Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about How to "High phase transition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare earth zirconate high-temp heat barrier coating material and its preparation method

A RE zirconate coating material for preparing high-temp heat barrier layer has a chemical formula: A2B2O7, where A is chosen from La, Nd, Sm, Gd, Dy, Er and Yb and B is Zr. It is prepared through ball grinding of raw materials, baking, die pressing, and reaction in air at 1550-1650 deg.C. It has low heat conductivity and high high-temp stability.

Owner:TSINGHUA UNIV

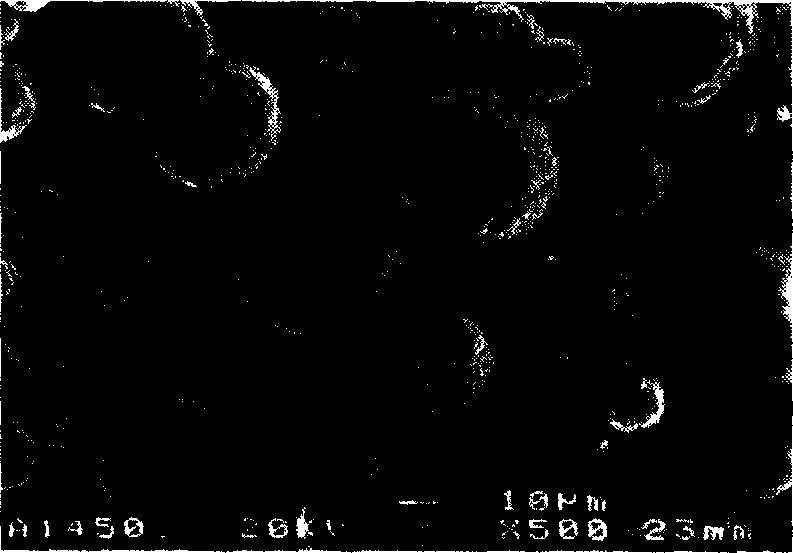

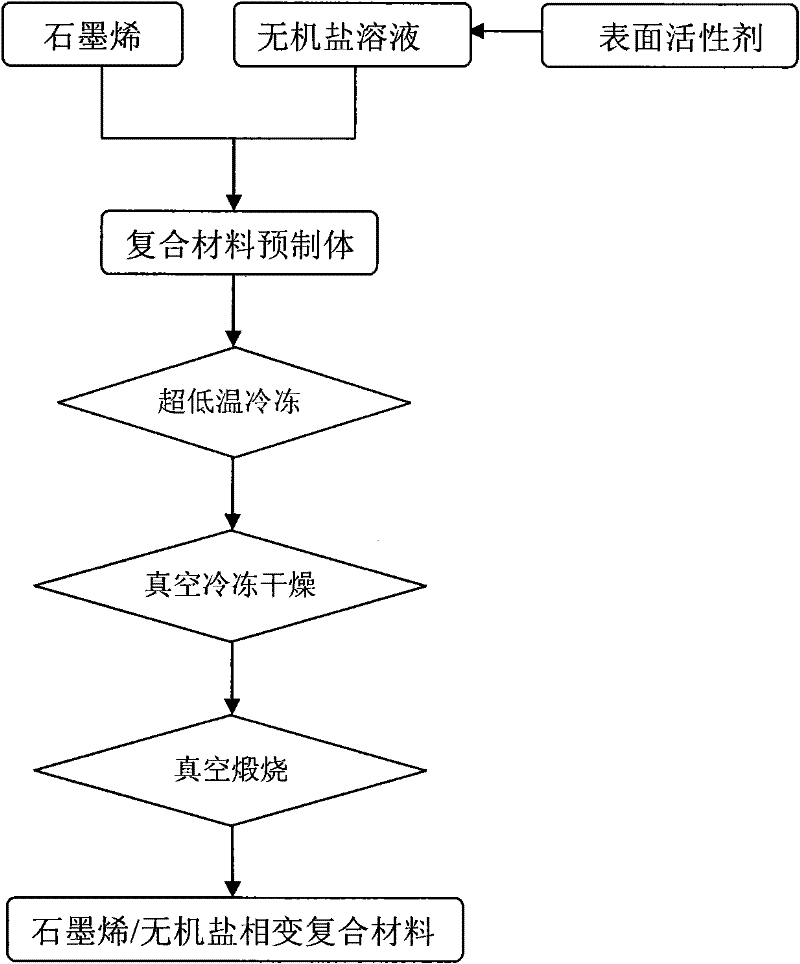

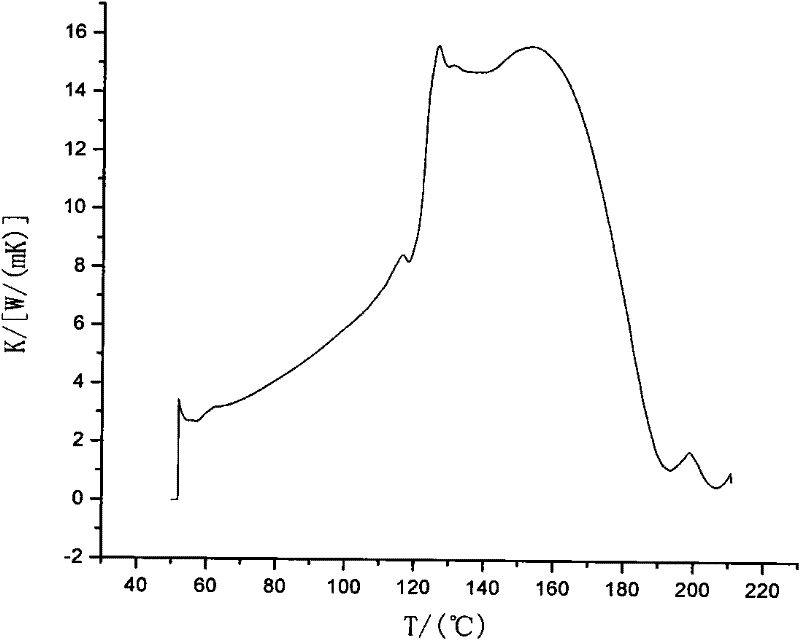

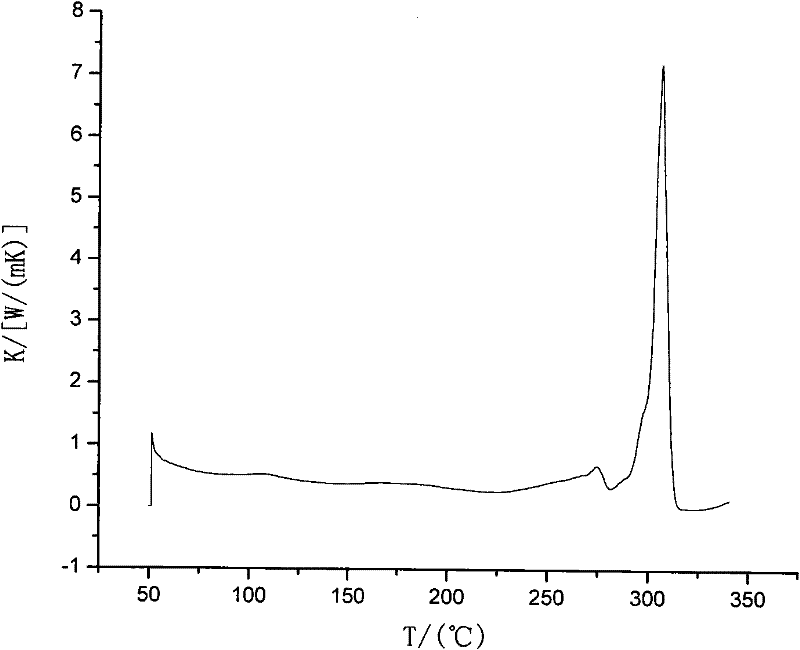

Method for preparing graphene and inorganic salt high-temperature phase change composite material

InactiveCN102344779AImprove thermal conductivityHigh energy storage densityHeat-exchange elementsInorganic saltsUltra Low Temperature Freezer

The invention relates to a method for preparing a graphene and inorganic salt high-temperature phase change composite material. The method comprises the following steps of: (1) preparing graphene sol; (2) preparing an inorganic salt solution, adding a surfactant, and mixing uniformly; (3) adding the graphene sol into the inorganic salt solution, and stirring until the graphene sol and the inorganic salt solution are mixed uniformly to obtain a composite material preform; (4) putting the composite material preform into an ultra-low-temperature freezer, quickly freezing to form a solid and taking out; (5) putting the solid-state composite material preform into a vacuum freezing dispersion drying instrument and drying; and (6) taking out after the drying of the composite material preform is finished, and calcining until the moisture is completely removed to obtain a grapheme / inorganic salt phase change composite material. Compared with the prior art, the method has the advantages that: the process is reasonable, easy to operate and low in cost; and the prepared grapheme / inorganic salt phase change composite material has the advantages of high coefficient of heat conductivity, high energy storage density and the like, has excellent performance, can meet different application requirements, and is suitable for industrialized production.

Owner:TONGJI UNIV

Nanometer molten salt phase-change energy storage solar furnace

InactiveCN103471256AWith heat storage functionNo outdoor operation requiredSolar heating energySolar heat devicesInsulation layerMolten salt

The invention discloses a nanometer molten salt phase-change energy storage solar furnace which comprises a Fresnel condenser, a phase-change energy storage heat exchanger, a longitude and latitude double-shaft tracker, stay rods, a V-shaped balance support and a bottom bracket. The phase-change energy storage heat exchanger with heat absorption, heat release and heat storage functions is mounted at a condensation focus of the Fresnel condenser, nanometer molten salt composite phase-change energy storage materials are arranged in the phase-change energy storage heat exchanger, a heat absorption cavity and a heat release furnace end are arranged on the phase-change energy storage heat exchanger, and a heat-insulation layer wraps the outside of the phase-change energy storage heat exchanger. Heat utilization requirements such as water heating, cooking and barbecue for general family life can be met by the solar furnace. Compared with the traditional direct condensation type solar furnace, the nanometer molten salt phase-change energy storage solar furnace has the advantages that the heat collecting temperature is high, outdoor operation is omitted, the nanometer molten salt phase-change energy storage solar furnace can continue being used at night without the sun, and the like.

Owner:GUANGDONG UNIV OF TECH

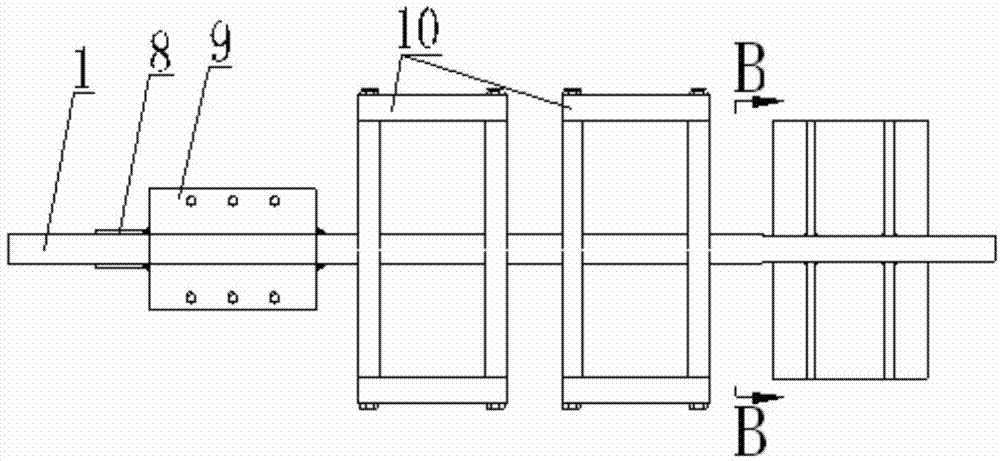

Device for heat shaping of thin-walled titanium alloy parts

The invention relates to a device for heat shaping of thin-walled titanium alloy parts. A first pressing mechanism is fixed at one end of a body, and a second pressing mechanism is fixed at the other end of the body. Two clamping mechanisms are mounted in the middle of the body. Two clamping plates of a lateral ejection mechanism are fixed on two lateral surfaces of the body respectively and located between the first pressing mechanism and the clamping mechanisms. A width inner-supporting mechanism is located between the two clamping plates of the lateral ejection mechanism, one end of the width inner-supporting mechanism is mounted in a to-be-shaped part, and cavity inner-supporting mechanisms are mounted on the upper surface and the lower surface of the width inner-supporting mechanism. One ends of the cavity inner-supporting mechanisms are mounted in the clamping mechanisms, so that a support body with a wedge-shaped inner cavity is formed in the to-be-shaped part. By the device, utilization rate of a heat treatment furnace is increased, and cost of vacuum heat shaping is lowered. Since the to-be-shaped parts are clamped symmetrically, main stresses of a tooling are symmetric in direction and offset each other, stress state of the tooling is improved, and deformation resistance of the tooling is enhanced indirectly.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

