Preparation method of PVDF (polyvinylidene fluoride) film and PVDF film

A technology of thin film and polyester film, which is applied in the field of PVDF film preparation, can solve the problem of difficult formation of β-phase PVDF, etc., and achieve the effect of convenient operation, simple process and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0037] Weigh a certain amount of PVDF powder into a round-bottomed flask, add 20mL of mixed solvent; heat and stir the flask at 60-90°C for more than 2 hours; place the flask in an ultrasonic cleaner, connect a vacuum pump, and ultrasonically pump for more than 10 minutes; Stir the flask slowly at 60-90°C for a while to obtain a transparent and uniform PVDF solution; place the cleaned glass plate on the film coating machine, adjust the width of the scraper slit and casting speed, and add the prepared PVDF Solution, casting to prepare PVDF film, and then place it in a drying oven at 80°C to dry; peel off the prepared PVDF film from the glass plate, with a thickness of 10-15 μm, cut a part of the film, cover the electrode, and measure the dielectric properties.

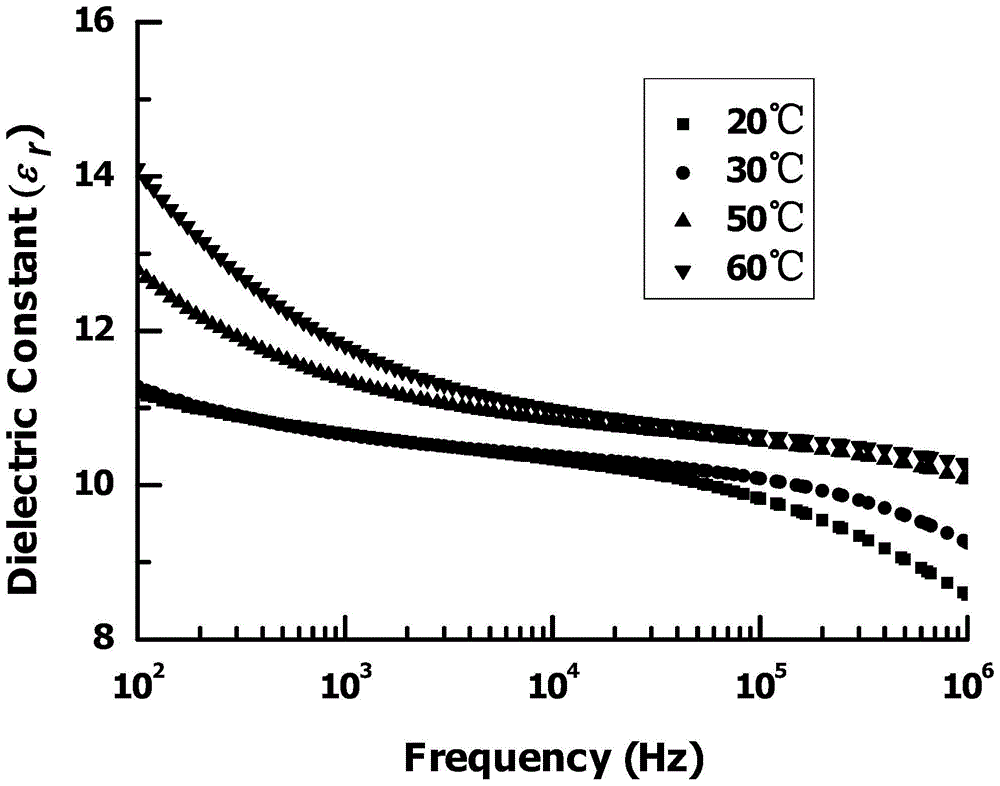

[0038] Table 1 The PVDF concentration used in Examples 1-6, the volume percentage of the poor solvent in the mixed solvent, and the dielectric properties of the resulting PVDF film

[0039]

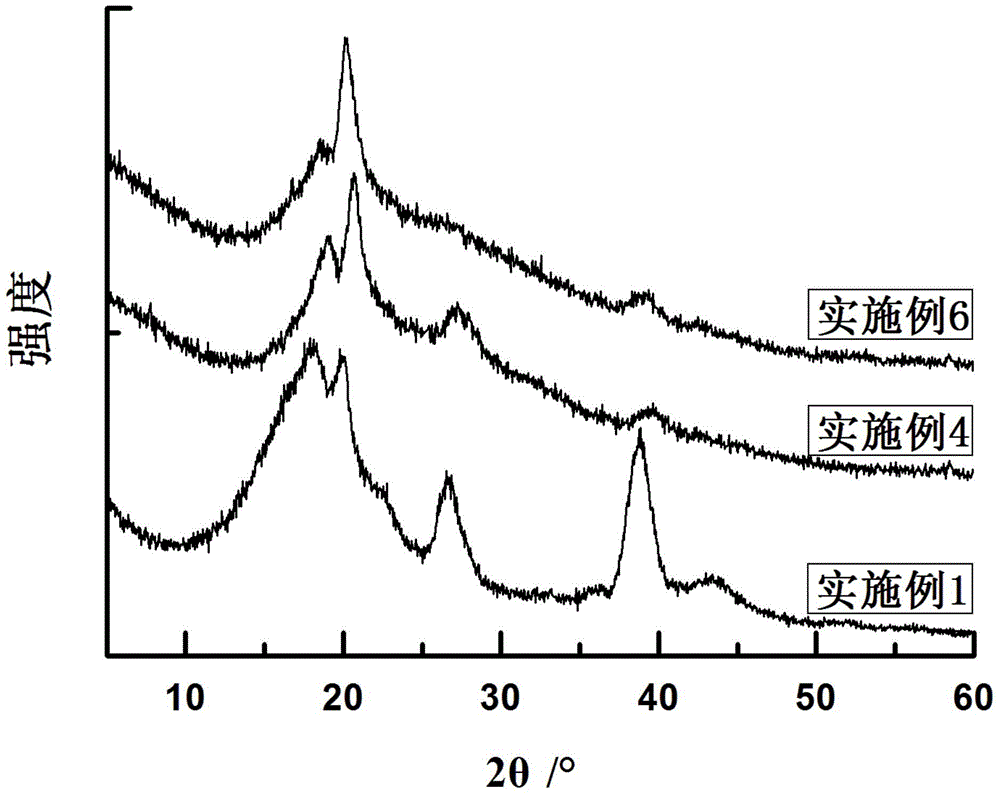

[0040] Depend on figure...

Embodiment 9

[0043] Weigh 60.0g of PVDF powder into a 500mL round bottom flask, add 180mL of poor solvent and 120mL of benign solvent; install a mechanical stirrer, heat and stir at 70°C for 2h; place the flask in an ultrasonic cleaner, connect a vacuum pump, and ultrasonically Pump air for 10 minutes; then place the flask at 70°C for 20 minutes to obtain a transparent and uniform solution; adjust the width of the scraper slit, the heating temperature of the bottom plate and the casting Speed, add the prepared and treated PVDF solution, and cast the PVDF film to prepare the PVDF film. The bottom plate is heated and dried. The PVDF film is wound together with the polyester film tape. Peel off the prepared PVDF film from the polyester film tape, and obtain a PVDF film with a thickness of 1-50 μm according to the width of the scraper slit, cut part of the film, cover the electrode, and measure the dielectric properties.

[0044] Prepare multiple bottles of PVDF solution in batches, and make P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com