Measuring apparatus for rate of self-contraction of cement concrete

A cement concrete and self-shrinking technology, which is applied in the field of building materials, can solve problems such as mold requirements, test result errors, and engineering non-compliance, and achieve the effects of reducing resistance, good sealing, and convenient formwork installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

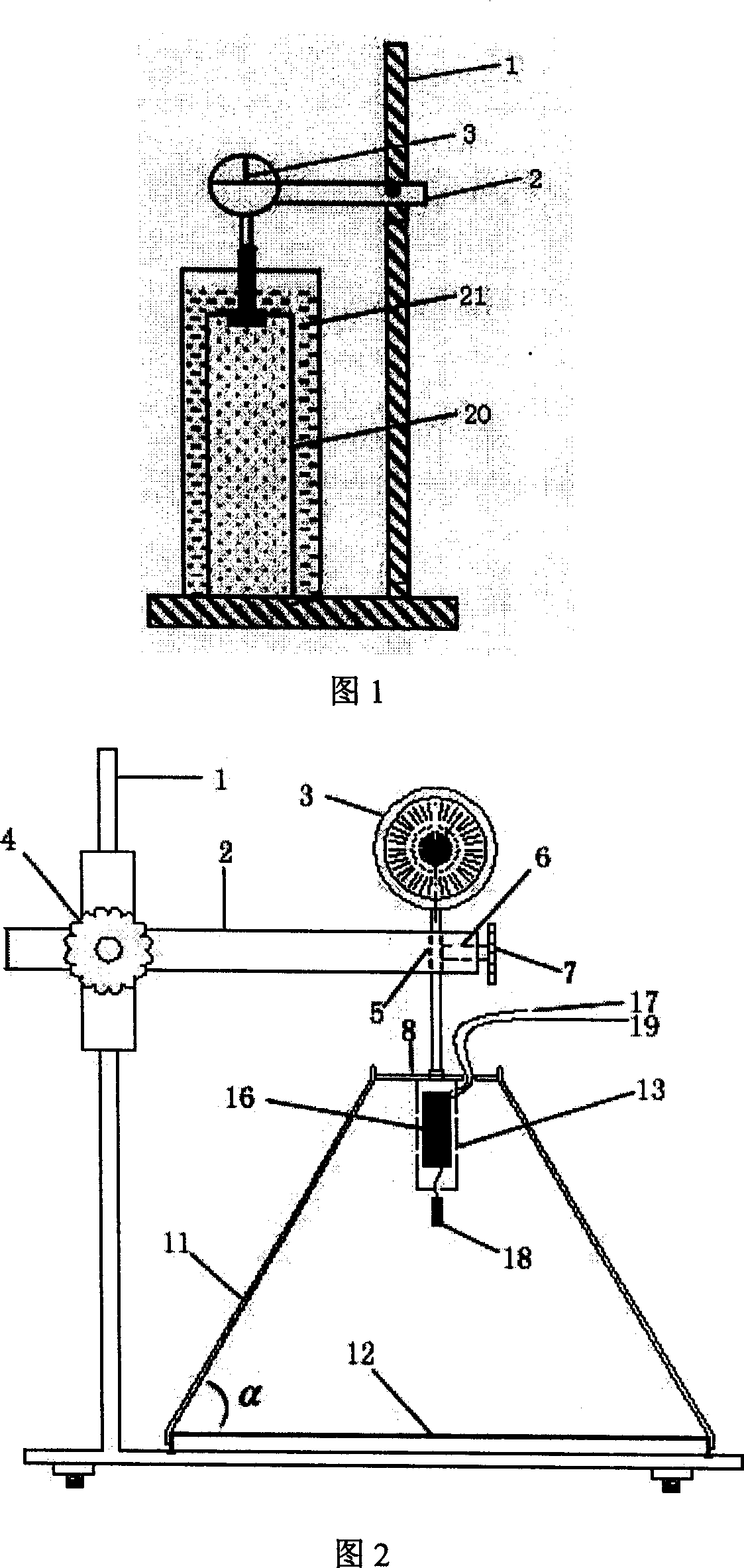

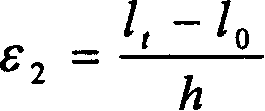

[0020] The present invention will be further described below, and the structural schematic diagram of the mechanical part of the present invention is shown in FIG. 2 . A connecting bracket is vertically fixed on a rectangular bottom plate, and the bracket is composed of a fixed pole 1 and a horizontal beam 2 with a smooth surface, and the through-hole screw 4 is used to tighten between the pole and the horizontal beam. The two ends of the horizontal beam respectively have a vertical through hole 5, and the diameter of the vertical through hole should be slightly greater than the diameter of the long rod of the measuring end of the dial gauge, and the long rod of the measuring end of the dial gauge can be inserted in the vertical through hole. There is a threaded hole 6 in the horizontal direction perpendicular to the vertical through hole, which is used to install the fixing screw 7 of the dial indicator. In the embodiment, the diameter of the upper end cover 8 of the hollow c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com