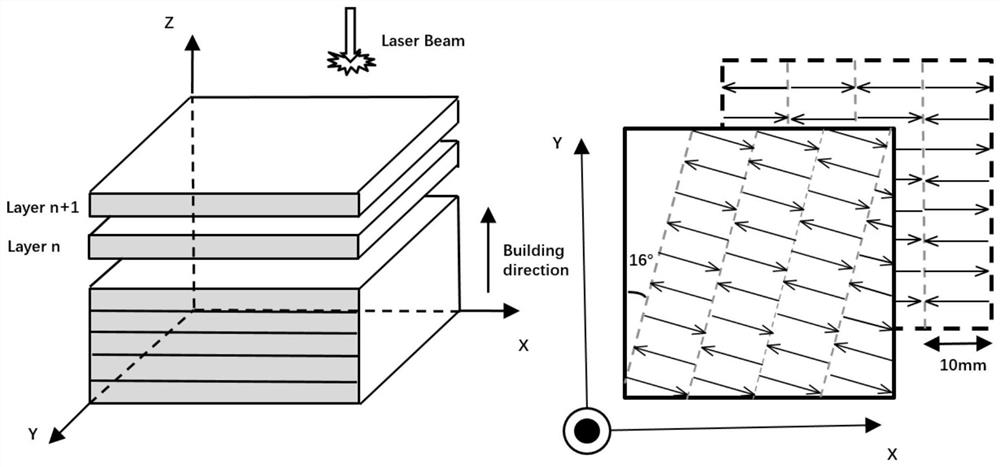

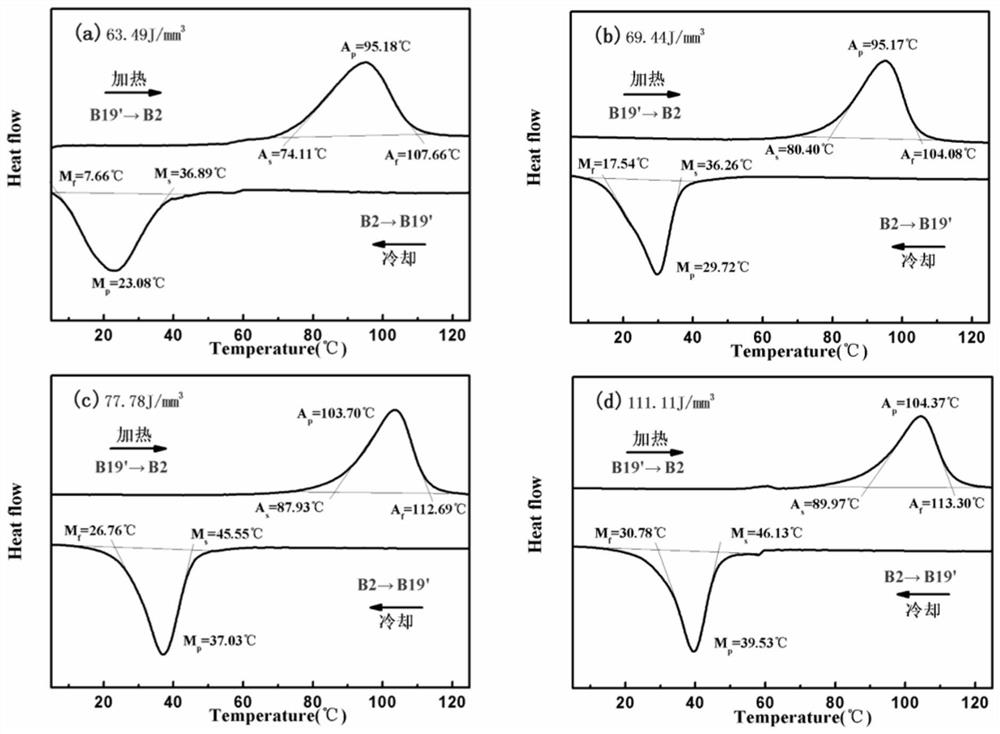

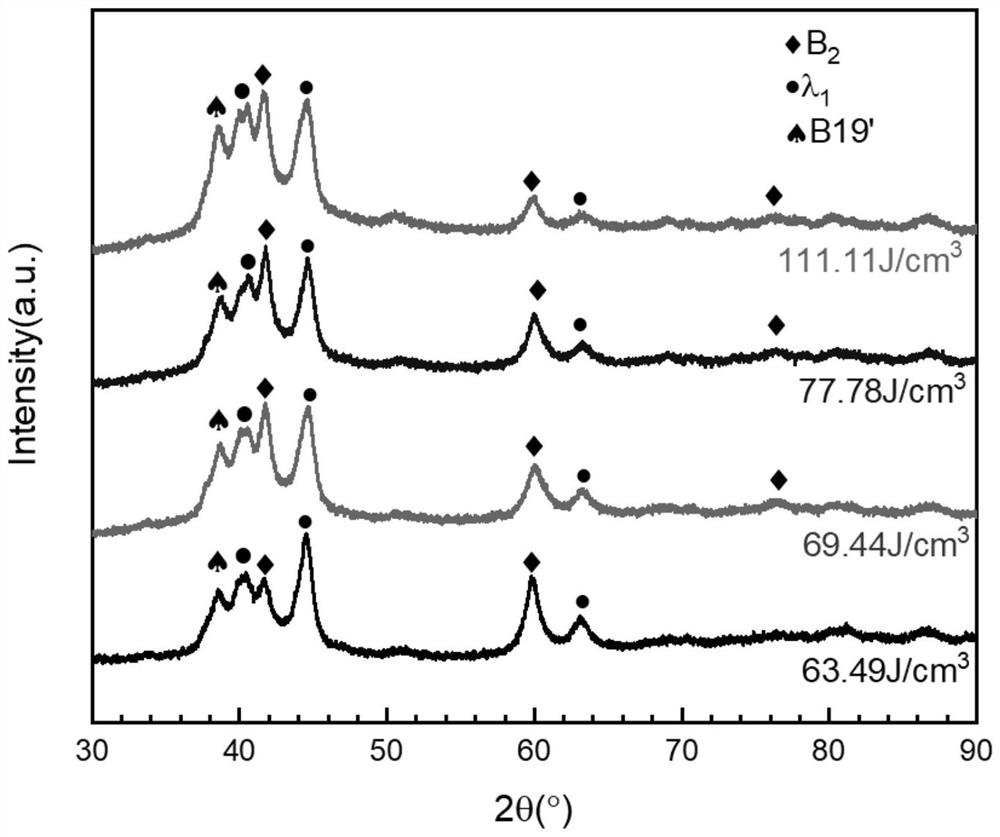

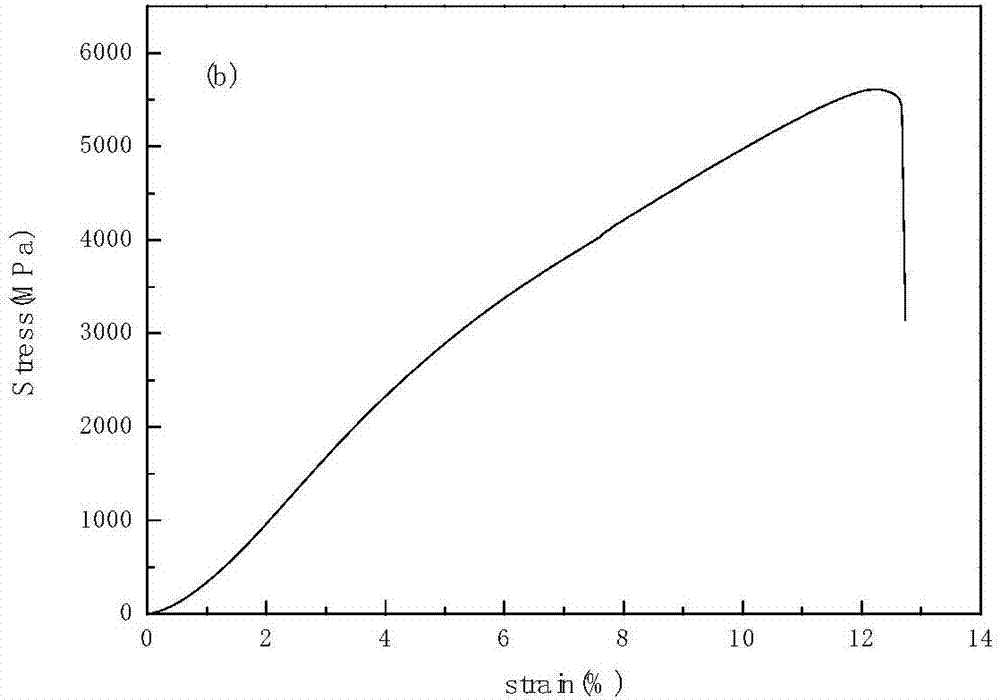

4D printing method of nickel-titanium-based ternary shape memory alloy

InactiveCN111842888AHas shape memory effectRaise the transition temperatureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingBinary alloy

The invention belongs to the technical field of 4D printing additive manufacturing, and discloses a 4D printing method of a nickel-titanium-based ternary shape memory alloy. The 4D printing method ischaracterized in that a selective laser melting technology is adopted for printing gas atomized prefabricated NiTiZr ternary alloy powder, and a component obtained through printing has the shape memory function; and the laser energy density is changed by changing the technological parameters adopted in the selective laser melting technology, and therefore the changes of the structure and performance of the printed piece are regulated and controlled. According to the 4D printing method, the ternary component Zr is introduced into an existing nickel-titanium binary alloy, the martensite phase transformation temperature is obviously increased, the selective laser melting technology is adopted for forming, and complex parts uniform in structure and high in density can be obtained while the excellent shape memory performance and mechanical performance are guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

Movable heat storage and discharge device based on pulsating heat pipes and heat storage and discharge method thereof

PendingCN106767082AGuaranteed uptimeSimple structureHeat storage plantsEnhanced heat transferCooling chamber

The invention provides a movable heat storage and discharge device based on pulsating heat pipes and a heat storage and discharge method thereof. The heat storage and discharge device comprises a shell, a heating chamber, a phase-change material chamber, a cooling chamber and the pulsating heat pipes, wherein the heating chamber, the phase-change material chamber, the cooling chamber and the pulsating heat pipe are all arranged in the shell; the heating chamber, the phase-change material chamber and the cooling chamber are separated by stainless steel partitions; at least one group of pulsating heat pipes pass through the partitions and are arranged in the shell; the parts, which are arranged in the heating chamber and the cooling chamber, of the pulsating heat pipes include straight pipe sections and elbows, and the parts, which are arranged in the phase-change material chamber, of the pulsating heat pipes are straight pipe sections; the parts, which are arranged in the heating chamber, of the pulsating heat pipes are evaporating sections, the parts, which are arranged in the phase-change material chamber, of the pulsating heat pipes are insulation sections, and the parts, which are arranged in the cooling chamber, of the pulsating heat pipes are condensation sections; and fluid inlets and outlets are formed in one end of the cooling chamber and the heating chamber. Phase-change heat transfer of working media in the pulsating heat pipes and phase-change heat storage of phase-change materials are used, so that waste heat is absorbed, stored, transferred and released, thereby effectively recycling the waste heat.

