Brown glaze and production method thereof

A raw material, albite technology, applied in the field of brown glaze and its preparation, can solve problems such as failure to meet regulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

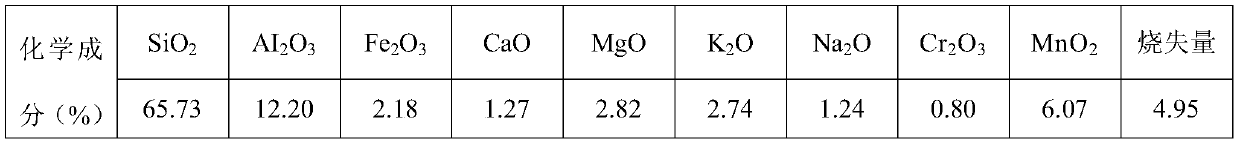

[0117] This embodiment discloses a brown glaze, which includes the following raw materials in parts by mass: 22 parts of Hongfa potassium feldspar, 10 parts of three-strong albite, 5 parts of Inner Mongolia clay, 14 parts of Shaanxi kaolin, 8 parts of forged talc, limestone 2 parts, 29 parts of quartz powder, 1.2 parts of iron oxide red, 0.8 parts of chromium oxide and 8 parts of Chongqing manganese oxide. The brown glaze in this embodiment includes the following chemical components:

[0118]

[0119] Present embodiment also provides a kind of preparation method of brown glaze, comprises the following steps:

[0120] (1) Prepare the following raw materials in parts by mass: 22 parts of Hongfa potassium feldspar, 10 parts of three-strong albite, 5 parts of Inner Mongolia clay, 14 parts of Shaanxi kaolin, 8 parts of forged talc, 2 parts of limestone, 29 parts of quartz powder , 1.2 parts of iron oxide red, 0.8 parts of chromium oxide and 8 parts of Chongqing manganese oxide....

Embodiment 2

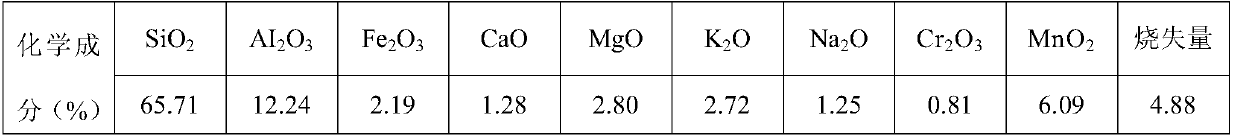

[0125] This embodiment discloses a brown glaze, comprising the following raw materials in parts by mass: 20 parts of Hongfa potassium feldspar, 9 parts of three-strong albite, 4 parts of Inner Mongolia clay, 12 parts of Shaanxi kaolin, 7 parts of forged talc, limestone 2 parts, 26 parts of quartz powder, 1 part of iron oxide red, 0.6 part of chromium oxide and 7 parts of Chongqing manganese oxide. The brown glaze in this embodiment includes the following chemical components:

[0126]

[0127] Present embodiment also provides a kind of preparation method of brown glaze, comprises the following steps:

[0128] (1) Prepare the following raw materials in parts by mass: 20 parts of Hongfa potassium feldspar, 9 parts of three-strong albite, 4 parts of Inner Mongolia clay, 12 parts of Shaanxi kaolin, 7 parts of forged talc, 2 parts of limestone, 26 parts of quartz powder , 1 part of red iron oxide, 0.6 part of chromium oxide and 6 parts of Chongqing manganese oxide.

[0129] (2)...

Embodiment 3

[0133] This embodiment discloses a brown glaze, which includes the following raw materials in parts by mass: 25 parts of Hongfa potassium feldspar, 12 parts of three-strong albite, 6 parts of Inner Mongolia clay, 17 parts of Shaanxi kaolin, 9 parts of forged talc, limestone 2.5 parts, 32 parts of quartz powder, 1.5 parts of iron oxide red, 1 part of chromium oxide and 10 parts of Chongqing manganese oxide. The brown glaze in this embodiment includes the following chemical components:

[0134]

[0135] Present embodiment also provides a kind of preparation method of brown glaze, comprises the following steps:

[0136] (1) Prepare the following raw materials in parts by mass: 25 parts of Hongfa potassium feldspar, 12 parts of three-strong albite, 6 parts of Inner Mongolian clay, 17 parts of Shaanxi kaolin, 9 parts of forged talc, 2.5 parts of limestone, 32 parts of quartz powder , 1.5 parts of iron oxide red, 1 part of chromium oxide and 10 parts of Chongqing manganese oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com