Rock salt type reconstructed super-lattice structure microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and superlattice technology is applied in the field of high-Q microwave dielectric ceramic materials and their preparation, and microwave dielectric ceramic materials. The effect of comprehensive microwave dielectric properties and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

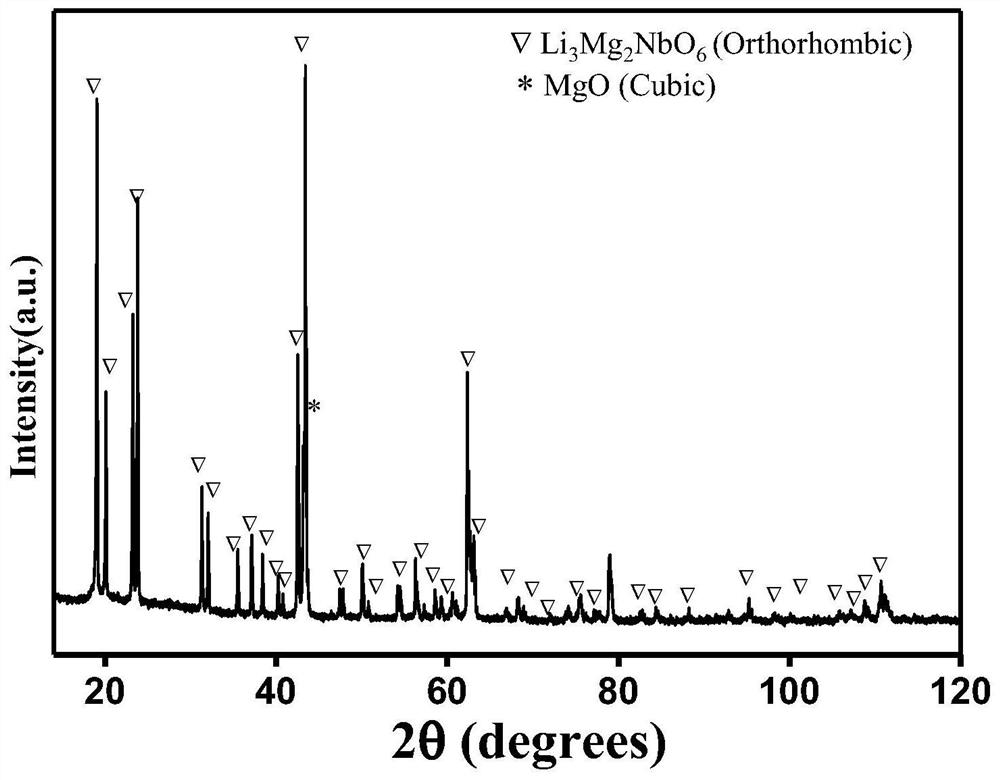

Image

Examples

Embodiment 1

[0059]Step 1: Magnesium carbonate (Mg (OH)2· 4mgco3· 5h2O), Li2CO3, NB2O5, TA2O5, TIO2And CuO, in accordance with 49.4%, 32.1%, 13.8%, 0.3%, 3.6%, and 0.8% mass ratio, and the ingredients form a mixture.

[0060]Step 2: a ball mill; zirconium dioxide ball is a ball mill, according to the mixture: Grinding ball: The mass ratio of alcohol is 1: 5: 2 to grind 6 hours to give a mixed uniform ball abrasive;

[0061]Step 3: Dry, sieve; the resulting ball abrasive from step 2 is dried and over 100 mesh sieve to dry the powder;

[0062]Step 4: Pre-feeding; the dry powder obtained by step 3 is placed in the alumina crucible, and the pre-bleed powder is obtained for 3 hours under 1010 ° C.

[0063]Step 5: Secondary ball milling; the base obtained by the step 4 is subjected to the second ball mill, and zirconium dioxide ball is a ball mill, according to the mixture: Grinding ball: alcohol is 1: 5: 2 to grind 3 hours Mix uniform secondary ball abrasive;

Embodiment 2

[0068]Step 1: Magnesium carbonate (Mg (OH)2· 4mgco3· 5h2O), Li2CO3, NB2O5, TA2O5, TIO2And ZnO, with a mass ratio of 47.8%, 32.6%, 13.5%, 0.4%, 4.5% and 1.2%, and the ingredients forming a mixture.

[0069]Step 2: A ball mill; zirconium dioxide ball is a ball mill, according to the mixture: Grinding ball: The mass ratio of alcohol is 1: 5: 2 to ground 7 hours to obtain a mixed uniform ball abrasive;

[0070]Step 3: Dry, sieve; the resulting ball abrasive from step 2 is dried and over 100 mesh sieve to dry the powder;

[0071]Step 4: Pre-feeding; the dry powder obtained by step 3 is placed in the alumina crucible, and prepared for 3 hours under 1050 ° C for 3 hours.

[0072]Step 5: Secondary ball milling; the base obtained by the step 4 is subjected to the second ball mill, and zirconium dioxide ball is a ball mill, according to the mixture: Grinding ball: alcohol is 1: 5: 2 to grind 3 hours Mix uniform secondary ball abrasive;

[0073]Step 6: Dry, sieve; drying the ball abrasive from step 5 and ove...

Embodiment 3

[0077]Step 1: Magnesium carbonate (Mg (OH)2· 4mgco3· 5h2O), Li2CO3, NB2O5, TA2O5, TIO2And NIO, in accordance with 42.7%, 33.7%, 13.8%, 0.56%, 7.84% and 1.4% mass ratio, and the ingredient formation mixture;

[0078]Step 2: A ball mill; zirconium dioxide ball is a ball mill, according to the mixture: Grinding ball: The mass ratio of alcohol is 1: 7: 4 to ground 7 hours to obtain a mixed uniform ball abrasive;

[0079]Step 3: Dry, sieve; the resulting ball abrasive from step 2 is dried and over 100 mesh sieve to dry the powder;

[0080]Step 4: Pre-feeding; the dry powder obtained by step 3 is placed in the alumina crucible, and the pre-bleed powder is obtained at 1090 ° C for 3 hours;

[0081]Step 5: Quadruple ball milling; the base obtained by the step 4 is second ball mill, based on zirconia ball as a ball mill, according to the mixture: Grinding ball: the mass ratio of alcohol is 1: 3: 1 for grinding 4 hours Mix uniform secondary ball abrasive;

[0082]Step 6: Dry, sieve; drying the ball abrasive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com