Titanium-based ultrafine grain or fine grain composite material with high compression ratio strength and preparation method thereof

A high compression ratio, composite material technology, applied in the field of metal ultra-fine grain and fine-grained alloy preparation, can solve the problem of no titanium-based ultra-fine grain and fine-grain composite material, and achieve uniform microstructure and grain, high Effects of oxygen content, high compression ratio strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

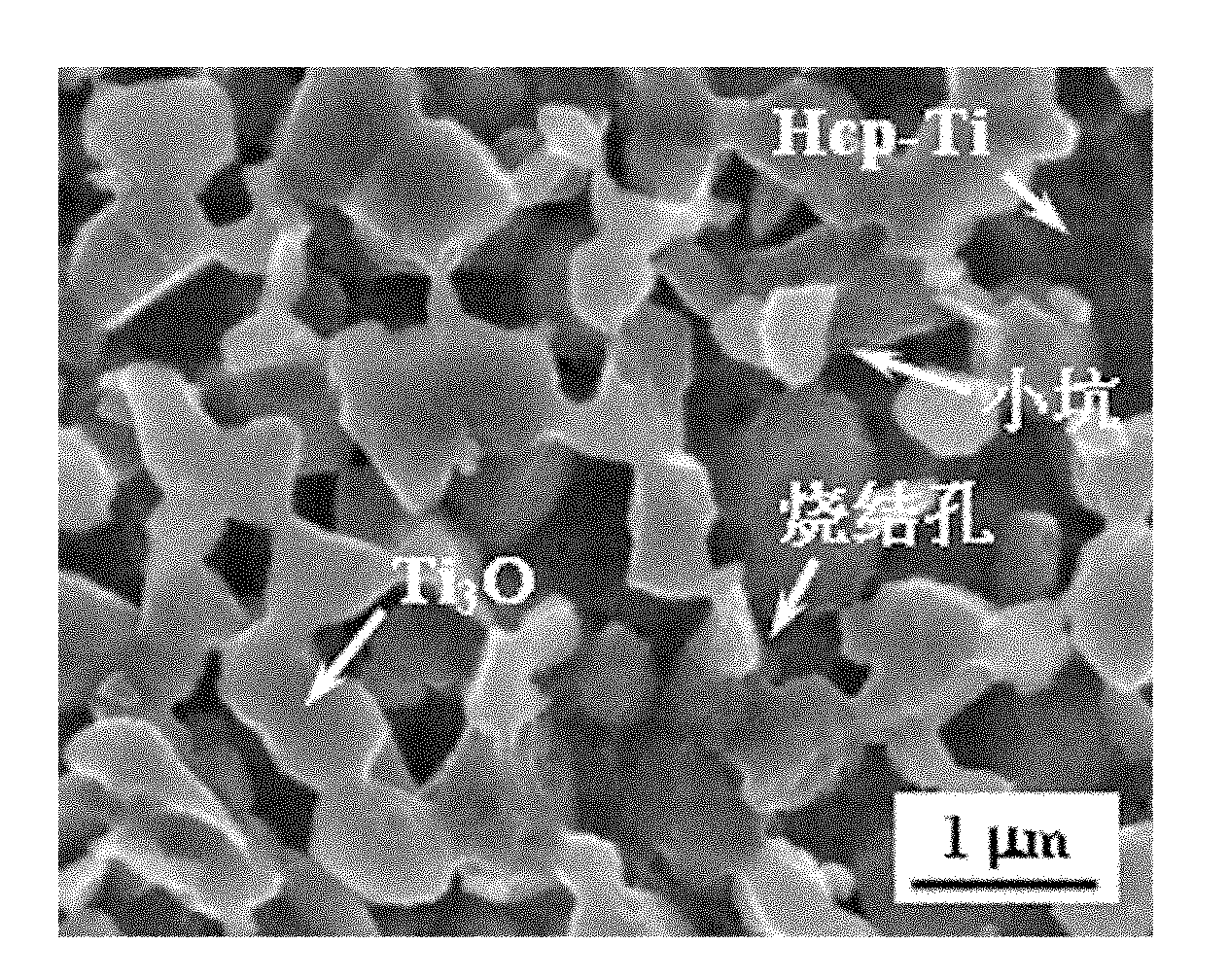

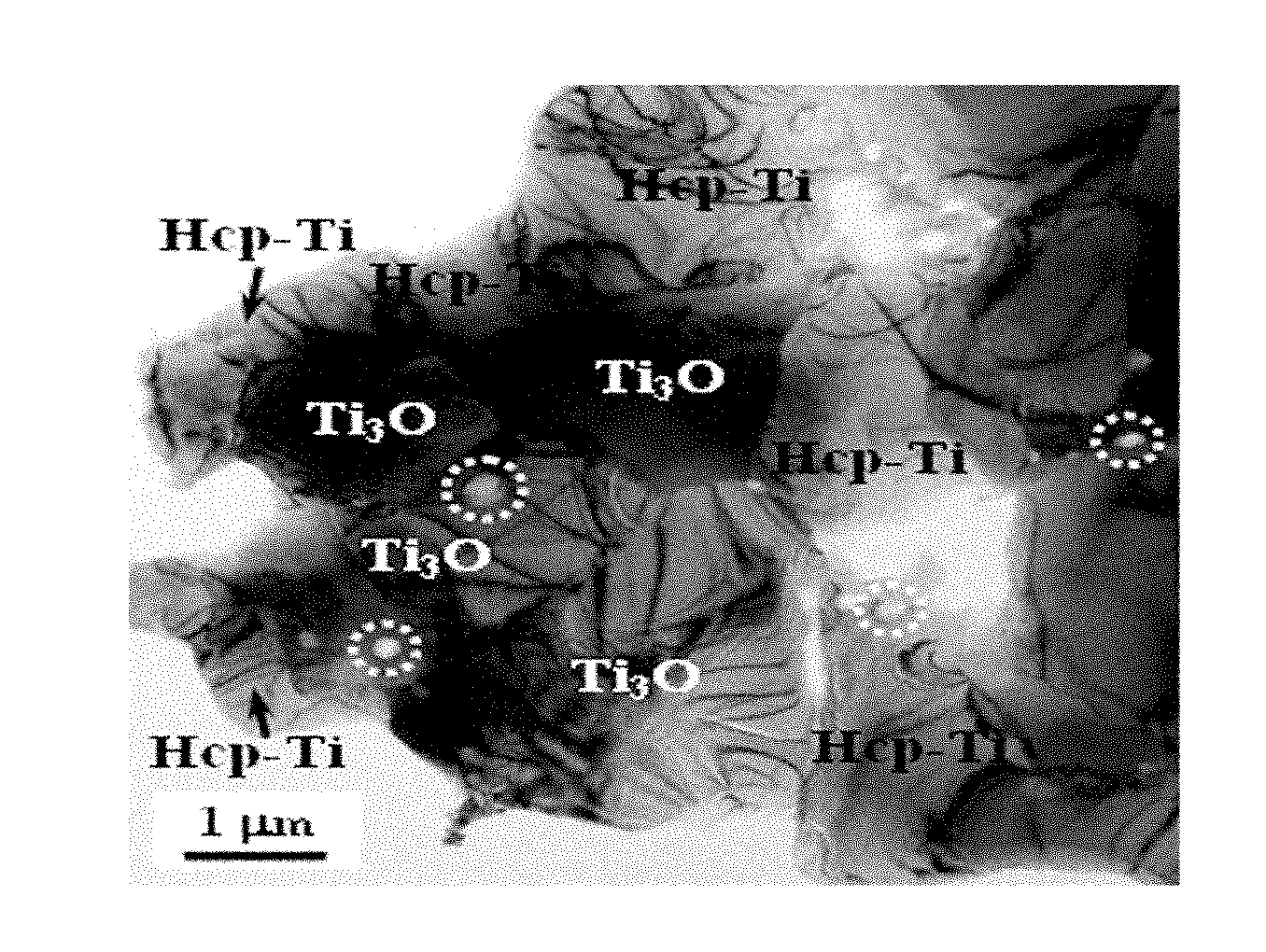

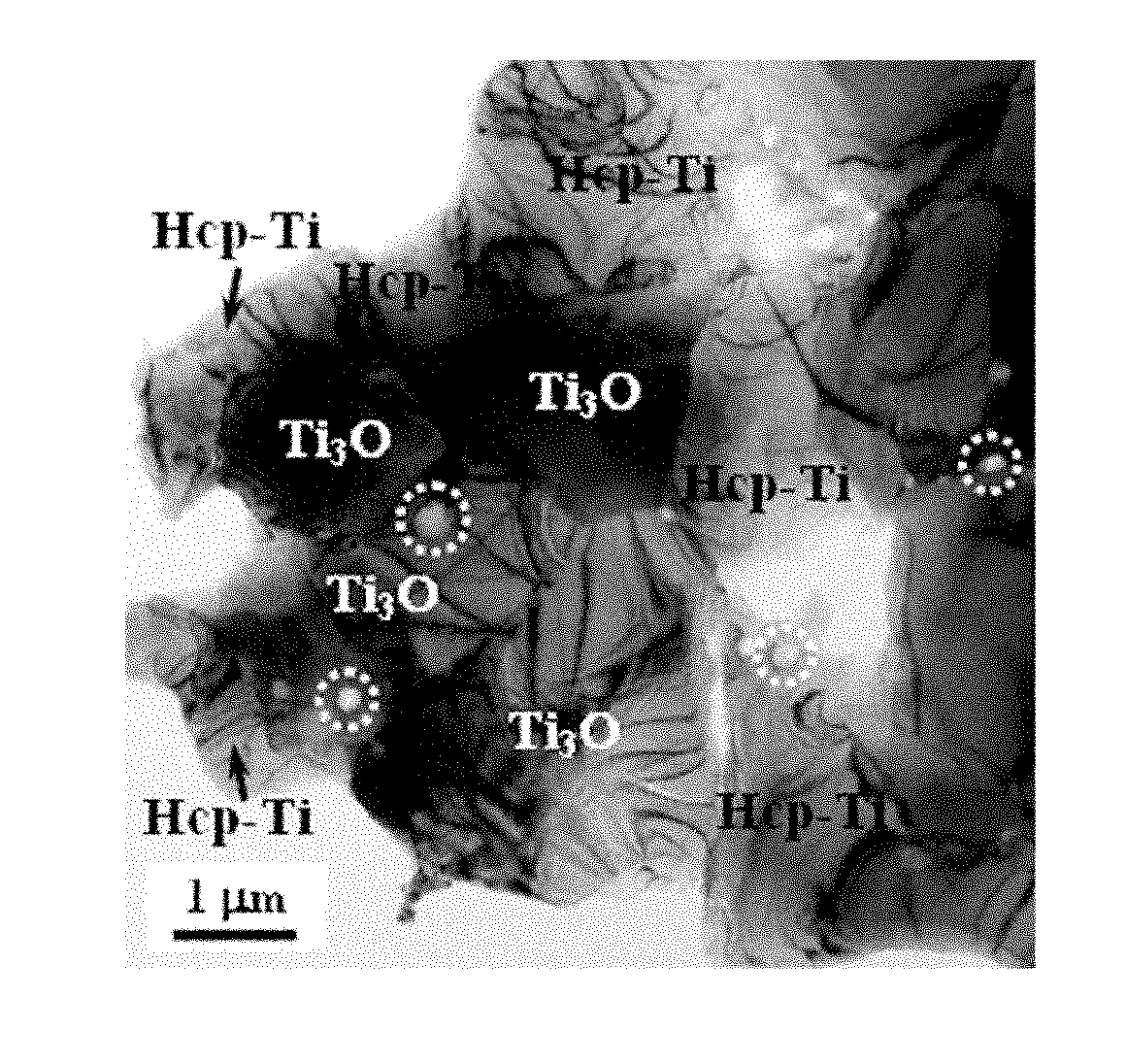

Embodiment 1

[0036] A titanium-based ultra-fine-grained composite material with high compression specific strength, the specific components and their content in atomic percentage are: Ti 85.5-92.5 at.%, O 6.0-8.8 at.%, N 1.3-1.9 at.% , Fe 1.0~1.9at.