Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Wide sintering temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alloy screw material and production technology of screws by adopting material

The invention relates to the technical field of injection screw production, and discloses an alloy screw material and a production technology of screws by adopting the material. The alloy screw material is prepared from the following raw material powder: 20-60% of Mo, 10-40% of FeB, 5-20% of Cr, 2-30% of Ni, 1-7% of Mn, 0.1-1% of C, and the balance of Fe. The production technology comprises the steps of die preparation, raw material preparation, blank pressing (isostatic cool pressing / die pressing), blank making (hot isostatic pressing / vacuum furnace sintering, normalizing treatment, and processing and molding. The alloy screw material provided by the invention is high in hardness, excellent in bending strength, high in breaking tenacity, excellent in abrasive resistance, and excellent in corrosion resistance, and the density of the material is close to that of a steel body ; the production technology for producing alloy screws by adopting the material is adopted, so that the plastic molding is more stable, the yield ratio for producing the alloy screws is greatly increased, and the long-term stability of injection screws during production is guaranteed.

Owner:东莞杰宇机械有限公司

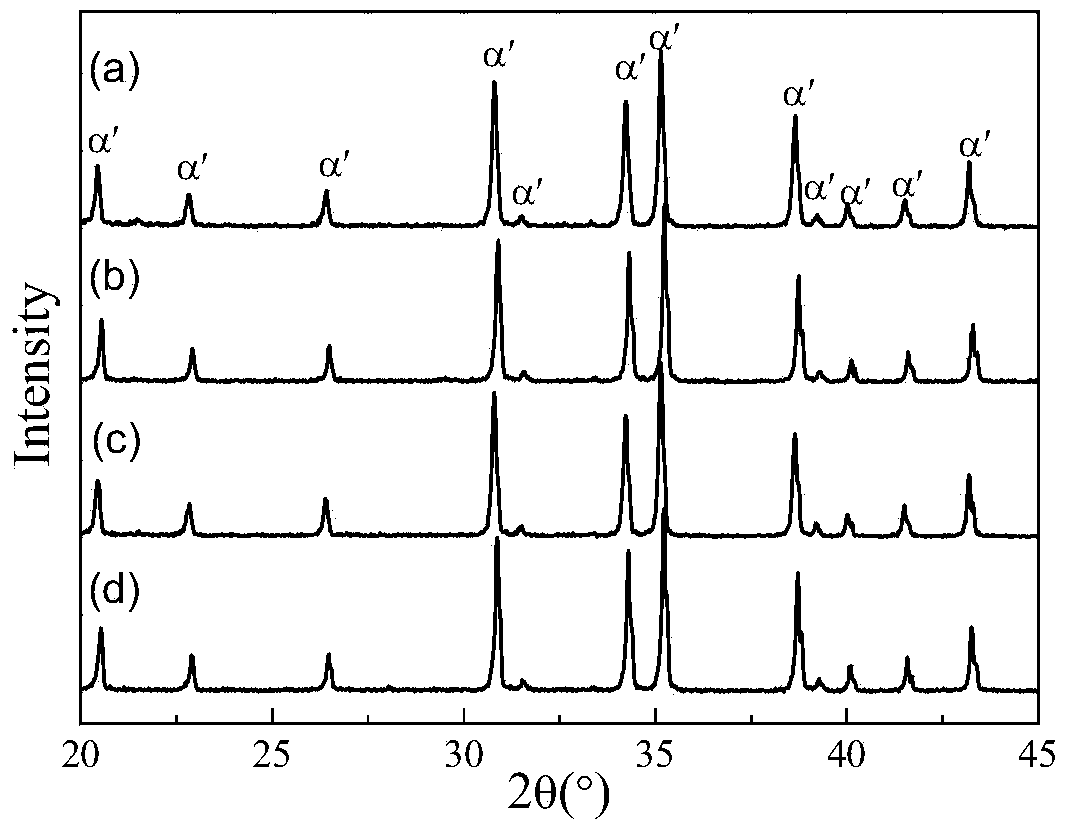

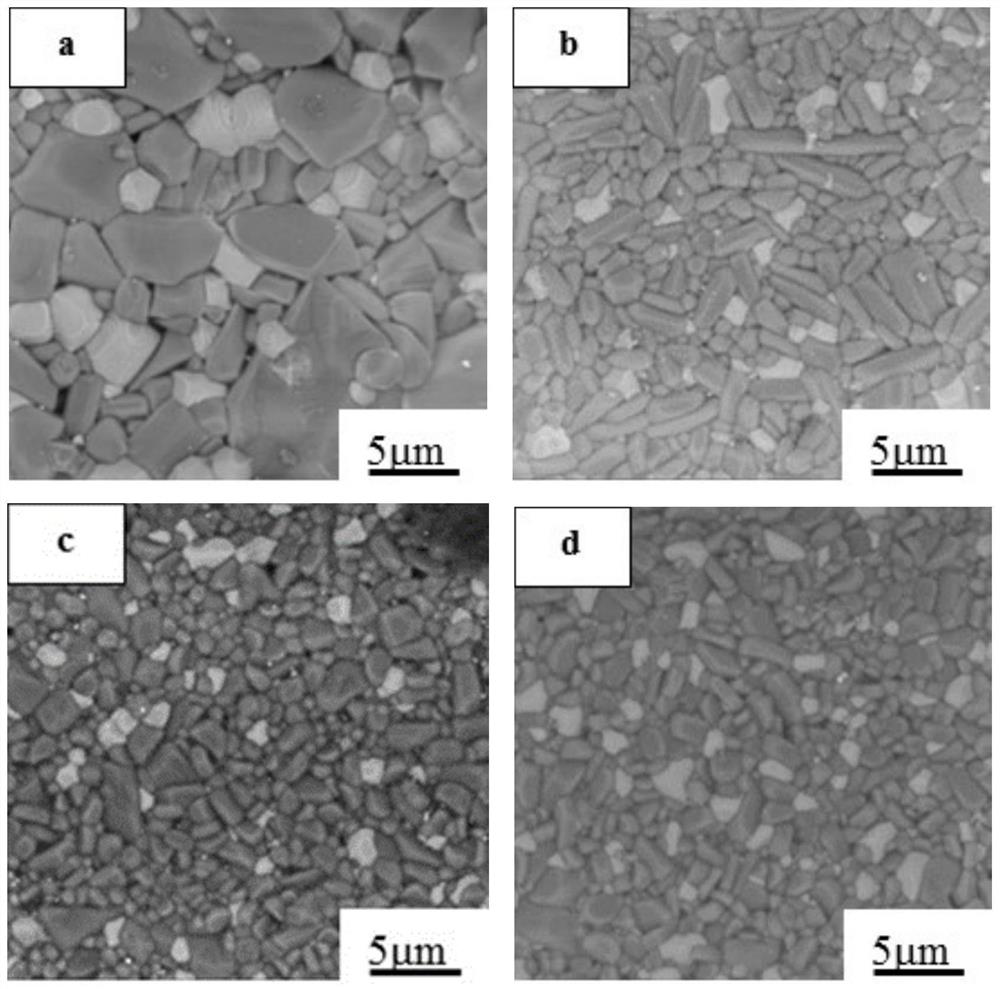

Nd-Fe-B rare earth permanent magnet material

ActiveCN1819075AReduce oxygen concentrationWide sintering temperature rangeMagnetic materialsRare earthAlloy

A rare earth permanent magnet material is based on an R-Fe-Co-B-Al-Cu system wherein R is at least one element selected from Nd, Pr, Dy, Tb, and Ho, 15 to 33% by weight of Nd being contained. At least two compounds selected from M-B, M-B-Cu and M-C compounds (wherein M is Ti, Zr or Hf) and an R oxide have precipitated within the alloy structure as grains having an average grain size of up to 5 mum which are uniformly distributed in the alloy structure at intervals of up to 50 mum.