Owner:SHANGHAI MARITIME UNIVERSITY

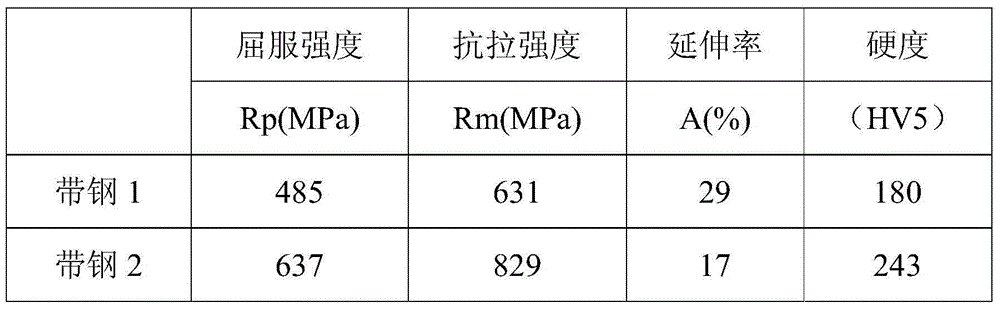

Rolling technology for high-carbon steel in thin slab casting and rolling

ActiveCN104438326AIncrease nucleation sitesUniform nucleationTemperature control deviceTension/compression control deviceThree stageSlow cooling

The invention provides a rolling technology for high-carbon steel in thin slab casting and rolling. The rolling technology includes the processes of continuous casting, heat evening, scale removing, rolling, inter-stand cooling, laminar cooling, reeling and insulation cover slow cooling. The rolling technology is characterized in that the rolling process includes three stages of Austenite perfect recrystallization rolling, non-recrystallization area Austenite rolling and two-phase area rolling. Medium-and-high-carbon steel structures rolled through the rolling technology are even and fine ferrite and particular pearlite, banded structures can be improved, the mechanical property is good, the annealing process does not need to be conducted before forming, cost is reduced, and quite high practicability is achieved.

Owner:武汉钢铁有限公司

Nanometer multi-layer composite phase-change film material for multilevel storage phase-change memory, as well as preparation and application thereof

InactiveCN102354729ASolve the shortcomingsSolve problemsMaterial nanotechnologyElectrical apparatusPhase-change memoryHeat stability

The invention relates to a Ge2Sb2Te5 / Ga30Sb70 nanometer multi-layer composite phase-change film for a multilevel storage phase-change memory. A monolayer Ge2Sb2Te5 film and a monolayer Ga30Sb70 film in the Ge2Sb2Te5 / Ga30Sb70 nanometer multi-layer composite phase-change film material are alternately ranged to form a multi-layer film structure, the thickness of the monolayer Ge2Sb2Te5 film and the thickness of the monolayer Ga30Sb70 film are respectively 10-133nm, and the total thickness of the Ge2Sb2Te5 / Ga30Sb70 nanometer multi-layer composite phase-change film material is 90-200nm. When the Ge2Sb2Te5 / Ga30Sb70 nanometer multi-layer composite phase-change film provided by the invention is applied to the phase-change memory, multilevel storage can be realized; and simultaneously, the Ge2Sb2Te5 / Ga30Sb70 nanometer multi-layer composite phase-change film has higher heat stability and stronger data retention performance.

Owner:TONGJI UNIV

Diesel vehicle oxidized form catalyst having low temperature activity and preparation method thereof

ActiveCN105797767ALow ignition temperatureImprove conversion rateGas treatmentMolecular sieve catalystsSlurryComposite oxide

The invention relates to a diesel vehicle oxidized form catalyst having low temperature activity and a preparation method thereof.The catalyst comprises a carrier and a coating applied to the carrier, the coating is loaded with noble metal, the coating comprises tungsten-aluminum silicon composite oxide and molecular sieves, the noble metal is one of Pt and Pd or a mixture of the two types of substances, the coated weight of the coating is 80-180 grams / liter, and the coated weight of the noble metal is 0.5-4.5 grams / liter.The preparation method comprises the steps of firstly, preparing the tungsten-aluminum silicon composite oxide through an equivalent-volume impregnation method, then making slurry with the molecular sieves and the tungsten-aluminum silicon composite oxide according to the mass ratio of 1: (2-10), adding the noble metal Pt and Pd, finally immersing the carrier into the slurry, and conducting drying and sintering, so that the diesel vehicle oxidized form catalyst is obtained.The preparation method of the catalyst is simple, the steps are easy to operate, the prepared diesel vehicle oxidized form catalyst is low in combustion temperature, high in conversion rate and good in thermal stability, good capability for oxidizing HC and CO in tail gas of a diesel vehicle is achieved, and good sulfur resistance is achieved.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

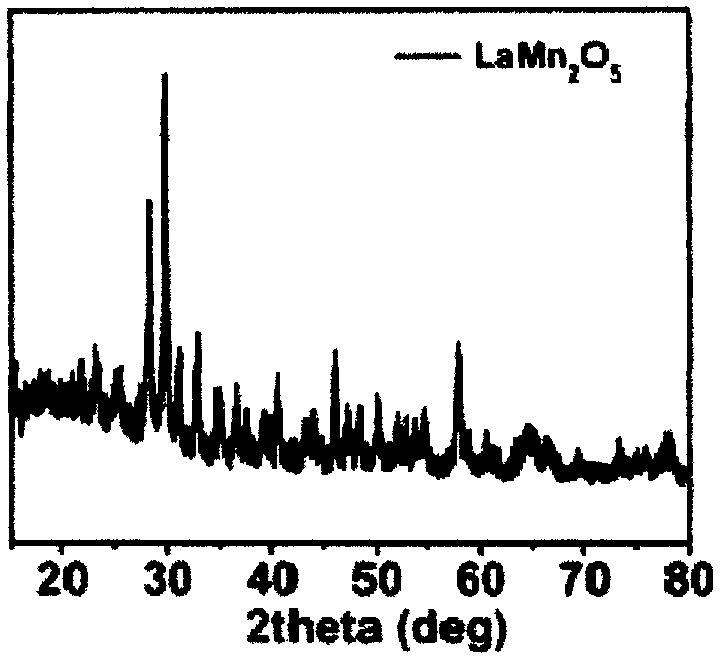

Manganese-based oxide catalyst

InactiveCN108355647ALow preparation temperatureShort cycleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAging resistanceNitrogen dioxide

The invention provides a manganese-based oxide catalyst. The catalyst is characterized in that the catalyst is a mullite oxide having a general formula of RMn2O5, wherein R is Pr, Nd, Eu, Gd, Tb, Dy,Ho, Er, Tm, Yb, Lu, Y or Bi. The catalyst can effectively catalytically oxidize nitrogen monoxide into nitrogen dioxide at a low temperature, has good aging resistance and good durability, and can effectively remove nitrogen oxides from automobile exhaust gas. A method for preparing the oxide has the advantages of few raw materials, simple steps, and convenience in operation. The hydrothermal synthesis method effectively reduces the preparation temperature of mullite to greatly save energy, and also has the characteristics of short preparation period, low device requirements and easiness in promotion.

Owner:NANKAI UNIV

Damage tolerant medium-strength titanium alloy

The invention discloses a damage tolerant medium-strength titanium alloy which is composed of, by mass, 5.5-7% of aluminum, 2.0-3.5% of zirconium, 2.0-3.5% of molybdenum, 2.0-3.5% of niobium and the balance of titanium and unavoidable impurities. Room-temperature tensile strength in an annealing state is 900-1000 MPa, room-temperature fracture toughness KIC is greater than or equal to 70 MPa.m1 / 2, and room-temperature fatigue crack propagation rate is da / dN is less than 3.5x10-5mm / cycle when R=0.1 and delta K=11 MPa.m1 / 2. The damage tolerant medium-strength titanium alloy does not contain element vanadium harmful to human body, element niobium difficult to being oxidized is added, raw material cost is not obviously increased generally while material performance is more stable, and safety and reliability of material application are improved.

Owner:WESTERN METAL MATERIAL

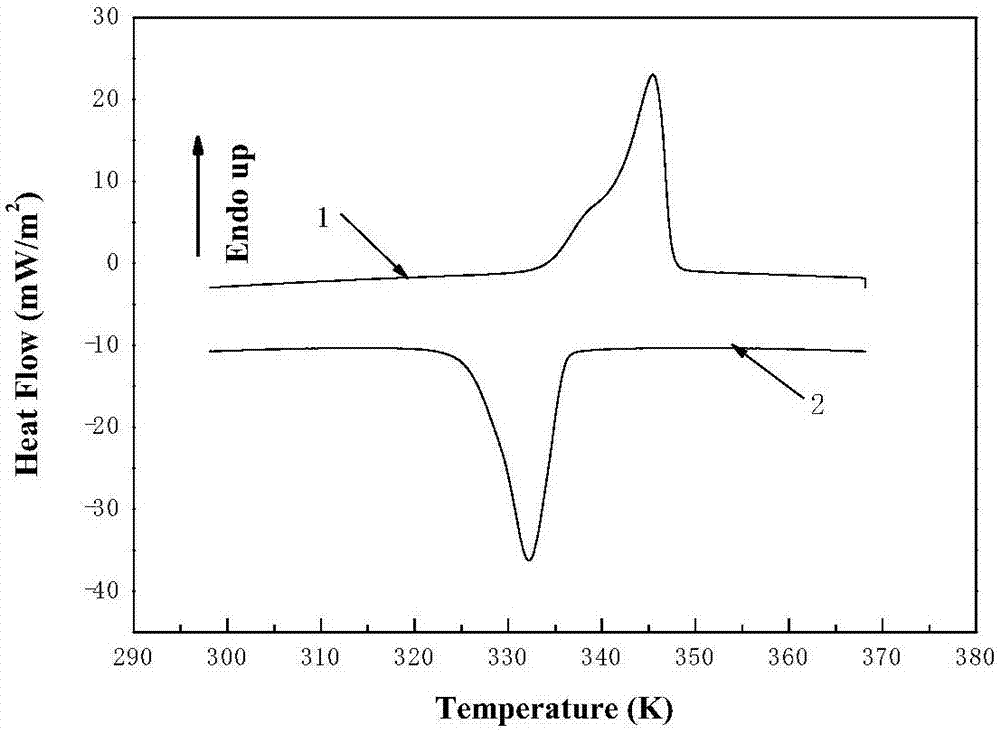

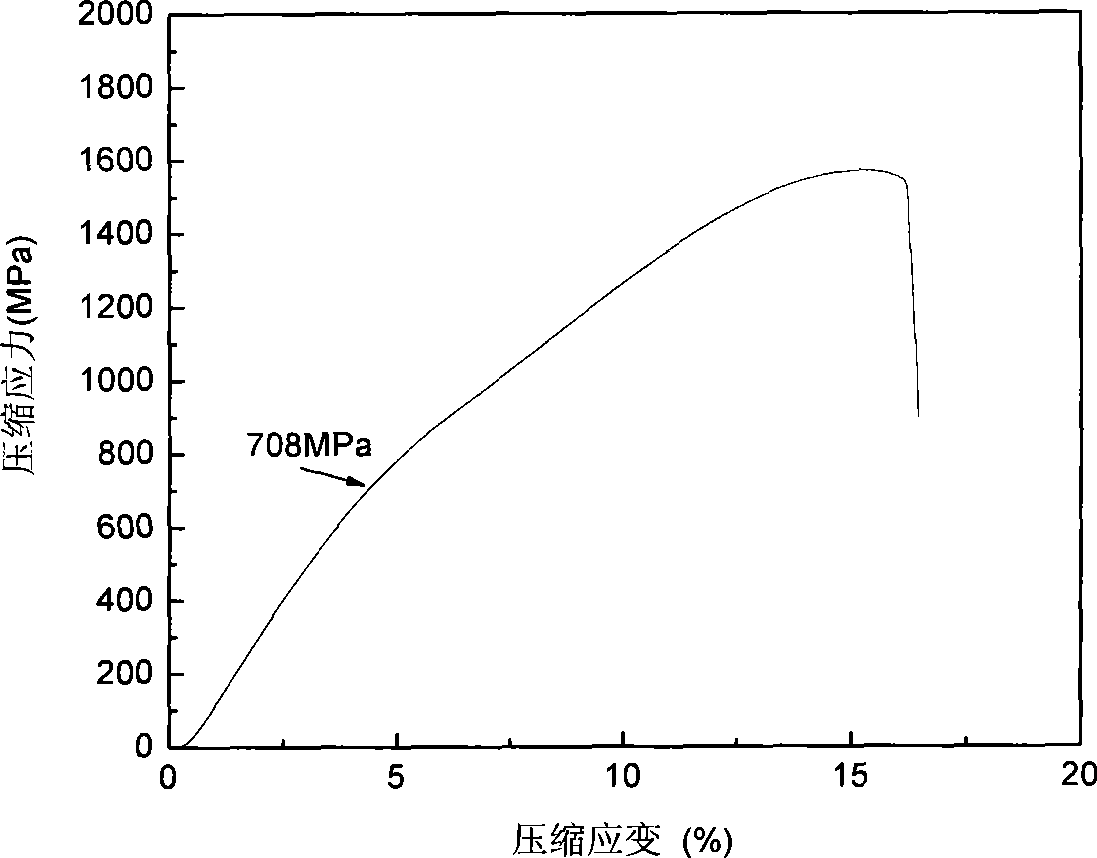

Preparation method for high strength Ni50Mn34In16 magnetic memory alloy

ActiveCN107058848AHigh breaking strengthRaise the strain at breakTransportation and packagingMetal-working apparatusHigh fractureMagnetic memory

The invention relates to a preparation method for a magnetic shape memory alloy, in particular to a preparation method for a high strength Ni50Mn34In16 magnetic memory alloy. The high strength Ni50Mn34In16 is prepared according to the following steps of material taking according to the atomic percent, mixing, forming, degreasing and sintering, and then the high strength Ni50Mn34In16 is obtained. The Ni50Mn34In16 alloy prepared by the method has higher fracture strength and fracture strain, the grain size of the magnetic shape memory alloy is tiny so as to drive the threshold value of a magnetic field to be reduced, the excellent magnetic property is achieved, and the train of thought is expanded for application of the high temperature and high plasticity shape memory alloy.