%, and the rest are inevitable trace impurities of nickel and carbon; its microstructure is represented by Hcp Ti 3 O is the matrix phase and Hcp Ti is the reinforcing phase; at the same time, both the matrix phase and the reinforcing phase contain dispersed FeTi 2 、NiTi 2 Or TiC nanocrystalline or ultrafine crystal compound particles.

[0037] The preparation method of the above-mentioned titanium-based ultrafine-grain composite material is a forming method combining high-energy ball milling technology and pulse current sintering technology, which includes the following steps and its process conditions:

[0038] Step 1: Preparation of amorphous titanium alloy powder by high energy ball milling

[0039] The initial powder is metal titanium po...

Embodiment 2

[0051] A titanium-based fine-grain composite material with high compression specific strength, the specific components and their content in atomic percentage are: Ti 85.5-92.5 at.%, O 6.0-8.8 at.%, N 1.3-1.9 at.%, Fe 1.0~1.9at.%, the rest are inevitable trace impurities of nickel and carbon; its microstructure takes Hcp Ti as the matrix phase, and Hcp Ti 3 O is the reinforcing phase, and at the same time, both the matrix phase and the reinforcing phase contain dispersed FeTi 2 、NiTi 2 Or TiC nanocrystalline or ultrafine crystal compound particles.

[0052] A preparation method of titanium-based fine-grained composite material with high compression specific strength is a forming method combining high-energy ball milling technology and pulse current sintering technology, which includes the following steps and its process conditions:

[0053] Step 1: Preparation of amorphous titanium alloy powder by high energy ball milling

[0054] The initial powder is metal titanium powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fracture strain | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com