Owner:SHIN ETSU CHEM CO LTD

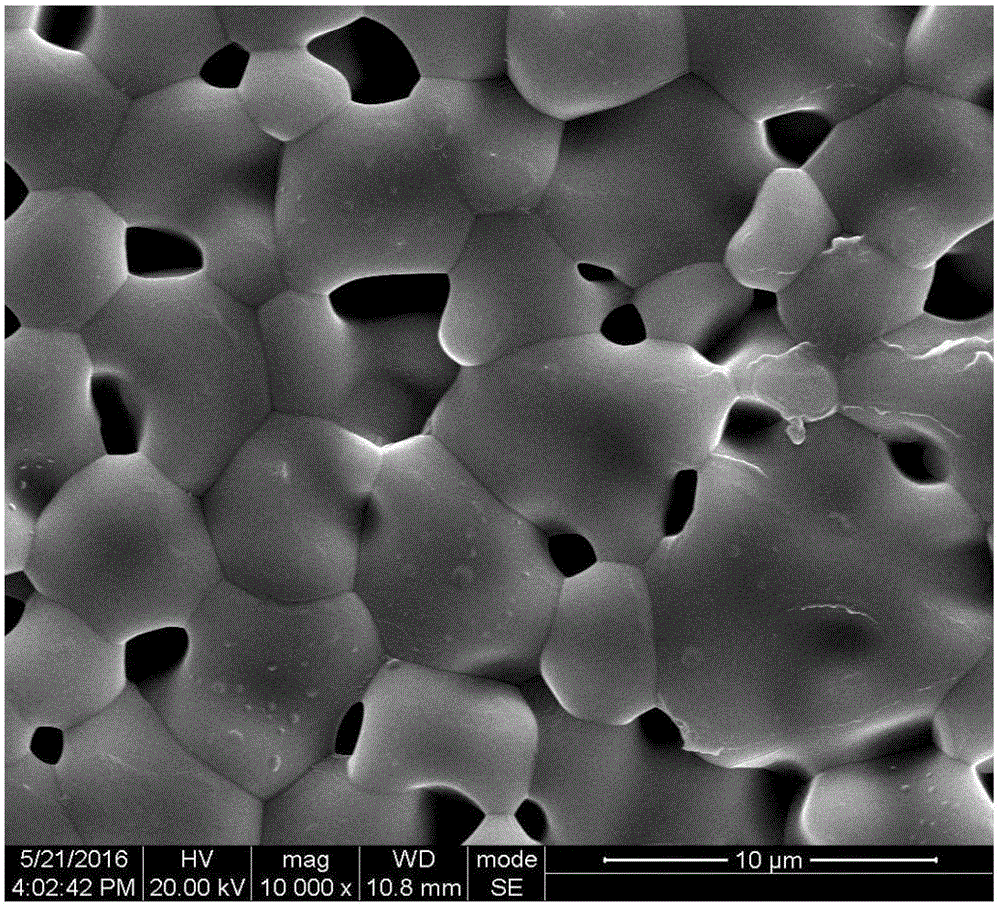

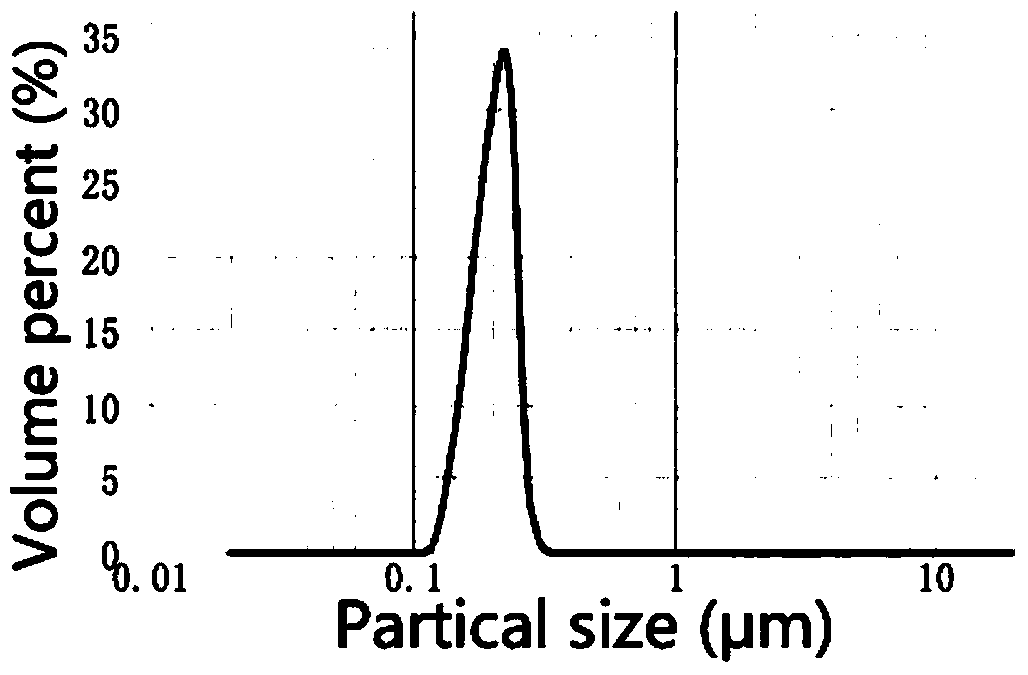

Preparation method for modified superfine low-oxygen water-atomized alloy powder used for diamond tool

The invention discloses a preparation method for modified superfine low-oxygen water-atomized alloy powder used for a diamond tool. The alloy matrix powder for a tool bit of the diamond tool can be manufactured through the method. The preparation method has the characteristics that the alloy powder is modified by adding multiple strengthening elements and the bending strength of a sintered matrix is improved at the same time; the superfine-grained alloy powder is manufactured through an ultrahigh-pressure water atomization technology, the alloy powder sintering compaction is lowered while the composition uniformity of single powder; the low-oxygen-content alloy powder is obtained through control over a smelting technique and a reduction technique, and the compactness of the sintered matrix is improved.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

A NiZnCu ferrite material and preparing method thereof

InactiveCN101552074AHigh sintering activityImprove permeabilityInorganic material magnetismMetallurgyInorganic oxide

The invention discloses a NiZnCu ferrite material, which is a ferrite material made by adding organic additives and inorganic oxide additives in the base raw material prescription of Fe[2] O [3], NiO, or Ni [2] O [3], CuO, ZnO. The reparing method includes: adding the raw material and the organic additives into the inorganic oxide additives, mixing with water, drying, sifting; presintering; joining the organic additives again, adding water for ball milling, mixing; drying and then sifting, to obtain the inventive NiZnCu ferrite material. Granulation, molding and sintering is required during manufacturing magnet ring. Compared with the existing technology, this invention adds organic additives twice to make the prescription and process simpler, reduce the cost and presintering temperature, improve the sintering activity of the presintering material so that the sintering temperature scope becomes wider, and obtain a NiZnCu ferrite material with a good consistency of production batches, suitability for industrial production, high magnetic permeability and Q value stability.

Owner:贵阳晶华电子材料有限公司

High-strength aluminum oxide ceramic metalized paste and preparation method thereof

The invention discloses high-strength aluminum oxide ceramic metalized paste and a preparation method thereof. The metalized paste disclosed by the invention is prepared from the following substances by weight percent: 70-85% of molybdenum powder, 5-15% of manganese powder, 5-15% of Al2O3 powder; 5-10% of silica powder, 0.2-1.2% of calcium oxide, 0.2-1.5% of magnesium oxide, 0.2-1.5% of zirconium oxide powder, and 0.2-1.0% of titanium dioxide powder. The preparation method comprises the steps of respectively putting the substances into an oven according to the ratio; baking for 1-2 hours at the temperature of 100-110 DEG C; putting the molybdenum powder into a ball grinder; adding absolute ethyl alcohol to grind for 24-48 hours; baking at 100-110 DEG C; and putting the manganese powder, the Al2O3 powder, the silica powder, the calcium oxide, the magnesium oxide, the zirconium oxide powder and the titanium dioxide powder into the ball grinder to grind for 4-6 hours; adding the grinded molybdenum powder to grind for 36-48 hours, so as to obtain the mixed powder of the materials; and adding a binder to the mixed powder to grind for 24-48 hours, so as to obtain the metalized paste.

