Riveting nut gun rapid dismantling device

The technology of a dismantling device and a rivet nut gun is applied in the field of quick dismantling devices for rivet nut guns, which can solve the problems of low work efficiency and inconvenient replacement of rivet nut rods, and achieve the effects of improving work efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

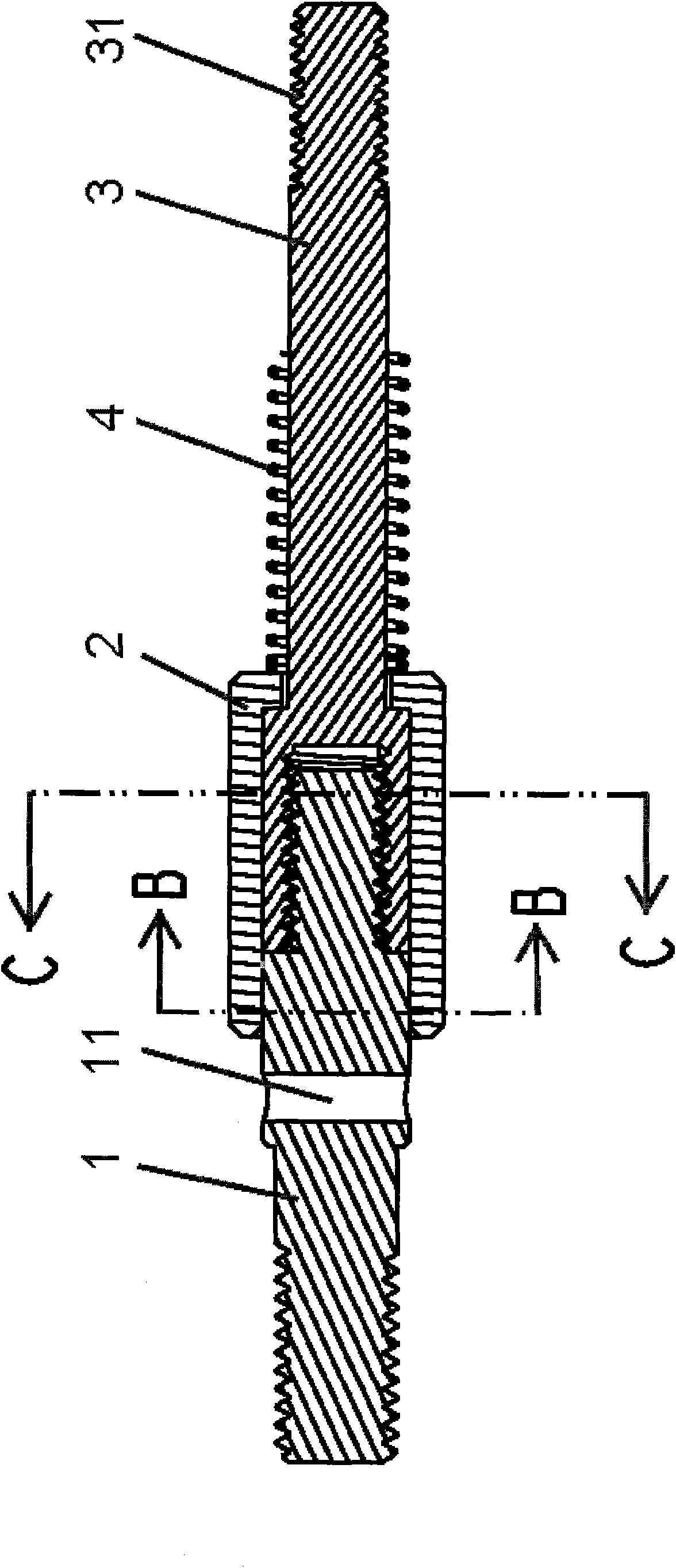

[0023] The structure of a quick release device for a rivet nut gun according to an embodiment of the present invention is as follows: Figure 1 to Figure 4 As shown, it comprises a rivet nut rod 1, a fixed sliding sleeve 2, a pull rod 3 and a spring 4; the rear end of the rivet nut rod 1 is provided with an external thread, and the front end of the pull rod 3 is provided with a Internal threads, the rivet nut rod 1 can be fixed on the front end of the pull rod 3 through the matching internal and external threads, and the rivet nut rod 1 and the pull rod 3 are connected by threads to ensure tensile strength.

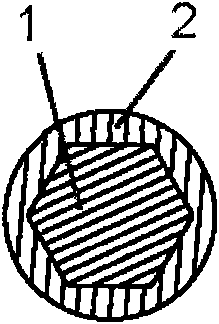

[0024] The exterior of the part of the rear end of the rivet nut rod 1 adjacent to the external thread is polygonal; the exterior of the front end of the pull rod 3 is the same polygon as the rear end of the rivet nut rod 1; The sleeve 2 is set on the pull rod 3, and its inner hole is a polygon matched with the polygon at the front end of the pull rod 3. The polygon of th...

Embodiment 2

[0037] The structure of a quick disassembly device for a rivet nut gun according to Embodiment 2 of the present invention is as follows: Figure 5 As shown, in this embodiment, the rear end of the rivet nut rod 1 is provided with an internal thread, and the front end of the pull rod 3 is provided with an external thread that matches the internal thread, and the rivet nut rod 1 can be passed through The matching thread is fixed on the front end of the pull rod 3 . All the other are the same as embodiment one.

[0038] The quick release device for a rivet nut gun in the embodiment of the present invention can be used for a manual rivet nut gun, a pneumatic rivet nut gun or an electric rivet nut gun.

[0039] By adopting the quick disassembly device of the rivet nut gun of the present invention, when replacing the rivet nut rod 1, it is only necessary to pull down the fixed sliding sleeve 2 and unscrew the rivet nut rod 1, which is convenient to use and improves work efficiency;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com