Low-power-consumption phase change film material for multistage phase change storage, and reparation method and application thereof

A technology of phase change storage and thin film materials, applied in electrical components and other directions, can solve the problems of slow phase change speed and high power consumption, and achieve the effect of improving storage density, reducing power consumption and increasing storage density.

- Summary

- Abstract

- Description

- Claims

- Application Information

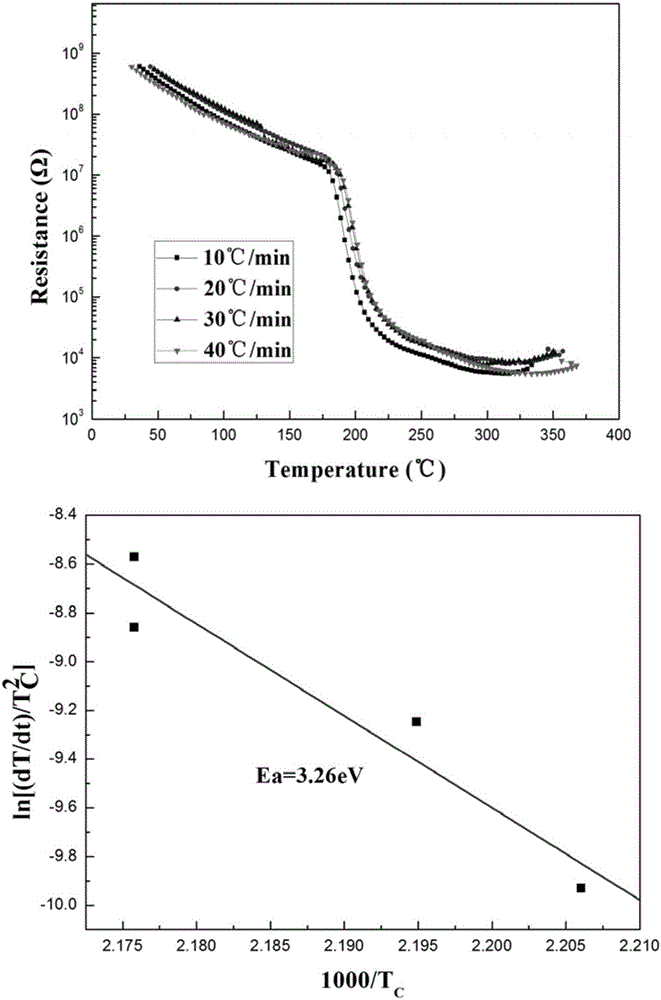

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The single-layer InTe phase-change film prepared in this example has a total thickness of 50 nm.

[0030] 1. Clean SiO2 2 / Si(100) substrate:

[0031] (a) Place the substrate in deionized water, and clean it ultrasonically for 20 minutes to remove dust particles on the surface of the substrate;

[0032] (b) Place the substrate in absolute ethanol, and clean it ultrasonically for 20 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0033] (c) repeating step (b) three times;

[0034] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0035] 2. Preliminary preparation for sputtering InTe film:

[0036] (a) Place the InTe target on the No. 1 target position, fix the processed substrate on the sample stage, and close the sealed vacuum chamber;

[0037] (b) Turn on the mechanical pump and preheat the molecular pump for 5 minutes. When the vacuum reaches 5Pa or below, start the molecular pump and pump the va...

Embodiment 2

[0042] This example prepares InTe-Ga 3 Sb 7 Nanocomposite film, the composition is [InTe(25nm) / Ga 3 Sb 7 (25nm)] 1 , with a total thickness of 50 nm.

[0043] 1. Clean SiO2 2 / Si(100) substrate:

[0044] (a) Place the substrate in deionized water, and clean it ultrasonically for 20 minutes to remove dust particles on the surface of the substrate;

[0045] (b) Place the substrate in absolute ethanol, and clean it ultrasonically for 20 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0046] (c) repeating step (b) three times;

[0047] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0048] 2. Sputtering [InTe(25nm)-Ga 3 Sb 7 (25nm)] 1 Film preparation:

[0049] (a) Combine InTe and Ga 3 Sb 7 The targets are respectively placed on the No. 1 and No. 2 target positions, and the processed substrate is fixed on the sample stage, and the sealed vacuum chamber is closed;

[0050] (b) Turn on the mechanic...

Embodiment 3

[0057] Preparation of InTe-Ge 2 Sb 2 Te 5 Nanocomposite film, the composition is [InTe(25nm) / Ge 2 Sb 2 Te 5 (25nm)] 1 , with a total thickness of 50 nm.

[0058] 1. Clean SiO2 2 / Si(100) substrate:

[0059] (a) Place the substrate in deionized water, and clean it ultrasonically for 20 minutes to remove dust particles on the surface of the substrate;

[0060] (b) Place the substrate in absolute ethanol, and clean it ultrasonically for 20 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0061] (c) repeating step (b) three times;

[0062] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0063] 2. Sputtering [InTe(25nm)-Ge 2 Sb 2 Te 5 (25nm)] 1 Film preparation:

[0064] (a) Combine InTe and Ge 2 Sb 2 Te 5 The targets are respectively placed on the No. 1 and No. 2 target positions, and the processed substrate is fixed on the sample stage, and the sealed vacuum chamber is closed;

[0065] (b) Tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com