Owner:JINZHOU METAL CERAMICS

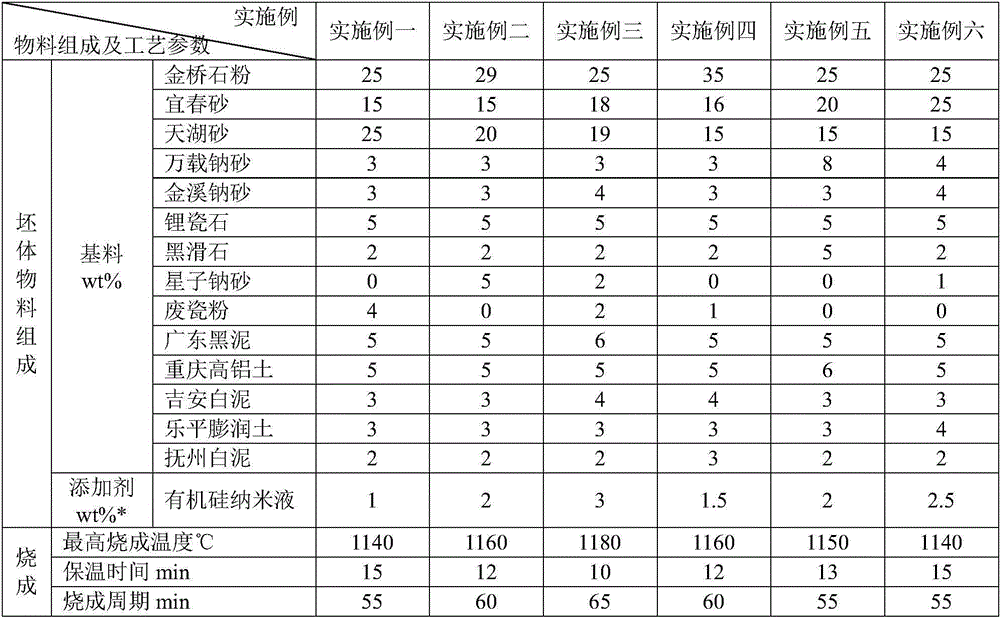

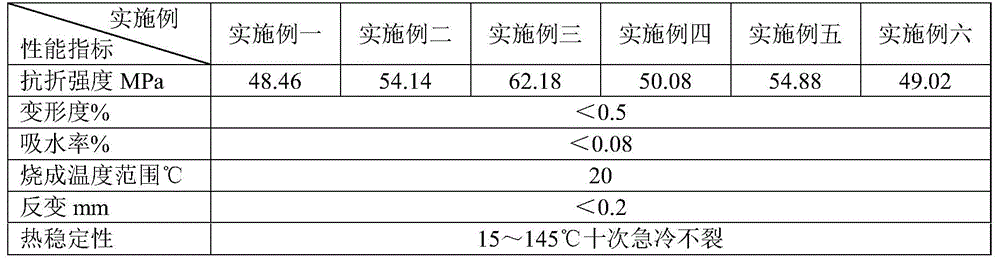

Ultralow-temperature low-deformation glazed green brick body and preparation method thereof

The invention discloses an ultralow-temperature low-deformation glazed green brick body which consists of a base stock and an additive, wherein the base stock is prepared from the following ingredients: 25-35wt% of Jinqiao limestone, 10-25wt% of Yichun sand, 10-25wt% of Tianhu sand, 3-8wt% of Wanzai sodium sand, 3-5wt% of Jinxi sodium sand, 5-10wt% of lithium chinastone, 2-5wt% of black talc, 0-5wt% of Xingzi sodium sand, 0-5wt% of waste porcelain powder, 5-8wt% of Guangdong black clay, 5-8wt% of Chongqing bauxite chamotte, 3-6wt% of Ji'an white mud, 3-8wt% of Leping bentonite and 2-5wt% of Fuzhou white mud; the additive refers to an organosilicone nano solution with solid content of 40% and accounts for 1-3wt% of the base stock. In addition, the invention also discloses a preparation method of the ultralow-temperature low-deformation glazed green brick body. The preparation method is easily available in raw material and low in price of raw materials, is capable of improving the product performance index, realizing decrease in sintering temperature, enlarging the sintering temperature range, ensuring the product quality and realizing energy consumption and consumption reduction, and is beneficial to promotion in sustainable development of industrial production.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Composite combining corundum based refractory materials

ActiveCN101423401AImprove high temperature resistanceStrong thermal shock resistanceSuperplasticizerMaterials science

The invention relates to a composite sialon-corundum fire-resisting material, which is characterized in that the formulation of the fire-resisting material comprises the following: 30 to 54 percent of corundum or aluminum oxide hollow sphere the diameter of which is between 3 and 1 millimeter, 7 to 30 percent of the corundum or the aluminum oxide hollow sphere the diameter of which is between 1 and 0.0088 milliliter, 16 to 30 percent of corundum powder the diameter d90 of which is less than 0.088 millimeter, 3 to 10 percent of alpha aluminum oxide micro powder, 2 to 8 percent of hydrated aluminum oxide, 0.2 to 2 percent of siliceous dust, 0 to 2 percent of barium aluminate cement, 0.05 to 0.4 percent of efficient water reducing agent (which is prepared from polycarboxylic acid, sulfonated naphthaldehyde polymer and sulfonated melamine polymer), 1 to 6 percent of polyacrylic acid emulsion, and 1 to 6 percent of water. The composite sialon-corundum fire-resisting material obviously has the advantages of coagulation, hardening, demolding, drying and heating performances remarkably similar to a low cement casting material, and good high-temperature resistant performance, and can be made into various products or be used as an unshaped material.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Inner electrode size and ceramic capacitor made by the size

InactiveCN1598982AReduce manufacturing costImprove electrical performanceFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorMiniaturization

The invention relates to the inner electrode stuff used in the slabbing multilayer ceramic capacitor and the ceramic capacitor made of the stuff. The abovementioned stuff includes the nickel metal powder, ceramic additive and organic carrier and their amount of weight is as follows: between 35% and 55% of nickel metal powder, between 2% and 20% of ceramic additive and between 35% and 65% of the organic carrier. The ceramic capacitor made of the stuff can solve the problems of craze of the ceramic body and production cost. The stuff in sintered in the protective atmosphere. The stuff doen't melt at the temperature of no more than 1450deg.C, makes no effect to the ceramics, reduces the production cost efficiently and produces the miniaturized products with excellent electrical property, high reliability and large capacity.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

