SMT intelligent pyroelectric infrared sensor

A pyroelectric infrared sensor technology, applied in the sensor field, can solve the problems of difficulty in adapting to the inevitable trend of optoelectronics, limiting the development of miniaturization, and unfavorable assembly line production, and achieves excellent mechanical properties, perfect application, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

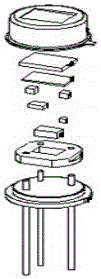

Embodiment 1

[0030] like Figure 4 As shown, the material of the substrate 1 is a metallized ceramic substrate, and is subjected to electromagnetic shielding treatment to reduce external electromagnetic interference. The infrared optical filter 5 is a spherical infrared glass, and is coated with a silicon-based anti-reflection film and a cut-off film filter on both sides. After the coated spherical infrared glass is sliced, it is embedded in the window on the cap, and is made of resin material. Adhesive, replace traditional optical filters, small size, meet the requirements of miniaturization. The signal processing module 3 is a digital intelligent control circuit chip module, which integrates a signal amplification circuit, an analog-to-digital conversion circuit, a low-pass / high-pass filter circuit and a signal output unit to meet the requirements of intelligence. The tube cap 6 and the substrate 1 are sealed and welded to form a patch-type intelligent pyroelectric infrared sensor with ...

Embodiment 2

[0032] like Figure 5 As shown, the material of the substrate 1 is an epoxy resin PCB board, and is subjected to electromagnetic shielding treatment to reduce external electromagnetic interference. The infrared optical filter 5 is a flat infrared glass, and is coated with a silicon-based anti-reflection film and a cut-off film filter on both sides, and adopts a cold processing process or a semiconductor etching process to process Fresnel stripes on the surface and embed it The window on the tube cap is glued firmly with resin material to replace the traditional optical filter, and the volume is small to meet the requirements of miniaturization. The signal processing module 3 is a digital intelligent control circuit chip module, which integrates a signal amplification circuit, an analog-to-digital conversion circuit, a low-pass / high-pass filter circuit and a signal output unit to meet the needs of intelligence. The tube cap 6 and the substrate 1 are sealed and welded to form a...

Embodiment 3

[0035] The pyroelectric ceramic material of the present embodiment consists of: (Pb 1-x-y La x Sr y ) (Mn 1 / 3 Nb 2 / 3 ) z (Zr 0.94 Ti 0.06 ) 1- z o 3 ; where: x=0.01, y=0.02, z=0.05. The pyroelectric ceramic material is prepared by the following method: (1) using PbO, ZrO 2 、TiO 2 , Nb 2 o 5 , MnO 2 , SrCO 3 and La 2 o 3 Prepare the above powder raw materials according to the elemental ratio, and mix them by wet ball milling; (2) The mixed raw materials are pre-fired at 800°C and the holding time is 2 hours to form ceramic calcined powder after pressure filtration and drying (3) Add the sintering aid ZnO into the ceramic calcined powder, grind and mix to form a ceramic slurry, and the mass of the sintering aid is 0.50wt% of the ceramic calcined powder; (4) use the ceramic slurry Based on the mass of the ceramic slurry, add 10wt% binder, 1.0wt% plasticizer and 0.1wt% release agent to the ceramic slurry for spray granulation to form ceramic particles; (5) pre-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com