Preparation of lithium iron phosphate nano composite microsphere

A technology of lithium iron phosphate and nanocomposite, applied in phosphorus compounds, chemical instruments and methods, electrode manufacturing, etc., can solve the problems of unsatisfactory high-rate performance of battery materials, complex synthesis process, and instability, etc., and is suitable for large-scale industrialization Excellent production and rate performance, high tap density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 LiFePO 4 Preparation of nanocomposite microspheres

[0059] 1.18g LiOH·H 2 O, 11.3g Fe(NO 3 ) 3 ·6H 2 O, 2.74g H 3 PO 4 Mix well, make 70ml aqueous solution, pour into 100ml Teflon-lined stainless steel reaction kettle, conduct hydrothermal reaction at 150°C for 24h, cool naturally to room temperature, remove all solvents to obtain precursor. Put the precursor in a tube furnace and burn it at 600 °C for 10 h under the protective atmosphere of high-purity argon to obtain the target product LiFePO 4 .

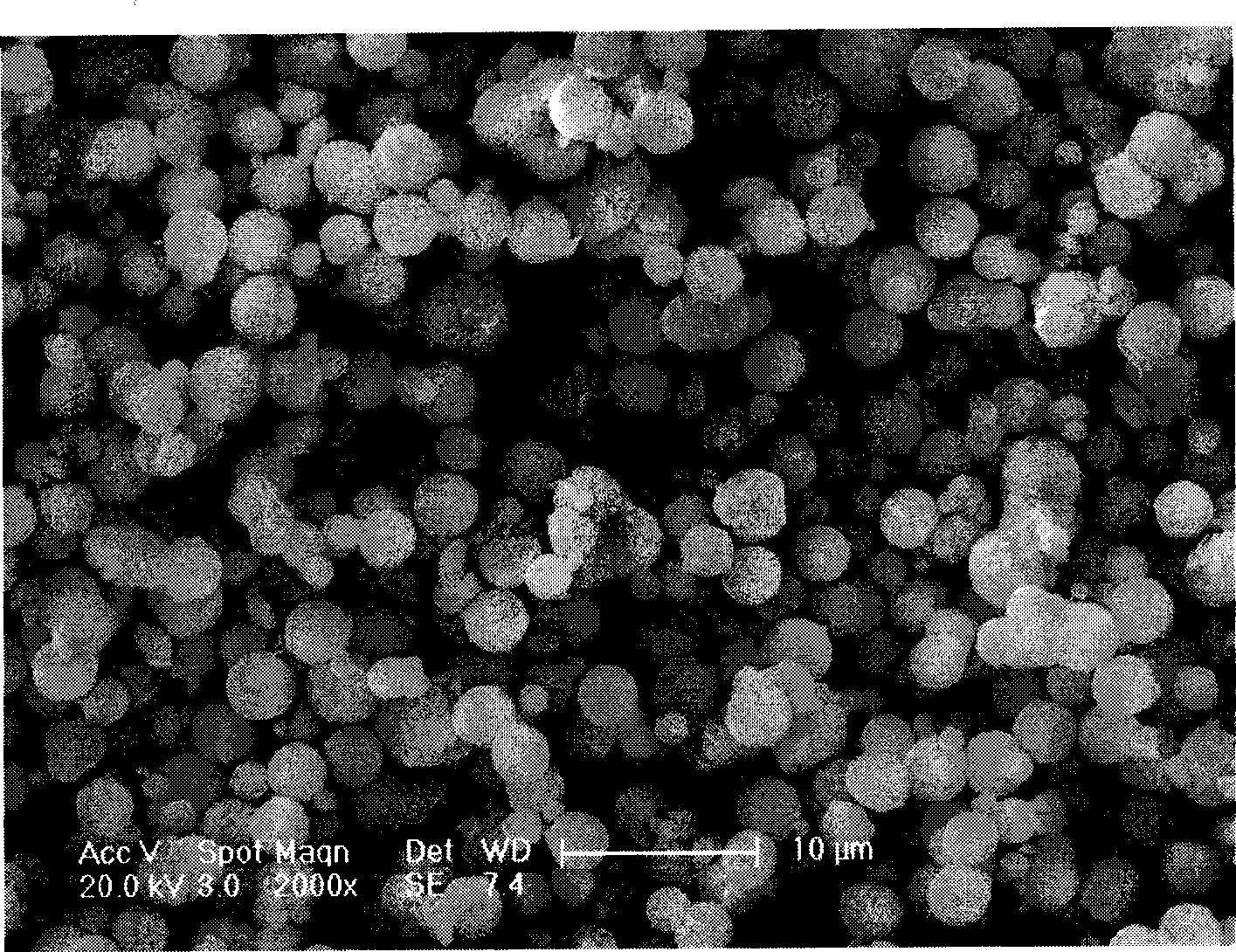

[0060] figure 1 For the resulting LiFePO 4 The SEM image of the material shows that the material synthesized by this method has a uniform and regular spherical structure with a particle size of 2-3 μm, and each microsphere is formed by the aggregation of nanoparticles of about 100 nm. There are abundant pores on the surface and inside of the microspheres, which are conducive to electrolyte infiltration.