Owner:DALIAN UNIV

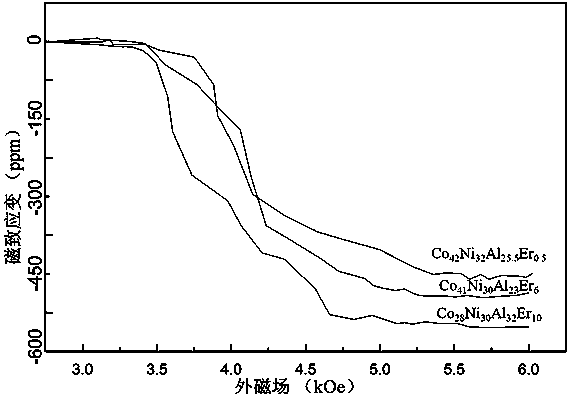

Rare-earth magnetic material with high magnetocrystalline anisotropy and large magnetoelastic strain and preparation method thereof

ActiveCN104018055AHigh magnetocrystalline anisotropyImprove ferromagnetismMagnetic materialsRare earthAlloy

The invention provides a rare-earth magnetic material with high magnetocrystalline anisotropy and large magnetoelastic strain and a preparation method thereof. The material has high magnetocrystalline anisotropy, and can provide large magnetocrystalline anisotropy under the action of an external magnetic field, so that the material is subjected to twin crystal rearrangement under the martensite state, so as to generate large magnetoelastic strain. The chemical formula of the alloy is CoxNiyAlzErj, wherein x is smaller than or equal to 42 and greater than or equal to 28; y is smaller than or equal to 32 and greater than or equal to 25; z is smaller than or equal to 35 and greater than or equal to 23; j is smaller than or equal to 10 and greater than or equal to 0.5; x+y+z+j is 100; x, y, z and j represent the mole percentage content. Compared with the existing alloy, the high-temperature magnetic shape memory alloy CoxNiyAlzErj disclosed by the invention has high magnetocrystalline anisotropy, high magnetoelastic strain and good mechanical property, and has important application in the fields of an actuator, a magnetosensitive element and a miniature electromechanical system.

Owner:SOUTHEAST UNIV

PH and temperature double-sensitive intelligent nanogel and preparation method thereof

The invention provides a pH and temperature double-sensitive intelligent nanogel and a preparation method thereof. The method comprises the following steps: adding ltaconic acid into sodium hydroxide solution to obtain partially neutralized ltaconic acid water solution; adding acrylamide, N-isopropyl acrylamide and a crosslinking agent into the partially neutralized ltaconic acid water solution, and stirring to obtain a transparent single mixture solution; adding the transparent single mixture solution into a mixed solvent containing oil-soluble solvent and Span80 / Tween 80 composite surfactant, stirring, heating to 40-60DEG C, and adding an oxidant and a reducing agent, to obtain intelligent transparent or semitransparent nanogel reversed-phase microemulsion; demulsifying and precipitating the intelligent transparent or semitransparent nanogel reversed-phase microemulsion with ethanol, washing, drying and grinding to the pH and temperature double-sensitive intelligent nanogel. The invention further provides the pH and temperature double-sensitive intelligent nanogel prepared by adopting the preparation method. The pH and temperature double-sensitive intelligent nanogel has good pH and temperature double sensitivity.

Owner:PETROCHINA CO LTD

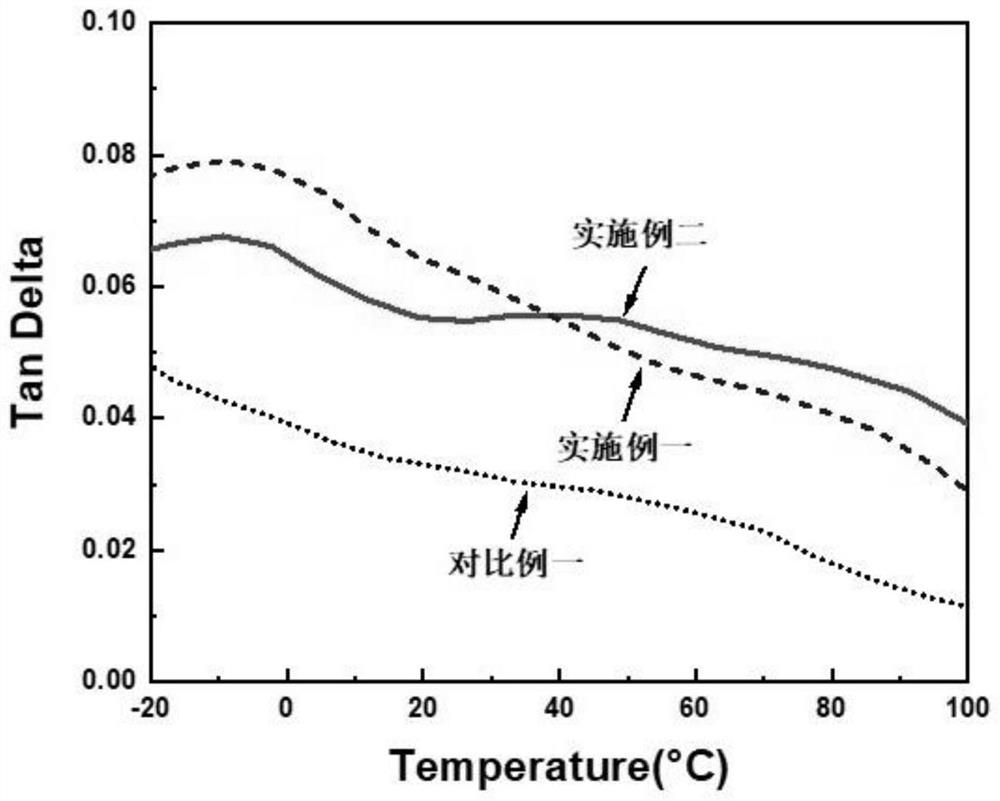

High-damping manganese-copper alloy for wide-temperature-range service and preparation method thereof

The invention discloses a high-damping manganese-copper alloy for wide-temperature-range service and a preparation method thereof. The high-damping manganese-copper alloy comprises the following chemical elements of, in percentage by mass, 15wt.%-25wt.% of Cu; 1wt.-5wt.% of Ni; 0.1wt.%-1.5wt.% of Co; 0wt.%-2.5wt.% of Fe; 0wt.%-1.5wt.% of Zn; 0wt.%-1.0wt.% of Sn; and the balance Mn and other inevitable impurities. According to the method, a directional solidification technology is used for being combined with a high-temperature magnetic field heat treatment technology, so that the damping performance of the alloy within the service temperature range is remarkably improved, and martensite twin crystals high in movement capacity and high-density dislocation good in mobility are induced to be formed through the amplitude modulation decomposition effect of chemical components in the high-temperature aging process, so that the purpose of preparing the high-damping manganese-copper-based alloy is achieved; the damping alloy is simple in preparation technology and high in production efficiency, the alloy system does not contain precious alloy elements, and the production cost is low.

Owner:SHANGHAI UNIV

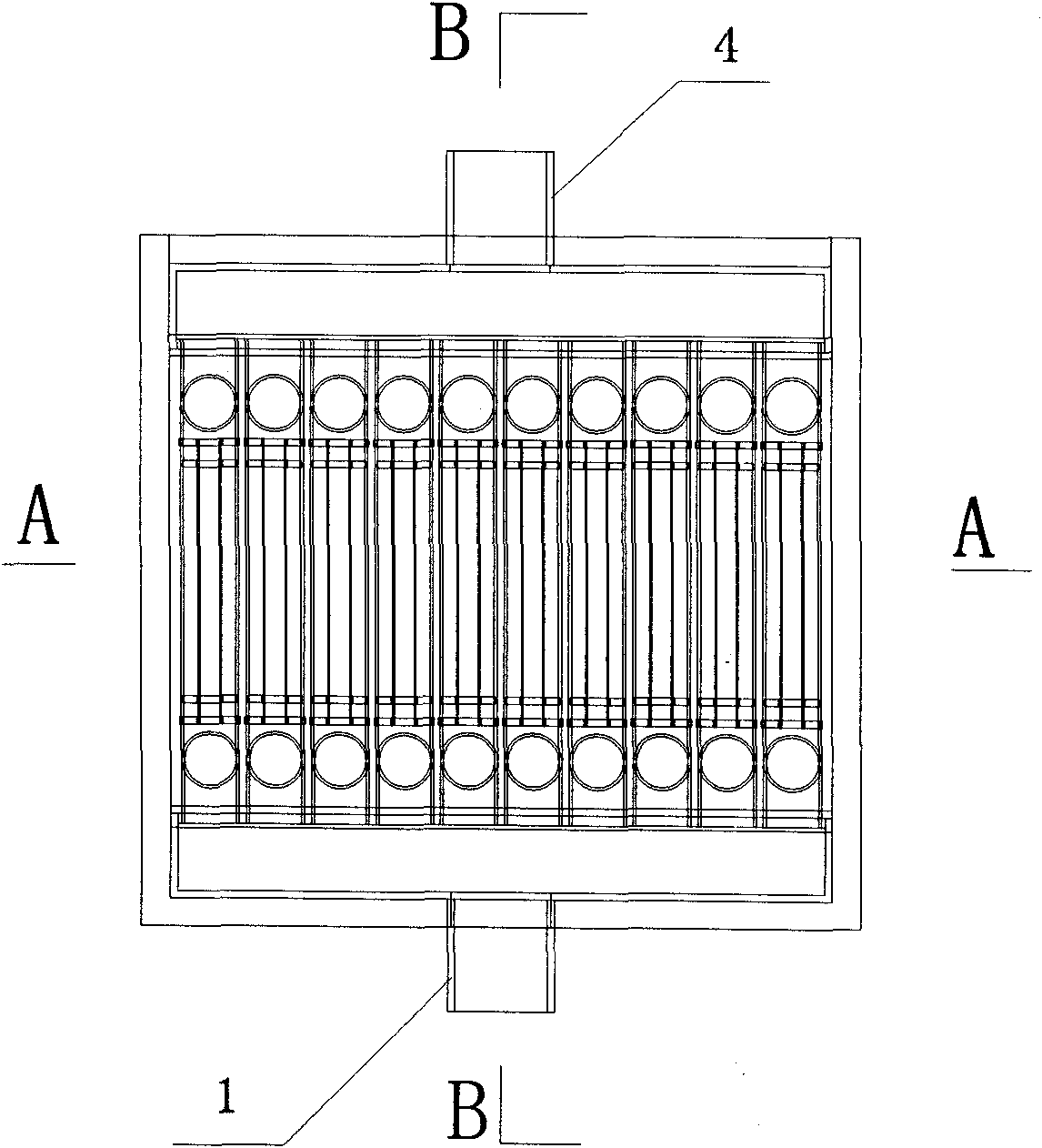

Bushing-type high temperature heat storage device applied to solar heat utilization

InactiveCN101818951AImprove heat transfer efficiencyHigh temperature and high heat exchange efficiencySolar heat devicesEmission reduction for energy storageHeat storage materialEngineering

The invention relates to a bushing-type high temperature heat storage device applied to solar heat utilization. The device is characterized by comprising an air inlet pipe, a heat storage room box body, a heat storage room door, an air outlet pipe, a first ventilation cavity, a second ventilation cavity, a heat storage material receiving pipeline, a coiled pipe, a heat storage material receiving pipeline support, a heat insulating material and a heat storage material, wherein the air inlet pipe is communicated with the first ventilation cavity positioned in heat storage space; the air outlet pipe is communicated with the second ventilation cavity positioned in the heat storage space; the coiled pipe is connected with a U-shaped pipe through an air flow pipeline; one end of the coiled pipe is communicated with the first ventilation cavity, and the other end of the coiled pipe is communicated with the second ventilation cavity; the heat storage material receiving pipeline is fixed with the air flow pipeline through the heat storage material receiving pipeline support; the heat storage material is encapsulated in the heat storage material receiving pipeline; and a heat transfer medium in the ventilation pipe is a gas. The bushing-type high temperature heat storage device has the advantages of simple structure, safety, reliability and high heat exchanging efficiency.