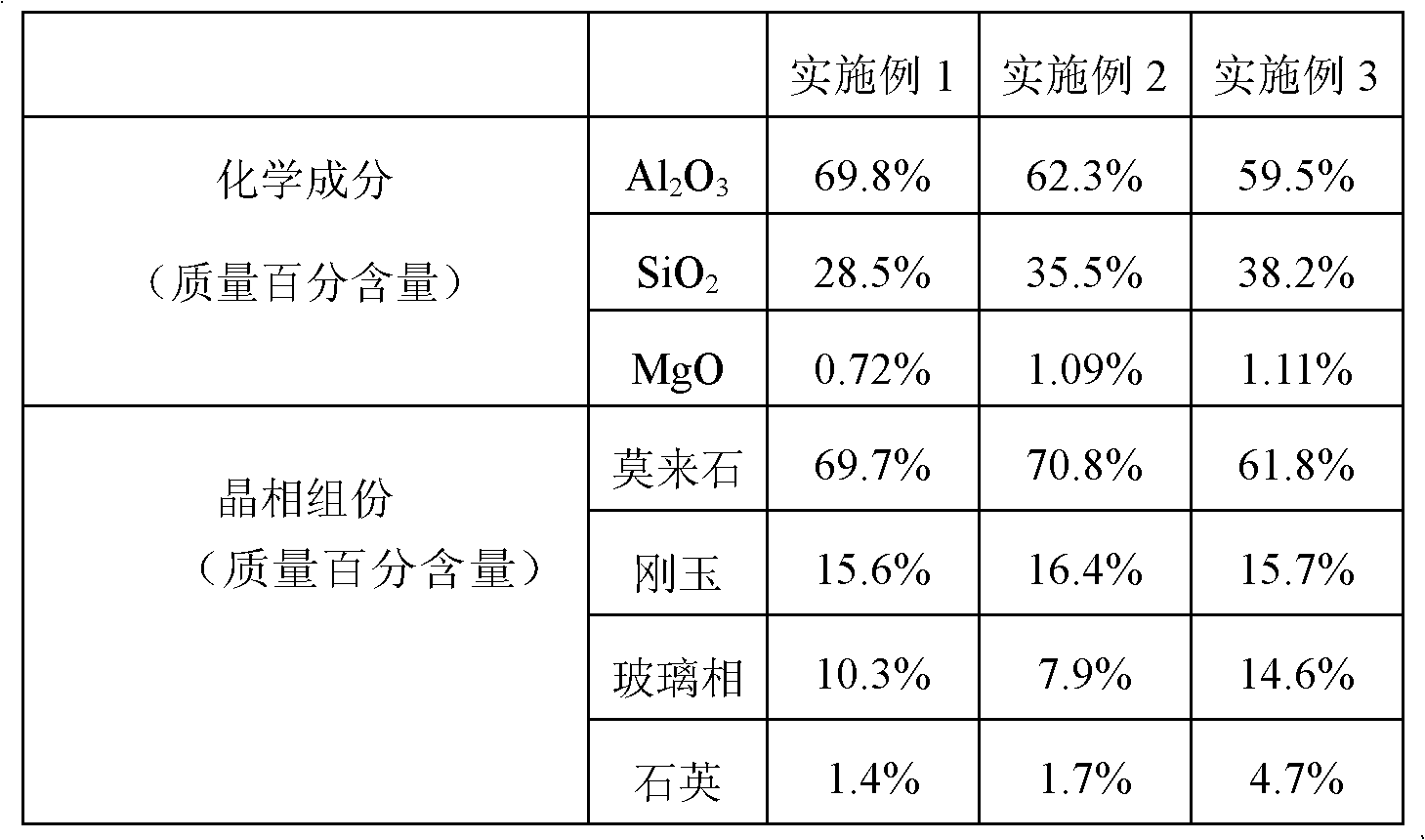

Casting-use straight-hole ceramic filter and preparation method thereof

InactiveCN102992781AWide sintering temperature rangeWith resistance to sudden cold and sudden heatProcess efficiency improvementPlasticizerMullite

The invention discloses materials used for preparing a casting-use straight-hole ceramic filter, a straight-hole ceramic filter, and a preparation method thereof. The materials used for preparing the casting-use straight-hole ceramic filter comprise, by weight, 50-70 parts of cured flint clay, 20-40 parts of aluminum oxide, and 3-10 parts of clay. The straight-hole ceramic filter preparation method comprises the steps that: a honeycomb ceramic molding technology is adopted, wherein the materials are sufficiently mixed with a binder and a water retaining agent; a plasticizer, a lubricant and water are added; and processes such as kneading, rough mixing, aging, refining, molding, shaping, drying, cutting, soot blowing, and sintering are carried out, such that the straight-hole ceramic filter is prepared. The costs of the materials used for preparing the straight-hole ceramic filter are low; mullite corundum is synthesized during the sintering process; and production cost is reduced.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

Glaze-crawling-proof protection coating for immersion type water gap slag line and preparation method of glaze-crawling-proof protection coating

The invention discloses a glaze-crawling-proof protection coating for an immersion type water gap slag line and a preparation method of the glaze-crawling-proof protection coating. The coating is prepared from a main material, water and dextrin; the main material is prepared from the following components in percentage by weight: 62 percent to 66 percent of tabular corundum, 15 percent to 17 percent of Suzhou clay, 3 percent to 5 percent of bentonite, 12 percent to 16 percent of active aluminum oxide and 0.5 percent to 1 percent of sodium silicate; the weight ratio of the water to the dextrin to the main material is (31 to 33):(0.6 to 0.8):100. The glaze-crawling-proof protection coating disclosed by the invention can be used for effectively preventing an anti-oxidization coating of the immersion type water gap slag line part from generating glaze crawling, so that the strength and anti-corrosion performance of the immersion type water gap slag line are improved, and the service life of an immersion type water gap can be prolonged for 2.5 hours to 3.5 hours.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

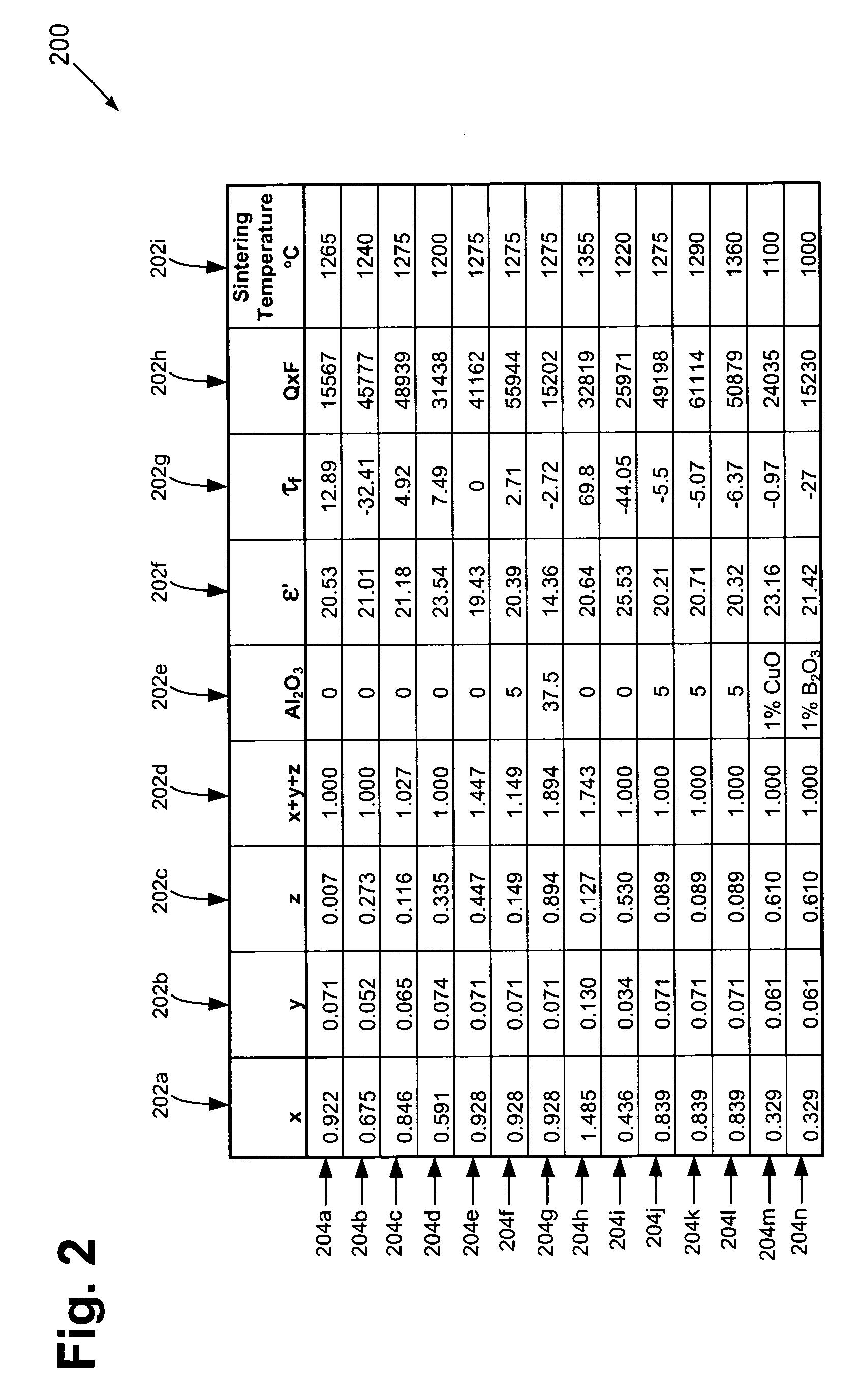

Dielectric ceramic composition having wide sintering temperature range and reduced exaggerated grain growth

ActiveUS7378363B2Wide sintering temperature rangeExtended temperature rangeCeramicsCopper oxideBoron oxide

According to one exemplary embodiment, a dielectric ceramic composition includes a main component group, where the main component group is represented by MgxCayZnzTiO2+x+y+z, where the sum of x, y, and z is less than or equal to 1.0 such that the dielectric ceramic composition has a wider sintering temperature range and reduced exaggerated grain growth. According to one embodiment, x can be greater than 0.0 and less than 1.0, y can be greater than 0.0 and less than 1.0, and z can be greater than 0.0 and less than 1.0. The dielectric ceramic composition can further include between 0.0 and 50.0 percent by weight of aluminum oxide. The dielectric ceramic composition can further include copper oxide. The dielectric ceramic composition can further include boron oxide.

