Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Raise the strain at break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

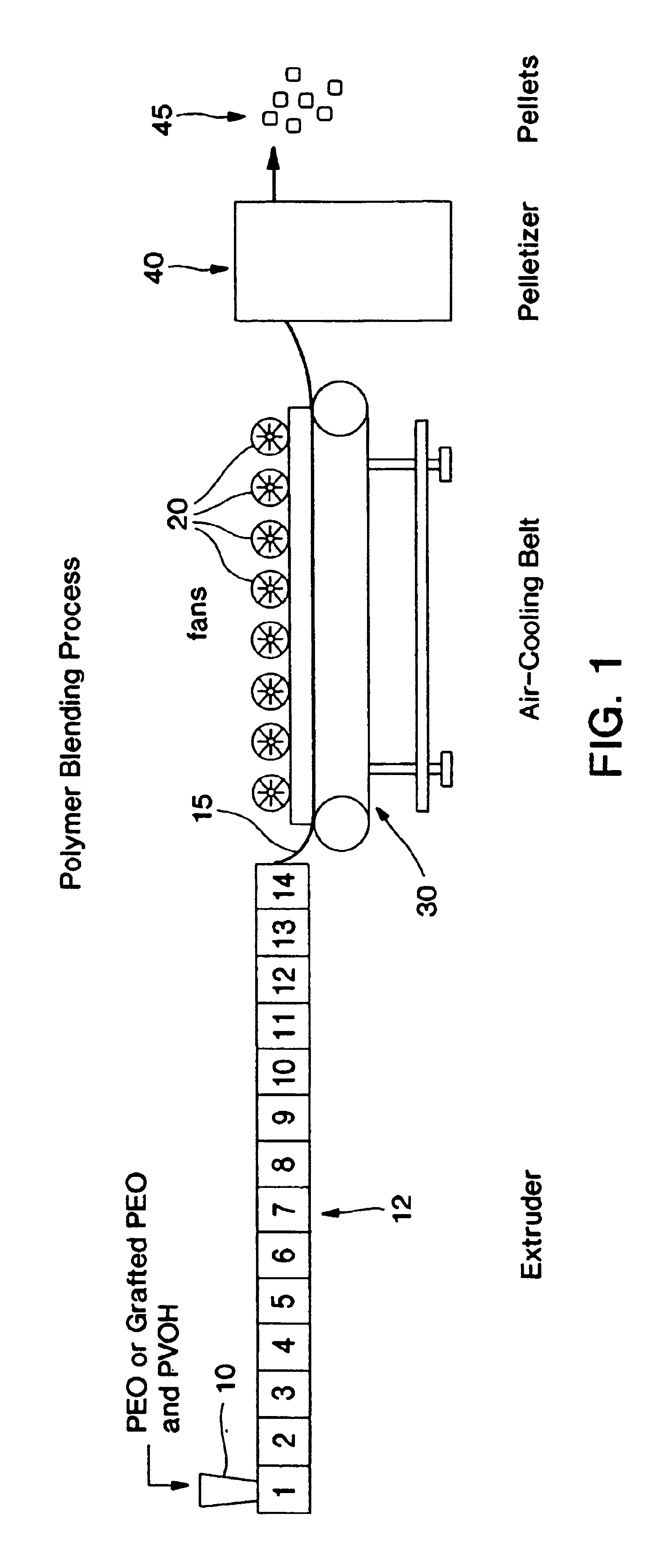

Method of making blends of poly(vinyl alcohol) and poly(ethylene oxide)

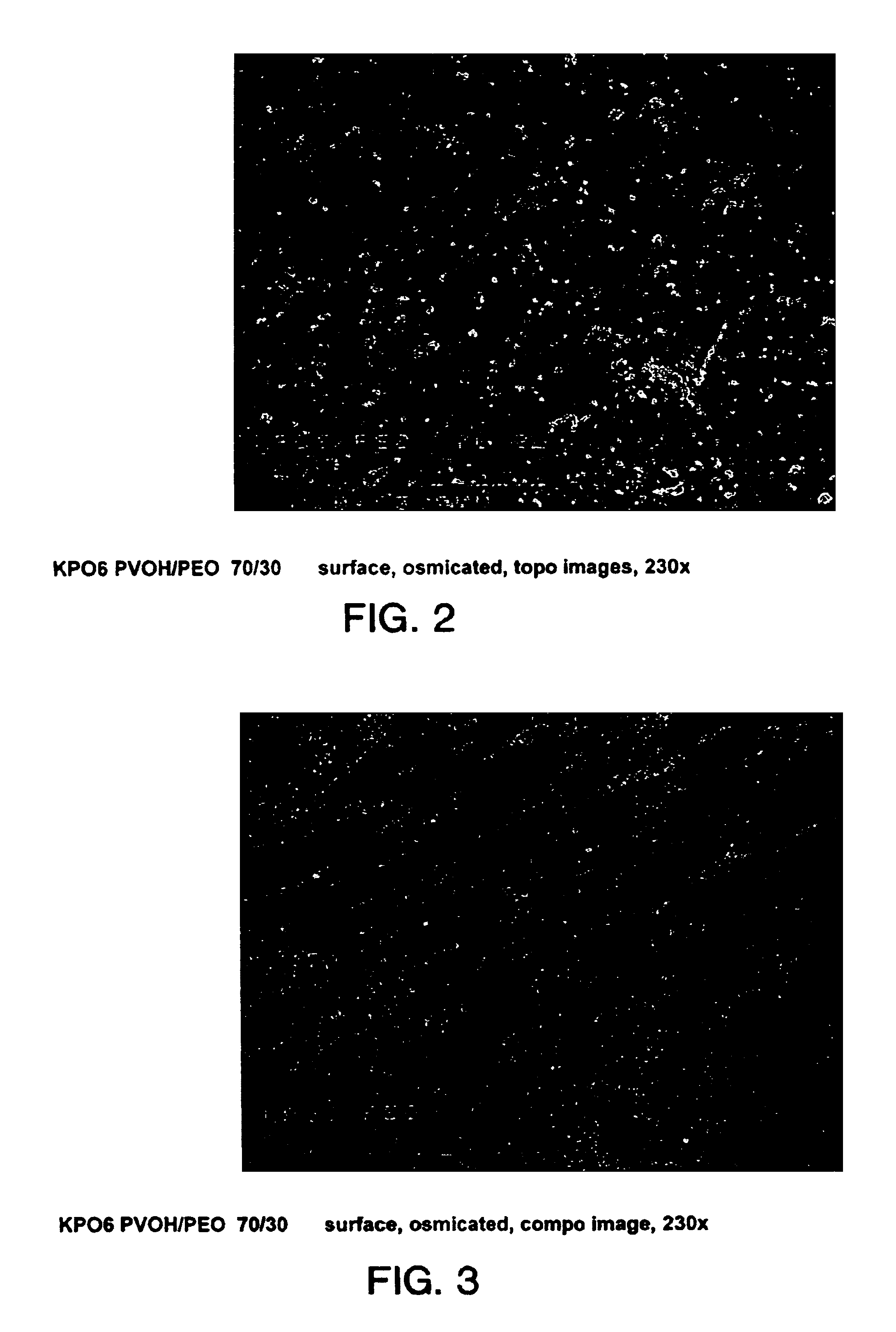

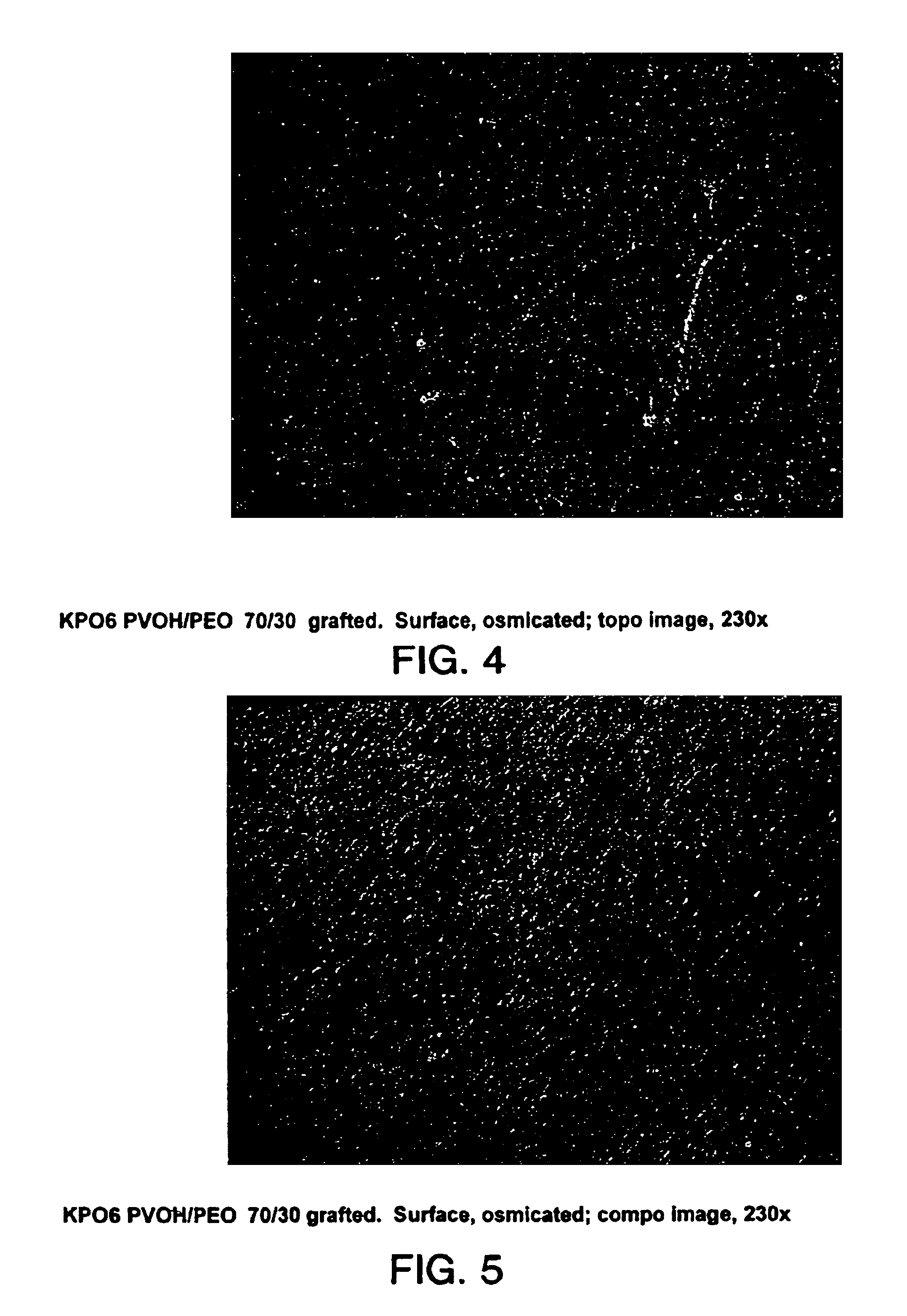

The present invention discloses water-soluble compositions comprising a blend of poly(ethylene oxide) and poly(vinyl alcohol) that have improved ductility over water-soluble compositions comprising poly(vinyl alcohol) alone. In one desirable embodiment of the present invention, the poly(ethylene oxide) component of the blend is grafted. Grafted poly(ethylene oxide) resins have improved processability and improved blend compatibility with poly(vinyl alcohol). Films comprising a melt blend of poly(vinyl alcohol) and grafted poly(ethylene oxide) have improved melt processability as well as other improved properties. Films comprising compositions of the present invention have improved ductility over films comprising poly(vinyl alcohol) alone while retaining much of the high strength and water solubility exhibited by such poly(vinyl alcohol) films.

Owner:KIMBERLY-CLARK WORLDWIDE INC

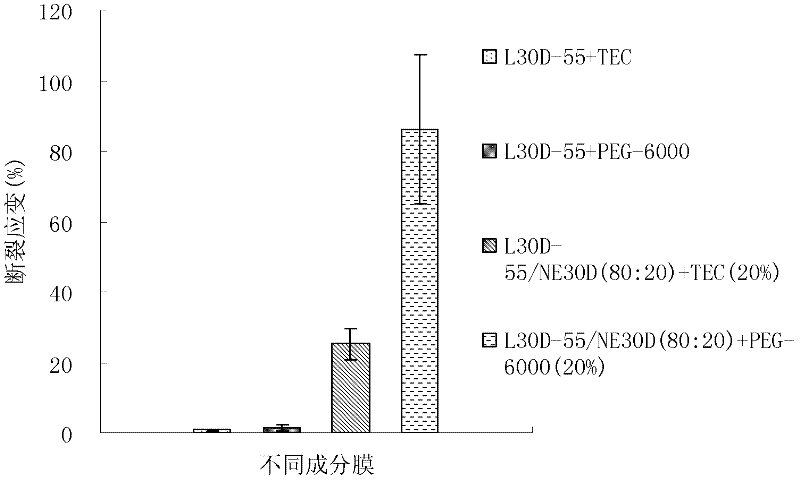

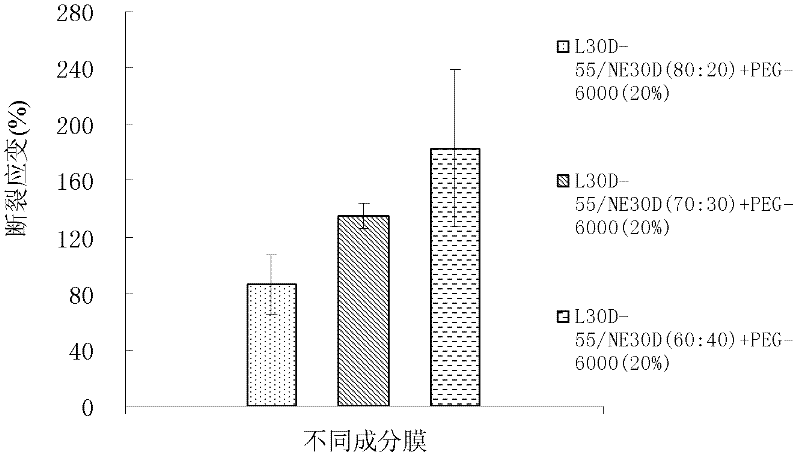

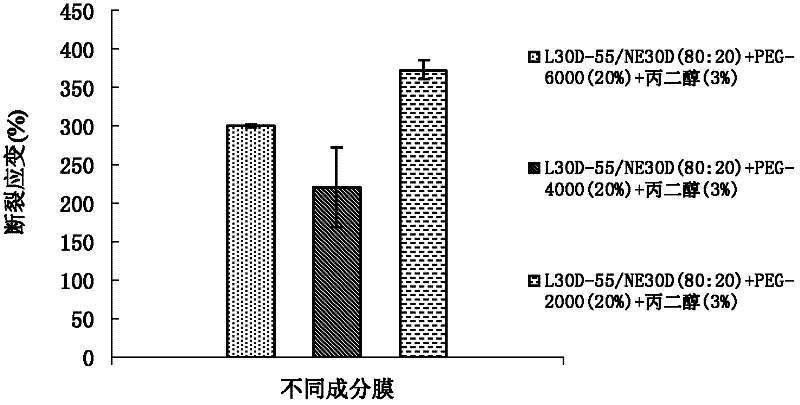

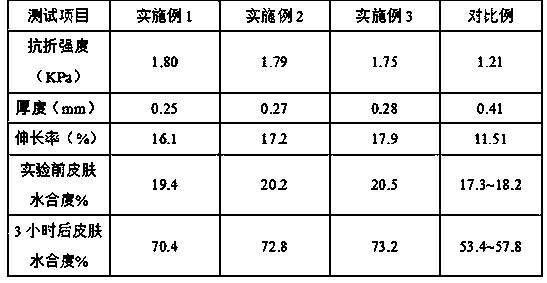

Coating membrane for micro pill tabletting and preparation method for coating membrane

ActiveCN102335433ARaise the strain at breakReduce dosagePharmaceutical delivery mechanismPharmaceutical non-active ingredientsAcrylic resinPlasticizer

The invention relates to the field of medicinal preparations, relates to a formula of a coating membrane which is suitable for micro pill tabletting and a preparation method for the coating membrane, in particular to a formula of a coating membrane for enteric micro pill tabletting. The medicinal micro pill coating membrane is characterized by consisting of an acrylic resin coating material, a macromolecular plasticizer and a micromolecular plasticizer, wherein the macromolecular plasticizer is macromolecular polyethylene glycol. In the formula, the toughness of the coating membrane can be improved obviously under the synergetic effect of the micromolecular plasticizer and the macromolecular plasticizer, and the coating membrane is applied to coated micro pills to ensure that the micro pill coating membrane is not crushed in the tabletting process, so that the coated micro pills are more suitable for the tabletting.

Owner:GUANGDONG HUANAN PHARMACEUTICAL GROUP CO LTD

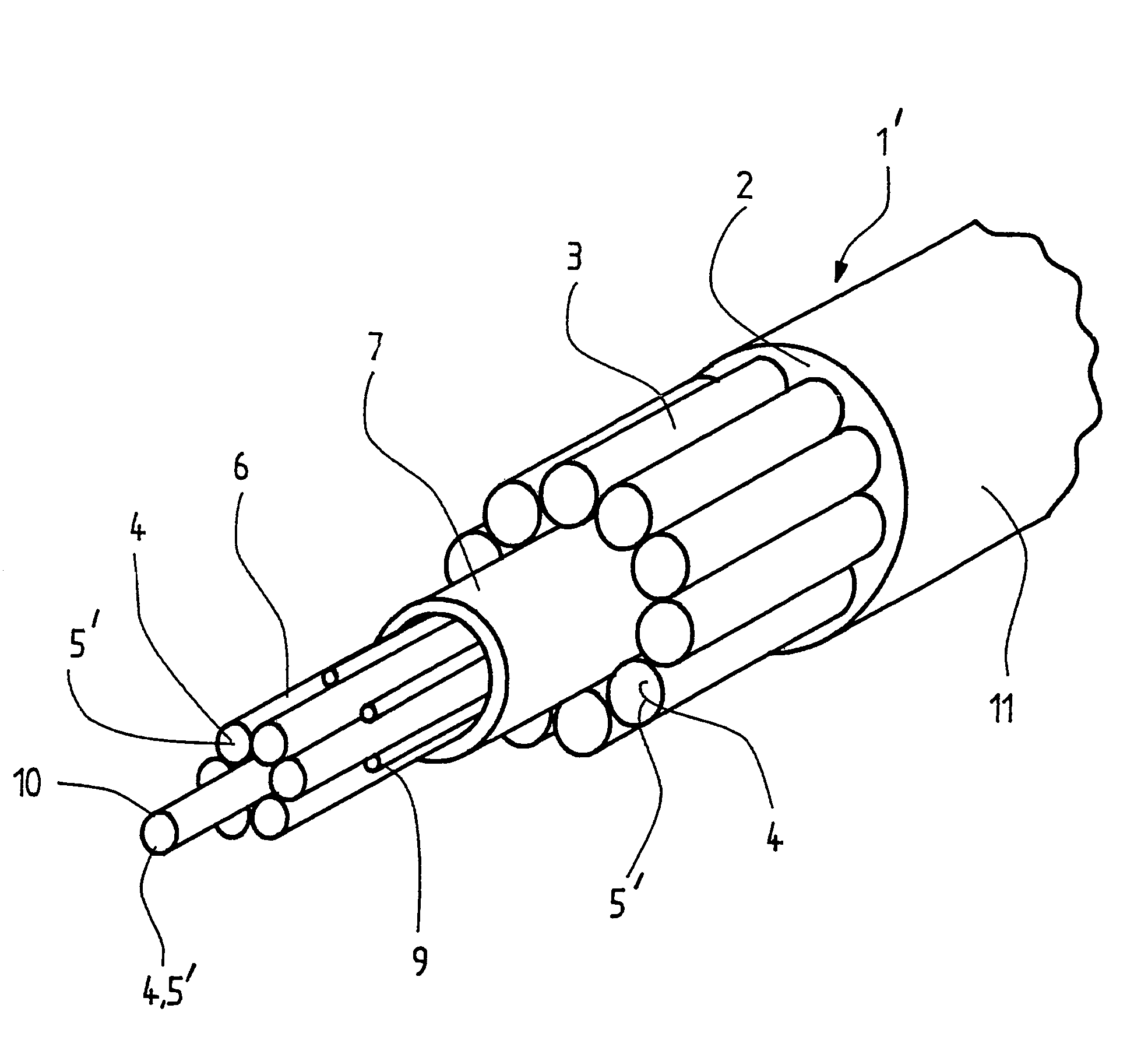

Reinforced synthetic cable for elevators

InactiveUS7828121B2Reduced service lifeToo-small modulus of elasticityWoven fabricsElevatorsSynthetic materialsEngineering

