Semiconductor component and method for producing the same

A technology of semiconductors and components, applied in the field of manufacturing vertical semiconductor components, can solve problems such as need, expensive technology, difficult to adjust metal masks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

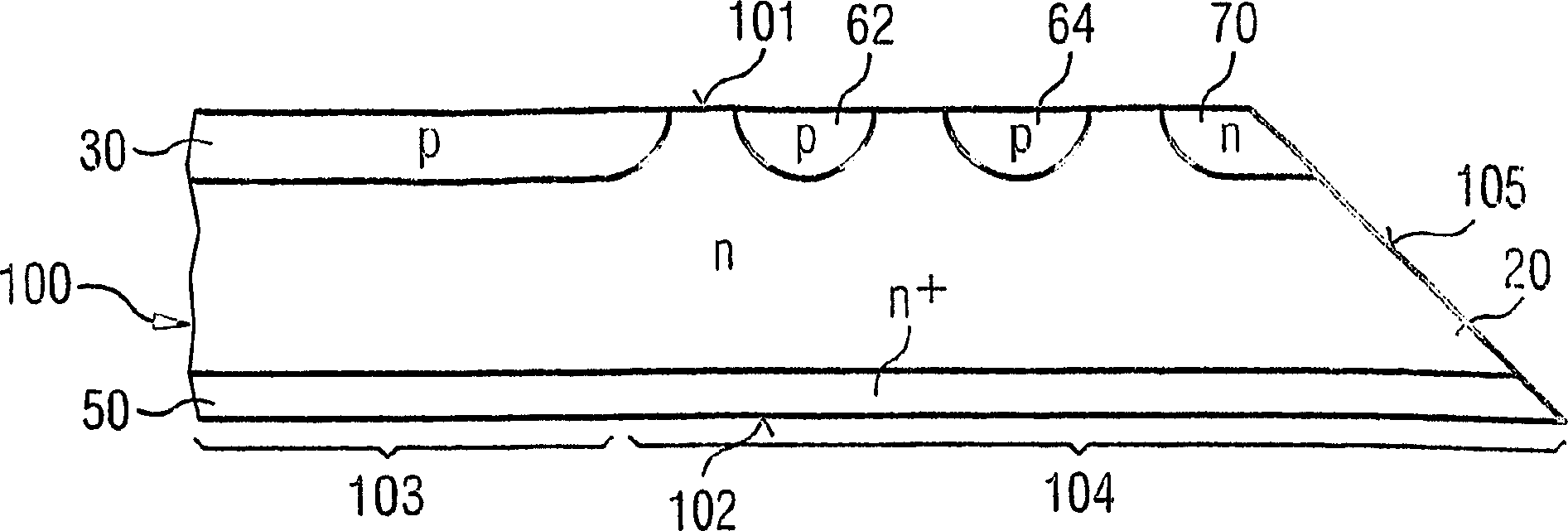

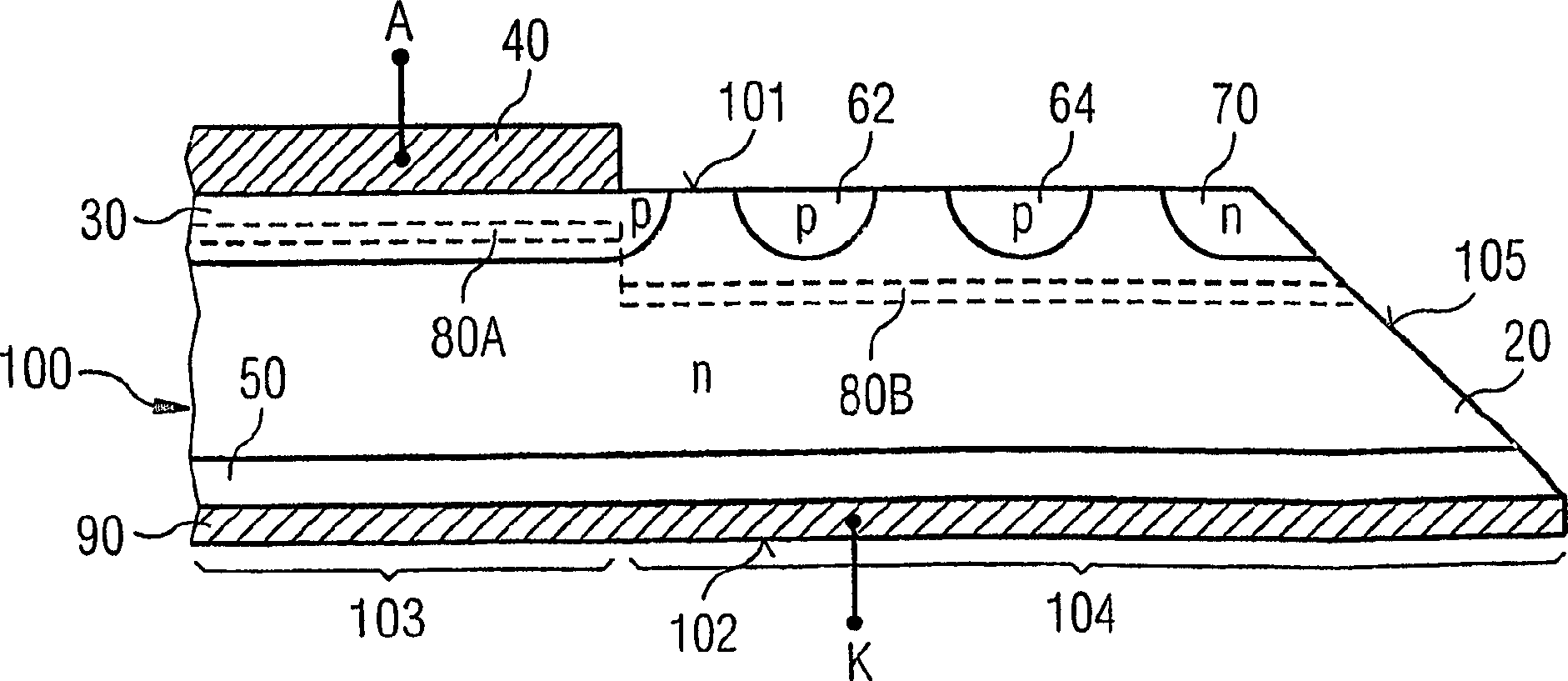

[0026] Below with the help of the fabrication of vertical power diodes Figure 1-3 A method for manufacturing a semiconductor element according to the present invention will be described. The method involves preparing figure 1 The semiconductor body 100 is partially shown in cross-section. The semiconductor body 100 has a front side 101 , a rear side 102 and, in the exemplary embodiment, a chamfered edge 105 . The semiconductor body comprises an inner region 103 spaced apart from an edge 105 and an edge region 104 arranged between the inner region 103 and the edge. The illustrated semiconductor body 100 has an n background doping, the semiconductor region having this background doping being referred to below as the first semiconductor region 20 . In the first semiconductor region 20, a p-doped second semiconductor region 30 is introduced in the inner region 103 below the front side 101, so that a p-doped second semiconductor region 30 is formed between the second semiconduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com