Owner:ALLUMAX TTI LLC

High frequency dielectric ceramic material sintered under low temp and its preparation

InactiveCN1431166AWide sintering temperature rangeLower sintering temperatureCeramicsDielectric ceramicsIon

A high-frequency dielectric ceramics sintered at low temp has a structure expressing formula: (Bi3xZn2-3x)(Znx-y / 3Nb2-x-2y / 3May)O7 and (Bi3xZn2-3x)(ZnxNb2-x-yMby)O7, where Ma=Sn or Zn, Mb=Sb, Ta, or Mo, x=0.45-0.67 and y=0-1.5. Its advantages are high dielectric coefficient (25-8), low medium loss, low sintering temp (840-1060 deg.C), high insulating resistance, and wide range of temp coefficients.

Owner:XI AN JIAOTONG UNIV

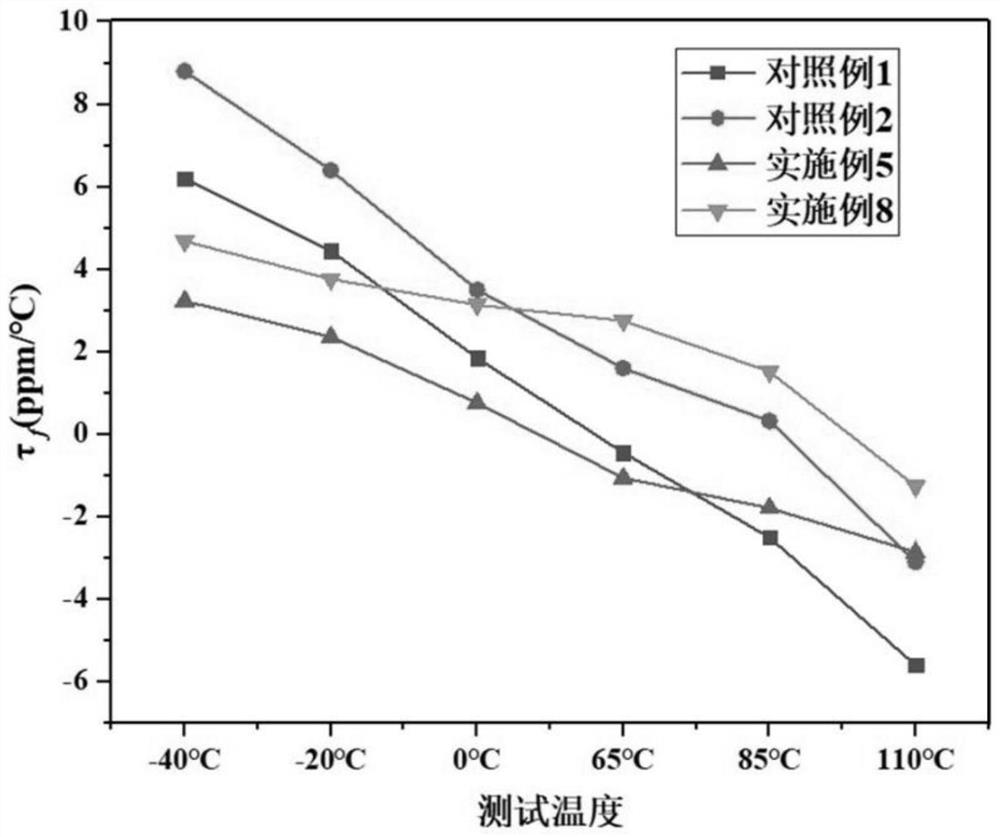

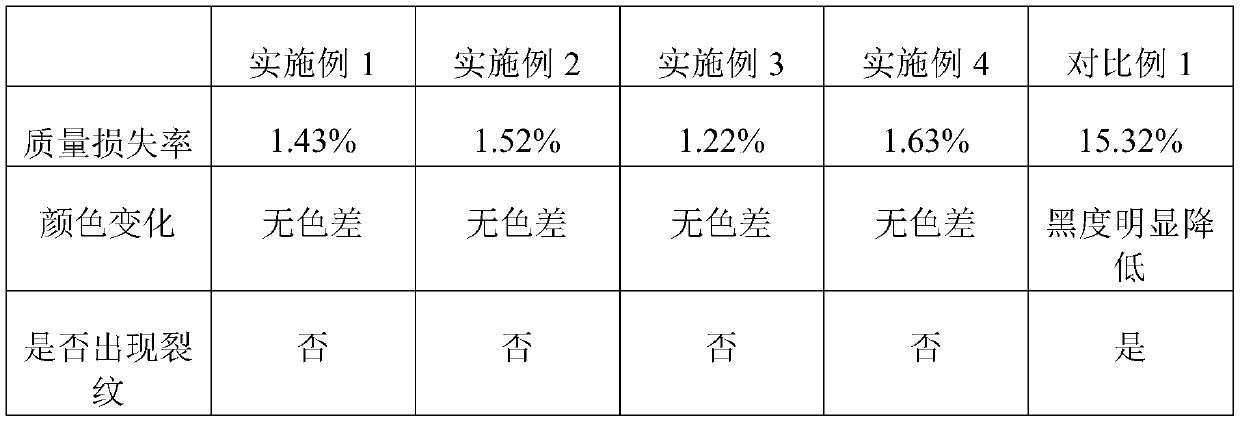

Novel ultra-low-loss microwave dielectric ceramic material and preparation method thereof

The invention discloses a novel ultra-low-loss microwave dielectric ceramic material and a preparation method thereof and belongs to the technical field of electronic information functional materials and devices. The general chemical formula of the ceramic material is Li(2+a)(Mg(1-b)Xb)3YO6.cZ, wherein X refers to Ca<2+> or Sr<2+>, Y refers to Ti<4+>, Sn<4+> or Zr<4+>, Z refers to one of MgO, ZnO and CaF2 or a combination of MgO, ZnO and CaF2, a is larger than or equal to 0.03 and smaller than or equal to 0.15, b is larger than or equal to 0.01 and smaller than or equal to 0.04, and c is larger than or equal to 0 and smaller than or equal to 0.15. Raw materials of the microwave dielectric ceramic material are prepared as per the general chemical formula, subjected to ball-milling mixing for the first time, pre-sintered at 980-1,200 DEG C, then subjected to ball-milling mixing for the second time and sintered at 1,250-1,400, and the material is prepared; the crystalline phase of a finished product is a cubic phase adopting an ordered rock salt structure. The performance of the microwave dielectric ceramic material is greatly improved, the relative dielectric constant epsilonr of the microwave dielectric ceramic material is adjustable in a range of 8-20, the quality factor Q*f value is in a range of 92,000-153,000 GHz, meanwhile, the temperature coefficient tauf of resonance frequency ranges from -23 ppm / DEG C to 5 ppm / DEG C, and the material has the stable performance and can meet the application requirements of modern microwave devices.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Silicon solar cell electrode silver coated copper sizing agent and preparing method thereof

ActiveCN104157331AImprove stabilityImprove reliabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureCeriumSilicon solar cell

The invention relates to a silicon solar cell electrode silver coated copper sizing agent and a preparing method of the silicon solar cell electrode silver coated copper sizing agent. Conductive component micro silver coated copper powder is the spherical micro metal powder with copper serving as the core, silver serving as the shell, and copper-tin-silver alloy serving as the middle layer, the copper content is 50 percent to 60 percent, the silver content is 30 percent to 40 percent, the tin content is 3 percent to 10 percent, the particle size is 1-3 microns, the tap density is 4.0-5.5 g / ml, the specific surface area is 0.5-1.5 m<2> / g, and the conductive component micro silver coated copper powder is prepared under the alkaline condition with glyoxylic acid or glyoxal serving as a reducing agent to conduct step-by-step reduction on copper sulfate, tin sulfate and a silver nitrate solution. A bismuth-silicon-boron-zinc-cerium-molybdenum system is adopted in lead-free glass powder, the softening temperature of the glass powder is 400-600 DEG C, the micro silver coated copper powder serves as the conductive component, a large amount of silver powder is saved, and the raw material cost of the conductive sizing agent is greatly reduced.