Owner:HUBEI KAIJIA ELECTRICAL TECH GROUP

Low-power-consumption phase change film material for multistage phase change storage, and reparation method and application thereof

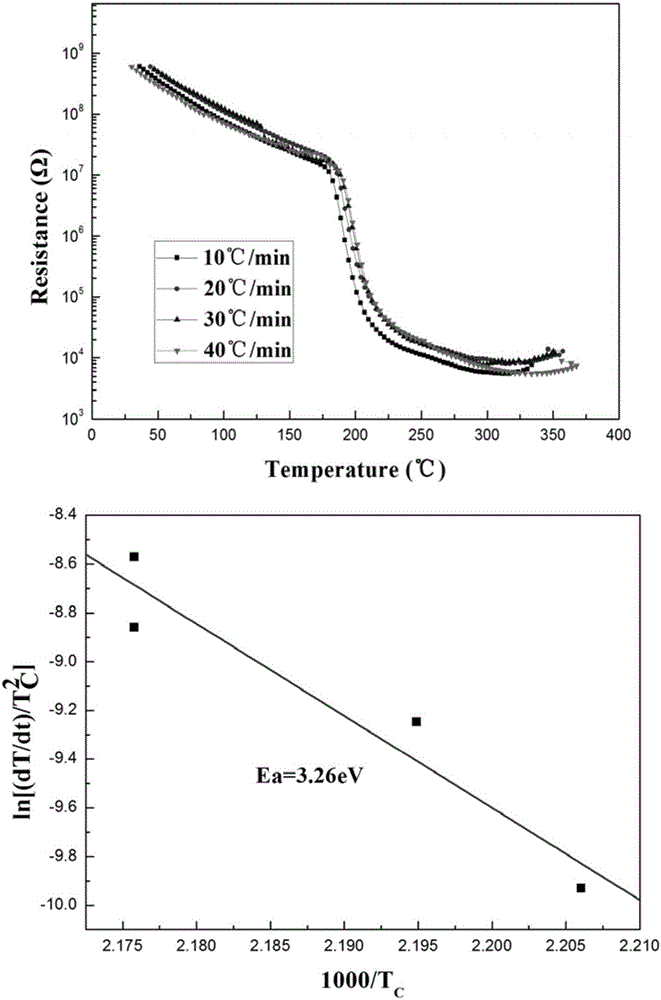

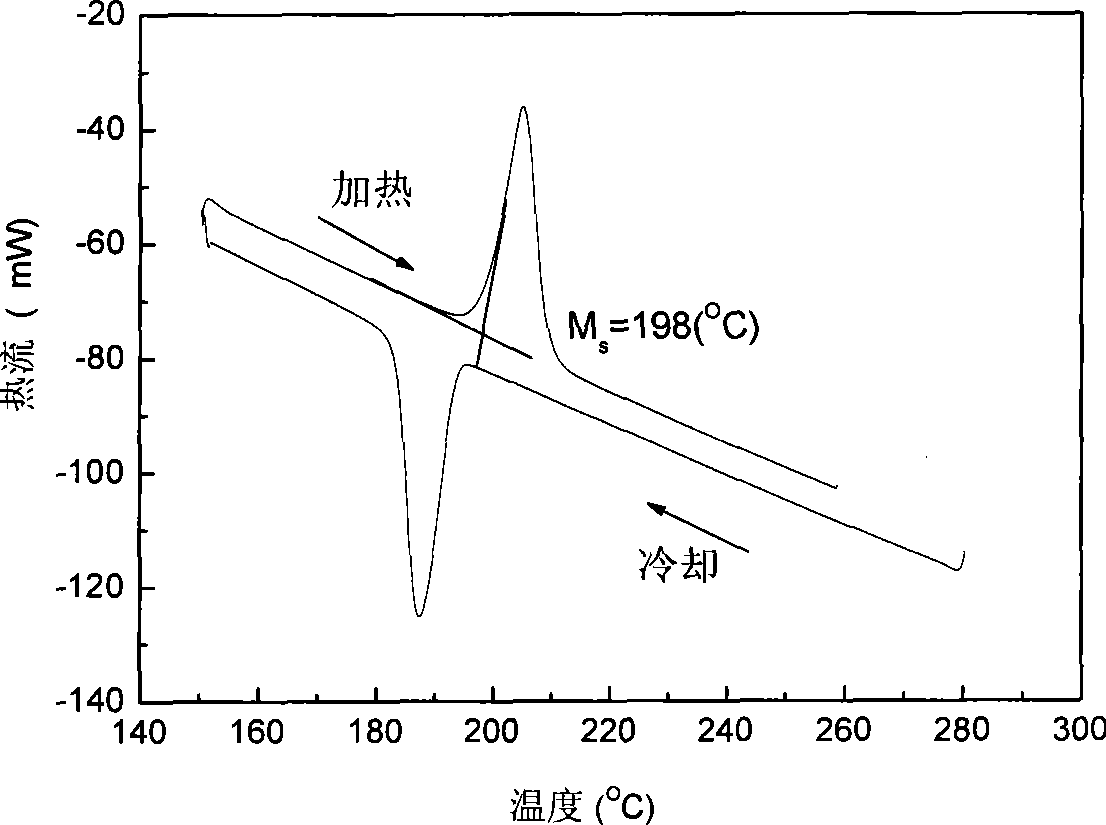

InactiveCN105070826AHigh phase transition temperatureImprove stabilityElectrical apparatusElectrical resistance and conductanceSemiconductor materials

The invention relates to a low-power-consumption phase change film material for multistage phase change storage, and a preparation method and an application thereof. A chemical component of the thin material is InTe([alpha])-X([alpha]), wherein [alpha] is the thickness of a single-layer InTe film and the thickness of a single-layer X film; and, on a SiO<2> / Si (100) substrate, InTe and Ga<3>Sb<7>, SnSe<2> or Ge<2>Sb<2>Te<5> are taken as target materials, argon is taken as a glow gas, an InTe film and a Ga<3>Sb<7>, SnSe<2> or Ge<2>Sb<2>Te<5> film are alternatively deposited, and then the low-power-consumption phase change film material for the multistage phase change storage is obtained through preparation. Compared with the prior art, the low-power-consumption phase change film contains a relative traditional semiconductor material Te in a phase change storage field, also contains an element In which can increase and stabilize a value of an amorphous resistor, and forms a large high-low resistor.

Owner:TONGJI UNIV

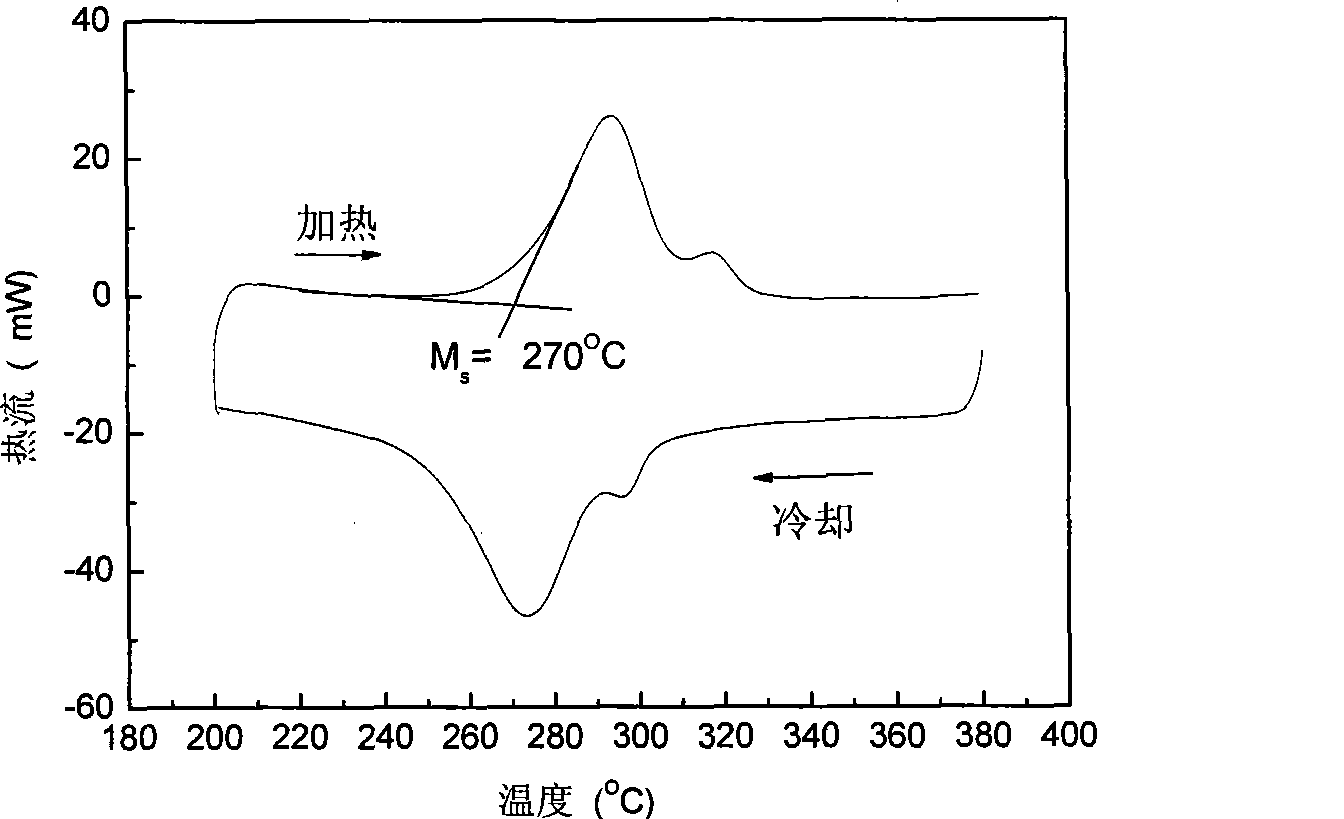

NiMnGaCu high temperature shape-memory alloy and manufacturing method thereof

InactiveCN101463445AHigh phase transition temperatureImproved thermal cycling stabilityMartensite transformationMemory effect

The invention provides a NiCoMnSn high temperature shape memory alloy and a preparation method thereof. Ni, Co and Sn are weighted according to the atomic percent of Ni43Co7Mn<50-x>Sn<x>; wherein, X equals to 7-10; the raw materials of Ni, Co, and Sn weighted in the first step are put in a no consumable vacuum arc furnace, vacuumed to cause that the vacuum degree of the background reaches 2*10<-2> - 5*10<-3>Pa, and then charged with high-purity argon till 500 Pa; the raw materials are melted to NiCoMnSn button-type cast ingot by using high temperature voltaic arc; a vacuum suction mold device is used for preparing a bar-shaped cast ingot with the 10mm diameter, thus obtaining the Ni43Co7Mn<50-x>Sn<x> high temperature shape memory alloy. The martensitic phase transformation temperature of the NiCoMnSn prepared by the invention ranges from 120 DEG C-300 DEG C; the alloying elements of the raw materials are relatively cheap. The preparation method is simple and the alloy has uniform components; therefore, the follow-up heat treatment is not needed. The shape memory effect can reach up to 3.8%. The stability of the thermal circulation is high. The alloy is a new high temperature shape memory alloy with the application prospect.