Owner:INVENTIO AG

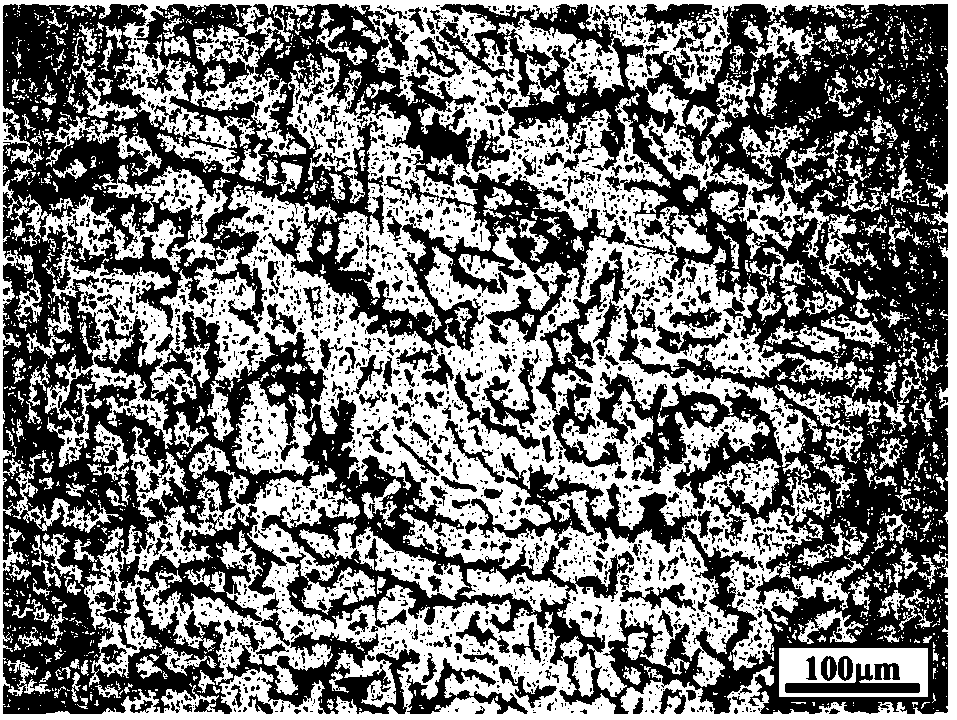

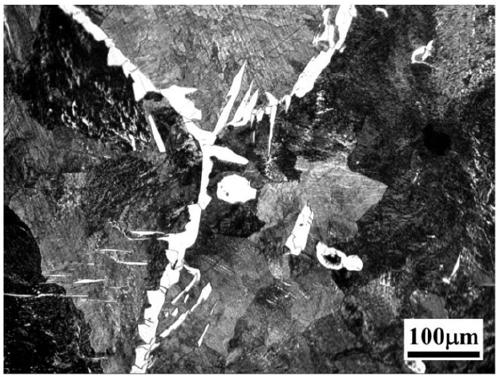

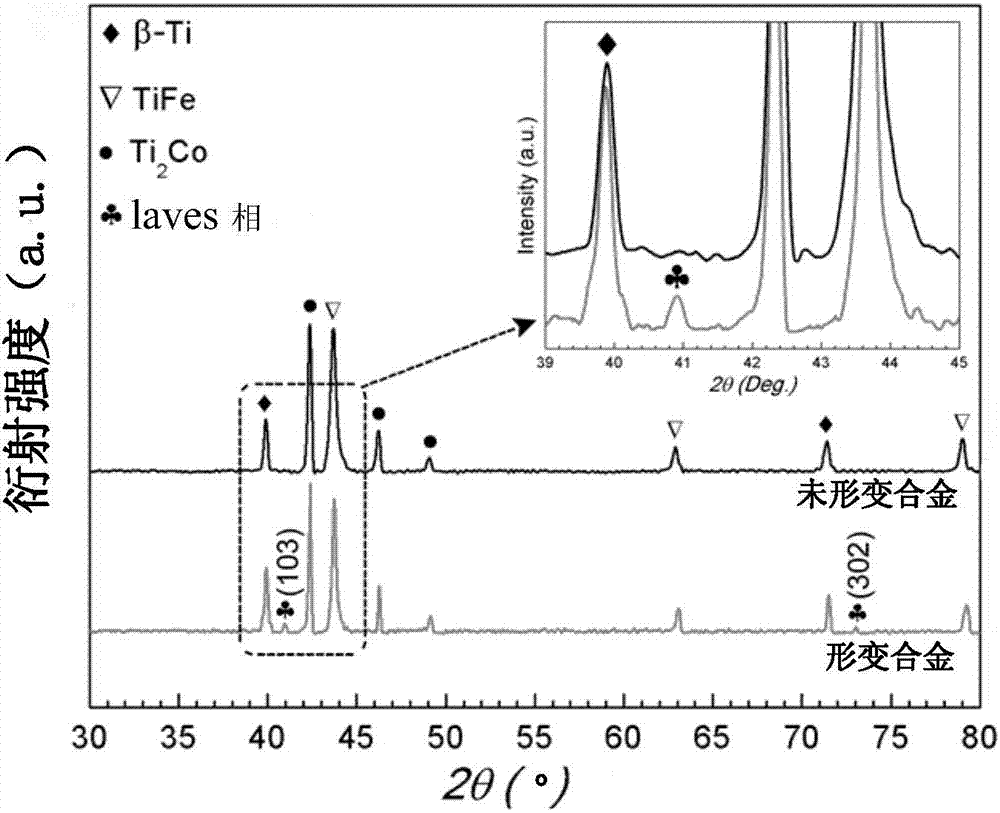

Multi-scale and double-state structure titanium alloy based on eutectic transformation, preparation and application