Owner:TIANJIN ZHONGKE CHEM

Magnesium-aluminum refractory material and preparation method therefor

The present invention relates to a magnesium-aluminum refractory material. The magnesium-aluminum refractory material is prepared by using magnesium aluminate spinel of different particle sizes as a raw material, and adding an auxiliary additive, nanometer magnesia, boron carbide, a binder and nanometer aluminium oxide. According to the product provided by the present invention, the organization structure is more uniform, and therefore strength and thermal shock resistance of the product are improved; the particle size of nano-zinc oxide is small, and therefore micro pores can be filled with the nano-zinc oxide, porosity of the product is reduced, and volume density is increased; and refractoriness is high, corrosion resistance is excellent, thermal shock resistance is good, and the sintering temperature range is wide.

Owner:长兴泓矿炉料有限公司

Large-sized special-shaped composite magnesium aluminate spinel product and technique for producing the same

ActiveCN101434492AHigh temperature resistantWith thermal shock resistanceMagnesium AluminateTemperature resistance

The invention relates to large or specific compound magnesium-aluminum spinel products with the formula of 48 to 56 percent of 5-1mm magnesium-aluminum spinel, 12 to 22 percent of 1-0.088mm magnesium-aluminum spinel, 16 to 25 percent of magnesium-aluminum spinel with d90 less than 0.088mm, 3 to 6 percent of magnesium-aluminum spinel with d90 less than 0.010mm, 3 to 15 percent of beta alumina powder with d95 less than 0.020mm, 2 to 6 percent of hydratable alumina, 1 to 5 percent of magnesium promoter, 0.05 to 0.4 percent of external efficient water reducing agents (polycarboxylic acid plus sulfonation naphthaldehyde polymer plus sulfonation melamine polymer), 1 to 6 percent of latex of the system of external polyacrylic acid and 1 to 6 percent of external water. The magnesium-aluminum spinel composite combined refractory has the following chemical compositions: 72 to 87 percent of Al2O3, 12 to 27 percent of MgO, 0.2 to 1.5 percent of Na2O and 0.1 to 0.5 percent of SiO2. The raw materials are weighed according to the ratios, and are mixed, molded and maintained to make billets, and then are subjected to the processes of drying, firing at the temperature of 1430 to 1650 DEG C and inspection and the like so as to make products of large or specific compound magnesium-aluminum spinel refractory. The magnesium-aluminum spinel product has excellent manufacturing performance and excellent performances of high-temperature resistance, erosion resistance and creep resistance. As the products are casted and moulded, large and specific products can be produced.

Owner:青岛中瑞泰旭催化剂有限公司

Rapid low-temperature preparation method for Y-alpha-SiAlON transparent ceramics

The invention relates to a rapid low-temperature hot-pressing sintering method for transparent Y-alpha-SiAlON ceramics, and belongs to the field of transparent ceramic material preparation. The method comprises the following steps: firstly, batching on the basis of an alpha-SiAlON composition design, preparing ultrafine mixed powder by adopting a planetary ball mill, and preparing the transparent Y-alpha-SiAlON ceramics by utilizing the obtained ultrafine mixed powder by adopting the technologies of high-temperature slow pressurizing and cooling with pressure, high-temperature rapid nitrogen-filling, high-temperature rapid heating and rapid cooling. According to the method, the densification process of the alpha-SiAlON ceramics is greatly promoted by adopting the technology of preparing the transparent Y-alpha-SiAlON ceramics by the ultrafine mixed powder, the sintering time is effectively shortened, the sintering temperature is remarkably reduced, and the rapid low-temperature sintering of the alpha-SiAlON ceramics is realized.

Owner:DALIAN MARITIME UNIVERSITY

Lead-free glass powder for electronic paste of solar battery, and preparation method for lead-free glass powder

The invention provides lead-free glass powder for electronic paste of a solar battery, and a preparation method for the lead-free glass powder. The lead-free glass powder comprises the following components in percentage by mass: 30 to 60 percent of B2O3, 2.5 to 20 percent of SiO2, 30 to 55 percent of Bi2O3, 0.1 to 5 percent of Na2O, 0.1 to 3 percent of ZnO, 1.5 to 10 percent of TiO2, 0.5 to 8 percent of ZrO2, and 0.5 to 5 percent of Al2O3. The method comprises the following steps of: preparing materials, performing ball-milling to obtain powder of which the granularity is less than 300 meshes, uniformly mixing, and raising temperature and preserving heat for multiple times to ensure that the raw materials are fully fused to form glass metal; pouring into deionized water and performing water quenching, and rapidly cooling the glass metal in water and cracking into small glass particles; and performing ball-milling on the small glass particles, stearic acid and an ethanol solution used as a ball-milling medium, and drying and screening to obtain the lead-free glass powder for the electronic paste. The lead-free glass powder is low in softening temperature, high in chemical stability, appropriate in expansion coefficient, high in acid and alkaline resistance and wear resistance, wide in sintering temperature range, low in manufacturing cost, and suitable for inorganic binding phase in the electronic paste of the solar battery, and does not contain toxic heavy metal oxide.

Owner:昆明高聚科技有限公司

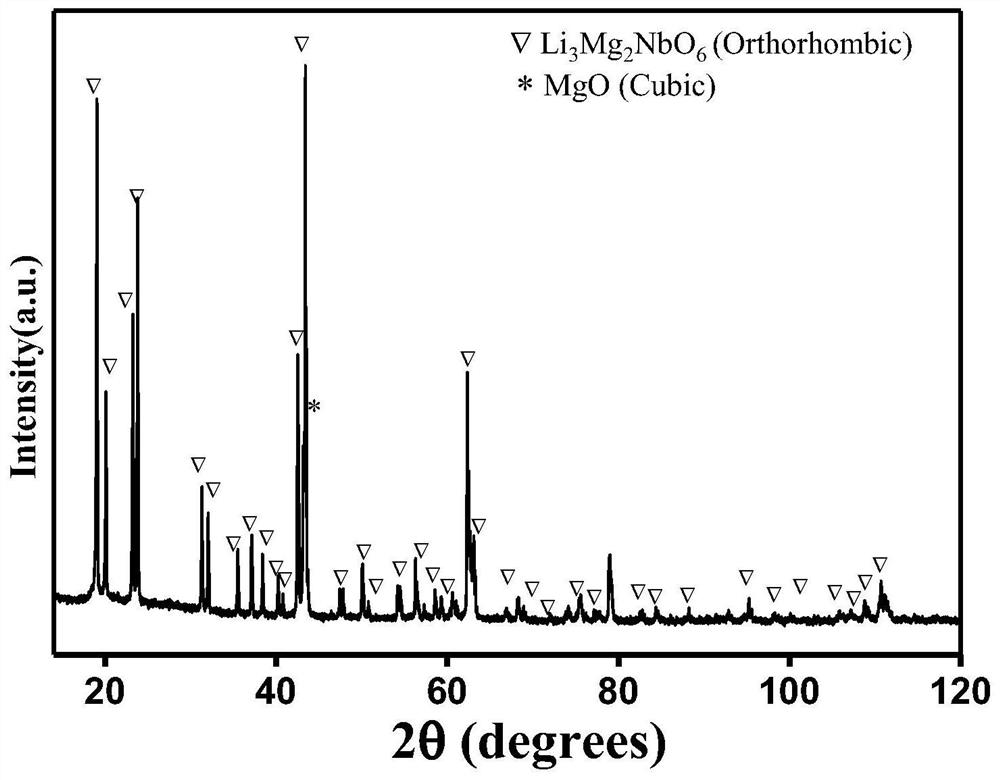

Rock salt type reconstructed super-lattice structure microwave dielectric ceramic material and preparation method thereof