Owner:如皋市生产力促进中心

Method for manufacturing transformation induced plasticity steel seamless tube on line

The invention belongs to the technical field of steel rolling, and particularly relates to a method for manufacturing a transformation induced plasticity steel seamless tube on line. The method comprises the following steps of: heating a wall cold-drawing seamless steel tube to a critical region of between 760 and 850 DEG C by using an intermediate frequency heating induction coil at a heating speed of at least 35 DEG C / s; cooling to a bainite region of between 380 and 450 DEG C at a speed of between 40 and 80 DEG C / s, and performing isothermal treatment for 10 to 40 seconds; and performing air cooling, water cooling or cooling naturally to a room temperature to obtain the transformation induced plasticity steel seamless tube. By measuring the transformation induced plasticity steel seamless tube prepared by the technical scheme, the tensile strength is 780 MPa level, the percentage of elongtation is more than or equal to 24 percent, a ratio of tensile strength to yield strength is less than or equal to 0.55, and a strain hardening index n is more than or equal to 0.24.

Owner:NORTHEASTERN UNIV

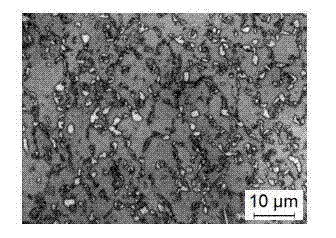

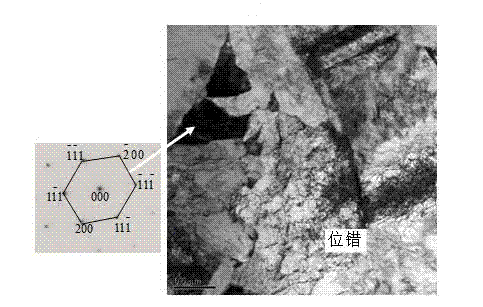

Sr and Mg doped amorphous apatite material and crystalline apatite material

InactiveCN105439110AHigh affinityPromote formationImpression capsNanotechnologySolubilityCalcium metabolism

The invention discloses an Sr and Mg doped amorphous apatite material and crystalline apatite material, belonging to the field of biomedical materials. The different concentrations of Sr and Mg doped amorphous apatite material is rapidly prepared by using Ca(NO3)2, Mg(NO3)2, Sr(NO3)2, (NH4)2HPO4 and ammonia-water as raw materials and then is transformed to the different concentrations of Sr and Mg doped nano calcium-deficient hydroxyapatite or nano tricalcium phosphate material through heat treatment. Compared with traditional hydroxyapatite crystalline materials, the amorphous material has higher solubility. The amorphous apatite material and the crystalline apatite material have the beneficial effects that after Sr and Mg doping, Sr can achieve the effects of promoting new bone formation, reducing reabsorption of bone, adjusting calcium metabolism and reducing the activity of osteoclast, and Mg can achieve the effects of affecting early growth of bone substances and regulating growth and remodelling of the bone substances; therefore the synthesized amorphous apatite and the crystallized product thereof have important roles in the fields of bone repair and bone transplantation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Inorganic phase-change energy storing particles, floor heating mortar and preparation method thereof

The invention provides inorganic phase-change energy storing particles, floor heating mortar and a preparation method thereof. The inorganic phase-change energy storing particles comprise the following components in percentage by mass: 20-50% of inorganic phase-change material, 10-25% of water, 0.1-1.5% of phosphorylated starch gum, 0.1-1.5% of water-absorbent resin, 10-35% of gypsum, and 15-35% of cement. The inorganic phase-change energy storing particles are prepared by the steps of preparing phosphorylated starch gum, preparing materials, mixing, pelletizing, coating, and covering with films. The floor heating mortar comprises 15-35% of cement, 10-25% of sand, 20-50% of inorganic phase-change energy storing particles, and 20-30% of water. The floor heating mortar is prepared by preparing materials, and mixing. According to the inorganic phase-change energy storing particles, the floor heating mortar and the preparation method thereof, the raw materials are wide in source; the chemical stability is high; the phase change temperature is low; leakage is avoided; the energy storing particles are good in energy storing effect, and high in stability; the floor heating mortar is highin strength, and the indoor temperature can be effectively conditioned, and the energy saving effect is good; and various buildings such as a house, a school and a hospital widely apply.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Pulsating heat pipe active thermal protection structure coupled with ablative resistant materials

ActiveCN109178348ASmall changes in aerodynamic shapeGood aerodynamic characteristicsCosmonautic thermal protectionThermal conductivityAerodynamics

A pulsating heat pipe active thermal protection structure coupled with ablative resistant materials comprises a thermal grooming device and ablative resistant materials, wherein the ablative resistantmaterials are coated on the periphery of the thermal grooming device and comprise an inner layer and an outer layer; the inner layer is a flexible foam, and the outer layer is a high thermal conductivity carbon / carbon material; the thermal grooming device comprises a cooling panel, a pulsating heat pipe group and a phase change cold storage box; the cooling panel is bonded with the ablative resistant materials; the pulsating heat pipe group is welded with the cooling panel; the phase change cold storage box is welded with the cooling panel and fixed with the end frame of the aircraft; and thepulsating heat pipe extends into the phase change cold storage box. The pulsating heat pipe active thermal protection structure coupled with ablative resistant materials combine ablation-resistant material with the thermal grooming device. By means of the active thermal protection structure of the sharp lead edge of the aircraft, ablation is reduced or no ablation occur, and the aerodynamic shapeof the aircraft is changed little, and the aerodynamic characteristic of the aircraft with high lift-to-drag ratio is maintained, and the problem of material failure caused by the local high heat ofthe aircraft is solved, and the extreme distribution of temperature is avoided, and the long-time heat insulation is realized.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

Vermicular graphite cast iron cylinder cover material of heavy-duty diesel oil engine and preparation technology thereof

A vermicular graphite cast iron cylinder cover material of a heavy-duty diesel oil engine comprises the following raw materials in percentage by weight: 3.60-3.90% of C, 1.90-2.50% of Si, 0.50-0.70% of Mn, 0.4-0.6% of Mo, 0.70-0.85% of Cu, 0.2-0.4% of Cr, 0.01-0.025% of Mg, 0.025-0.04% of Re, not greater than 0.070% of P, not greater than 0.015% of S, and the balance Fe and inevitable impurities.A preparation technology comprises the steps of pressing from the bottom of a ladle and nucleating by a ladle bottom pouring method; supplementing a nucleating agent while 78-85% of molten iron is output; and then nucleating along with stream. According to the preparation technology adopting the design, the comprehensive mechanical property of the material is obviously improved; and moreover, thevermicularity and the pearlite content are stable; and the production cost is decreased.

