Method for manufacturing transformation induced plasticity steel seamless tube on line

A phase change-induced plasticity and seamless pipe technology, applied in the field of steel rolling, can solve the problems of long heating time of steel pipe, unsatisfactory performance improvement effect, and difficulty in obtaining fine grains, etc., and achieve excellent cold forming performance, good strength-plasticity Matching, Effect of High Work Hardening Index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The chemical composition of the steel used in this embodiment is: 0.146%C, 1.227%Si, 1.321%Mn, 0.0295%Nb, 0.024%Ti, 0.004%S, 0.001%P, and the balance is Fe and impurities. ;

[0029] A cold-drawn seamless steel pipe with a wall thickness of 1.3mm and a diameter of 42mm is heated to a critical zone of 800°C at a heating rate of 35°C / s with an intermediate frequency heating induction coil, and annealed for 10s;

[0030] Compressed air is used for cooling, and the steel pipe annealed in the critical zone is cooled to 420°C in the bainite zone at a rate of 60°C / s, and isothermally treated for 30s;

[0031] The steel pipe after the isothermal treatment in the bainite zone is air-cooled to room temperature to obtain a phase transformation induced plasticity steel seamless pipe.

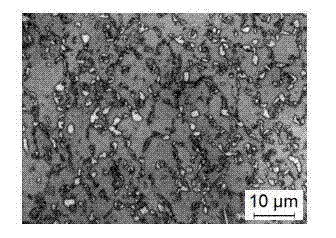

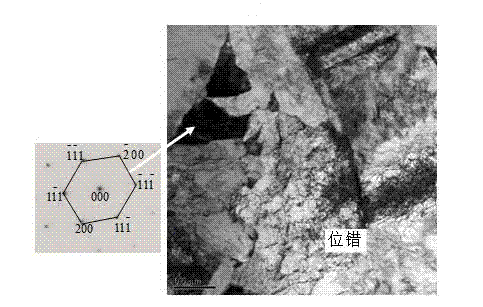

[0032] Metallographic samples were cut from the middle part of the prepared phase change induced plasticity steel seamless pipe, and after grinding and polishing, Lepera (mass fraction was 1%Na 2 S...

Embodiment 2

[0037] The chemical composition of the steel used in this embodiment is: 0.146%C, 1.127%Si, 1.321%Mn, 0.0295%Nb, 0.024%Ti, 0.003%S, 0.004%P, and the balance is Fe and impurities. ;

[0038] A cold-drawn seamless steel pipe with a wall thickness of 1.3mm and a diameter of 42mm is heated to a critical zone of 810°C at a heating rate of 600°C / s by an intermediate frequency heating induction coil, and annealed for 20s;

[0039]Compressed air is used for cooling, and the steel pipe annealed in the critical zone is cooled to 420°C in the bainite zone at a rate of 60°C / s, and isothermally treated for 30s;

[0040] Air-cool the steel pipe after isothermal treatment in the bainite zone to room temperature to obtain the phase transformation induced plasticity steel seamless pipe of the present invention.

[0041] The rapid heating in this example makes the steel pipe sample almost lose the preheating process, and the sample reaches the predetermined critical temperature in a very short...

Embodiment 3

[0045] The chemical composition of the steel used in this embodiment is: 0.14%C, 1.30%Si, 1.60%Mn, 0.015%Nb, 0.02%Ti, 0.002%S, 0.002%P, and the balance is Fe and impurities.

[0046] A cold-drawn seamless steel pipe with a wall thickness of 5mm and a diameter of 1000mm is heated to a critical zone of 850°C at a heating rate of 400°C / s with an intermediate frequency heating induction coil, and annealed for 5s;

[0047] Cool the steel pipe after the annealing treatment in the critical zone to 450℃ in the bainite zone at a rate of 80℃ / s by using compressed air for cooling, and perform isothermal treatment for 40s;

[0048] The steel pipe after the isothermal treatment in the bainite zone is water-cooled to room temperature to obtain the phase transformation induced plasticity steel seamless pipe of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com