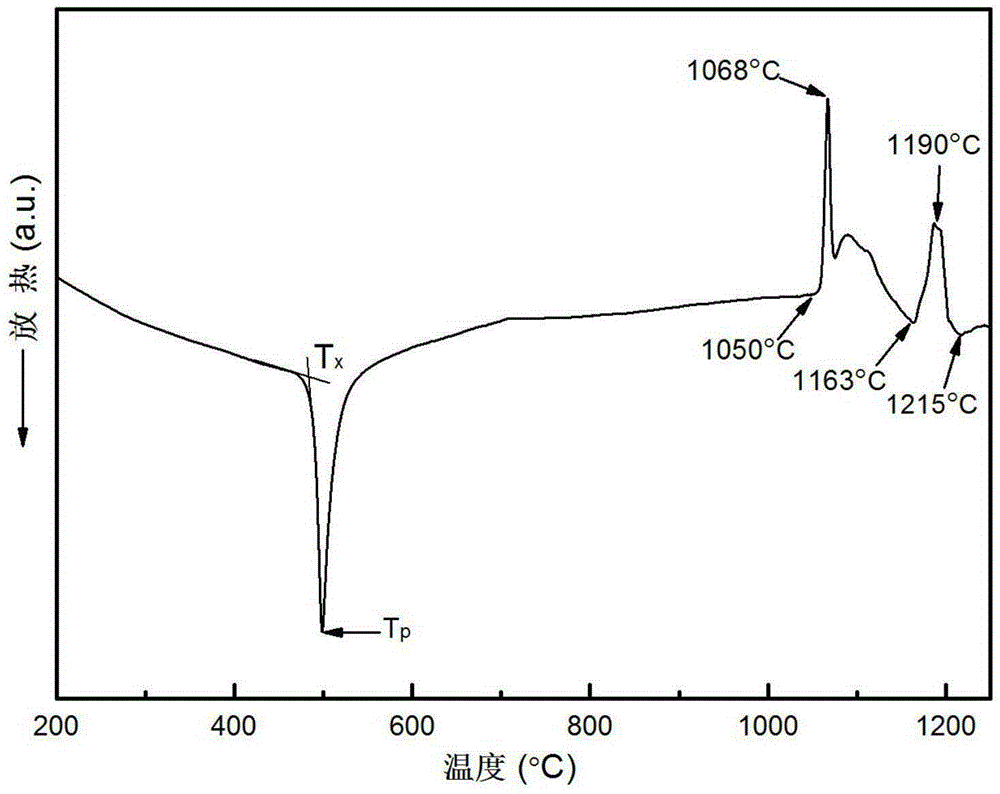

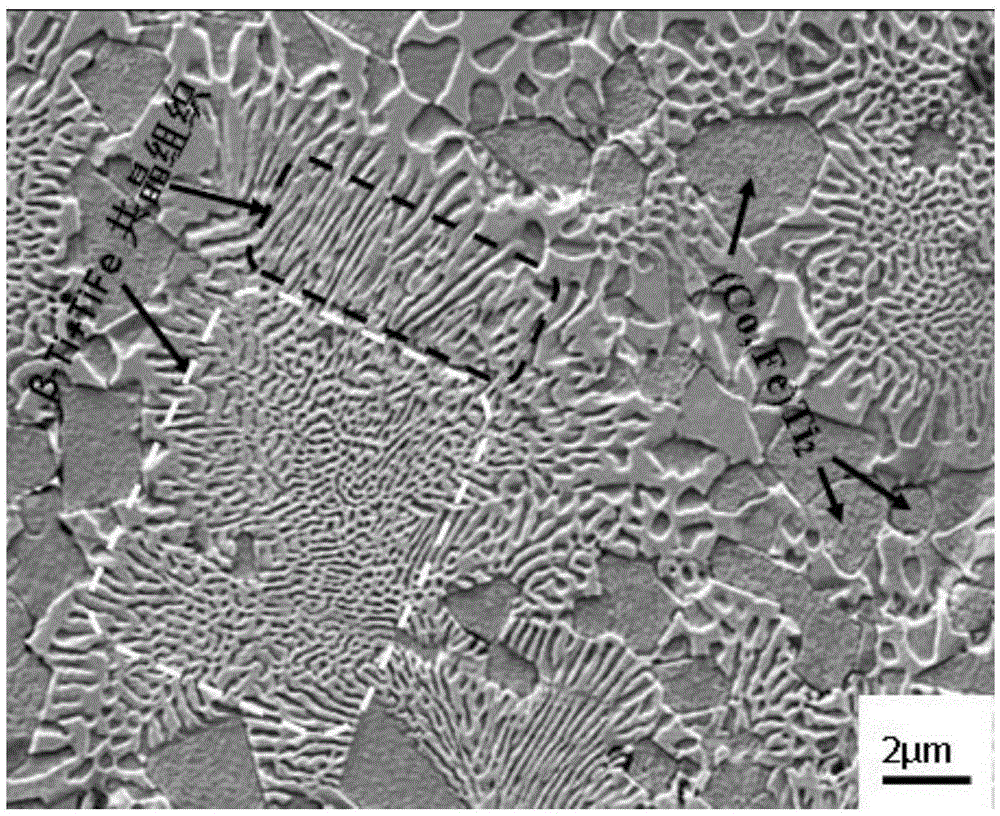

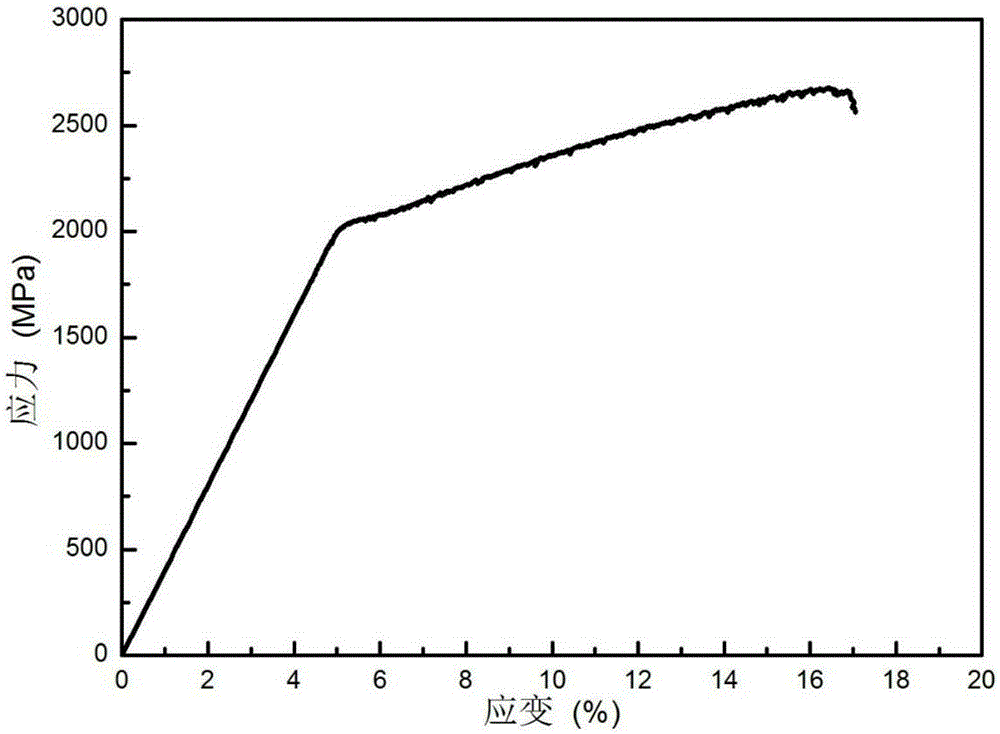

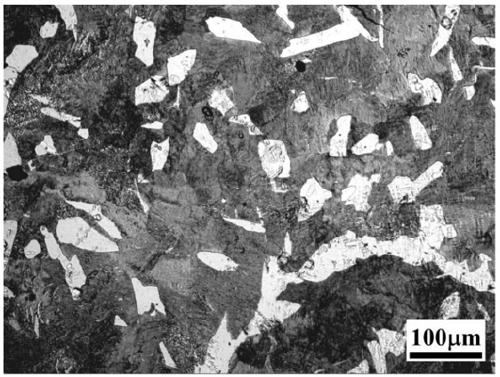

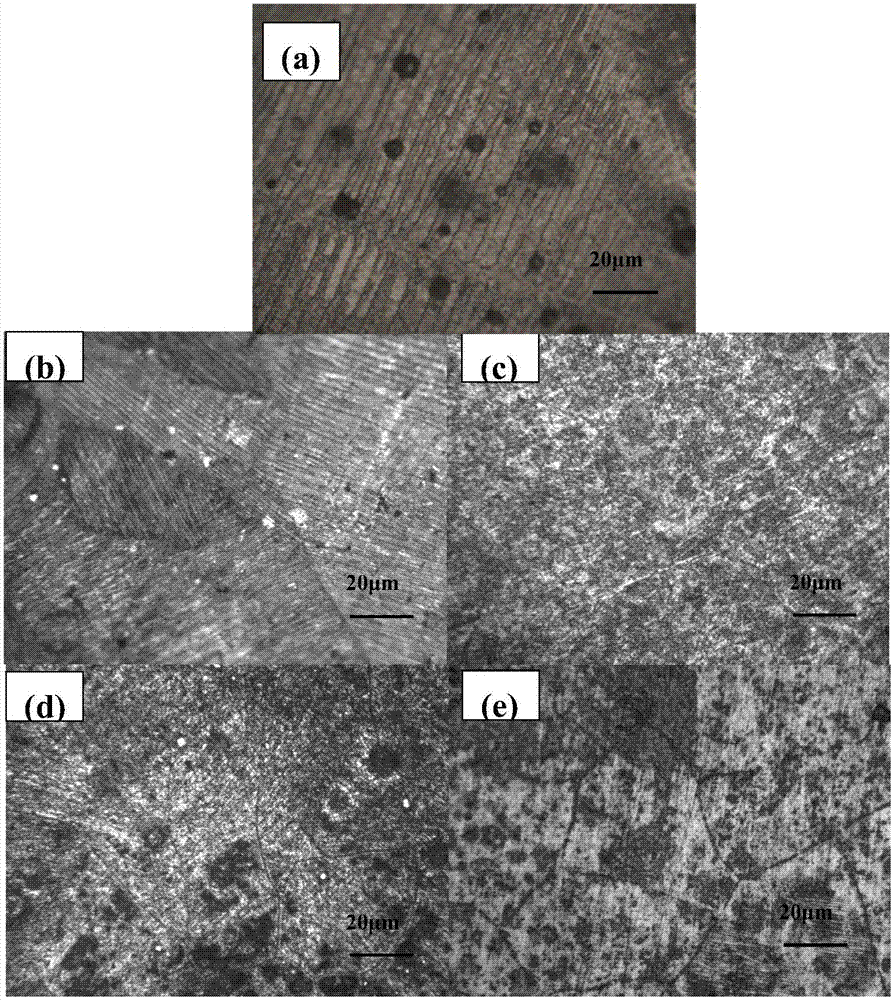

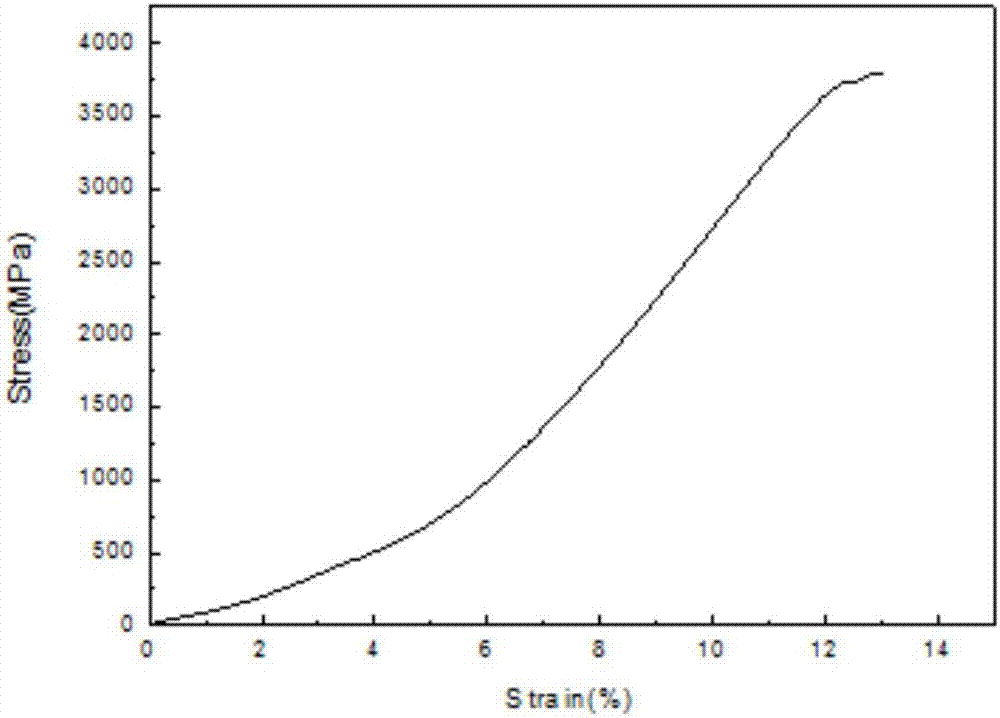

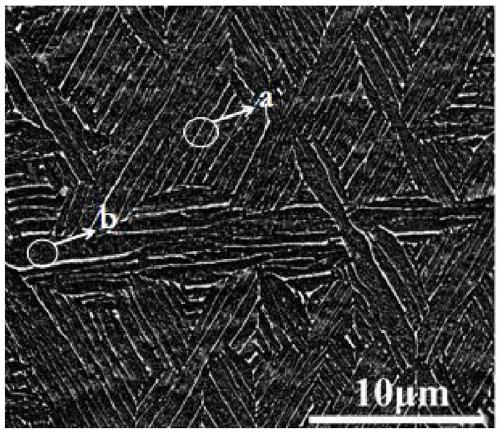

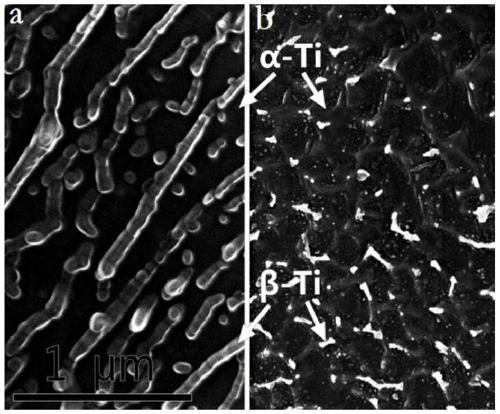

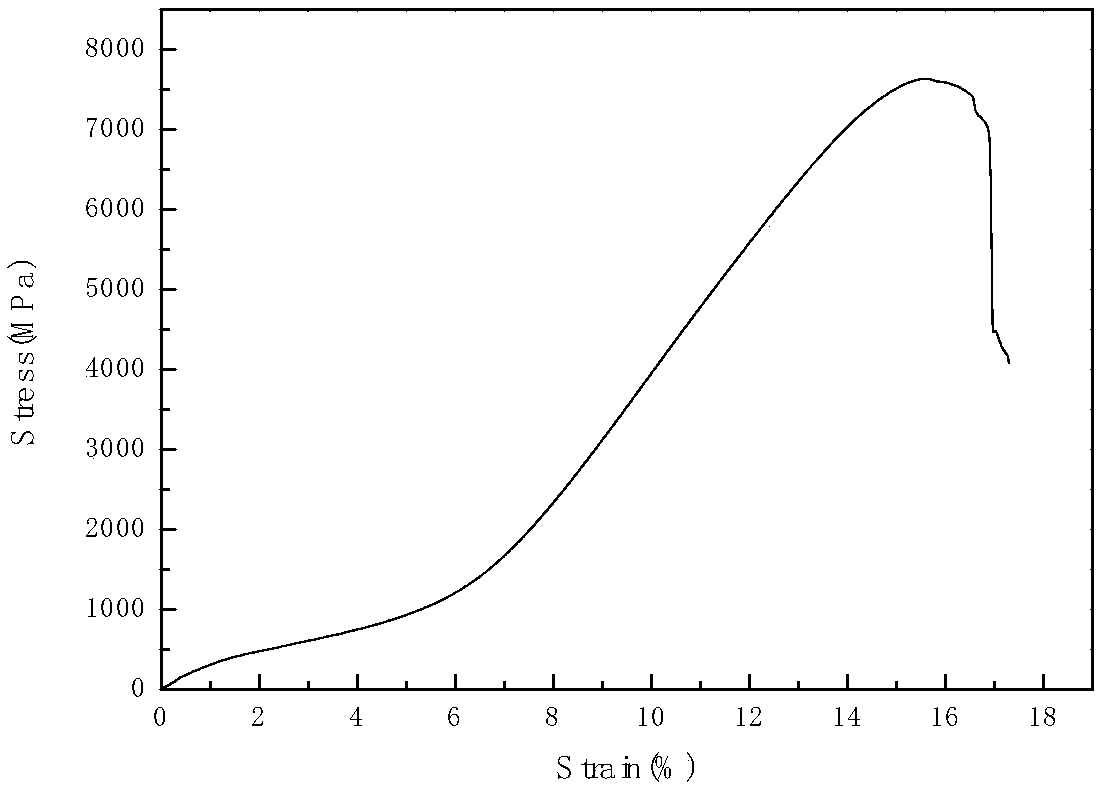

The invention belongs to the technical field of alloy machining and discloses a multi-scale and double-state structure titanium alloy based on eutectic transformation, preparation and application. The alloy is prepared from, by atomic percent, 52.5-62% of Ti, 10.0-14.1% of Nb, 5.5-21.5% of Fe, 8-16.3% of Co and 5.8-6.7% of Al. The microstructure of the multi-scale and double-state structure titanium alloy comprises a lamellar-type eutectic structure base body of nanocrystalline and ultra-fine grains, and an isometric crystal second phase of the micron size. A preparing method includes the three steps of powder mixing, alloy powder preparing through high-energy ball grinding and semi-solid sintering of alloy powder. The sintering temperature is controlled to be between the beginning temperature of eutectic transformation and the melting beginning time, so that the obtained alloy has the nanometer and superfine-scale lamellar-type eutectic structure and an isometric crystal coexisting multi-scale and double-state structure of the micron size, and the performance of the alloy is more superior.

Owner:SOUTH CHINA UNIV OF TECH

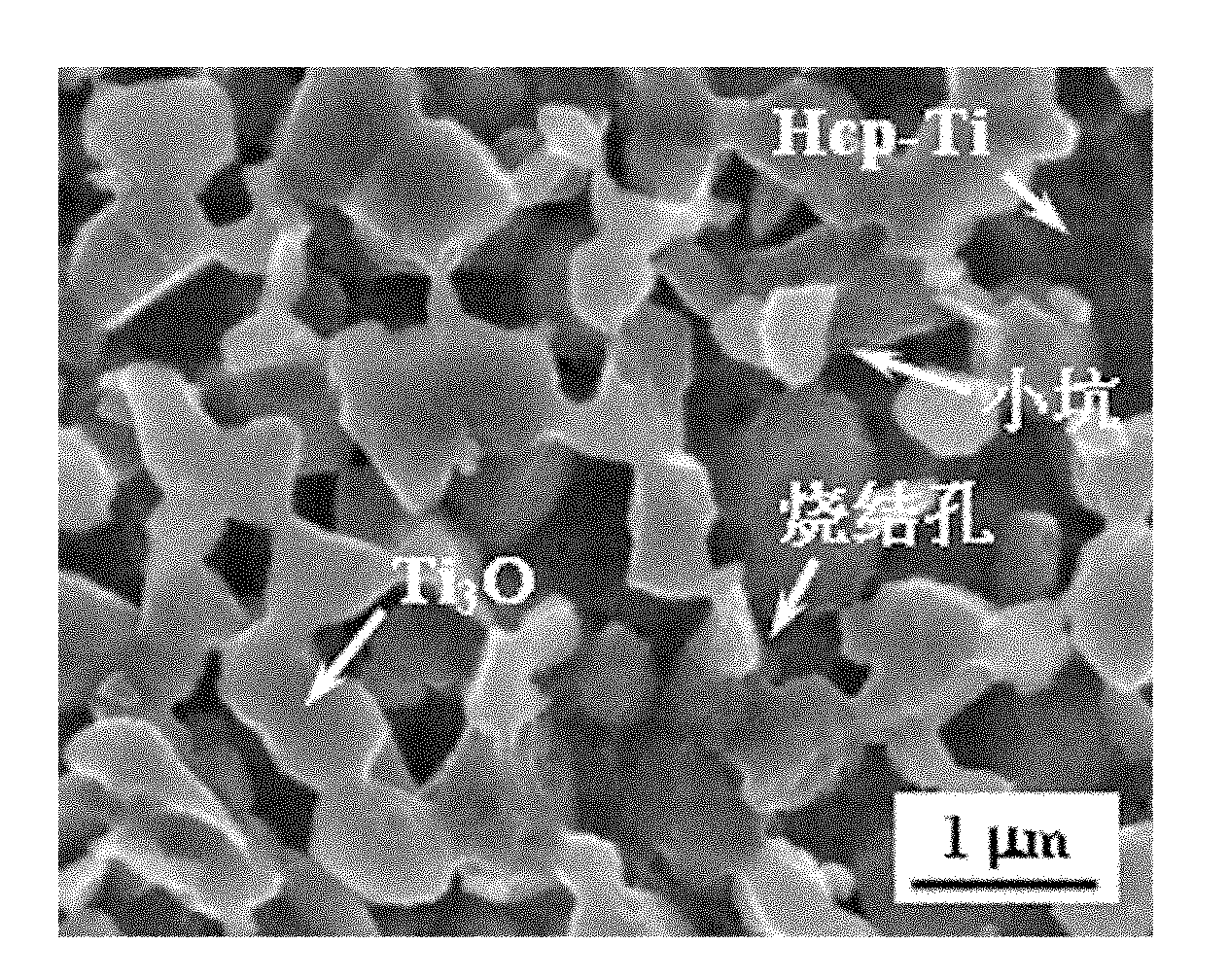

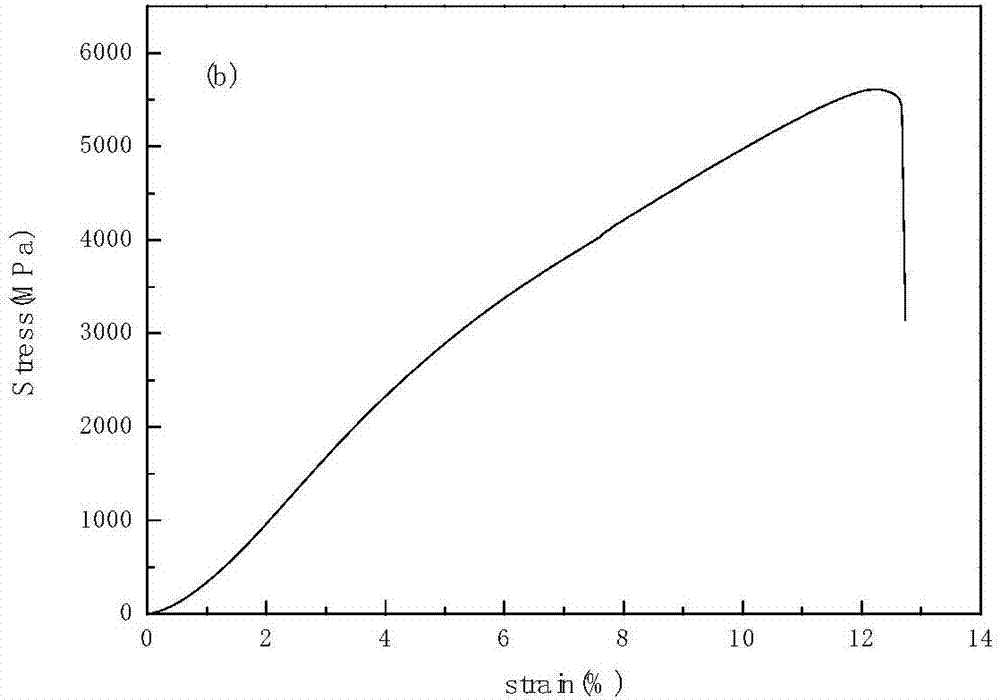

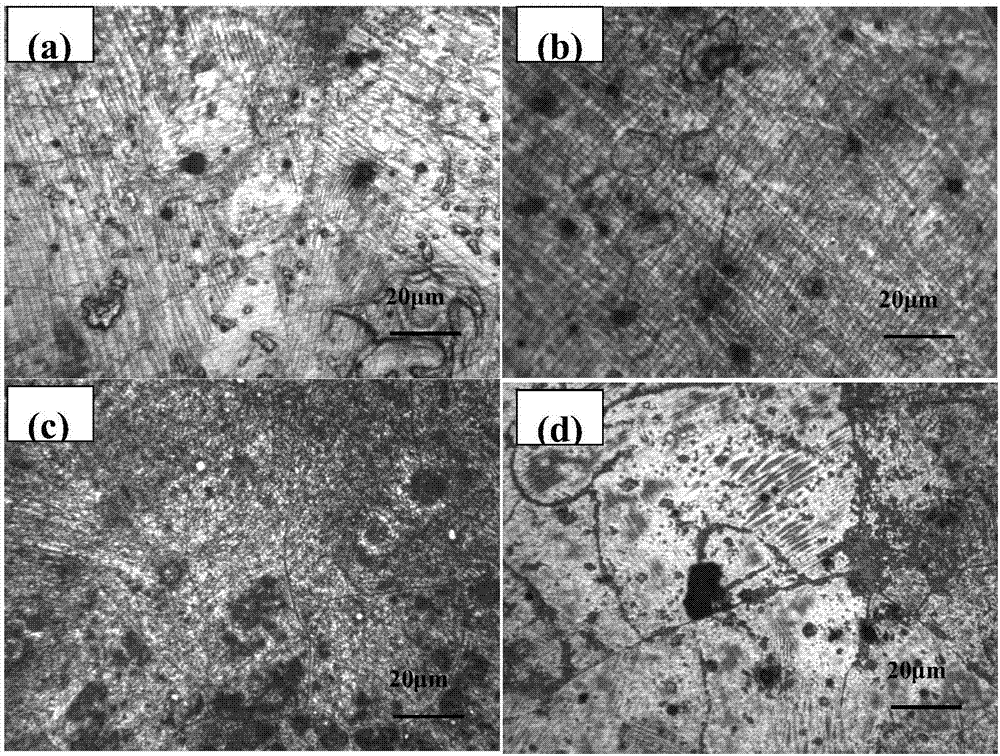

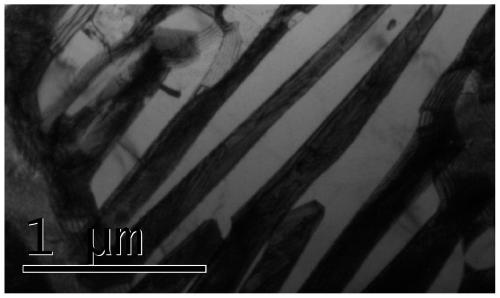

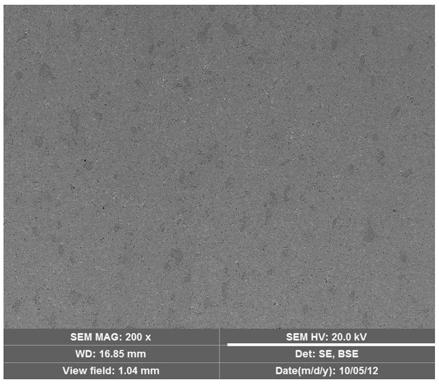

Titanium-based ultrafine grain or fine grain composite material with high compression ratio strength and preparation method thereof

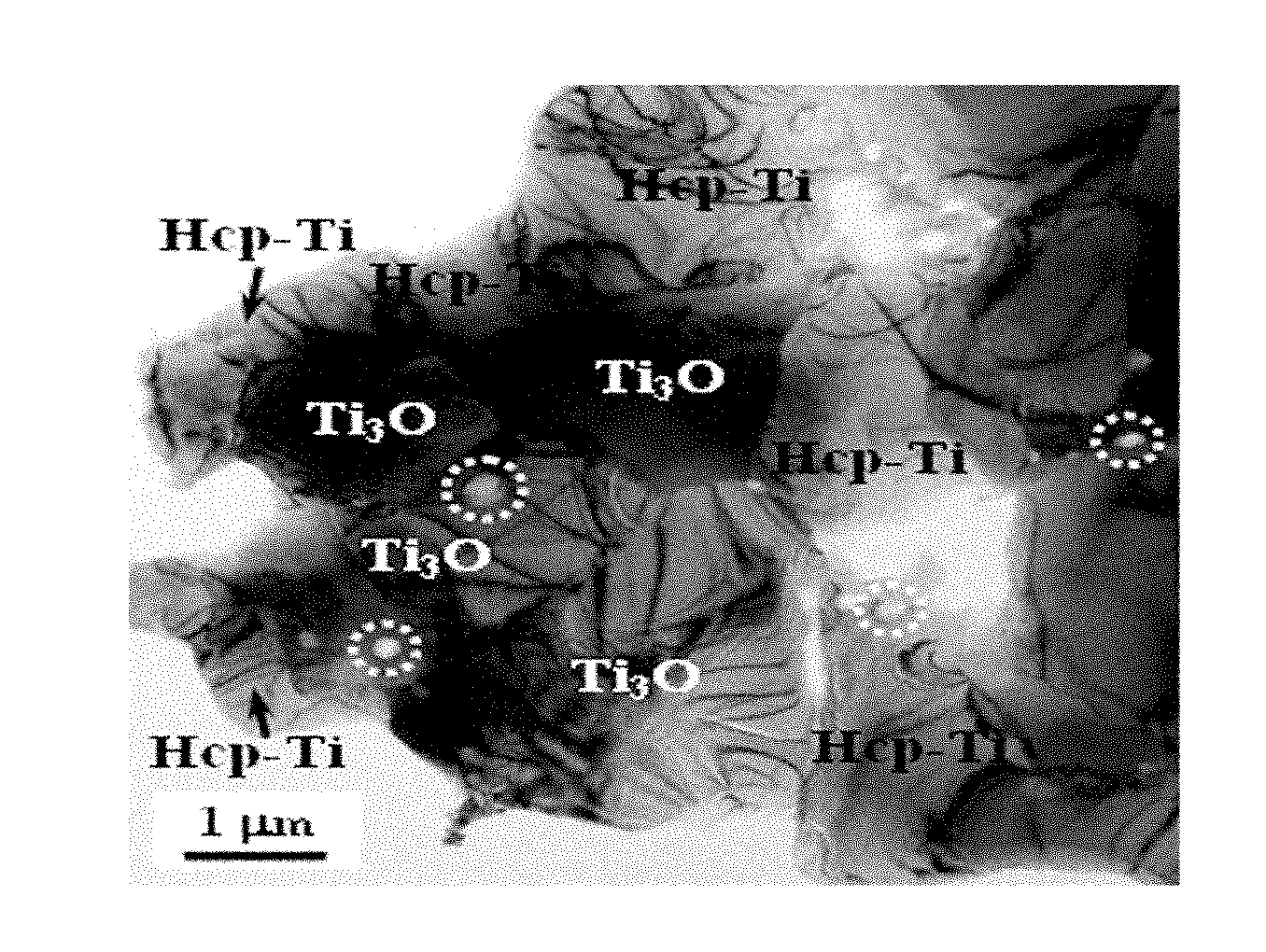

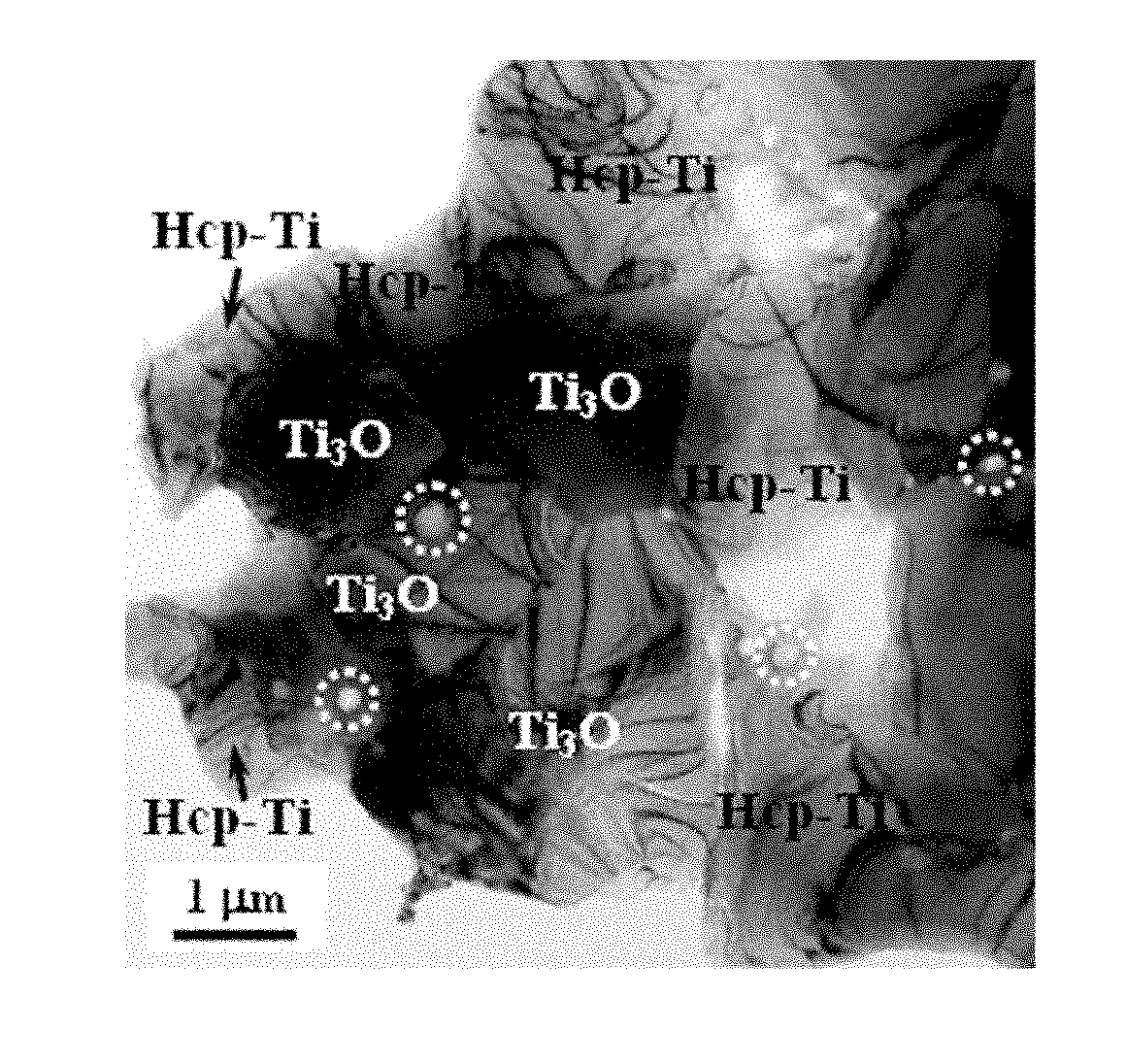

The invention discloses a titanium-based ultrafine grain or fine grain composite material with high compression ratio strength and a preparation method thereof. In a microstructure of the titanium-based ultrafine grain composite material, Hcp Ti3O is taken as a matrix phase and Hcp Ti as an enhanced phase; and in a microstructure of the titanium-based fine grain composite material, Hcp Ti is taken as the matrix phase and Hcp Ti3O as the enhanced phase. The preparation method comprises the following steps of: interruptedly exposing powder in the air until the initial powder becomes amorphous state titanium alloy powder by a high-energy ball; and quickly sintering by adopting pulse current at the sintering temperature Ts being not less than 740K and not more than 1,473K and the sintering pressure of at least 40MPa for 1-10 minutes. The method has simple process and convenient operation; grains have controllable size, high finished rate, raw materials saving and near net shape; and the large-sized titanium-based ultrafine grain or fine grain composite material has excellent comprehensive mechanical property and favorable popularization and application prospect.