Owner:DONGFENG COMML VEHICLE CO LTD

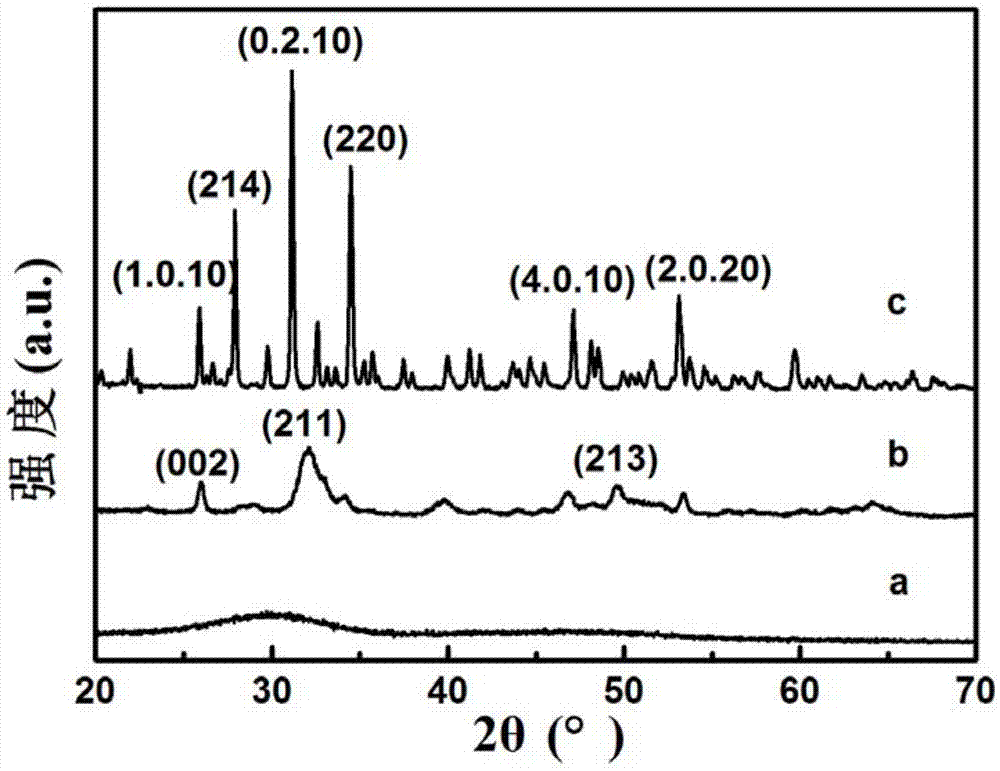

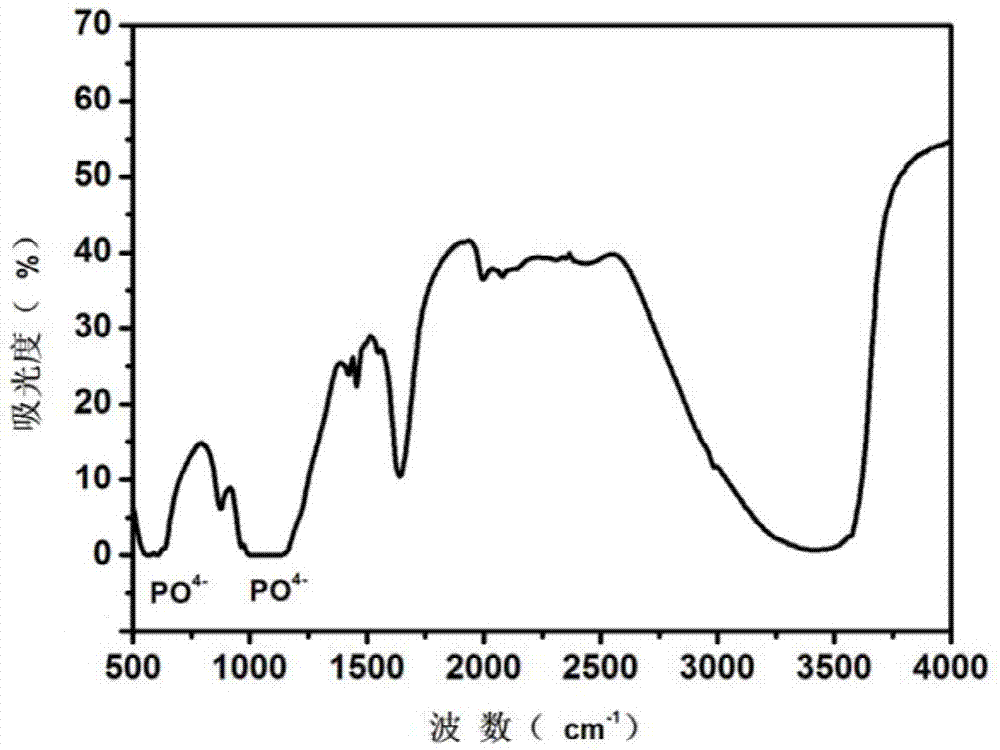

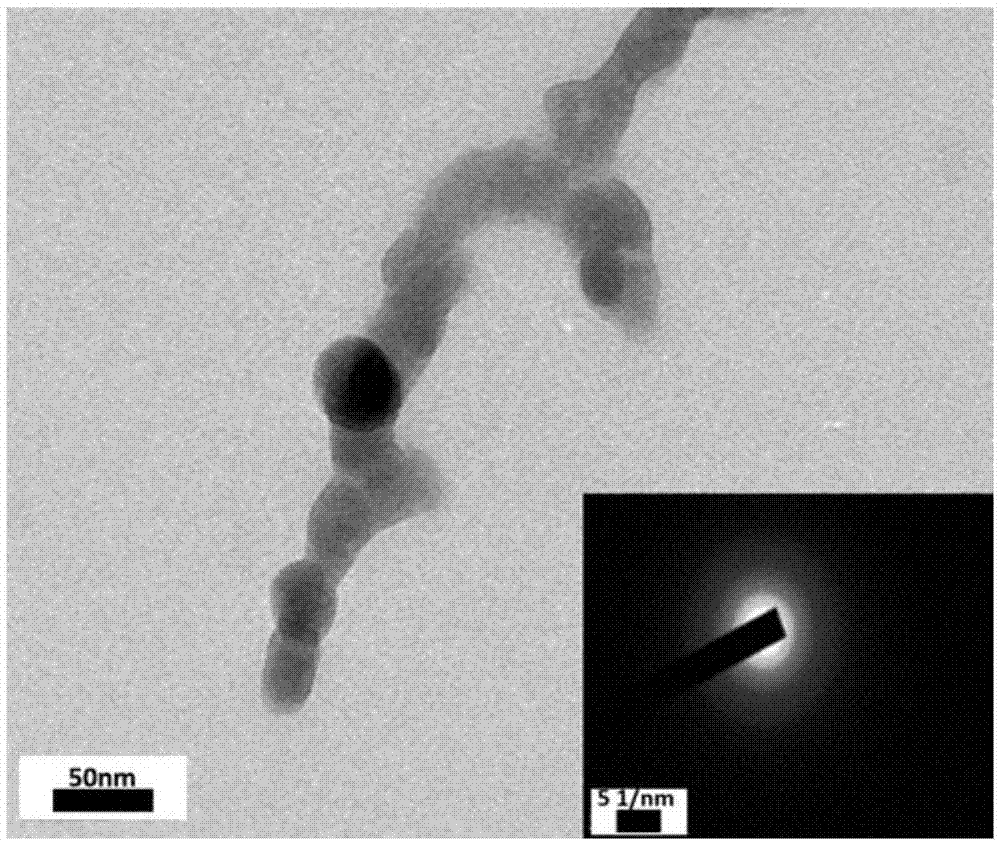

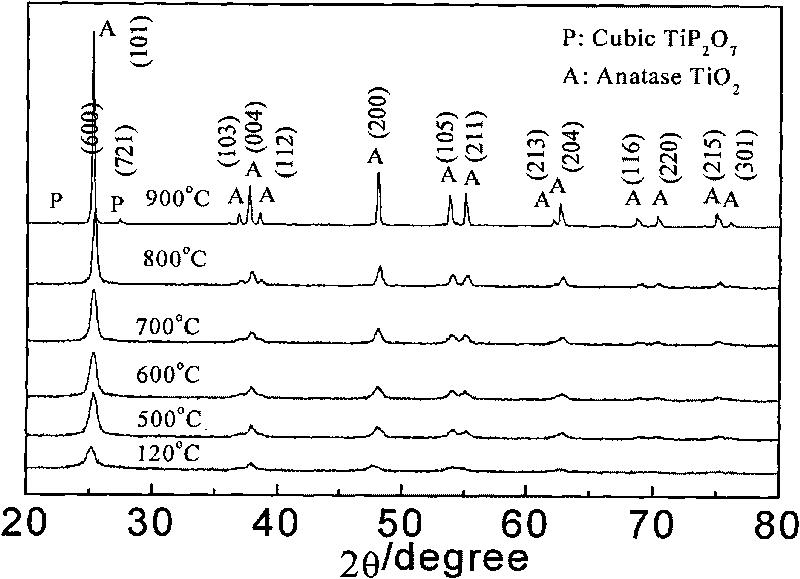

Phosphor doping type nano titanium dioxide having efficient sunlight catalytic capability and preparation method thereof

InactiveCN101690896AHigh phase transition temperatureWater/sewage treatment by irradiationWater contaminantsPhotocatalytic degradationChemistry

The invention relates to phosphor doping type nano titanium dioxide having efficient sunlight catalytic capability and a preparation method thereof. The average grain size of the phosphor doping type nano titanium dioxide is no more than15nm, and the specific surface of the nano titanium dioxide is 126.9m<2> / g. The preparation method is: taking tetrabutyl titanate as titanium source and phosphoric acid as phosphorus source, and using sol-gel method to synthesize phosphor doping type nano titanium dioxide grains; and grinding the obtained solid to be fine, and calcining at 400-900 DEG C to obtain P doping nano titanium dioxide grains. The best calcination temperature is 500 DEG C. The invention only requires to add phosphoric acid in alcoholic solution of tetrabutyl titanate to obtain phosphor doping nano titanium dioxide grains. When the nano grains are used for performing photocatalytic degradation on dye rhodamine B, sunlight can be directly adopted as the light source, and under the same conditions, the efficiency of photocatalytic degradation can exceed the commercial P25.

Owner:NANJING NORMAL UNIVERSITY

Metal fluoride high-temperature phase change energy storage microcapsule, preparation method and application thereof

ActiveCN111394067AExpand material sourcesLow costHeat-exchange elementsPhysical chemistryCarbonization

The invention provides a metal fluoride high-temperature phase change energy storage microcapsule, a preparation method and application thereof. The preparation method of the high-temperature phase change microcapsule comprises the following steps: dispersing metal fluoride particles into a solution of phenolic resin, adding a poor solvent into the system, inducing phase separation of phenolic resin for deposition on the surfaces of the metal fluoride particles, performing heating, controlling in-situ curing of the phenolic resin, performing filtering, collecting solids, and conducting post-curing to obtain phenolic resin coated metal fluoride microcapsules, and conducting carbonizing treatment to obtain the carbon shell layer coated metal fluoride microcapsules. The phase change energy storage microcapsule provided by the invention has a core-shell structure, wherein the core is a simple metal fluoride, the shell is formed by carbonizing phenolic resin at high temperature, and the prepared high-temperature phase change heat storage microcapsule has the advantages of high coating rate, good heat-conducting properties, good high-temperature resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

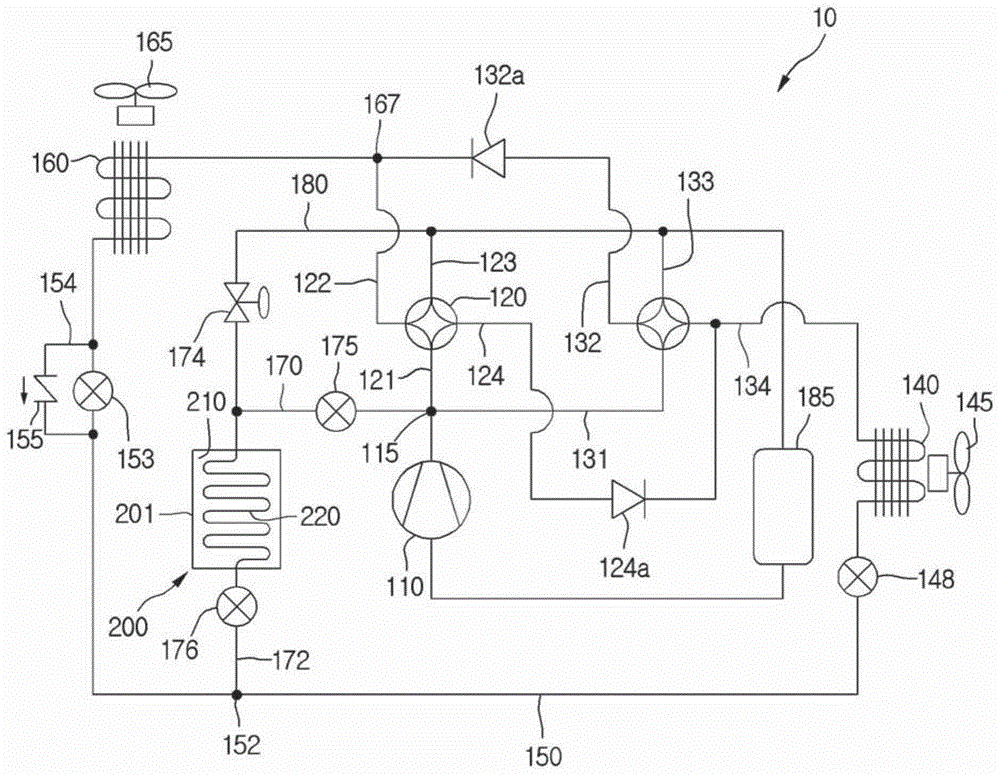

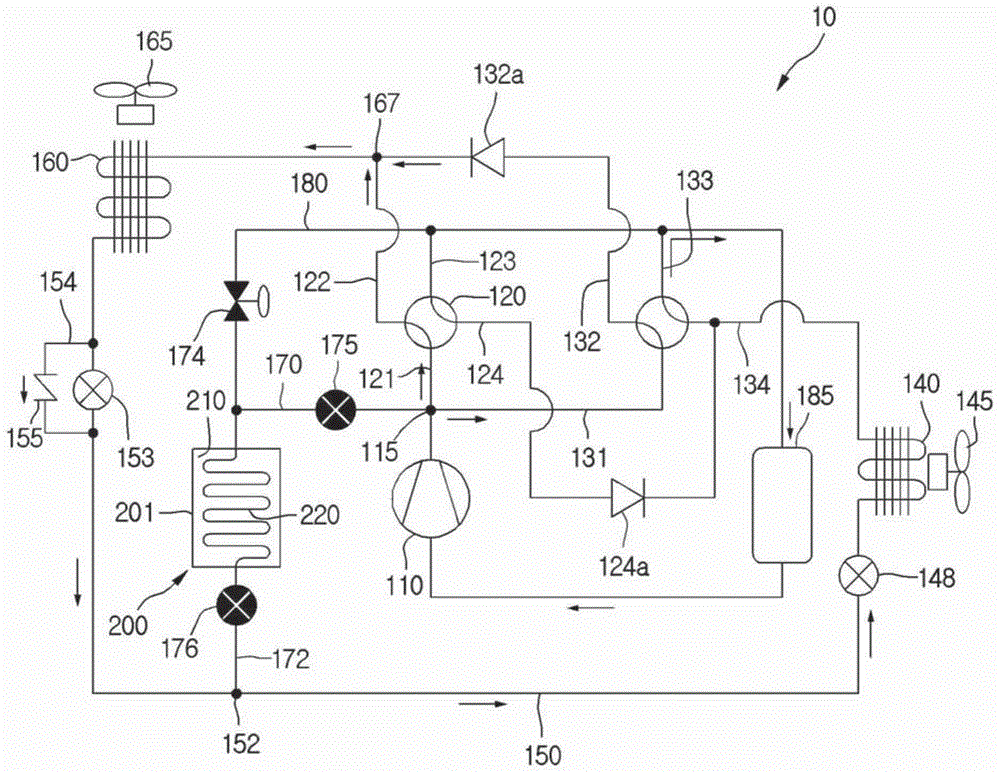

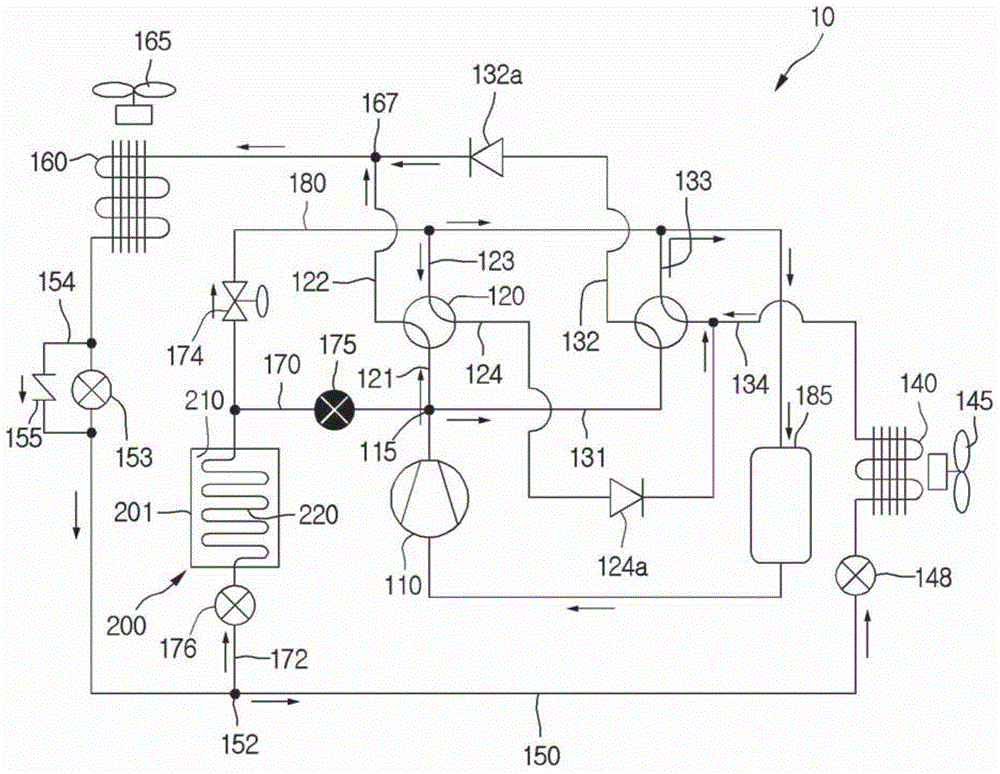

Heat accumulating type air conditioning plant and control method thereof

ActiveCN105299797AEasy to defrostFunction increaseMechanical apparatusHeat storage plantsEngineeringAir conditioning