The invention provides a rock salt type reconstructed super-lattice structure microwave dielectric ceramic material and a preparation method thereof. The general chemical formula of the material is Li3+x(1-yAy)2-2xNb1-xTi2xO6Mg, and A is one or more of divalent ions: Cu2+, Zn2+, Ni2+ and Co2+, 0.08<=x<=0.3 or 0.8<=x<=0.92 and 0<y<=0.05; the preparation method comprises the following steps: burdening, ball milling, drying and sieving, pre-sintering, granulating, compression molding and sintering. The prepared material has a typical rock salt type reconstruction short-range ordered super-latticestructure, is highly compact in micro-structure, free of pores and micro-cracks and high in quality factor, Q*f ranges from 9,000 GHz to 13,000 GHz, the relative dielectric constant [epsilon]r rangesfrom 16 to 21, and the frequency temperature coefficient [tau]f ranges from -30 ppm / DEG C to +3 ppm / DEG C. The formula does not contain volatile toxic metals such as Pb, Cd and the like, and the material is stable in performance, and can meet the application requirements of modern microwave devices.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

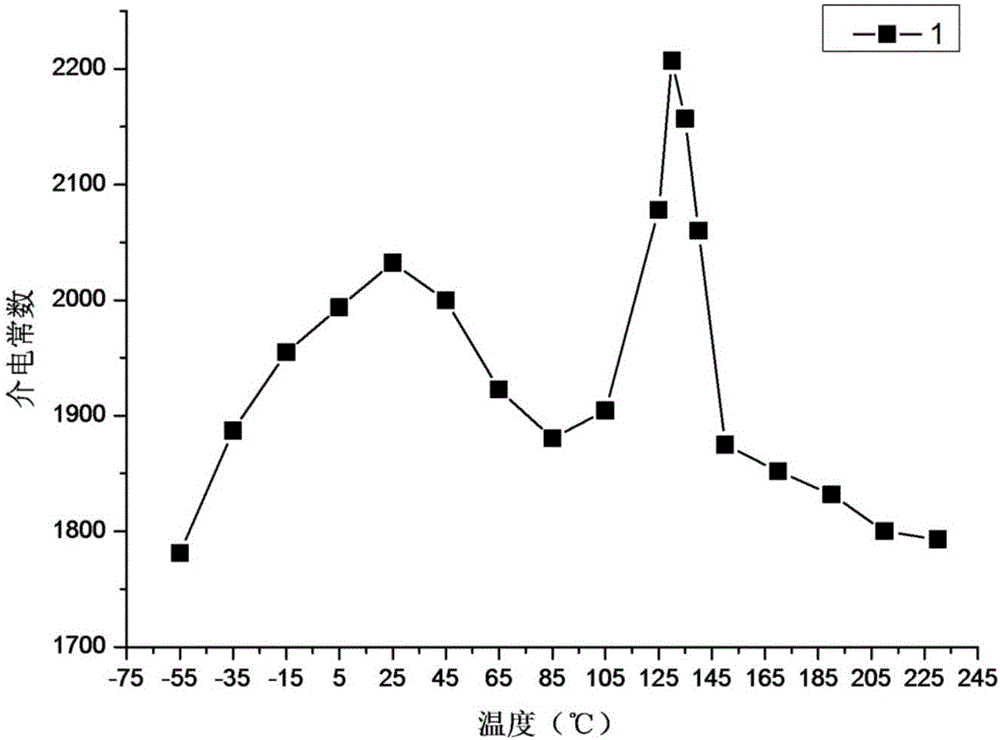

LTCC low-frequency dielectric ceramic capacitor material and preparation method thereof

InactiveCN106747417AExcellent dielectric propertiesHigh dielectric room temperature constantFixed capacitor dielectricDielectric lossWorking temperature

The invention discloses an LTCC low-frequency dielectric ceramic capacitor material and a preparation method thereof. The material uses BaTiO3 as a main material with the addition of 0.5% to 6.8% of a sintering aid and 1% to 11% of a metal oxide in weight percentages on the basis of the BaTiO3. The sintering aid is prepared from the following raw materials in percentages by weight: 0.3% to 32% of Bi2O3, 1% to 28% of K2CO3, 1% to 22% of TiO2, 3% to 38% of LiF and 2% to 31% of SiO2; the metal oxide is prepared from the following raw materials in percentages by weight: 0.2% to 32% of Nb2O5, 0.5% to 28% of Co3O4, 0.9% to 22% of WO3, 0.4% to 37% of MnCO3, 0.6% to 33% of Re2O3 and 1.1% to 10% of CuO. The sintering temperature is high (800 DEG C to 900 DEG C) and accords with and exceeds the EIA X9R standard, the material has the advantages of being low in dielectric loss, high in dielectric constant, high in reliability, high in uniformity and environment-friendly, the working temperature range is between -55 DEG C and +230 DEG C, and the material adapts severe environment requirements.

Owner:TIANJIN UNIV

Anti-oxidation refractory material and preparation method thereof

The invention relates to an anti-oxidation refractory material and a preparation method thereof. The anti-oxidation refractory material is prepared through adding an auxiliary additive, graphene, a binder and nano-alumina to a main raw material magnesium aluminate spinel with different particle sizes. The above product has a uniform microstructure, so the strength and the thermal shock resistance of the product are improved; nanometer zinc oxide has fine granularity and can be used to fill fine pores, so the porosity of the product is reduced, and the bulk density is improved; and the anti-oxidation refractory material also has the advantages of high refractoriness, good anti-oxidation performance, excellent erosion resistance, good thermal shock resistance and wide sintering temperature range.

Owner:长兴泓矿炉料有限公司

Flux for high acid resistance automotive glass printing ink and preparation method thereof

The invention provides flux for high acid resistance automotive glass printing ink and a preparation method thereof. The base material of the flux comprises the following raw materials in parts by mass: 1 to 4 parts of lithium oxide, 0 to 3.5 parts of sodium oxide, 0 to 2 parts of potassium oxide, 1 to 4 parts of calcium oxide, 0.5 to 3 parts of magnesium oxide, 2 to 7 parts of boron oxide, 0.5 to3 parts of phosphorus pentoxide, 20 to 30 parts of silicon oxide, 1 to 5 parts of titanium oxide, 1 to 5 parts of zirconium oxide, 55 to 65 parts of lead oxide, and 2 to 5 parts of an applied acid proofing agent. The flux has a wide softening temperature range and a wide swelling coefficient range within a formula component, the range of the ratio of the flux to a toner is wide, and the formed printing ink can be fired into light and matt effects in different degrees. The glass printing ink prepared through the flux has a high hiding rate, a wide sintering temperature range and high adhesiveforce and weather resistance, and meanwhile has high acid resistance.

Owner:JIANGSU BAIFU TECH CO LTD

SMT intelligent pyroelectric infrared sensor

InactiveCN105698936AImprove anti-interference abilityStrong product weightSensing radiation from moving bodiesManufacturing cost reductionControl signal

The invention relates to a chip-type intelligent pyroelectric infrared sensor, which is a closed structure shell composed of a tube cap and a substrate. The upper surface of the tube cap has a window, and an infrared optical filter is embedded on the window; and the tube cap and the A receiving space is formed between the substrates, and the receiving space accommodates and encapsulates the infrared sensitive element, the supporting component and the signal processing module; the infrared sensitive element is fixed by the supporting component, and the supporting component and the signal processing module are directly fixed on the substrate. The pyroelectric infrared sensor of the present invention has the characteristics of miniaturization, intelligence, and the ability to output multiple control signals. This packaging structure is suitable for SMT automatic patch and reflow soldering processes, which is conducive to mass automatic production and improves manufacturing efficiency. Reduce manufacturing costs.