Owner:SOUTH CHINA UNIV OF TECH

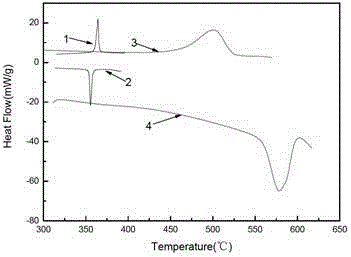

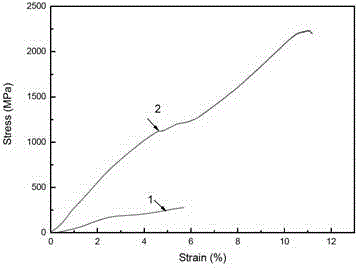

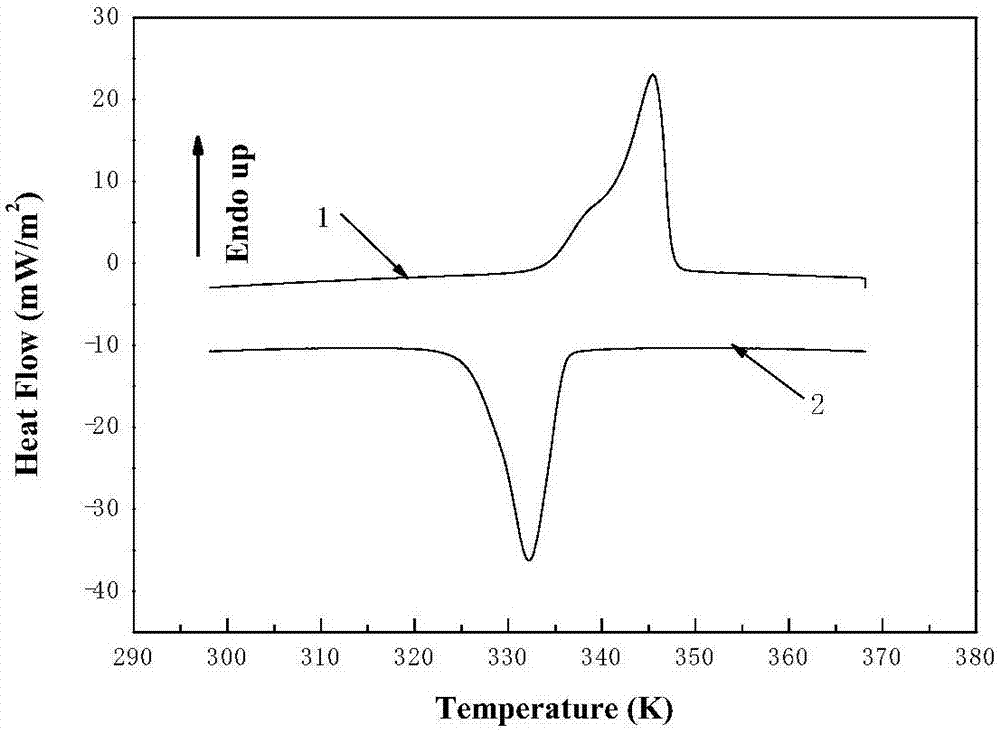

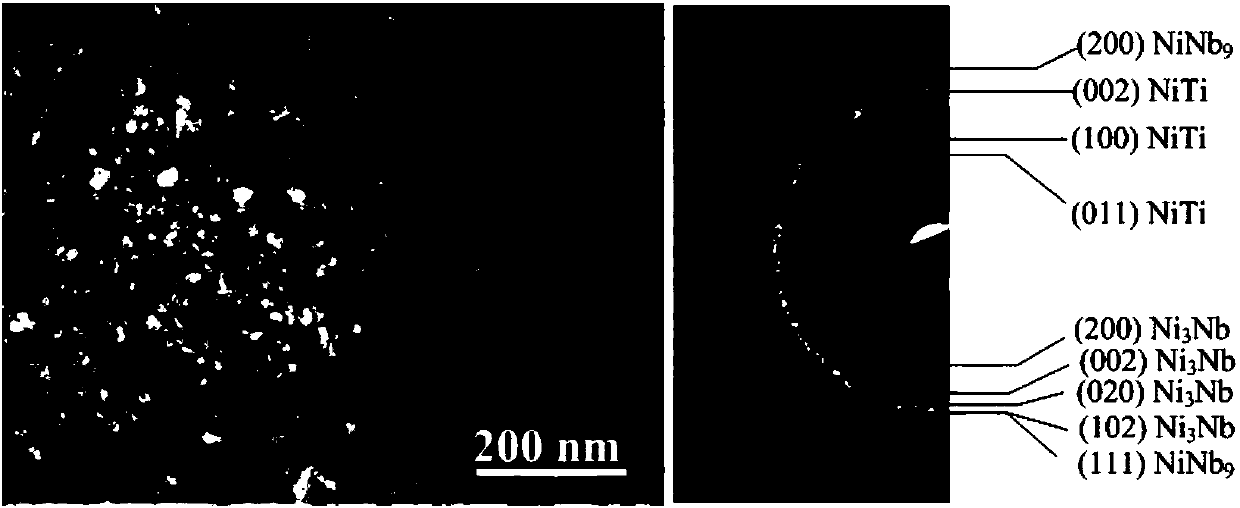

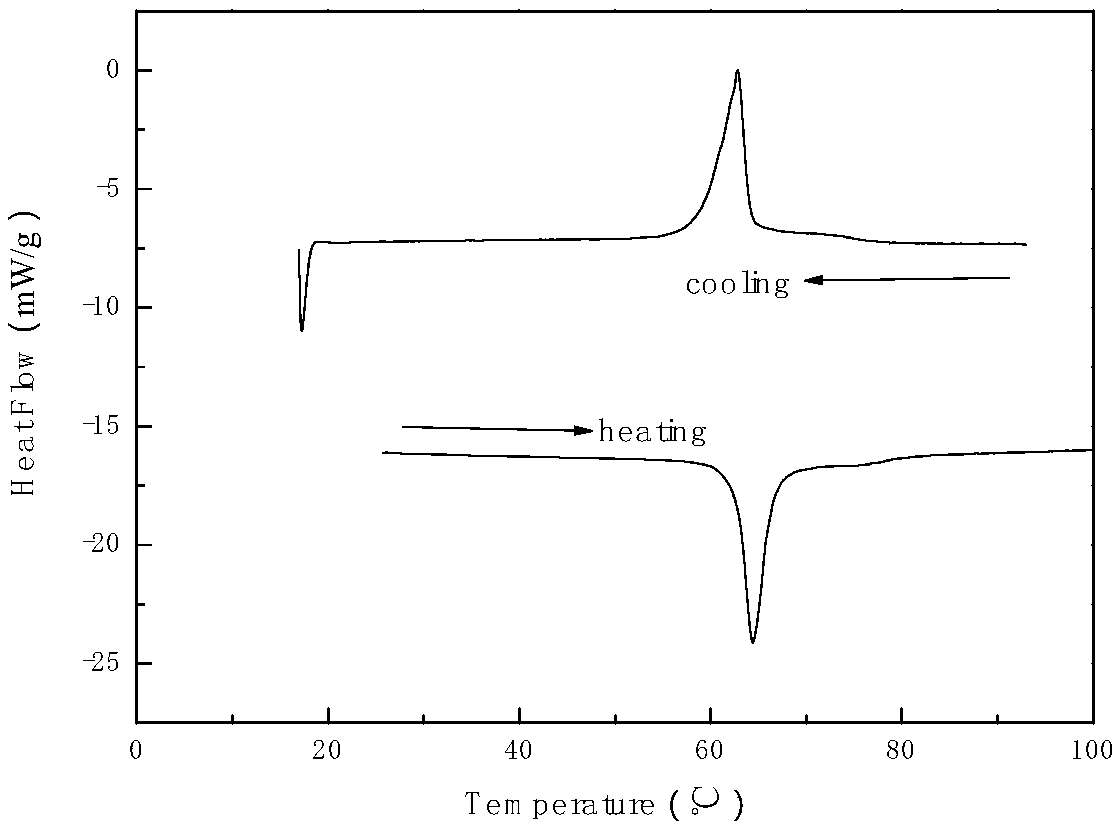

Magnetic shape memory alloy and preparation method thereof

InactiveCN102719721AHigh breaking strengthRaise the strain at breakMagnetic materialsBreaking strengthShape-memory alloy

The invention relates to a magnetic shape memory alloy which comprises, in atomic percent, 45.4 parts of Ni, 41.5 parts of Mn, 11.1 parts of In and 2 parts of Gd. The breaking strength of the alloy is 2201MPa, and the martensite phase transition starting temperature of the alloy is 557 DEG C. The breaking strength of the prepared alloy, which is 2201MPa, is about 1820Mpa higher than that of an existing alloy comprising 45.4 parts of Ni, 41.4 parts of Mn, 13.1 parts of In and 0.1 part of Gd; the martensite phase transition starting temperature of the alloy, which is 557 DEG C, is about 200 DEG C higher than that of the existing alloy comprising 45.4 parts of Ni, 41.4 parts of Mn, 13.1 parts of In and 0.1 part of Gd, and the phase transition lag of the alloy is about 150 DEG C; and the breaking strain of the alloy is improved by 200% as compared with that of the existing alloy comprising 45.4 parts of Ni, 41.4 parts of Mn, 13.1 parts of In and 0.1 part of Gd. The prepared alloy comprising 45.4 parts of Ni, 41.5 parts of Mn, 11.1 parts of In and 2 parts of Gd is high in ductility.

Owner:DALIAN UNIV

Preparation method for high strength Ni50Mn34In16 magnetic memory alloy

ActiveCN107058848AHigh breaking strengthRaise the strain at breakTransportation and packagingMetal-working apparatusHigh fractureMagnetic memory

The invention relates to a preparation method for a magnetic shape memory alloy, in particular to a preparation method for a high strength Ni50Mn34In16 magnetic memory alloy. The high strength Ni50Mn34In16 is prepared according to the following steps of material taking according to the atomic percent, mixing, forming, degreasing and sintering, and then the high strength Ni50Mn34In16 is obtained. The Ni50Mn34In16 alloy prepared by the method has higher fracture strength and fracture strain, the grain size of the magnetic shape memory alloy is tiny so as to drive the threshold value of a magnetic field to be reduced, the excellent magnetic property is achieved, and the train of thought is expanded for application of the high temperature and high plasticity shape memory alloy.

Owner:DALIAN UNIV

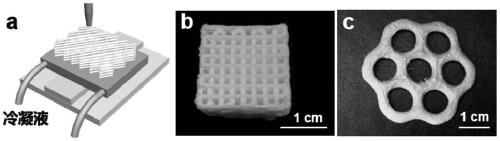

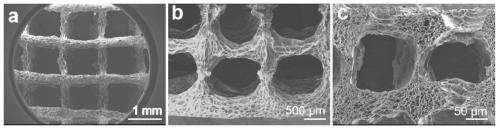

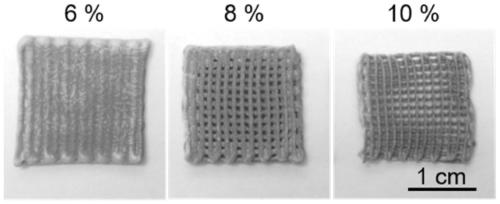

3D printing polyimide aerogel and preparation method thereof

ActiveCN111234297AEasy to synthesizeThe synthesis process is green and environmentally friendlyAdditive manufacturing apparatusAdditive manufacturing with liquidsPolymer scienceComputer printing

The invention relates to a 3D printing polyimide aerogel and a preparation method thereof. The polyimide aerogel is obtained by printing a polyamide acid solution into a set structure through a 3D printer, assisting a cold plate to freeze, solidify and mold, and then performing deep freezing, freeze drying and thermal imidization. According to the preparation method, a 3D structure is accurately and effectively constructed through a 3D printing technology, a polyamic acid solution can well keep the 3D printing structure through cold plate assisted molding, then the polyimide aerogel with a specific structure is obtained, the synthesis process is simple, environmentally friendly and easy to operate, and the preparation method is a green preparation method.

Owner:DONGHUA UNIV

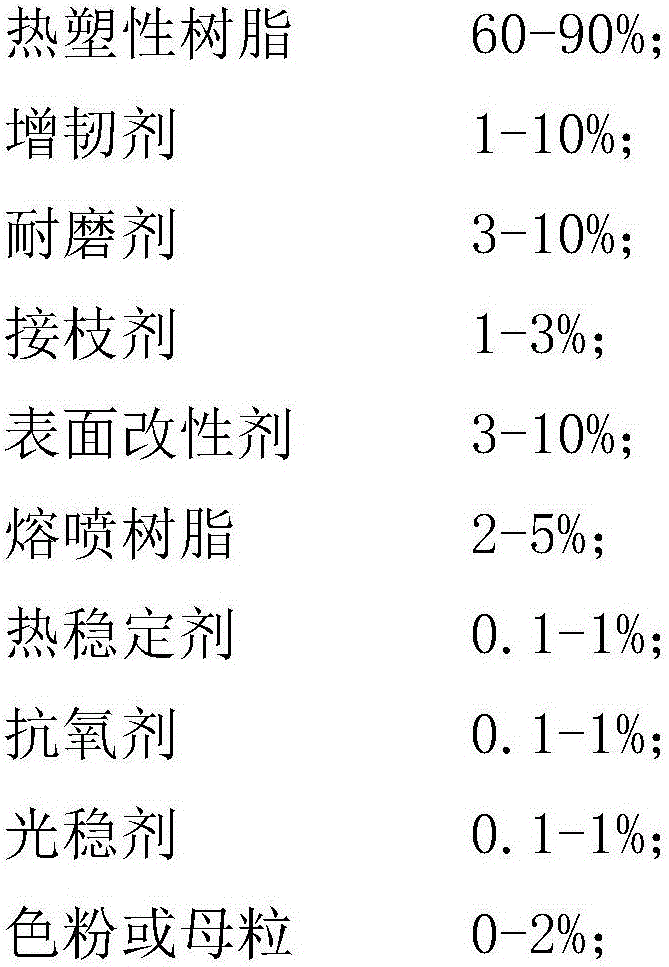

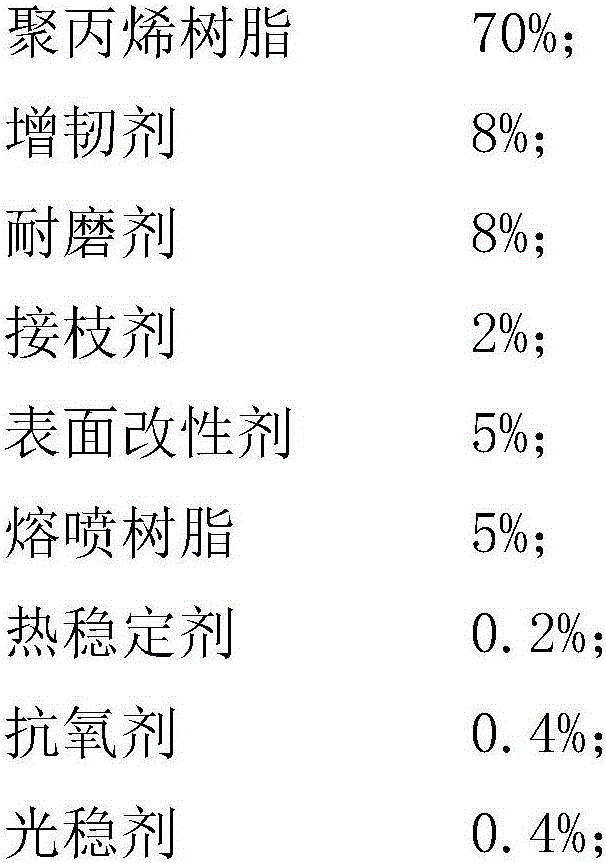

Formula and preparation method of special compound additive for polypropylene film material

InactiveCN104558826AProlonged oxidation induction periodHigh tensile strengthPolymer scienceColor index

The invention relates to a formula of a special compound additive for a polypropylene film material. The formula comprises an antioxidant 626, an antioxidant 1010, a deacidification agent DHT-4A and a nucleating agent HyperformHPN-20E. The preparation method comprises the following steps: mixing and stirring the components, throwing the uniformly mixed and stirred components into a squeezing granulator for granulation, and sieving the obtained granules by using 1-5 layers of sieves, wherein granules with apertures equal to or larger than 4mm are finished products, and the granules with apertures smaller than 4mm are recycled. The formula provided by the invention is low in production cost, can be used for increasing the oxidation induction time of the polypropylene film material to be equal to or more than 35 minutes, reducing the yellow color index, improving the fracture strain and increasing the tensile strength of the film, the transparency and stiffness of the special compound additive for the polypropylene film material are high, no dust pollution is generated, various addition procedures in a polypropylene device in the traditional working manner are replaced by one addition procedure, and the good performance of a single agent can be protected.

