Tubular pile die screw

A mold and screw technology, applied in the field of molding equipment, can solve the problems of low production efficiency, large and heavy pipe pile mold screws, etc., and achieve the effect of convenient mold clamping and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

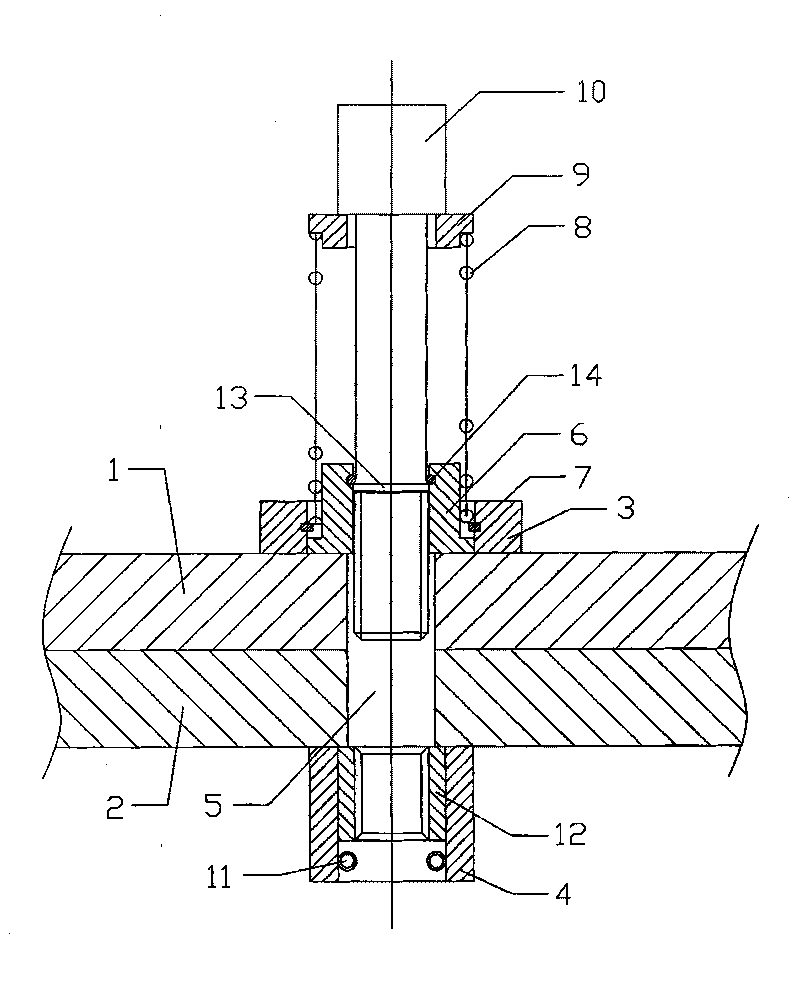

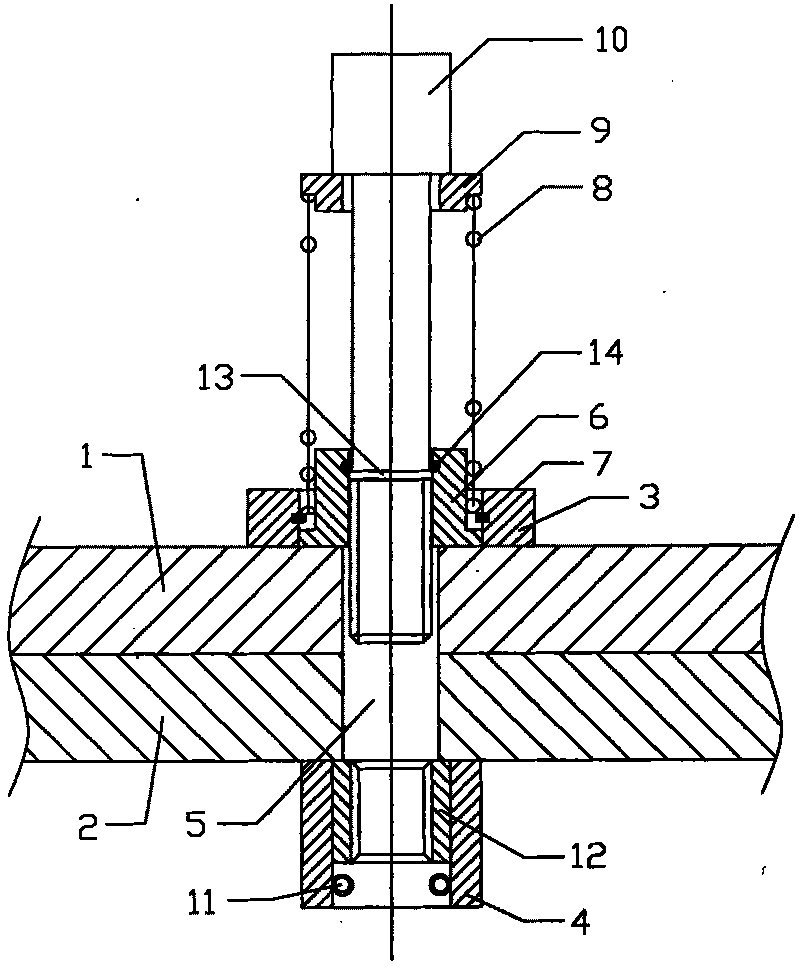

[0010] refer to figure 1 , figure 2 , a pipe pile mold screw of the present invention, comprising an upper mold 1 and a lower mold 2, the edges of the upper mold 1 and the lower mold 2 are correspondingly fixed with a plurality of upper seats 3 and lower seats 4, and the bolt fixing holes 5 penetrate the upper seat 3 , upper die 1, lower die 2 and lower seat 4, the upper seat 3 is provided with a spring pad 6, the lower spring pad 6 is clamped in the upper seat 3 by a snap ring 7, between the lower spring pad 6 and the upper seat 3 A spring 8 is sleeved, and the upper end of the spring 8 is covered with an upper spring pad 9, and a bolt 10 runs through the upper spring pad 9, spring 8, lower spring pad 6, bolt fixing holes 5 and the lower seat 4 from top to bottom. 4 is provided with a nut 12 for locking the bolt 10 through a latch 11, the bottom of the bolt 10 is fixed with a protruding ring 13, and the inner side of the lower spring pad 6 is fixed with a protruding ring 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com