Propeller arrangement structure capable of achieving internally cooperative jet flow and controlling method

A collaborative jet and propeller technology, applied to propellers, aircraft parts, transportation and packaging, etc., can solve the problems of engine thrust and efficiency loss, parasitic resistance moving parts, difficulty in meeting the design requirements of high-performance high-altitude airship propellers, etc., to improve aerodynamics Efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

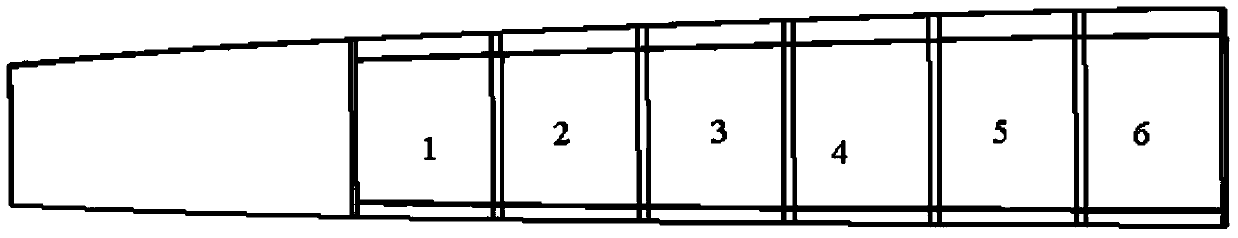

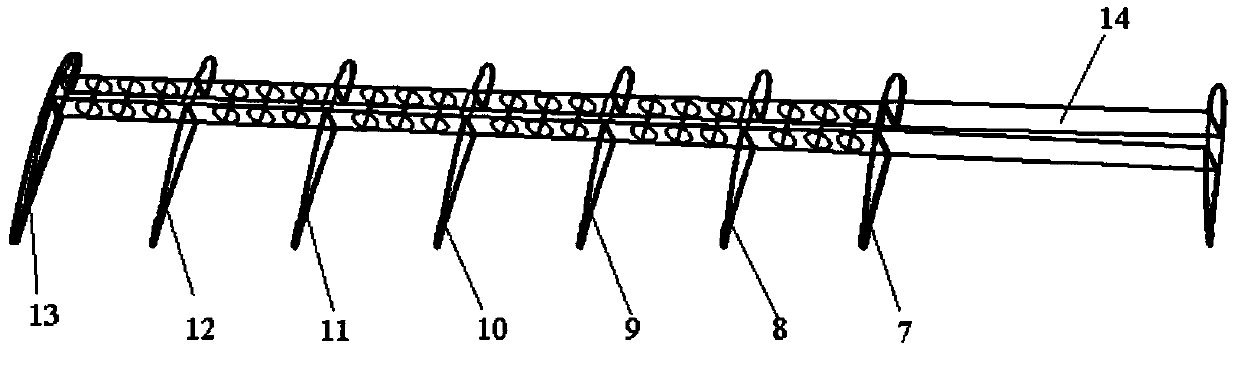

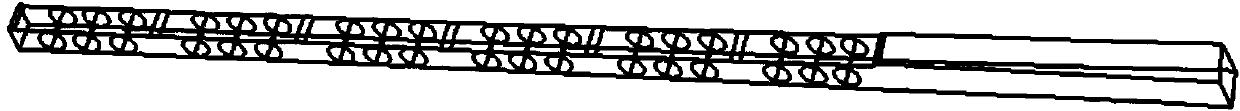

[0044] The present invention provides a propeller layout configuration that can realize internal coordinated jet flow. Along the spanwise direction of the propeller blade, the blade is divided into a plurality of isolated single cavities that are continuously arranged in sections through the structural frame of the propeller blade. Independent coordinating jet devices are arranged in a single cavity; each coordinating jet device includes: an air inlet, an air outlet, and at least one jet power device; wherein, the air inlet is arranged at the isolated single cavity where the coordinating jet device is located At the rear edge of the upper skin, the air outlet is arranged at the front edge of the upper skin of the isolated single chamber where the coordinated jet device is located, and the jet power device is installed in the inner space of the isolated single chamber where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com