Owner:江苏汉光实业股份有限公司

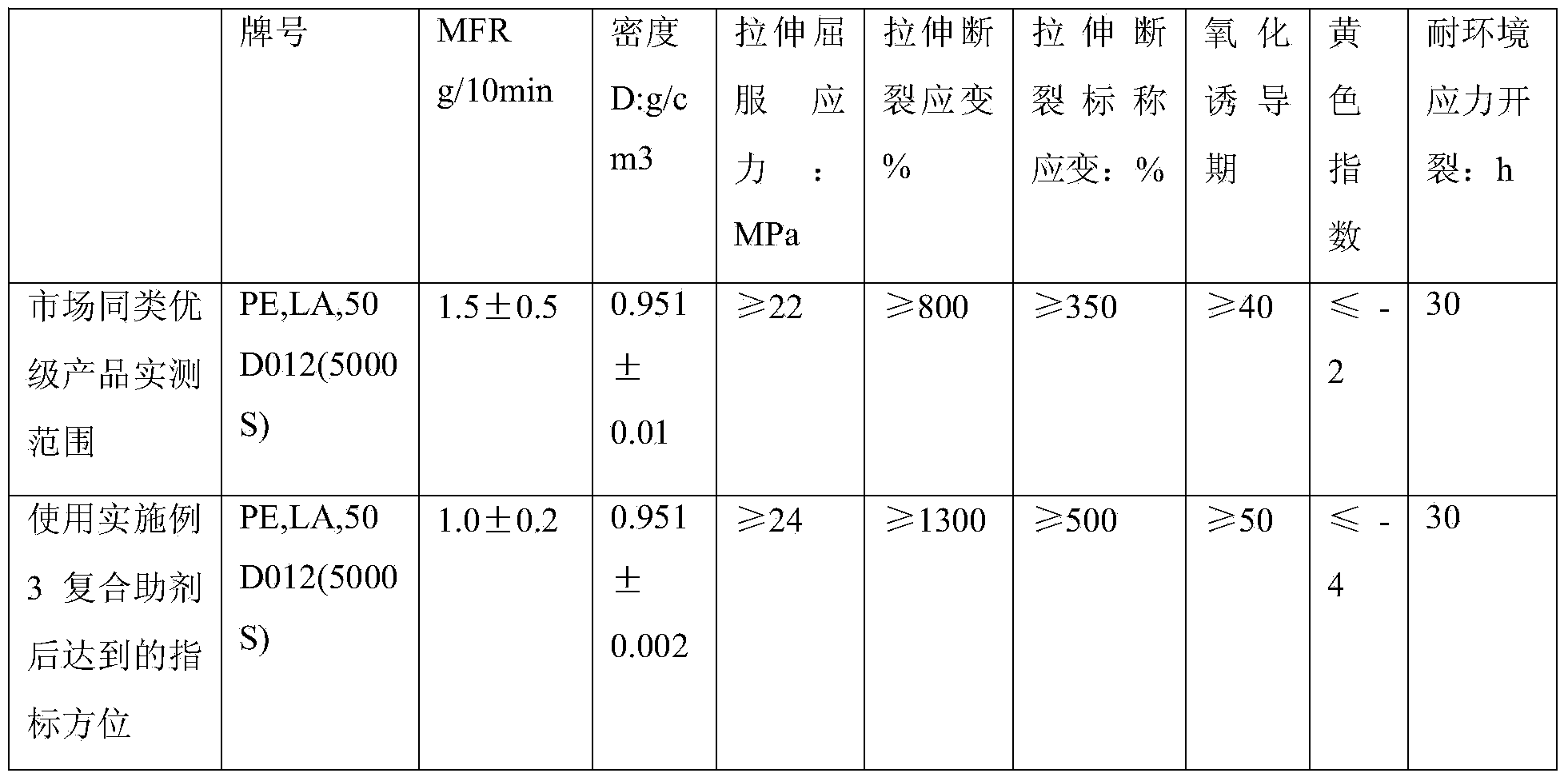

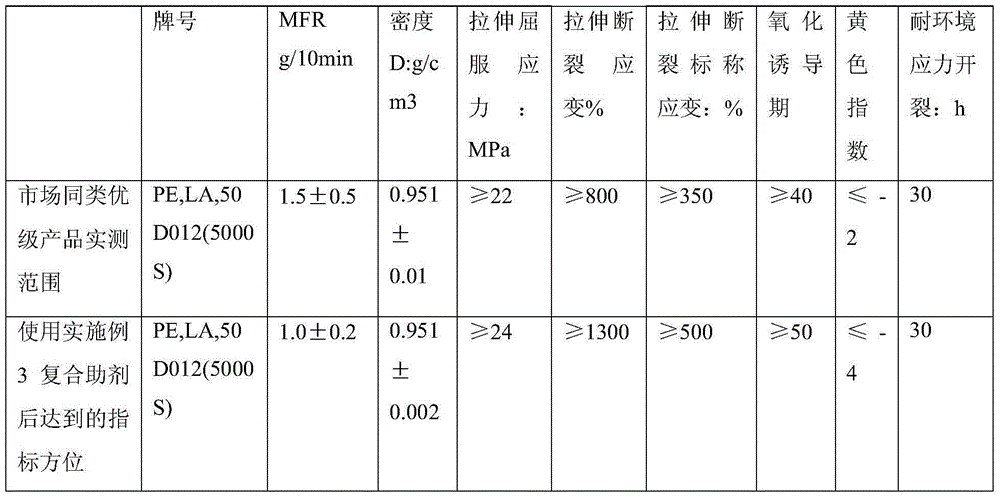

High-density polyethylene compound additive and preparation method thereof

The invention discloses a high-density polyethylene compound additive and a preparation method thereof, and belongs to the field of chemical engineering. The compound additive comprises an antioxidant, a nucleating agent, an acid acceptor and an antistatic agent, wherein the antioxidant comprises an antioxidant 330, an antioxidant 168 and an antioxidant 1076. The preparation method of the compound additive comprises the following steps: mixing the raw components, and uniformly stirring; granulating the uniformly mixed components so as to obtain granules; and sieving the obtained granules. The compound additive has the advantages that the 5000S-oxidation induction time can be prolonged to above 50 minutes through the synergistic effect among the additives, the yellow index is reduced, the fracture strain is improved, and the like.

Owner:江苏汉光实业股份有限公司

Method using nanocrystalline to refine aluminum alloy and improve strength and toughness

The invention discloses a method using nanocrystalline to refine an aluminum alloy and improve strength and toughness. The method comprises the following steps of (1) preparing a multi-element metal glass alloy ingot; (2), preparing a metal glass thin strip; (3) preparing a nanocrystalline thin strip; (4) crushing the nanocrystalline thin strip; (5) preparing a nano-crystal-containing prefabricated block; (6) performing hot-extrusion forming on the nano-crystal-containing prefabricated block; (7) preparing the aluminum alloy which is reinforced and treated by novel nanocrystalline; and (8) performing heat treatment on the reinforced aluminum alloy. According to the technical scheme, the steps are reasonable. The room temperature strength and toughness of the aluminum alloy is greatly improved while the structure is refined, and especially the room temperature strength and the fracture strain of the aluminum alloy is greatly improved. The method is high in efficiency and low in cost, and has huge industrial application potential and value.

Owner:JILIN UNIV

Graphene and rare earth scandium synergistically-reinforced cast aluminum alloy and application of graphene and rare earth scandium synergistically-reinforced cast aluminum alloy to aspect of automobile hub

The invention relates to a graphene and rare earth scandium synergistically-reinforced cast aluminum alloy and application of the graphene and rare earth scandium synergistically-reinforced cast aluminum alloy to the aspect of an automobile hub. The graphene and rare earth scandium synergistically-reinforced cast aluminum alloy is prepared from the raw material components in percentage by mass: 6.0-8.0% of Si, 0.20-0.45% of Mg, 0.50-0.60% of Sc, 0.003-0.007% of graphene, less than or equal to 0.05% of Li, less than or equal to 0.05% of Be, less than or equal to 0.05% of B, less than or equal to 0.05% of Na, less than or equal to 0.05% of P, less than or equal to 0.10% of Ti, less than or equal to 0.10% of V, less than or equal to 0.05% of Cr, less than or equal to 0.10% of Mn, less than orequal to 0.10% of Fe, less than or equal to 0.05% of Ni, less than or equal to 0.10% of Cu, less than or equal to 0.10% of Zn, less than or equal to 0.05% of Zr, less than or equal to 0.05% of Sn, less than or equal to 0.10% of Pb and the balance of Al. The graphene and rare earth scandium synergistically-reinforced cast aluminum alloy has excellent comprehensive mechanical performance and electrical conductivity performance and is especially suitable for the aspect of the automobile hub.

Owner:广州埃烯金属科技有限公司

Wear-resistant sole material and preparation method thereof

The invention provides a wear-resistant sole material. The wear-resistant sole material consists of the following raw materials in parts by weight: 10-60 parts of wear-resistant thermoplastic elastomer, 40-90 parts of nitrile rubber, 0.5-5 parts of zinc stearate, 0.1-2 parts of an antioxidant 1098, 0.1-2 parts of white mineral oil and 1-10 parts of talcum powder. The wear-resistant sole material prepared by the invention has good mechanical properties and wear resistance.

Owner:柯祥

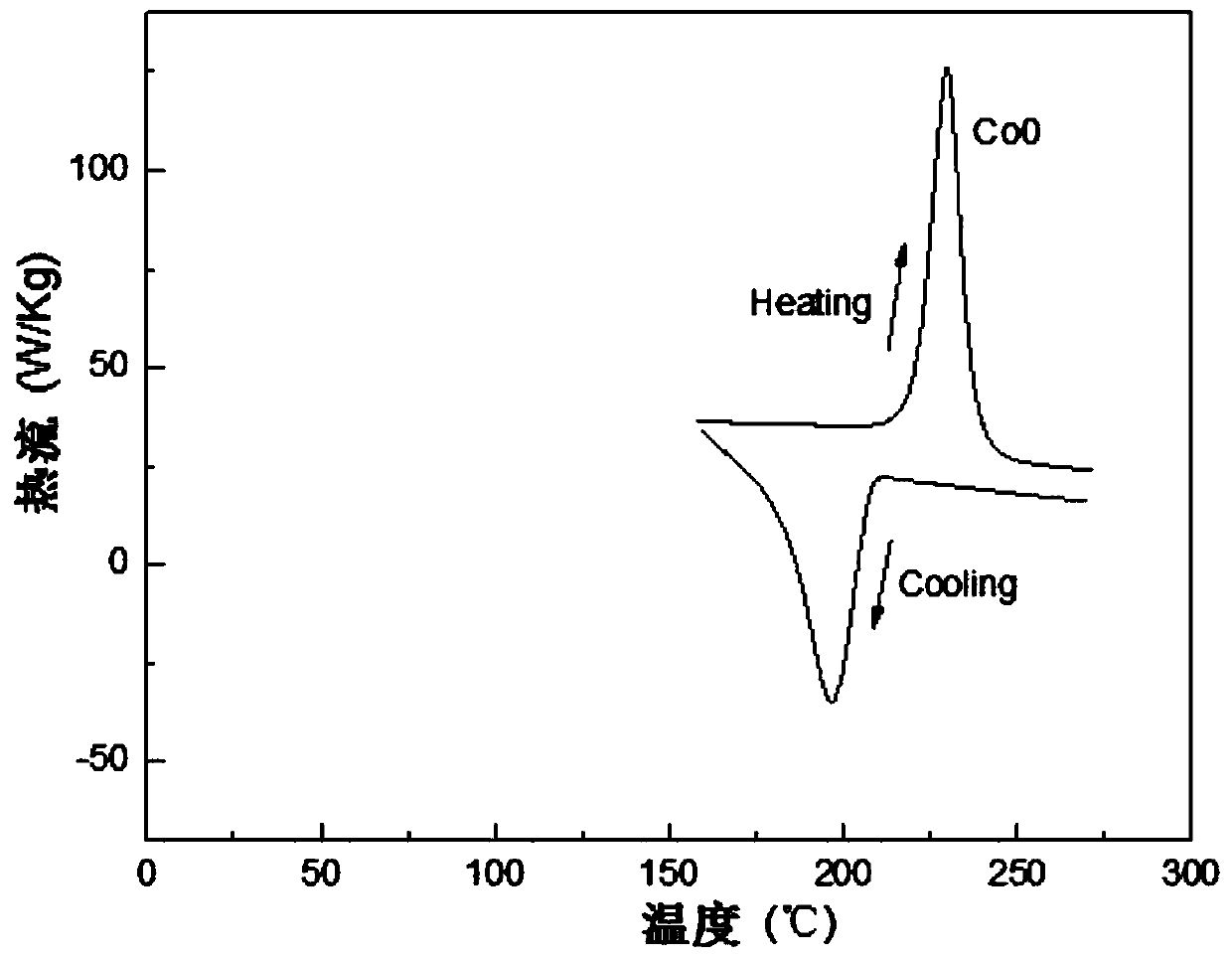

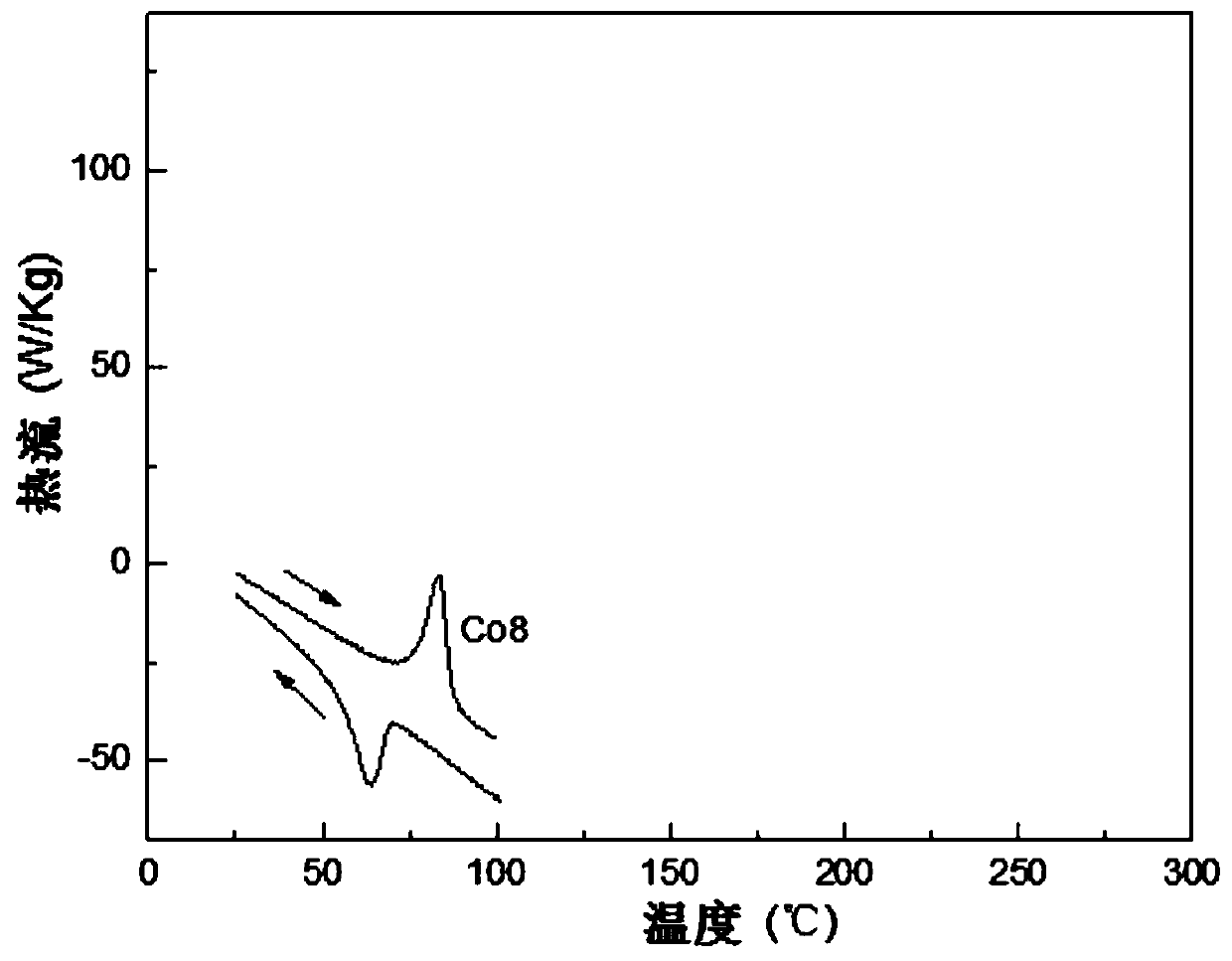

High-temperature high-toughness Ni-Co-Mn-Sn-Cu alloy with high magnetocaloric effect, preparation method, and application thereof

InactiveCN110423934AIncrease working temperatureImprove mechanical propertiesInorganic material magnetismCoils manufactureShape-memory alloyAlloy

The invention relates to a high-temperature high-toughness Ni-Co-Mn-Sn-Cu alloy with a high magnetocaloric effect, a preparation method, and application thereof, belongs to the technical field of magnetic materials, and particularly relates to the high-temperature high-toughness Ni-Co-Mn-Sn-Cu alloy with the high magnetocaloric effect, the preparation method, and the application thereof. The invention aims to solve the problems that an existing Ni-Mn-Sn ferromagnetic shape-memory alloy system is high in brittleness and hard to meet the use requirement under high temperature environment. A chemical general formula is Ni48-xCoxMn37Sn9Cu6, wherein x is mole fraction and is larger than 0 and smaller than or equal to 12; and the sum of mole number of elements in the alloy is 100. The method comprises the steps of (1) preparing materials; (2) carrying out electric arc meting; and (3) carrying out homogenization treatment so as to finally obtain an Ni48-xCoxMn37Sn9Cu6 magnetic refrigeration alloy material.

Owner:HARBIN UNIV OF SCI & TECH

Carbon/ceramic heat-resistant composite material and preparation process thereof

InactiveCN1793037AObvious advantagesObvious positive effectCeramic shaping apparatusRoom temperatureFree cooling

The invention relates to a carbon / ceramic heat proof compounding material and the manufacturing method. The wt% of the material is C squama 25-65, ceramic powder SiC+B4C 30-60, of which SiC: SiC+B4C=5:1, TiO2 5-13, adopting acetone phenolic resin as binding agent. Mixing the constituents, molding at the pressure of 30-50MPa, keeping the temperature and cooling to room temperature, the material would be gained. The invention has the feature of light, high intensity, high toughness, antifriction, high temperature poof, and anti-oxidation.

Owner:NORTHEASTERN UNIV

In-situ micro nanometer TiC particle strengthened and toughened ordinary carbon steel and preparation method thereof

The invention discloses in-situ micro nanometer TiC particle strengthened and toughened ordinary carbon steel. The in-situ micro nanometer TiC particle strengthened and toughened ordinary carbon steelis characterized by being composed of, by weight, 0.38-0.50% of carbon, 0.17-0.37% of silicon, 0.50-0.80% of manganese, 0.02-0.015% of phosphorus, 0.028-0.26% of sulfur, 0.039-1.09% of chromium, 0.11-0.25% of nickel, 0.05-0.25% of copper, 0.03-1.00% of in-situ nanometer TiC particle pre-dispersed alloy containing 20-40% by weight of nanometer TiC, and the balance iron. In the ordinary carbon steel, nanometer TiC particles are used as structure regulating agents and strengthening agents of the ordinary carbon steel, and thus the toughness and plasticity of the ordinary carbon steel are improved. The invention further provides the in-situ micro nanometer TiC particle pre-dispersed alloy and a preparation method thereof.

Owner:JILIN UNIV

Preparation method of high-strength and high-plasticity Ni-Mn-Ga-Nb memory alloy

The invention relates to a preparation method of high-strength and high-plasticity Ni-Mn-Ga-Nb memory alloy. The method comprises the steps of taking raw materials according to an atomic percent, vacuumizing, smelting, adding Mn element and continuously smelting, cleaning, carrying out heat preservation, quenching in water and carrying out homogenization treatment; after that, changing aging temperature and aging time to obtain aged Ni53Mn25Ga21Nb1 alloy. The prepared Ni53Mn25Ga21Nb1 alloy has the advantages of being good in toughness, high in strength, and the like. The method provided by the invention is simple to operate and stable in performance of the prepared alloy, and expands a new idea for the field of high-strength and high-plasticity shape memory alloy.

Owner:DALIAN UNIV

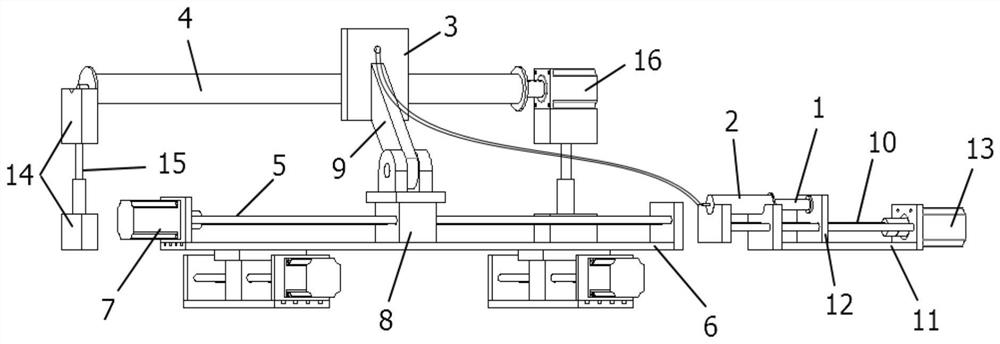

Production technology of continuous fiber reinforced thermoplastic composites (CFRTP) pultruded profiles

The invention discloses a production technology of continuous fiber reinforced thermoplastic composites (CFRTP) pultruded profiles, comprising the steps: (1) leading out continuous fiber through a creel, and keeping the continuous fiber in the same plane through a silk-through shelf; then, spreading the continuous fiber to the specified areal density under the action of floating tension rollers and differential dispersion rollers, next, applying molten thermoplastic resin, passing through a W mould cavity, rolling and cooling with continuous metal rollers, curling and rolling-up to obtain continuous fiber reinforced prepreg tapes, and slitting the prepreg tapes into prepreg strip lines with the same width upon completion of preparation; (2) putting the prepreg strip lines on a reel, starting a tractor to pull the prepreg strip lines into a preheating area for softening, then leading the prepreg strip lines into a mould, pulling and leading out the prepreg strip lines after hot modeling, transfer molding and cold molding of the prepreg strip lines in the mould, and then performing later cutting and processing to obtain the finished product.