The present invention provides a heat accumulating type air conditioning plant and a control method thereof. The heat accumulating type air conditioning plant is able to be driven through double heat sources and double loads of a heat storage tank. The heat accumulating type air conditioning plant comprises a compressor, an outer heat exchanger, an indoor heat exchanger and a heat storage tank, and also comprises a first valve device and a second valve device which are used for switching the flow direction of refrigerating fluid compressed in the compressor; a first branch part arranged at the outlet of the compressor and configured to perform branching the refrigerating fluid compressed in the compressor to the first valve and the second valve or the heat storage tank; a first storage tank connection pipe configured to extend from the first branch part to the heat storage tank, a condenser pipe configured to extend from the outer heat exchanger to the indoor heat exchanger, and a second storage tank connection pipe configured to extend from the heat storage tank to the condenser pipe.

Owner:LG ELECTRONICS INC

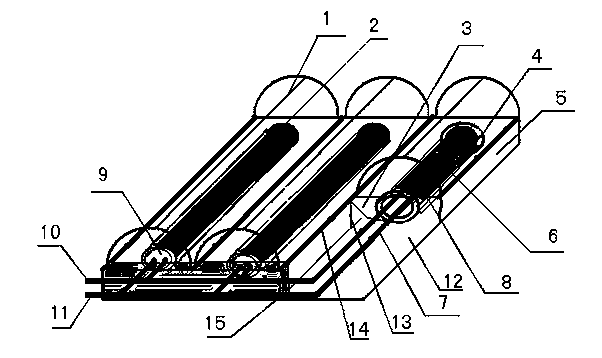

Light condensation solar water heater device based on phase-change heat accumulation

ActiveCN103615814AIncrease profitIncrease solar radiation energySolar heating energySolar heat devicesThermodynamicsSolar water

A light condensation solar water heater device based on phase-change heat accumulation comprises a cylindrical lens light condenser, a vacuum heat collecting pipe, a phase-change medium, two aluminum slot walls, a water heat substrate, a heat exchanging pipe, an aluminum alloy outer frame, reinforcing ribs, a small platform, a cold water main pipe, and a hot water main pipe. The cylindrical lens light condenser covers the uppermost of the vacuum heat collecting pipe. The light rays entering the cylindrical lens light condenser are condensed to form a light focal strip. The lower portion of the cylindrical lens light condenser is connected with the aluminum slot walls of the water heater substrate. The two aluminum slot walls form two plane mirrors in angled opposition. Parts of the light rays refracted by the light condenser is condensed to the vacuum heat collecting pipe, and the other parts, do not project to the vacuum heat collecting pipe, of the light rays are reflected by the two aluminum slot wall plane mirrors and projected to the vacuum heat collecting pipe. The phase-change medium and the U-shaped heat exchanging pipe are disposed inside the vacuum heat collecting pipe. The vacuum heat collecting pipe is fixedly clamped into a clamp groove formed in the water heat substrate.

Owner:徐州野马锂电科技有限公司

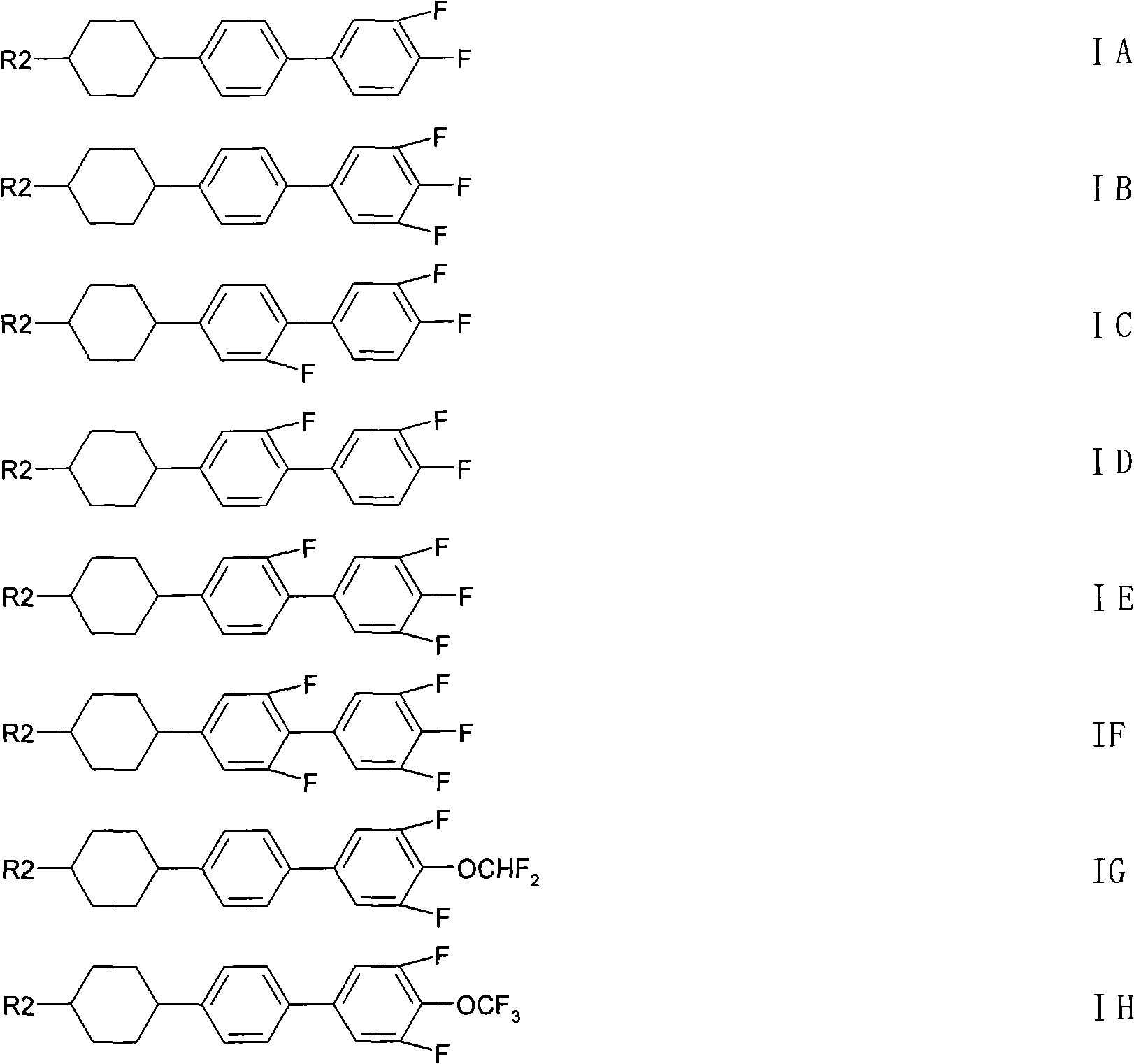

Nematic liquid crystal composition

InactiveCN101608120AImprove performanceLower average response timeLiquid crystal compositionsPolymer scienceTotal response

The invention provides a nematic liquid crystal composition, which comprises 5 to 50 weight percent of nematic liquid crystal composition represented by a formula I, wherein R1 is an alkyl having 1 to 12 carbon atoms or an group formed by substituting a -CH=CH- for one or two nonadjacent groups of the alkyl; and L1, L2, L3 and L4 are Hs or Fs independent from one another; M is F, -CN, -OCF3 or -OCHF2. The composition of the invention has excellent performance and extremely short total response time (ttot=ton+toff), particularly excellent response in a low temperature state, such as 30 DEG C below zero. In addition, the composition has high phase-transition temperature, a clearing point up to 12 DEG C and excellent temperature dependence and can be used in 16 channels at a working temperature of between 40 and 80 DEG C below zero and TN-LCDs at a temperature of below 40 and 80 DEG C below zero.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

Liquid crystal composition having high-speed response property and liquid crystal display using the same

ActiveUS7045176B2Increase brightnessIncreased refractive index anisotropyLiquid crystal compositionsThin material handlingCrystallographyLiquid-crystal display

The present invention relates to a liquid crystal composition having a high-speed response property and a liquid crystal display using the same, more particularly to a liquid crystal composition, wherein the liquid crystal has a high phase transition temperature, large birefringence index and modulus of elasticity, and a wide operable nematic temperature range, so that a high-speed response can be obtained to be useful for many liquid crystal devices including LCDs, and a liquid crystal display using the same.

Owner:SAMSUNG DISPLAY CO LTD

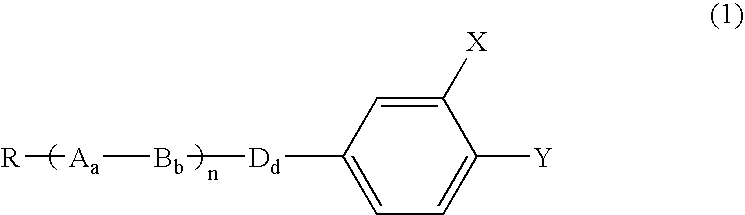

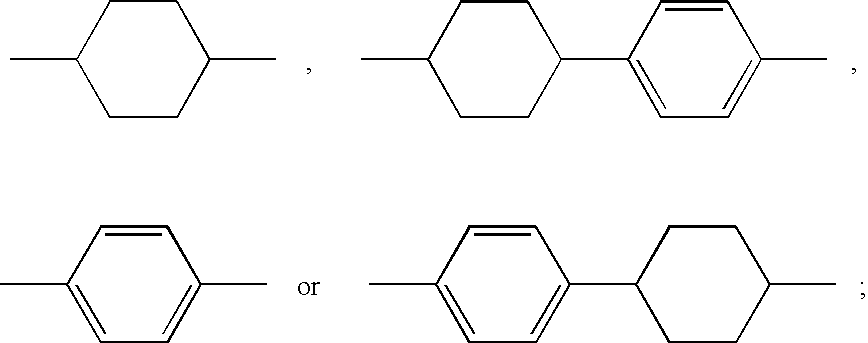

Nematic liquid crystal composition

InactiveUS7063805B2High phase transition temperatureIncrease speedLiquid crystal compositionsNon-linear opticsCrystallographyDielectric anisotropy

A nematic liquid crystal composition includes a compound of formula (1) and a host mixture:wherein ‘R’ is chosen from CnH2n+1O, CnH2n+1, CnH2n+1S or CnH2n−1; ‘n’ is an integer of 1 to 15; ‘A’ is‘a’ is 0 or 1; ‘B’ is —CH2CH2—, —C═C—, —C≡C— or‘b’ is 0 or 1; ‘D’ is—CH2CH2—, —C═C— or —C≡C—; ‘d’ is 0 or 1; ‘X’ is H, F, Cl, Br, NCS or CN; and ‘Y’ is from NCS, SCN or F. A liquid crystal display apparatus employing the nematic liquid crystal composition has a high response speed and a high phase transition temperature. In addition, the nematic liquid crystal composition has an augmented birefringence and a dielectric anisotropy. The liquid crystal display apparatus using the nematic liquid crystal composition may have an enhanced brightness.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com