Nano modified epoxy vacuum pressure impregnation resin and preparation method thereof

A technology of vacuum pressure impregnation and nano-modification, used in epoxy resin coatings, climate sustainability, sustainable manufacturing/processing, etc. Improved performance, good process performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a nano-modified epoxy vacuum pressure impregnation resin and a preparation method thereof.

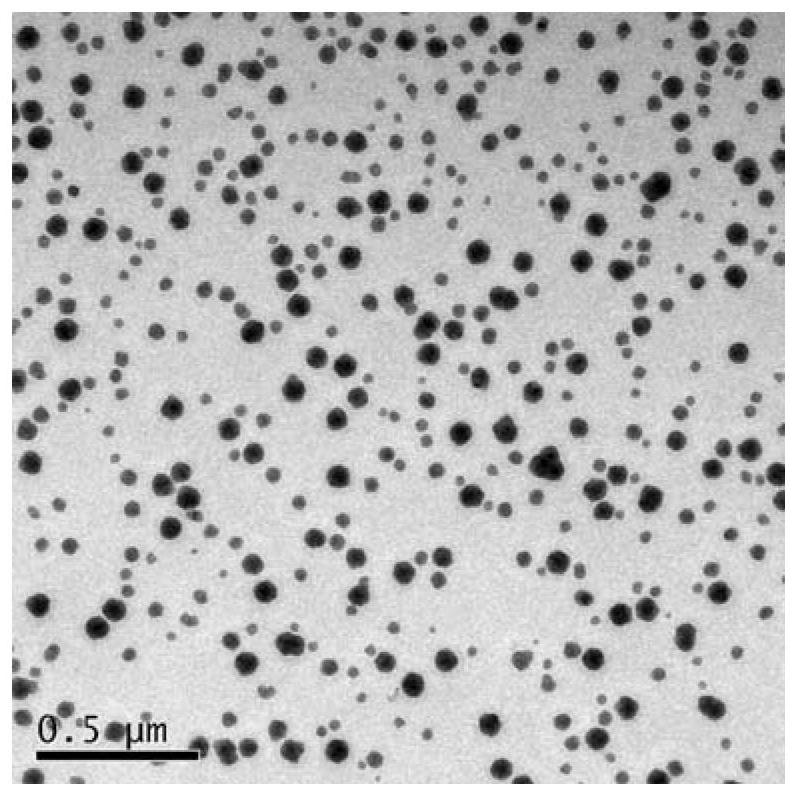

[0034] The raw material composition of nano-modified epoxy vacuum pressure impregnation resin is: bisphenol A type epoxy resin (epoxy equivalent is 170 grams / equivalent) 800g, benzyl glycidyl ether 200g, methyl hexahydrophthalic anhydride 900g , Nano silica (particle size about 20nm) 143g, titanate dispersant 20g, silane coupling agent (KH560) 20g and defoamer (BYK-093) 18g.

[0035] The preparation process of nano-modified epoxy vacuum pressure impregnation resin is as follows:

[0036] (1) 800g of bisphenol A type epoxy resin is processed by molecular distillation technology, mixed with 200g of benzyl glycidyl ether, 10g of titanate dispersant and 20g of silane coupling agent KH560, and stirred evenly to obtain a matrix solution;

[0037] (2), in the homogeneous emulsifier, 143g nano-silicon dioxide is intermittently added in the matrix solution of st...

Embodiment 2

[0041] This embodiment provides a nano-modified epoxy vacuum pressure impregnation resin and a preparation method thereof.