Owner:山东极威新材料科技有限公司

Multi-scale structure alloy material, preparation method and application thereof

The present invention relates to a multi-scale structure alloy material, a preparation method and application thereof. The preparation method includes the following steps that (1), powder densification and sintering are carried out, specifically, alloy powder is put into a sintering mold and sintered after pre-pressing, and the sintering pressure is 20-100MPa, wherein the starting temperature of an alloy powder phase change peak<=the sintering temperature Ts<=the end temperature of the alloy powder phase change peak; (2), high pressure treatment is carried out, specifically, after sintering, pressure cooling is carried out, and the cooling pressure is 10-500MPa; and (3), pressure relief cooling is carried out, specifically, when the pressure cooling temperature is reduced to 550-600 DEG C,the pressure relief is carried out quickly, and the alloy material is obtained by cooling. Based on the preparation method, a simple and easy-to-operate material forming and preparation method is developed. The preparation of the alloy material and a subsequent treatment technology are combined into one to realize the integral forming of the double-scale / multi-scale nano / ultra-fine grain structure alloy material. The alloy material with high strength and toughness is prepared by in-situ regulating the microstructures and grain sizes of an alloy.

Owner:GUANGZHOU INST OF RAILWAY TECH

Method for preparing fiber nonwoven fabric for facial masks

InactiveCN108914368AAchieve modificationPromote absorptionConjugated cellulose/protein artificial filamentsNon-woven fabricsPolymer scienceGenipin

The invention belongs to the field of cosmetics, and particularly relates to a method for preparing a fiber nonwoven fabric for facial masks. The method adopts natural silk as a raw material, and obtains preprocessed silk fibroin liquid through degumming and dialysis; the natural Genipin with non-toxic side effects and CaCl2 are used as a crosslinking agent, so that the tensile strength and the breaking strain are improved. Some of the fat-soluble components of the skin can be dissolved, and the absorption of other effective nutrients can be improved. The method utilizes elastase and pepsin tocarry out secondary enzymatic hydrolysis of the preprocessed squid skin liquid, increases the number of free amino groups therein, and allows the protein in the squid skin liquid and the saccharide substances in the system to form a stable crosslinked network system. The method can effectively reduce the problem that the mechanical properties are degraded due to water absorption and swelling whenthe non-woven fabric acts on the mask nutrient solution, and the interaction of the components can avoid the problem of unintentional tearing. The method solves the problem that the fiber nonwoven fabric for facial masks which is commonly used at present is easy to be torn in use.

Owner:高昕文

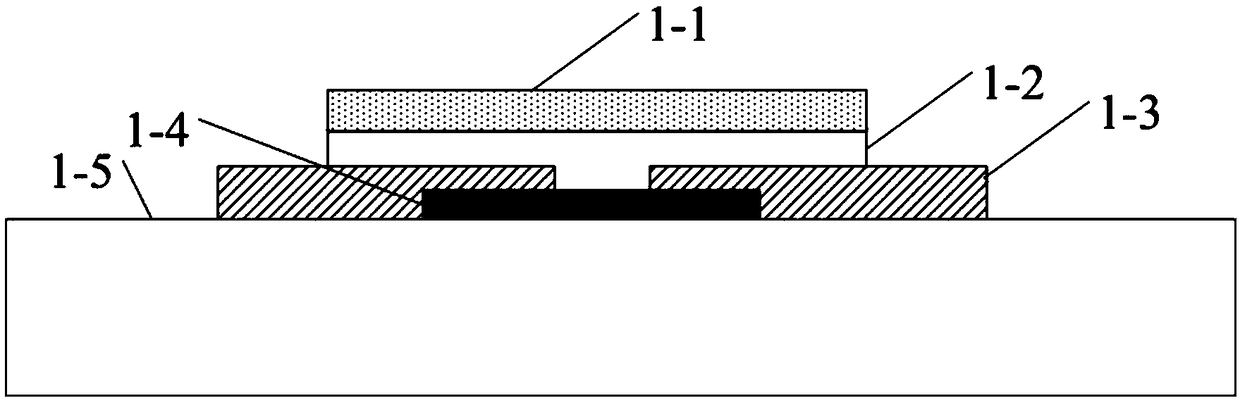

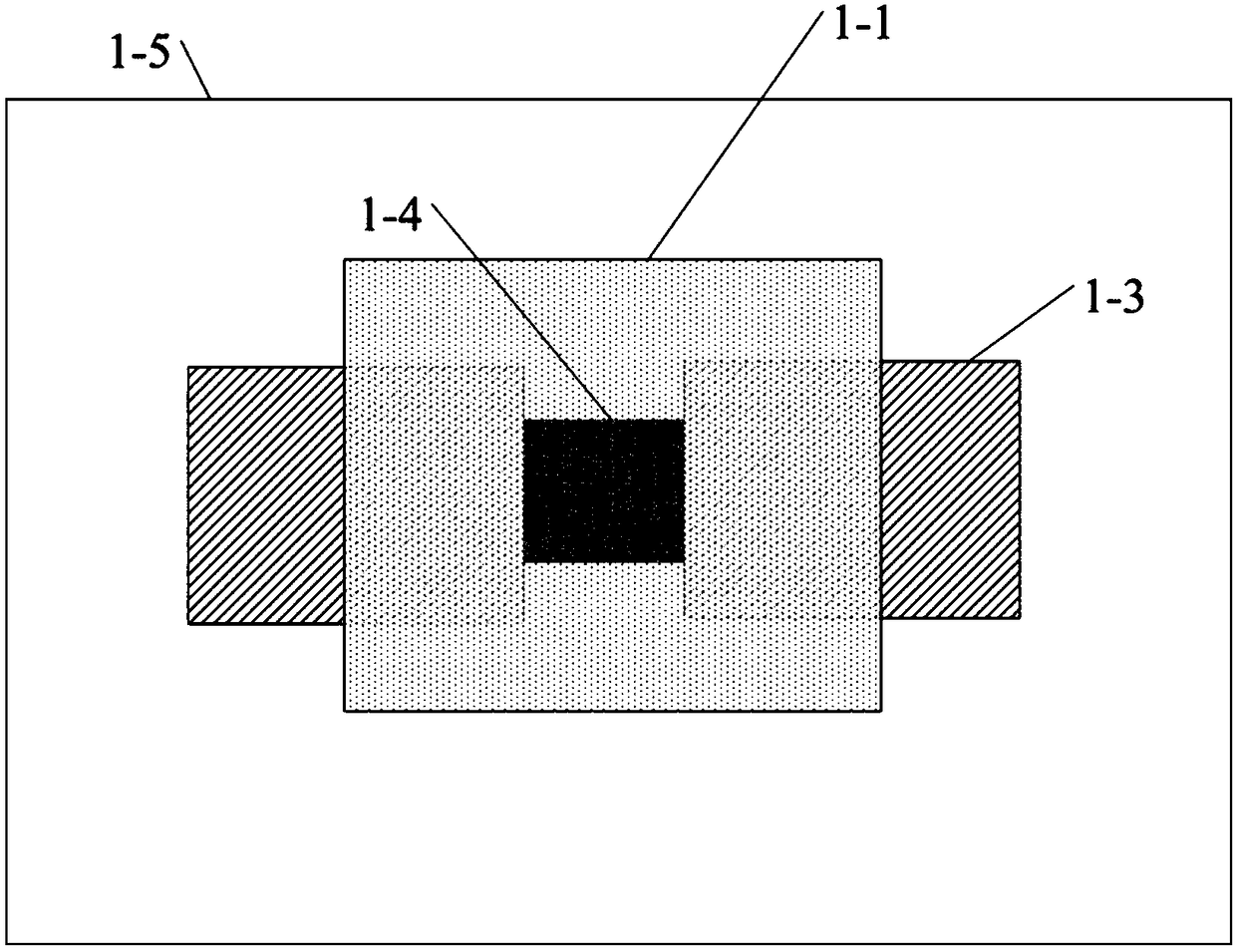

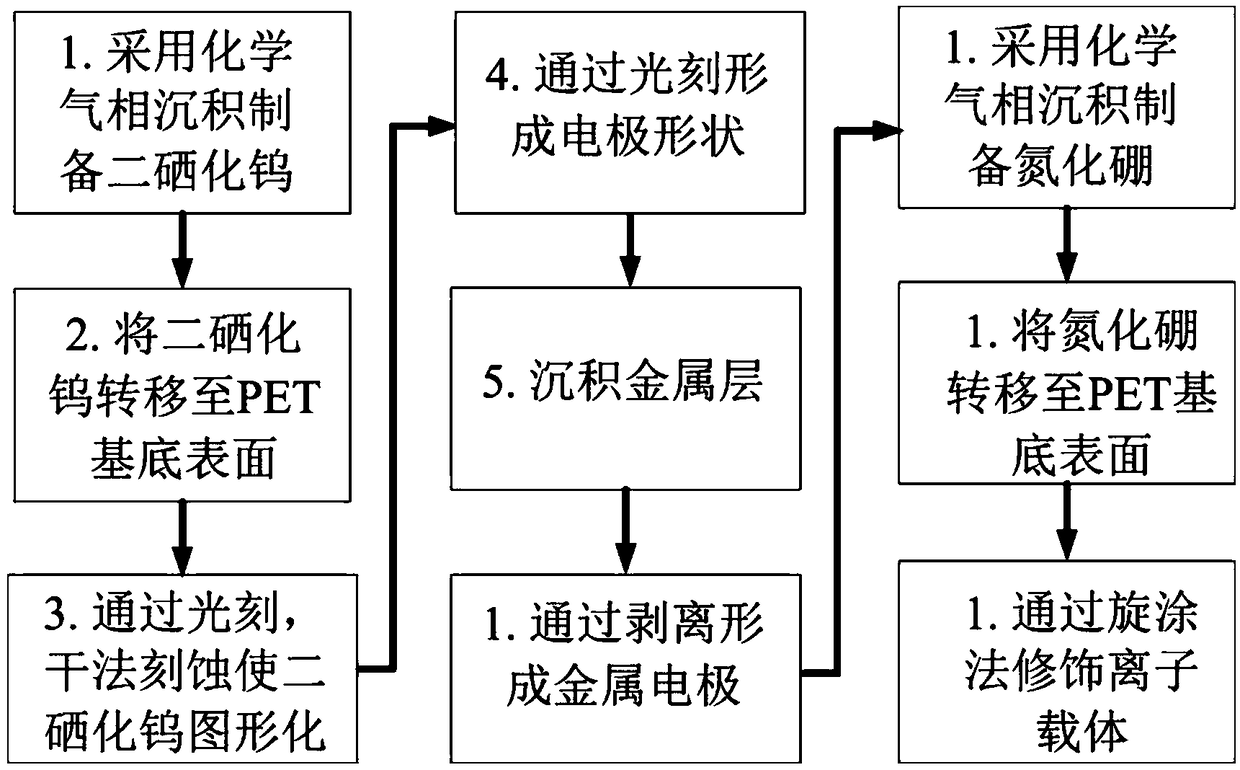

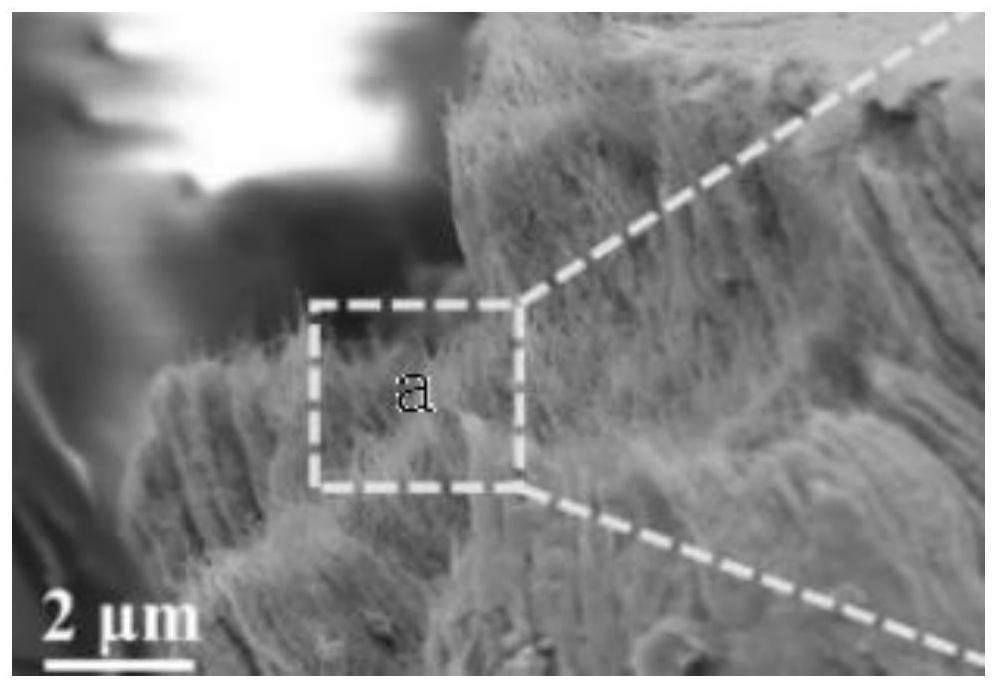

Flexible ion sensor based on tungsten diselenide

PendingCN108845017AHigh sensitivityLarge specific surface areaMaterial analysis by electric/magnetic meansSensor arrayMicrometer

The invention discloses a flexible ion sensor based on tungsten diselenide and belongs to the technical field of MEMS (Micro-electromechanical Systems). The flexible ion sensor is characterized in that sensor array is made of tungsten diselenide as a sensitive material; the sensor structurally comprises an ion carrier, a boron nitride layer, a tungsten diselenide layer and a flexible substrate, wherein both ends of the tungsten diselenide layer are connected with a metal electrode; the ion carrier has a thickness of 20-200 micrometers; the boron nitride layer is a single layer or consists of multiple layers; the metal electrode is made of a material of any one of Au, Ag, Cu, Al and Pt and has a thickness of 20-200 nanometers; the tungsten diselenide layer is a single layer or consists of multiple layers; the upper surface of the tungsten diselenide layer is completely covered by the ion carrier and the boron nitride layer. As the tungsten diselenide is adopted as the sensitive material, the boron nitride is adopted as a protection layer and the ion carrier is adopted as a selecting layer, the sensitivity, the stability and the selectivity of the flexible ion sensor can be improved,the sensor has excellent bending resistance and is easy to process.

Owner:TSINGHUA UNIV

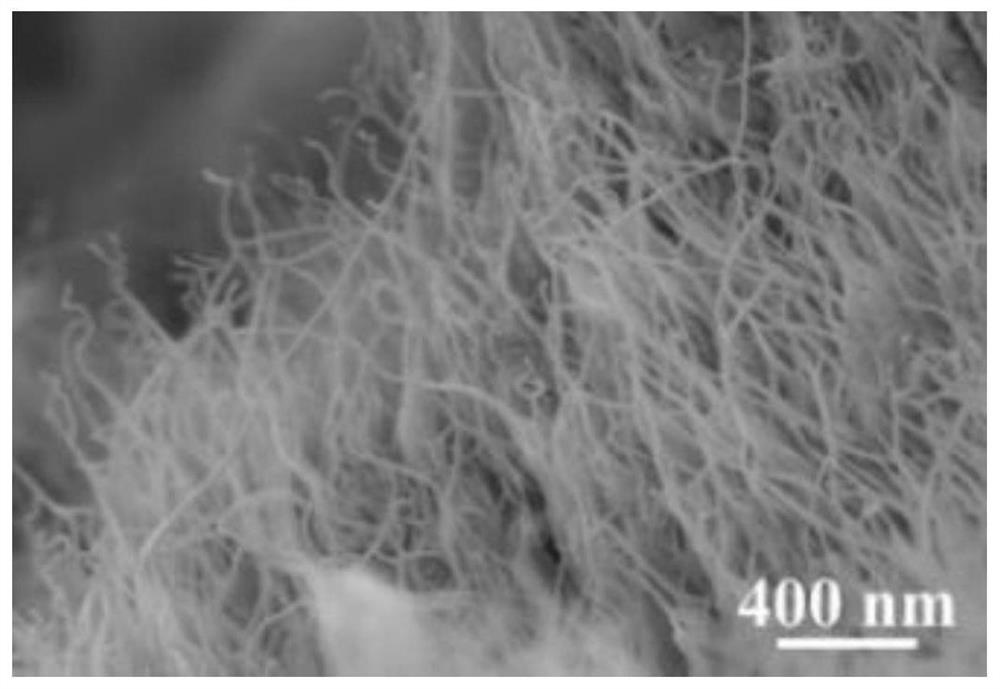

Method for chemical crosslinked modified carbon nanotube fibers

InactiveCN111607848ASuitable for diffusionKeep fitWet spinning methodsArtificial filament chemical after-treatmentFiberPolymer science

The invention provides a method for chemical crosslinked modified carbon nanotube fibers, and belongs to the technical field of fiber preparation. The method for the chemical crosslinked modified carbon nanotube fibers is used for solving the problems that existing carbon nanotube fibers are poor in comprehensive performances and prone to unevenly dispersing in the process, have the defects and are prone to creeping when the carbon nanotube fibers are subjected to external force, short in service cycle and low in stability in use. The method for the chemical crosslinked modified carbon nanotube fibers comprises the following steps that 1, hyaluronic acid is dissolved in deionized water, then carbon nanotubes are added, and the mixture is ultrasonically dispersed to obtain spinning dope; 2,wet spinning technology is used for injecting the spinning dope into a solidification solution to obtain the hyaluronic acid / carbon nanotube fibers; 3, the hyaluronic acid / carbon nanotube fibers areplaced and soaked a mixed aqueous solution of 1-ethyl-3-[3-(dimethylamino)propyl]carbodiimide and a 1-hydroxybenzotriazole monohydrate, a hexamethylene diamine solution is added for cross-linking reaction, the mixture is washed and then dried at room temperature to obtain the chemical crosslinked modified carbon nanotube fibers.

Owner:HARBIN ENG UNIV

Continuous fiber-reinforced thermoplastic composite resin rib

The invention provides a continuous fiber-reinforced thermoplastic composite resin rib. The continuous fiber-reinforced thermoplastic composite resin rib is made by coating and splicing a continuous fiber-reinforced thermoplastic composite material into lines and performing pultrusion; continuous fiber-reinforced resin prepreg is prepared from 55 to 70 parts of continuous fiber and 30 to 45 parts of modified resin. The product has high designability, and the resin and the fiber can be selected reasonably according to actual demands in order to achieve a best economical effect; the continuous fiber-reinforced thermoplastic composite resin rib has the advantages of light weight, high specific strength, high specific modulus, high corrosion resistance, high waterproofness and high abrasion resistance; the product is inertial to a plurality of acids and alkalis, and has impact resistance and a high breaking strain value; high designing flexibility is achieved, the requirements on particular application can be met by selecting proper fiber kinds, fiber contents and fiber orientations; the selected resin is thermoplastic resin, so that pollution gas is not produced in a production process, the resin can be recycled.

