Drill pipe joint precision die forging process

A technology for oil drill pipe joints and precision die forging, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. It can solve the problems of poor concentricity of the center hole, large machining allowance, and low production efficiency. Achieve the effect of reducing the length-to-diameter ratio, improving the surface quality of forgings, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

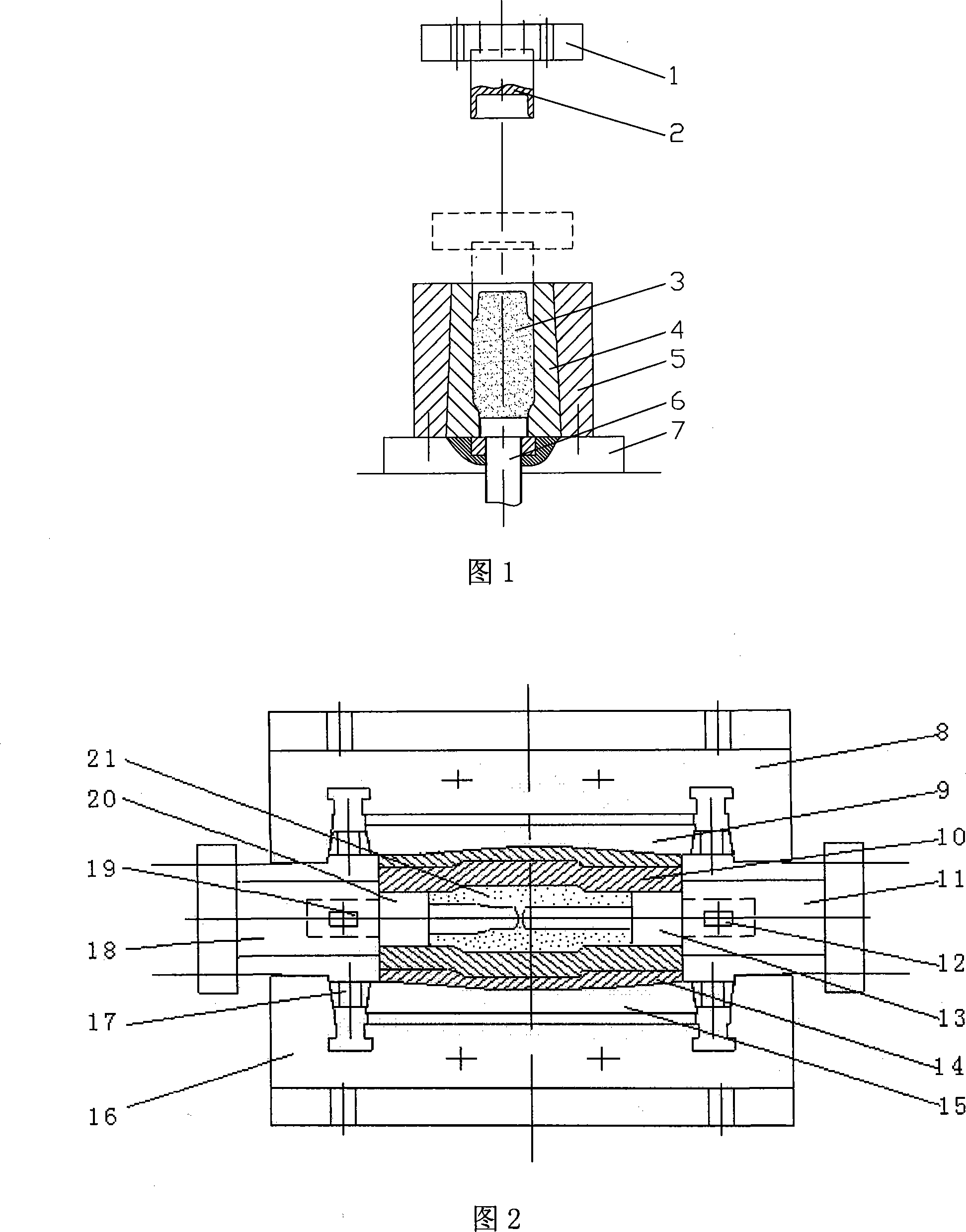

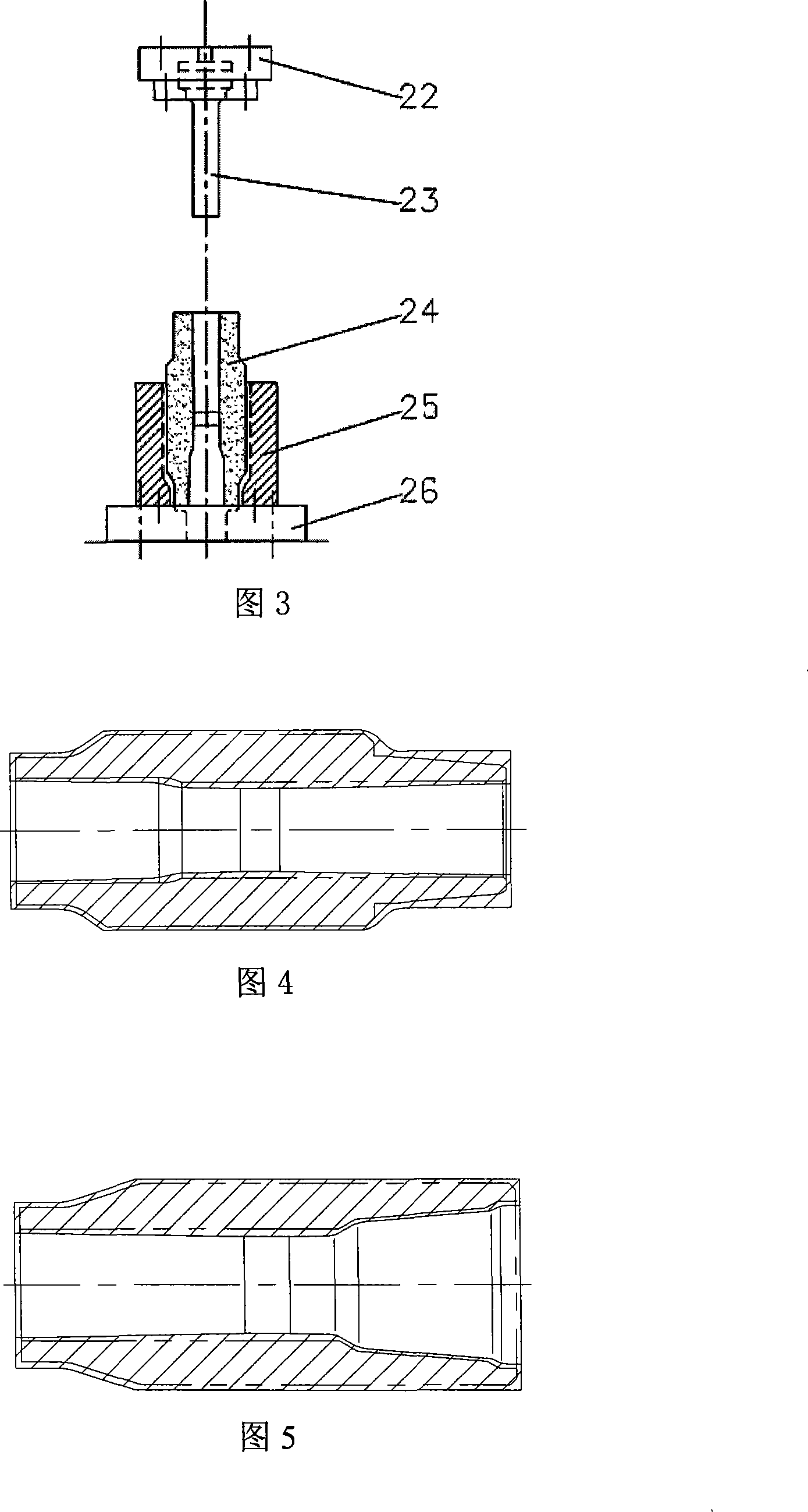

[0018] Fig. 1, Fig. 2 and Fig. 3 of the present invention are schematic diagrams of joint die forging process and die structure. First, design the joint die forging drawing according to the joint part drawing proposed by the user, and calculate the blank size (diameter and length) according to the forging drawing. Then, according to the design rule and calculation method of the present invention, the continuous skin position of the joint die forging is determined, and the shape and size of the preform are optimized. Then, according to the calculation method of joint die forging force energy process parameters provided by the present invention, the upsetting extrusion force in the billet making process, the extrusion force and die tension in the forming process, and the punching force in the punching process are determined. Then the joint die forging forming process and its corresponding molds can be designed - billet mold, forming mold and punching mold.

[0019] The design o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com