Ejecting adhesive dispenser based on dual-function cylinder

A double-acting cylinder and spray point technology, which is used in devices and coatings for coating liquid on the surface, can solve the problems of high price, difficult purchase of spare parts and matching, and achieves low cost, low processing accuracy requirements, and reduced length. The effect of diameter ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

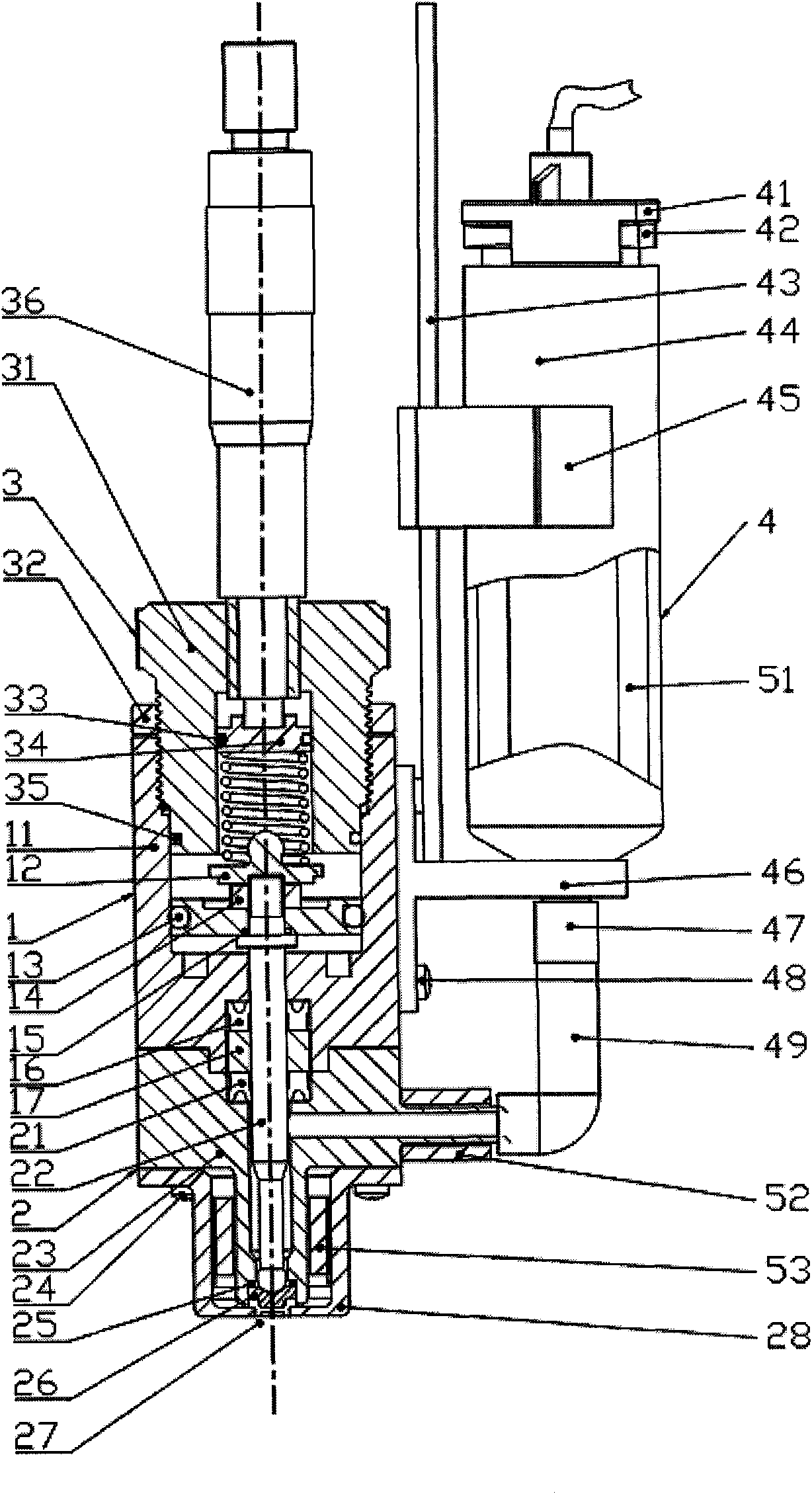

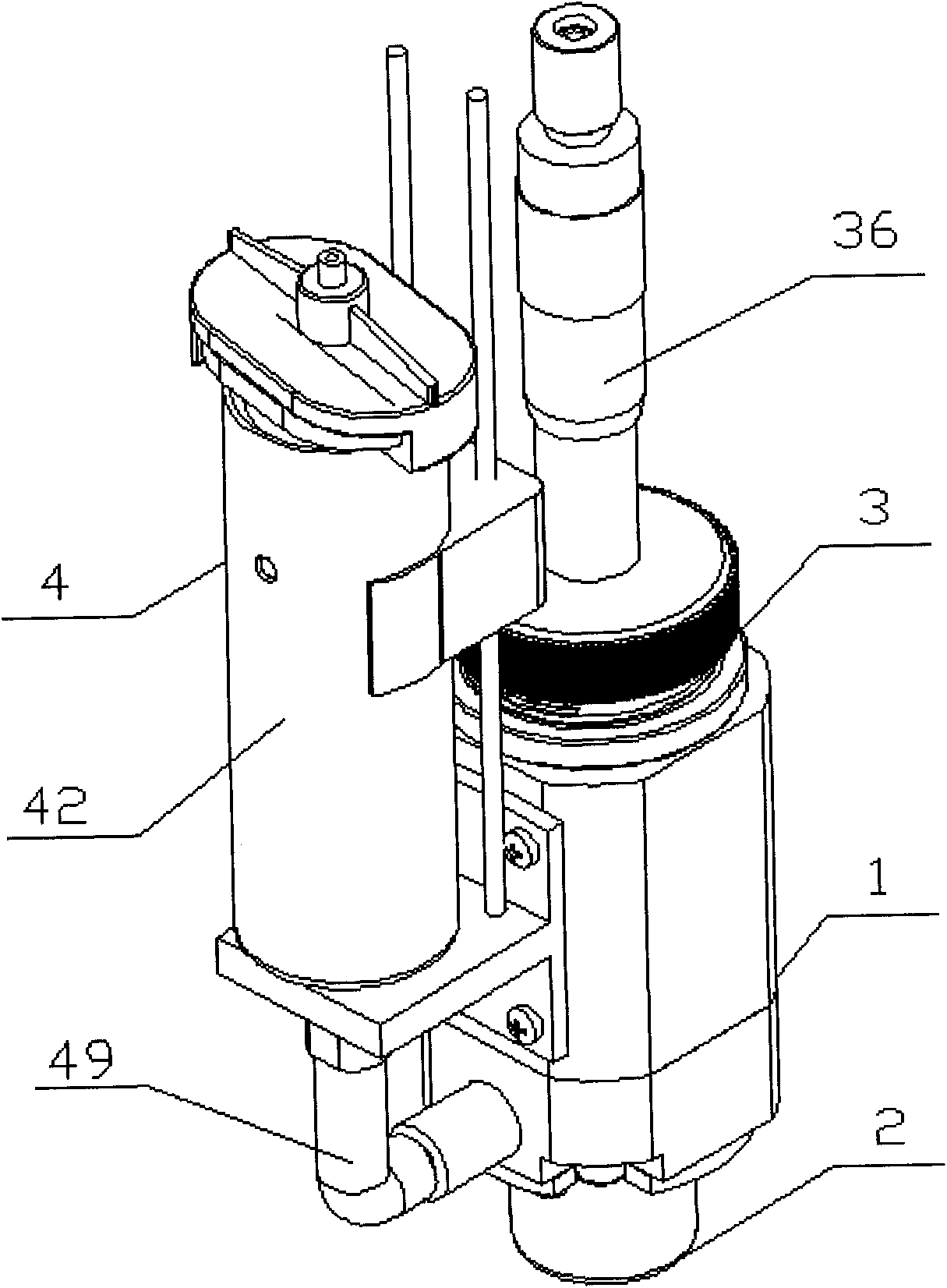

[0023] Embodiment one: if figure 1 As shown, the present invention includes a driving mechanism 1, an injection mechanism 2, a glue supply mechanism 4 and a three-stage heating device. The above-mentioned spraying mechanism, and the lower end of the piston rod in the driving mechanism extends to the injection needle in the spraying mechanism to control dispensing; the glue supplying mechanism is fixedly installed on one side of the driving mechanism, and its lower part communicates with the spraying mechanism through a feeding pipe. Mechanism, the glue supply is controlled by the injection needle; the heating device is from the feeding mechanism to the injection mechanism through the feeding pipe, and a three-stage heating device is provided.

