Aluminum stressed skin structure of passenger car body side walls and processing method thereof

A processing method and skin technology, which are applied to the superstructure, superstructure sub-assemblies, vehicle components, etc., can solve the problem of easy cracking of the paint at the joints of the skin, easy skin collapse, and large deformation of the side wall skin, etc. problems, to achieve the effect of reducing the risk of skin cracking, reducing the risk of cracking, and overcoming skin cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

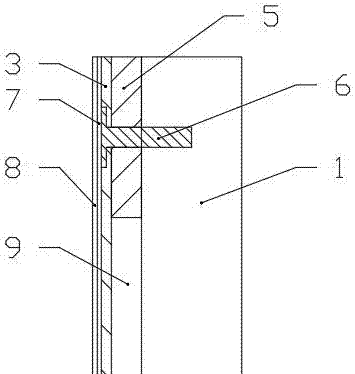

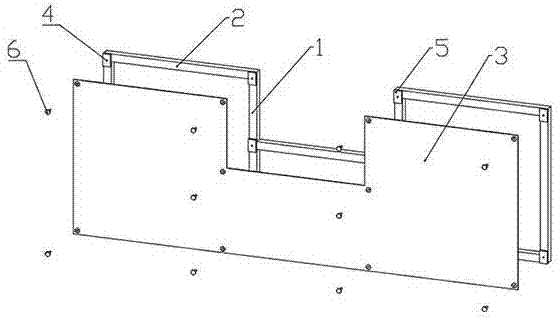

[0032] The invention discloses an aluminum skin structure for the side wall of a passenger car body. The side wall of the car body includes a side frame and an aluminum skin 3. The side frame is formed by welding a column frame 1 and a beam frame 2. The column frame 1 is arranged longitudinally. And the lower end is connected with the chassis of the passenger car, and the crossbeam frame 2 is horizontally arranged between the adjacent column frames 1 . The aluminum skin 3 is covered on the side frame, and the aluminum skin 3 and the side frame together form the side wall of the vehicle body.

[0033] The aluminum skin 3 and the side frame are bonded and fixed by adhesive glue 9. At the same time, a liner 5 is set on the column frame 1. The liner 5 has skeleton riveting points 4, and the aluminum skin 3 is also riveted by rivets 6. It is fixed on the skeleton riveting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com