Owner:红石极威实业集团有限公司

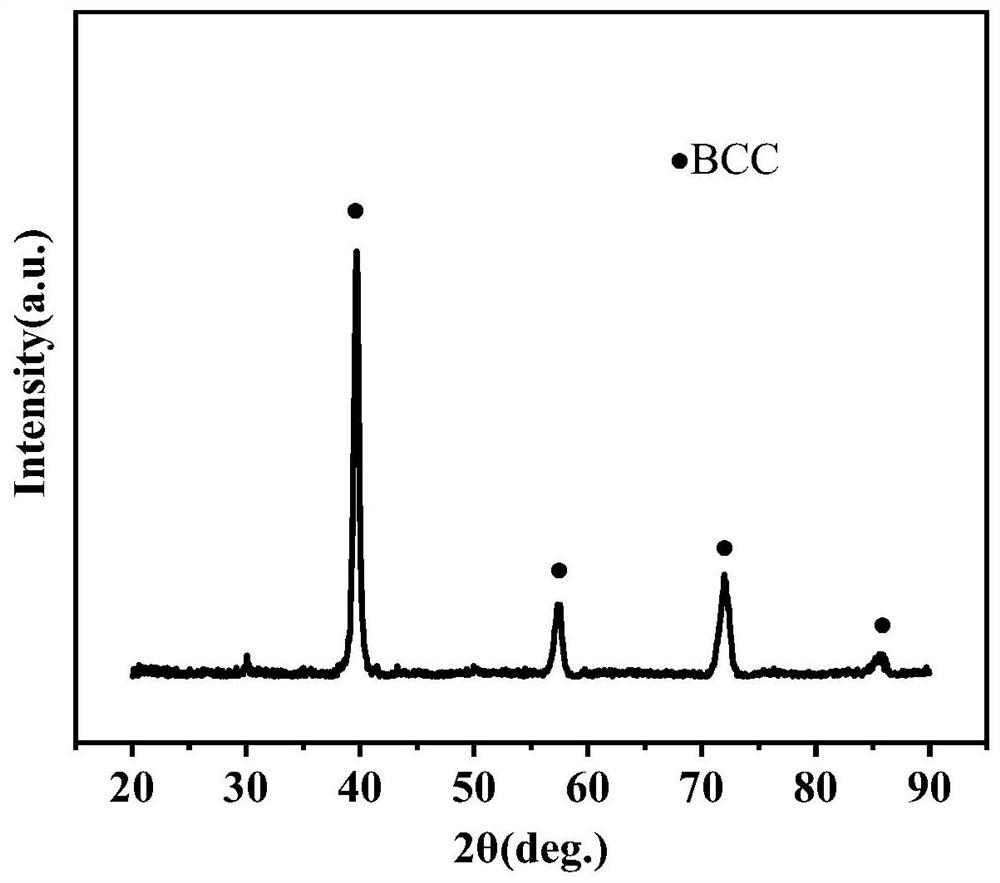

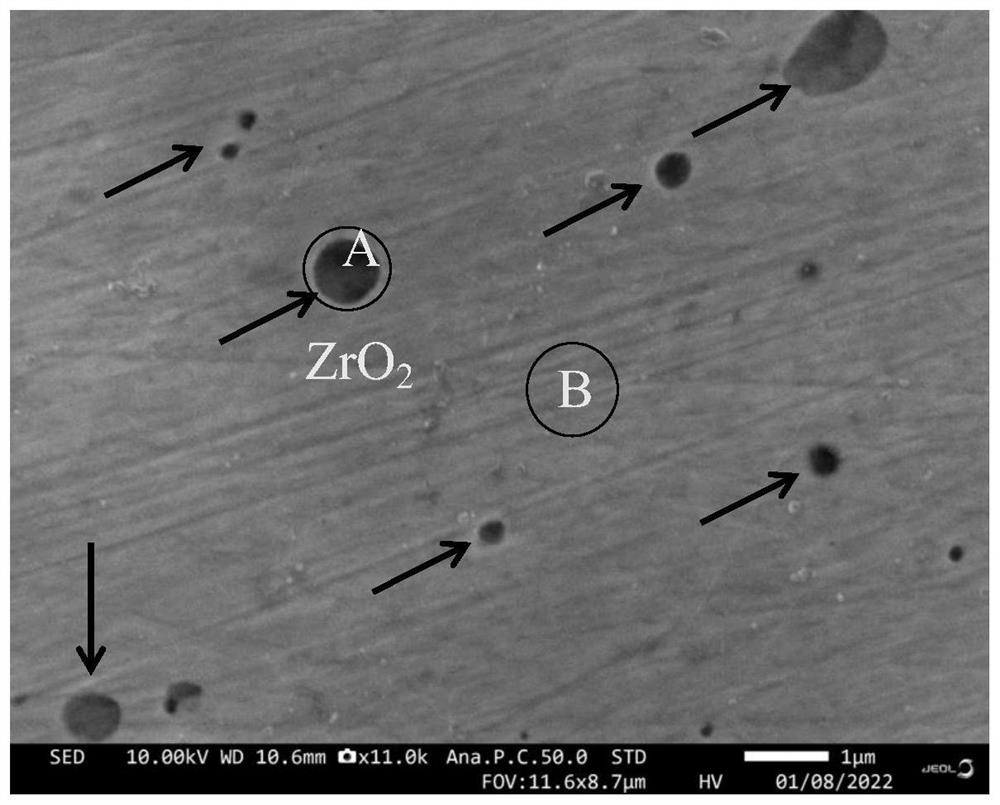

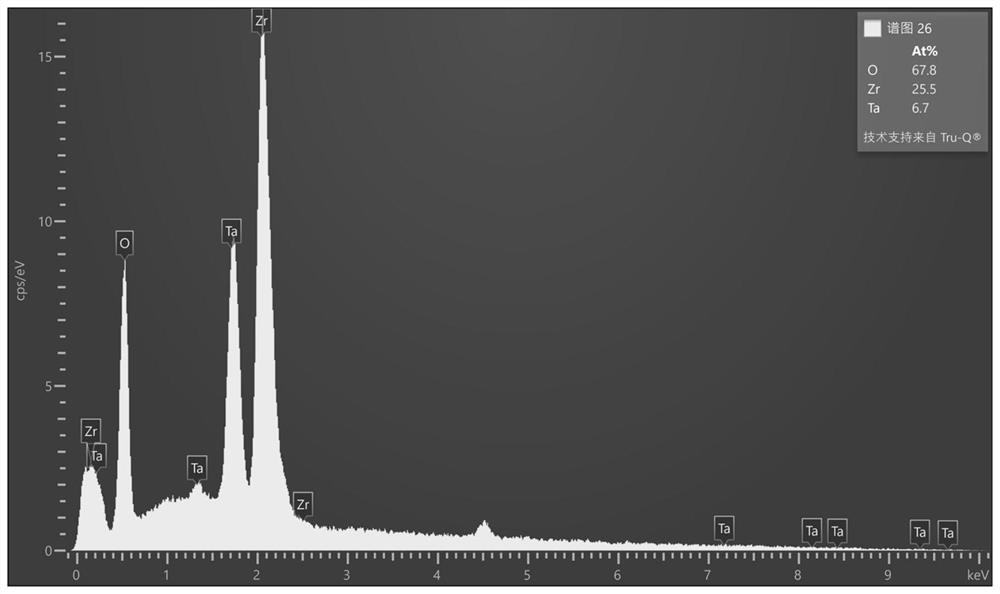

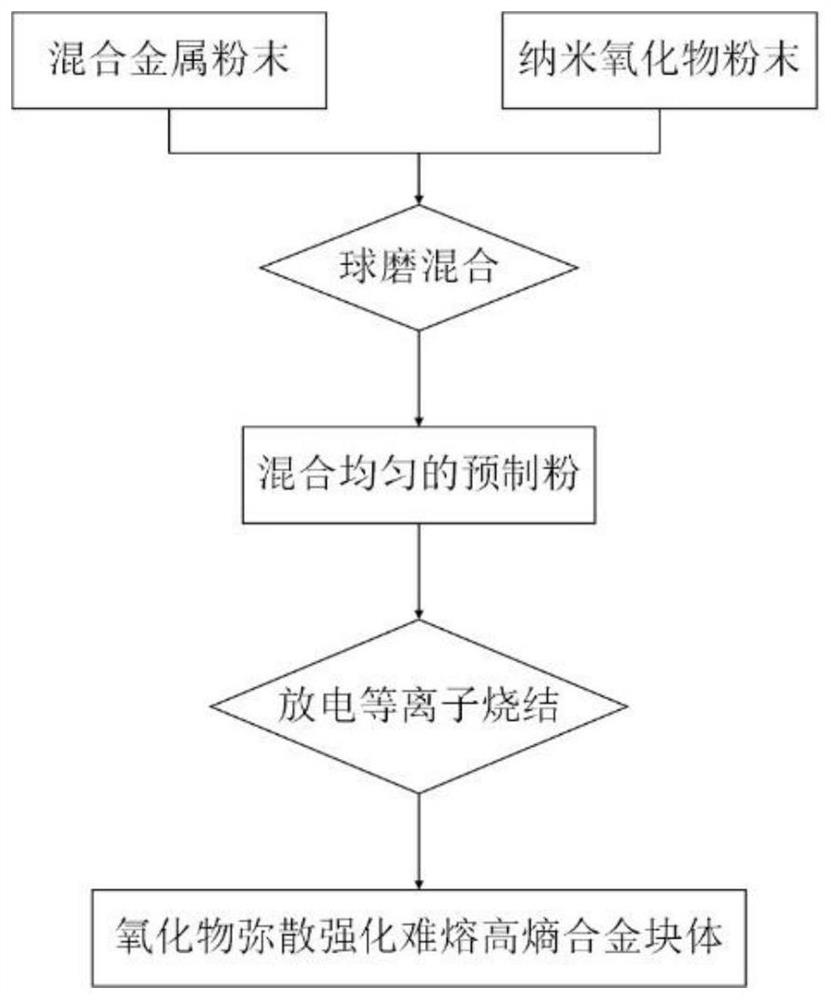

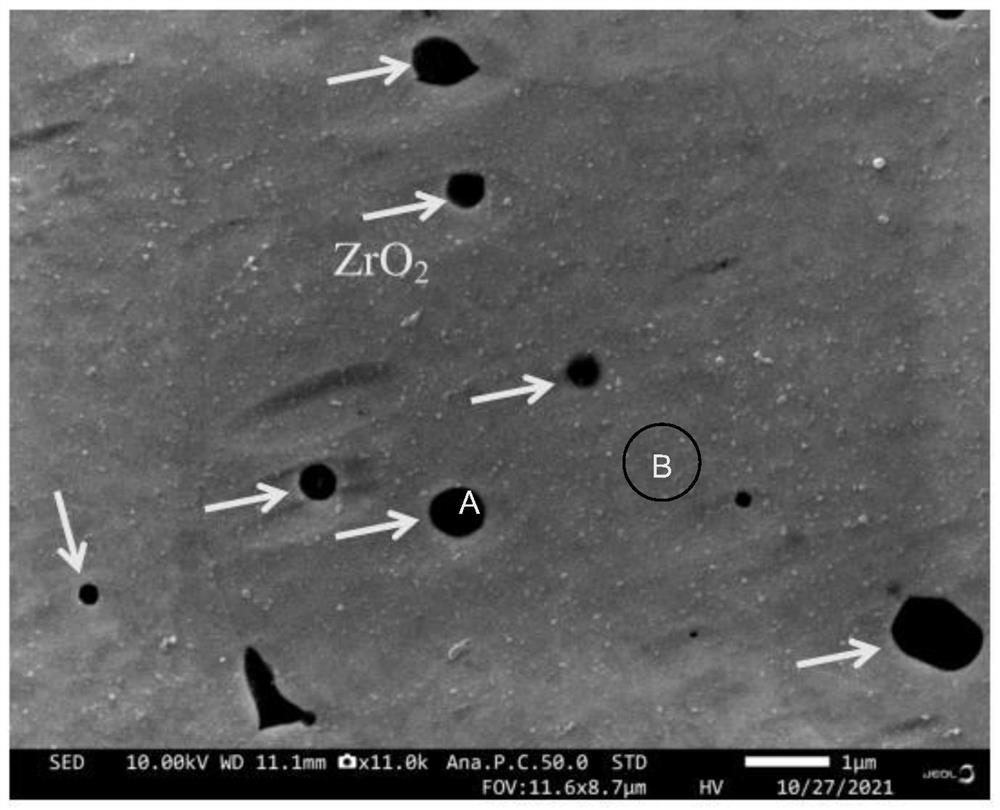

Preparation method of nano zirconium dioxide reinforced NbMoTaW refractory high-entropy alloy

ActiveCN114774727ALow industrial application valueHigh industrial application valueHigh entropy alloysNanoparticle

The invention relates to a preparation method of a nano zirconium dioxide reinforced NbMoTaW refractory high-entropy alloy, which comprises the following steps of: ball-milling and mixing metal powder formed by mixing Nb powder, Mo powder, Ta powder and W powder with equal molar ratio or nearly equal molar ratio and nano ZrO2 particles in a high-energy ball mill to obtain mixed powder; and the obtained mixed powder is placed in a graphite mold, pressure sintering is conducted in a high vacuum state through a spark plasma sintering method, and the high-strength ZrO2 reinforced NbMoTaW refractory high-entropy alloy is obtained. According to the method, the technological process is simple, the cost is low, the efficiency is high, the ZrO2 enhanced NbMoTaW refractory high-entropy alloy which is uniform in structure, fine in crystal grain and high in strength and plasticity and has nano ZrO2 dispersed distribution is obtained, compared with the prior art, the room-temperature plasticity of the NbMoTaW refractory high-entropy alloy is greatly improved, and the alloy has the advantages of being high in strength and plasticity. The defects of composition segregation, long mechanical alloying test period and low powder yield caused by an existing casting method preparation process are effectively overcome.

Owner:HENAN UNIV OF SCI & TECH

Method for synthesizing NiMnGaCo magnetic memory alloy at high temperature through combustion reaction

The invention discloses a method for synthesizing a NiMnGaCo magnetic memory alloy at a high temperature through a combustion reaction and relates to the preparation method of the magnetic shape memory alloy. According to the method, the combustion reaction is adopted for the first time to synthesize the novel magnetic NiMnGaCo shape memory alloy, and a way is expanded for the application of the high-temperature and high-plasticity shape memory alloy. The high-strength and high-plasticity NiMnGaCo is prepared through the following steps that materials are taken according to the atomic percentand are mixed to be uniform and sintered, and then the high-strength and high-plasticity NiMnGaCo is obtained. The magnetic shape memory alloy NiMnGaCo prepared through the method has the advantages of being good in toughness, high in strength, fine in organization and the like.

Owner:DALIAN UNIVERSITY

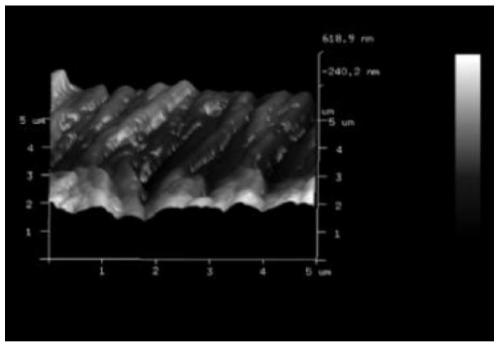

Electrostatic spinning device and spinning method

PendingCN111926397ASmall diameterHigh degree of alignmentFilament/thread formingSpinningSpray nozzle

The invention belongs to the technical field of electrostatic spinning, and discloses an electrostatic spinning device. The device comprises a propulsion mechanism, wherein the propulsion mechanism isused to feed a spinning solution stored inside an injector into a spray nozzle by controlling the movement of a piston core rod inside a syringe barrel of the injector, the spray nozzle is arranged on a spinneret slab, the spinneret slab is connected with a moving mechanism, the moving mechanism is used to control the spinneret slab to move in the axis direction of a winding roller and adjust thedistance between the spinneret slab and the winding roller, both ends of the winding roller are arranged on an adjusting mechanism, and the adjusting mechanism is used to adjust the height differencebetween the winding roller and the spinneret slab. The invention further discloses a spinning method of the electrostatic spinning device.

Owner:SHANGHAI OCEAN UNIV

A kind of high-density polyethylene composite auxiliary agent and preparation method thereof

The invention discloses a high-density polyethylene compound additive and a preparation method thereof, and belongs to the field of chemical engineering. The compound additive comprises an antioxidant, a nucleating agent, an acid acceptor and an antistatic agent, wherein the antioxidant comprises an antioxidant 330, an antioxidant 168 and an antioxidant 1076. The preparation method of the compound additive comprises the following steps: mixing the raw components, and uniformly stirring; granulating the uniformly mixed components so as to obtain granules; and sieving the obtained granules. The compound additive has the advantages that the 5000S-oxidation induction time can be prolonged to above 50 minutes through the synergistic effect among the additives, the yellow index is reduced, the fracture strain is improved, and the like.