Embodiment 2

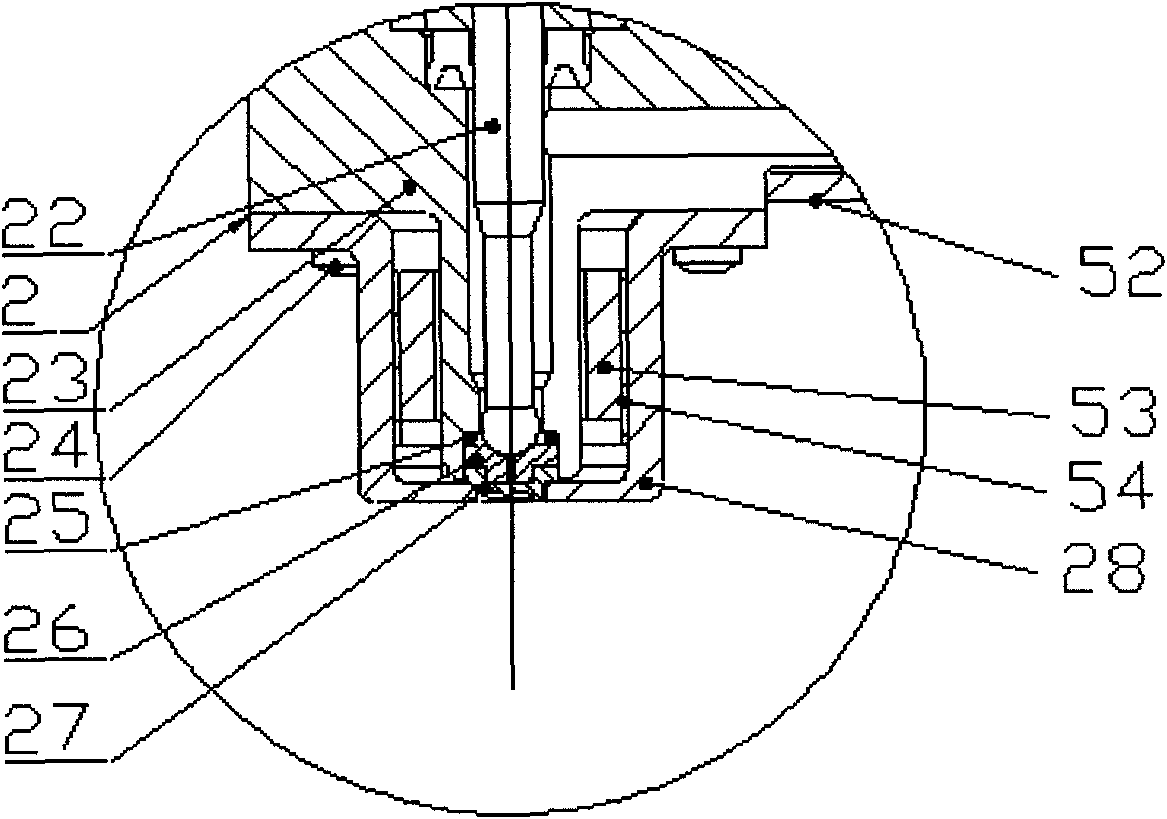

[0024] Embodiment two: if figure 2 , 3 As shown, the driving mechanism 1 includes an upper valve body 11, a piston 18 and an O-ring 13 that divide the inner cavity of the upper valve body into two upper and lower cavities, and the upper cavity and the lower cavity respectively pass through the upper air supply pipe and the lower Gas supply pipe. The piston and the piston rod 22 are connected by a piston fixing nut 14, and an O-ring 15 is used between the piston and the piston rod 22. A buffer disc 12 is arranged on the top of the piston rod 22 for bearing spring pressure and impact force, and a spring 19 is arranged on the upper end of the buffer disc. The stroke fine-tuning and pre-pressure adjusting mechanism 3 includes a stroke fine-tuning nut 31 and a differential head 36 , the stroke fine-tuning nut 31 is threadedly connected with the upper valve body 11 and locked with a round nut 32 . An O-shaped sealing ring 35 is used between the bottom of the stroke fine-tuning n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com