Owner:SENBA SENSING TECH CO LTD

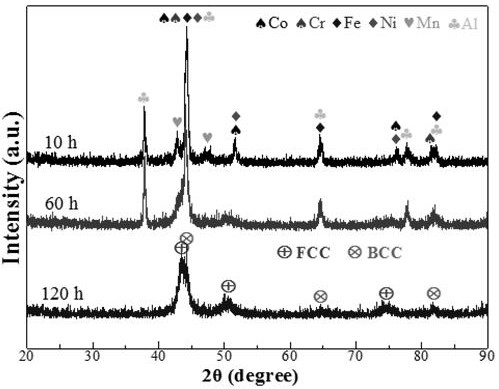

Preparation method of high-strength high-toughness corrosion-resistant nickel-based composite material and high-strength high-toughness corrosion-resistant nickel-based composite material

The invention discloses a preparation method of a high-strength high-toughness corrosion-resistant nickel-based composite material and the high-strength high-toughness corrosion-resistant nickel-basedcomposite material. According to the composite material, (CoCrFeNiMn)<100-x>Alx dual-phase high-entropy alloy is adopted as a particle additive phase, and pure nickel is adopted as a matrix. The high-entropy alloy contains nickel elements, forms a concentration gradient with the nickel matrix, and promotes sufficient diffusion of nickel atoms between two phases in the sintering process, the interface bonding state is good, and the bonding strength is high. Based on the metastability characteristics, the dual-phase high-entropy alloy decomposes under high temperature and pressure conditions and forms a reinforcing phase in situ on the nickel matrix. The preparation process is simple, the obtained composite material is high in relative density, a submicron-scale aluminum-rich oxide and a nano-scale solid solution precipitation reinforcing phase are generated in situ, the composite material has the comprehensive mechanical properties of high hardness, high strength and excellent plasticity, and the seawater corrosion resistance is good.

Owner:UNIV OF JINAN

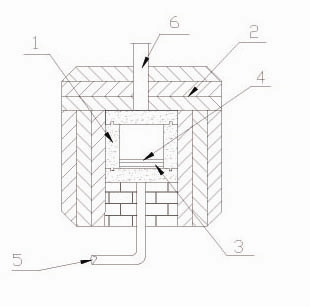

Fully-closed high temperature microwave sintering roller kiln

The invention discloses a fully-closed high temperature microwave sintering roller kiln, which aims to overcome the shortcomings of high noise, relatively poorer tightness and proneness to the occurrence of kiln arching of the conventional sintering kiln which is a gear drive mechanism. The fully-closed high temperature microwave sintering roller kiln comprises a closed kiln body consisting of a top plate, side plates and a bottom plate. Multi-layer fiberboards are arranged on the two sides and top part of the kiln body. A roller bed is arranged on the bottom plate of the kiln body, and is provided with a push plate for conveying materials. The push plate is driven by a roller bed drive system arranged in a cavity of the kiln body. The fully-closed high temperature microwave sintering roller kiln has a simple structure, low manufacturing cost, high tightness, high product sintering efficiency, high sintering quality and a wide sintering temperature range, is energy-saving, environmentally-friendly, safe and reliable and avoids the phenomenon of kiln arching.

Owner:湖南航天有限责任公司

Clay composition for sintered noble metal objects and method of producing, clay composition for sintered noble metal objects and method of producing sintered noble metal

InactiveCN1504288AHigh densitySmall shrinkageTransportation and packagingMetal-working apparatusMetallurgyAqueous solution

A clay composition for shaping noble metal is formed of a kneaded mixture of a mixed powder of noble metal having as main components thereof 30 to 70% by weight of a powder having an average particle diameter in the range of 2.2 to 3.0 mum and 70 to 30% by weight of a powder having an average particle diameter in the range of 5 to 20 mum with an aqueous solution of an organic binder.

Owner:AIDA CHEM IND

High-performance silicon carbide ceramic material and preparation method thereof

PendingCN112778014AImprove sintered densityImprove toughnessChemical industryCarbide siliconSpray Granulation

The invention relates to a high-performance silicon carbide ceramic material and a preparation method thereof. The preparation method comprises the following steps of raw material preparation, ball-milling mixing, spray granulation, compression molding and sintering. Through the adding proportion of alpha-silicon carbide powder and beta-silicon carbide powder in the raw materials, grain boundary strengthening and grain refinement are facilitated, and further, the obdurability and the hardness of the silicon carbide ceramic are improved. The sintering temperature range can be expanded by proper sintering aid composition, and convenience is brought to process control; the sintering aid is B4C, C and AlN, and when the mass ratio of B4C to C to AlN is (1-2): (1.5-3): (1-3), the sintering aid can better improve the interface bonding strength between silicon carbide grains and promote the improvement of high-temperature strength. When the sintering temperature is 2050 DEG C, the sintering density of the silicon carbide ceramic material is high. The prepared silicon carbide ceramic material has excellent room-temperature and high-temperature mechanical properties.

Owner:东莞市康柏工业陶瓷有限公司

Ultralow-loss yttrium aluminum garnet microwave dielectric ceramic material and preparation method thereof

The invention provides an ultralow-loss yttrium aluminum garnet microwave dielectric ceramic material, the chemical general formula of the material is Y3-xAl5-yRzO12, and R is one or more selected from Mg < 2 + >, Ga < 3 + >, Si < 4 + >, Ti < 4 + > and Nb < 5 + > heterovalent ions; 0 < = x < = 0.15, 0 < = y < = 0.8 and 0.03 < = z < = 1.5; the invention also provides a preparation method of the ultralow-loss yttrium aluminum garnet microwave dielectric ceramic material. The preparation method comprises the following steps: burdening, ball milling, drying and sieving, presintering, dry pressing,isostatic cool pressing, vacuum sintering and atmosphere control annealing. The prepared material is typical ultralow-loss garnet type aluminum-based microwave dielectric ceramic, Q * f ranges from 180000 GHz to 220000 GHz, the relative dielectric constant epsilonr ranges from 8 to 12, and the frequency temperature coefficient tauf ranges from -33 ppm / DEG C to -22 ppm / DEG C. The formula does notcontain volatile toxic metals such as Pb, Cd and the like, the performance is stable, and the raw materials are sufficiently supplied in China, so that the low cost of the high-performance microwave ceramic becomes possible.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Frequency-stable low-dielectric microwave dielectric ceramic material and preparation method thereof

ActiveCN112919894AOptimizing Frequency Temperature CoefficientImprove frequency stabilityCeramicsFrequency stabilizationMicrowave

The invention relates to a frequency-stable low-dielectric microwave dielectric ceramic material and a preparation method thereof. The material is prepared from the following components in percentage by mass: 70-90% of a main-phase ceramic material A, 10-30% of an auxiliary-phase ceramic material B and 0-1.0% of an oxide sintering aid C, The main-phase ceramic material A is MgxMeySiO2+x+y; the auxiliary-phase ceramic material B is composed of aRO-bRe2O3-cTiO2, R is at least one of Ca or Sr, Re2O3 is at least two of Sm2O3, Nd2O3, Y2O3, Al2O3 and La2O3; and the oxide sintering aid C is at least one of MnO2, WO3 and CeO2. The dielectric constant of the prepared microwave dielectric ceramic material is 9.5-13.6, the frequency temperature coefficient tau f is continuously adjustable between -16 ppm / DEG C and 13 ppm / DEG C, and the ceramic material has good frequency stability and is suitable for the fields of new-generation mobile communication, high-frequency network communication and the like.

Owner:JIAXING GLEAD ELECTRONICS CO LTD

Inking process of automobile glass

Relating to the technical field of glass, the invention discloses an inking process of automobile glass. The method includes the steps of: 1) preparation of varnish; 2) preparation of low-melting-point glass powder; 3) preparation of glass ink; 4) pretreatment of an automobile glass substrate: wiping the automobile glass substrate with acetone and then performing drying; 5) primary sintering: printing glass ink on the plane at the peripheral edge of the pretreated automobile glass substrate in a silk-screen printing mode to form an ink layer, and performing primary sintering; and 6) secondarysintering: spraying nitrogen with silicon carbide composite particles to the surface of the ink layer, performing secondary sintering, then taking out the product, and conducting cooling. The siliconcarbide layer with corrosion resistance is prepared on the surface of the automobile glass ink layer to increase the roughness of the automobile glass ink surface, thus endowing the surface of the automobile glass ink layer with super-hydrophobicity, preventing acid rainwater from contacting the surface of the ink layer, and prolonging the service life of the glass ink layer.

Owner:陈圆圆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com