High-damping manganese-copper alloy for wide-temperature-range service and preparation method thereof

A technology of manganese-copper alloy and high damping, which is applied in the field of preparation methods of manganese-copper-based alloys with high performance, can solve the problems of unsatisfactory vibration and noise control requirements, unstable damping performance of manganese-copper alloy, complex alloy preparation process, etc., and achieve favorable The effect of micron-scale twinning movement, suitable dislocation slip, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

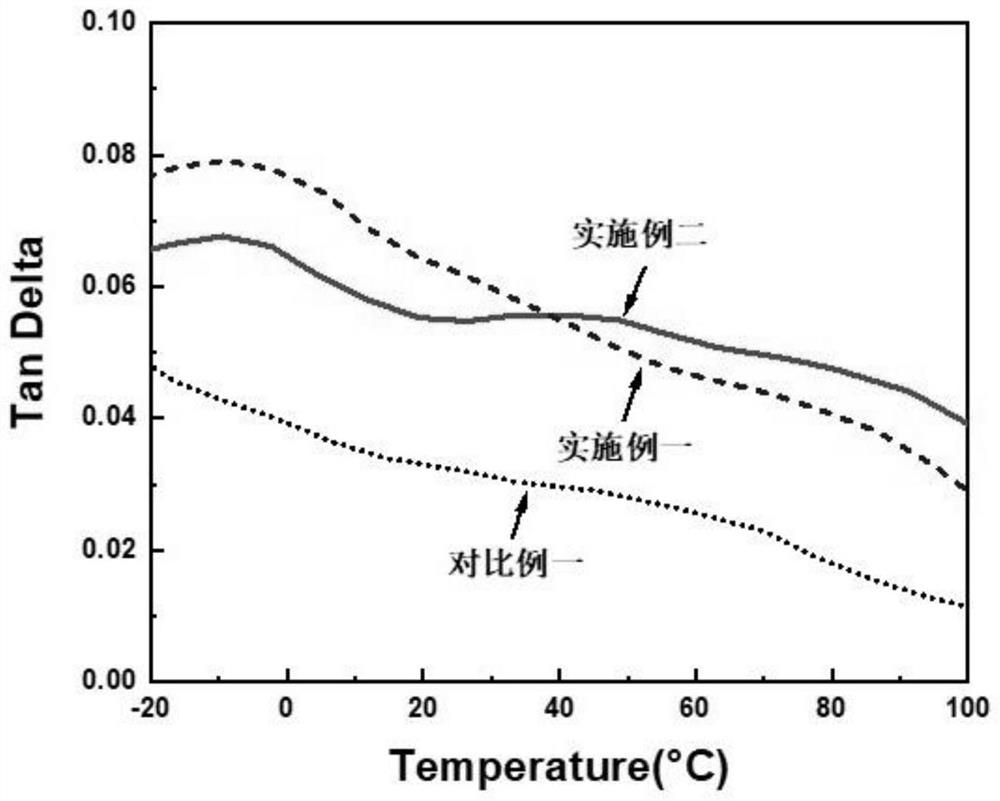

Embodiment 1

[0052] In this embodiment, a high-damping manganese-copper alloy for service in a wide temperature range, the mass percentage ratio of chemical elements is: Mn-15wt.%Cu-5wt.%Ni-2.5wt.%Fe-0.1wt .% Co.

[0053] A preparation method of the high-damping manganese-copper alloy used in this embodiment for service in a wide temperature range, comprising the following steps:

[0054] (1) Raw material preparation and master alloy material preparation:

[0055] Weigh the raw materials according to the proportion of alloy elements by weight percentage: 15wt.% Cu, 5wt.% Ni, 2.5wt.% Fe, 0.1wt.% Co, the balance is Mn, put the raw materials in a crucible, and place them in a vacuum induction Melt in the smelting furnace, pass through the argon protective atmosphere during the melting, induction heating to 1350 ℃, keep warm for 30 minutes, so that the raw materials are fully melted, and then cast and solidify the casting master alloy ingot to obtain the cast manganese-copper-based alloy;

...

Embodiment 2

[0063] This embodiment is basically the same as Embodiment 1, especially in that:

[0064] In this embodiment, a high-damping manganese-copper alloy for service in a wide temperature range has a mass percentage ratio of chemical elements: Mn-20wt.%Cu-4.5wt.%Ni-0.5wt.%Co.

[0065] A preparation method of the high-damping manganese-copper alloy used in this embodiment for service in a wide temperature range, comprising the following steps:

[0066] (1) Raw material preparation and master alloy material preparation:

[0067] Weigh the raw materials according to the proportion by weight of the alloy elements: 20wt.% Cu, 4.5wt.% Ni, 0.5wt.% Co, and the balance is Mn. Put the raw materials in a crucible and melt them in a vacuum induction melting furnace. During the melting period, a protective atmosphere of argon gas is introduced, induction heating is carried out to 1350°C, and the temperature is kept for 30 minutes to fully melt the raw materials, and then cast and solidify the ...

Embodiment 3

[0075] This embodiment is basically the same as the previous embodiment, and the special features are:

[0076] In this embodiment, a high-damping manganese-copper alloy used for service in a wide temperature range, its chemical element mass percentage ratio is: Mn-20wt.%Cu-3wt.%Ni-1.5wt.%Zn-0.5wt .%Co-1.0wt.%Sn.

[0077] A preparation method of the high-damping manganese-copper alloy used in this embodiment for wide temperature range service, comprising the following steps:

[0078] (1) Raw material preparation and master alloy material preparation:

[0079] Weigh the raw materials according to the proportion of alloy elements by weight: 20wt.% Cu, 3wt.% Ni, 1.5wt.% Zn, 0.5wt.% Co, 1.0wt.% Sn, the balance is Mn, put the raw materials in the crucible Put it in a vacuum induction melting furnace and melt it. During the melting period, argon protective atmosphere is introduced, induction heated to 1350 ° C, and kept for 40 minutes, so that the raw materials are fully melted, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com