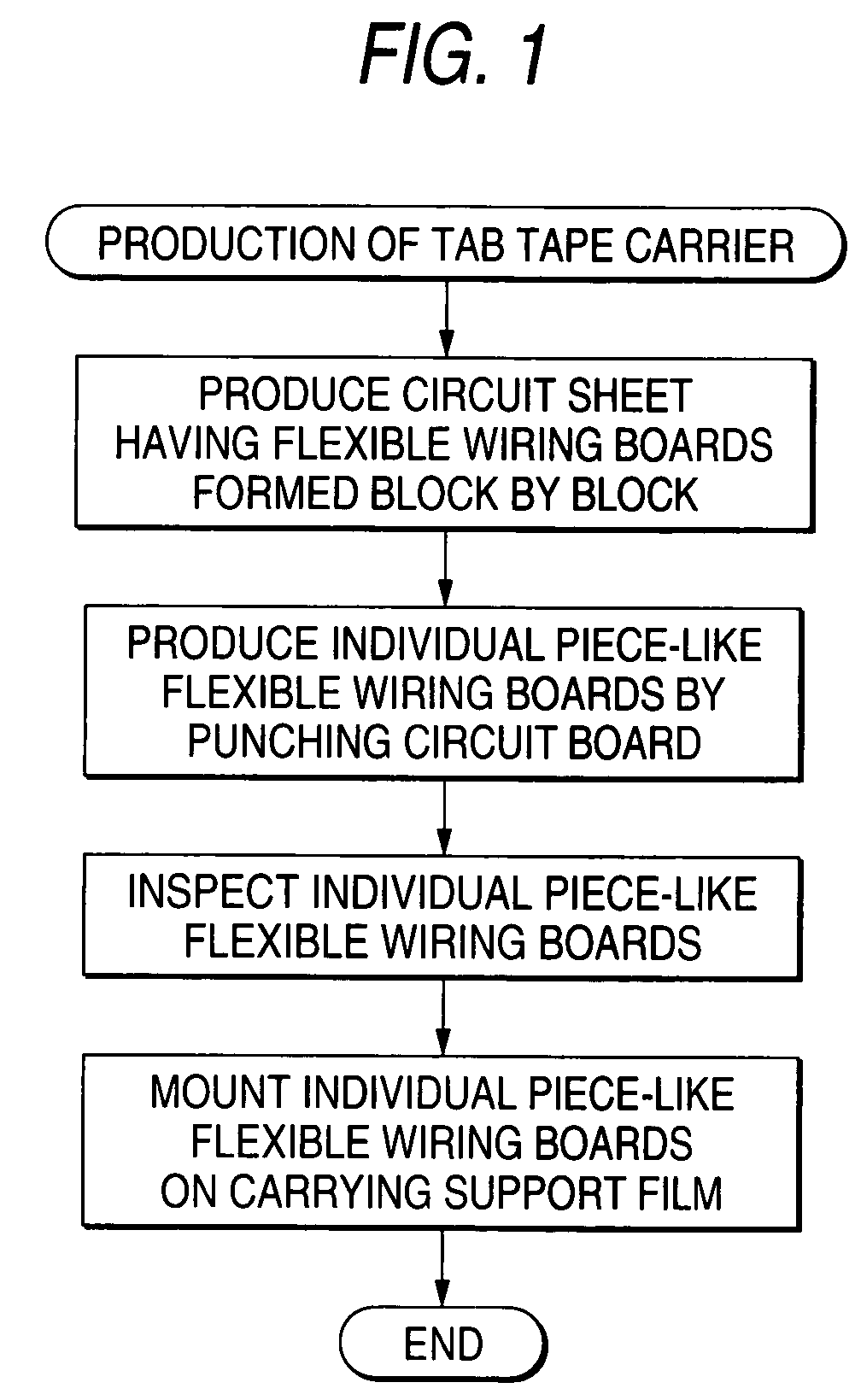

Tape carrier

InactiveUS7439451B2Improve connection reliabilityIncrease productivitySemiconductor/solid-state device detailsPrinted electric component incorporationMagnetic tapeEngineering

Only individual piece-like flexible wiring boards produced separately and judged to be non-defective products in an inspection step in advance are mounted at regular intervals on a carrying support film to thereby obtain a TAB tape carrier. According to this method, the yield on continuous production can be improved while the step of replacing defective flexible wiring boards found by inspection with non-defective flexible wiring boards can be omitted after mounting of the flexible wiring boards. A difference in level between the respective flexible wiring boards can be prevented from being caused by the replacement, so that high connection reliability can be ensured.

Owner:NITTO DENKO CORP

Processing method of stacked-layer film and manufacturing method of semiconductor device

InactiveUS20150214041A1Reduce thicknessEasy to shapeSemiconductor/solid-state device manufacturingSemiconductor devicesHigh frequency powerExcess oxygen

In a processing method of a stacked-layer film in which a metal film is provided on an oxide insulating film, plasma containing an oxygen ion is generated by applying high-frequency power with power density greater than or equal to 0.59 W / cm2 and less than or equal to 1.18 W / cm2 to the stacked-layer film side under an atmosphere containing oxygen in which pressure is greater than or equal to 5 Pa and less than or equal to 15 Pa, the metal film is oxidized by the oxygen ion, and an oxide insulating film containing excess oxygen is formed by supplying oxygen to the oxide insulating film.

Owner:SEMICON ENERGY LAB CO LTD

Slider for linear motion rolling guide unit

ActiveUS7780356B2Smooth rolling movementImprove the lubrication effectLinear bearingsShaftsManufacturing cost reductionLinear motion

A slider for a linear motion rolling guide unit can ensure a smooth rolling movement and a reliable lubricating capability and eliminate the need for accurate dimension control to reduce the manufacturing costs. A lubricating member A has a lubricating face 20 exposed on an outer peripheral face of a turning corner 10 in an end cap 2. The rolling elements 11 are lubricated by making contact with the lubricating face 20 while rolling through the turning corner. The lubricating face 20, exposed on the arced face 10b of the turning corner, and the outer peripheral face of the turning corner maintain the relation of crossing each other at two intersections. The lubricating face 20 is longer than the distance between the two intersections. Recessed areas 21 are formed between the outer peripheral face of the turning corner 10 and the lubricating face 20 in the surplus length regions.

Owner:NIPPON THOMPSON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com