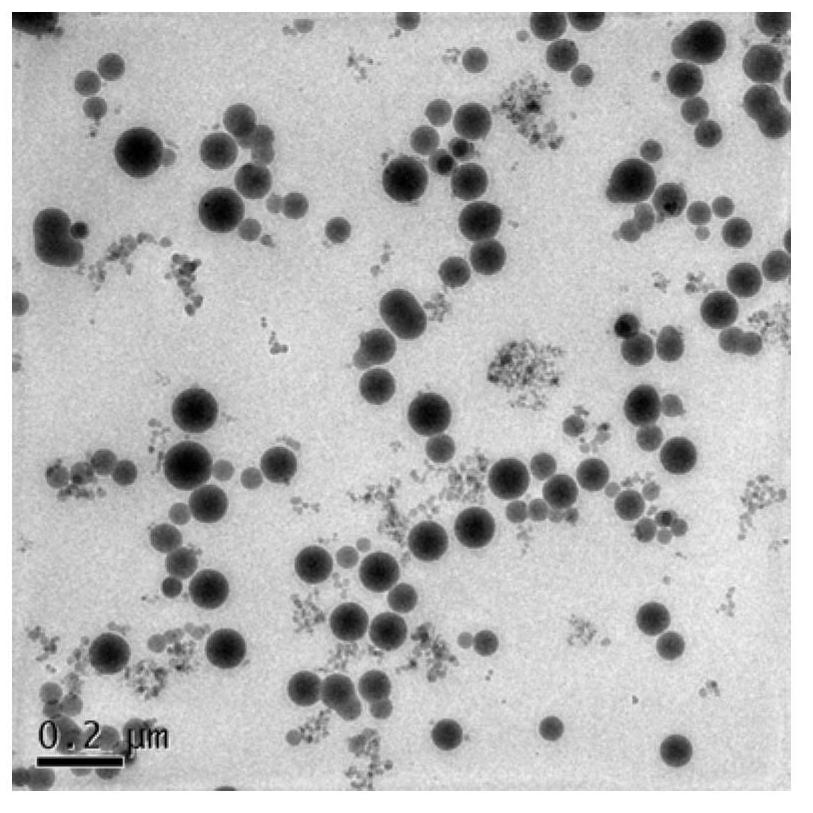

[0042] The raw material composition of nano-modified epoxy vacuum pressure impregnation resin is: bisphenol A type epoxy resin (epoxy equivalent is 172 grams / equivalent) 600g, cresyl glycidyl ether 180g, methyltetrahydrophthalic anhydride 780g , Nano-titanium dioxide (particle size about 25nm) 82g, polyester dispersant 6g, titanate dispersant 12g, silane coupling agent (KH550) 15g and defoamer (BYK-A530) 10g.

[0043] (1) After 600g of bisphenol A type epoxy resin is processed by molecular distillation technology, mix with 180g of cresyl glycidyl ether, 6g of polyester dispersant and 15g of silane coupling agent KH550, and stir to obtain matrix solution;

[0044] (2), in the homogeneous emulsifier, 82g nano-titanium dioxide is intermittently added in the matrix solution obtained in step (1) in 4 times, each time of discontinuity is 20 minutes, during thi...

Embodiment 3

[0048] This embodiment provides a nano-modified epoxy vacuum pressure impregnation resin and a preparation method thereof.

[0049] The raw material composition of nano-modified epoxy vacuum pressure impregnation resin is: bisphenol A type epoxy resin (epoxy equivalent is 171 g / equivalent) 1000g, ethylene glycol diglycidyl ether 200g, methyl nadic acid anhydride 1100g, nano Aluminum oxide (particle size about 30nm) 80g, nano silicon carbide (particle size about 40nm) 70g, modified acrylate dispersant 10g, titanate dispersant 18g, silane coupling agent (KH560) 24g and defoamer (DAPRO DF 957) 20g.

[0050] The preparation process of nano-modified epoxy vacuum pressure impregnation resin is as follows:

[0051] (1), 1000g bisphenol A type epoxy resin, 200g ethylene glycol diglycidyl ether, 10g modified acrylate dispersant and 24g KH560 are added in the airtight mixing tank, stir evenly, obtain matrix solution;

[0052] (2), in the homogeneous emulsifier, 80g nano-mica powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com