Owner:江苏汉光实业股份有限公司

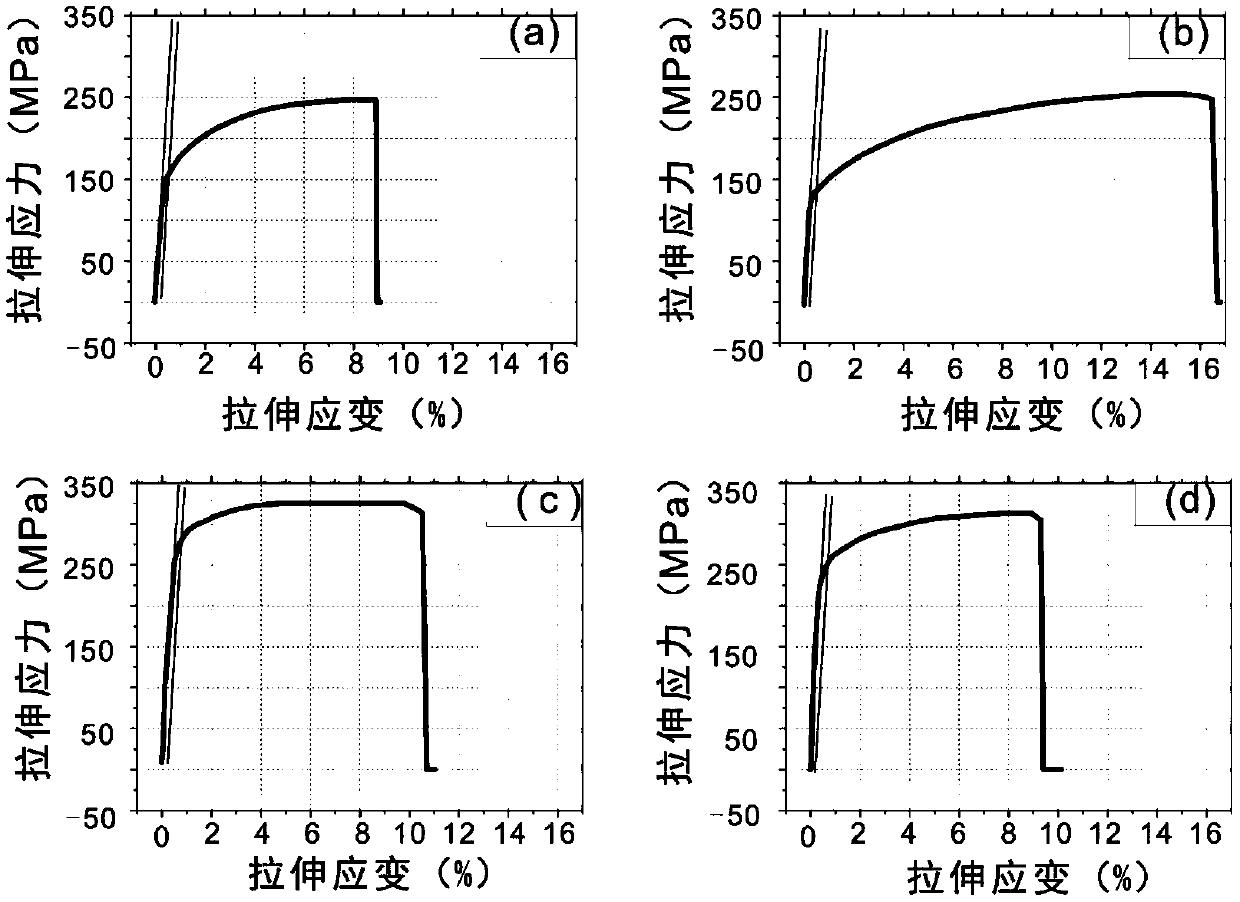

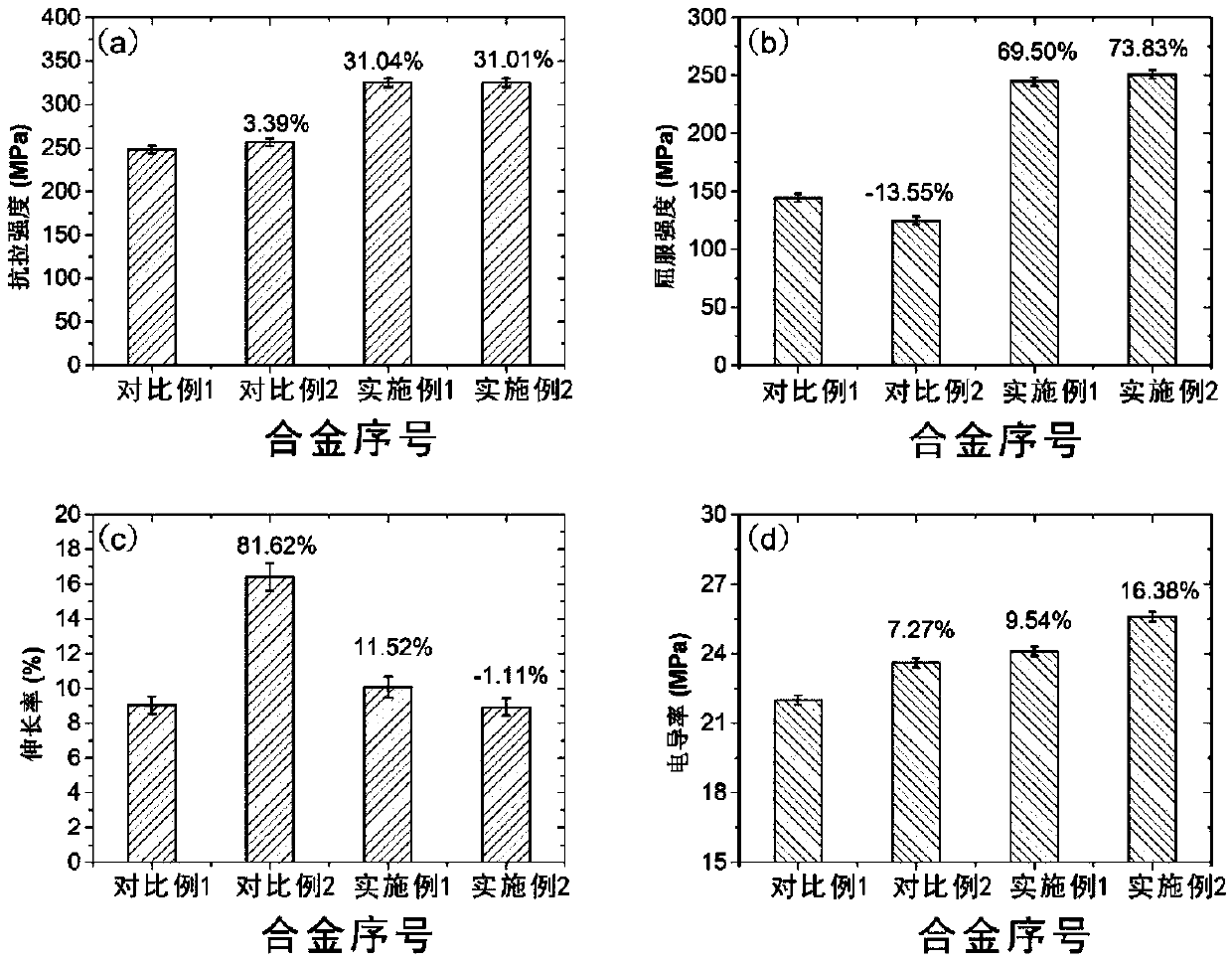

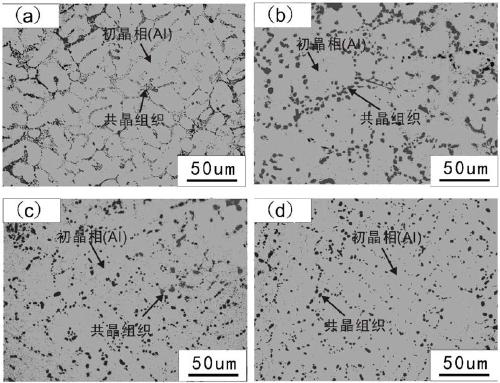

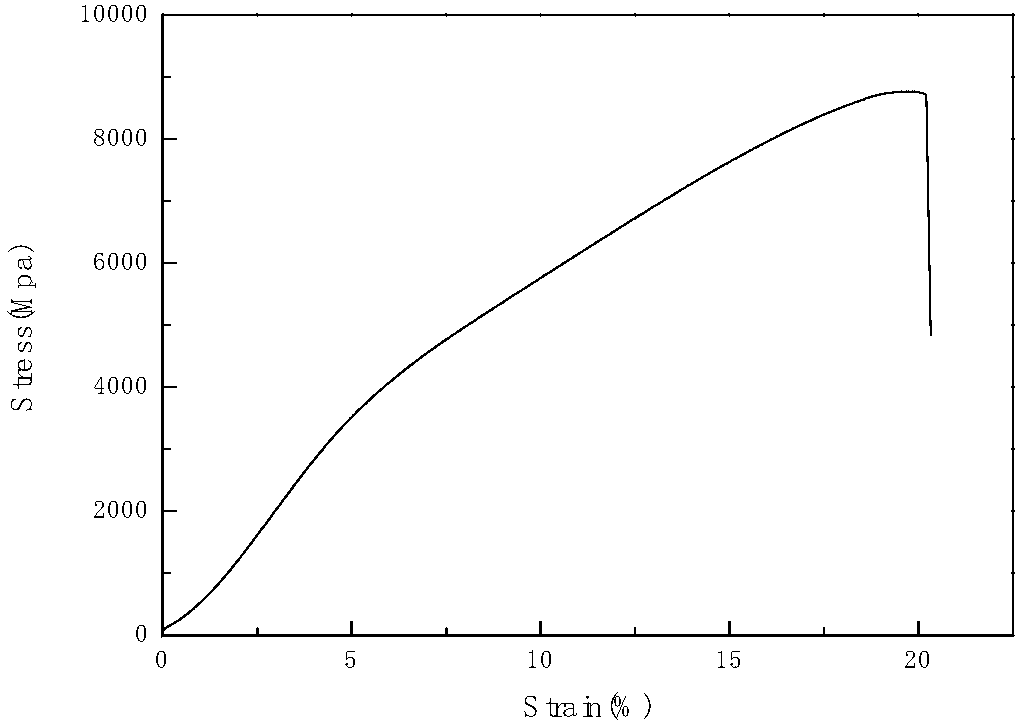

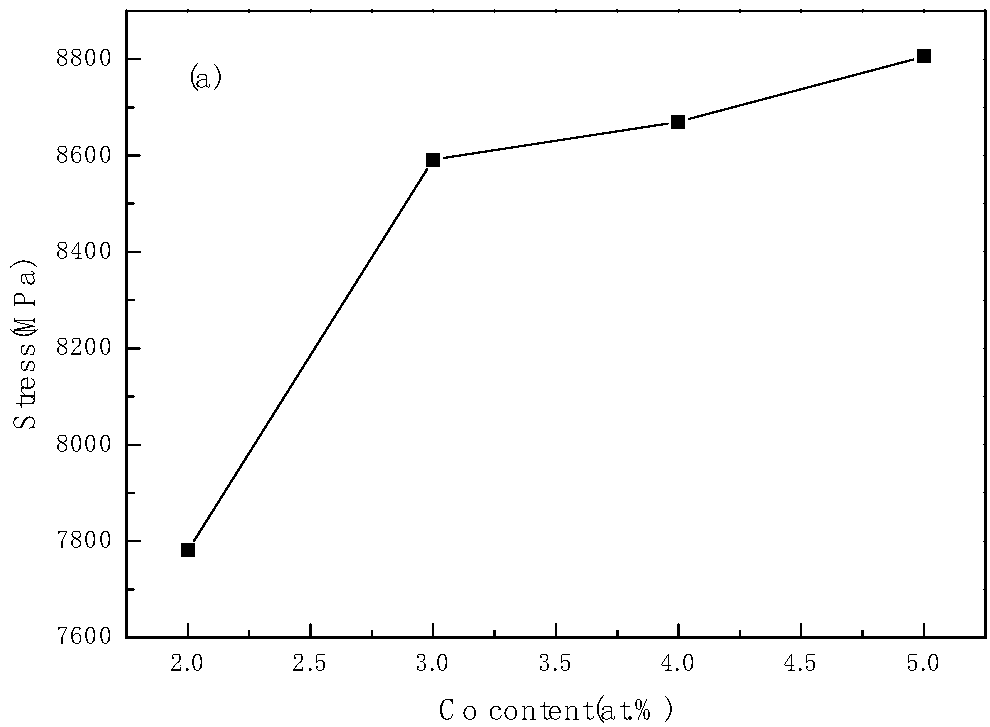

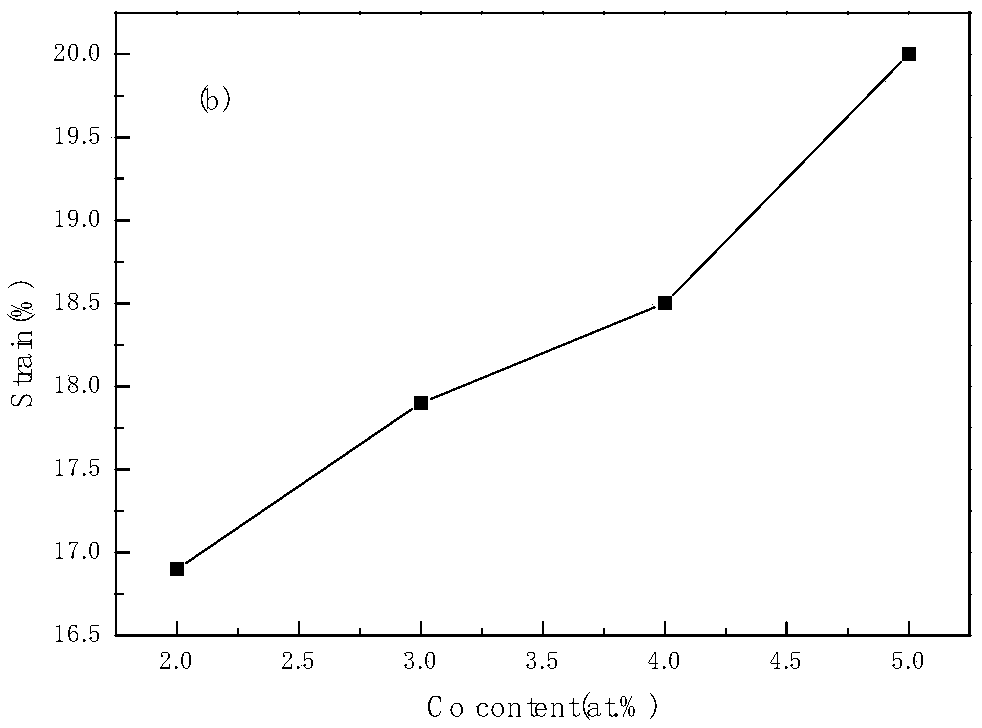

Preparation method of high-strength high-plasticity Ni50Mn34In11Co5 magnetic memory alloy

ActiveCN108085523AHigh breaking strengthRaise the strain at breakTransportation and packagingMetal-working apparatusFine structureMagnetic memory

The invention relates to a preparation method of high-strength high-plasticity Ni50Mn34In11Co5 magnetic memory alloy. High-strength high-plasticity Ni50Mn34In16-xCox(x=2,3,4,5) is obtained through material acquisition according to atomic percentages, mixing, forming, degreasing and sintering. The prepared magnetic shape memory alloy Ni50Mn34In16-xCox(x=2,3,4,5) has the advantages of good toughness, high strength, fine structure and the like, and develops an idea for the application of high-temperature high-plasticity shape memory alloy.

Owner:DALIAN UNIV

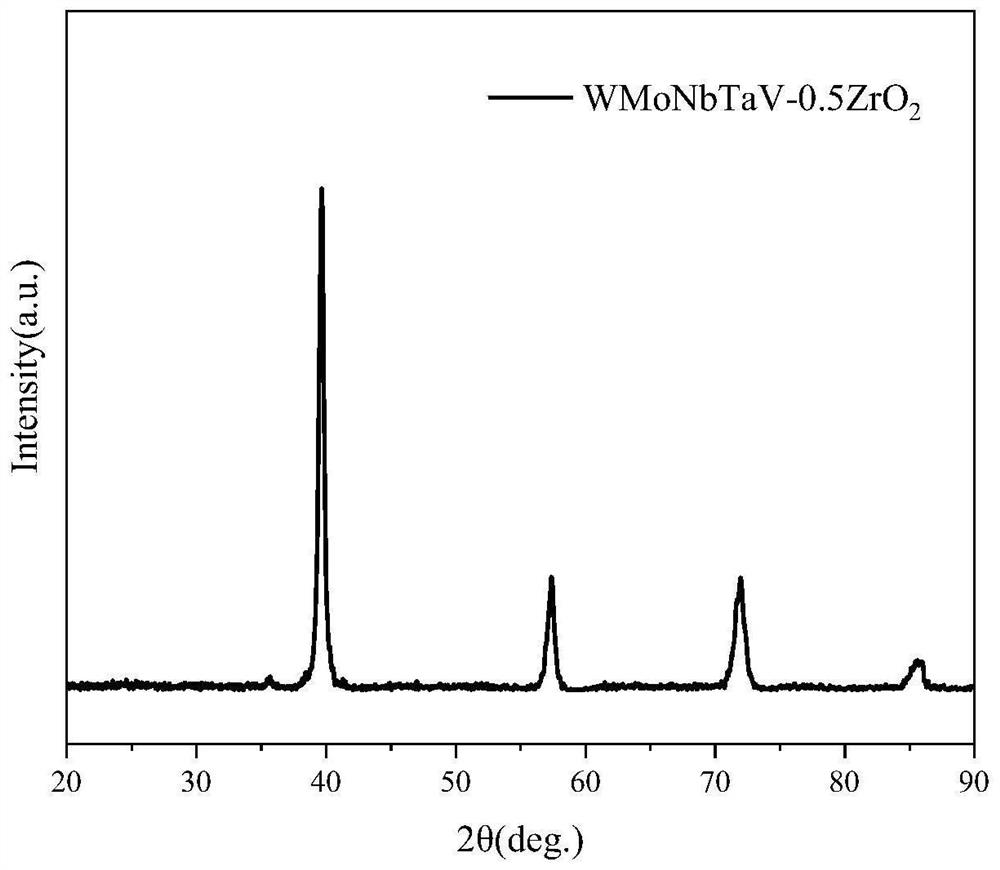

Preparation method of ceramic particle reinforced refractory high-entropy alloy

PendingCN114799155AHigh strengthImprove plasticityTransportation and packagingMetal-working apparatusHigh entropy alloysNanoparticle

The invention relates to a preparation method of a ceramic particle reinforced refractory high-entropy alloy, which comprises the following steps of: ball-milling and mixing metal powder formed by mixing W powder, Mo powder, Nb powder, Ta powder and V powder with equal molar ratio or nearly equal molar ratio and nano ZrO2 particles in a high-energy ball mill to obtain mixed powder; and the obtained mixed powder is placed in a graphite mold, pressure sintering is conducted in a high-vacuum state through a spark plasma sintering method, and the nano ZrO2 reinforced WMoNbTaV refractory high-entropy alloy is obtained. The method is simple in technological process, low in cost and high in efficiency, the nano ZrO2 particles are introduced into the WMoNbTaV matrix, the strength and plasticity of the WMoNbTaV refractory high-entropy alloy are improved, compared with the prior art, the room-temperature plasticity of the WMoNbTaV refractory high-entropy alloy is greatly improved, and the problems that component segregation and long mechanical alloying test period caused by an existing casting method preparation technology are effectively solved, and the mechanical alloying performance of the WMoNbTaV refractory high-entropy alloy is greatly improved are solved. And the powder yield is low.

Owner:HENAN UNIV OF SCI & TECH

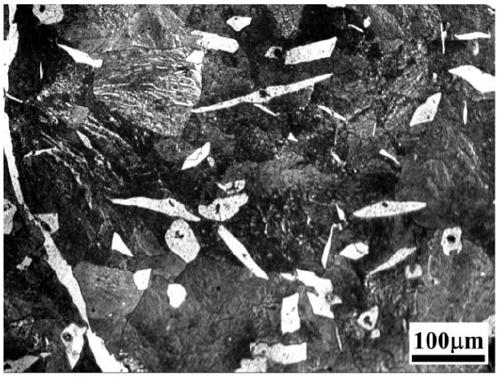

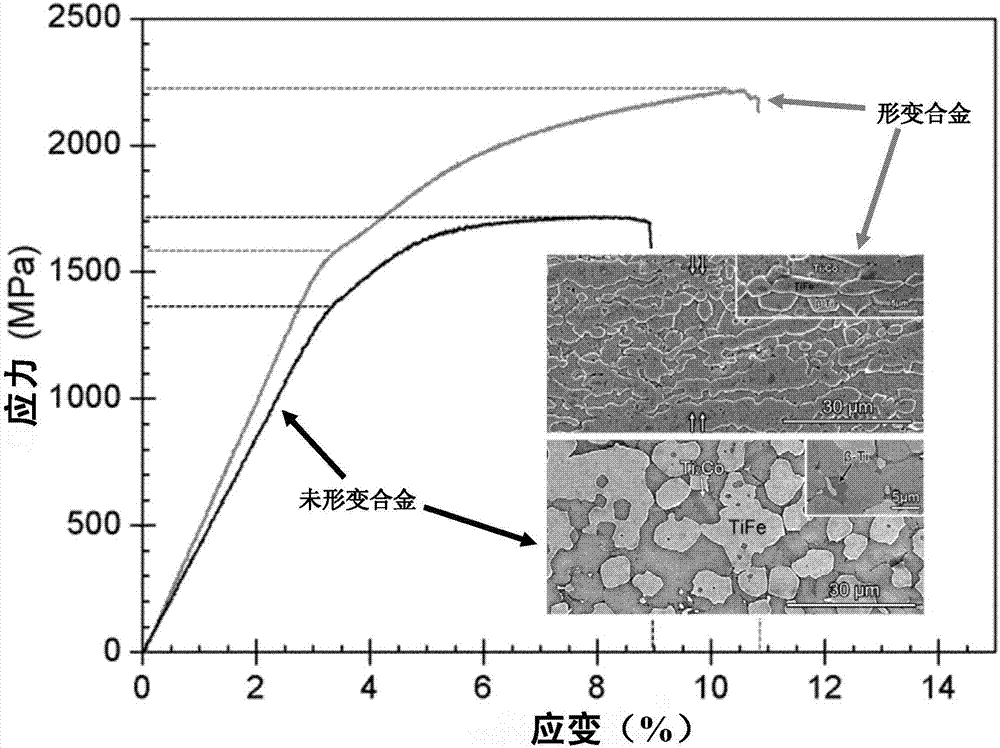

Deformation-induced laves phase dispersion toughening titanium alloy and preparation method thereof

The invention belongs to the technical field of alloy processing and discloses a deformation-induced laves phase dispersion toughening titanium alloy and a preparation method thereof. Materials comprising, by atom, 62.5-65% of Ti, 25.5-27.5% of Fe and 7.5-12% of Co are mixed evenly and then sequentially subjected to high energy ball milling and semi-solid sintering, and thus a sintered titanium alloy is obtained; the yield strain capacity of the sintered titanium alloy is tested; and then the obtained sintered titanium alloy is highly deformed by 3.5%-5.5% at a certain strain speed rate, it isguaranteed that the deformation quantity is larger than or equal to the yield strain capacity, and the deformation-induced laves phase dispersion toughening titanium alloy is obtained. By controllingthe strain speed rate and the total strain capacity of alloy loading, precise adjustment and control of the precipitation quantity and the grain size of Laves are achieved, so that the alloy has thenanometer and ultrafine-scale strip-shaped and isometric crystal coexisting multi-scale dual-state structure, and the alloy performance is better.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com