Carbon fiber reinforced cylinder structure

A reinforced cylinder, carbon fiber technology, applied in the direction of building elements, etc., can solve the problems of heavy weight and weak bearing capacity, and achieve the effect of high specific strength, large specific modulus, and improving structural strength and effective life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

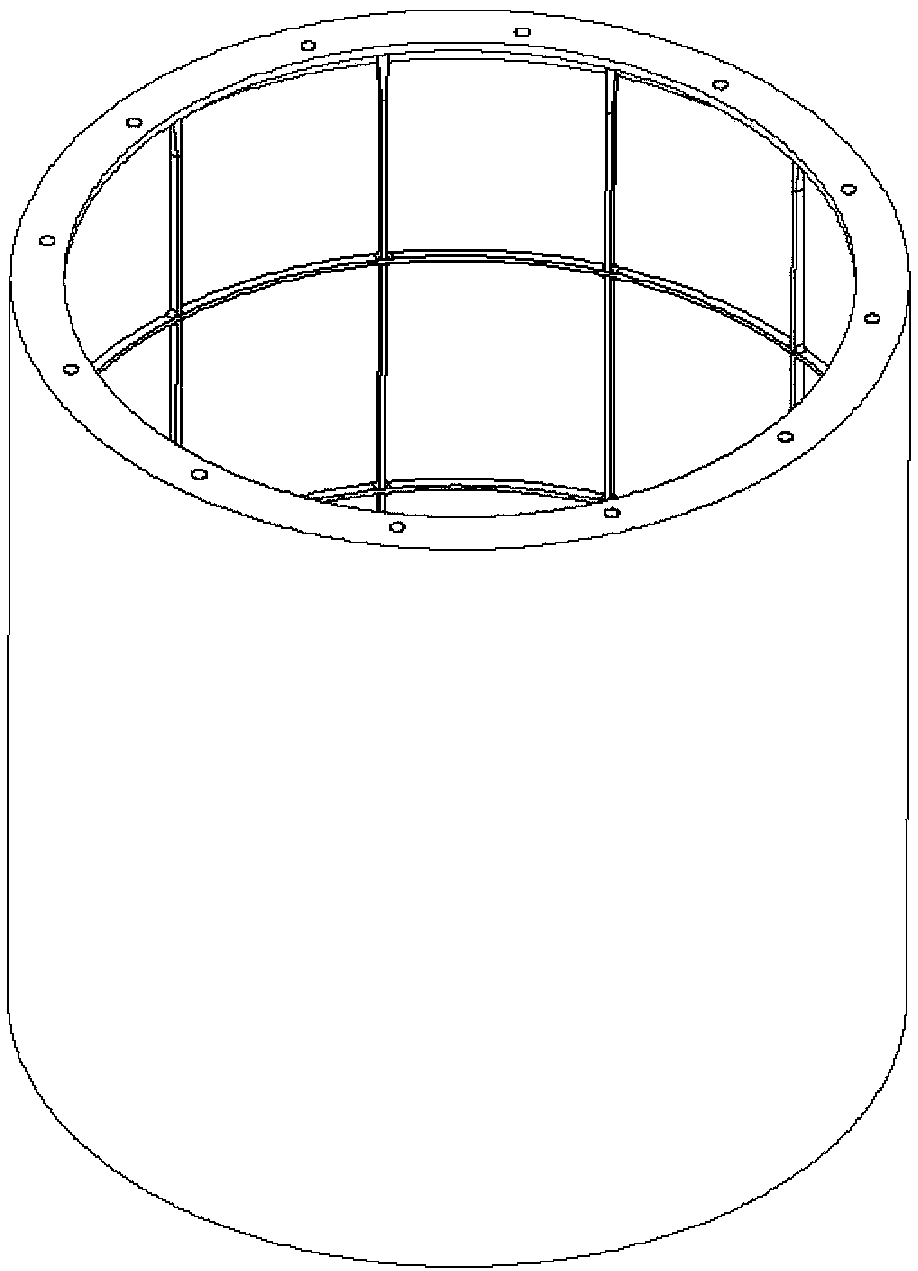

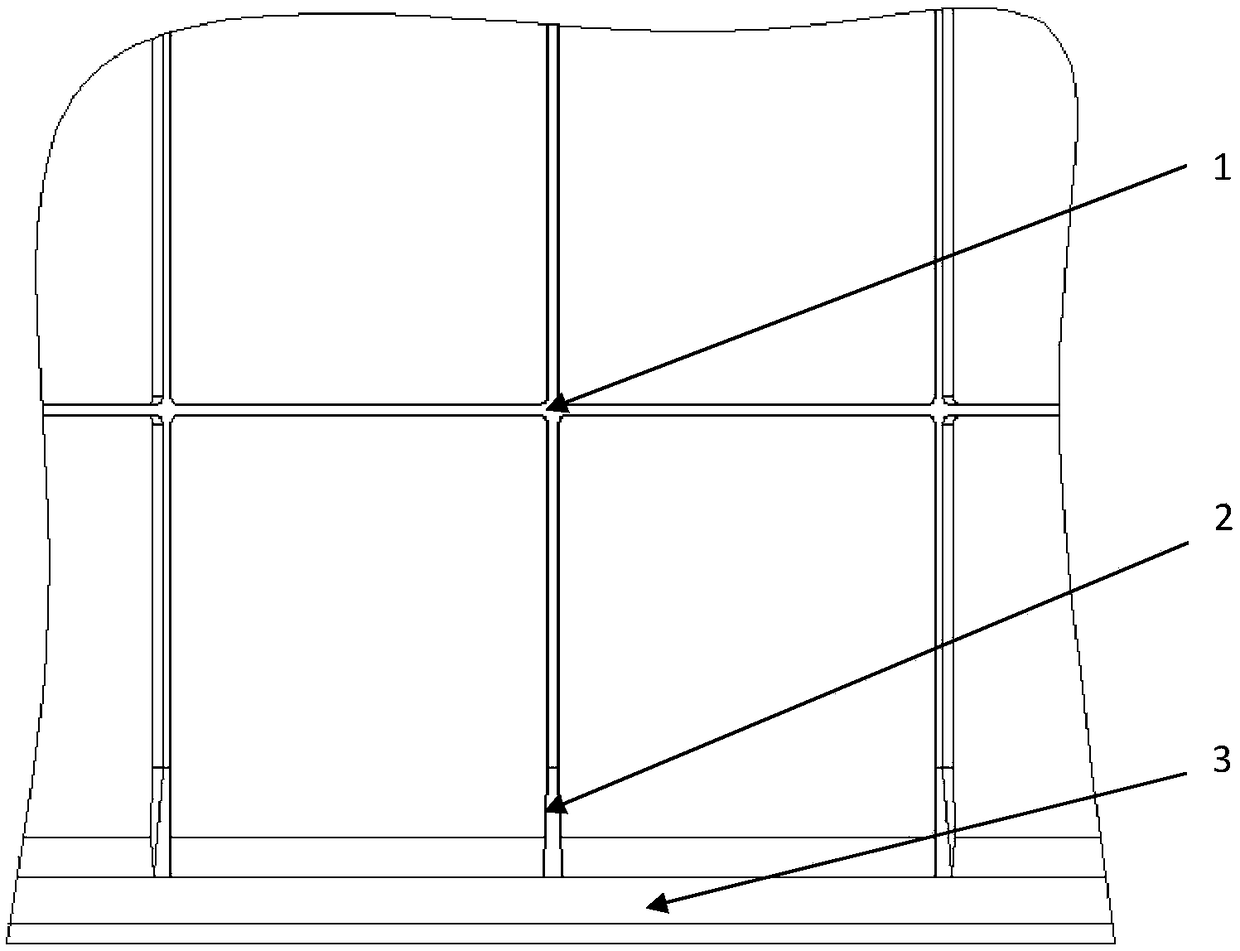

[0012] see figure 1 , The reinforced cylindrical structure of the present invention is composed of vertical and horizontal ribs and a skin. The vertical and horizontal rib network structure is adopted, and the exterior is wound with carbon fiber prepreg tape to manufacture the skin. The vertical and horizontal ribs use continuous fibers in the 0-degree direction, and the skin adopts quasi-isotropic layup, 0°, ±45°, 90° The layup ratio is 25:50:25, and the longitudinal and horizontal bars are designed with precise R angles at the intersection nodes to ensure that the fibers of the longitudinal and horizontal bars are continuous and uninterrupted during the forming process. , the lower width is calculated according to the specific method: the lower width of the slope is the cross-sectional area of the longitudinal rib divided by the thickness of the skin thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com