Embodiment 2

[0061] Example 2 Carbon-coated LiFePO 4 Preparation of nanocomposite microspheres

[0062] 0.60g LiCl, 3.55g Fe 2 (SO 4 ) 3 ·6H 2 O, 1.61 g NH 4 h 2 PO 4 Mix well with 2g citric acid to make 70ml aqueous solution, pour it into a 100ml Teflon-lined stainless steel reaction kettle, conduct a hydrothermal reaction at 200°C for 3 hours, cool naturally to room temperature, and remove all solvents to obtain a precursor. Add 30% mass of polyethylene glycol to the precursor, mix it evenly, place it in a tube furnace, and burn it at 650°C for 20h under a high-purity argon protective atmosphere to obtain the target product LiFePO 4 / C.

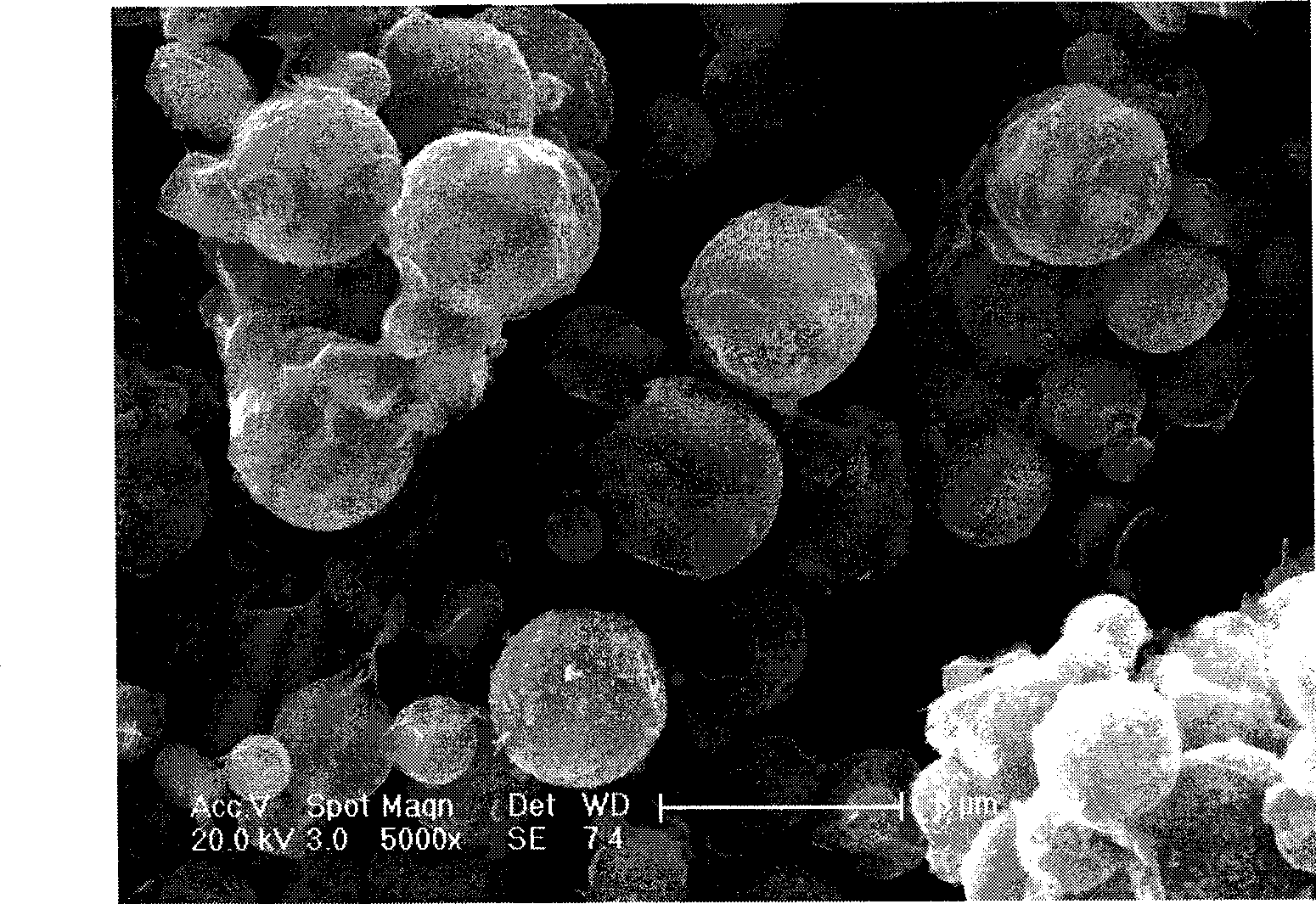

[0063] figure 2 For the obtained LiFePO 4 SEM image of / C material, and figure 1 Similar obtained materials also have a spherical structure with a particle size of 2-3 μm, and the surface is relatively figure 1 smoother, indicating that the organic pyrolytic carbon can be 4 A complete and uniform coating layer is formed on the surface. Th...

Embodiment 3

[0064] Example 3, LiFe 0.98 Mg 0.02 PO 4 Preparation of nanocomposite microspheres

[0065] 4.46g FeCl 3 , 3.22 g NH 4 h 2 PO 4 , 0.14g Mg(NO 3 ) 2 ·6H 2 O mixed evenly, made into a 70ml aqueous solution, poured into a 100ml stainless steel reactor with Teflon lining, reacted hydrothermally at 130°C for 6h, cooled naturally to room temperature, removed all solvents to obtain a precursor, added to the precursor 1.23g LiOH·H 2 O and 25% mass of glucose, mixed evenly, placed in a tube furnace, and burned at 650°C for 20h under a nitrogen-hydrogen mixture containing 5% hydrogen to obtain the target product LiFe 0.98 Mg 0.02 PO 4 / C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com